Page 1

Dew Point Analyser

Model 1638

August 2009

Page 2

Page 3

CONTENTS

SPECIFICATIONS .......................................................................................................................... 3

1

2 DESCRIPTION .............................................................................................................................. 13

3 INSTALLING & COMMISSIONING .......................................................................................... 19

4 OPERATOR FUNCTIONS ........................................................................................................... 33

5 SETTING UP THE TRANSMITTER ........................................................................................... 39

6 MAINTENANCE ........................................................................................................................... 57

APPENDICES

APPENDIX 1 PROBE OR SENSOR EMF TABLES ............................................................................. 62

APPENDIX 2 % OXYGEN SCALE TO LOGARITHMIC .................................................................... 65

APPENDIX 3 SAMPLE LOG PRINT OUT ........................................................................................... 66

APPENDIX 4 CIRCUIT SCHEMATICS ................................................................................................ 67

APPENDIX 5 MODBUS™ REGISTER MAP AND APPLICATION NOTES ..................................... 76

Note: This manual includes software modifications up to Version 8.11, May, 2006

© Copyright NOVATECH CONTROLS PTY. LTD. - 1996 - 2008

This manual is part of the product sold by Novatech Controls Pty. Ltd. ("Novatech Controls") and is provided to the

customer subject to Novatech Controls' conditions of sale, a copy of which is set out herein. Novatech Controls'

liability for the product including the contents of this manual is as set out in the conditions of sale.

All maintenance and service of the product should be carried out by Novatech Controls' authorised dealers.

This manual is intended only to assist the reader in the use of the products. This manual is provided in good faith but

Novatech Controls does not warrant or represent that the contents of this manual are correct or accurate. It is the

responsibility of the owner of the product to ensure users take care in familiarising themselves in the use, operation and

performance of the product.

The product, including this manual and products for use with it, are subject to continuous developments and

improvement by Novatech Controls. All information of a technical nature and particulars of the product and its use

(including the information in this manual) may be changed by Novatech Controls at any time without notice and

without incurring any obligation. A list of details of any amendments or revisions to this manual can be obtained upon

request from Novatech Controls. Novatech Controls welcome comments and suggestions relating to the product

including this manual.

Neither the whole nor any part of the information contained in, or the product described in, this manual may be adapted

or reproduced in any material form except with the prior written approval of Novatech Co ntrols Pty. Ltd.

All correspondence should be addressed to:

Technical Enquires

Novatech Controls Pty Ltd

309 Reserve Road

Cheltenham Victoria 3192 Phone: Melbourne +61 3 9585 2833

Australia Fax: Melbourne +61 3 9585 2844

Website:

http://www.novatech.com.au/

August 2009

1638 Dew Point Analyser 1

Page 4

USING THIS MANUAL

The Novatech 1638 Oxygen Transmitter has a variety of user-selectable functions.

They are simple to use because each selection is menu driven. For options you are not sure about; read the manual on

that particular item.

Please read the safety information below and the ‘Installation’ section before connecting power to the analyser.

CAUTION 1

The probe or sensor heater is supplied with mains voltage. This supply has electrical shock danger to maintenance

personnel. Always isolate the analyser before working with the probe or sensor.

The EARTH wire (green) from a heated probe or sensor must ALWAYS be connected to earth.

CAUTION 2

Combustion or atmosphere control systems can be dangerous. Burners must be mechanically set up so that in the worst

case of equipment failure, the system cannot generate explosive atmospheres. This danger is normally avoided with

flue gas trim systems by adjustment so that in the case of failure the appliance will not generate CO in excess of 400

ppm in the flue. The CO level in the flue should be measured with a separate CO instrument, normally an infrared or

cell type.

CAUTION 3

The oxygen sensor which is heated to over 700°C (1300°F) and is a source of ignition. Since raw fuel leaks can occur

during burner shutdown, the analyser has an interlocking relay that removes power from the probe or sensor heater

when the main fuel shut-off valve power is off. If this configuration does not suit or if it is possible for raw fuel to

come into contact with a hot oxygen probe or sensor then the Model 1638 analyser with a heated probe or sensor will

not be safe in your application.

An unheated probe can be utilised in such applications, however the oxygen readings are valid only above 650°C

(1200°F).

August 2009

2 1638 Dew Point Analyser

Page 5

1

SPECIFICATIONS

Section

Number

MODEL 1638 OXYGEN & DEW POINT ANALYSER ................................................................. 4

1.1

1.2 SERIES 1230 OXYGEN PROBES & SENSORS ............................................................................ 7

1.3 PURGE & CALIBRATION CHECK ACCESSORIES .................................................................. 11

1.4 FILTER PURGE PRESSURE SWITCH ........................................................................................ 11

August 2009

1638 Dew Point Analyser 3

Page 6

1.1 MODEL 1638 OXYGEN & DEW POINT ANALYSER

A

p

r

A

DESCRIPTION

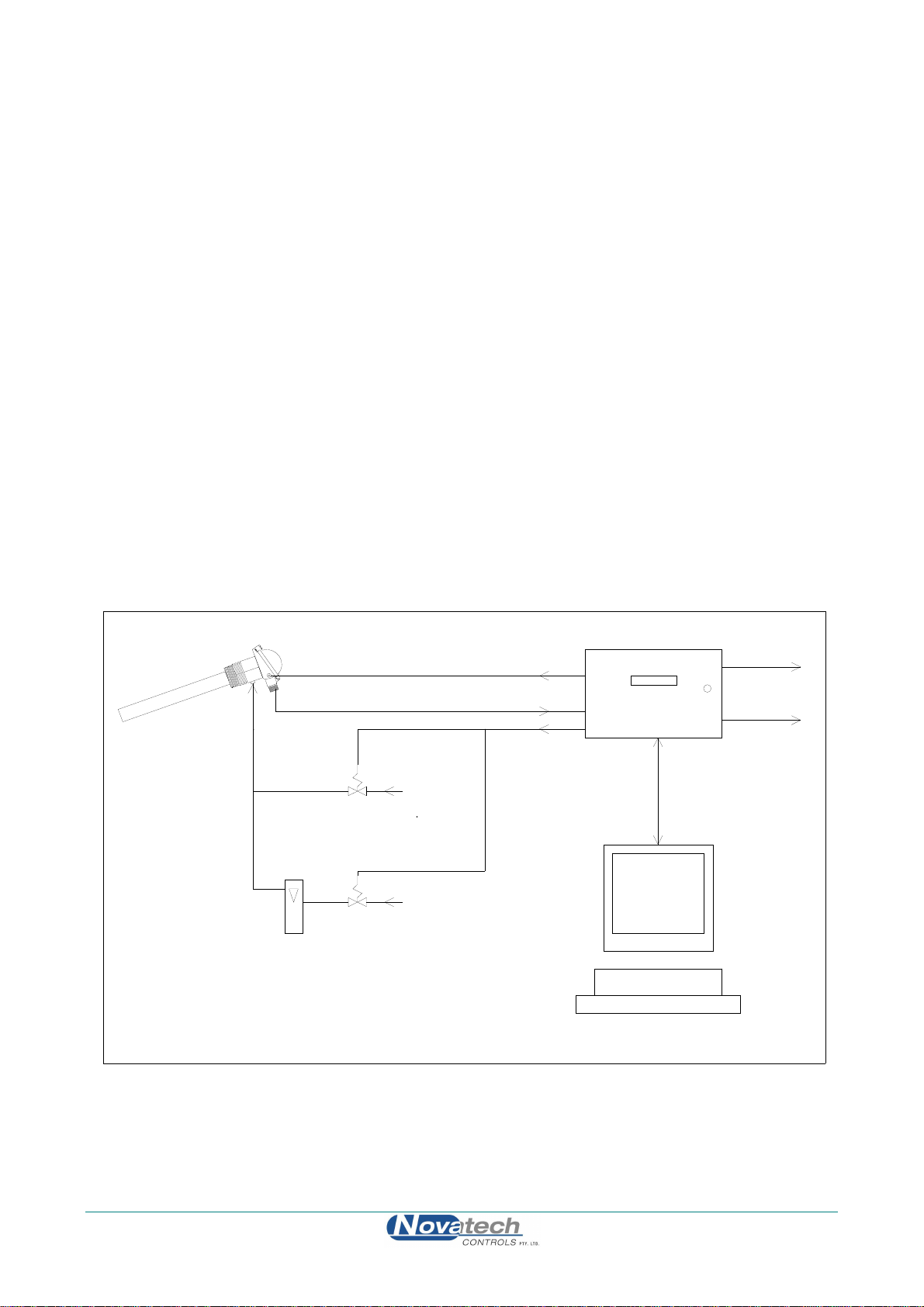

The Novatech model 1638 oxygen analyser / transmitter provides in-situ measurement for one or two oxygen probes in

annealing and other furnaces with protective atmospheres of hydrogen / nitrogen. The analyser provides local

indication of oxygen and dew point plus sixteen other selectable variables.

One or two oxygen sensing probes in one process can be controlled from one analyser to providing an average and/or

individual probe signals. Two linearised and isolated 4 to 20 mA output signals are provided for oxygen and for dew

point. Alarms are displayed at the analyser and relay contacts activate remote alarm devices. The analyser, which is

available for heated or unheated zirconia oxygen probes, provides automatic on-line gas calibration check of the probe

and filter purging. The electronics self-calibrates all inputs every minute.

The 1638 has a keyboard for selecting the output range, thermocouple type, etc., as well as maintenance and

commissioning functions. The instrument is microprocessor based and all adjustments are made using the keyboard.

• Used for product quality control to avoid blueing or browning of steel products during the annealing process

• Used for monitoring hydrogen / nitrogen protective atmospheres in applications such as lead holding furnaces

• Automatic selection of second probe on probe failure

• Simple to install

• Linear output of % oxygen and dew point for recording or control

• Built in safety features

• 24 different alarm conditions that warn the operator of oxygen, dew point, probe or analyser problems

• Isolated RS 232-C printer/computer interface and an RS 485 MODBUS network interface

• Safety interlock relay for heated oxygen probes

Zirconia Oxygen Probe

Flowmeter

Reference Ai

Cable

Calibratio

Checking

1638

Oxygen

nalyser

Com

uter and/or Printer

(Optional)

Recorder/

controller

larms

Oxygen Probe and Analyser System

August 2009

4 1638 Dew Point Analyser

Page 7

SPECIFICATIONS

Inputs

• Zirconia oxygen probe, heated or unheated

• Furnace thermocouple, field selectable as type K or R

• Process purge complete / main flame established safety interlock (for heated probes)

• Purge pressure switch

• Remote alarm accept

Outputs

• Two linearised 4 to 20 mA DC outputs, max. load 1000Ω

• Common alarm relay

• Three other alarm relays with selectable functions

Computer

• RS 232-C or RS 485 for connection of a computer terminal or printer for diagnostics of the analyser, sensing

probe, or process. This connection is suitable for network connection to computers, DCSs or PLCs using

MODBUS protocol.

Range of Output 1

Field selectable from the following:

Output Zero Range Span Range

Dew point -60°C to +20°C -40°C to +40°C

-76°F to +84°F -56°F to +104°F

Linear oxygen 0 to 99 % 1 to 100 %

Oxygen, reducing range 1.0

If 2 probes are used -

Linear oxygen, probe 1 0 to 99 % 1 to 100 %

Reducing oxygen output probe 1 1.0

Dew point, probe 1 -60°C to +20°C -40°C to +40°C

-76°F to +84°F -56°F to +104°F

Linear O

Reducing O

, probe 1 & 2 averaged 0 to 99 % 1 to 100 %

2

, probe 1 & 2 averaged 1.0

2

Dew point, probe 1 & 2 averaged -60°C to +20°C -40°C to +40°C

-76°F to +84°F -56°F to +104°F

Note:

The average dew point, linear O

and Reducing O2 selections will automatically select to the operating probe if one

2

probe fails, or selects probe 1 if both probes fail.

Range of Output 2

Field selectable from the following:

Output Zero Range Span Range

Linear O

0 to 99 % 1 to 100 %

2

Oxygen, reducing range 1.0

Dew point -60°C to +20°C -40°C to +40°C

-76°F to +68°F -40°F to +104°F

Sensor EMF 0 to 1200 mV in 100 mV steps 100 to 1300 mV in 100 mV steps

Aux Temperature 0 to 1300°C in 100°C steps 100 to 1400°C in 100°C steps

If 2 probes are used -

Linear O

, probe 2 0 to 99 % 1 to 100 %

2

Oxygen, reducing range, probe 2 1.0

Dew point, probe 2 -60°C to +20°C -40°C to +40°C

-76°F to +68°F -40°F to +104°F

Probe EMF 1 0 to 1200 mV in 100 mV steps 100 to 1300 mV in 100 mV steps

Probe EMF 2 0 to 1200 mV in 100 mV steps 100 to 1300 mV in 100 mV steps

-16

% oxygen 1.0

-16

% oxygen 1.0

-16

% oxygen 1.0

-16

% oxygen 1.0

-16

% oxygen 1.0

-30

% oxygen

-30

% oxygen

-30

% oxygen

-30

% oxygen

-30

% oxygen

August 2009

1638 Dew Point Analyser 5

Page 8

Range of Indication, Upper Line

• Oxygen auto ranging from 10

-30

to 100 %

• Dew point -60 °C to +40 °C, -76 °F to +104 °F

Indication Choice, Lower Line

Any or all of the following can be selected for lower line display:

• Dew point probe 1

• Dew point probe 2 **

• Dew point probe 1 and 2 averaged **

• Date - time

• Run Hours since last service

• Date of last service

• Oxygen probe 2 **

• Oxygen probe 1 and 2 averaged **

• Probe EMF 1

• Probe EMF 2 **

• Temperature probe 1

• Auxiliary Temperature *

• Temperature probe 2 **

• Impedance probe 1

• Impedance probe 2 **

• Ambient Temperature

• Ambient Relative Humidity

* If the analyser is enabled for 1 probe

** If the analyser is enabled for 2 probes

Accuracy

• ±1% of actual measured oxygen value with a repeatability of ±0.5% of measured value.

Relay Contacts

• 0.5A 24 VAC, 1A 36 VDC

Environmental Rating

• Operating Temperature: -25 to 55°C

• Relative Humidity: 5 to 95% (non-condensing)

• Vibration: 10 to 150Hz (2g peak)

Power Requirements

• 240 or 110V, 50/60 Hz, 105 VA (heated probe)

• 240 or 110V, 50/60 Hz, 5 VA (unheated probe)

Weight

• Analyser, 3.75 kg

Degree of Protection

• IP65 without reference air pump

• IP54 with reference air pump

Mounting

• Suitable for wall or surface mounting.

August 2009

6 1638 Dew Point Analyser

Page 9

1.2 SERIES 1230 OXYGEN PROBES & SENSORS

DESCRIPTION

Novatech series 1230 oxygen probes and sensors employ state-of-the-art zirconia sensors and advanced materials,

which provide the following benefits:

• Improved control due to fast response time to typically less than four seconds

• Cost-efficient design provides improved reliability

• Longer-life probes with greater resistance to corrosion from sulphur and zinc contaminants in flue gas

• Low cost allows maintenance by replacement

• Reduced probe breakage due to greater resistance to thermal shock and mechanical damage during installation and

start-up

• Series 1230 probes are simple to install and maintain. All models provide direct measurement of oxygen level.

On-line automatic calibration check is available if required. Probes may be used with Novatech combustion

controllers and some analyser models from other manufacturers.

All Novatech oxygen probes are designed and manufactured to exacting standards of performance and reliability.

Series 1230 probes are the result of extensive research and development by Novatech, industry and government

agencies. Novatech Controls provides application and after sales support for oxygen probes, sensors and analysers,

worldwide.

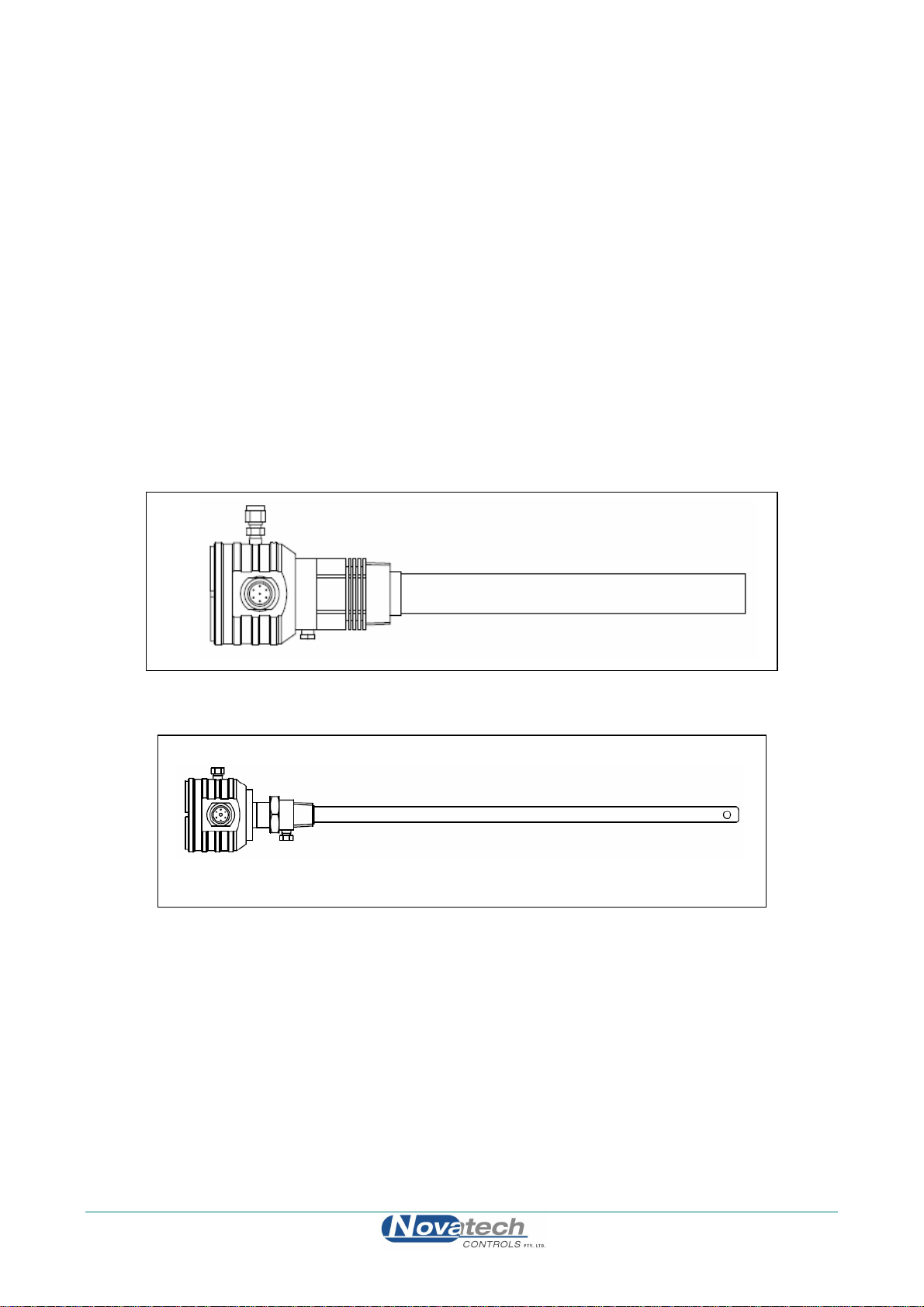

Model 1231 Heated Oxygen Probe

Model 1232 Unheated Oxygen Probe

August 2009

1638 Dew Point Analyser 7

Page 10

1234OXYGEN

SENSOR

GAS INLET 1/4" TUBE ELBOW

NOVATECH

CONTROLS

EXHAUST

ID LABEL

CABL E GLAND

EXHAUST 1/4" NPT FEM ALE

Model 1234 Oxygen Sensor

STANDARD PROBE ‘U’ LENGTHS

1231 1232

250 mm (10”) 500 mm (20”)

350 mm (14”) 750 mm (30”)

500 mm (20”) 1000 mm (40”)

750 mm (30”) 1500 mm (60”)

1000 mm (40”)

1500 mm (60”)

2000 mm (80”)

Ordering Information

1. Probe insertion length (from process end of mounting thread to probe sensing tip).

2. Mounting thread (process connection), BSP or NPT (for size of thread refer to specifications).

3. Lagging extension length, if required.

4. If model 1232 probe, state preferred thermocouple type (refer to specifications).

August 2009

8 1638 Dew Point Analyser

Page 11

OXYGEN PROBE SPECIFICATIONS

MODEL 1231 1232

Application Furnaces operating Furnaces operating

below 900°C above 700°C with

refer to note 1 no contaminants.

Temperature Range 0 to 900°C 700 to 1400°C

(0 to 500°C with filter fitted)

Length 250 to 2000 mm 500 to 1000 mm

Process 1 1/2" BSP 3/4" BSP

Connection or NPT or NT

Electrical Weather-proof plug-in connector or optional screw terminals. The plug connector is

Connection supplied with the cable. Ex(e) heads have screw terminals.

Cable Order a specific length with the analyser except for hazardous installations where the

cable is supplied by the customer.

Heater Yes No

Furnace Thermocouple Refer to note 3 R or S, integral

Response Time Typically < 4 secs. Typically < 1 sec

Head Temperature -25 to 100°C with weatherproof connector

-25 to 150°C with screw terminals

Reference Gas Ambient air 50 cc/min approx. Pump supplied with analyser

Ref Air Connection 1/4" Tube Integral air line in probe cable or external ¼” tube.

Optional Filter Sintered titanium alloy

particulate filter, replaceable,

30 or 15 micron.

Calibration Check Gas 1/8" NPT female 1/8" NPT female

Connection

Weight 2 kg plus 165 g / 100 mm 1 kg plus 100 g / 100 mm

Notes:

1. Care must be taken to avoid contact with explosive or inflammable gases with 1231 heated probes. Novatech

analysers have built in safety protection.

2. Please contact factory for corrosives other than sulphur or zinc. We can provide test materials to try in your

atmosphere.

August 2009

1638 Dew Point Analyser 9

Page 12

OXYGEN PROBE MODEL SELECTION GUIDE

Heated probes-temperature range 0-900°C.

1231 - U Length - Outer - Internal - Mounting

Sheath Thermocouple Thread

Basic model 2. 250mm 1.316 SS max 850°C 1. Type K max 900°C 1. BSP

3. 500mm 2. Inconel *(1) 2. NPT

4. 750mm

5. 1000mm

6. 1500mm

7. 2000mm

*Note:

1. The Inconel option has all inconel wetted parts except for the ceramic sensor and viton ‘O’ rings.

Unheated probes for clean gases-temperature range 700-1400°C.

1232 - U Length - Outer Sheath - Internal Thermocouple - Mounting Thread

Basic model 3. 500mm 1. 253 MA-max 1200°C 1. Nil *(2) 1. 3/4” BSP fixed

4. 750mm 4. Type R max 1400°C 2. 3/4” NPT fixed

5. 1000mm

6. 1500mm

3. High Purity Alumina

max 1300°C Horizontal

max 1400°C Vertical

4. 446 SS max 1000°C

*Note:

1. For applications up to 1200°C it may be more economical to use a separate type “K” or “N” thermocouple than the

internal “R” thermocouple. It is important that a separate thermocouple senses the same temperatures as the oxygen

probe tip.

August 2009

10 1638 Dew Point Analyser

Page 13

1.3 PURGE & CALIBRATION CHECK ACCESSORIES

Due to the absolute measurement characteristics of zirconia sensors and the self calibration features of Novatech

analysers, probe calibration checks with calibrated gas are not normally required. In some installations however

customers prefer the have a calibration check facility.

Novatech probes and analysers provide a ready method of connecting on-line calibration check gases. They provide

on-line automatic checking of probe and analyser calibration, as well as a probe purge facility.

The absolute characteristics of zirconia sensors require only one calibration check gas to properly check the probe’s

performance. Where required however, the dual gas calibration check facility can be utilised .

Dirty furnace applications often require the back purge facility to keep a probe filter free from blockage. (In these

applications, it is more reliable to install probes pointing vertically dow nwards with no filter). Purge and calibration

check solenoid valves can be operated manually or automatically from a 1638 analyser.

The external components required for automatic / manual gas calibration checking are:

• A calibration check gas flow meter/regulator

• A mains voltage (240 or 110 VAC) solenoid valve for each calibration check gas

The external components required for automatic / manual purging are:

• A mains voltage (240 or 110 VAC) purge solenoid valve

• A purge pressure switch, 0 to 35 kPa (0 to 5 psi), to test for filter blockage.

The user should supply:

• Span gas cylinder(s), typically 2 % oxygen in nitrogen or a similar percentage of 0

gas stream being measured, to ensure fast recovery.

• A 100 kPa (15 psi) clean and dry nitrogen supply when filter purging is required.

close to the normal level in the

2

1.4 FILTER PURGE PRESSURE SWITCH

To automatically sense a blocked probe filter, a pressure sensor should be connected to the ‘purge’ line to the probe

‘cal’ port. It should be adjusted so that it energises just above the purge pressure with a new or clean filter installed.

The switch contacts should be connected to terminals 12 & 13 (PURGE FL SWITCH). If the filter is still blocked or

partly blocked after an auto purge cycle, the pressure switch will energise and cause a ‘Probe Filter Block ed’ alarm.

The contacts must be normally closed.

The pressure switch should have an adjustable range of 0 to 35 kPa (0 to 5 psi).

August 2009

1638 Dew Point Analyser 11

Page 14

August 2009

12 1638 Dew Point Analyser

Page 15

2

DESCRIPTION

Section

Number

THE ANNEALING PROCESS (OR OTHER SIMILAR APPLICATIONS) ................................ 14

2.1

2.2 THE OBJECTIVE OF ATMOSPHERE MONITORING............................................................... 14

2.3 WHAT DO WE NEED TO MEASURE? ....................................................................................... 14

2.4 ZIRCONIA OXYGEN PROBE MEASUREMENT ....................................................................... 14

2.5 OTHER TYPES OF OXYGEN MEASUREMENT ....................................................................... 14

2.6 DEW POINT MEASUREMENT .................................................................................................... 14

2.7 IN-SITU OXYGEN PROBES ........................................................................................................ 14

2.8 THE ZIRCONIA SENSOR ............................................................................................................. 15

2.9 THE ANALYSER ........................................................................................................................... 16

2.10 ALARMS ........................................................................................................................................ 16

2.11 HEATER ......................................................................................................................................... 16

2.12 APPLICATIONS WHERE SENSING POINT IS NOT AT ATMOSPHERIC PRESSURE ......... 16

2.13 PROBE IMPEDANCE .................................................................................................................... 16

2.14 AUTO CALIBRATION – ELECTRONICS ................................................................................... 16

2.15 AUTO CALIBRATION CHECKING – PROBES ......................................................................... 17

2.16 AUTO PURGE ................................................................................................................................ 17

2.17 RS 485 AND RS 232C PORT ......................................................................................................... 17

2.18 AUXILIARY TEMPERATURE THERMOCOUPLE ................................................................... 17

2.19 WATCHDOG TIMER .................................................................................................................... 17

2.20 BACK-UP BATTERY .................................................................................................................... 17

August 2009

1638 Dew Point Analyser 13

Page 16

DESCRIPTION

2.1 THE ANNEALING PROCESS (OR OTHER SIMILAR APPLICATIONS)

The annealing process is carried out in an atmosphere of hydrogen and nitrogen to protect the surface of the steel from

oxidising and discolouring during the annealing process. There is usually some air leakage in a furnace and the

hydrogen serves to “mop up” the oxygen by combining with it to form water vapour.

2.2 THE OBJECTIVE OF ATMOSPHERE MONITORING

The primary objective of monitoring the furnace atmosphere is to be able to measure whether the steel product in the

furnace will become oxidised during the process and to raise an alarm to warn the operator that there is a problem.

2.3 WHAT DO WE NEED TO MEASURE?

The variable that we need to measure to monitor the atmosphere to prevent oxidation of the product is the oxygen

partial pressure at the surface of the steel. At any particular furnace temperature, there is a unique oxygen partial

pressure, above which the steel will tend to oxidise and below which no oxidation will occur. The steel acts as a

catalyst in the hydrogen / nitrogen bringing the gas at the surface close to chemical equilibrium. The composition of

the gas at the surface is normally different from that of the gas nearby. For example, trace oxygen is quickly converted

to water vapour.

In the gas, a reaction to form water vapour requires collisions involving two hydrogen molecules and one oxygen

molecule, the probability of which is low. On the surface of the steel, one or the other of the molecules becomes partly

immobilised. This increases the probability of successful collisions to form water vapour. Essentially, gas molecules

are held on the steel surface, waiting for the complementary molecule(s) to arrive.

2.4 ZIRCONIA OXYGEN PROBE MEASUREMENT

The catalytic process which occurs on the surface of the steel also occurs on a zirconia oxygen sensor. This means that

the measurement of the oxygen level with a zirconia oxygen sensor exactly duplicates the equilibrium conditions of the

gas at the surface of the steel. It measures the oxidation potential of the gas or its potential to damage or discolour the

steel.

2.5 OTHER TYPES OF OXYGEN MEASUREMENT

Other types of oxygen analysers such as a paramagnetic analyser measure the unreacted molecular level of oxygen in

the furnace atmosphere, which has no direct thermodynamic relationship with the effect of the gas on the steel. These

analysers are not useful for measuring the oxidation potential in annealing furnace atmospheres.

2.6 DEW POINT MEASUREMENT

Dew point measurement was commonly used in the past because dew point analysers were the only technology

available at the time. Dew point can be related to the oxidation potential of the furnace atmosphere but the relationship

depends on how much hydrogen is available at the surface of the steel. With dew point held constant, if the hydrogen

level varies, so will the oxidation potential of the atmosphere. Dew point measurement is not the best method of

measurement because of this. Also dew point instruments normally have limited reliability in on-line applications on

annealing furnaces.

With a known hydrogen level, the dew point in the furnace can be calculated. This is provided as an output on a

standard Novatech 1638 analyser but we recommend the use of the oxygen output from the same analyser. Both

outputs are available simultaneously for operators who are more used to furnace dew point levels. The dew point

output however is only an approximate guide if the hydrogen level in the furnace varies.

2.7 IN-SITU OXYGEN PROBES

There are very few oxygen probes on the market, which can operate reliably in an annealing furnace atmosphere at

furnace temperatures. Novatech probes have been developed in co-operation with BHP steel for annealing furnace

applications to provide a reliable measurement for monitoring both continuous and batch furnaces. BHP now have 60

Novatech probes and analysers installed to protect their products during the annealing process. These sensing probes

give long life with no need for calibration. The most important feature however is that Novatech oxygen probes

measure the oxygen partial pressure just as it occurs at the surface of the steel.

August 2009

14 1638 Dew Point Analyser

Page 17

2.8 THE ZIRCONIA SENSOR

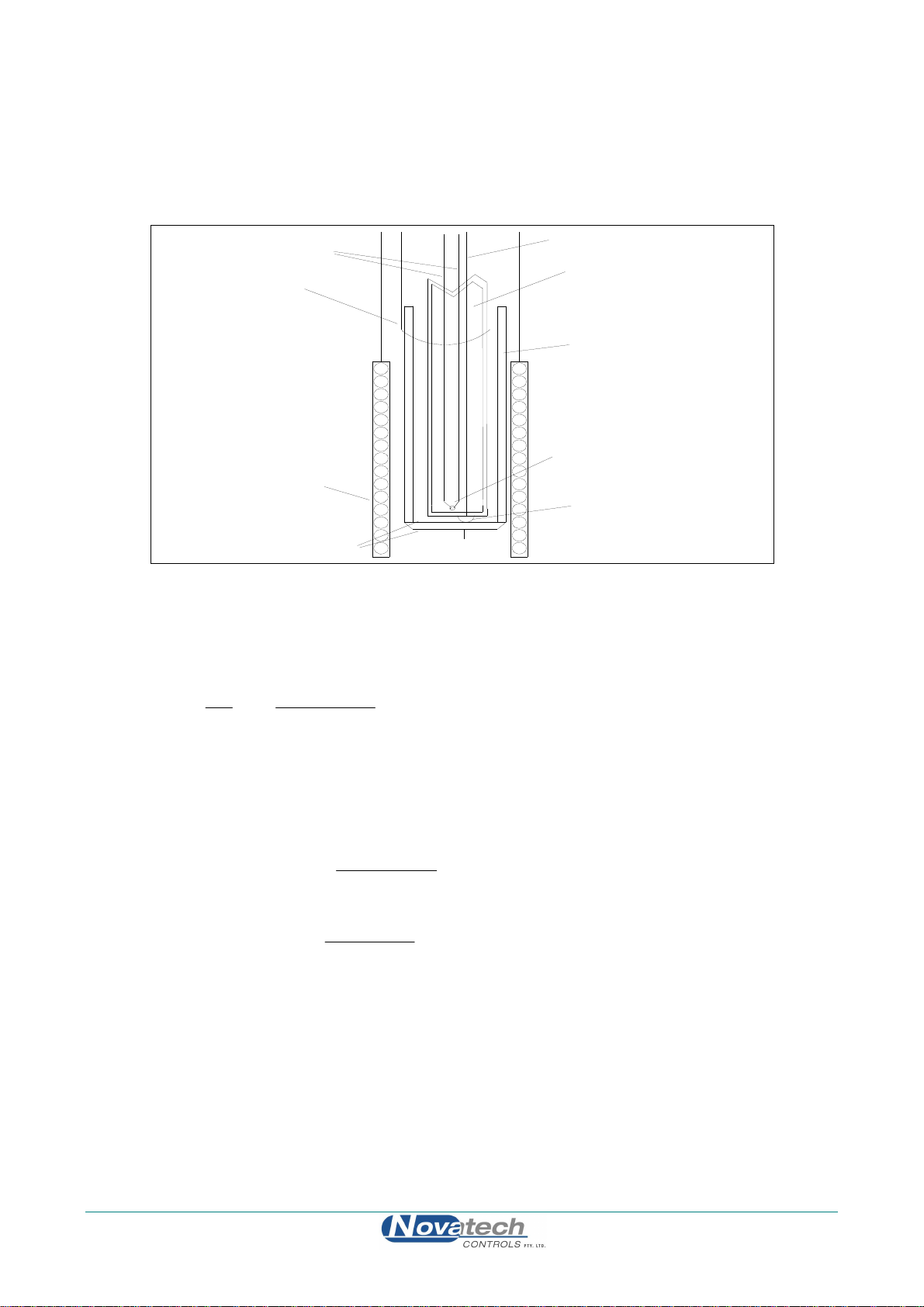

(

The analyser input is provided from a solid electrolyte oxygen probe, which contains a zirconia element and

thermocouple. The probe is designed to be inserted into a furnace. Sampling lines and filters are not required for insitu probes. When a sampling line is required, the sample flows to the sensor under process pressure in most

applications. In applications where the process pressure is negative or neutral, a su ction pump will be required. A

reference air pump is provided in the 1638 oxygen analyser. The internal construction of a probe is shown as follows.

Thermocouple

Wires

External Wire

Contact

Internal electrode wire

Four-Bore Thermocouple

Insulating Tubing

Alumina Tube

Heater

(required only

with heated

probes)

Electrode Material

Ziconia Disc

Thermocouple

Junction

Internal Electrode

Schematic View of a Sensor Assembly

The heater control in the 1638 analysers consists of a time proportioning temperature controller and solid state relay so

that the thermocouple junction is controlled to 720°C. Probes operating in a combustion environment above 650°C do

not require a heater. When exposed to different oxygen partial pressures at the outside and inside of the sensor, an

EMF (E) is developed which obeys the Nernst equation:

log

⎛

⎜

e

⎜

⎝

RT

millivoltsE

)(

=

4

F

)

insidePO

2

()

outsidePO

2

Where T is the temperature (K) at the disc (>650°C), R is the gas constant, F is the Faraday constant and (PO

and (PO

) OUTSIDE are the oxygen partial pressures at the inner and outer electrodes, respectively, with the higher

2

⎞

⎟

⎟

⎠

) INSIDE

2

oxygen partial pressure electrode being positive.

If dry air at atmospheric pressure, (21 % oxygen) is used as a reference gas at the inner electrode, the following

equations are obtained:

2

−

×=

log10154.2)(

TmillivotsE

e

()

21.0

outsidePO

2

Transposing this equation

() ( )

2

ATMoutsideO

=

−

exp21.0%

ER

421.46

T

The 1638 transmitter solves this equation which is valid above 650°C. The probe heater, or the process maintains the

sensor temperature at this level.

August 2009

1638 Dew Point Analyser 15

Page 18

2.9 THE ANALYSER

The 1638 analyser is a transmitter with two 4 to 20 mA outputs. One output is % oxygen or dew point with selectable

zero and span. The second output can be selected as dew point, oxygen, auxiliary temperature or sensor EMF. Four

alarm relays are provided. Refer to the sections 4.2 and 4.3 for more details.

The 1638 analyser is designed to operate with either one or two heated or unheated, zirconia probes in one process. If

two probes are being used, the analyser can average the two oxygen and dew point signals, alarm when there is a high

difference, transmit and display the average and/or individual oxygen signals.

If heated probes are being used, the analyser will maintain the temperature of the sensor(s) at 720°C. The analyser

solves the Nernst equation and will provide accurate oxygen measurements up to 1500°C (2730°F), although most

probes are suitable only to 1400°C (2250°F). 1231 heated probes are limited to 900°C (1650°F).

2.10 ALARMS

Refer to OPERATOR FUNCTIONS Section 4 for details on alarm functions.

2.11 HEATER

CAUTION

The probe heater is supplied with mains voltage. This supply has electrical shock danger to maintenance personnel.

Always isolate the analyser before working with the probe.

The EARTH wire (green) from the probe / sensor must always be connected to earth.

The heater is supplied from the mains power directly, and the temperature is controlled initially at over 700°C (1300°F)

after turn on.

2.12 APPLICATIONS WHERE SENSING POINT IS NOT AT ATMOSPHERIC

PRESSURE

To apply the 1638 analyser to processes, when the pressure at the point of measurement is significantly above or below

atmospheric pressure, then compensation must be applied. (Refer to Set-up Steps 34 and 35 in Section 5.5). If two

sensors are being used, they must be close to the same pressure.

2.13 PROBE IMPEDANCE

The probe impedance is a basic measurement of the reliability of the oxygen reading. A probe with a high impedance

reading will eventually produce erroneous signals. The analyser regularly checks the probe impedance and if the

impedance is above the maximum level for a specific temperature then the impedance alarm will be activated. Typical

probe impedance is 1 KΩ to 8 KΩ at 720° C.

2.14 AUTO CALIBRATION – ELECTRONICS

The analyser input section is self calibrating. There are no adjustments. The analog to digital converter input stages are

checked against a precision reference source and calibrated once every minute. Should the input electronics drift

slightly then the drift will be automatically compensated for within the microprocessor. If a large error occurs due to an

electronic fault then an ‘ADC CAL FAIL’ alarm will occur.

A one-off calibration procedure of the precision reference sources should never need to be repeated for the instrument

life unless the instrument has been repaired. For a description of the calibration procedure, refer to ‘Setting Up The

Analyser’ Section 5.5, items 7, 8 9 and 10.

The digital to analog converters or output section of the analyser are tested for accuracy every minute and if they are

found to have an error then a ‘ADC CAL FAIL’ alarm will occur. The D/A sections are re-calibrated by pressing the

‘AUTO CAL’ button on the keyboard while in 'SET-UP' mode.

All output signals will drop to 0 mA for a one second period. It is suggested that a D/A re-calibration be performed

after the instrument has stabilised, approximately 30 minutes after first switching on and after Setting Up The Analyser

Section 5.5, items 6, 7, 8 and 9 have been completed, and then annually.

August 2009

16 1638 Dew Point Analyser

Page 19

2.15 AUTO CALIBRATION CHECKING – PROBES

On-line automatic gas calibration check is not normally required. Where it is required however, the probe can be

checked for accuracy in-situ and on-line. Solenoid valves can admit up to two calibrated gas mixtures into the probe

via solenoid valves under microprocessor control on a timed basis. For details on installation refer Section 3.11. For

details on setting up this facility refer to Set-up steps 41 to 53 in Section 5.5.

During probe auto calibration checking, the analyser output will freeze and remain frozen for a further adjustable

period, allowing the probe time to recover and continue reading the furnace oxygen level.

Calibration check gases may be manually admitted by pressing the ‘CAL’ buttons on the keyboard while in ‘RUN’

mode. The analyser output is frozen during the pressing of these buttons and immediately becomes active when the

button is released. If calibration gas checking is enabled in the Set-up menu for either gas, an automatic gas cycle can

be started by pressing the ‘CAL’ buttons in RUN mode. The cycle can be terminated by pressing any other button.

2.16 AUTO PURGE

In steel annealing applications it is expected that the furnace will be gas fired. However, in oil and coal fired plant, it is

possible for the probe sensing filter to become blocked. An automatic purge cycle can be set up so that a blast of air or

nitrogen, maximum 100 kPa., will automatically back-flush the probe filter on a timed basis. Refer to Set-up steps 36

to 40 in Section 5.5. A purge pressure switch will sense if there is insufficien t flow to clear the filter during the purge

cycle. In this case a ‘PROBE FILTER’ alarm will occur. The probe can be manually purged from the keyboard while

in ‘RUN’ mode. The analyser output is not frozen during or after the pressing of this button.

Automatic or manual purge is not available if two probes are being used. However, one of the gas check output could

be used to purge the filter.

2.17 RS 485 AND RS 232C PORT

The serial port is for connecting a printer, a data logger, or any computer with an RS485 MODBUS or 232-C port. It

can be used to monitor the transmitter and process by logging the values of functions selected in step 70 of the Set-up

menu in Section 5.5. The log period may be selected in step 71, and the baud rate may be set in set-up step 72.

Alarms, including the time they occurred, will be transmitted to the printer and computer whenever they are first

initiated, accepted and cleared. The protocol for the serial port is eight data bits, one stop bit, no parity. Please contact

the factory for further details on serial communications with external systems such as computers, DCS’s or PLC’s.

The MODBUS address is set in step 81 of the set-up menu.

2.18 AUXILIARY TEMPERATURE THERMOCOUPLE

A furnace thermocouple should also be connected when an additional temperature display or transmitted signal is

required. This input is not available if two probes are being used.

2.19 WATCHDOG TIMER

The watchdog timer is started if the microprocessor fails to pulse it within any one second period, (ie. fails to run its

normal program). The microprocessor will then be reset up to three times until normal operation is resumed. Reset

cycles are displayed by the POWER light on the keyboard. A steady ‘ON’ light indicates normal operation. If the

program has not resumed normal operation after three attempts to reset, the common alarm relay will be activated. The

reset function will continue repeatedly after the alarm. If a successful reset is achieved, the alarm will be cancelled and

the analyser will continue to run normally.

2.20 BACK-UP BATTERY

The transmitter’s RAM and real-time clock are backed up by a lithium battery in the event of power failure. All set-up

variables are saved and the clock is kept running for approximately ten years with the power off. The battery module

should be replaced every 8 years. (It is the battery shaped device clipped in a socket labelled M1 on the 1630-1 PCB)

August 2009

1638 Dew Point Analyser 17

Page 20

August 2009

18 1638 Dew Point Analyser

Page 21

3

INSTALLING & COMMISSIONING

Section

Number

MOUNTING THE ANALYSER .................................................................................................... 20

3.1

3.2 INSTALLING A 1231 OXYGEN PROBE ..................................................................................... 20

3.3 INSTALLING THE AUXILIARY THERMOCOUPLE ................................................................ 21

3.4 SHIELD CONNECTIONS ............................................................................................................. 21

3.5 ELECTRICAL CONNECTIONS ................................................................................................... 22

3.6 HEATER INTERLOCK RELAYS ................................................................................................. 24

3.7 CONNECTING AN OXYGEN PROBE CABLE .......................................................................... 24

3.8 CONNECTING THE AUXILIARY THERMOCOUPLE (OPTIONAL) ...................................... 26

3.9 CONNECTING THE OUTPUT CHANNELS ............................................................................... 26

3.10 CONNECTING THE ALARMS ..................................................................................................... 26

3.11 CONNECTING THE AUTOMATIC PURGE AND CALIBRATION CHECK SYSTEM .......... 27

3.12 CONNECTING REFERENCE AIR ............................................................................................... 27

3.13 CONNECTING THE DUAL FUEL INPUT .................................................................................. 28

3.14 CONNECTING THE PRINTER ..................................................................................................... 28

3.15 CONNECTING THE ANALYSER TO A MODBUS™ NETWORK ........................................... 29

CONNECTING POWER ................................................................................................................ 30

3.16

3.17 COMMISSIONING – SET-UP MODE .......................................................................................... 30

3.18 COMMISSIONING – RUN MODE ............................................................................................... 30

3.19 BURNER BYPASS SWITCH ........................................................................................................ 30

3.20 CHECKING THE ALARMS .......................................................................................................... 30

3.21 PROBE CALIBRATION ................................................................................................................ 30

3.22 FILTER PURGING ......................................................................................................................... 31

3.23 CALIBRATION GAS CHECK ...................................................................................................... 31

3.24 DUST IN THE FURNACE ............................................................................................................. 31

INSTALLATION

COMMISSIONING

August 2009

1638 Dew Point Analyser 19

Page 22

INSTALLATION

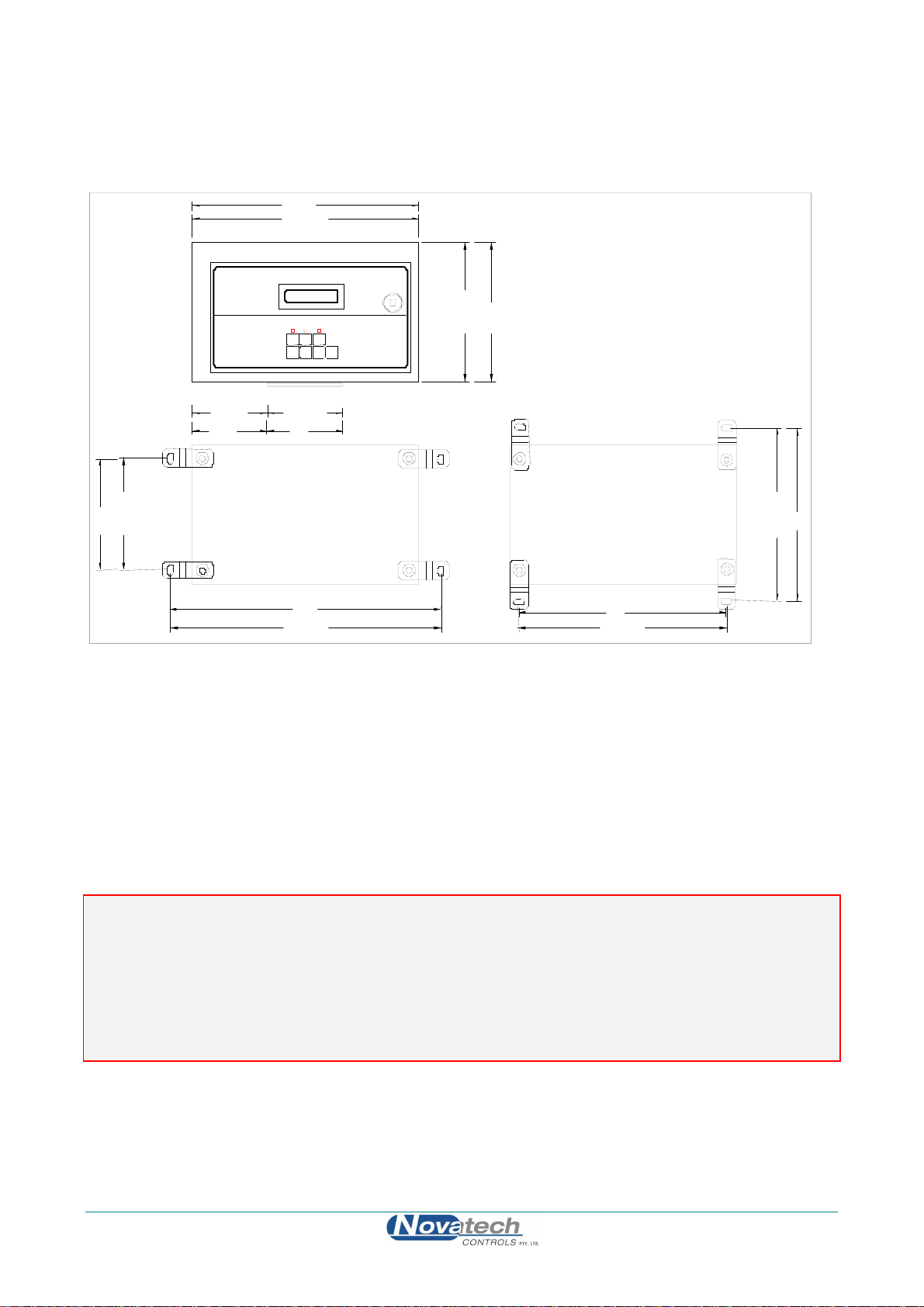

3.1 MOUNTING THE ANALYSER

Surface mount the transmitter case on to a flat surface or bracket, using the four mounting brackets provided.

40mm

1.6"

11"

280mm

Gland Plate

200mm

8"

180mm

7"

REAR VI EW

6"

150mm

Horizontal Mounting Brackets

12.8"

REAR VIEW

Vertical Mounting Brackets

9.8"

250mm325mm

9"

225mm

Case Mounting Dimensions

3.2 INSTALLING A 1231 OXYGEN PROBE

Weld a BSP or NPT socket to the furnace in a suitable position for sensing the furnace atmosphere. For the correct size

of socket refer to probe data in Section 1. The oxygen probe is normally installed pointing vertially upwards in

removable cover, coil annealing furnace. Probes can be mounted at any angle. If there are any particulates in the

furnace, the filter can be omitted by pointing the probe vertically downwards. Otherwise the filters may have to be

replaced periodically.

If installing a probe into a hot environment, slide the pro be in slowly to avoid thermal shock to the internal ceramic

parts. If the furnace is 1000°C, it should take approximately ten minutes to install a 500 mm. probe, moving it in about

20 mm steps.

CAUTION

The oxygen probe should protrude into the furnace at least 25 mm. If the furnace has high velocity fan circulation a

filter should be used on 1231 oxygen probes or, in extreme cases, a flow diverting vane. Without a filter or vane the

fan velocity can cool the 1231 heater.

Although it is rare, occasionally a probe may sense oxygen vastly differently from the average reading in the furnace.

If it occurs, then the probe should be moved, or a longer probe installed. This phenomena is normally caused by

stratification of the furnace atmosphere.

August 2009

20 1638 Dew Point Analyser

Page 23

3.3 INSTALLING THE AUXILIARY THERMOCOUPLE

Weld a 1/2 inch BSP mounting socket to the furnace within about 300 mm, and upstream of the oxygen probe. The

thermocouple should be of similar length to the oxygen probe to prevent furnace temperature distribution errors.

3.4 SHIELD CONNECTIONS

All external wiring to the 1638 analyser should be shielded. Do not connect shields at the field end. Simply clip off

and insulate. An extra terminal strip may be required to connect all shields together. This should be supplied by the

installer.

August 2009

1638 Dew Point Analyser 21

Page 24

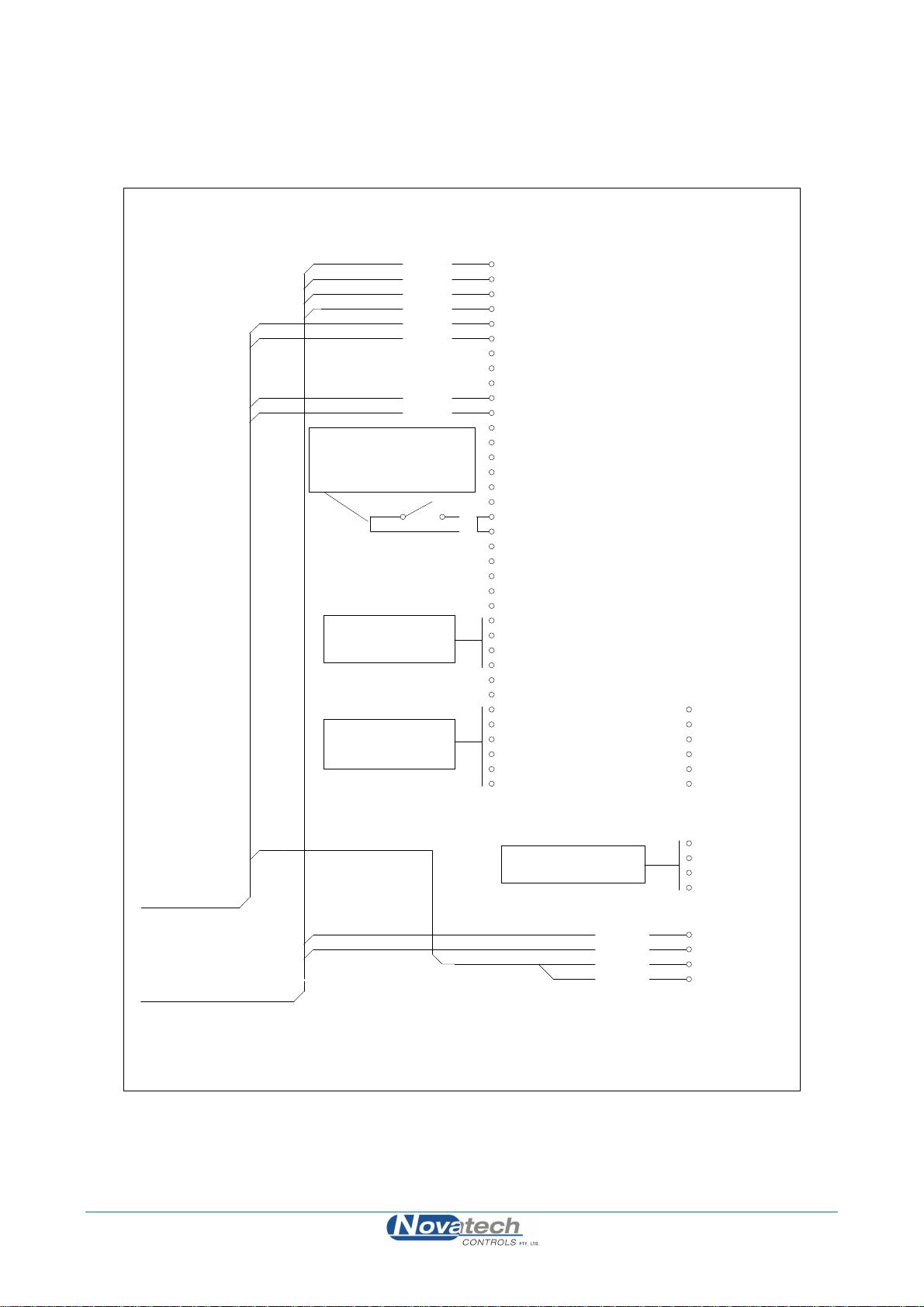

3.5 ELECTRICAL CONNECTIONS

All wiring should comply with local electrical codes. The printed circuit boards are fully floating above earth. All

earth and shield connections should be connected to the earth stud on the LHS inside the case. Before connection of

mains power check that the 115 / 230 volt power selector switch is set to the correct voltage.

Burner safety

or if safety

not required

terminals 18 &

4- 20mA Out put s

Selectable

ran g e s

Op t i o na l Alarm

Re l a y Co nt a c t s

Normally Closed

Ora nge

Brown

Black

Blue

Black

Blue

Ora nge

Brown

1

Probe +

2

Probe -

3

Probe TC+

4

Probe TC-

5

Probe TC2 / Aux+

6

Probe TC2 / Aux-

7

+12V

8

RGCI/ P+

RGCI/ P-

9

Sen s # 2 +

10

Sen s # 2 -

11

Purge Flow

12

Purge Flow

13

Fuel 1 / 2

14

Fuel 1 / 2

15

Re mot e Ala rm

16

Re mot e Ala rm

17

18

Bur n e r On I n pu t

19

Bur n e r On I n pu t

20

RS- 2 3 2 Rx

21 RS- 232 Tx

22 Network -

Net wor k +

23

Ser i a l Common

24

Ou t p u t 1 +

25

26 Output 127 Output 2+

28 Output 229 Common Alarm

30 Common Alarm

31 Alarm 2

32 Alarm 2

33 Alarm 3

34 Alarm 3

35 Alarm 4

36 Alarm 4

41

Pur ge Sol

42

Pur ge Sol

43 Cal 1 Sol

44 Cal 1 Sol

45 Cal 2 Sol

46 Cal 2 Sol

Ma i n s Po we r

240/ 115VAC

SENSOR # 2

White

White

White

White

SENSOR # 1

47 Mains E

48

49 Mains N

50 Mains A

51 Heater #1

52 Heater #1

53 Heater #2

54 Heater #2

Connection Diagram for 1638 Analyser and one or two 1231 Heated Sensors

August 2009

22 1638 Dew Point Analyser

Page 25

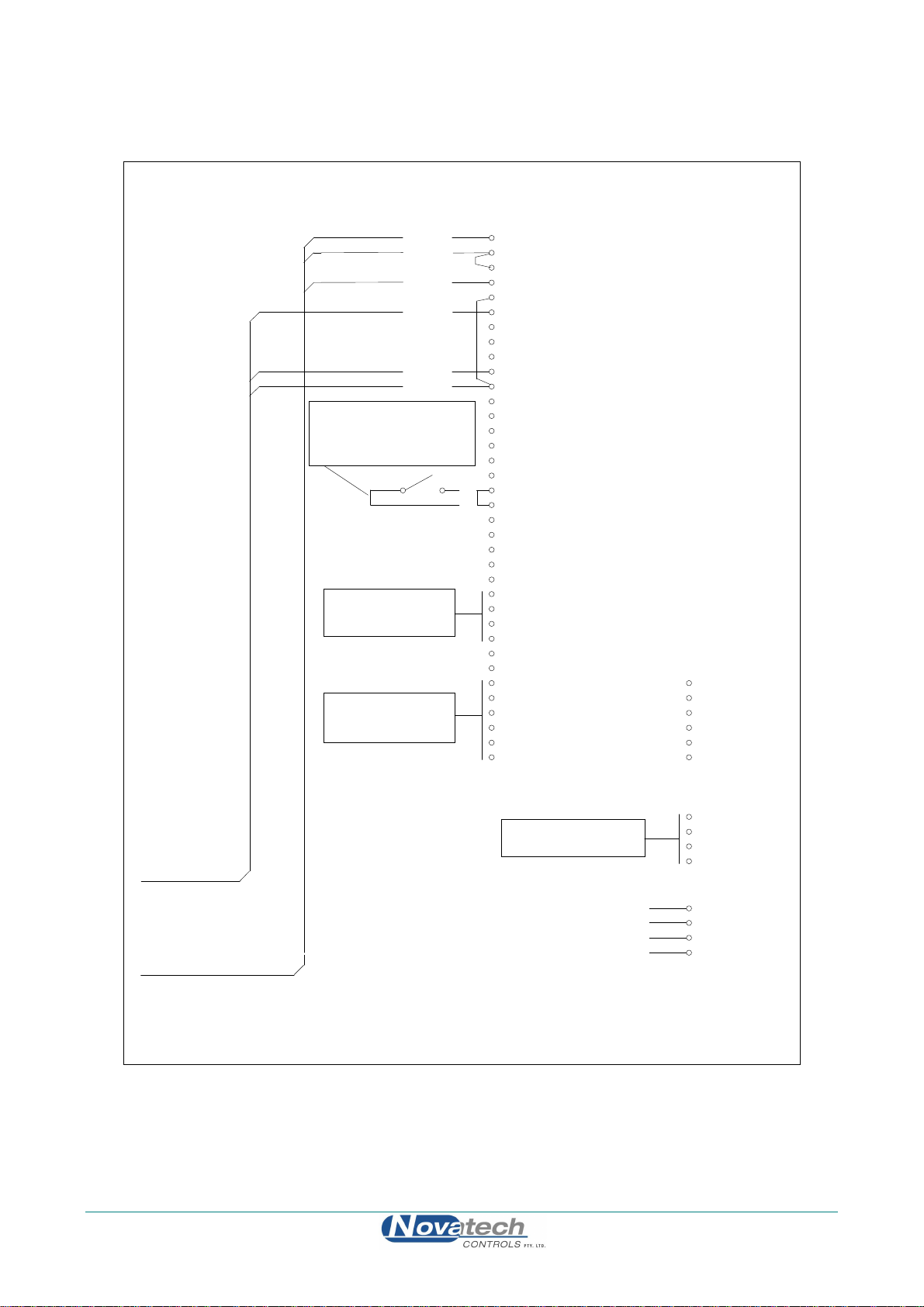

All wiring should comply with local electrical codes. The printed circuit boards are fully floating above earth. All

earth and shield connections should be connected to the earth stud on the LHS inside the case. Before connection of

mains power check that the 115 / 230 volt power selector switch is set to the correct voltage.

Burner safety lock

or if safety interlock

not required, link

terminals 18 & 19

4- 20mA Out puts

Selectable

ran g e s

Op t i o na l Alarm

Re l a y Co nt a c t s

Normally Closed

Ora nge

Black

Red

Red

Ora nge

Black

1

Probe +

2

Probe -

3

Probe TC+

4

Probe TC-

5

Probe TC2 / Aux+

6

Probe TC2 / Aux-

7

+12V

8

RGCI/ P+

RGCI/ P-

9

Sen s # 2 +

10

Sen s # 2 -

11

Purge Flow Swit ch

12

Purge Flow Swit ch

13

Fuel 1 / 2

14

Fuel 1 / 2

15

Re mot e Alarm Reset

16

Re mot e Alarm Reset

17

Bur n e r On I n pu t

18

Bur n e r On I n pu t

19

RS- 2 3 2 Rx

20

21 RS- 232 Tx

22 Network -

Net wor k +

23

Ser i a l Common

24

Ou t p u t 1 +

25

26 Output 127 Output 2+

28 Output 229 Common Alarm

30 Common Alarm

31 Alarm 2

32 Alarm 2

33 Alarm 3

34 Alarm 3

35 Alarm 4

36 Alarm 4

41

Pur ge Sol

42

Pur ge Sol

43 Cal 1 Sol

44 Cal 1 Sol

45 Cal 2 Sol

46 Cal 2 Sol

47 Mains E

Mai ns Power Suppl y

240/ 115VAC

PROBE #2

PROBE #1

48

49 Mains N

50 Mains A

51 Heater #1

52 Heater #1

53 Heater #2

54 Heater #2

Connection Diagram for 1638 Analyser and one or two 1232 Unheated Sensors

August 2009

1638 Dew Point Analyser 23

Page 26

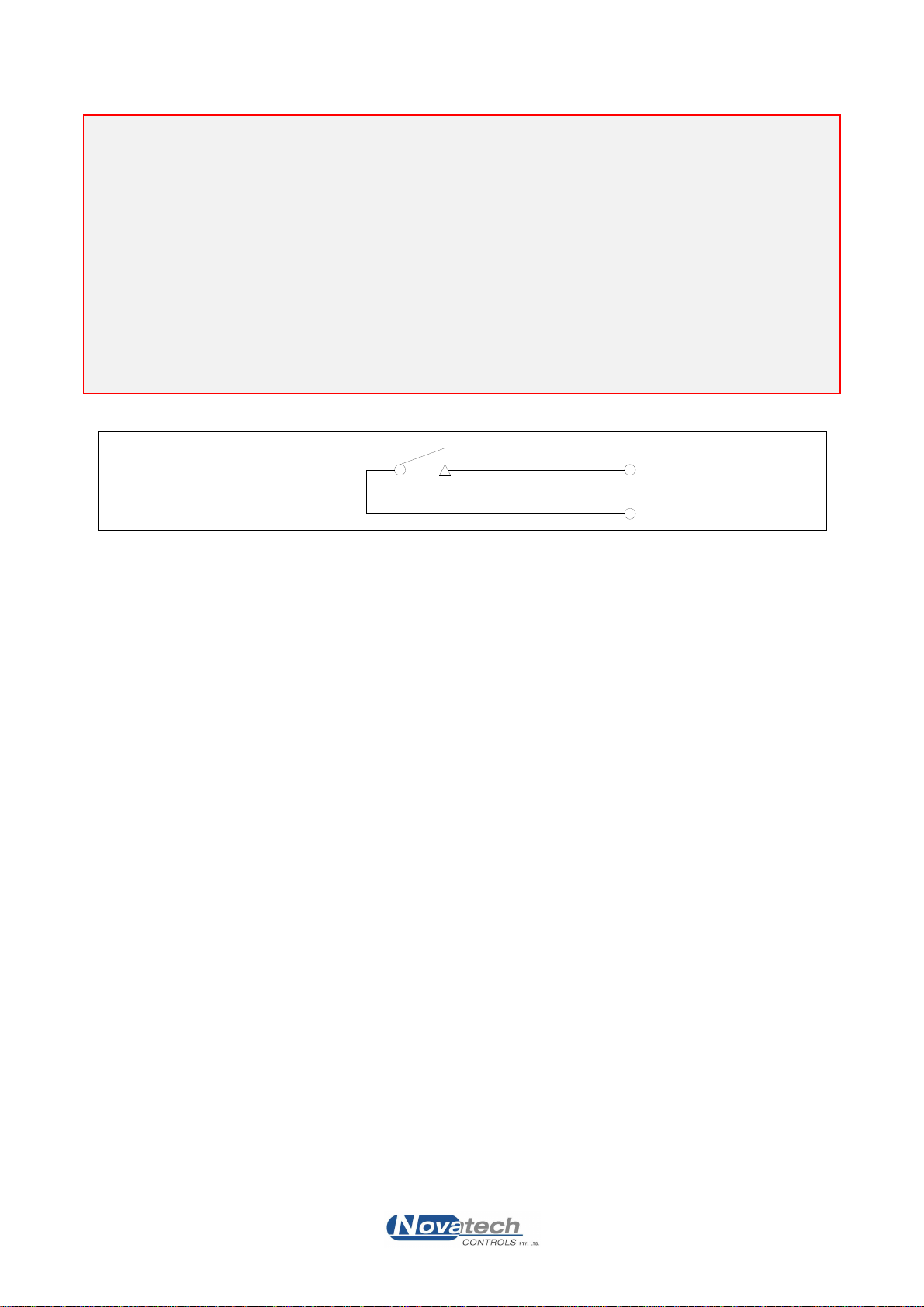

3.6 HEATER INTERLOCK RELAYS

CAUTION

Explosion protection for heated probes is achieved by switching the power to the probe heater off whenever the main

fuel valve is closed.

The principle of safety is that if the main fuel valve is open then main flame has been established. With this primary

source of ignition on, the probe heater can be safely switched on. The most dangerous situation is if fuel or hydrogen

leaks into the furnace when the fuel valve is closed. When power is removed from the main fuel valve the heater

should be switched off.

To achieve this protection, connect a main fuel valve voltage free contact to the ‘BURNER ON SWITCH’ terminals 18

& 19. When the main fuel valve is open, the voltage free contact should be closed. For installations where there is no

risk of explosion, connect a link between terminals number 18 & 19.

For Safety Interlock

Contact must be closed

when main fuel valve is open

18

Burner on Switch

19

Heater Supply Interlock Connection For Heated Probes

3.7 CONNECTING AN OXYGEN PROBE CABLE

Connect the probe lead as shown in the following drawings. Unheated probe leads have integral reference air tube. An

adaptor has been supplied to connect this tube to quarter inch flexible PVC tubing, from the air pump or reference air

supply.

August 2009

24 1638 Dew Point Analyser

Page 27

F

A

B

k

B

Blue

W

e

W

e

M

E

S

d

C

T

l

e

e

e

r

e

r

(

G

E

A

Plug mounted

on head viewed

from outside of

head.

1/4" PVC tube to

reference air supply.

Reducing Fitting

B

Ref Air

CD

Probe Head

Connector

Zirconia

Sensor

A

B

E

Probe

Thermocouple

(Optional)

Note 1: Jumper terminals 3 & 4

to terminals 5 & 6 if

efficiency or flue

temperature display is

required.

Use copper wire.

C

Other

Shields

Mains

Earth

Green &

Yellow

(Shield)

Orange

Black

*Note 1

Red

Shield

Common

Terminal Block

(By Installer)

1 Probe +

2 Probe 3 Probe TC +

4 Probe TC -

Earth Stud

Connection of Probe Cable for Unheated Probes Model 1232

Zirconi a

Sensor

Pr ob

Ther m ocoupl

Pr ob

Heate

Pr ob

Ear th

Pr obe

Connecto

C

B

F

Or ange

rown

lac

1 Pr obe +

2 Pr obe 3 Pr obe TC +

4 Pr obe TC -

D

E

Gr een &

Ot her

Shiel ds

Yel low

(Shiel d)

G

Gr een

hi t

hi t

hi el

ommon

er mina

By Ins taller )

51

52

ai ns

ar th

Ear th

Connection of Probe Cable for Heated Probes Model 1231

August 2009

1638 Dew Point Analyser 25

Page 28

3.8 CONNECTING THE AUXILIARY THERMOCOUPLE (OPTIONAL)

For 1231 heated probes, the auxiliary thermocouple must be a separate TC with the junction isolated from earth,

mounted near to and upstream of the oxygen probe. It can be either type K or R. It is optional. If efficiency, oxygen

deficiency or auxiliary temperature display or transmitted signals are not required, then an auxiliary TC is not

necessary.

3.9 CONNECTING THE OUTPUT CHANNELS

The two 4 to 20 mA DC output channels are capable of driving into a 1000Ω load.

3.10 CONNECTING THE ALARMS

A common alarm, which should be connected for all installations initiates on alarms functions described below. Three

additional alarm relays are available for selectable functions as listed in Section 4.2 and 4.3. Each relay has normally

closed contacts. The contacts will open in alarm condition except for the optional horn function which operates with

normally open contacts. Relays are connected as follows:

Relay Terminal Numbers

Common Alarm 29 & 30

Alarm 2 31 & 32

Alarm 3 33 & 34

Alarm 4 35 & 36

Common Alarms All of the following conditions will cause a common alarm ADC Warning

DAC Warning

ADC Calibration Fail

DAC Calibration Fail

Sensor 1 Fail

Sensor 2 Fail **

Heater 1 Fail

Heater 2 Fail **

Sensor 1 TC Open

Sensor 2 TC Open **

Aux. TC Open

Reference Air Pump Fail

Mains Frequency Check fail

Probe Filter Blocked

Gas 1 or 2 Calibration Check Error

Memory device fail

Burner bypass Switch on

Watchdog Timer

The watchdog timer is a special alarm. It will force the common alarm to activate in the event of a microprocessor

failure. There will not be an alarm message displayed, but the analyser will reset.

Alarms can be accepted by either pressing the alarm button (viewing the alarm messages), or by temporarily closing a

switch connected to terminals 16 & 17, REM ALARM RESET.

Alarm relay 2 to 4 Select any one or all of the following for each relay. Refer 5 to Section 5.5, steps 54 to 66

Oxygen Deviation High **

Dew point Deviation High **

High oxygen probe 1

High oxygen probe 2

High dew point probe 1

High dew point probe 2

High oxygen deviation between probes

High dew point deviation between probes

Probe under temperature

Calibration check in progress

Probe purge in progress

Alarm horn function (Relay 4 only)

** These alarms are only available if two sensors are selected

August 2009

26 1638 Dew Point Analyser

Page 29

3.11 CONNECTING THE AUTOMATIC PURGE AND CALIBRATION CHECK SYSTEM

CAUTION

The purge and calibration solenoid valves are supplied with mains voltage. This supply has electrical shock danger to

maintenance personnel. Always isolate the analyser before working with the purge and calibration solenoid valves.

The on-line auto purge and calibration check system is optional. For details on its operation refer to Sections 1.3, 1.4,

2.9 and 2.10.

To automatically sense a blocked probe filter, a pressure sensor should be connected to the ‘purge’ line to the probe

‘cal’ port. It should be adjusted so that it energises just above the purge pressure with a new or clean filter installed.

The switch contacts should be connected to terminals 12 & 13 (PURGE FL SWITCH).

If the filter is still blocked or partly blocked after an auto purge cycle, the pressure switch will energise and cause a

‘Probe Filter Blocked’ alarm.

After installation the purge/cal system should be tested thoroughly for leaks. Any leaks can cause significant errors if

the furnace is at negative pressure. If the furnace is at positive pressure, an outward leak can cause corrosion in the

purge/cal system piping and fittings.

Note: If two probes are being used, the purge is not available, and Cal 2 gas must be connected to probe 2.

Automatic Purge & Calibration check System Wiring Schematic

Calibration Check Gas

Flowmeter/Regulator

25 litres/min

240VAC

To Oxygen Probe

'CAL' port

From terminals 43 & 44

240VAC

From terminals 45 & 46

240VAC

From terminals 41 & 42

CAL Check Gas #1

140 kPa max

CAL Check Gas #2

140 kPa max

Clear & Dry Purge

Air Supply

140 kPa Max

Automatic Purge & Calibration check System Piping Schematic

3.12 CONNECTING REFERENCE AIR

A 1/4” tube connector on the analyser should be connected via a nylon, copper or stainless steel tube to the ‘REF’

connector on the probe.

If two probes are being used, a “T” union must be supplied to provide reference air supply to both probes.

August 2009

1638 Dew Point Analyser 27

Page 30

3.13 CONNECTING THE DUAL FUEL INPUT 3.13 CONNECTING THE DUAL FUEL INPUT

r

A

If efficiency display is required and the appliance is capable of firing more than one fuel, then an external contact must

If efficiency display is required and the appliance is capable of firing more than one fuel, then an external contact must

be connected for the analyser to determine which fuel is being burnt. See Figure 3.12 for details.

be connected for the analyser to determine which fuel is being burnt. See Figure 3.12 for details.

Contacts to be open FUEL 1

is running and closed when

FUEL 2 is running.

14

FUEL 1/2

15

Fuel Selector Input Contact Connection Fuel Selector Input Contact Connection

3.14 CONNECTING THE PRINTER 3.14 CONNECTING THE PRINTER

A printer with a serial port, or a data logger, or a computer terminal may be connected to RS 232-C or the network port.

A printer with a serial port, or a data logger, or a computer terminal may be connected to RS 232-C or the network port.

Data is logged out of the port as arranged in Set-up steps 70 and 71. The baud rate is selectable in set-up step 72. The

Data is logged out of the port as arranged in Set-up steps 70 and 71. The baud rate is selectable in set-up step 72. The

RS-232 protocol for the serial port is eight data bits, one stop bit, no parity.

RS-232 protocol for the serial port is eight data bits, one stop bit, no parity.

vailable for RS-485

Printer or Data Logge

Network

Serial Port Connections Serial Port Connections

20

R-232 R

0

21 R-232 T

1

22 Network

2

23

Network

3

24

Serial

4

-

+

August 2009

28 1638 Dew Point Analyser yser

Page 31

3.15 CONNECTING THE ANALYSER TO A MODBUS™ NETWORK

The analyser can be networked to other analysers and to a network master. The network uses the analyser RS485 port.

Up to 31 analysers can be connected to the network, and can be interrogated by the Network Master.

NOTE: Hardware Protocol Selection

For the RS485 port on the analyser to operate, the link LK3 on the 1630-1 printed circuit board (mounted on the door

of the analyser) must be set to the RS485 position. The LK3 is accessed by removing the cover from the door PCB. It

is located at the bottom of the circuit board.

NOTE: Terminating Resistor

There is a terminating 100 ohm resistor fitted to the 1630-1 PCB. Link LK2, in the bottom left-hand corner of the PCB

on the door, is used to connect the terminating resistor. Link LK2 must be removed on all analysers except

on the end of the network line

string, a terminating resistor should be enabled with LK2 at each end if the network line.

The protocol of the network is –

Baud Rate 9600

Parity none

Stop Bits 1

RS485 Half Duplex

Mode RTU (binary mode)

For more details see Section 2.12 and Appendix 6.

. If the network line from the analysers is taken from the middle of the analyser network

the analyser

Network Connections

August 2009

1638 Dew Point Analyser 29

Page 32

COMMISSIONING

3.16 CONNECTING POWER

Before commissioning the probe, sensor or transmitter, read the CAUTION paragraphs at the front of this manual.

Check that the mains supply voltage switch is set for the correct supply voltage, and that the green / yellow EARTH

wire MUST be connected to earth.

3.17 COMMISSIONING – SET-UP MODE

Press the SET-UP button to select the ‘SET-UP’ mode. Most of the default settings of the functions will be co rrect, or

will have been pre-set at the factory. Refer to Section 5.5 for more details.

Check the following set-up functions 2 to 6 Date /time

7 to 10 Reference voltages

11 & 12 Probe offset

22 & 23 Sensor type

26 to 28 Output channel #1

29 to 31 Output channel #2

37 Auto purge

41 Auto gas calibration checking

54 to 69 Alarm set-up

80 Hydrogen level

3.18 COMMISSIONING – RUN MODE

When the analyser is turned on it will go to RUN mode. The SET-UP/RUN button will toggle between the two modes.

The upper line of the display will now read ‘% OXYGEN’. If the probe temperature is not above 650°C, a “Probe Low

Temperature” message will be flashed on the lower line. The probe temperature can be checked on the lower line of

the display.

3.19 BURNER BYPASS SWITCH

Heated probes and sensors should have their heater supply interlocked. If the combustion appliance is not running,

then power will not be supplied to the heater. To commission an oxygen probe when the main burner is turned off,

switch power off the analyser, remove the probe from the furnace.

Re-apply power to the analyser, press the BURNER BY-PASS switch into the ‘DOWN’ or ‘ON’ position . This will

apply power to the probe heater even when the plant is not running. The offset can now be set and calibration checked

with appropriate calibration check gases (typically 2% oxygen in nitrogen).

Ensure that the burner by-pass switch and the power are turned off before the p robe is re-installed. An alarm will occur

if the BURNER BY-PASS switch is turned on (down) during normal operation.

3.20 CHECKING THE ALARMS

If any alarms are present the alarm LED will be lit, either flashing or steady. To interpret the alarms, press the alarm

button until all alarm functions have been displayed. Rectify the cause of each alarm until no further alarms appear on

the display. For details on the operation of the alarm button and the alarm functions refer to Section 4.

3.21 PROBE CALIBRATION

The zirconia sensor provides an absolute measurement of oxygen partial pressure. There are no calibration

adjustments, apart from ‘SENSOR OFFSET’, for the probe. The probe EMF is either correct or replacement is

required. To check that the probe is functioning correctly, firstly check that the high impedance alarm is not activated

causing a ‘SENSOR FAIL’ alarm. The actual impedance can be displayed on the lower line. It should be less than 9

KΩ at 720°C.

Once it has been established that the impedance is normal, the offset may be set using the millivolt level marked on the

oxygen probe. Refer to Section 5.5.11. The probe offset can b e tested on site. A small flow of air must be admitted to

both the ‘REF’ and ‘CAL’ ports when testing the probe offset. If the probe is in the process, the air must fully purge

the probe sensor without interference from the process gas sample.

August 2009

30 1638 Dew Point Analyser

Page 33

3.22 FILTER PURGING

Purging probe filters is controlled from the ‘PURGE’ button on the analyser when in ‘RUN’ mode. If ‘AUTO

PURGE’ has been enabled in set-up 37, pressing the PURGE button will start the automatic cycle. Pressing any other

button will cancel the auto purge cycle. If AUTO PURGE was not enabled, the purge solenoid will only stay open for

as long as the button is pressed. Gradually adjust the purge gas supply regulator, increasing the pressure until sufficient

flow is obtained to clear the filter. This is best checked with a dirty filter after a period of operation, by withdr awing

the probe from service and watching any build up on the filter being blown off at the set pressure. Normally 30 kPa (5

psi) is adequate but the air pressure may be set as high as 100 kPa (15 psi).

3.23 CALIBRATION GAS CHECK

If the installation has a filter purge facility, set this up first. Refer to the previous paragraph. Press the ‘CAL 1 or

‘CAL 2’ button while in ‘SET UP’ mode to obtain a reasonable flow through the calibration check gas flow meter. If

air is being used as a calibration check gas, use the air from the regulator for filter purge. Then, when setting up a gas

for calibration checking, set the pressure from the calibration gas cylinder so that it is the same as the pressure set on

the air regulator. Then the setting on the rotameter / flow regulator will be the same as that for the air flow. Required

flows are about 2 litres per minute.

Air is not the best gas for calibration checking on a zirconia sensor. The output of a zirconia sensor with reference air

is zero millivolts. It is better to choose a gas value which provides a reasonable output from the sensor and which is

near to the process oxygen level. A cylinder with 2% oxygen in nitrogen is a commonly used calibration gas. The

maximum pressure on the calibration check gas cylinder regulators is 100 kPa (15 psi).

Note: If two probes were selected in set-up 1, ‘Cal Gas 2’ must be connected to probe 2.

3.24 DUST IN THE FURNACE

For unheated probes with no filter, entrained solids or dust in the furnace does not present a problem unless the dust,

when settled, is not porous. Allow the dust in the process to build up on the probe. It will form a porous layer slowing

the response time. To avoid mechanical abrasion of the electrode material in installations with unheated oxygen

probes, pack ‘SAFFIL’ or equivalent alumina based ceramic fibre in the sensing holes to protect the electrode. Do not

use silica based ceramic fibres such as ‘KAOWOOL’, which can attack the electrode at high temperatures. Once the

dust has built up the response time of the probe will be slower.

For heated probes the preferred method of mounting for dust laden applications is facing vertically downwards with the

filter removed. Probes can also be mounted horizontally with no filter with some dusts. An occasional automatic back

purge is helpful in this case.

Normally heated probes are supplied with filters for applications with particulate in the furnace. The probe response

time should be tested when the probe is first installed, and then regularly until it remains constant for a significant

period. Filter purging should be set up on the time periods determined by these tests. To test the probe response time,

use a stop watch to obtain the time for a probe to achieve a 63 % change from one reading to another. If a p r obe filter

blocks completely in a short period of time, then there is no option but to use the probe without the filter.

August 2009

1638 Dew Point Analyser 31

Page 34

August 2009

32 1638 Dew Point Analyser

Page 35

4

OPERATOR FUNCTIONS

Section

Number

DISPLAY BUTTON ....................................................................................................................... 34

4.1

4.2 ALARM BUTTON ......................................................................................................................... 35

4.3 ALARM SCHEDULE ..................................................................................................................... 35

4.3.1 SUMMARY OF ALARMS – COMMON ALARM ....................................................................... 35

4.3.2 SUMMARY OF ALARMS – SELECTABLE ALARMS .............................................................. 36

4.3.3 ALARM RELAYS .......................................................................................................................... 37

4.4 POWER LAMP ............................................................................................................................... 37

4.5 BURNER BYPASS SWITCH ........................................................................................................ 37

August 2009

1638 Dew Point Analyser 33

Page 36

OPERATOR FUNCTIONS (RUN MODE)

4.1 DISPLAY BUTTON

The upper line on the display will always read % oxygen for probe 1. The following are available for display on the

lower line.

1. DEW POINT MEASURED BY PROBE 1

2. DEW POINT MEASURED BY PROBE 2 **

3. DEW POINT AVERAGE MEASURED BY PROBES 1 AND 2 **

4. OXYGEN PROBE 2 **

5. OXYGEN AVERAGE OF PROBES 1 AND 2 **

6. SENSOR 1 EMF (millivolts)

7. SENSOR 2 EMF (millivolts) **

8. SENSOR 1 TEMPERATURE

9. SENSOR 2 TEMPERATURE ** or AUXILIARY TEMPERATURE

10. SENSOR 1 IMPEDANCE

11. SENSOR 2 IMPEDANCE **

12. AMBIENT TEMPERATURE

13. AMBIENT RELATIVE HUMIDITY

14. DATE / TIME

15. RUN HOURS SINCE LAST SERVICE

16. DATE OF LAST SERVICE

** available when 2 sensors selected in set-up 1

Any number of these variables can be displayed sequentially by pressing the ‘DISPLAY’ button. Items can be selected

for display or deleted in Set-up step 33 on the keyboard. In addition to the above lower line displays, the analyser will

automatically display:

“Sensor 1 Temp Low”, when probe one is below 650°C

“Sensor 2 Temp Low”, when probe two is below 650°C

“Gas 1 ON”, “Gas 2 ON” for Calibration check Gas 1 or 2

“Purging Probe”

“Sensor 1 Thermocouple Wrong Polarity”

“Sensor 2 Thermocouple Wrong Polarity”

“Aux Thermocouple Wrong Polarity”

NOTE:

2. The run time will be the period of time the BURNER ON SWITCH (terminals 18 & 19) contact is closed (ie.

main fuel valve open). If no explosion protection is required, a permanent bridge between the BURNER ON

SWITCH terminals will register run time whenever the analyser is powered.

3. This timer can be used as a probe replacement and/or boiler service schedule aid. The start time is reset by

changing the ‘SERVICE DAY’ in set-up mode on the keyboard.

4. If you hold the display button down as you switch on the power, the maximum ambient temperature which the

instrument has been subjected to, will be displayed. This temperature should be less than 50°C.

August 2009

34 1638 Dew Point Analyser

Page 37

4.2 ALARM BUTTON

Repeatedly pressing the ‘ALARM’ button will produce alarm displays in sequence on the lower line of the LCD

display. If an alarm has cleared prior to pressing the ‘ALARM’ button, it will not re-appear on a second run through

the alarms. Active alarms which have been previously displayed will have ‘acc’ (accepted in lower case), displayed

alongside. New alarms will not have ‘ACC’ (in upper case) displayed until a second press of the ‘ALARM’ button.

After the last active alarm is indicated, the lower line of the display will return to the last displayed lower line variable.

Alarms may also be accepted remotely by a temporary closure of a switch connected to terminal 16 & 17, ‘REMOTE

ALARM RESET’.

The alarm ‘LED’ will flash when there is an un-accepted alarm. Pressing the ‘ALARM’ button will cause the LED to

go steady if any alarms are still active, or extinguish if there are no active alarms. The horn relay will operate when an

alarm occurs. Pressing ‘ALARM’ will mute a horn relay (if one of the user configurable relays have been selected as a

‘Horn’ relay) which will re-initiate on any new alarms.

4.3 ALARM SCHEDULE

4.3.1 SUMMARY OF ALARMS – COMMON ALARM

1. ‘Sensor 1 Fail’

2. ‘Sensor 2 Fail’

Oxygen cell or electrode failure (high impedance), (inhibited under 650°C).

3. ‘Heater 1 Fail’

4. ‘Heater 2 Fail’

In the first 20 minutes of power being applied to the heater after being switched on, this alarm will not occur, but a

‘Sensor # Lo Temp’ display will occur and common alarm relay will be activated. Refer to Section 6.11. If an ADC

alarms occurs, the heaters will automatically be turned off.

5. ‘Sensor 1 TC Open’

6. ‘Sensor 1 TC Open’

Probe thermocouple is open circuit. The heater in heated probes will switch off.

7. ‘Aux TC Open’

Stack thermocouple is open circuit. If the thermocouple is not needed, select “NO T/C” for “Aux TC Type” or place a

short circuit between terminals 5 & 6.

8. ‘Ref Pump Fail’

The reference air pump in the analyser has failed.

9. ‘ADC Cal Fail’

The analog to digital converter has been found to fall outside the normal calibration specifications. In this case the

probe heater will automatically be turned off.

10. ‘Mains Freq’

The sample of the mains frequency has failed.

11. ‘DAC Cal Fail’

The digital to analog and voltage isolator circuit has been found to fall outside the normal calibration specifications.

This check is only performed when the ‘AUTO CAL’ button is pressed. Refer to Section 6.3.

12. ‘Probe Filter

Blocked probe filter. This test is only performed when automatic purging of the probe is requested. Refer to step 36 in

the set-up menu Section 5.5. This alarm will not reset until the next purge cycle which can be initiated manually or

automatically.

13. ‘Gas 1 Cal Err’

Probe does not correctly calibrate to calibration check gas 1.

14. ‘Gas 2 Cal Err’

Probe does not correctly calibrate to calibration check gas 2.

August 2009

1638 Dew Point Analyser 35

Page 38

15. ‘Burner bypass’

The safety interlock relay has been bypassed by turning on the ‘BURNER BYPASS’ switch on the terminal printed

circuit board. Refer to Section 3.18

16. ‘Watchdog Timer’

Microprocessor error. This alarm will not appear on the display. The common alarm relay will be forced open circuit.

If the watchdog timer senses a malfunction in the microprocessor, it will attempt to reset the analyser every 2 seconds.

After two resets the alarm relay contacts will go open circuit.

17. ‘BB RAM Fail”

The battery backed memory module has failed in service. The device normally lasts 10 years. It is the plug-in battery

like module on the 1630 -1 board, labelled M1.

4.3.2 SUMMARY OF ALARMS – SELECTABLE ALARMS

NOTE: The process alarms must be enabled in set-up 54 if required.

There are three user configurable alarm relays. Any or all of the following functions can be selected for each relay.

18. ‘Dew Point 1 High”

The dew point measured by probe 1 (Dew Point 1 High) is above the limit set in set-up 59, and has been there for

longer than the time set in set-up 60.

19. ‘Dew Point 2 High”

The dew point measured by probe 2 (Dew Point 2 High) is above the limit set in set-up 61, and has been there for

longer than the time set in set-up 62.

20. ‘Oxygen % 1 High”

The oxygen measured by probe 1 (Oxygen % 1 High) is above the limit set in set-up 55, and has been there for longer

than the time set in set-up 56.

21. ‘Oxygen % 2 High”

The oxygen measured by probe 2 (Oxygen % 2 High) is above the limit set in set-up 57, and has been there for longer

than the time set in set-up 58.

22. ‘Oxygen % deviation High”

The oxygen difference measured by probe 1 and 2 is above the limit set in set-up 65, and has been there for longer than

the time set in set-up 66.

23. ‘Dew point deviation High”

The dew point difference measured by probe 1 and 2 is above the limit set in set-up 63, and has been there for longer

than the time set in set-up 64.

24. ‘Probe Temperature’

The probe temperature is under 650°C. The oxygen an dew point readings are therefore invalid. If the sensor heater

has been on for more than 20 minutes and the temperature is less than 650°C a ‘heater fail’ alarm will occur.

NOTE:

The ‘Probe Temp’ relay function is used with unheated probes to indicate oxygen reading is invalid (the probe is below

650°C), in case the process temperature falls below this level. For heated probes this relay will be energised while the

probe is heating up from ambient.

25. ‘Cal in Progress’

A calibration check is occurring, either manual ( in RUN mode) or automatic

26. ‘Probe Purge’

A probe purge is occurring, either manual ( in RUN mode) or automatic

27. Alarm Horn

This is not an alarm condition. If one of the three user configureable alarm relays have ‘Alarm Horn’ enabled, the relay

will have closed contacts only when there is an un-accepted alarm on the analyser. Press the alarm button twice to

accept any new alarm and to cancel the horn relay. This is only available on relay 4.

August 2009

36 1638 Dew Point Analyser

Page 39

4.3.3 ALARM RELAYS

The alarm relays are fail safe. That is, the contacts will be closed during normal operation, and will be open circuit if

there is an alarm or if the power is removed from the analyser.

4.4 POWER LAMP

Illuminates when power is connected to the analyser. If the lamp is flashing, the watchdog timer is attempting to reset

the microprocessor. Replace the 1630-1 microprocessor PCB.

4.5 BURNER BYPASS SWITCH

This switch is mounted on the terminal PCB near the POWER switch.

Before the heater in a heated probe, or the alarms will be enabled, the probes must be enabled. There are two ways of

doing this.

Use the safety interlock on terminals 18 & 19 (BURNER ON switch), or press the BURNER BYPASS switch to the

ON position. While the BURNER BYPASS switch is on there will be an alarm, “Burner Bypass”.

If it is not needed to have the analyser interlocked with the combustion appliance terminals 18 & 19 can be connected

together.

August 2009

1638 Dew Point Analyser 37

Page 40

August 2009

38 1638 Dew Point Analyser

Page 41

5

SETTING UP THE TRANSMITTER

Section

Number