Page 1

VARIABLE FLOW MINI-PUMP INSTRUCTIONS

Pump I (Model 3384)—Ultra Low Flow [ ]

Pump II (Model 3385)—Low Flow [ ]

Pump III (Model 3386)—Medium Flow [ ]

Pump IV (Model 3389)—Medium/High Flow [ ]

SPECIFICATIONS

Type: Variable flow, self-priming, peristaltic pump

Flow control: Variable

Flow rates: Pump I—Ultra Low Flow: 0.005 to 0.900 ml/min

Pump II—Low Flow: 0.03 to 8.20 ml/min

Pump III—Medium Flow: 0.4 to 85.0 ml/min

Pump IV—Medium Flow: 4.0 to 600 ml/min

Silicone tubing temperature range: -80 to 500°F (-62 to 260°C)

Motor: 12 VDC variable

Case: ABS plastic

Dimensions: 65/8 x 43/4 x 41/

inches

(16.8 x 12.0 x 11.5 cm)

2

Weight: 11/4 lb (567 g)

Power: 120 V, 60 Hz; 9 or 12 V battery; or European 220 V, 50 Hz

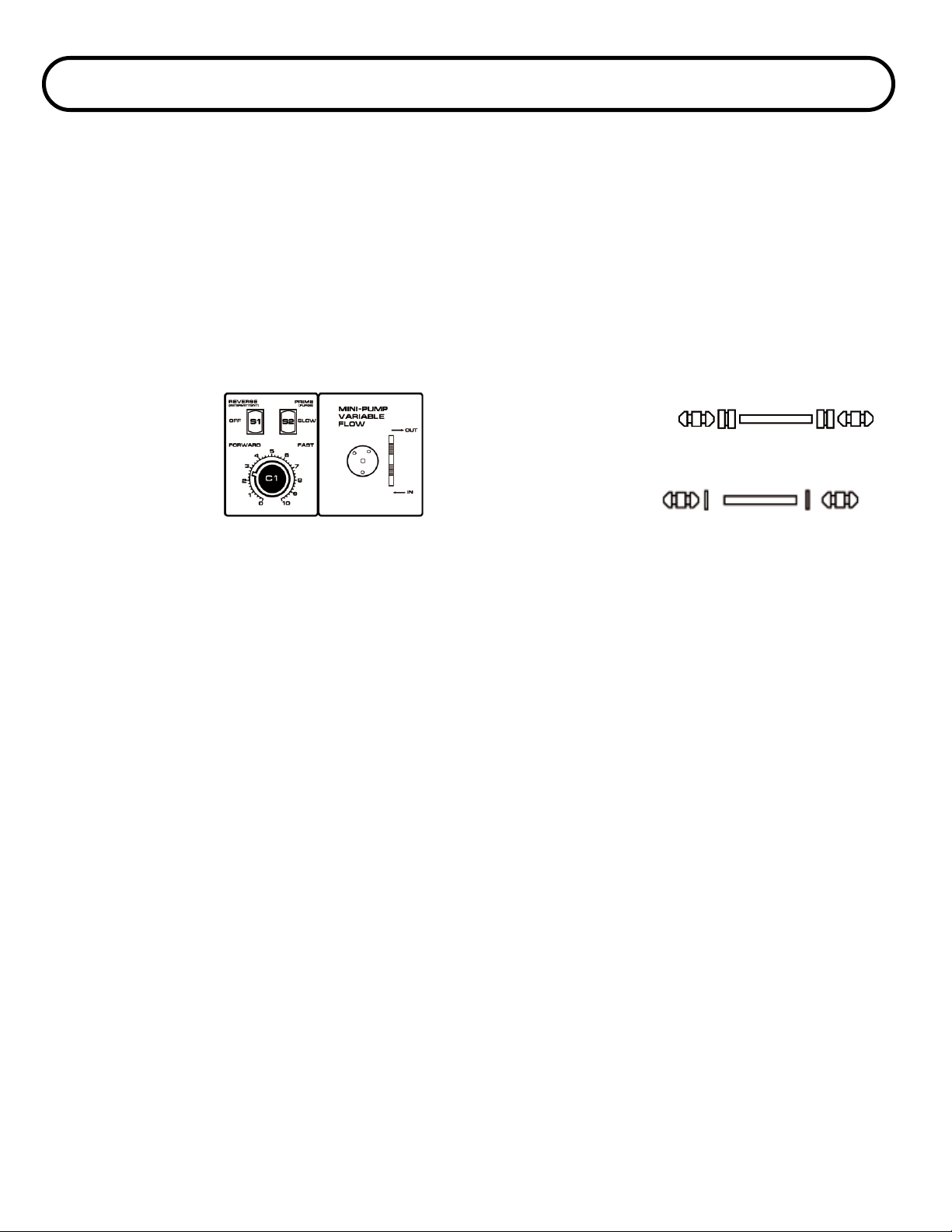

CONTROL PANEL

S1: Power/Direction switch:

For selecting FORWARD,

REVERSE, and power OFF.

S2: Pump Speed switch:

For selecting FAST, SLOW,

and PRIME (PURGE).

C1: Variable Flow Control:

For varying flow rate.

Figure 1 Control Panel

GENERAL INFORMATION

Variable flow Mini-Pump is a bidirectional, self-priming peristaltic pump for

precise low-flow deliveries. The squeezing action of the rollers on the tubing

progressively moves fluid through the tubing in advance of the rollers, resulting in

a peristaltic pumping action. The flow is proportionate to the speed of the pump

head and the inside diameter of the tubing, both of which can be varied. A

variable speed flow control and five different sized tubing assemblies provide fine

resolution with a wide range of flow rates. A PRIME (PURGE) setting is provided

to facilitate high speed emptying/filling operations. Mini-Pump is powered by a

12-volt wall adapter that plugs into a wall receptacle. A battery power cord is

also supplied for portable operation of the pump using a 9- or 12-volt battery.

SETUP

There are two power cords available; this enables Mini-Pump to operate from a

standard (120-volt, 60-hertz wall receptacle or European accessory adaptor

220-volt, 50-hertz) and from a 9- or 12-volt battery. Connect one end of the

appropriate power cord to the Mini-Pump and the other end to a power source,

the Mini-Pump is now ready to use.

AC Power Cord: This 6-foot cord has a single male plug on one end and a

wall adapter on the other. Insert the single male plug into the power receptacle

at the back of the pump housing and the wall adapter into a wall receptacle.

Battery Power Cord: This 7-inch cord has a single male plug on one end

and a 9-volt battery connector on the other. Insert the single male plug into the

power receptacle at the back of the pump housing and connect the battery

connector to a 9-volt battery.

NOTE: Mini-Pump can also be operated from a 12-volt car/storage battery by

properly splicing the wires to the 9-volt connector. Results are comparable to

those on ac operation. Operation of the pump on a 9-volt battery produces

slower speeds and flow rates. A standard 9-volt battery runs the pump for a

relatively short time (30 min or less) before becoming exhausted.

OPERATION

1. Release the protective transparent cover by depressing the tab on the plastic

retaining clip located at the bottom of the cover. The hinged cover can then

be raised to gain access to the pump head and tubing assembly.

2. Take the tubing assembly (plastic fittings and attached tubing) and wrap the

tubing around the pump head (white roller). Slide each plastic slotted fitting

into each metal slotted U-shaped retaining bracket.

3. Attach tubing to the IN and OUT barbed fittings on the pump.

4. Move Power/Direction switch (S1) to FORWARD, to activate pump head.

5. Move the Pump Speed switch (S2) to PRIME (PURGE), to quickly fill the

tubing with liquid.

6. Move the Pump Speed switch (S2) to SLOW or FAST.

7. Within each of the two speed ranges (SLOW and FAST), the flow rate can be

varied for precise delivery by rotating the Variable Flow Control knob (C1).

The adaptor tip is positive (+). Polarity reversal will damage

this product.

Selecting a higher reference number increases the revolutions per minute and the flow

rate of the pump.

8. Select a tubing size with a mid-range for the expected flow rate.

9. To extend tubing life, select a tubing size with the largest diameter pos-sible for the

desired output and operate pump at lower speeds (without stalling the pump). If too

large a diameter tubing is selected, and the pump is set at too slow a speed, the pump

motor may stall or stop.

10. The tubing in the tubing assembly will eventually wear out and must be replaced. To

replace tubing read the following sections: “Tubing Assemblies,” “Tubing,” etc.

NOTE: If very accurate flow control is important, allow the pump to operate for approximately 20

minutes to condition the tubing.

CAUTION: Mini-Pump is engineered to provide years of satisfactory service if handled

properly. Here are a few precautions:

• Do NOT run the pump in reverse for long periods of time. This will shorten the life of the

motor.

• Do NOT manually turn the pump head. Turning the pump head manually will damage the

pump gears.

• Do NOT touch the pump head while it is turning.

• This product is not designed for nor intended for use in patient-related applications.

TUBING ASSEMBLIES

Slotted

(see Fig. 2)

Figure 2 Slotted Tubing Assembly Configuration

Slotted tubing assemblies consist of a length of tubing with each end terminating in a

straight barbed fitting with a slotted tube-lock holding the fitting in place.

Washer

(see Fig. 3)

Washer tubing assemblies consist of

a length of tubing with each end

Figure 3 Washer Tubing Assembly Configuration

terminating in a straight barbed fitting with a washer tube-lock holding the fitting in place.

Complete tubing assemblies are available (see “Accessories” section).

TUBING

For replacement of the tubing only, consult the chart below for cutting the tubing to the

proper length.

Pump I—Ultra Low Flow

Tubing I.D. Approx. Tubing Length Approx. Flow Rate

1

/50”, 0.5mm . . . . . . . . . . . 3.25”, 83mm . . . . . . . . . . 0.005 – 0.013 ml/min

*1/32”, 0.8mm . . . . . . . . . . . . 3.5”, 89mm . . . . . . . . . . . 0.008 – 0.03 ml/min

1

/16”, 1.6mm . . . . . . . . . . . 4.25”, 108mm . . . . . . . . . . 0.05 – 0.17 ml/min

3

/32”, 2.4mm . . . . . . . . . . . 4.5”, 114mm . . . . . . . . . . . 0.08 – 0.36 ml/min

3

/16”, 4.8mm . . . . . . . . . . . 5.0”, 127mm . . . . . . . . . . . 0.35 – 0.96 ml/min

1

/4”, 6.4mm . . . . . . . . . . . 4.375”, 111mm . . . . . . . . . . 0.38 – 1.80 ml/min

*Not supplied with pump

Pump II—Low Flow

Tubing I.D. Approx. Tubing Length Approx. Flow Rate

1

/50”, 0.5mm . . . . . . . . . . . 3.25”, 83mm . . . . . . . . . . . 0.03 – 0.06 ml/min

*1/32”, 0.8mm . . . . . . . . . . . . 3.5”, 89mm . . . . . . . . . . . 0.04 – 0.14 ml/min

1

/16”, 1.6mm . . . . . . . . . . . 4.25”, 108mm . . . . . . . . . . . 0.25 – 0.8 ml/min

3

/32”, 2.4mm . . . . . . . . . . . 4.5”, 114mm . . . . . . . . . . . . 0.4 – 1.7 ml/min

3

/16”, 4.8mm . . . . . . . . . . . 5.0”, 127mm . . . . . . . . . . . . 1.7 – 4.6 ml/min

1

/4”, 6.4mm . . . . . . . . . . . 4.375”, 111mm . . . . . . . . . . . 1.8 – 8.2 ml/min

*Not supplied with pump

Pump III—Medium Flow

Tubing I.D. Approx. Tubing Length Approx. Flow Rate

1

/50”, 0.5mm . . . . . . . . . . . 3.25”, 83mm . . . . . . . . . . . . 0.4 – 0.8 ml/min

*1/32”, 0.8mm . . . . . . . . . . . . 3.5”, 89mm . . . . . . . . . . . . 0.6 – 2.2 ml/min

1

/16”, 1.6mm . . . . . . . . . . . 4.25”, 108mm . . . . . . . . . . . 3.0 – 12.0 ml/min

3

/32”, 2.4mm . . . . . . . . . . . 4.5”, 114mm . . . . . . . . . . . . 5.0 – 20.0 ml/min

3

/16”, 4.8mm . . . . . . . . . . . 5.0”, 127mm . . . . . . . . . . . 17.0 – 60.0 ml/min

1

/4”, 6.4mm . . . . . . . . . . . 4.375”, 111mm . . . . . . . . . . 18.0 – 85.0 ml/min

*Not supplied with pump

Pump IV—Medium/High Flow

Tubing I.D. Approx. Tubing Length Approx. Flow Rate

1

/16”, 1.6mm . . . . . . . . . . . 4.75”, 121mm . . . . . . . . . . . . 4 – 34 ml/min

3

/32”, 2.4mm . . . . . . . . . . 5.375”, 137mm . . . . . . . . . . . 20 – 90 ml/min

3

/16”, 4.8mm . . . . . . . . . . . 5.5”, 140mm . . . . . . . . . . . . 40 – 280 ml/min

1

/4”, 6.4mm . . . . . . . . . . . 5.375”, 137mm . . . . . . . . . . . 80 – 600 ml/min

(Instructions continued on page 2)

Page 2

(Instructions continued from page 1)

Slightly shorter tubing reduces the diameter by stretching the tubing and reducing

the flow. The flow rate can be reduced slightly by cutting the tubing slightly shorter

than indicated by the chart.

NOTE: The lengths given are for silicone tubing only, other tubing may require

slightly shorter or longer lengths. The flow rates listed are for silicone tubing supplied

with Mini-Pump.

For best results—

• Select a tubing size with a mid-range for the expected flow rate.

• To extend tubing life, select a tubing size with the largest diameter possible for

the desired output and operate the pump at lower speeds (without stalling the

pump). If too large a diameter tubing is selected, and pump is set at too slow a

speed, the pump motor may stall or stop.

TUBING ASSEMBLY REMOVAL

1. Release the protective, transparent cover by depressing the tab on the plastic

retaining clip located at bottom of the cover. The hinged cover can then be raised

to gain access to pump head and tubing assembly.

2. The tubing assembly is held in place by a slotted tube-lock at each end which is

fastened securely by friction fit in a metal U-shaped retaining bracket.

3. Grasp the tube-lock (white round slotted part) on each side of the retaining

bracket, and remove it by lifting upward.

4. Remove the other tube-lock in the same manner.

PREPARATION FOR INSTALLATION (TUBING ONLY)

1. After removing the tubing assembly, slide the slotted tube-lock on each end away

from the barbed fittings. Remove the barbed fittings and tube-locks from the

tubing, discarding the tubing.

2. Prepare a new length of tubing for installation by sliding a tube-lock over the end

of the tubing. Insert a fitting on the end of the tubing. Make certain to slide the

tubing over the barbed portion of the fitting. Repeat this procedure for the other

end of the tubing. The tubing assembly is now ready for installation.

TUBING ASSEMBLY INSTALLATION

The 1/4-inch (6.4mm) tubing assemblies have tube-locks that consist of nylon

washers—they are not slotted. All other tubing assemblies have tube-locks that are

slotted.

REPLACEMENT TUBING ONLY

Cat. No. Description

3360 . . . 1/50-inch I.D. Silicone tubing, 25 ft. (all pumps)

3361 . . . 1/32-inch I.D. Silicone tubing, 25 ft. (all pumps)

Uses the identical fittings/nipples as the 1/50" tubing

3362 . . . 1/16-inch I.D. Silicone tubing, 25 ft. (all pumps)

3363 . . . 3/32-inch I.D. Silicone tubing, 25 ft. (all pumps)

3364 . . . 3/16-inch I.D. Silicone tubing, 25 ft. (all pumps)

3365 . . . 1/4-inch I.D. Silicone tubing, 25 ft. (Cat. #3384 and #3385)

3366 . . . 1/4-inch I.D. Silicone tubing, 25 ft. (Cat. #3386 and #3389)

REPLACEMENT TUBING ASSEMBLIES

Cat. No. Description

3371 . . . 1/50-inch I.D. Silicone tubing and fittings/nipples for Cat. #3384, #3385

and #3386

3372 . . . 1/16-inch I.D. Silicone tubing and fittings/nipples for Cat. 3384, #3385

and #3386

3373 . . . 3/32-inch I.D. Silicone tubing and fittings/nipples (fitting color coded red

inside )for Cat. #3384, #3385 and #3386

3374 . . . 3/16-inch I.D. Silicone tubing and fittings/nipples (fitting color coded blue

inside) for Cat. #3384, #3385 and #3386

3375 . . . 1/4-inch I.D. Silicone tubing and fittings/nipples for Cat. #3384 and

#3385

3376 . . . 1/4-inch I.D. Silicone tubing and fitting/nipples for Cat. #3386

3390 . . . 1/50-inch I.D. Silicone tubing and fittings/nipples for Cat. #3389

3391 . . . 1/16-inch I.D. Silicone tubing and fittings/nipples for Cat. #3389

3392 . . . 3/32-inch I.D. Silicone tubing and fittings/nipples for Cat. #3389

3393 . . . 3/16-inch I.D. Silicone tubing and fittings/nipples for Cat. #3389

3394 . . . 1/4-inch I.D. Silicone tubing and fittings/nipples for Cat. #3389

ACCESSORIES

Control Cat. No. 3280 Tight-Seal™ Hose/Tubing Clamp Assortment

includes 5 each of 13 different sizes. Clamps have an inside diameter of 0.246 to

1.610 inches. Clamps securely fasten tubing on connectors, pumps, glassware, and

filtration units. Chemical-corrosion-resistant, rustproof, and nonconducting nylon is

ideal for use in wide-temperature range of 32 to 194°F.

Slotted Tube-Lock Fittings

1. Press one slotted tube-lock into the metal U-bracket.

2. Feed the tubing around the pump head (stretching the tubing slightly to ensure a

good wraparound fit).

3. Press the second tube-lock into the other metal U-bracket.

Washer Tube-Lock Fittings

1. Slip one end of the tubing assembly into the U-bracket with the washer to the

right of the bracket.

2. Feed the tubing around the pump head (stretching the tubing slightly to ensure a

good wraparound fit).

3. Slip the second end of the tubing assembly into the other U-bracket with the

washer to the right of the bracket.

TUBING

This specially formulated pump tubing is made from FDA-approved ingredients. The

unique manufacturing process achieves a tubing flexibility greater than other tubing.

It is ultratranslucent so that the flow of the liquid can be observed. It is nontoxic,

odorless, and tasteless. It may be used to transfer ultrapure deionized/distilled water

with zero contamination. It is biocompatible, resilient, stretchable, and resistant to

compression set. Its high “weatherability” properties resist ultraviolet light, ozone,

and gases. May be used in the lab and outdoors. It may be autoclaved. Designed for

pumping very hot and very cold liquids, -80 to 500°F (-62 to 260°C).

REPLACEMENT SETS OF TUBING

Cat. No. Description

3370 .... Replacement set of tubing and fittings/nipples for pump

Cat. #3384 and #3385. Identical to the set supplied with the pump.

Supplied with 1/50, 1/16, 3/32, 3/16, and 1/4-inch I.D. tubing and

corresponding fittings/nipples.

3377 .... Replacement set of tubing and fittings/nipples for pump

Cat. #3386. Identical to the set supplied with the pump. Supplied with

1/50, 1/16, 3/32, 3/16, and 1/4-inch I.D. tubing and corresponding fittings/

nipples.

3378 .... Replacement set of tubing and fittings/nipples for pump

Cat. #3389. Identical to the set supplied with the pump. Supplied with

1/16, 3/32, 3/16, and 1/4-inch I.D. tubing and corresponding fittings/nipples.

Control Cat. No. 3285 Tight-Ties™, Cable Ties Assortment includes

400 ties with lengths from 4 to 14 inches. One-piece, self-locking ties are made of

chemical-corrosion-resistant, rustproof, and nonconducting nylon, ideal for use in

wide-temperature range of -40 to 185°F.

Control Cat. No. 3367 European Power Supply 220 volts, 50 hertz

(Powers Pumps I, II, or III).

WARRANTY, SERVICE OF RECALIBRATION

For warranty, service, or recalibration contact:

CONTROL COMPANY

4455 Rex Road

Friendswood, Texas 77546 USA

Ph. 281-482-1714 Fax 281-482-9448

E-mail sales@control3.com

www.control3.com

Control Company is ISO 9001 Quality-Certified

by DNV and ISO 17025 accredited as a

Calibration Laboratory by A2LA.

Cat. No. 3384/3385/3386/3389

Variable Flow Mini-Pump Instructions

92-3385-00

Rev.3 091307

Traceable® is a registered trademark of Control Company

© 2007 Control Company

Loading...

Loading...