Page 1

Adam Equipment

PTS SERIES

With AE402 Indicator

(P.N. 3106610715, Revision E, April 2011)

Adam Equipment 2011 ©

Page 2

Adam Equipment 2011 ©

Page 3

Thank you for purchasing the ADAM PTS Pallet Truck.

For your safety and correct operation, please read the following instructions

carefully before using it.

CONTENT

1.0 SAFETY ............................................................................................................................. 3

2.0 INSTRUCTION ..................................................................................................................5

2.1 SPECIFICATIONS ......................................................................................................... 5

2.2 PACKING LIST..............................................................................................................5

3.0 INSTALLATION.................................................................................................................. 8

3.1 AE 402 ASSEMBLY .................................................................................................... 10

4.0 CALIBRATION .................................................................................................................13

5.0 TROUBLE SHOOTING .................................................................................................. 14

6.0 MAINTENANCE ..............................................................................................................15

1 Adam Equipment 2011 ©

Page 4

2 Adam Equipment 2011 ©

Page 5

1.0 SAFETY

• To prevent damage to the scale, please read these operating instructions thoroughly.

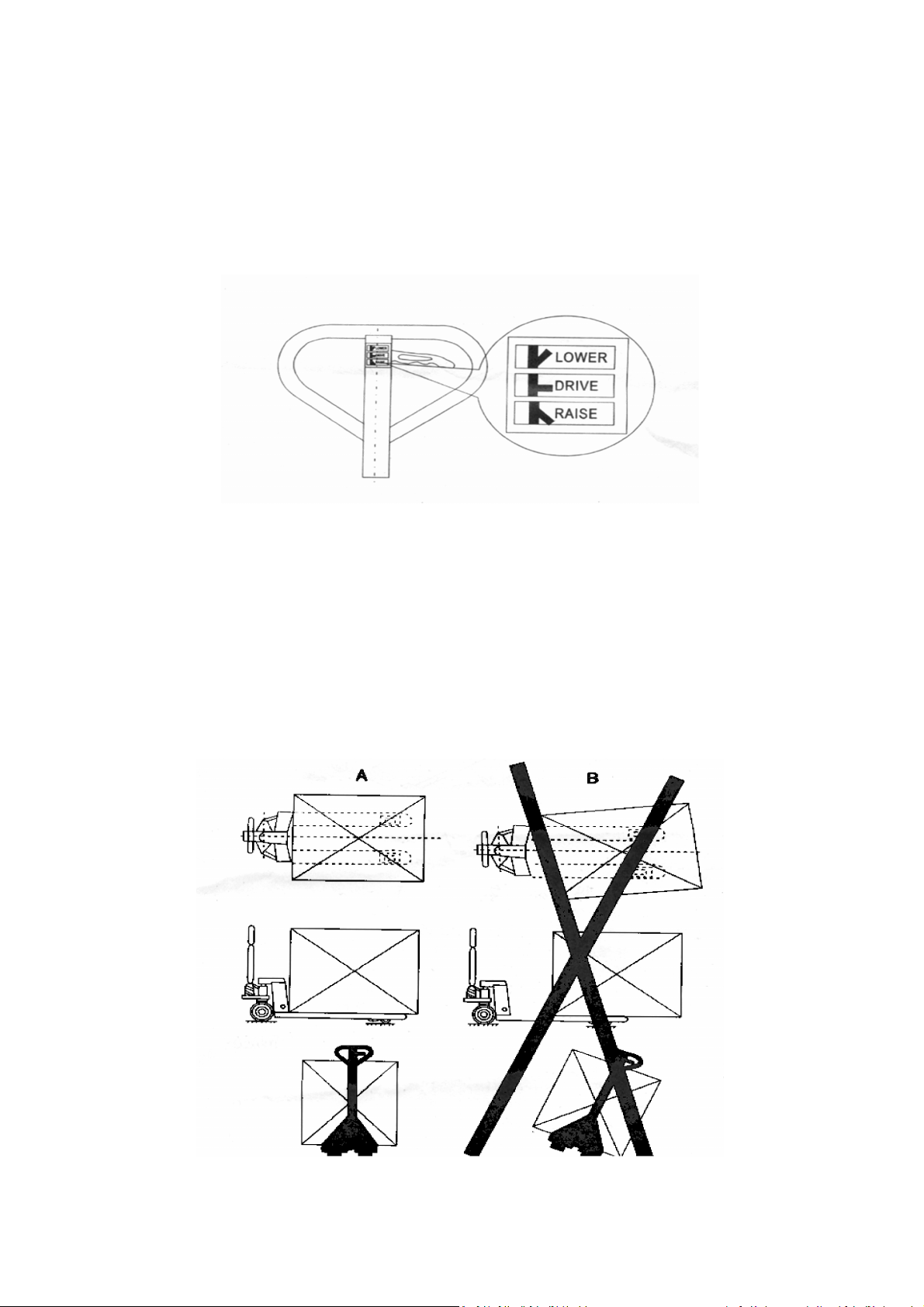

• When using the pallet truck, please keep the handle in the DRIVE position.

• This pallet truck must be operated by trained personnel only.

• Check the pallet truck first before using it making sure that the wheels, handles and forks

are fitted correctly and secure

• Avoid unsuitable and uneven floor surfaces

• Please wear protective clothing where necessary

• Allow 60cm clearance from the pallet truck when operating.

• Pay attention and focus on the object you are lifting

• Do not overload.

3 Adam Equipment 2011 ©

Page 6

4 Adam Equipment 2011 ©

Page 7

2.0 INSTRUCTION

2.1 S

PECIFICATIONS

Common specifications

Model PTS 2000 PTS 5000a

Load cell Capacity 2000 kg 5000Lb

Resolution 0.5 kg 1Lb

Fork length 1150mm (45.25“) 1220mm (48”)

Fork Width (each) 160mm (6.3”) 160mm (6.3”)

Fork Width (total) 540mm (21.25”) 680mm (26.77”)

Fork Height 77mm increasing to 192mm

(3” – 7.5”)

Net Weight 125 kg (275 Lb) 135 kg (297 Lb)

77mm increasing to 192mm

(3” – 7.5”)

See the User Manual for the Indicator supplied with the PTS for more

information about the weighing features and operation.

2.2 P

Part No. Part name QTY

3101410695 Indicator mounting bracket, upper 1

301177255 M4 x 6 SS Soc Head cap Screw din912-A2

3106610715 PTS Manual/Instructions 1

3101010700 M4 Allen key 1

3101710929 Roller pin φ 20 x 86 1

3101710930 Spring pin φ 5 x32 1

3101711228

3101210931 Handle 1

2100010935 AE402 indicator assembly 1

3104010713 AE402 load cell cable 1

ACKING LIST

Split Pin φ5×50(galvanized)

4

1

5 Adam Equipment 2011 ©

Page 8

6 Adam Equipment 2011 ©

Page 9

7 Adam Equipment 2011 ©

Page 10

3.0 INSTALLATION

Please follow the installation instructions to ensure correct operation of your

PTS. In transportation the handle is removed from the truck, this needs to be

installed following the instructions below:

NOTE: Do not lower the handle down fully until completing the instructions

below.

1) Insert the roller pin into the hole of roller rack, securing the handle to the

frame.

2) Fit the split pin through the holes provided.

3) Pass the chain through the center hole of the roller pin. Secure the end of

the chain to the slot on the end of the unloading plate.

4) Remove the transit rod before use. Press the handle down only far enough to

release any pressure on the transit rod, then pull the transit rod free.

8 Adam Equipment 2011 ©

Page 11

9 Adam Equipment 2011 ©

Page 12

3.1 AE 402 ASSEMBLY

Rear view of AE 402 Indicator

Fit the PTS to Indicator cable as shown in the picture below:

5 pin connector

fitted here

10 Adam Equipment 2011 ©

Page 13

The Indicator bracket is fitted to the PTS using 4 x M4 screws as the picture

below shows, these should be tightened using the Allen Key supplied .

M4 x 6 Screws

4 places

The Indicator cable goes through the hole on the bracket and connects to the

Indicator using the 7 pin connector.

7 pin connector

fitted here.

11 Adam Equipment 2011 ©

Page 14

Plastic fasteners used to

secure Indicator to the

The AE 402 indicator is placed into the mounting bracket, and secured using

the two plastic fasteners as shown below:

bracket.

12 Adam Equipment 2011 ©

Page 15

4.0 CALIBRATION

The PTS is factory calibrated, please refer to the user manual for the indicator

supplied (AE 402) when further calibration when required.

13 Adam Equipment 2011 ©

Page 16

5.0 TROUBLE

No.

1

2

3

4 Oil spillage

5

Problem Cause Solution

Forks cannot ascend

to the maximum

height

Forks can not be

raised

Forks can not

descend

Forks descend when

the trigger is not in

descend position

SHOOTING

Inadequate hydraulic oil in the chamber. Refill oil chamber. See Figure 1.

No hydraulic oil.

Oil is not clean.

Position of the goods are to one side of the truck

Aging or damaged seals. Call for Service.

The oil could be unclean

Some parts of the hydraulic system are damaged.

Refill oil chamber. See Figure 1 .

Change oil

Relocate load.

.

Change the oil.

Vent the air.

Call for Service.

Fig 1

14 Adam Equipment 2011 ©

Page 17

6.0 MAINTENANCE

• Please check the oil every six months , we suggest you use hydraulic oil: ISO

VG32

• Whilst in transit air may enter into the hydraulic pump, this may result in the

forks not raising when first used. Please move the handle up and down

several times to allow air to escape.

• Routine maintenance is necessary. You should focus on the wheels and

handle assemblies. When the truck is not in use, remove the items on the

forks, and reset the forks to their lowest position.

• All the bearings and axles have been lubricated, please check at regular

intervals

15 Adam Equipment 2011 ©

Page 18

16 Adam Equipment 2011 ©

Page 19

accordance with the instruction manual, may cause harmful interference to radio communications.

Manufacturer’s Declaration of Conformity

This product has been manufactured in accordance with the harmonised European standards, following the

provisions of the below stated directives:

Electro Magnetic Compatibility Directive 2004/108/EC

Low Voltage Directive 2006/95/EC

Adam Equipment Co. Ltd.

Bond Avenue, Denbigh East

Milton Keynes, MK1 1SW

United Kingdom

FCC COMPLIANCE

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. The

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

Operation of this equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

Shielded interconnect cables must be employed with this equipment to insure compliance with the pertinent

RF emission limits governing this device.

Changes or modifications not expressly approved by Adam Equipment could void the user's authority to

operate the equipment.

WEEE COMPLIANCE

Any Electrical or Electronic Equipment (EEE) component or assembly of parts intended to be incorporated

into EEE devices as defined by European Directive 2002/95/EEC must be recycled or disposed using techniques

that do not introduce hazardous substances harmful to our health or the environment as listed in Directive

2002/95/EC or amending legislation. Battery disposal in Landfill Sites is more regulated since July 2002 by

regulation 9 of the Landfill (England and Wales) Regulations 2002 and Hazardous Waste Regulations 2005. B

are set to impose targets for

Adam Equipment 2011 ©

Page 20

ADAM EQUIPMENT is an ISO 9001:2008 certified global organisation with more than 30

years experience in the production and sale of electronic weighing equipment. Products are

sold through a world wide distributor network supported from our company locations in the

UK, USA, SOUTH AFRICA and AUSTRALIA.

ADAM’s products are predominantly designed for the Laboratory, Educational, Medical and

Industrial Segments. The product range is as follows:

-Analytical and Precision Laboratory Balances

-Counting Scales for Industrial and Warehouse applications

-Digital Weighing/Check-weighing Scales

-High performance Platform Scales with extensive software

features including parts counting, percent weighing etc.

-Crane scales for heavy-duty industrial weighing

-Digital Electronic Scales for Medical use

-Retail Scales for Price computing

© Copyright by Adam Equipment Co. Ltd. All rights reserved. No part of this

publication may be reprinted or translated in any form or by any means without the

prior permission of Adam Equipment.

Adam Equipment reserves the right to make changes to the technology, features,

specifications and design of the equipment without notice.

All information contained within this publication is to the best of our knowledge

timely, complete and accurate when issued. However, we are not responsible for

misinterpretations which may result from the reading of this material.

The latest version of this publication can be found on our Website.

Visit us at www.adamequipment.com

Adam Equipment 2011 ©

Loading...

Loading...