Novatech Pulsafeeder MicroVision Timer Installation Manual

Timer

sales@novatech-usa.com

www.novatech-usa.com

Tel: (866) 433-6682 Fax: (866) 433-6684

Tel: (281) 359-8538 Fax: (281) 359-0084

MicroVision

MICROPROCESSOR TIMER CONTROLLER

Installation Operation Manual

72-910-23 Rev.F

Page 1 of 30

Table of Contents

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

1. INTRODUCTION ................................................................................................................................ 4

2. MICROVISION FEATURES ............................................................................................................... 4

2.1 Output Relays ................................................................................................................................ 4

2.2 Inputs: ........................................................................................................................................... 4

2.3 Drum Levels .................................................................................................................................. 5

2.4 Flow Switch .................................................................................................................................. 5

2.5 Water Meter .................................................................................................................................. 5

2.6 Alarm Relay (Relay #5) ................................................................................................................ 5

3. INSTALLATION ................................................................................................................................. 6

3.1 Opening The Enclosure ................................................................................................................. 6

3.2 Location ........................................................................................................................................ 6

3.3 Mounting Hardware ...................................................................................................................... 7

3.4 Flow Sensor Switch ...................................................................................................................... 7

3.5 TYPICAL INSTALLATION ........................................................................................................ 8

4. IMPORTANT SYMBOL INFORMATION ......................................................................................... 8

5. ELECTRICAL WIRING ...................................................................................................................... 9

5.1 RELAY BOARD CONNECTIONS ........................................................................................... 10

5.2 Conduit Models (Wiring High Voltage) ..................................................................................... 10

5.3 LOW VOLTAGE CONNECTIONS .......................................................................................... 11

5.4 Inputs........................................................................................................................................... 12

5.4.1 Input # 1 .............................................................................................................................. 12

5.4.2 Input # 2 to # 4 .................................................................................................................... 12

5.4.3 Input # 5 .............................................................................................................................. 12

5.5 Alarm Relay ................................................................................................................................ 12

6. FRONT PANEL DESCRIPTION ....................................................................................................... 13

6.1 Keypad Operation ....................................................................................................................... 13

7. CONTROLLER PROGRAMMING ................................................................................................... 14

7.1 Menu Tree ................................................................................................................................... 14

7.2 Menu Navigation ........................................................................................................................ 14

7.3 Home screen ................................................................................................................................ 15

7.4 Main Menu .................................................................................................................................. 15

7.5 Status Screen ............................................................................................................................... 15

7.6 Configure Menu .......................................................................................................................... 16

7.7 Date/Time Menu ......................................................................................................................... 17

7.8 HOA Outputs Menu .................................................................................................................... 17

7.9 Inputs Menu ................................................................................................................................ 18

7.10 Drum Levels Sub Menu .............................................................................................................. 18

7.11 Display Contrast Setting ............................................................................................................. 19

7.12 Gallons or Liters ......................................................................................................................... 19

7.13 Scrolling ...................................................................................................................................... 19

7.14 Totalizers..................................................................................................................................... 19

7.15 Password Setting ......................................................................................................................... 20

8. Troubleshoot Screen ........................................................................................................................... 20

9. Software Version ................................................................................................................................ 21

10. Factory Reset Function ................................................................................................................... 21

11. Settings Menu ................................................................................................................................. 21

11.1 Timer Mode Menus ..................................................................................................................... 22

11.2 Timer Modes – Pulse Timer Menu ............................................................................................. 22

11.3 28 Day Menu ............................................................................................................................... 23

11.4 28 Day Menu – Days/Weeks Menu ............................................................................................ 23

11.5 Cycle Timer Menu ...................................................................................................................... 24

72-910-23 Rev.F

Page 2 of 30

11.6 Cycle Timer Menu – Start Times ................................................................................................ 24

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

12. Factory Defaults .............................................................................................................................. 25

13. TROUBLESHOOTING GUIDE .................................................................................................... 26

14. MAINTENANCE ........................................................................................................................... 27

15. SPECIFICATIONS ......................................................................................................................... 27

16. MOUNTING HOLE PATTERN (Footprint) .................................................................................. 28

17. Factory Service Policy .................................................................................................................... 29

18. Warranty ......................................................................................................................................... 29

72-910-23 Rev.F

Page 3 of 30

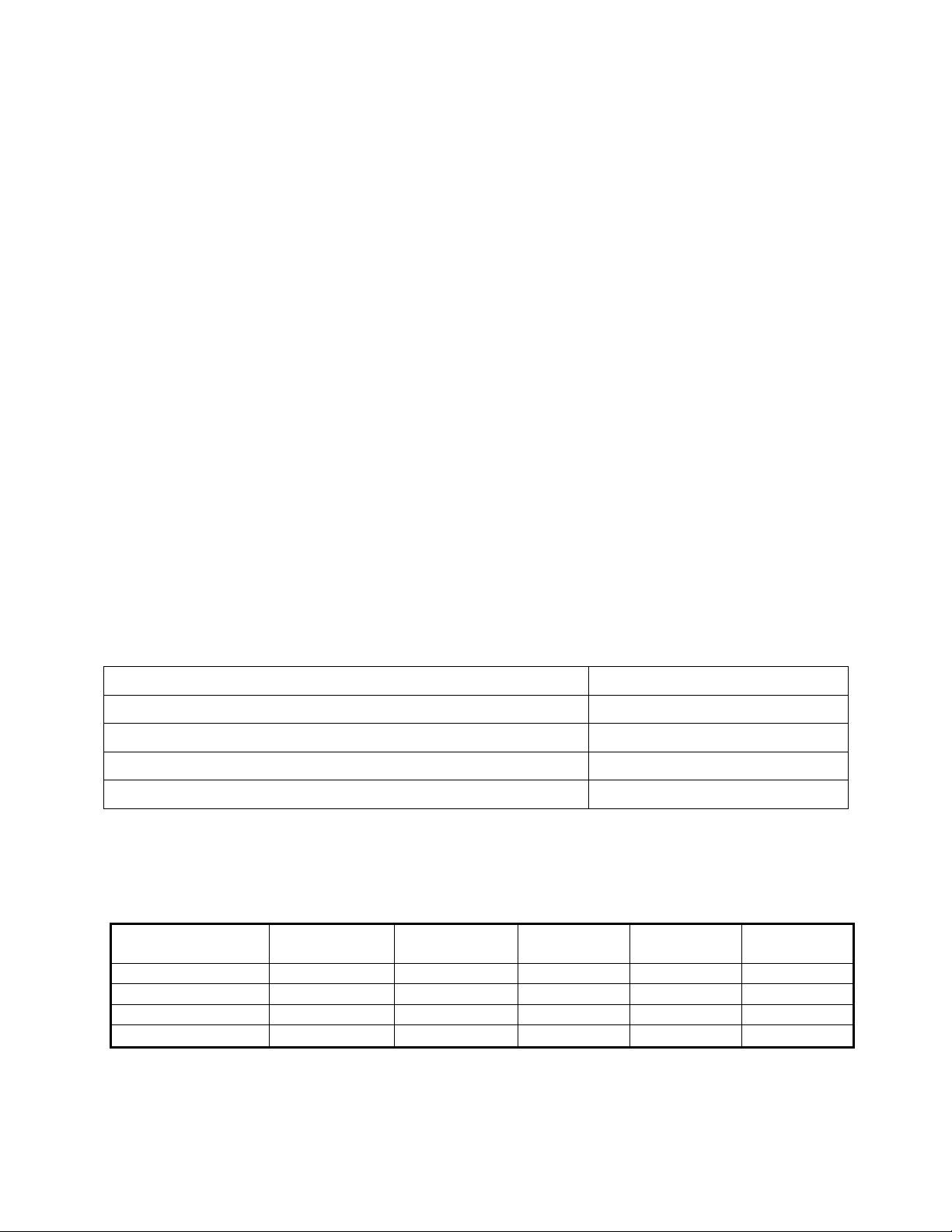

RELAY STATUS

LED COLOR

ON (FORCED ON FOR 5 MIN.)

AMBER

OFF

RED

AUTOMATIC ‘ON’

GREEN

AUTOMATIC ‘OFF’

OFF

Programmable

Inputs

Input 1

Input 2

Input 3

Input 4

Input 5

Drum Level

X ( Timer 1)

X (Timer 2)

X (Timer 3)

X (Timer 4)

X (Timer5)

Water meter

X X X X X

Hall effect

X

Flow

X

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

1. INTRODUCTION

The MicroVision microprocessor based cooling tower controller has been designed to

control up to four (4) independent powered timer outputs. Each output can be

programmed in any one of the following modes, Pulse timer, Percent timer, 28 day

Biocide timer, or as a cycle timer. Relay number 5 may be programmed as an alarm

dry contact or as a fifth timer with a dry contact output.

The MicroVision has five (5) output relays assigned as follows:

Relay 1 – Timer #1

Relay 2 – Timer #2

Relay 3 – Timer #3

Relay 4 – Timer #4

Relay 5 – Alarm or Timer #5 (normally open dry contact)

2. MICROVISION FEATURES

2.1 Output Relays

The control of the four HANDS – OFF – AUTO (HOA) output relays can be controlled

using the HOA menu.

2.2 Inputs:

The MicroVision has 5 digital inputs that can be programmed as follows:

72-910-23 Rev.F

Page 4 of 30

2.3 Drum Levels

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

When an input is defined as a drum level it is linked to the corresponding relay

output. For example, if input #1 is set as drum level, it will be linked to relay one

and may be set by the user to either deactivate the relay, or only to activate an

alarm.

2.4 Flow Switch

MicroVision has a dry contact flow switch option for input number 5 only that will deactivate all of the control output relays upon a no-flow indication. An Alarm

condition will be indicated and “No Flow” will be displayed. This input is active closed:

Open = no flow; closed = flow.

If a flow switch input or other alarm condition exists, the four (4) LED’s will flash until

the alarm condition is cleared.

2.5 Water Meter

Each input may be programmed as water meter inputs that are capable of reading

a dry contact water meter. Input number one can be set to read a hall effect type

water meter. Through programming this input can be used to feed inhibitor as well as

totalizing water consumption.

2.6 Alarm Relay (Relay #5)

MicroVision has a dedicated dry contact relay that can be used to interface with

process control equipment or visual indicators. This relay is un-powered and may also

be programmed as a timer.

72-910-23 Rev.F

Page 5 of 30

3. INSTALLATION

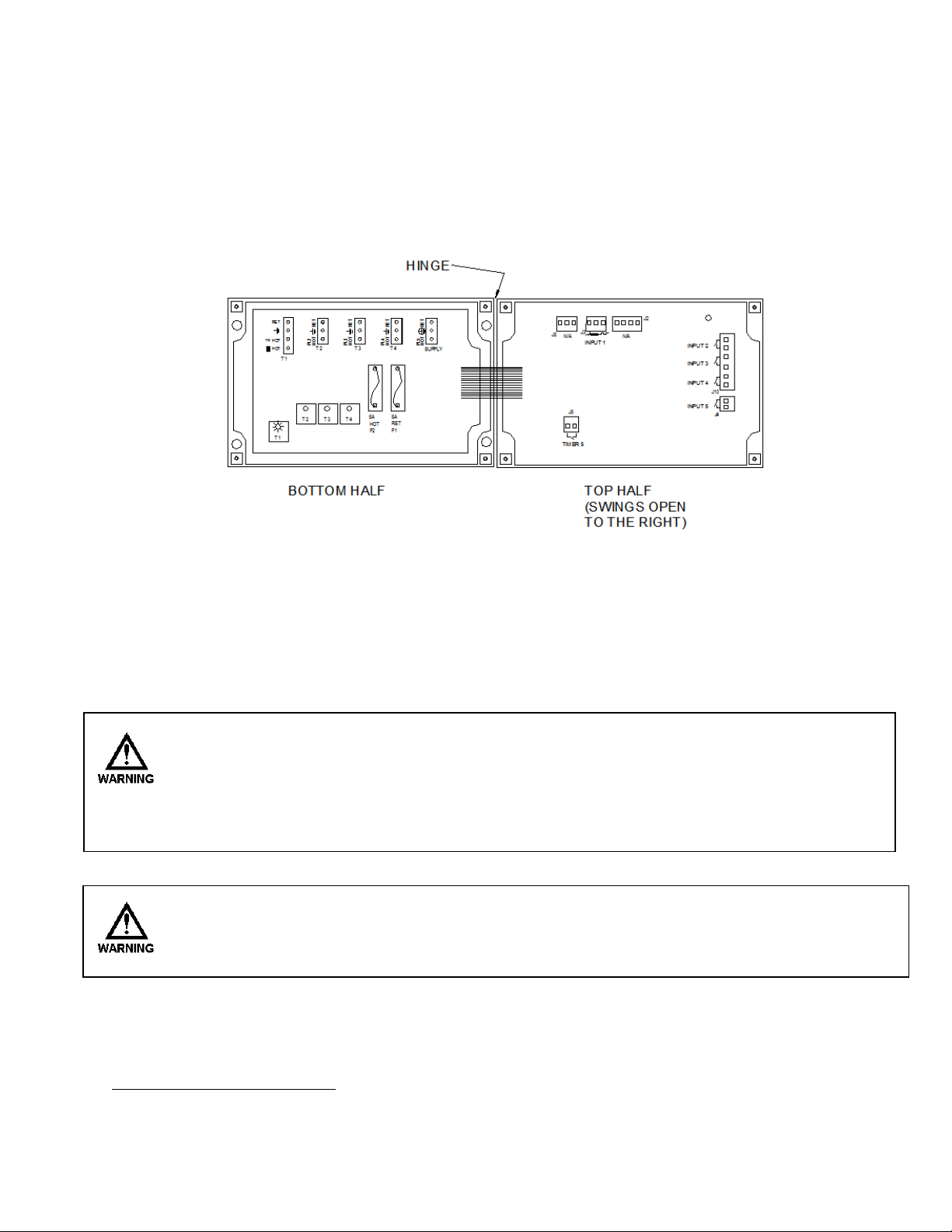

3.1 Opening The Enclosure1

Loosen the four (4) screws on the front of the controller and carefully swing the top of the

case to the right (Fig. 1).

Fig. 1

3.2 Location

Select a mounting location convenient to grounded electrical and plumbing connections. It

is recommended that you mount the controller on a wall or other vertical surface with

adequate lighting at a comfortable level. Installation should comply with all national, state,

and local codes.

AVOID LOCATIONS WHERE THE CONTROLLER WOULD BE SUBJECTED TO EXTREME COLD OR

HEAT {LESS THAN 0°F (-17,8°C) OR GREATER THAN 122°F (50°C)}, DIRECT SUNLIGHT,

VIBRATION, VAPORS, LIQUID SPILLS, OR EMI (ELECTROMAGNET INTERFERENCE; E.G., STRONG

RADIO TRANSMISSION AND ELECTRIC MOTORS.)

SAFETY PROTECTION PROVIDED BY THE EQUIPMENT MAY BE IMPARED IF THE

EQUIPMENT IS USED IN A MANNER NOT SPECIFIED BY THE MANUFACTURER. THIS CONTROLLER IS

INTENDED FOR INDOOR USE ONLY.

1

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

Trained service personnel are required for all electrical connections. This product does not contain operator

serviceable parts.

72-910-23 Rev.F

Page 6 of 30

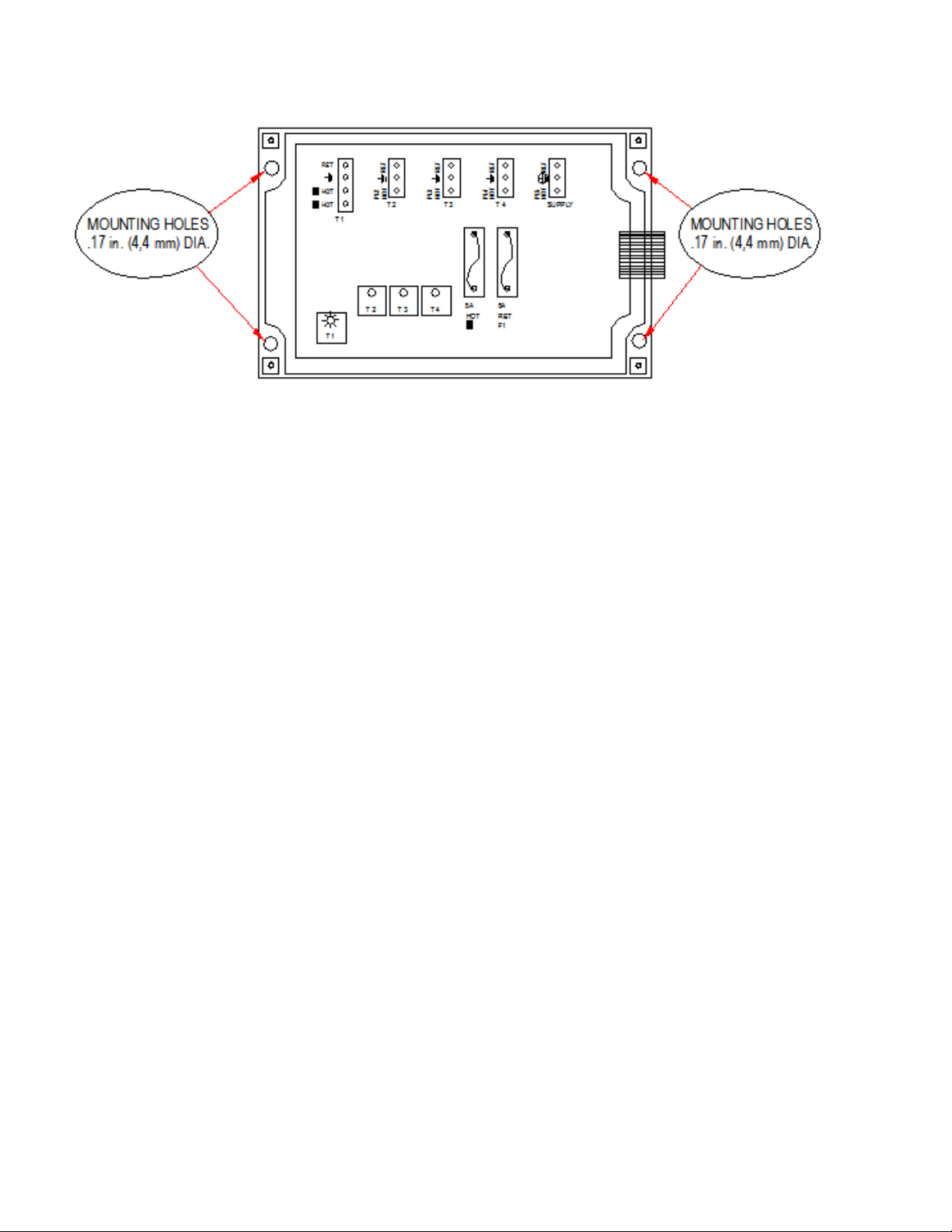

Fig. 2

Mount the bottom half of the controller using the four (4) holes provided (Fig. 2).

3.3 Mounting Hardware

For panel mounts without threaded inserts, four number 8 self taping screws are the minimum

recommendation.

For panel mounts with threaded inserts, four 8-32 screws are the minimum recommendation.

Panel mount hardware should support 25lbs. For hole locations, see the mounting hole

pattern (Fig. 9) found on the page 22 of manual.

3.4 Flow Sensor Switch

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

If your controller is provided with a flow switch, install the flow switch so that flow

enters into the bottom of the flow switch tee, and out of the side of the tee. The flow

switch must always be installed in a vertical position so that the sensor wire is coming

out of the top, and the internal (red) flow shuttle is able to rise when there is flow and

drop when there is no flow. The flow switch is activated when 1 GPM (3,8 LPM) is

going through it, and is deactivated when the flow drops below 1 GPM (3,8 LPM).

72-910-23 Rev.F

Page 7 of 30

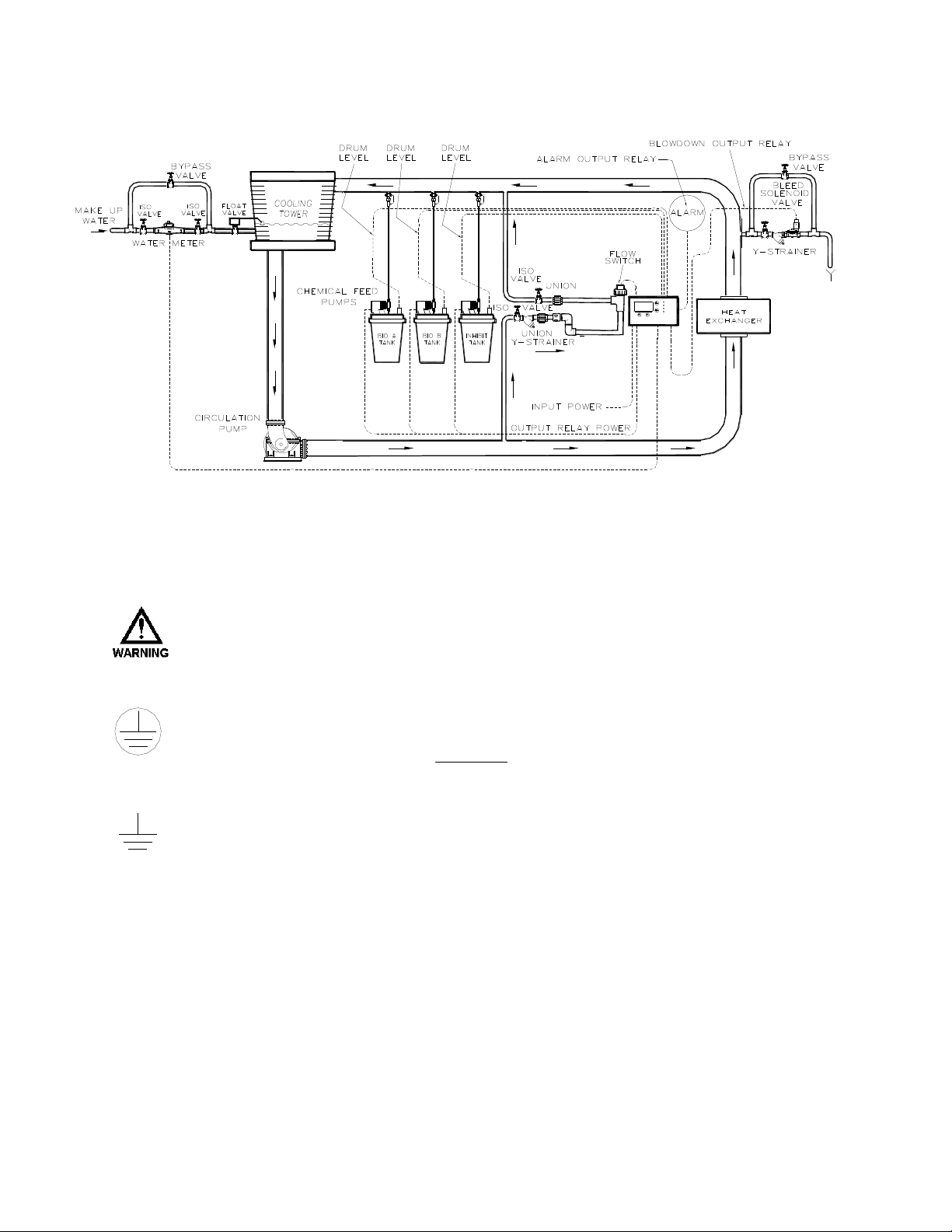

3.5 TYPICAL INSTALLATION

MicroVision

Timer 1

DISPLAY

SCREEN

TIMER

Timer 2

Timer 3

Timer 4

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

Fig. 3

4. IMPORTANT SYMBOL INFORMATION

Warning indicates a condition that could cause damage to both

the equipment and the personnel operating it. Pay close attention

to any warning.

Primary Supply Ground must be connected to earth ground for safe

operation of your controller.

Chassis Ground – Connect your equipment’s ground wire here for

safe operation of your external devices.

72-910-23 Rev.F

Page 8 of 30

5. ELECTRICAL WIRING2

Controller must be wired in accordance with all applicable electrical codes.

Input power must be 120 or 220VAC Single Phase.

Trained service personnel are required for all electrical connections. This

product does not contain operator serviceable parts.

Devices attached to any Relay connection must be Single Phase and rated for

the same voltage as the input voltage to the product. (e. g. 120VAC MicroTrac

controllers support 120VAC relay attached devices exclusively and 220VAC

MicroTrac controller support 220VAC relay attached devices exclusively.)

Input power cord must be disconnected from power source prior to opening the

product’s enclosure and making any electrical connections.

The controller should be connected to a dedicated power branch (i.e., its own

wiring, circuit breaker, etc.). For best results, the ground should be

independent (true earth) not shared.

A switch or circuit-breaker, marked as the unit’s disconnecting device should

be included in the installation. It should be in close proximity to the unit and

easily reached by the user.

2

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

The MicroVision electronic input circuitry is fuse protected on both the hot and neutral inputs using

a replaceable five (5) amp fuse (Fig .6). For additional protection of your instrument, use of a surge

protector is recommended.

Pre-wired controllers are supplied with a 3-wire grounded power cord and 3-wire grounded

receptacle cords for all controlled line voltage outputs.

Trained service personnel are required for all electrical connections. This product does not contain operator

serviceable parts.

72-910-23 Rev.F

Page 9 of 30

Loading...

Loading...