Page 1

NOVATEK-ELECTRO Ltd

Intelligent industrial electronics

TIME DELAY RELAY

REV-120

OPERATING MANUAL

The quality management system of development and production complies with the requirements

of ISO 9001:2015

Dear Customer,

Company thanks you for purchasing our products.

You will be able to use properly the product after carefully studying the Operating Manual.

Keep the Manual throughout the service life of the product.

www.novatek-electro.in

Page 2

- 2 -

REV-120 NOVATEK-ELECTRO

ATTENTION! ALL REQUIREMENTS OF THIS OPERATION MANUAL ARE COMPULSORY TO BE MET!

WARNING! – PRODUCT TERMINALS AND INTERNAL COMPONENTS ARE UNDER

POTENTIALLY LETHAL VOLTAGE.

TO ENSURE THE PRODUCT SAFE OPERATION IT IS STRICTLY FORBIDDEN THE

FOLLOWING:

– TO CARRY OUT MOUNTING WORKS AND MAINTENANCE WITHOUT DISCONNECTING THE

PRODUCT FROM THE MAINS;

– TO OPEN AND REPAIR THE PRODUCT INDEPENDENTLY;

– TO OPERATE THE PRODUCT WITH MECHANICAL DAMAGES OF THE CASE.

IT IS NOT ALLOWED WATER PENETRATION ON TERMINALS AND INTERNAL ELEMENTS OF THE

PRODUCT.

During operation and maintenance the regulatory document requirements must be met, namely:

Regulations for Operation of Consumer Electrical Installations;

Safety Rules for Operation of Consumer Electrical Installations;

Occupational Safety in Operation of Electrical Installations;

Installation, adjustment and maintenance of the product must be performed by qualified personnel

having studied this Operation Manual.

The product is safe for use under keeping of the operating rules.

Page 3

- 3 -

NOVATEK-ELECTRO REV-120

This Operation Manual is intended to familiarize you with arrangement, the requirements for safety,

operation and maintenance procedures of the time delay relay REV–120 (hereinafter referred to as the

"product", "REV–120").

The product meets the requirements of the following:

• Low-voltage switchgear; Part 1; General rules (IEC 60947-1);

• Low-voltage circuit breaker and controller; Part 6-2; multifunctional equipment; Control and safety

switching equipment (ІEC 60947-6-2);

• Electromagnetic compatibility; Industrial, scientific and medical RF equipment; electromagnetic

interference characteristics; standards and measuring procedure (CISPR 11);

• Electromagnetic compatibility; Part 4-2; Testing and measurement techniques; Electrostatic discharge

immunity test (IEC 61000-4-2).

Harmful substances in amounts exceeding maximum permissible concentrations are not available.

Terms and abbreviations:

• It periodically flashes – the indicator short-time enabling.

• It periodically is off – the indicator short-time disabling.

1. APPLICATION

1.1. Product application

The time delay relay REV-120 is the microprocessor-based device intended for on/off switching the load in

user-defined time intervals.

REV-120 can be operated by ten operation modes:

on-delay;

time delay when energizing;

periodic with on-delay;

periodic with time delay when energizing;

off-delay (when control contact opening);

pulse I (when control contact closing);

pulse II (when control contact opening);

on/off delay (according to control contact);

pitch of the load relay (during each control contact closing);

pulse generator of 0.5 s.

1.2. Software revision history

19.05.2016 v2 Primary version of the program

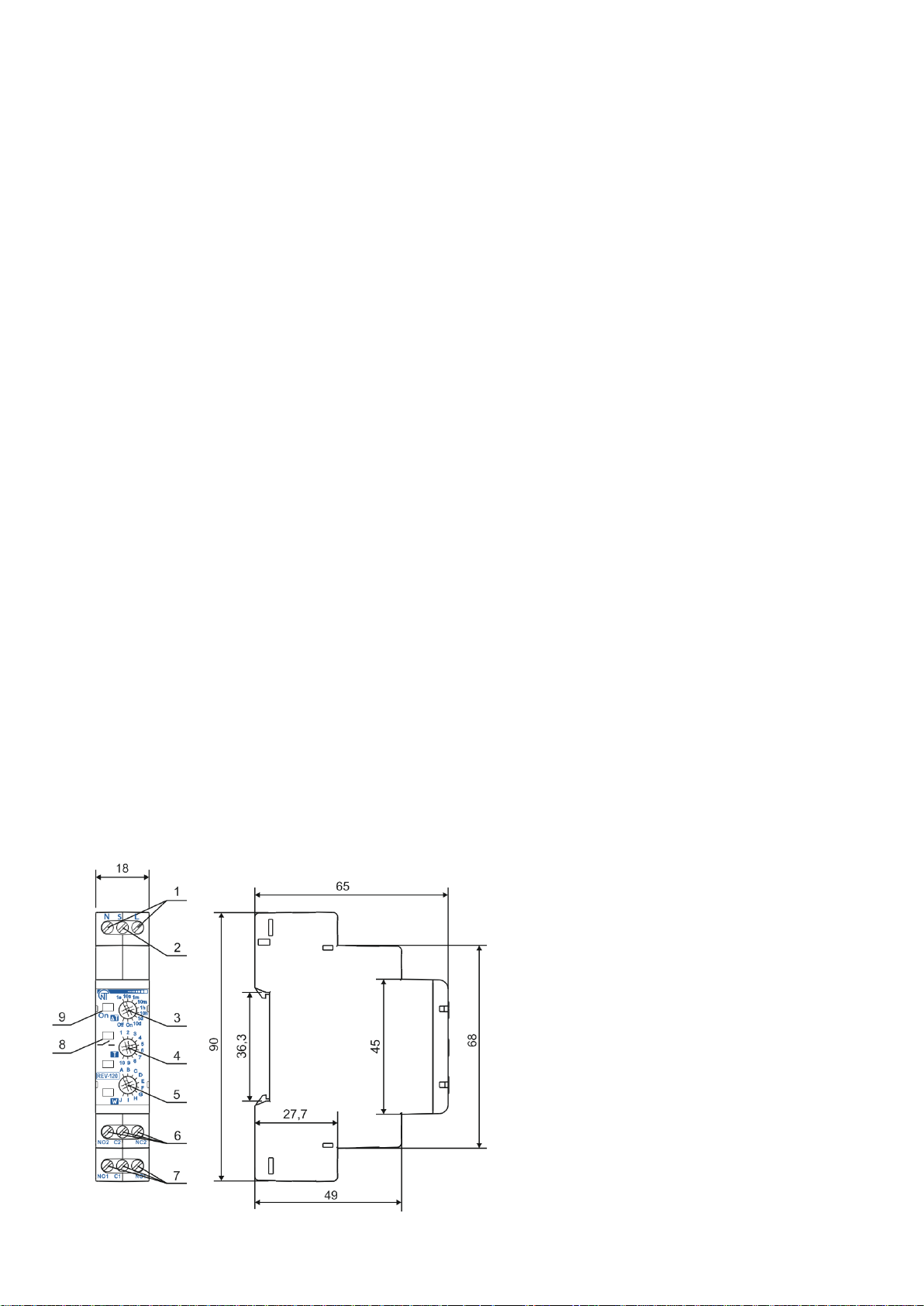

1.3. Controls, overall and mounting dimensions of REV–120

Controls, overall and mounting dimensions are shown in Fig.1.

1 – input contacts ~230/240 V L, N;

2 – input control contact S;

3 – regulator for setting the time interval ∆T;

4 – regulator for setting the time Т;

5 – regulator for setting the operation mode W;

6, 7 – output contacts of load relay:

NO1 / NO2 – normally open contact (further

NO);

NC1 / NC2 – normally closed contact

(further NC);

С1 / С2 – switching contact (further С);

8 – LED indicator of load relay ON;

9 – LED indicator of power ON.

Fig.1 – Controls, overall and mounting dimensions of REV–120

Page 4

- 4 -

REV-120 NOVATEK-ELECTRO

1.4. Operation conditions

The product is designed for operation in the following conditions:

– Ambient temperature: from minus 30 to +55 °С;

– Atmospheric pressure: from 84 to 106.7kPa;

– Relative air humidity (at temperature of +25 °С): 30 … 80%.

ATTENTION! The product is not intended for operation in the following conditions:

– Significant vibration and shocks;

– High humidity;

– Aggressive environment with content in the air of acids, alkalis, etc., as well as severe contaminations

(grease, oil, dust, etc.).

2. SPECIFICATIONS

Basic specifications of REV–120 are given in Table 1.

Specifications of the load relay contacts are given in Table 2.

Table 1 – Basic Specifications

Description

Value

Operating supply voltage, V

230/240 V

Frequency of supply mains, Hz

45 – 62

Voltage at which service capability is maintained, V

130-300

Permissible harmonic configuration (unsinusoidality) of power supply voltage

EN 50160

Readiness time when energizing, s, no more than

0.4

Accuracy of time delay, %, no less than

0.5

Accuracy of time setting (accuracy of scale), %, no less than

2.5

Number of operation modes

10

Adjustment range of time is divided into 10 subranges

0.1 … 1 s

1 … 10 s

6 s … 1 min

1 … 10 min

6 min … 1 h

1 … 10 h

0.1 … 1 day

1 … 10 day

Continuously ON

Continuously OFF

Time delay adjustment

smooth

Service of the product

Switchgear and control gear

Rated operating condition

Continuous

Type and quantity of contacts (switching)

2

Climatic design version

CN 3.1

Protection rating of case

ІР40

Protection rating of terminal box

ІР20

Commutation lifetime of output contacts if cos=1:

- under load of 6 А, time, no less than

- under load of 1 А, time, no less than

100,000

1,000,000

Power consumption (under load), W, no more than

0.5

Permissible contamination level

II

Overvoltage category

II

Electric shock protection class

II

Rated insulation voltage, V

450

Rated impulse withstand voltage, kV

2.5

Wire cross-section for connection to terminals, mm²

0.5-2

Tightening torque of terminal screws, N*m

0.4

Weight, kg, not more

0.150

Overall dimensions, H x D x L, mm

90 x 65 x 18

Product installation (mounting) is on standard 35mm DIN rail

The product remains functional at any position in space

Case material is self-extinguishing plastic

Page 5

- 5 -

NOVATEK-ELECTRO REV-120

Table 2 – Specifications of output contacts of the load relay

сos

Max. current at

U~250 V, А

Max. switching

power, VA

Max. permissible

continuous AC voltage, V

Max. current at

UDC=28 V, A

1 6 1500

250

3

3. INTENDED USE

3.1. Preparation for operation

3.1.1. Preparation for connection:

Unpack the product (we recommend to keep the original packing for the entire warranty period of the

product operation);

Check the product for damage after transportation; in case of such damages detection, contact the

supplier or manufacturer;

Carefully study the Operation Manual (pay special attention to the connection diagram to power

the product);

If you have any questions regarding the installation of the product, please contact the manufacturer by

telephone number indicated at the end of this Operating Manual.

3.1.2. General

If the temperature of the product after transportation or storage differs from the temperature of the

environment at which it is supposed to be operated, then before connecting to the mains hold the product

under operating conditions within two hours (because there is possible moisture condensation on the

elements of the product).

ATTENTION!

THE PRODUCT IS NOT DESIGNED FOR LOAD COMMUTATION IN CASE OF SHORT CIRCUITS.

THEREFORE, THE LOAD POWER SUPPLY CIRCUIT SHOULD BE EQUIPPED WITH THE CIRCUIT

BREAKER FOR CURRENT OF 6 A MAXIMUM.

ATTENTION! ALL CONNECTIONS MUST BE PERFORMED WHEN THE PRODUCT IS DEENERGIZED.

Error when performing the installation works may damage the product and connected devices.

To ensure the reliability of electrical connections you should use flexible (stranded) wires with insulation for

voltage of no less than 450 V, the ends of which it is necessary to be striped of insulation for 5±0.5 mm and

tightened with bootlaces. The cable cross section to connect the load depends on current (power) of the load.

For example for the current of 6 A it is no less than 1.5 mm2. Wires fastening should exclude mechanical

damage, twisting and abrasion of the wire insulation.

IT IS NOT ALLOWED TO LEAVE EXPOSED PORTIONS OF WIRE PROTRUDING BEYOND THE

TERMINAL BLOCK.

For reliable contact it is necessary to perform tightening of screws of the terminal block with the force

specified in Table 1.

When reducing the tightening torque, the junction point is heated, the terminal block may be melted and

wire can burn. If you increase the tightening torque, it is possible to have thread failure of the terminal block

screws or the compression of the connected wire.

To improve operational properties of the product it is recommended to install the fuse or its

analogue for 1 A current in power supply circuit for REV-120.

3.2. Product connection

3.2.1. Adjustment of the product

Before connecting the device, you should configure it. Its setting is performed in the following order:

• The operation mode adjustment;

• The time interval adjustment;

• The time delay adjustment.

For precise positioning the regulators ∆T and W it is recommended to rotate them to the extreme left and

then turning right to count the desired number of positions (fixation of position).

Note – when changing the operation mode or time intervals of the product under the power supply, it is

necessary to consider that the changes will take effect only after de-energizing (for at least 1 s) and reenergizing of the product.

Page 6

- 6 -

REV-120 NOVATEK-ELECTRO

ATTENTION! Not to break or rotate the regulators to excessive extent, please do not use excessive

force when performing installation operations.

3.2.1.1. The product operation mode adjustment

List of the REV-120 operation modes is given in table 3.

Find the desired mode of the product operation according to Table 3 and set the regulator for the operation

mode setting W to the required position (Fig.1 it.5).

Table 3 – Product operation modes

Name and W knob

position

Description

On-delay

After energizing, the set delay time t (Т

regulator) occurs. During the delay time

the indicator ON of the load relay (Fig.1

it.8) periodically flashes.

At the end of the delay time the load

relay contacts NO and C are closed,

the indicator ON of the load relay is on

and the product goes into standby

mode until power-off.

Time delay when

energizing

After energizing, the load relay contacts

NO and C are closed, the indicator ON

of the load relay (Fig.1 it.8) is on and

the set delay time t (Т regulator) occurs.

During the delay time the indicator ON

of the load relay periodically is off.

At the end of the delay time the load

relay contacts are opened, the indicator

ON of the load relay is off and the

product goes into standby mode until

power-off.

Periodic with on-delay

After energizing, the set delay time t

(Т regulator) occurs. During the

delay time the indicator ON of the

load relay (Fig.1 it.8) periodically

flashes.

At the end of the delay time the load

relay contacts NO and C are closed

for the set time t and the indicator

ON of the load relay is on. During the

delay time the indicator ON of the

load relay periodically is off.

At the end of the delay time the load

relay contacts are opened, and the product starts fulfillment of algorithm from the

beginning.

Periodic with time delay

when energizing

After energizing, the load relay contacts

NO and C are closed, the indicator

ONof the load relay (Fig.1 it.8) is on and

the set delay time t (Т regulator) occurs.

During the delay time the indicator ON

of the load relay (Fig.1 it.8) periodically

is off.

At the end of the delay time the load

relay contacts NO and C are open for

the set time t and the indicator ON of

the load relay is off. During the delay

time the indicator ON of the load relay periodically flashes.

At the end of the delay time the product starts fulfillment of algorithm from the

beginning.

Page 7

- 7 -

NOVATEK-ELECTRO REV-120

Table 3 (Continued)

Name and W knob

position

Description

Off-delay

After energizing, the product goes

into standby mode, in this case the

load relay contacts NO and C are

open, and the indicator ON of the

load relay (Fig.1 it.8) is off.

When control contact S is closed

with power supply terminal L, the

load relay contacts are closed, the

indicator ON of the load relay is on

and the product goes into standby

mode.

When control contact S is open, the set delay time t (Т regulator) occurs. During the

delay time the indicator ON of the load relay periodically is off.

At the end of the delay time the load relay contacts are open, the indicator ON of the

load relay is off and the product goes into standby mode.

In case of repeated closing of the control contact S, the algorithm is repeated.

Pulse 1

After energizing, the product goes

into standby mode, in this case the

load relay contacts NO and C are

open, and the indicator ON of the

load relay (Fig.1 it.8) is off.

When control contact S is closed,

the load relay contacts are closed,

the indicator ON of the load relay is

on and the set delay time t (Т

regulator) occurs. During the delay

time the indicator ON of the load

relay periodically is off.

At the end of the delay time the load relay contacts are open, the indicator ON of the

load relay is off and the product goes into standby mode.

In case of opening and repeated closing of the control contact S, the algorithm is

repeated.

Pulse 2

After energizing, the product goes

into standby mode, in this case the

load relay contacts NO and C are

open, and the indicator ON of the

load relay (Fig.1 it.8) is off.

When control contact S is closed,

the product continues being in

standby mode.

When control contact S is open, the

load relay contacts are open, the

indicator ON of the load relay is on

and the set delay time t (Т regulator) occurs. During the delay time the indicator ON

of the load relay periodically is off.

At the end of the delay time the load relay contacts are open, the indicator ON of the

load relay is off and the product goes into standby mode.

In case of closing the control contact S, the algorithm is repeated.

Page 8

- 8 -

REV-120 NOVATEK-ELECTRO

Table 3 (Continued)

Name and W knob

position

Description

On/off delay

After energizing, the product goes

into standby mode, in this case the

load relay contacts NO and C are

open, and the indicator ON of the

load relay (Fig.1 it.8) is off.

When control contact S is closed, the

set delay time t (Т regulator) occurs.

During the delay time the indicator

ON of the load relay periodically

flashes.

At the end of the delay time the load relay contacts are closed, the indicator ON of

the load relay is on and the product goes into standby mode.

When control contact S is open, the set delay time t (Т regulator) occurs. During the

delay time the indicator ON of the load relay periodically is off.

At the end of the delay time the load relay contacts are open, the indicator ON of the

load relay is off and the product goes into standby mode.

In case of repeated closing of the control contact S, the algorithm is repeated.

Pitch of the load relay

After energizing, the product

goes into standby mode, in this

case the load relay contacts NO

and C are open, and the

indicator ON of the load relay

(Fig.1 it.8) is off.

When control contact S is

closed, the load relay contacts

and the indicator ON of the load

relay change its state to the

opposite, and the product switches to standby mode.

When control contact S is open, the product continues being in standby mode.

In case of repeated closing of the control contact S, the algorithm is repeated.

Pulse generator of

0.5 s

After energizing, the set delay time

t (Т regulator) occurs. During the

delay time the indicator ON of the

load relay (Fig.1 it.8) periodically

flashes.

At the end of the delay time the

load relay contacts NO and C are

closed for 0.5 s, the indicator ON of

the load relay is on for 0.5 s and

the product goes into standby

mode until power-off.

3.2.1.2. Time interval adjustment

List of time intervals is given in Table 4.

Find the required time interval in Table 4 and set the regulator setting for the time interval ∆T (Fig.1 it.3) to

the required position.

Table 4 – Time intervals

∆T knob position

Time interval

∆T knob position

Time interval

1 s

from 0.1 to 1 s

10 h

from 1 to 10 h

10 s

from 1 to 10 s

1 d

from 0.1 to 1 day

1 m

from 6 s to 1 min

10 d

from 1 to 10 days

10 m

from 1 to 10 min

ON

Continuously ON

1 h

from 6 min to 1 h

OFF

Continuously OFF

Page 9

- 9 -

NOVATEK-ELECTRO REV-120

3.2.1.3. Time delay adjustment

Time delay adjustment is performed by the regulator for setting Т time.

Based on the selected time interval (it.3.2.1.2), set the required time delay.

3.2.2. Product connection

Connect the product in accordance with the diagram given in Fig.2.

QF1 – Circuit breaker (fuse), maximum current is 6 А;

Fig.2 – Product connection diagram

3.3. Use of the product

After the power supply to the product the indicator ON (Fig.1 it.9) is on, there is small pause (no more than

400 ms) before the product begins to operate according to the selected operation mode.

The enabled load relay status corresponds to the closed condition of the contacts NO1-C1 (NO2-C2) and

the open condition of the contacts NC1-C1 (NC2-C2).

The disabled load relay status corresponds to the open condition of the contacts NO1-C1 (NO2-C2) and

the closed condition of the contacts NC1-C1 (NC2-C2).

Periodic flashing of LED indicator of the load relay indicates the time delay after which the load relay will

on.

Periodic disabling of LED indicator of the load relay indicates the time delay after which the load relay will

off.

4. MAINTENANCE

4.1. Safety precautions

THE TERMINALS AND THE PRODUCT INTERNAL ELEMENTS CONTAINS POTENTIALLY

LETHAL VOLTAGE.

DURING MAINTENANCE IT IS NECESSARY TO DISABLE THE PRODUCT AND

CONNECTED DEVICES FROM THE MAINS.

4.2. Maintenance of the product must be performed by qualified service personnel.

4.3. Recommended frequency of maintenance is every six months.

4.4. Maintenance procedure:

1) Check the connection reliability of the wires, if necessary, clamp with the force specified in Table 1;

2) Visually check the integrity of the housing, in case of detection of cracks and damages to remove the

product from service and send for repair;

Page 10

- 10 -

REV-120 NOVATEK-ELECTRO

3) If necessary, wipe with cloth the front panel and the product housing.

Do not use abrasives and solvents for cleaning.

5. SERVICE LIFE AND MANUFACTURER WARRANTY

5.1. The lifetime of the product is 10 years. Upon expiration of the service life, contact the manufacturer.

5.2. Shelf life is 3 years.

5.3. Warranty period of the product operation is 5 years from the date of sale.

During the warranty period of operation (in the case of failure of the product) the manufacturer is

responsible for free repair of the product.

ATTENTION! IF THE PRODUCT HAS BEEN OPERATED IN VIOLATION OF THE REQUIREMENTS OF

THIS MANUAL, THE MANUFACTURER HAS THE RIGHT TO REFUSE IN WARRANTY SERVICE.

5.4. Warranty service is performed at the place of purchase or by the manufacturer of the product.

5.5. Post-warranty service of the product is performed by the manufacturer at current rates.

5.6. Before sending for repair, the product should be packed in the original or other packing excluding

mechanical damage.

You are kindly requested, in case of return of the product and transfer it to the warranty (post-

warranty) service, in the field of the claims data, list the detailed reason for return.

6. TRANSPORTATION AND STORAGE

The product in the original package is permitted to be transported and stored at the temperature from

minus 45 to +60 °C and relative humidity of no more than 80 %.

7. ACCEPTANCE CERTIFICATE

REV–120 has been manufactured and accepted in accordance with the requirements of current technical

documentation and classified as fit for operation.

Seal Head of QCD Date of manufacture

_____________ _____________

8. CLAIMS DATA

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

The Company is grateful to you for the information about the quality of the product and suggestions for its

operation.

For all questions, please contact the manufacturer:

NOVATEK ELECTRO INDIA PVT. LTD.

C-30, Patparganj Industrial Area, F.I.E.

Delhi – 110092, INDIA;

Tel.: +91 11 42143253

Tel./fax: +91 11 43010600

www.novatek-electro.in

Date of sale __________

Loading...

Loading...