Page 1

PMB Moisture Analyzer

(P.N. 9618, Revision D, June 2009)

Adam Equipment

Software revisions V1.27 and up

© Adam Equipment Company 2009

Page 2

Easy Reference:

Model name of the analyzer:

Serial number of the unit:

Software revision number

(Displayed when power is first turned

on):

Date of Purchase:

Name of the supplier and place:

© Adam Equipment Company 2009

Page 3

1.0 CONTENTS

1.0 CONTENTS ...........................................................................................................................1

2.0 INTRODUCTION....................................................................................................................3

3.0 SET UP ..................................................................................................................................5

3.1 UNPACKING AND SETTING UP YOUR ANALYZER....................................................................................5

3.2 ASSEMBLING THE ANALYZER....................................................................................................................6

3.3 LEVELLING THE ANALYZER........................................................................................................................7

3.4 WARM-UP TIME............................................................................................................................................7

3.5 LOCATING AND PROTECTING YOUR ANALYZER.....................................................................................8

3.6 SAFETY.........................................................................................................................................................9

4.0 DISPLAY and KEYPAD ......................................................................................................13

4.1 NUMERIC ENTRY METHOD.......................................................................................................................15

5.0 REAR PANEL INTERFACES..............................................................................................16

5.1 POWER........................................................................................................................................................16

5.2 DATA INTERFACES....................................................................................................................................16

5.2.1 FILES ON A USB MEMORY DEVICE ............................................................................................17

5.3 SECURITY LOCK ........................................................................................................................................17

6.1 SETUP OF METHOD...................................................................................................................................18

6.1.1 MANUALLY SETTING TEST PROCEDURES.................................................................................20

6.1.2 PRINT CURRENT SETTINGS.........................................................................................................26

6.2 STORE TEST SETTINGS...........................................................................................................................27

6.3 RECALL TEST SETTINGS ..........................................................................................................................28

6.4 DELETE TEST SETTINGS ..........................................................................................................................29

6.5 REVIEW TEST SETTINGS.........................................................................................................................29

6.6 STORE and RECALLING TEST SETTINGS FROM USB MEMORY...........................................................29

7.0 RUNNING A TEST...............................................................................................................33

8.0 PRINT AND STORE RESULTS...........................................................................................37

8.1 PRINTING FINAL TEST RESULTS .............................................................................................................37

8.2 STORING TEST RESULTS .........................................................................................................................37

8.3 RECALLING TEST RESULTS ...................................................................................................................38

8.4 DELETING TEST RESULTS......................................................................................................................38

9.0 STORING RESULTS IN USB MEMORY.............................................................................40

10.0 ANALYZER MENUS............................................................................................................42

10.1 SUPERVISOR MENUS................................................................................................................................42

10.1.1 SERIAL INTERFACE PARAMETERS.............................................................................................44

10.1.2 SETUP PARAMETERS...................................................................................................................45

10.1.3 CALIBRATION.................................................................................................................................47

10.1.3.1 MASS CALIBRATION.....................................................................................................................47

10.1.3.2 TEMPERATURE CALIBRATION.....................................................................................................48

10.1.3.3 CALIBRATION REPORT.................................................................................................................51

10.1.4 PASSCODES ..................................................................................................................................52

10.1.4.1 FORGOTTEN PASSCODES...........................................................................................................52

10.2 STORE AND RECALL ANALYZER SETTING FROM USB MEMORY.......................................................53

11.0 SERIAL INTERFACE..........................................................................................................56

11.1 RS-232 HARDWARE ...................................................................................................................................56

11.2 USB SERIAL HARDWARE ..........................................................................................................................56

11.3 INPUT COMMANDS ....................................................................................................................................57

11.4 PRINTING RESULTS...................................................................................................................................57

11.5 ANALYZER CONFIGURATION THROUGH THE SERIAL INTERFACE.....................................................60

11.5.1 TEST PARAMETERS......................................................................................................................60

11.5.2 ANALYZER SETUP PARAMETERS ...............................................................................................61

11.5.3 ANALYZER RECALL PARAMETERS .............................................................................................62

11.5.4 REQUEST VALUES OF PARAMETERS........................................................................................ 62

11.6 CONTINUOUS OUTPUT .............................................................................................................................63

12.0 SPECIFICATIONS & FEATURES.......................................................................................64

13.0 MENU STRUCTURE............................................................................................................67

14.0 SAMPLE PREPARATION...................................................................................................73

15.0 GUIDANCE NOTES.............................................................................................................75

16.0 WARRANTY STATEMENT ................................................................................................80

1

| Page © Adam Equipment Company 2009

Page 4

2

| Page © Adam Equipment Company 2009

Page 5

2.0 INTRODUCTION

Thank you for selecting the PMB Moisture Analyzer.

This Instruction Manual will familiarize you with the installation, accessories,

trouble-shooting, after sales service information, general maintenance of the

analyzer, etc. and will guide you through the various applications.

Please read this Manual thoroughly before starting the operation. If you need

any clarifications, feel free to contact your supplier or Adam Equipment.

PRODUCT OVERVIEW

The PMB Moisture analyzers are ideal for laboratory and general purpose

weighing.

FEATURES:

• Large easy to read LCD display with

backlight

• Bi-directional RS-232 interface and

USB interface.

• USB Host connection for memory

device

• Can be configured to print a GLP

Compliant report after each calibration

to include the time, date, analyzer

number and a verification of the

calibration

• 400 watt Halogen Heater

• Rapid heat Function

• Capacity tracker

• Date and time

• Easy to use, sealed keypad

• Password protection

• Security locking point

• Multiple languages for display and

printing

3

| Page © Adam Equipment Company 2009

Page 6

4

| Page © Adam Equipment Company 2009

Page 7

3.0 SET UP

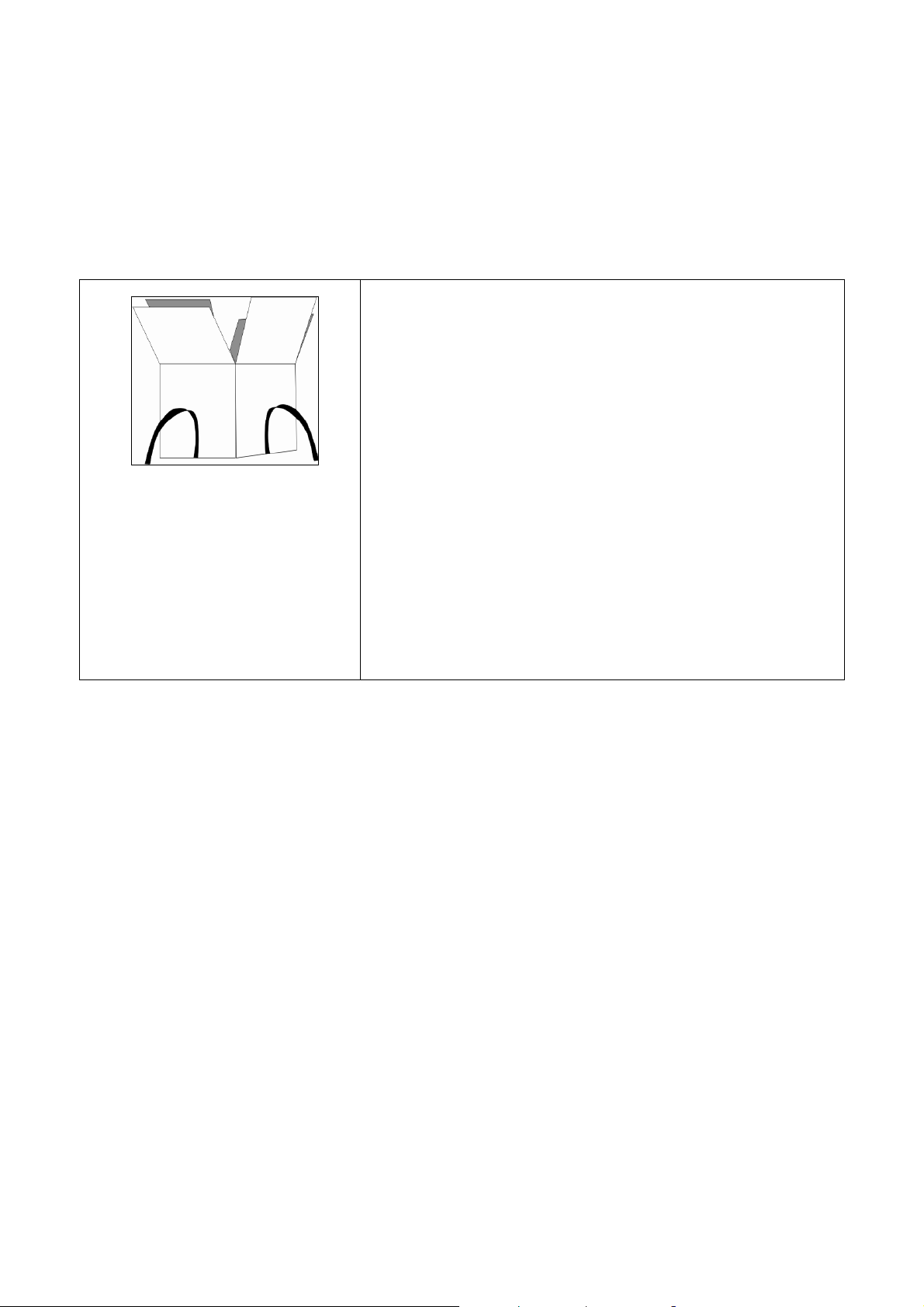

3.1 UNPACKING

AND SETTING UP YOUR ANALYZER

Remove the analyzer from the packing by carefully lifting it out of the box.

Inside the box you will find everything needed to start using the analyzer-

9 AC power cable

9 Pan Support

9 Stainless Steel Lower Chamber Insert

9 Sample Pan Lifter

9 Sample Pans (x10)

9 Spare Fuse, T5Amp

9 This User Manual

For PMB supplied from the USA only:

9 RS-232 Interface Cable for use with a PC

9 USB to PC cable

9 USB driver software on CD

IMPORTANT:

Before applying power the analyzer make sure the analyzer is configured for

the power in your area. The analyzer will have a label on the rear panel

showing the voltage required. 115VAC (±10%) or 230VAC (±10%). If the

label does not match your power do not attempt to use the analyzer, damage

to the analyzer could result.

5

| Page © Adam Equipment Company 2009

Page 8

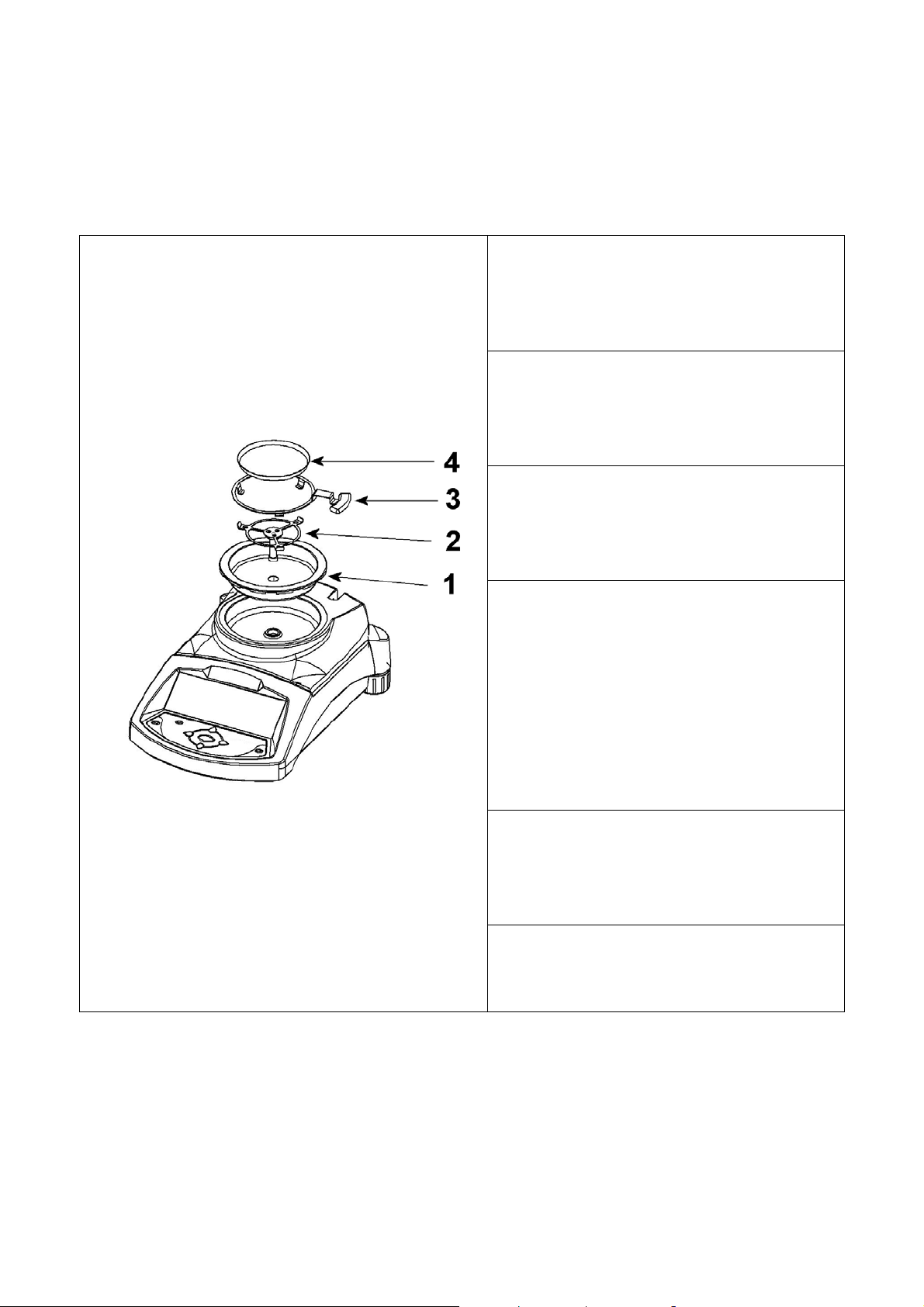

3.2 ASSEMBLING

THE ANALYZER

For best performance, let the analyzer warm up for 30 minutes before using.

z Locate the analyzer on a solid

surface, free from vibration with

good ventilation around it.

z Place the lower reflector (1) into

the base of the weighing

chamber

z Gently place the pan support

(2) into the access hole. Rotate

to position.

z Place the sample pan lifter (3)

into the weighing chamber,

rotate so the tangs on the lifter

do not interfere with the pan

supports and the handle exits

the chamber using one of the

gaps in the cover.

z Place an empty aluminium

weighing tray (4) on the pan

support

z Level the analyzer using the

adjustable feet and spirit level

For some applications it is desirable to run the analyzer in a dummy run to

warm up the weighing chamber and the surrounding area before doing the

actual test. See section 14 for other ideas to help ensure accurate test

results.

6

| Page © Adam Equipment Company 2009

Page 9

3.3 LEVELLING THE ANALYZER

After placing the analyzer in a suitable location,

level it by using the spirit level on the rear of the

analyzer. To level the analyzer turn the two

3.4 WARM-UP TIME

adjustable feet at the rear of the analyzer until

the bubble in the spirit level is centred.

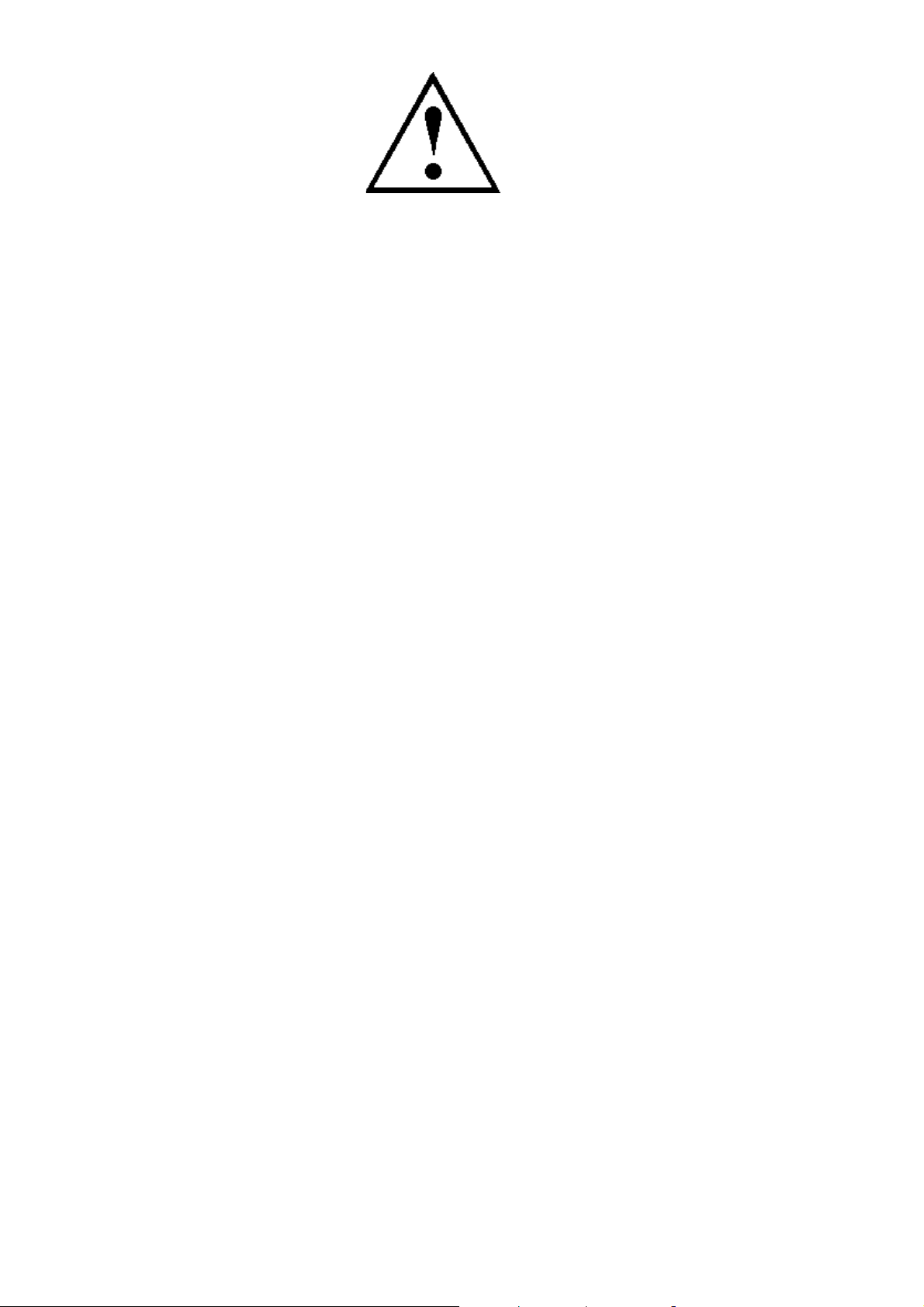

Attach the power supply cable to the connector

on the rear of the analyzer. The master power

switch is on the rear panel, next to the mains

cable. Turn the power on.

The display will indicate the analyzer serial

number and the software revision number

followed by the capacity of the analyzer. Next

the analyzer will run a self-test by displaying all

segments. The display will show zero weight

accompanied by the Î0Í symbol.

Before you start weighing, you have to wait for the analyzer to achieve a

stable internal temperature. In addition it may be necessary for some

material test to preheat the weighing chamber so that the delay to reach

operating temperature is minimised.

A stable sign

~ is shown when the analyzer is in

stable condition. It will turn off if the analyzer is

not stable.

Exact zero is shown when the “Î0Í “ symbol

is on to the left of the display area.

7

| Page © Adam Equipment Company 2009

Page 10

3.5 LOCATING AND PROTECTING YOUR ANALYZER

In order to keep your analyzer functioning at its best we suggest that you do

the following:

Avoid extremes of temperature. Do not place in

direct sunlight or near air conditioning vents.

Make sure there are no heat sensitive or

flammable material above the analyzer. The

exhaust from the weighing chamber can be very

hot.

Make sure the analyzer is located on a strong

table and free from vibration.

Avoid unstable power sources. Do not use near

large users of electricity such as welding

equipment or large motors.

Keep free from vibration. Do not place near

heavy or vibrating machinery.

Avoid high humidity that might cause

condensation. Keep away from direct contact

with water. Do not spray or immerse the

analyzers in water.

Do not place near open windows, airconditioning vents or fans that may cause a

draft and unstable readings.

Keep the analyzers clean. Clean up spills in the weighing chamber

before they become baked on.

8

| Page © Adam Equipment Company 2009

Page 11

3.6 SAFETY

This Moisture Analyzer complies with the European Council Directives and

international standards for electromagnetic compatibility, and safety

requirements.

Improper use or handling can result in damage or injury.

To prevent damage to the equipment, read these operating instructions

thoroughly. Keep these instructions in a safe place.

For safe and dependable operation please follow these instructions.

• The Moisture Analyzer is used for determination of the moisture in

samples. Do not use it for any other purpose. Improper use is dangerous

and can cause injury or damage to other property.

• The Moisture Analyzer must be operated as described in this manual. The

environment must be controlled so that hazardous materials or conditions

are not present.

• The Moisture Analyzer must be operated only by trained personnel who

are familiar with the properties of the samples used and with the operation

of the instrument. Do not leave the analyzer unattended when running a

test.

• Make sure before getting started that the voltage printed on the rear panel

is identical to your local voltage.

• Your Moisture Analyzer is supplied with a 3-pin power cable with a

grounding conductor. Use cables that meet the safety standards for your

location and include the earth ground conductor.

• DO NOT disconnect the earth ground connection.

• The mains cable should not touch the enclosure where it can be heated

during the test.

• Remove the power cable if the Moisture Analyzer is serviced.

9

| Page © Adam Equipment Company 2009

Page 12

• Protect the Moisture Analyzer from external liquids. Clean any spills

immediately.

• If there are any visible damage to the Moisture Analyzer or the power

cable, Stop using the instrument immediately. Unplug the power and

isolate the analyzer. Do not use until the faults have been repaired.

• All repairs must be done by a trained technician. There are no user

serviceable parts in the enclosure.

• Contact Adam Equipment or your dealer for assistance.

HOT SURFACES

• During test the cover of the heating chamber can become very hot,

especially near the top vent. Keep all material away from the vent area.

Do not touch hot surfaces.

• leave 20 cm (about 8 inches) around the moisture analyzer and 1 m (3 ft.)

above.

• Samples will be hot after a test. Do not use bare fingers to pick up any

samples pans or touch the materials. The internal surfaces of the

weighing chamber may be hot for some time after a test.

MATERIALS

• The PMB moisture analyzer is not suitable for all materials. During the

drying process samples will be heated to high temperatures. Materials that

are flammable or explosive should not be tested.

10

| Page © Adam Equipment Company 2009

Page 13

• Materials that emit toxic, caustic or noxious fumes should only be tested in

suitable fume hoods or with other ventilation.

• Materials that will have a film on the surface during drying may cause high

internal pressures to be present. These materials should not be tested

using this method.

• Materials that emit aggressive or corrosive fumes (such as acids) should

be tested using small quantities of material in an area with good

ventilation.

• See Section 14 for further information on sample preparation.

The user shall be liable and responsible for any damage that arises in

connection with this moisture analyzer.

11

| Page © Adam Equipment Company 2009

Page 14

12

| Page © Adam Equipment Company 2009

Page 15

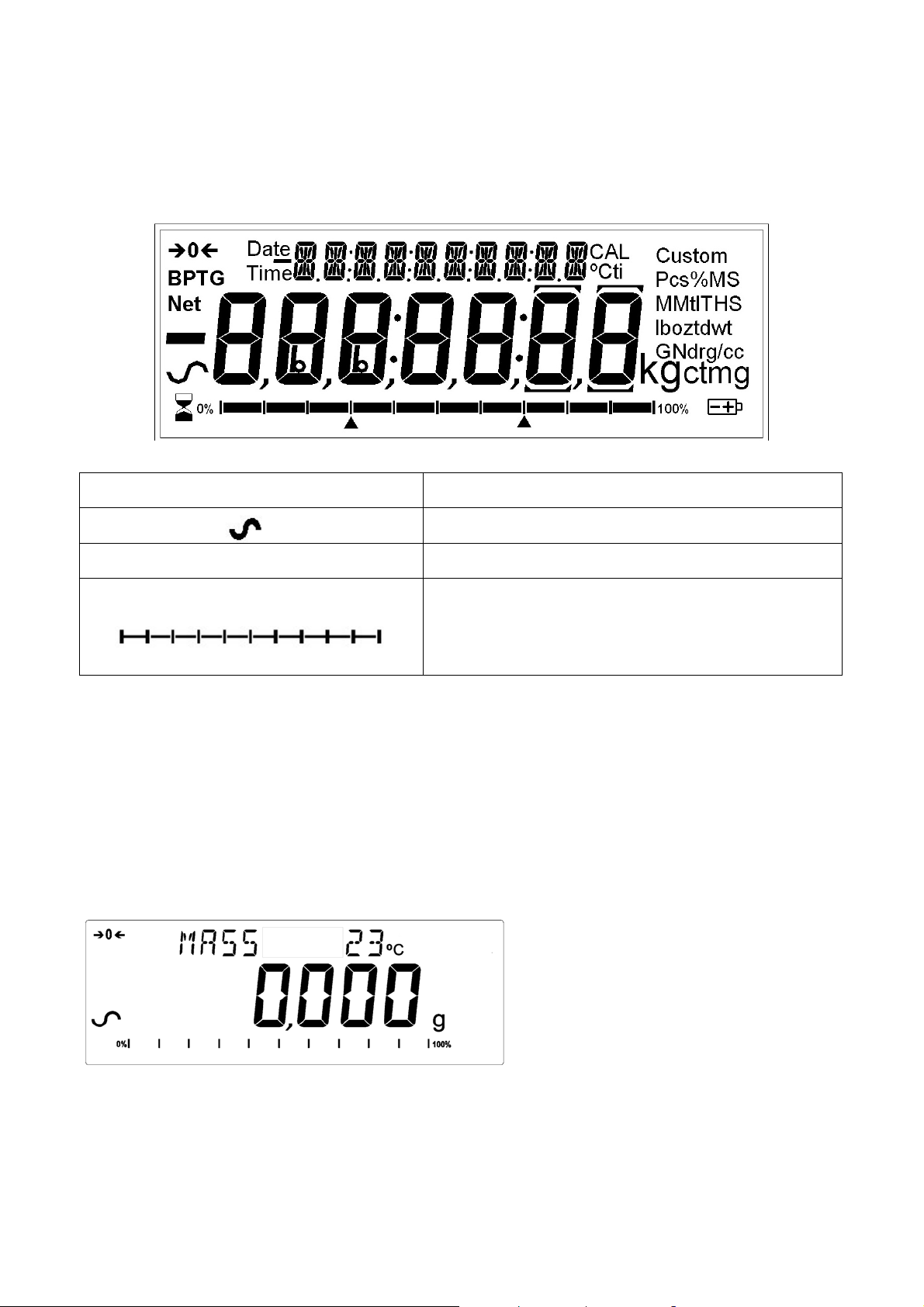

4.0 DISPLAY AND KEYPAD

The LCD has unique symbols to indicate the following:

Î0Í

Zero

Stable

Net

Net weight

A bar graph indicating the proportion of

the analyzer capacity being used by the

weight on the pan

Note: Some symbols shown on the display are not used in the analyzers.

During the moisture test the main display will show the percent moisture. It

can be switched to other values using the [Dspl] key. For example current

mass.

The secondary display will show the elapsed time and temperature during a

test.

Typical Displays that would be used are:

Weighing:

Showing no weight on the pan,

stable and at zero point.

13

| Page © Adam Equipment Company 2009

Page 16

During a typical Moisture test:

Showing a test in progress for

13:25, with a current

temperature of 123ºC and

20.05% moisture, the test is still

running.

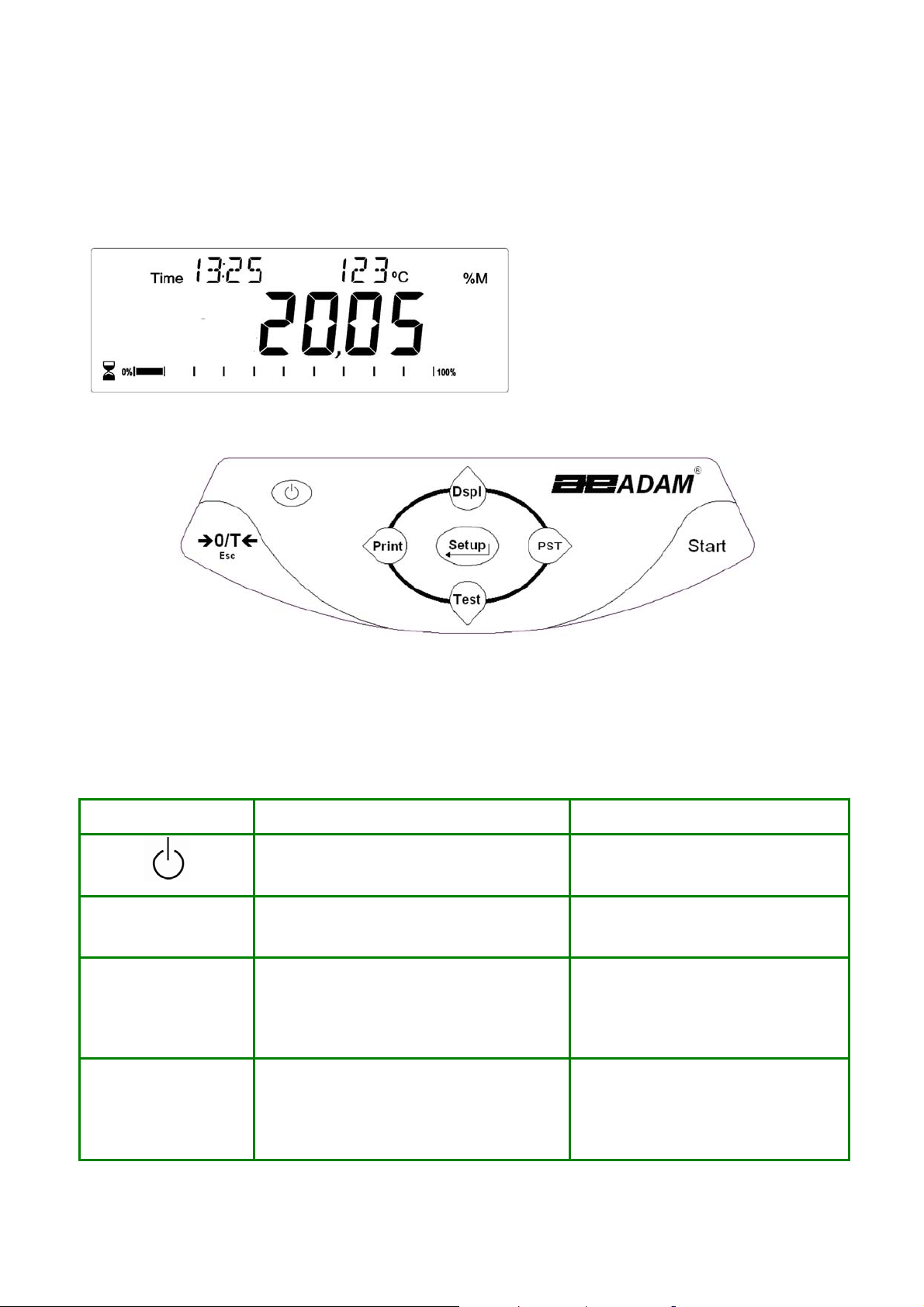

The keypad has second function keys to allow a selected menu item or value

to be incremented or changed. Right/left shift to change the active digit and

up/down to increment or decrement a value.

The keypad has the following keys to operate the analyzer.

Keys Primary function Secondary function

[Î0/TÍ] or [Esc]

[Start]

[Test] / Ð or

[Down]

To turn the analyzer to ON or

Standby

A combined zero and tare function To escape from setup functions

To begin the moisture test after all

settings and sample preparation

has been completed. During a test,

used to stop the test.

-Selects moisture test parameters

such as temperature, method,

results.

-

and modes

-

-Scrolls through menu options

To decrement or change a

displayed value

14

| Page © Adam Equipment Company 2009

Page 17

[PST] / Î or

[Right]

[Print] / Í or

[Left]

[Dspl] / Ï or

[Up]

[Setup/Enter]

Store or Recall pre-stored test

parameters.

Instructs the analyzer to print data To advance a flashing digit by

Changes the display to read other

data during a moisture test.

Enters the Setup parameters

(Supervisor Menus)

4.1 NUMERIC ENTRY METHOD

To advance a flashing digit by

one position to the right.

To go back by one step during

setup functions

one position to the left

To increase or change a

displayed value or scroll

through options forward

Enters a function or saves a

value while manually entering

unit weight or check weighing

limits

To set a value when required, use the keys as given below-

- [Dspl/Up] and [Test/Down] keys to increase or decrease the flashing digit

- [Print/Left] and [PST/Right] keys to advance or move back the digit

- [Setup/Enter] key to accept the value

15

| Page © Adam Equipment Company 2009

Page 18

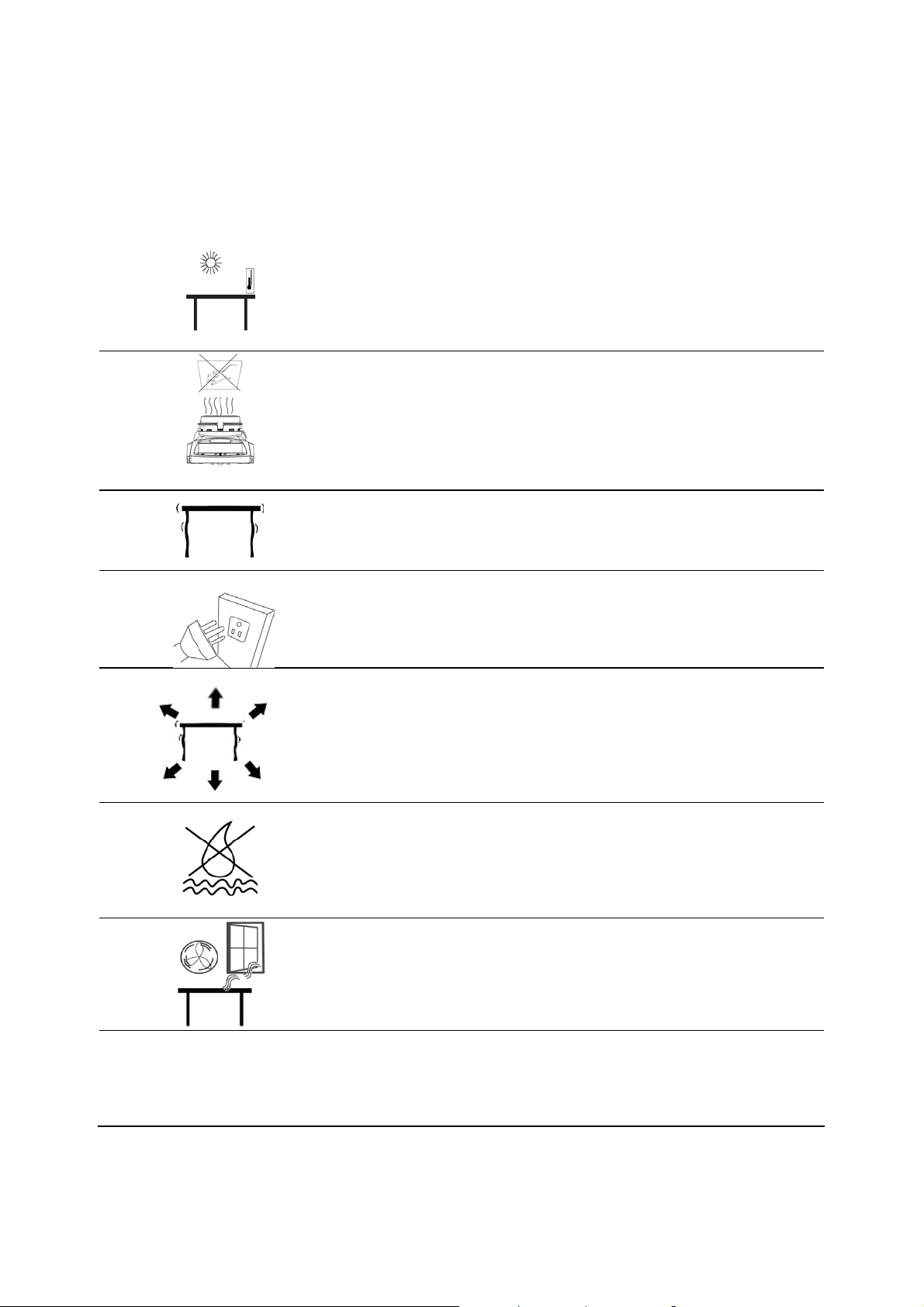

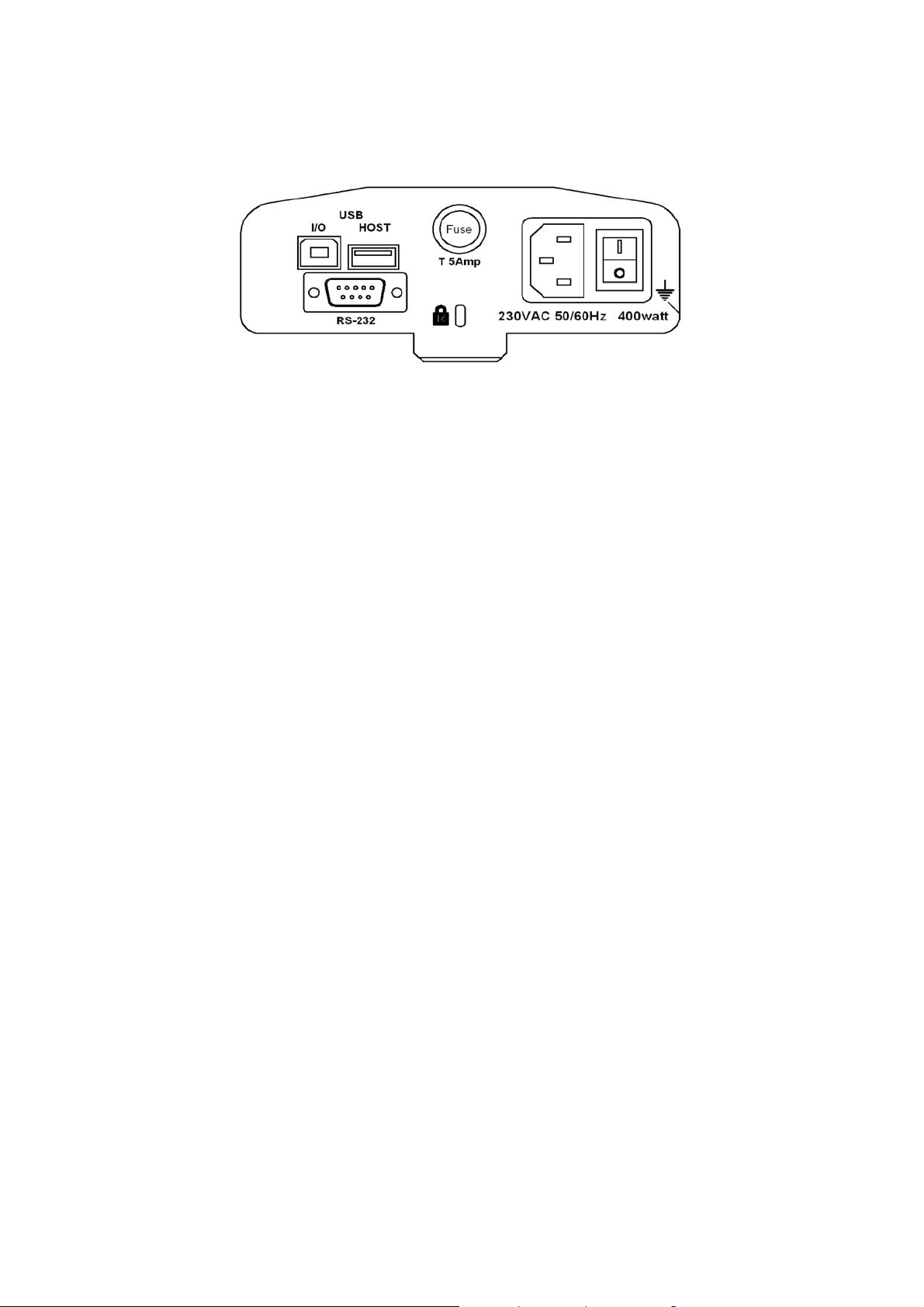

5.0 REAR PANEL INTERFACES

The rear panel has connectors for the data interface, fuse holder, security

lock location and power supply input.

POWER

5.1

Make certain your analyzer is compatible with the mains power supply in your

area. If the voltage is not the same the analyzer can be damaged. Contact

your supplier if you require assistance.

The fuse should only be replaced with a time lag type fuse of the correct

current rating. The fuse is a standard 5 x 20mm size. To replace the fuse

remove all power from the analyzer, unscrew the fuse holder cover to extract

the old fuse, replace with a new fuse. If the fuse should blow again, the

analyzer must be serviced by a qualified service representative. There are no

user serviceable parts inside. Contact your supplier.

5.2 DATA

INTERFACES

The analyzer has data interfaces for a variety of applications.

The RS232 interface is a general purpose serial interface for communications

with the analyzer, using a DE-9P type connector. Refer to section 11.0 for

details of the interface.

The USB I/O interface is similar to the RS-232 in that it is also a serial

interface. The functions of the RS-232 and USB I/O are similar. See section

11.0 for more details on using the USB I/O.

16

| Page © Adam Equipment Company 2009

Page 19

The USB Host is designed to allow a USB memory device to be used as an

external memory for the analyzers. The set-up parameters for operation and

test procedures can be stored and up-loaded from the memory device.

Results of drying test can be stored in the USB memory device. See sections

6.5 and 9.0 for further details on using the USB Host with a memory device.

Adam Equipment supply AdamDU Data Collection software that will allow

the user to use the full capabilities of the data interfaces. Contact your

supplier or Adam Equipment for more details.

5.2.1 FILES ON A USB MEMORY DEVICE When a USB memory device is used the analyzer will create a series of folders used to store files. These folders are called, REPORT, PRESET, CONFIG and RESULT, all under a master folder called MOISTURE .

X:\ MOISTURE

X:\ MOISTURE\REPORT

X:\ MOISTURE \PRESET

X:\ MOISTURE \CONFIG

X:\ MOISTURE \RESULT

Where X is the device letter your computer will assign to the memory device.

When the memory device is first plugged into the PMB the memory is

inspected and the folders will be created if they do not already exist. This

process may take a few seconds before the analyzer will show a display

allowing access to the USB memory.

All files are stored in a text format with a file type of .txt. The files used by

the analyzer are all small enough that any size memory device will work.

5.3 SECURITY

LOCK

The centre of the rear panel has a location to mount a Kensington type

security lock. Refer to the instructions that come with the lock for details.

17

| Page © Adam Equipment Company 2009

Page 20

6.0 BASIC OPERATION

When first turned on the analyzer will act as a basic balance showing grams

weight on the display.

If a passcode has been set to limit access to the weighing functions of the

analyzer the display will show “PASSCODES”. The display will change to

show 7 digits set to zero with the rightmost digit flashing. Use the numeric

entry method (see section 4.1) to enter the code. Make sure to enter the

correct passcode to continue. See the Section 10.1.4 for details.

While in the weighing mode the test conditions for a drying test can be set.

6.1 SETUP

OF MET H O D

The PMB analyzer is set to perform a drying test using a method determined

by the user. The drying method can be input from a number of different

sources.

• Using the keyboard

• Recalled from the internal memory of the analyzer

• Recalled from a memory stick plugged into the USB host connector

• Entered from a PC using the RS232 or USB interface.

Regardless of the method used it will be necessary to program the analyzer

with the following:

Type of test:

• % moisture =100 * ((initial mass - dry mass)/initial mass)

• % solid =100 * (dry mass/initial mass)

• % moisture vs. dry weight =100 * ((initial mass - dry mass)/dry mass)

Also called ATRO Moisture

• % solid vs. dry weight = 100 * (Initial mass/dry mass)

Also called ATRO Solid

ATRO Moisture or Solid test are special applications specific to some

industries. %Moisture and %Solid are the more common calculations.

18

| Page © Adam Equipment Company 2009

Page 21

Heat Control

• Single temperature, heat to a set temperature.

• Ramp to temperature, Ramp to final temperature in a user set time.

• Step temperature, heat to Temp 1, for X minutes, then temp 2 for X

minutes, then Temp 3 for X minutes. A maximum of 3 steps can be

used.

Set temperatures as required for these options. 50-160ºC.

For Ramp set the time to final temperature.

For Step set the temperature and the time at each step.

Interval

Set the time interval at which the results are computed and printed. Range is

1 to 99 seconds.

Rapid heat

Set the rapid heat function to be on, off or under user control.

Rapid heat will cause the target temperature to be 145% (or 160ºC, which

ever is less) of the value set for Single or the first Step for a time of 3

minutes. For example is the Single temperature is 105ºC, the rapid heat will

heat to 105X 1.45= 152ºC for 3 minutes then maintain 105º after that time.

If set to Rapid = Off

The rapid heat function is disabled.

Rapid =On

The rapid heat function will occur every time a test is started, either manually

or automatically.

Rapid = MANUAL

When a test is started Manually, the user will be asked if Rapid heat should

be used or not.

End Point Determination (manual stop active in all tests)

19

| Page © Adam Equipment Company 2009

Page 22

• Time, Test ends at the end of a preset time.

• Stable result, test ends if the results are stable within a value set by the

user.

• Time or stable result, combines both methods. Stop whichever occurs

first, a stable result or the end of a preset time.

For timed test the user sets a time of typically 5 minute to 99 minutes

Set stable results criteria. The test will stop when the weight changes less

than a preset amount in a preset time. The default setting is 0.002g in 15

seconds for PMB 53, and 0.02g in 15 seconds for PMB 202. The user can

set other values depending upon model.

Start Criteria

• Start Manually when the [Start] key is pressed

• Start Automatically when cover lowered.

Delays 5 seconds after cover is down before beginning.

Print settings:

To set if the analyzer should print and store results and when printing if the

compete test results or only the summary is printed and stored in the

analyzers internal memory.

Default settings (stored in PST 00, see section 6.3) are:

% Moisture

Single Temperature = 110ºC

Rapid = Off

Interval Time = 5 seconds

End Point Determination = Time and stable result

Time 60minutes, and

Stable PMB 53 = 0.002g/15 seconds or Stable PMB 202 = 0.02g/15 seconds

Start Criteria = manual start.

Print Test = on

Print Format = Complete

6.1.1 MANUALLY SETTING TEST PROCEDURES

20

| Page © Adam Equipment Company 2009

Page 23

Press the [Test] key to set the test procedure. During the process use the

numeric entry procedure described in section 4.1 to enter or change a setting.

Pressing [Print] at any time during this procedure will print a list of the current

settings. See 6.1.2

Pressing [Tare] will always escape back to normal weighing without a change

to the parameter being displayed. Any parameter changed before this time

will be accepted.

PROCEDURE

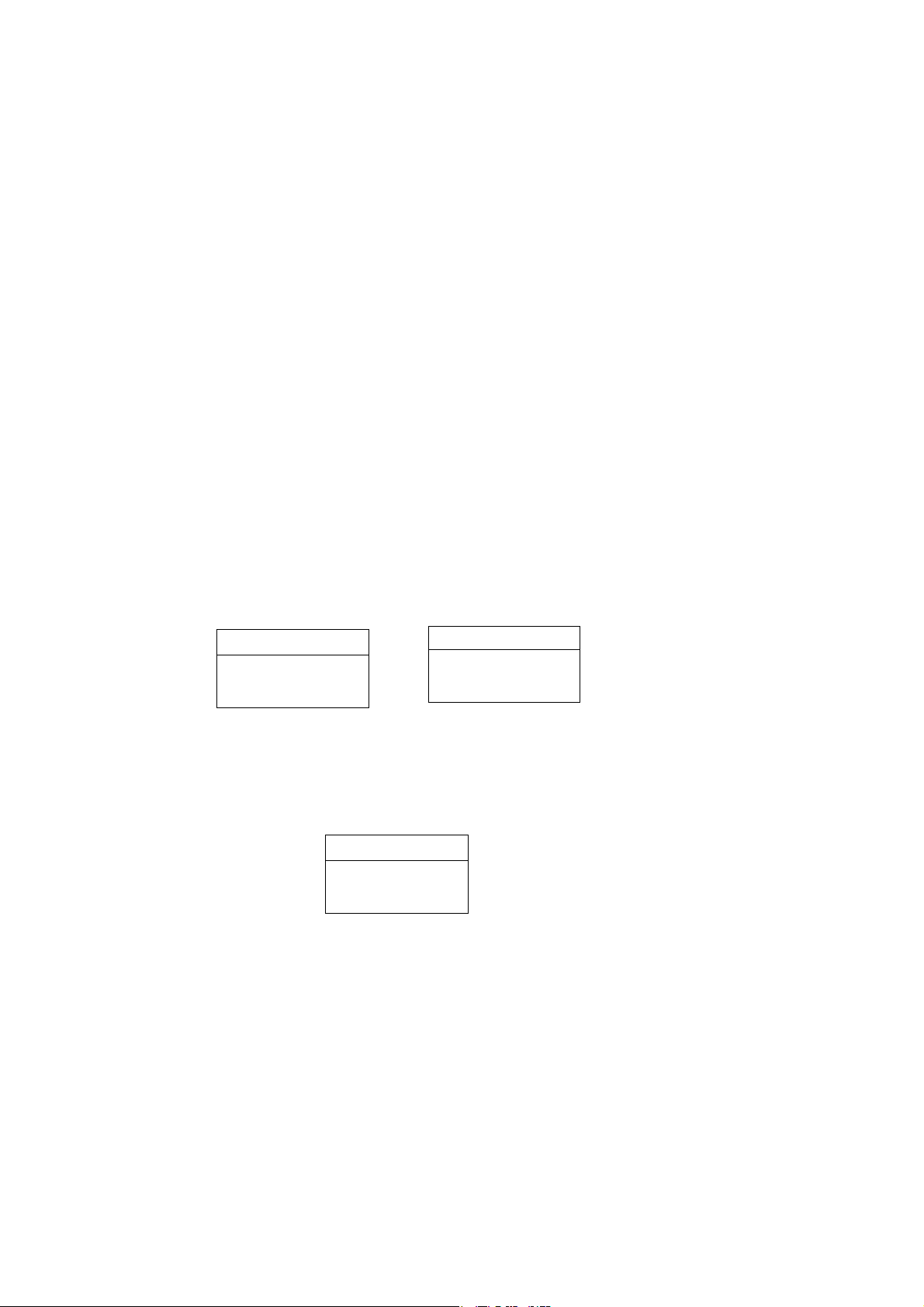

Press [Test] to show “rESULt” with the current setting displayed,

Options are “Moisture”, “Solid”, “ATRO Moist”, “ATRO Solid”

Use arrow keys, [Dspl] and [Test], to change and press [Setup/Enter] to

continue.

Heating Control, show “HEAt”

Options are: “Single”, “Ramp”, “Step”

The next settings will depend upon which heating option was selected:

MOISTURE

result

SINGLE

Keat

ATRO MOIST

result

“Single” Selected

Show “Single” “123 C” with the left digit flashing. The user can use the

[Menu] key (right arrow) to select another digit or the up and down arrows to

set the temperature, Range is 050 C to 160 C

21

| Page © Adam Equipment Company 2009

Page 24

“Ramp” Selected

Show “Ramp” the temperature as above for setting the temperature and then

change to “Ramp Time” and “ XX:XX ”, minutes and seconds.

Use the arrow keys to select the digit to change. The user can select a time

up to 99:59.

RAMP ºC

123

time should be set long enough to allow the heater to warm the sample

gently.

SINGLE

123

RAMP TIME

10:00

ºC

RAMP TIME

06:00

The ramp

“Step” Selected

Show “Step 1” and set the temperature of step one as for the single heat

settings above. When the value is set the display will show “Time 1” to set

the time the first step is held. Enter the value as above. The minimum time

for step 1 is 3 minutes.

When set press [Setup/Enter] to show “Step 2” and set this temperature

and time and then go to “Step 3” and set this temperature and time.

If only 2 steps are required set the time for step 3 to 00:00. The analyzer will

ignore this setting.

Interval Setting

The next setting will be to set the time interval the analyzer uses to determine

results and to print the current result. The analyzer will compute the percent

moisture or solid at the time interval desired. The new result will be displayed

and printed as described below.

22

| Page © Adam Equipment Company 2009

Page 25

Display “Interval” “Sec XX” The user can change the value using the arrow

keys. Range is 01 to 99 Seconds. Typical results will be computed every 515 seconds.

The next setting is the operation of the Rapid heat Function.

Display will show “Rapid”

OFF

rapid

Options are to set Rapid heat to Off, On or User selectable.

The Rapid heat function is only active for single or step heating. For ramp

heating it is disabled.

INTERVAL

se[10

ON

rapid

USER

rapid

The next setting is the End Point Determination or Stop Condition.

Display will show “STOP”

Options are “Time”, “Stable” or “Time/Stab”

The next steps will depend upon the option selected.

TIME

St0p

TIME/STAB

St0p

23

| Page © Adam Equipment Company 2009

Page 26

“Time” selected

Enter the time the test should run. The test will stop when this time is

reached.

Display will show “Min XX”. This sets the minutes to run a test. The range is

04 to 99 minutes.

“Stable” selected

Enter the conditions to be used to determine if the results are stable. The

amount of weight change to be used to determine if the test is finished,

followed by the time to be used for the weight to change. For example 0.006g

in 15 seconds would be a typical setting. Longer times or (smaller weight

changes) could be used to ensure better stability or shorter times (larger

weight changes) to ensure a faster determination. For example 0.006g in 5

seconds will end a test quicker (but possibly less accurately ) than 0.002g in

15 seconds. The user sets the weight first, then the time,

Display shows “ STAB RANGE” “ XX”. Set the range from 1 to 10 display

divisions. For the PMB 50 1 division = 0.002g, For the PMB 200 1 division =

STOP TIME

Min 30

0.02g.

Then the display shows “ Stop Time” “ Sec XX”. Range is 01 to 99 seconds.

Time/Stable will combine these 2 settings.

STABLE

St0p

TIME/ STAB

St0p

STAB RANGE

02

STOP TIME

min 30

STAB TIME

sec15

STOP RANGE

02

STOP TIME

sec15

24

| Page © Adam Equipment Company 2009

Page 27

Start Method

The last setting is the Start method. The analyzer will either start a test

automatically whenever the cover is lowered (after a 5 second delay to allow

stability), or manually when the [Start] key is pressed.

Display will show “START”

Options are “Manual” or “Auto”

Print Control

To allow the analyzer to print the results during the test. If the print is set to

ON the analyzer will also store the results to memory using the file name

given by the user. See Section 7.0

Display will show

Options are “On” or “Off”

MANUAL

start

PRINT TEST

0n

The display then changes to the format of the print test.

Options are “Complete ” or “Summary ” test results. See section 11.3

After setting the last parameter press [Tare/Esc] to return to normal weighing

and ready to begin a new test.

25

| Page © Adam Equipment Company 2009

FORMAT

C0MP

FORMAT

SUMM

Page 28

6.1.2 PRINT CURRENT SETTINGS When setting the test parameters the [Print] key will cause the current parameters to be printed as shown below. However if the display is awaiting a numeric entry the [Print] key will move the flashing digit to the left.

For example (English language version shown) :

CURRENT TEST SETTINGS

DATE: 08/01/2009

TIME: 14:44:49

SER NO:AE00001234

USER NO:1234567

From the Real Time Clock

Analyzer Serial number

User ID number

Preset: PST 01

ABCD-01234

Result %MOISTURE

If Preset test is used, blank if not

from a preset test.

Heating:Ramp

112 C

27:00

Rapid Manual

Interval: 05 Sec

Stop: TIME/STABLE

60 Min

0.002 g

15 Sec

Start: MANUAL

Current test settings for heating

Printing interval

Stop Criteria

Start Criteria

26

| Page © Adam Equipment Company 2009

Page 29

6.2

It will be possible to store up to 49 test procedures/settings. There is also a

factory default that is permanently stored as PST 00. see sec. 6.1

To Store the current settings press the [PST] key. The display will give the

user the option to store, recall or delete a Preset Test. The display will show

“PST STORE” or “PST RECALL” or “PST DELETE”. Use the up/down arrow

keys, [Dspl] and [Test], to select either store or recall.

If Store is selected the display will then show “PST STORE XX” with the

STORE TEST SETTINGS

PST STORE

number showing the ID for the next empty location. For example if PST 01,

02, & 03 are already stored the next number is PST 04. If the user wishes

to overwrite a previously stored value they can change the number and

continue. Using the up/down arrow keys, [Dspl] and [Test]. If the user has

stored positions 1,2, and 4 then when this process begins the first blank

location is PST 03, so that is the value to be displayed. Then the next time

PST 05 would be shown.

Press [Setup/Enter] to select the PST number shown. If this number already

has a test method stored then ask if the test should be overwritten. To

continue the user must press [Setup/Enter] to overwrite the old results and

store new ones.

PST STORE

05

OVERWRITE?

Pressing the [Tare] key will escape without clearing the

old result.

27

| Page © Adam Equipment Company 2009

Page 30

When storing a test procedure the user has the option of adding a text or

numeric name to the test. The top display will show “PST NAME” then show

“- - - - - - - - - “ . To enter a name, use the up/down arrow keys to cycle

through numbers and letters. Use the left right arrows to move the flashing

digit to the left or right.

— . / 0 1 2 3 4 5 6 7 8 9 A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

Up to 10 characters can be used to describe the test. Press [Setup/Enter]

at any time to finish the description. If no name is added the field will be

shown as blanks when the name is shown during the recalling process.

6.3 RECALL

Recalling the test settings can be done by selecting “PST RECALL” then

scrolling through the stored settings using the up/down arrow keys to find the

desired settings and then pressing the [Setup/Enter] key to recall them.

When the PST XX number has been selected the name given to the test will

be displayed

If PST 00 is selected the default test settings are recalled. These can never

PST NAME

TEST SETTINGS

BREAD-4

be cleared or overwritten. If a test is not stored it is not displayed, i.e. If only 3

tests are stored then only those 3 plus the default are seen when recalling the

test settings.

28

| Page © Adam Equipment Company 2009

Page 31

Press the [Setup/Enter] key to recall PST 07.

The display will show:

The analyzer will then return to normal.

6.4 DELETE

To delete anythe test setting select “PST DELETE” then scrolling through the

TEST SETTINGS

BREAD-3

PST 07

RECALL OK

stored settings using the up/down arrow keys to find the desired settings and

then pressing the [Setup/Enter] key to delete it.

The display will then show the next test setting stored or if the memory is

empty a message will be shown. Press [Tare/Esc] to return to normal.

6.5 REVIEW

To review the current settings press the [Test] key then advance through the

settings pressing the [Setup/Enter] key at each option to retain the current

value. If any setting needs to be changed it can be modified as described in

section 6.1.

6.6 STORE

To store or recall test settings stored on a USB memory device, simply plug

TEST SETTINGS

AND RECALLING TEST SETTINGS FROM USB MEMORY

the device into the USB hub interface. The analyzer will detect the memory

has been inserted and display a screen to guide you.

The display will show a message showing the USB device is inserted:

29

| Page © Adam Equipment Company 2009

Page 32

To select the option of storing all of the test settings

stored in the analyzer memory to the USB memory device press the [Dspl]

key to change the menu option to select Preset Store, “PST ST”.

Press [Select] to enter the test saving function.

Once the file has been saved the display will show

CONFIG LD

USB

PST ST

USB

SUCCESS

USB

For 2 seconds then return to the USB display.

To recall any stored test procedure press the [Dspl] key to show the test load

screen.

Press the [Setup/Enter] key to enter the test load function. The display will

show the file name of the first test file found.

PST ST

USB

PST LD

USB

PST 01

PSt

30

| Page © Adam Equipment Company 2009

Page 33

To load this file press the [Setup/Enter] key again. Or to choose a different

file press the [Dspl] key to advance through the other files available, pressing

the [Setup/Enter] key when the desired file is shown.

PST 06

PST

After loading the file the display will show a Success message and return to

the USB screen.

To continue, the USB device should be removed. The analyzer will return to

normal weighing automatically. Or press the [Tare] key to escape back to

normal weighing.

To store or recall other test files plug the USB memory device back into the

analyzer.

The test files contain data to set the parameters of the test procedures in a

text file. All files will be in English regardless of the language selected for the

display. A typical test file will appear as:

Result=0;

Heat=1;

Ramp Temp=112;

Ramp Time=27:00;

Interval Time=05;

Stop mode=2;

Stop time=60;

Stable Range=0.002;

Stable Time=15;

Start mode=0;

Name=ABCD-0123

Rapid=1

savepos=01;

31

| Page © Adam Equipment Company 2009

Page 34

The meaning of the text in the file is given below. Different test settings will create a file

with different information. Not all settings are printed if they are not used by the test

program.

Text message Description Range of Values

Result=1;

Heat=1;

Single Temp=100;

Step temp1=050;

Step Time1=30:00;

Step temp2=080;

Step Time2=30:00;

Step temp3=050;

Step Time3=30:00;

Ramp Temp=100;

Ramp Time=30:00;

Rapid=0;

Interval Time=20;

Stop mode=0;

Stop time=10;

Stable Range=0.002;

Stable Time=10;

Start mode=0;

Name=ABCD1234

Rapid=1;

savepos=01;

Calculation of results 0=%M, 1=%S, 2=%Atro_M,

3=%Atro_S

Heating profile to be used 0=Single, 1=Step, 2=Ramp

Temperature for single heat

setting

Temperature for first heat of a

step profile

Time for the first heat of a step

profile

Temperature for 2

step profile

Time for the 2

profile

Temperature for 3

profile

Time for the 3rd heat of a step

profile

Final temperature of a ramp

profile

Time to reach final temperature Time 02:00 to 99:00

Rapid heat function setting, 0= Off, 1= On, 2= User

Time period used to print interim

test results

Stop mode for drying test 0=Stable, 1=Time, 2=Stab and

Time to stop test time = 3 to 99 min default=20;

Weight the analyzers uses to

determine if the results are stable

at the end of test.

Time used to compare weight

during a test to determine if the

results are stable at the end of

test.

Start test manually or when the

cover is closed

Name assigned by the user if the

test results are to be stored

Enable Rapid heating function 0= Off, 1= On, 2= Manual

Memory location the results are

stored in.

nd

heat of a

nd

heat of a step

rd

heat of a step

50C to 160C

50C to 160C, 00C is off

Time 02:00 to 99:00

50C to 160C, 00C is off

Time 02:00 to 99:00

50C to 160C, 00C is off

Time 02:00 to 99:00

50C to 160C

5 sec to 99 sec

Time default=2

Set from 0.001 to 0.099 for PMB

53 or 0.01 to 0.99 for PMB 202

5 sec to 99 sec

0=Manual 1=Auto

Up to 10 characters of alpha-

numeric characters, plus . / -

01 to 49

32

| Page © Adam Equipment Company 2009

Page 35

7.0 RUNNING A TEST

If necessary the user can set a new set of values for a test setting or recall a

pre-stored set of values. See section 6. The last used set of values are

stored so they are always shown initially, even after power has been turned

off. That way if the last test settings are still valid the user can immediately

use them.

The basic operation after test settings are set is as follows:

Place an empty sample pan on the analyzer.

Press [Tare] to zero the weight.

Fill the sample pan with the sample. See Section 14 for assistance in how

to prepare a sample.

Place the filled pan on the analyzer.

Lower the lid of the weighing chamber, if automatic

start has been selected the test will begin after a 5 second delay.

If Manual start has been selected press the [Start] key.

MASS 23

0.000g

MASS 23ºC

5.670g

ºC

The test will begin.

If the rapid heat function has been set to MANUAL the display will ask if the

user wants the rapid heat function to operate during this test.

The display will show the last setting used, either:

33

| Page © Adam Equipment Company 2009

Page 36

Use the [Up] or [Down] keys to change the option, then press [Enter] to

continue the test.

The top line will show the time elapsed time of the test and the chamber

temperature. The main display will show the current result, updated at the

interval time selected when setting test parameters.

OFF

rapid

ON

rapid

03:45 RA 100ºC

16.12%

If the Rapid heat is active a “RA” will be displayed in front of the temperature

reading.

An “A” will be on the left side of the display if %Moisture /Dry or %Solid/Dry is

the result selected. The %M or %S will be on the right side of the display

showing %Moisture or %Solid.

The display will continue to be updated at the time interval set for the test.

During the test the [Dspl] key can be pressed to see other information such

as current mass, other results such as %Solid, time remaining if time limit is

set for the test. Each alternate display is shown for 5 seconds then return to

normal display, or if [Dspl] is pressed again go to the next alternate display.

Current Mass

03:45 100ºC

4.756g

34

| Page © Adam Equipment Company 2009

Page 37

% Solid

Atro Moisture

Time Left

(if time limit is set)

The Alternate displays in order are:

Mass

% Moisture

SOLID

83.88%

ATRO MOIST

3.78%

TIME LEFT

14:21

% Solid

% Atro Moisture

% Atro Solid

Time Remaining for test if time limit set

During the test the user can stop the test at any time by pressing the [Start]

key again. Otherwise it continues until the stop condition is met.

When the test has stopped the beeper will sound 3 short beeps (if enabled,

see sec. 10.1.2) and the display will show the end result:

12:44 ASTOP

76.47%

This display shows the test was automatically stopped as stability was

reached in 12:44 minutes. If it had stopped at the end of the time period it

would have TSTOP on the top line and if manually stopped it would have

MSTOP.

35

| Page © Adam Equipment Company 2009

Page 38

At this time the final results are displayed. These results will include elapsed

time of the test and final % result.

Display other data by pressing the [Dspl] key. To show the initial mass, final

mass and the file name used by the analyzer to store the results in internal

memory.

.

START MASS

5.670g

The final values for the results can be printed again to the Serial interface

by pressing the [Print] key. See section 8.

To return to normal weighing press the [Tare] key.

END MASS

1.334g

RES00033

ST0RED

36

| Page © Adam Equipment Company 2009

Page 39

8.0 PRINT AND STORE RESULTS

If the test parameters are set to allow the test results to be printed (see

section 6.1.1) then the results of the test are printed both before and after

the test is complete. The initial part of the printout will show the test

conditions, If the test printing parameter has been set to complete then the

results will be printed at the interval time. When a test is completed, the user

can print a result from the test. At the same time as the printing is happening

the results are stored in the analyzer memory. The results can be recalled

from the analyzer memory for printing over the serial interface.

8.1 PRINTING

FINAL TEST RESULTS

While the final values for the test are being displayed after the test has

ended, press the [Print] key to output the final results. The format of these

results are the same as the last lines of the complete printout:

LAST TEMP: 111C

TEST TIME: 05:30 Min

FINAL MASS: 11.820 g

MASS LOSS: 0.521 g

RESULT: 4.27 %M

8.2 STORING

TEST RESULTS

If the test settings include the printing of results being enabled the analyzer

will store the results of the test into memory. (See section 6.1.1) The test

results will be stored using the file name given to it automatically by the

analyzer. In the form RESxxxxx

The analyzer is capable of holding up to 99 test results. If the analyzer

memory is full the display will show an MEM FULL message. Delete some of

the stored results to make room for new test results. See section 8.4.

37

| Page © Adam Equipment Company 2009

Page 40

8.3 RECALLING

When a test result has been stored in the analyzer memory it can be recalled

to the display.

During normal weighing mode press the [Dspl] key. The display shows

Pressing the [Dspl] or [Test] will change the option to PRINT, DELETE or

DELETE ALL.

When the selection shows PRINT , press [Setup/Enter] and the display will

show the first stored test result using the file name given it when stored.

TEST RESULTS

PRINT

Press the [Dspl] or [Test] key to change the file name to the next available.

When the test result desired is found press the [Setup/Enter] Key to recall

the details and print them in the same format they were stored in, See section

11.0

Pressing [Tare] will return the analyzer to normal operation.

8.4 DELETING

When a test result has been stored in the analyzer memory they can be

deleted individually or all at one time.

TEST RESULTS

RES00032

38

| Page © Adam Equipment Company 2009

Page 41

To delete all test results from memory, during normal weighing mode press

the [Dspl] key until the display shows

When the selection shows DELETE ALL , press [Setup/Enter] to delete all

test results. The display will ask if you are sure you want to delete all results.

press [Setup/Enter] again. The display will count down from 99 to 0 during

the time it takes to remove all the files.

To delete an individual test result continue as above except press the [Dspl]

or [Test] will change the option to DELETE..

DELETE ALL

When the selection shows DELETE , press [Setup/Enter] and the display

will show the first stored test result using the file name given it when stored.

Press the [Dspl] or [Test] key to change the file name to the next available.

When the desired test result is found press the [Setup/Enter] Key to delete

just this file. The display will then show DELETED then the next available

file. Press [Setup/Enter] to delete this file if desired.

Pressing [Tare] will return the analyzer to normal operation.

RES00033

39

| Page © Adam Equipment Company 2009

Page 42

9.0 STORING RESULTS IN USB MEMORY

A memory stick plugged into the USB host connector will allow for mass

storage of test results. The procedure is similar to the method used to store

test settings, See section 6.5.

To store the results of a drying test on a USB memory, simply plug the

memory into the USB hub interface. The analyzer will detect the memory

has been inserted and display a screen to guide you.

The display will show a message showing the USB memory is installed:

Then it will display the first selection of actions that can be performed.

To select other options press the [Dspl] key to change the display to select

Result Store, PST Store, PST Load, Configuration store or Configuration

load.

To Store test results select

VERIFY

USB

RESULT ST

USB

RESULT ST

USB

Press [Select] to enter the test saving function. All of the test results stored

in the analyzer memory will be copied to the USB memory. The file names

will be the same as those used to store internally.

40

| Page © Adam Equipment Company 2009

Page 43

Once the file has been saved the display will show

For 2 seconds then return to the USB display.

STORE OK

USB

CONFIG LD

USB

The test data file is a text file that has the same arrangement as the Serial

Interface sample given in section 11.

41

| Page © Adam Equipment Company 2009

Page 44

10.0 ANALYZER MENUS

The PMB has a number of submenus for setting the operation of the analyzer

and the communications. The main topics are:

PASSCODES

to control unauthorised access to the menu system.

PMB ANALYZER SETTINGS

Setting of date and time

Date format, YMD, MDY, DMY

User ID

Key Buzzer On/Off

Test Buzzer On/Off

Backlight , On, Off, Auto

Filter and Auto zero settings

Language Selection

SERIAL I/O

Baud rate

Parity

Continuous output

Time for continuous output

CALIBRATION

Weight Calibrate

Temperature Calibration

Cal Report On/Off

10.1 SUPERVISOR MENUS

Pressing the [Setup/Enter] key while in normal weighing gives access to the

menus.

42

| Page © Adam Equipment Company 2009

Page 45

When [Setup/Enter] is pressed and passcodes are not enabled the display

will show the first section of the menus, Serial interface. If passcodes are

enabled, the analyzer will ask for it by displaying :

With the right digit flashing.

Enter the correct passcode using the numeric entry method.

If a wrong code is entered the analyzer will return to weighing mode

If the passcode has been enabled and entered, the analyzer will allow the

operator to access the Supervisor’s menus

The [Dspl] and [Test] keys will cycle through the main headings, pressing

the [Setup/Enter] key will enter the heading and sub-parameters or options

can be set. Press [PST]

PASSCODE

000000

to come out of a sub-menu and go up one level or

[Esc] to return to normal weighing from any menu

43

| Page © Adam Equipment Company 2009

Page 46

10.1.1 SERIAL INTERFACE PARAMETERS

The parameters affecting the serial setup are set in a similar manner to the

other parameters.

Press [Setup/Enter] when “SERIAL” is displayed to enter the sub-menu.

The parameters that can be set are shown below, default values are in bold:

BAUD RATE

Set the Baud Rate to 2400, 4800, 9600, 19200 or

38400

PARITY

Set the Parity to OFF, EVEN or ODD

CONTINUOUS To output the weight only at the interval time set in the

INTERVAL parameter. Overrides the printing of any

test results. Option is ON or OFF.

INTERVAL Sets the time in seconds between output of weight

values, if CONTINUOUS output is turned on.

These parameters apply to both the RS-232 and the USB Serial Interfaces.

The interfaces operate in parallel so they both output the same data at the

same time. It is up to the user to beware to prevent possible conflicts if both

interfaces could receive data at the same time.

44

| Page © Adam Equipment Company 2009

Page 47

10.1.2 SETUP PARAMETERS The user parameters that control the analyzer are shown under the SETUP.

When “SETUP” is displayed, press the [Setup/Enter] key. The options for

each parameter can be scrolled through by using the [Up] or [Down] keys.

TIME Set Time using the numeric entry method

(see section 6.1)

DATE FORMAT

EUROPE (dd/mm/yy)

Select the format the date will be shown

in.

USA (mm/dd/yy)

ASIA (yy/mm/dd)

DATE Set Date using the numeric entry method

(see section 6.1)

Set year, month date when requested.

USER ID Enter a user number to identify this

analyzer

KEY BEEPER

When enabled will beep any time a key is

pressed.

On= Enable

OFF= Disable

TEST BEEPER When enabled will beep 3 times quickly

when a drying test is completed.

On= Enable

OFF= Disable

BACKLIGHT

On

OFF

AUTO

FILTER Set the amount of filtering used for

45

| Page © Adam Equipment Company 2009

Page 48

weighing. If sever vibration is present a

slower filter may be helpful, for maximum

speed use the fast filter.

Select SLOW, NORMAL or FAST

LANGUAGE Select the language,

English, German, French or Spanish

The sub-menu is entered by pressing [Setup/Enter] –

Use the [Up] and [Down] keys to increase or decrease the value for setting.

Press [Setup/Enter] to accept the setting and advance to the next item in the

menu

Press [PST] to advance to setting of the next parameter or [Esc] to return to

normal weighing

46

| Page © Adam Equipment Company 2009

Page 49

10.1.3 CALIBRATION

This menu allows the user to calibrate the weight or the chamber

temperature.

Press [Setup/Enter] when “CALIBRATE” is displayed.

The options for each parameter can be scrolled through by using the [Up] or

[Down] key

CAL MASS Begin the mass calibration function.

Return to weighing when finished.

CAL TEMP Begin the temperature calibration of

the weighing chamber, Return to

weighing when finished.

CAL REPORT On = Enabled. Prints out Calibration

report after successful calibration

(either mass or temperature)

OFF = Disabled

Press [PST] to advance to setting of the next menu which is “PASSCODES”

or [Esc] to return to normal weighing.

10.1.3.1 MASS CALIBRATION Enter the menu for Calibration section. Select CAL MASS. Press [Setup/Enter].

Display will guide you through the steps.

Display will show “Load 0g” , Unload the pan and remove the sample pan.

Press [Setup/Enter].

The display will prompt to select the mass to be used for calibration, i.e.

“LOAD 50g”, Use the UP/DOWN arrow keys to select the alternate mass

47

| Page © Adam Equipment Company 2009

Page 50

size if desired. For PMB 53 calibrate using 20 or 50grams, For PMB 202

calibrate with 100 or 200grams. Press [Setup/Enter].

Place the calibration weight shown on the centre of the weighing pan, When

the stable indicator is on press [Setup/Enter]. The analyzer will calibrate to

the weight selected.

When calibration is complete the display will return to weighing. If there is a

problem an error message will be show. If the weight is unstable “Error Stab”

will be displayed, If the weight is too small “Error Low” will be shown, If the

weight is too large “Error High” will be shown. After calibration the analyzer

will return to normal operation and print the calibration report if it has been

enabled. The determination of being high or low will depend upon the

calibration values stored during the dealer calibration.

10.1.3.2 TEMPERATURE CALIBRATION You must have a Temperature Calibration Accessory to complete the temperature calibration. The calibration will require 30-40 minutes to complete.

Place a sample pan on the pan support during this test.

Place the temperature probe to be used to monitor the temperature within

the weighing chamber on or near the sample pan.

Close the chamber.

Enter the menu for calibration section. Select the Temperature Calibration

option, CAL TEMP.

Press the [Setup/Enter] key.

The display will guide you through the steps necessary to calibrate the

temperature of the heating chamber.

When the analyzer chamber is closed the display will show

48

| Page © Adam Equipment Company 2009

Page 51

with the timer running. The timer will count up to 20:00 to allow time for the

chamber to come to a steady (room) temperature. During this time observe

the temperature in the chamber.

During this time the beeper will sound every minute to remind you that a

calibration test is in progress.

Note the temperature from the Temperature Calibration Accessory. This is

the first temperature to be entered for the lower calibration point.

When the temperature is stable and constant for some time press

[Setup/Enter] to enter the lower temperature value.

FIRST

00:00

The display will change to allow the value to be entered.

Using the numeric entry method, enter the temperature inside the chamber,

for example 23.8ºC you would enter:

Press [Setup/Enter] to continue the test.

FIRST

000.0

FIRST TEMP

023.8

The heaters will turn on and begin heating the test chamber. The timer will

show the elapsed time as before. The chamber will be heated to

approximately 150ºC.

49

| Page © Adam Equipment Company 2009

Page 52

At the end of 20 minutes the beeper will sound, read the temperature in the

chamber. Any time after the 20 minutes, press [Setup/Enter] to enter the

second temperature value.

Enter this value as before, Pressing [Setup/Enter] to confirm and store the

value.

The analyzer will return to normal weighing.

Leave the analyzer to cool

During the 20 minute soaking time you can force the timers to stop if you

observe the chamber temperature is stable by pressing the [Setup/Enter]

key. Then enter the temperature as described.

If the test is not completed as shown above, the temperature test will be

abandoned, the display will show “TEMP CAL FAIL” and the analyzer will

return to normal without the temperature calibration changing. The test will

be stopped if the second temperature is not entered with 30 minutes of

SEC TEMP

000.0

starting the high temperature test.

These values will be accepted only if they are within acceptable limits of the

values stored during the dealer calibration. See Section 7.2.2.2

50

| Page © Adam Equipment Company 2009

Page 53

10.1.3.3 CALIBRATION REPORT During weight or temperature calibration the analyzer can print a report showing details of the calibration. The format of the reports are:

MASS CALIBRATION

DATE: 21/02/2009

TIME: 14:21:32

SER NO: AE001234

USER NO: 123456

WT REF: _ _ _ _ _ _ _

MASS: 50 g

CALIBRATION BY:

_ _ _ _ _ _ _ _ _ _ _

TEMPERATURE CALIB.

DATE: 21/02/2009

TIME: 14:37:12

SER NO: AE001234

USER NO: 123456

TEMP REF: _ _ _ _ _ _ _

TESTED 23ºC/ 142ºC

CALIBRATION BY:

_ _ _ _ _ _ _ _ _ _ _ _

From Analyzer RTC

From Memory

From memory, blank if

not set

User to fill in details

Text, showing cal wt

used or temperature

settings used.

Room to sign

Extra line feeds

English language version shown in the example.

51

| Page © Adam Equipment Company 2009

Page 54

10.1.4 PASSCODES To enable the security features in this analyzer it is necessary to set

passcodes. There are 2 passcodes called Operator Passcode and

Supervisor Passcode. The Operator Passcode allows an authorised user to

operate the basic weighing functions of the analyzer but will not allow access

to the Supervisor Menus if the Supervisor Passcode has been set.

To change or disable a Passcode it will be necessary to enter the current

passcode.

Press [Setup/Enter] when “PASSCODES” is displayed to enter this section.

OPERATOR Enter the current passcode (OLD) first then enter a new

passcode if desired. A passcode set to zero will disable

the security feature and allow unlimited access.

SUPERVISOR First enter the current passcode (OLD) and then enter a

new passcode if desired. A passcode set to zero will

disable the security feature and allow unlimited access.

10.1.4.1 FORGOTTEN PASSCODES

Keep a record of the passcode to ensure you can access this section again.

If however you have forgotten your passcode you can still gain access by

entering a universal code.

If you have forgotten the current passcode a code of “15” will always allow

you to enter the Supervisor area.

Using the Supervisor menus go to the PASSCODE section and reset the

operator or Supervisor passcode using the “15” code as the old number when

requested.

52

| Page © Adam Equipment Company 2009

Page 55

10.2

To store or recall analyzer settings on a USB memory , simply plug the

memory into the USB hub interface. The analyzer will detect the memory

has been inserted and display a screen to guide you.

The display will show a message showing the USB is installed:

To select the option of storing the configuration data to the memory press the

[Dspl] key to change the display to select Configuration Store

STORE AND RECALL ANALYZER SETTING FROM USB MEMORY

CONFIG LD

USB

CONF STORE

USB

Press [Select] to enter the configuration saving function. The display will

show a suggested file name. The name will be the next logical name for the

configuration file based on what data is already on the USB memory. For

example if CONFIG1 and CONFIG2 are already stored, then it will display

CONFIG3.

Press [Select] to confirm the action. Or press [Tare] to escape back to the original USB

display.

CONFIG3

USB

CONFIG3

Store

53

| Page © Adam Equipment Company 2009

Page 56

Once the file has been saved the display will show

For 2 seconds then return to the USB display.

To recall any stored test procedure press the [Dspl] key to show the configuration load

screen.

Press the [Select] key to enter the test load function. The display will show the file name

of the first file found.

To load this file press the [Select] key again. Or to choose a different file press the [Dspl]

key to advance through the other files available.

To continue the USB device should be removed. the analyzer will return to normal

weighing automatically. Or press the [Tare] key to escape back to normal weighing.

To store or recall other files plug the USB memory back into the analyzer.

STORE OK

USB

CONFIG LD

USB

CONFIG LD

USB

CONFIG1

USB

CONFIG1

LOAD

54

| Page © Adam Equipment Company 2009

Page 57

The configuration file is a text file that would appear as the left column below. All

configuration files will be in English regardless of the language selected for the analyzers.

Baud Rate=2; #0=2400,1=4800,2=9600,3=19200,4=38400,default=1;

Parity=0; #0=none,1=Even,2=Odd ,default= 0;

Print Test=1; #0=off,1=on, default=1;

Output Format=0; #0=complete 1=summary ,default=0;

Continuous=1; #0=off,1=on, default=0;

Interval=20; #00-99 ,default=1;

Date Format=1; #0=Europe,1=USA,2=ASIA default=0;

User ID=1234567890; #length=10 alpha-numeric characters;

Key Beeper=1; #0=off;1=on default=1;

Test Beeper=1; #0=off;1=on default=1;

Backlight=2; #0=off,1=on,2=auto default=2;

Filter=1; #0=slow,1=normal,2=fast, default=1;

Stability=2; #0=1d,1=2d,2=5d,3=10d default=2;

Auto Zero=3; #0=off,1=1d,2=2d,3=5d default=5;

Operator=000000; #operator password ,must be 6 bytes;

Supervisor=000000; #Supervisor password ,must be 6 bytes;

Calibration Report=1; #0=off,1=on default=1;

Language=1; #0=English, 1=German, 2=French, 3= Spanish

If there is a problem loading a configuration or PST file from the USB the display will show

the message FAIL. A report will be written on the USB memory in the reports folder.

Open the report file using Notebook or other word processor to read the message. The

message will give a brief description of the reason for the failed attempt. A line of data may

have an incorrect value or command or it may not be possible to complete the command

as it is restricted to the service personal.

Try correcting the command or removing the line the command is on and repeating the

loading procedure.

55

| Page © Adam Equipment Company 2009

Page 58

11.0 SERIAL INTERFACE

The analyzers have the ability to send or receive data over the serial

interface. Using either the RS-232 or the USB serial interface.

The weighing data can be sent over the interface either automatically or when

the user presses the [Print] key.

The user has control over what data is to be printed.

11.1 RS-232 HARDWARE

The RS-232 interface is a simple 3 wire connection. The input and output

connections are:

Connector: 9 pin D-sub miniature plug

Pin 2 Input to analyzer RXD

Pin 3 Output from analyzer TXD

Pin 5 Signal ground GND

Handshaking is not applied.

Baud rate: 2400, 4800, 9600, 19200, 38400

Parity: NONE (=8N1), EVEN (=8E1) or ODD (=8 O 1)

All lines are terminated with carriage return and line feed (<CR><LF>).

In continuous output mode, the serial output format will be a single line in the

form “12.567 g<CR><LF>”.

11.2 USB SERIAL HARDWARE

The USB interface is a standard USB connection. To use the USB interface it

is necessary to plug the analyzer into the USB port of a PC.

The PC will recognise the new device and search for a suitable driver. If

none are found a message will be displayed to guide the user through the

installation of suitable software.

56

| Page © Adam Equipment Company 2009

Page 59

The drivers for the USB interface are available from the Adam Equipment

web site. Go to

www.adamequipment.com. Download the software and

activate the install program, follow the instructions to install the software.

Once the software is installed the PC will list a new COMM port for use with

programs or applications such as AdamDU or other terminal programs.

11.3 INPUT COMMANDS

The analyzer can be controlled with the following commands sent using

remote keys such as from a PC. The commands can be sent in both upper

case letters and lower case letter, i.e. “!KT” or “!kt” are both acceptable.

Press the Enter key of the PC after each command (the action of Carriage

Return is denoted as <CR> as shown below).

Basic Input Commands:

!KT<CR>

Tares the analyzer to display the net weight. This is the same as pressing

the [Zero / Tare] key when the analyzer is in the normal weighing mode.

!KS<CR>

Will begin or end a drying test, the same as pressing the [Start] key.

Note: The RS-232 and USB can both be connected to by external

equipment. The interfaces operate in parallel so they both output the same

data at the same time. It is up to the user to beware in order to prevent

possible conflicts if both interfaces could receive data at the same time. This

may cause some commands to be received with errors.

11.4 PRINTING

RESULTS

The analyzer can print results during a test at the time intervals selected, see

section 6.1.1. In this case the format of the printing will be as shown below.

The first section will print the initial conditions and the settings used for a test.

During the test the current results will be printed. At the end of the test the

final results will be printed.

57

| Page © Adam Equipment Company 2009

Page 60

A typical test report will look as:

MOISTURE TEST

FILE NAME: RES00032

DATE: 13/12/2008

TIME: 09:38:07

SER NO: AE12345678

TEST NO: _ _ _ _ _ _ _ _ _

USER NO: 9876543210

Preset: PST 05

Bread-4

Result: % Moisture

Heating: Step

Temp: Step 1 120 C

Time 1 04:00

Step 2 110 C

Time 2 90:00

Rapid On

Interval: 30 Sec

Stop: Time/Stable

60 Min

0.002 g

30 Sec

Start: Manual

INIT MASS: 12.341 g

MODE TEMP TIME RESULT

Step0 65C 00:30 1.26 %M

Step0 159C 01:00 2.11 %M

Step0 157C 01:30 3.15 %M

Step0 158C 02:00 3.79 %M

Step0 156C 02:30 4.11 %M

Step1 157C 03:00 4.19 %M

Step1 149C 03:30 4.22 %M

Step1 140C 04:00 4.24 %M

Step2 131C 04:30 4.26 %M

Step2 120C 05:00 4.27 %M

Step2 111C 05:30 4.27 %M

*********** AUTO STOP ***********

LAST TEMP: 111C

TEST TIME: 05:30 Min

FINAL MASS: 11.820 g

MASS LOSS: 0.521 g

RESULT: 4.27 %M

Heading

File name used by analyzer to store result

From Analyzer

Serial number

A blank line for users to fill in a number if they wish.

User number

Preset method if used.

Test settings

Measured initial mass.

Test Heading

Results printed once every 30 seconds as set by the

INCR time. Note temperature during first part of test is

120C X 130% as the Rapid function was enabled.

Step0 signifies the rapid function is active. After 3

minutes the Step1 value is the target.

TIME STOP if timed out or MAN STOP if user stopped

Summary of the test

English language version shown in the example.

58

| Page © Adam Equipment Company 2009

Page 61

After the test has finished the user can print either the complete test again or

only a summary by pressing the [Print] key before returning to normal

weighing.

The complete report is a copy of the data as shown above. If the summary

report is selected then the following is printed. Similar to the above except

without the interval readings.

MOISTURE TEST

FILE NAME: RES00032

DATE: 13/12/2008

TIME: 09:38:07

SER NO: XXXXXXXXXXX

USER NO: XXXXXXXXXXX

TEST NO: _ _ _ _ _ _ _ _ _

Preset: PST 05

Bread-4

Result: % Moisture

Heating: Step

Temp: Step 1 120 C

Time 1 04:00

Step 2 110 C

Time 2 90:00

Rapid Manual

Interval: 30 Sec

Stop: Time/Stable

60 Min

0.002 g

30 Sec

Start: Manual

INIT MASS: 12.341 g

*********** AUTO STOP ***********

LAST TEMP: 111C

TEST TIME: 05:30 Min

FINAL MASS: 11.820 g

MASS LOSS: 0.521 g

RESULT: 4.27 %M

Heading

File name used by analyzer to store result

From Analyzer

Add serial number

Add user number

Leave a blank line for users to fill in a number if

they wish, not from Analyzer memory

Settings of the test conditions

Measured initial mass.

TIME STOP if timed out or MAN STOP if user

stopped

Summary of results

Extra LF’s at end of the report

59

| Page © Adam Equipment Company 2009

Page 62

11.5 ANALYZER

CONFIGURATION THROUGH THE SERIAL

INTERFACE

The analyzer can use the serial interface to set parameters for weighing test

and for analyzer configuration. The parameters are set by sending a line of

data that has the description and the setting desired.

It is possible to create a text file that contains all the data necessary to set he

test conditions for a particular test (or analyzer configuration) and send this

to the analyzer. The commands are not case sensitive, i.e. parity=0 and

PARITY=0 are both accepted.

11.5.1 TEST PARAMETERS The parameters that control a test are listed below. To change a test parameter it is necessary to send a command for the parameter to modify along with the value to change.