Page 1

«NOVATEK-ELECTRO» Ltd

Intelligent Industrial Electronics

РН-11

SINGLE PHASE DIGITAL

VOLTAGE INDICATOR

OPERATING MANUAL

Quality control system on the production complies with requirements ISO 9001:2008

Review the Operating manual before using the unit.

Dear customer,

Company NOVATEK-ELECTRO LTD. thanks you for purchasing our products.

You will be able to use properly the product after carefully studying the Operating Manual.

Keep the Operating Manual throughout the service life of the product.

UKRAINE, Odessa www.novatek-electro.com

Page 2

- 2 -

PH-11 NOVATEK-ELECTRO

ATTENTION! ALL REQUIREMENTS OF THIS OPERATING MANUAL ARE COMPULSORY TO BE MET!

WARNING! – PRODUCT TERMINALS AND INTERNAL COMPONENTS ARE UNDER POTENTIALLY

LETHAL VOLTAGE

TO ENSURE THE PRODUCT SAFE OPERATION IT IS STRICTLY FORBIDDEN THE FOLLOWING:

TO CARRY OUT MOUNTING WORKS AND MAINTENANCE WITHOUT DISCONNECTING THE PRODUCT

FROM THE MAINS;

TO OPEN AND REPAIR THE PRODUCT INDEPENDENTLY;

TO OPERATE THE PRODUCT WITH MECHANICAL DAMAGES OF THE CASE.

IT IS NOT ALLOWED WATER PENETRATION ON TERMINALS AND INTERNAL ELEMENTS OF THE

PRODUCT.

If the temperature of the unit after transportation or storage is different from the temperature of the environment

in which its operation is assumed, then before connecting to the mains keep the unit in operation conditions for two

hours (because on the unit elements condensation may be available).

During operation and maintenance the regulatory document requirements must be met, namely:

Regulations for Operation of Consumer Electrical Installations;

Safety Rules for Operation of Consumer Electrical Installations;

Occupational Safety when in Operation of Electrical Installations

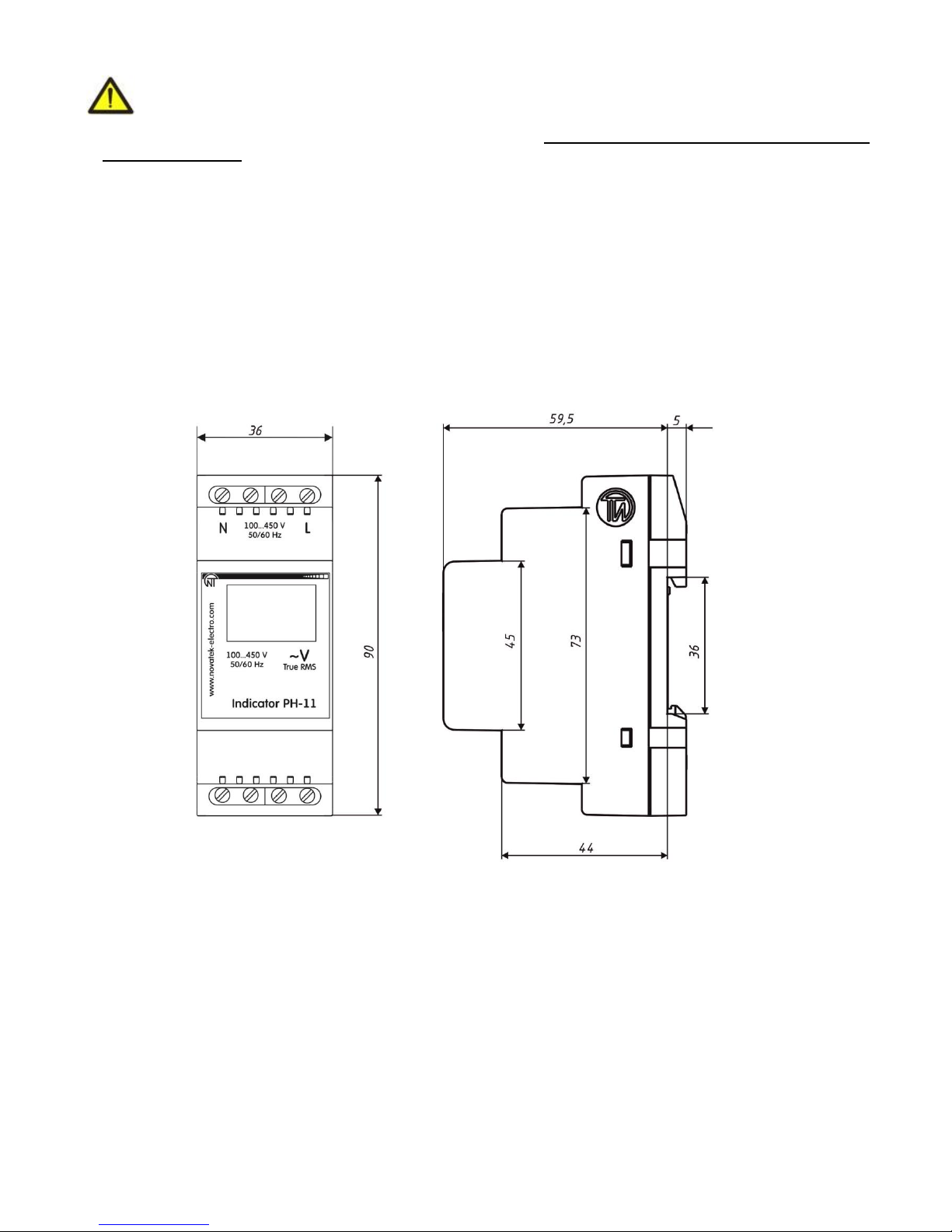

N – Network zero

L – Phase

Figure 1 – Overall and setting dimensions

The present Operating Manual is intended for familiarization with the design, safety requirements, operation and

maintenance procedure of the single phase digital voltage indicator РН-11 (hereinafter referred to as “the device”, “РН-

11”).

The device meets the requirements:

PH-11 complies with the requirements of the following international standards:

EN 60947-1; EN 55011; EN 60947-6-2.

Harmful substances in quantities exceeding the maximum permissible concentrations are not available.

Page 3

- 3 -

NOVATEK-ELECTRO PH-11

1. APPLICATION

1.1 РН-11 is designed to measure and display the RMS voltage of the single phase. The measured voltage

applied to terminals L, N of the devices at the same time is the supply voltage.

ATTENTION! DO NOT USE PH-11 IN LINE VOLTAGE CIRCUITS (380-415 V). PROLONGED MEASUREMENT

OF THE HIGHER VOLTAGE (MORE THAN 350 V) CAN REDUCE THE SERVICE LIFE OF THE DEVICE.

1.2 Overall and setting dimensions diagram

The overall and setting dimensions, is provided in Figure 1.

1.3 Operating Conditions

EM-486 is designed for operation in the following conditions:

Ambient temperature: from minus 35 to +55°С;

Atmospheric pressure: from 84 to 106.7 kPa;

Relative air humidity (at temperature of +25°С) 30 … 80%.

ATTENTION! The unit is not intended for use:

- in conditions of significant vibration and shocks;

- in high humidity conditions;

- in corrosion environments with content in the air of acids, alkalis, etc., as well as severe contamination (grease,

oil, dust, etc.).

2. TECHNICAL CHARACTERISTICS

The technical characteristics are resulted in the tables 1 and 2.

Table 1- General information

Item

Value

Purpose of device

Control and distribution equipment

Typical operation

Continued

Mounting

to standard 35 mm DIN-rail

Protection degree:

- face panel

- terminal block

IP40

IP20

Index protection of electrical shock

II

Climatic version

NC 3.1

Permissible degree of pollution

II

Overvoltage category

II

Nominal voltage of insulation, V

450

Rated impulse withstand voltage, kV

2.5

Connecting plugs cross section of conductors, mm2

0.3-3.3

Maximum torque of terminal screws, Nm

0.4

Table 2 - Main Technical Specifications

3. INTENDED USE

3.1. Preparation for operation

3.1.1. Preparation for connection:

Unpack the product (we recommend to keep the original packing for the entire warranty period of the product

operation);

Check the product for damage after transportation; in case of such damages detection, contact the supplier or

manufacturer;

Rated voltage, V

230

Rated voltage frequency, Hz

48 – 62

Harmonical configuration (nonsinusoidality) of power supply voltage

EN 50160:2010

Adjustment voltage ranges, V

100 – 450

Precision measurements of voltage in range 150 – 250 V, V

2

Precision measurements of voltage in range 100 – 450 V, V

4

Minimal operation voltage level at which PH-11 will keep working, V

90

Maximal operation voltage level at which PH-11 will keep working, V

450

Power consumption, W ,not more than

3.5

Overall dimensions (2 S-modules) H*B*L, mm

90*36*59,5

Operating position - arbitrary

Housing material - self-extinguishing plastic

Page 4

- 4 -

PH-11 NOVATEK-ELECTRO

Carefully study the Operation Manual (pay special attention to the connection diagram to power the

product);

If you have any questions regarding the installation of the product, please contact the manufacturer by

telephone number indicated at the end of this Operating Manual.

3.2 Product connection

To ensure the reliability of electrical connections you should use flexible (stranded) wires with insulation for

voltage of no less than 500 V, the ends of which it is necessary to be striped of insulation for 5±0.5 mm and

tightened with bootlaces. Recommended cable cross section for connection is not less 1 mm2. Wires fastening

should exclude mechanical damage, twisting and abrasion of the wire insulation.

IT IS NOT ALLOWED TO LEAVE EXPOSED PORTIONS OF WIRE PROTRUDING BEYOND THE TERMINAL

BLOCK.

For reliable contact it is necessary to perform tightening of screws of removable terminal block with the force

specified in Table 1.

When reducing the tightening torque, the junction point is heated, terminal block may be melted and wire cane burn. If

you increase the tightening torque, it is possible to have thread failure of terminal block screws or the compression of the

connected wires.

To improve operational properties of the product it is recommended to install the fuse or its analogue for

1 A current in power supply circuit for PH-11.

3.2.1 Connect the device (terminals L, N) to the mains.

3.2.2 Apply the supply voltage.

When applying the voltage to the indicator for short moment (0.2 s) it displays the inscription “”, and then the

RMS value of the measured voltage appears.

If the RMS value of the measured voltage is less than 100 V, then the indicator displays the code "". If the

RMS value of the measured voltage is more than 450 V, then the indicator displays the code "".

4 MAINTENANCE

4.1 Safety precautions

THE TERMINALS AND THE PRODUCT INTERNAL ELEMENTS CONTAINS POTENTIALLY LETHAL

VOLTAGE.

DURING MAINTENANCE IT IS NECESSARY TO DISABLE THE PRODUCT AND CONNECTED

DEVICES FROM THE MAINS

4.2 Maintenance of the unit should be performed by persons admitted to the operation and have the appropriate

permission.

4.3 The recommended frequency of maintenance is every six months.

4.4 Maintenance Procedure:

1) check the wires connection reliability, if necessary – clamp with force as specified in Table 3.1;

2) check visually the housing integrity;

3) if necessary, wipe with cloth the front panel and the unit housing.

It is not allowed to clean the unit with abrasive materials or organic compounds (alcohol, gasoline, solvents, etc.).

5 SERVICE LIFE AND WARRANTY

5.1 Service life – is 10 years. Contact manufacturer upon the expiry of the service life.

5.2 Guaranteed storage life – is 3 years.

5.3 Warranty period of the unit operation is 5 years from the date of sale.

During the warranty period the Manufacturer is responsible for free repair of the unit, if the Consumer has

complied with the requirements of this Operating Manual.

ATTENTION! IF THE UNIT HAS BEEN OPERATED WITH VIOLATION OF THE REQUIREMENTS OF THIS

OPERATION MANUAL, THE MANUFACTURER HAS THE RIGHT TO REFUSE WARRANTY SERVICE.

5.4 Warranty service is performed at the place of purchase or by the Manufacturer of the product.

5.5 Post-warranty service is performed by the Manufacturer at current rates.

5.6 Before sending for repair, the unit should be packed in the original or other packaging excluding mechanical

damage.

Please, when returning the unit or sending it for warranty or post warranty repair, in reclamation data line in passport,

explain in details the reason of returning.

6 TRANSPORTATION AND STORAGE

PH-11 in the shipping box should be stored indoors at a temperature of -45 to +60 C and relative humidity of no

more than 80% with no vapors available in the air, capable of producing harmful effect on the shipping box and unit

materials.

Page 5

- 5 -

NOVATEK-ELECTRO PH-11

7 ACCEPTANCE CERTIFICATE

PH-11 is manufactured and accepted in accordance with the applicable technical documentation and considered

as fit for use.

Stamp Head of quality division Date of manufacture

__________________ _________________

Date of sale ___________________

8 DATA ON CLAIMS

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

Please contact the manufacturer should you have any questions.

"Novatek-Electro" Ltd.

59, Adm. Lazarev Str.,

Odessa, Ukraine, 65007

Tel. +38 (0482) 37-48-27, +38 (048) 738-00-28;

Tel/Fax +38 (0482) 34-36-73;

www.novatek-electro.com

VN170518

Loading...

Loading...