Page 1

Instruction Manual

gyM

sy...

PC 700 pH/mV/Conductivity/ºC/ºF

Bench Meter

Part of Thermo Fisher Scientific 68X541704 Rev. 1 Feb. 2010

Tech nol o

adeEa

Page 2

Page 3

Page 4

TABLE OF CONTENTS

1. INTRODUCTION.............................................................. 1

2. GETTING STARTED........................................................ 2

2.1 Keypad Functions ...................................................................2

2.2 LCD Annunciators ................................................................... 3

2.3 Meter Connections .................................................................. 3

3. CONDUCTIVITY ELECTRODE ....................................... 4

4. PH AND MV CALIBRATION............................................ 4

4.1 pH Calibration .........................................................................4

4.2 Millivolt (mV) Offset Adjustment ..............................................6

5. CONDUCTIVITY AND TDS CALIBRATION.................... 6

5.1 Automatic or Manual Calibration ............................................. 6

5.2 Single or Multi-Point Calibration.............................................. 7

5.3 General Calibration Tips .........................................................8

5.4 Automatic Conductivity Calibration Procedure ........................ 8

5.5 Manual Conductivity & TDS Calibration Procedure................. 9

5.6 Temperature Calibration .........................................................9

6. CONDUCTIVITY AND TDS MEASUREMENT................ 10

6.1 Taking Measurements............................................................. 10

6.2 Automatic and Manual Ranging ..............................................10

7. HOLD FUNCTION............................................................ 11

8. STORING AND RECALLING DATA ............................... 11

9. SETUP FUNCTIONS........................................................ 12

9.1 1.0 CAL (Calibration)............................................................... 12

9.2 2.0 ELE (Electrode Information).............................................. 12

9.3 3.0 ConF (Configuration)......................................................... 13

9.4 3.1 rdY (Ready / Stability Indicator)......................................... 13

9.5 3.2 ºC ºF (Celsius or Fahrenheit) ............................................ 13

Page 5

9.6 3.3 buFF (pH Buffers & Calibration Points)—pH only .............13

9.7 3.3 AtC (Auto Temp Compensation)—Con & TDS only .......... 13

9.8 3.4 tdS (TDS factor)—Con & TDS only ................................... 14

9.9 3.5 t.CO (Temperature Coefficient)—Con & TDS only............ 14

9.10 3.6 t.nr (Normalization Temperature in ºC)—Con & TDS only 14

9.11 3.7 ACAL (Auto Conductivity Calibration)—Con & TDS only ..15

9.12 3.8 SPC (Single Point Calibration)—Con & TDS only ............. 15

9.13 3.8 CELL (Nominal Cell Constant)—Con & TDS only ............. 15

9.14 4.0 rSt (Reset)......................................................................... 16

9.15 5.0 CLr (Clear Memory) ..........................................................16

10. CALCULATING TDS CONVERSION FACTOR.............. 17

11. CALCULATING TEMPERATURE COEFFICIENTS........ 18

12. REPLACEMENTS AND ACCESSORIES........................ 19

13. TROUBLESHOOTING GUIDE......................................... 20

14. SPECIFICATIONS............................................................ 22

15. WARRANTY..................................................................... 24

16. RETURN OF ITEMS......................................................... 25

Page 6

1. INTRODUCTION

Thank you for purchasing our PC 700 series benchtop meter.

This microprocessor-based meter is economical and simple to

use. The design incorporates a large LCD for clear viewing, yet

offers a small footprint to conserve space.

The PC 700 measures pH, mV (ORP), conductivity, or TDS

simultaneously with temperature (ºC or ºF).

Each meter includes a convenient slide-out card for quick

reference. Also included is an electrode arm and metal bracket

which can be easily attached to the left or right side of the meter

according to your preference.

The PC 700 benchtop meter replaces our popular pH/CON 510

series meter that was introduced in 2000.

We take great pride in every instrument we manufacture

and hope this one serves you well.

1

Page 7

2. GETTING STARTED

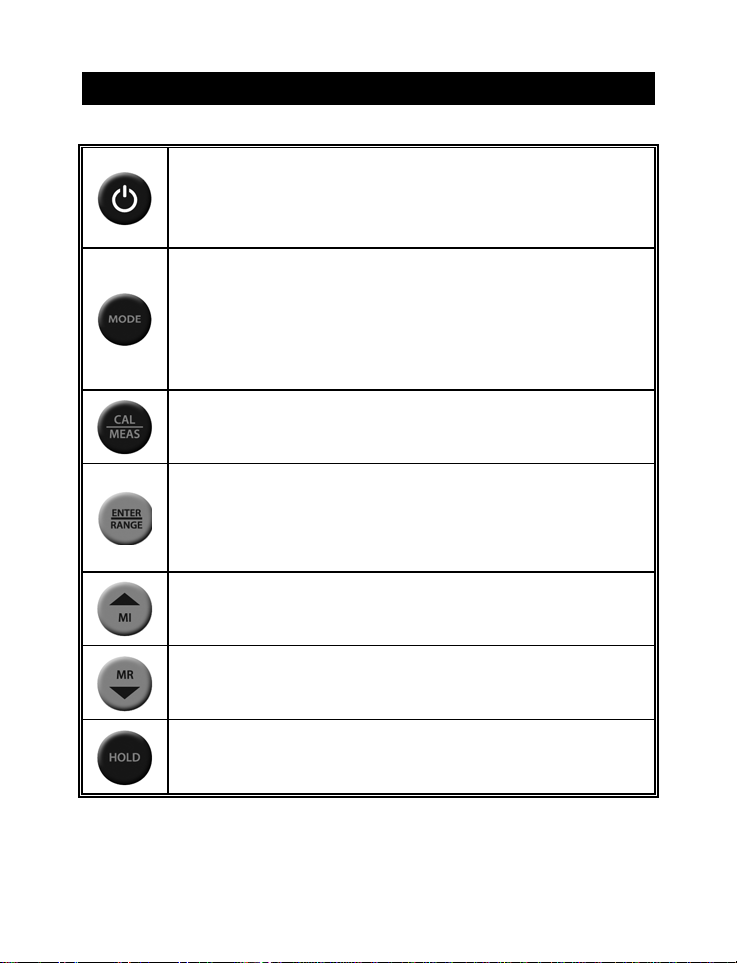

2.1 Keypad Functions

Powers the meter on and off. Upon power on, the meter

automatically begins in the mode that was last used.

Calibration and memory values are retained even if meter

is unplugged.

Toggle between available measurement modes—

pH/Temp, mV/Temp, Conductivity/Temp, or TDS/Temp.

Also used to switch to Temperature calibration during pH,

mV, Conductivity or TDS calibration modes.

Press and hold for 5 seconds to enter SETUP mode.

Toggles between measurement and calibration modes.

In SETUP mode, returns user to the measurement mode.

Confirms calibration values in CAL mode.

Confirms selections in SETUP mode.

Changes Con/TDS range and resolution in MEAS mode.

View recalled values in memory mode.

MI (Memory Insert) stores values into memory.

Increase value. Scroll up in SETUP & CAL modes.

MR (Memory Recall) recalls values from memory

Decrease value. Scroll down in SETUP & CAL modes.

Freezes measured reading. Press again to resume

live reading.

2

Page 8

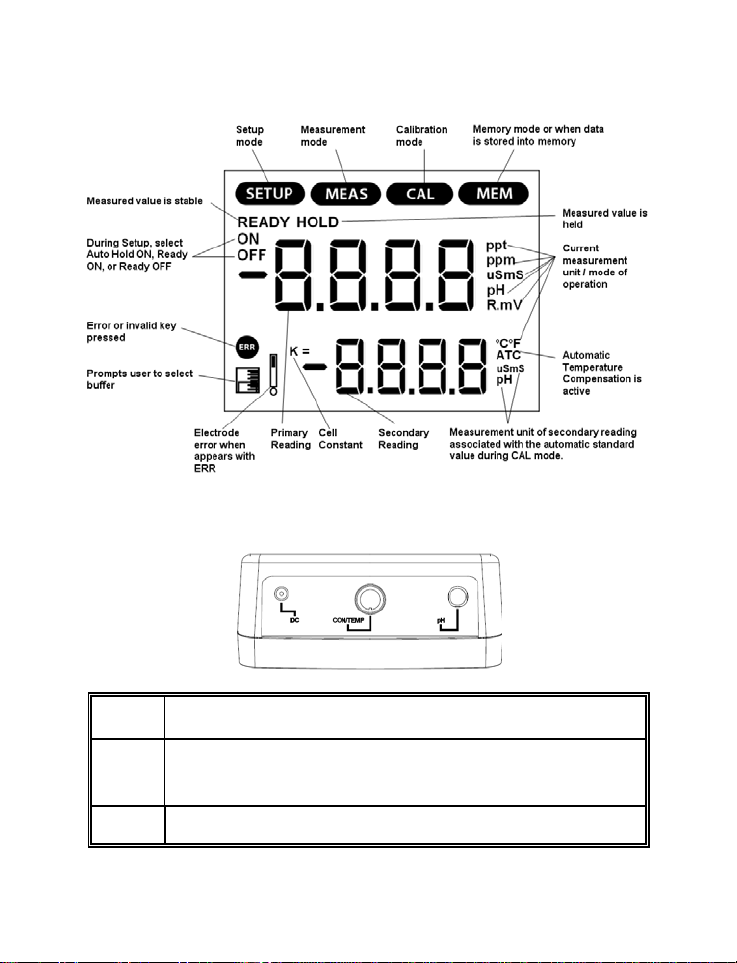

2.2 LCD Annunciators

2.3 Meter Connections

DC

CON/

TEMP

pH

Power supply

8-pin DIN connection for 2-cell Con/TDS/Temp electrode

BNC connection for pH, or ORP (Redox) electrode

3

Page 9

3. CONDUCTIVITY ELECTRODE

The PC 700 includes an electrode with a nominal cell constant of k

= 1.0, built-in temperature sensor, and 1 meter cable. The Ultem

body housing has good chemical resistant properties. The

electrode design offers fast temperature response and reduces air

entrapment, ensuring accurate, repeatable, and stable readings.

he wetted materials of the probe include:

T

Polyetherimide (Ultem) – protective probe guard

Polybutylterphalate (Valox) – sensor housing

Stainless Steel (SS 304) – 2 bands

The protective probe guard can be removed temporarily for

cleaning however it must be re-attached during measurement and

calibration. Erroneous results will occur while the probe guard

is removed.

Always immerse the probe beyond upper steel band for best

results. Use the fill line on the outside of the probe guard for

reference.

4. PH AND MV CALIBRATION

4.1 pH Calibration

For best results, periodic calibration with known accurate standards

recommended. Calibrate with standards that bracket your intended

measuring range while including a neutral standard (pH 7.00 or 6.86).

For example, if you expect to measure samples from

c

alibration with 4.01, 7.00, and 10.01 will work well.

The PC 700 meter can be calibrated with up to 5 buffers. The

non-vola

down.

The follo

tile memory retains all calibration values upon meter shut

wing calibration standards are automatically recognized;

pH 6.2 to pH 9.5,

is

4

Page 10

1) Press as needed to select pH.

USA buffer group 1.68, 4.01, 7.00, 10.01, 12.45

NI 5 ST buffer group 1.68, 4.01, 6.86, 9.18, 12.4

e buffer group See Section 9.6 to change th

Dip the pH and ATC electrodes into pH buffer and press 2)

secondary display will lock on the appropriate buffer value. Provide

ing for best results. When the READY indicator appears, prstirr ess

to accept. The primary reading will flash briefly before the

secondary display begins scrolling the remaining available buffers.

3) r.

Rinse the pH and ATC electrodes then dip into the next pH buffe

The secondary display will lock on the appro ate buffer value.

When the READY indicator appears, press

primary reading will flash briefly then display the percent efficiency

(slope) before the secondary display begins scrolling the remaining

available buffers.

4)

To calibrate another buffer repeat step 3) or press

the measurement mode. Note: The meter will automatically return

to measurement mode upon successful completion of the numbe

specified calibration points. To spec

calibration points see Section 9.6.

IPS: A single poT

pH 6.86 buffers.

When the first calibration value is acce

ca

all prior libration values are erased.

ress P

mode.

at any time to abort calibration and return to measurement

int (offset) calibration is only allowed with pH 7.00 or

ify a different number of pH

pted during a new calibration,

pri

to accept. The

. The

to return to

r of

5

Page 11

4.2 Millivolt (mV) Offset Adjustment

Oxidization Reduction Potential (ORP or Redox) is not a precise

measurement, but is useful as a relative indicator. As such, mV offset

adjustment is not meant to enhance accuracy, but rather to make

readings comparable to a reference. Commercial ORP solutions are

often used as a check s

verified to be close to a given value, instea of being used as a

calibration standard in which adjustments made in an attempt to

match the ORP value.

tandard in which a meter/electrode system are

d

are

nect an ORP electrode and press as needed to select

1) Con

(or R.mV).

2) Dip the ORP el

(i.e. Zobel, Light’s, quinhydrone, or iodidetriiodide) and stir.

3) Press when the reading is stable he prima display shows

the relative millivolt value (R.m ) whi he secon ry display sho

factory default mV value.

the

Adjust the R.mV value using

) or . Press 4 to accept or

to cancel. The meter allows an adjustable maximum value of

150± mV from the factory default mV value.

Note: When an offset has been stored successfully, R.mV replac

mV.

ectrode into a solution with a known mV value

. T ry

V le t da ws

mV

es

5. CONDUCTIVITY AND TDS CALIBRATION

5.1 Automatic or Manual Calibration

The PC 700 is capable of automatic or manual calibration for

conductivity, and manual calibration for TDS.

In the automatic calibration mode, the meter will automatically se

one of (4) conductivity calibration standard values depending on the

range and normalization temperature being used (TABLE 1).

lect

6

Page 12

If you only use calibration standards that are listed in TABLE 1,

automatic calibration is recommended. If you intend to calibrate with

one or more standards that are not l

be set for manual calibration i

The factory default is automati

an ere i

ge this setting. Th

available

for e 1.

conductivity rang

isted in TABLE 1, the PC 700 must

nstead.

c conductivity calibration. See Section

s no automatic calibration value 9.11 to ch

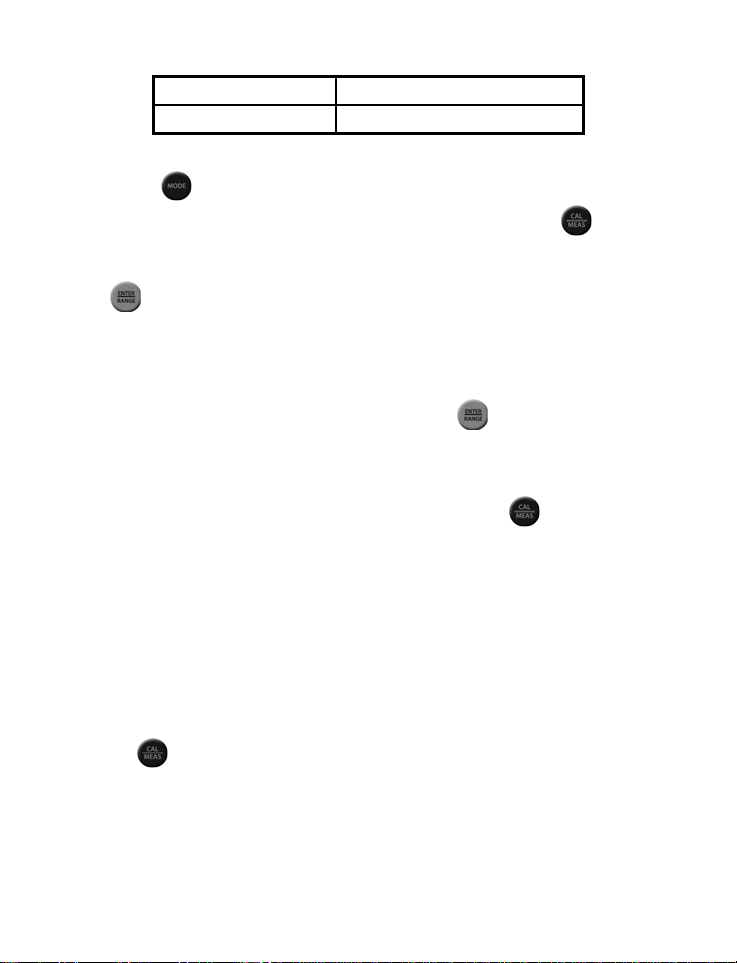

TABLE

1

Auto Calibratio es matic n Valu

R e ang

#

r 1 0.00 – 20.00 μS None None

r 2 20.1 – 200.0 μS 84 μS 76 μS

r 3 201 – 2000 μS 1413 μS 1278 μS

r 4 2.01 – 20.00 mS 12.88 mS 11.67 mS

r 5 20. 111.8 mS 1 – 200.0 mS 102.1 mS

Conductivity

Range

N ation Temp ormaliz erature

25 ºC 20 ºC

Range

#

r 1 0 – 10.00 ppm none

r 2 1 0.1 – 100.0 ppm

r 3 101 – 1000 ppm

r 4 1.01 – 10.00 ppt

r 5 10.1 – 100 ppt

5.2 Single or Multi-Point Calibration

Use Single-Point Calibration to apply a single calibration value across

all ranges.

TDS Range

(us r) ing 0.5 TDS facto

Automatic Calibration

Values

none

none

none

none

7

Page 13

Use Multi-Point Calibration for individual calibration in each range. T

ill restrict an individ

w

only. When using multi-point calib

range that you expect to use for b

The factory default is Single-Point Calibration. See Section 9.12 to

change this setting.

5.3 General Calibration Tips

or best results, periodic calibration with known accurate standards is

F

recommended. A maximum of one calibrati

performed. If multiple calibration points are used in the same range,

the most recent one will replace the previous one.

When the electrode is replaced, it is best to clear the calibration to the

factory default values (see Section 9.14).

Rinse or immerse the probe before

with clean water (deionized water is ideal).

The PC 700 has non-volatile memor

values, as well as meter settings and memory values upon meter shut

down or unexpected power loss.

To protect from erroneous calibrations, the allowable tolerance is ±40%

of the

factory default value.

Low conductivity standard solutions (less than 20 µS) ar

are very temperature dependent. As a result, reproducible calibration

results are challenging in lowest measurement range #1 (0.00

µS).

5.4 Automatic Conductivity Calib

ual calibration so that it is applied to one range

ration, perform a calibration in each

est results.

on point per range can be

calibration and between samples

y which will retain all calibration

e unstable and

ration Procedure

his

to 20.0

1) Press

2) Dip the electrode into th . e conductivity standard and press

Provide stirring for best results.

3) The primary display will show the factory default value, while the

secondary display will lock on the appropriate automatic standard

value from TABLE 1.

as needed to select conductivity (μS or mS).

8

Page 14

4) When the READY indicator appears, press to accept. The

mode upon successful calibration.

5.5 Manual Conductivity & TDS Calibration Procedure

t primary reading will flash briefly before returning to measuremen

1) Press

as needed to select conductivity (μS or mS) or TDS

(ppm or ppt) calibration.

2) Dip the electrode into the calibration standard and press

.

Provide stirring for best results.

The primary display will show the current reading,3) while the

secondary display will be the factory default value. Adjust the

conductivity or TDS reading using or . Press to

accept. The primary reading will flash briefly before returning to

measurement mode upon successful calibration.

5.6 Temperature Calibration

The thermistor sensor used for automatic temperature compensation

and measurement is accurate and stable, so frequent calibration isn’t

req mended upon probe

uired. Temperature calibration is recom

replaceme whenever the temperature reading is suspect, or if

nt,

matching against a certified thermometer is desired.

1) n with a known accurate temperature

Place the probe into a solutio

such as a constant temperatur

2) Press

followed by . The primary display shows the

e bath.

measured temperature while the secondary display shows the

factory default temperature.

) Adjust the temperature using

4 or . Press to accept or

he meter allows a

º

( r ± 9 F) from the factory default temperature.

o

n adjustable maximum value of ± 5

º

C to cancel. T

9

Page 15

6. CONDUCTIVITY AND TDS MEASUREMENT

6.1 Taking Measurements

1) Rinse the electrode with de-ionized or distilled water before use

to remove any impurities. Gently shake excess water droplets.

2) Dip the pro

(utilize the fill line on the out

reference).

3) Allow time for the reading to stabilize. Note the reading on the displa

The clear yellow protective probe guard must be attached durin

measurement. Erroneous results will occur while the probe guard is

removed.

6.2 Automatic and Manual Ranging

The PC 700 automatically selects the optimum range in which your

readings appear. Refer to TABLE 1 for a list of the available ranges.

be into the sample beyond the upper steel band

side of the probe guard for

y.

g

To turn-off automatic ranging, press

that manual ranging is active. To manually

press

again. After range 5, automatic ranging is resumed.

. MEAS will flash, indicating

select the next range,

F(ror example, a reading of 465 μS will automatically settle in range 3

3). Using manual range advancement this will read as 0.47 mS in

range 4 (r4), and 0.5 mS in range 5 (r5).

Automatic ranging is typically used since this will always provide the

best resolution.

10

Page 16

7. HOLD FUNCTION

For prolonged observation of a reading, press during

measurement mode to freeze the display. The “HOLD” indicator will

display when the reading is held. To release the held value and

resume measurement, press

memory by pressing

.

again or insert the held value into

8. STORING AND RECALLING DATA

The PC 700 can retain up to 100 data points into memory for

later retrieval.

1) In the measurement mode, press

into memory. The stored memory location value (StO) is briefly

displayed.

2) To recall data from memory, press

recent stored data is displayed first. Press or to select the

location of the desired data, then press to accept.

3) Press to return to the stored data location. Press to return

to measurement mode. To erase stored data, see Section 9.15.

to insert the measured value

. The location of the most

11

Page 17

9. SETUP FUNCTIONS

Use the setup feature to customize your instrument operation. First,

select the appropriate measurement mode you wish to adjust by

pressing

Conductivity, or TDS). During measurement, press and hold

seconds to enter SETUP mode of the parameter being measured.

Press

Press to select the program or confirm selection.

Press

9.1 1.0 CAL (Calibration)

9.2 2.0 ELE (Electrode Information)

TIP: When multiple pH slopes exist, the slope that is available to view

will depend on the measured value before entering SETUP mode.

For example, if pH calibration values pH 4.01, 7.00 and 10.01 were

completed, there will be two slope values; one that corresponds to pH

values below 7.00 and another that corresponds to pH values above

7.00. If the measured pH value was 5.23 when setup mode was

entered, the pH slope that corresponds to values lower than 7.00 will

be available to view. If no calibration is stored, the offset will be 0.0

mV and the slope is 100%.

until the desired units are displayed (i.e. pH, mV,

or to change programs or change options.

to go back one level or return to measurement mode.

Press

Press

Press to view % slope (SLP)—pH mode.

Press

and TDS modes.

to view stored calibration points.

to view mV offset (OFS)—mV and pH modes.

to view cell efficiency in each range—conductivity

12

for 5

Page 18

9.3 3.0 ConF (Configuration

)

Press

3.19.4 rdY (Ready / Stability Indicator)

Press

Press or to choose READY “On”, READY “OFF”, or

Auto HOLd.

Press

9.5 3.2 enheit) ºC ºF (Celsius or Fahr

Press

Press or to select ºC or ºF.

Press to confirm.

.6 3.3 buFF (pH Buffers & Calibration Points)—pH only 9

Press

Press or to select “USA” or “NIST” buffer group

Press

(pH and Ion only).

to access set-up programs 3.1 thru 3.9.

.

to confirm.

.

.

de ly). (pH mo on

or to select number of Calibration Points

Press

AtC (Auto Temp Com9.7 3.3 pensation)—Con & TDS only

Press

to confirm.

.

13

Page 19

Press or to select “Yes” or “No”.

Press to confirm.

9.8 3.4 n & TDS only

tdS (TDS factor)—Co

ress

P

Press or to select the desired TDS factor (.40 to

1.00).

Press

9.9 3.5 t.CO (Temp efficient)—Con & TDS only

The tem c e amount of change in conductivity per

degree temperature (% per ºC). The PC 700 is factory set to a

temperature coefficient of 2.1 % per ºC. For most applications t

provide good results. The meter allows adjustment from 0.0 to 10.0.

TIP: Select 0.0% for uncompensated measurements. The temperature

will be measured by the electrode and displayed in measurement

mode—without compensation.

See Section 11 – Calculating Temperature Coefficients.

9.10 3.6 t.nr (Normalization Tempera

When Au ompensation is used, measurements

are adjusted by the temperature coefficient to the normalization

temperature. The default value is 25 ºC.

erature oefficient is thp

Press

Press or to select the desired value (0.00 to 10.0).

Press to confirm.

tomatic Temperature C

.

to confirm.

erature Co

his will

.

ture in ºC)—Con & TDS only

14

Page 20

Press .

Press or to select the desired value (15.0 to 30

Press

ACAL to nductivity Calibration)—Con & TDS

3.7 (Au Co

See Sectio for more deta atic Conductivity Calibration.

9.12 3.8 Po

See Sectio for details o

9.13 3.8 No al

The PC 700 includes a probe with a nominal cell constant (k) of 1.0.

Use prob k parately) for improved

performa ce in extreme sample ranges. Use this setup function to

change the cell constant if necessary. Meter default is 1.0 to m

included probe.

k = 0.1 ideal for low measurements <20 µS (<10 ppm).

k = 1.0 ideal for mid-range measurements

k = 10 ideal for high measurements >20 mS (>10 ppt).

n 5.1 ils on Autom

ress

Press or to select “Yes” (Automatic) or “No” (Manual).

Press to confirm.

SPC (Single int Calibration)—Con & TDS only

n 5.2

ress

Press or to select “Yes” (Single) or “No” (Multi).

Press to confirm.

CELL ( min Cell Constant)—Con & TDS only

es with = 0.1 and 10 (sold se

n

to confirm.

. P

n Single Point & Multi Point Calibration.

. P

.0).

only9.11

atch the

Press

Press or to select 0.1, 1.0, or 10.0

Press to confirm.

.

15

Page 21

9.14 4.0 rSt (Reset)

. Press

or Press to select “Yes” (Reset) or “No” (Cancel).

sIf “Yes”, pres or to select “Cal” (calibration reset

ete reset to factory default settings). only) or “FCt” (compl

Press

9.15 5.0 o

CLr (Clear Mem ry)

Press

Press or to select “Yes” (Erase memory) or “No”.

Press to confirm.

to confirm.

.

16

Page 22

10. CALCULATING TDS CONVERSION FACTOR

You can calibrate TDS using the value of the calibration standard solution

at a standard temperature such as 25 ºC. To determine the conductivityto-TDS conversion factor use the following formula:

Factor = Actual TDS ÷ Actual Conductivity @ 25 ºC

Actual TDS: Value from the solution bottle label or as a

standard made using high purity water and precisely weighed

salts.

ppm = milligram of salt(s) per liter of water = mg/L

ppt = gram of salt(s) per liter of water = g/L

Actual Conductivity: Value measured using a properly

calibrated Conductivity/Temperature meter.

Both the Actual TDS and the Actual Conductivity values must be in the

same magnitude of units. For example, if the TDS value is in ppm the

conductivity value must be in µS; if the TDS value is in ppt the conductivity

value must be in mS.

Check your factor by multiplying the conductivity reading by the factor in

the above formula. The result should be in TDS value.

When the TDS factor is set to 1.0, Conductivity = TDS.

17

Page 23

11. CALCULATING TEMPERATURE COEFFICIENTS

To determine the temperature coefficient of your sample solution use this

formula:

Where:

tc = Temperature coefficient 25 = 25 ºC

C

= Conductivity at Temp 1 CT2 = Conductivity at Temp 2

T1

T1 = Temp 1 T2 = Temp 2

NOTE: A controlled temperature water bath is ideal for this procedure.

1. Immerse the probe into a sample of your solution and adjust the

temperature coefficient to 0% (that is, no compensation) by following

instructions as described in Section 9.9.

2. Wait for 5 minutes. Note T1 and CT1 (conductivity at T1).

3. Condition the sample solution and probe to a temperature (T2) that is

about 5 ºC to 10 ºC different from T1, and note the conductivity

reading C

.

T2

NOTE: Record your results for future reference. Ideally T1 and T2 should

bracket your measurement temperature, and should not differ by

more than 5 ºC.

4. Calculate the temperature coefficient of your solution according to the

formula shown above.

5. Enter the calculated temperature coefficient into the meter.

The calculated temperature coefficient will now be applied to all the meter

readings.

18

Page 24

12. REPLACEMENTS AND ACCESSORIES

Part number Ordering Code

Item Description

PC 700 with pH electrode (ECFC7252101B / 59001-

70), conductivity/temp electrode (CONSEN9501D /

35608-74), integral stand,100/240 VAC

PC 700 with integral stand, 100/240 VAC - 35413-20

Plastic, Gel-filled, Double-junction pH electrode ECFC7252201B 35641-51

Plastic, Gel-filled, Single-junction pH electrode ECFC7252101B 59001-70

Replacement conductivity/temp electrode, k = 1.0 CONSEN9501D 35608-74

Epoxy/platinum conductivity/temp electrode, k = 0.1 - 35608-72

Glass/platinum conductivity/temp electrode, k = 1.0 - 35608-76

Epoxy/platinum conductivity/temp electrode, k = 10.0 - 35608-78

SMPS, 100/240 VAC, 9V, 6W power adapter 60X030130 35615-07

10 μS, (20) x 20mL Sachets ECCON10BS 35653-09

84 µS, 480 mL bottle* ECCON84BT 00653-16

447 μS, 480 mL bottle ECCON447BS 00653-47

500 μS, 480 mL bottle ECCON500BT -

1413 μS, 480 mL bottle* ECCON1413BT 00653-18

1413 μS, (20) x 20mL Sachets* ECCON1413BS 35653-11

2764 μS, 480 mL bottle ECCON2764BT 00653-20

2764 μS, (20) x 20mL Sachets ECCON2764BS 35653-12

5.0 mS, 480 mL bottle ECCON5000BT -

12.88 mS, 480 mL bottle* ECCON1288BT 00606-10

15 mS, (20) x 20mL Sachets ECCON15000BS 35653-13

111.8 mS, 480 mL bottle* ECCON1118BT -

*Automatic Calibration Standard Value at 25 ºC

Eutech

Instruments

ECPC70043S

01X543601

Oakton

Instruments

35413-00

19

Page 25

13. TROUBLESHOOTING GUIDE

PROBLEM CAUSE SOLUTION

No display Main power not switched

“Ur” (Under

range)

“Or” (Over

range)

in primary or

secondary

display

Slow

response

Meter not

responding to

key press

Secondary

display

continually

scrolls

on. AC Adapter socket not

inserted properly.

Measured value is out

of range.

Electrode not connected.

Electrode clogged, dirty

or broken.

Meter not calibrated.

Wrong temp value.

Dirty electrode.

Temperature of sample is

changing.

Manual HOLD or Auto

HOLD is active.

Worn keypad.

Invalid key; Button is not

functional in the current

operation mode.

The conductivity calibration

standard is not within 40%

of expected value during

automatic calibration.

The pH buffer is >1 pH unit

from the available pH

buffers remaining for

calibration.

Switch on the power supply.

Re-insert AC Adapter.

Check electrode is connected.

Clean or replace electrode.

Recalibrate the meter.

Confirm measurement condition.

Treat samples to bring within

meter measuring range.

Reset meter.

Clean the electrode.

Allow temperature to stabilize.

Press

HOLD. See Section 9.4 to disable

Auto Hold feature if enabled.

Contact Technical Service.

Press alternate key.

Select valid key depending on

current mode.

Ensure that the conductivity

electrode guard is attached.

Use fresh standard or use an

alternate calibration standard.

Use fresh standard or use an

alternate calibration standard.

Verify the USA or NIST buffer

selection. Check pH electrode.

to deactivate manual

20

Page 26

reading

Slow

response

CAL

during pH

CAL mode

Calibration error.

Buffer value does not

match displayed value or

electrode is disconnected

or failing.

Broken or worn electrode Replace electrode Unstable pH

External ‘noises’ or

induction (electrical ‘noise’

caused by a nearby motor)

Dirty electrode. Clean & rehydrate the electrode

Calibration was attempted

using only 1-point that was

not pH 7 (USA) or pH 6.86

(NIST).

Use fresh buffer solutions.

Check electrode connection.

Clean & recondition electrode.

Replace electrode.

Remove or switch off interfering

device

Recalibrate using 2 or more pH

points or use pH 7 (USA)

or use pH 6.86 (NIST).

21

Page 27

14. SPECIFICATIONS

pH Range 0.00 to 14.00 pH

Resolution 0.01 pH

Accuracy

Calibration Points Up to 5 points with Auto-buffer recognition

Buffer Options

Slope Display Yes (with offset)

mV Range

Resolution

Accuracy

Offset Adjustment Up to ±150 mV

Conductivity Range

TDS Range

(0.5 TDS factor)

Resolution 0.05 % Full Scale

Accuracy ±1% Full Scale

Temperature

Range (Meter) 0.0 to 100.0 ºC / 32.0 to 212.0 ºF

Compensation

Type & Range

Resolution 0.1 ºC / ºF

Accuracy ± 0.5ºC / ± 0.9ºF

Calibration

Coefficient 0.0 to 10.0% per ºC

Normalization 15.0 to 30.0 ºC (adjustable)

0 to 10.00, 100.0 ppt

USA : pH 1.68, 4.01, 7.00, 10.01,12.45

NIST: pH 1.68, 4.01, 6.86, 9.18 ,12.45

0.1 mV ( 199.9 mV), 1 mV beyond 200 mV

0.2 mV ( 199.9 mV), 2 mV beyond 200 mV

Automatic with supplied cell or Manual.

0.0 to 80 ºC / 32.0 to 176.0 ºF with supplied cell

Offset in 0.1 º increments; Offset range: 5 ºC / 9 ºF

0.01 pH + 1 count

2000 mV

0 to 20.00, 200.0, 2000 µS

0 to 20.00, 200.0 mS

0 to 10.00, 100.0, 1000 ppm

(max 200.0 ppt @ 1.0 TDS factor)

0.0 to 100 ºC / 32.0 to 212.0 ºF,

22

Page 28

Cell Constant 0.1, 1.0, 10.0 (selectable)

TDS Factor 0.40 to 1.00 (adjustable)

Calibration points

Auto-ranging Yes

Hold Function Yes

Memory 100 data sets

Input BNC, 8-pin DIN

Power AC/DC 9V, 6W Adapter (100/240 VAC, 50-60Hz)

Dimensions (mm) meter only = 175 (L) x 155 (W) x 69 (H)

Automatic (4 points); Maximum 1 per range

Manual (5 points); Maximum 1 per range

23

Page 29

15. WARRANTY

This meter is supplied with a warranty against significant deviations in

material and workmanship for a period of THREE years from date of

purchase whereas probe with a SIX month warranty.

If repair or adjustment is necessary and has not been the result of abuse

or misuse within the designated period, please return – freight prepaid –

and correction will be made without charge. Eutech Instruments/Oakton

Instruments will determine if the product problem is due to deviations or

customer misuse.

Out of warranty products will be repaired on a charged basis.

The warranty on your instrument shall not apply to defects resulting from:

Improper or inadequate maintenance by customer

Unauthorized modification or misuse

Operation outside of the environment specifications of

the products

24

Page 30

16. RETURN OF ITEMS

Authorization must be obtained from our Customer Service Department or

authorized distributor before returning items for any reason. A “Return

Material Authorization” (RMA) form is available through our authorized

distributor. Please include data regarding the reason the items are to be

returned. For your protection, items must be carefully packed to prevent

damage in shipment and insured against possible damage or loss.

Eutech Instruments will not be responsible for damage resulting from

careless or insufficient packing. A restocking charge will be made on all

unauthorized returns.

NOTE: Eutech Instruments Pte Ltd /Oakton Instruments reserve the right

to make improvements in design, construction, and appearance of

products without notice.

25

Page 31

Page 32

sales@novatech-usa.com

www.novatech-usa.com

Tel: (866) 433-6682 Fax: (866) 433-6684

Tel: (281) 359-8538 Fax: (281) 359-0084

For more information on our products, please contact our channel

partner or visit our websites listed below:

Oakton Instruments

625 E Bunker Court

Vernon Hills, IL 60061

USA

Tel: (1) 888-462-5866

Fax: (1) 847-247-2984

info@4oakton.com www.4oakton.com

Distributed by:

Eutech Instruments Pte Ltd

Blk 55, Ayer Rajah Crescent,

#04-16/24

Singapore 139949

Tel: (65) 6778 6876

Fax: (65) 6773 0836

eutech@thermofisher.com

www.eutechinst.com

Part of Thermo Fisher Scientific

Loading...

Loading...