Novak SUPER SPORT User Manual

SENSOR-BASED

INSTRUCTION MANUAL

BRUSHLESS MOTOR SYSTEM

How do you make a great hobby even more fun?

Eliminate motor maintenance & increase efficiency.

We’ve done it! People have seen the benefits of brushless

motor systems in many industries--now you too will enjoy

the maintenance-free, high-efficiency performance of

brushless that is designed specifically for your R/C car.

We combined the racing technology of our top of the line

speed controls with the efficiency of sensor-based brushless

motors to bring you the Super Sport Brushless Motor System,

giving you a sport-level brushless system with excellent low

speed driveability, extended run time, great torque available

over a broad power band, and Novak relaibility.

Equipped with Novak’s Variable Throttle Step Technology

for the smoothest throttle response, One-Touch Set-Up for

ease of programming, and the security of Radio Priority

Circuitry, the Super Sport has it all!

SPECIFICATIONS

Input Voltage 4-7 cells (1.2 volts DC/cell)

ESC Case Width 1.32” [33.5 mm]

ESC Case Depth 1.75” [44.4 mm]

ESC Case Height 1.05” [26.7 mm]

ESC Weight (w/o wires) 1.70 ounce [48.2 gr]

ESC Power Rating 225 Watts @ 25

°

C trans.temp.

B.E.C. Voltage 6.0 volts DC/3.0 amps

Wire Length (Battery/Motor) 9 inches

Signal Harness (replaceable) 9 inches

[22.86 cm]

[22.86 cm]

ESC Throttle Programs 6 (3 w/Rev. & 3 Fwd/Brk)

Motor Diameter 1.41” [35.8 mm]

Motor Length 2.08” [52.8 mm]

Motor Weight 6.40 ounce [181.4 gr]

Motor Power Rating 196 Watts

Motor Kv 5800 RPM/Volt DC

Motor Kt 0.45 Inch-Ounce/Amp

Motor Commutation Sensor-Based Electronic

Motor Magnet Material Neodymium

(1pc/multi-pole)

PRECAUTIONS

• WATER & ELECTRONICS DON’T MIX! Never allow

water, moisture, or other foreign materials to get inside

the speed control, motor, or on the PC Boards.

• CHECK MOTOR SCREWS Remember to check all motor

screws for loosening. The 3 main 4-40 socket head screws

on the shaft end of the motor may become loose after a

few runs of the motor, and will need to be tightened.

• 4 TO 7 CELLS ONLY Never use fewer than 4 or more

than 7 cells (8.4 volts DC) in the main battery pack.

• POWER CAPACITOR REQUIRED The attached external

power capacitor MUST be used with the Super Sport.

Failure to use Power Capacitor will damage speed control

and void the warranty!

• NOVAK MOTORS ONLY The Super Sport ESC has been

specially designed for use with sensor-based Novak

Brushless Motors Only! You may replace motor with any

Novak sensored motor rated less than 225W (ESC’s rating).

• NO REVERSE VOLTAGE! Reverse battery polarity will

damage the speed control.

• DISCONNECT BATTERIES WHEN NOT IN USE Always

disconnect the battery pack from the speed control when

not in use to avoid short circuits and possible fire hazard.

• TRANSMITTER ON FIRST Always turn on the power of

your transmitter first so that you will have control of the

radio equipment when you turn on the speed control.

• INSULATE WIRES Always insulate exposed wiring with

heat shrink tubing to prevent short circuits.

• NO SOLVENTS Exposing the speed control or motor to

any type of solvents can damage the exposed material.

SENSOR-BASED DESIGN

The benefits of a sensor-based brushless motor design are:

• CONSTANT ROTOR POSITION KNOWLEDGE Always

knowing what angle the rotor is at, allows instantaneous

response and smooth transitions from neutral to drive.

• SMOOTH/CONTROLLED LOW SPEED DRIVEABILITY

Rotor positioning is key to smooth acceleration without

delivering abrupt and uncontrolled bursts of power.

• STRONG & CONSISTENT BRAKES & STARTING TORQUE

Again, rotor position knowledge results in consistent starts

and stops, without hesitation or inconsistent lag times

before acceleration or braking.

• LOCKED ROTOR & THERMAL PROTECTION Position

and temperature sensors inside motor provide

unparalleled thermal protection for your investment, while

allowing you to run pack after pack without worrying

about overheating the motor, ESC, or magnets.

Part #3005

STEP 1

The Super Sport ESC comes with the industry standard

nector on a user-replaceable input harness. This connector

works with all major radio brands. However, with some older

style receivers, the wiring sequence in the

must be changed. This is an important step, because the

receiver electronics may be damaged if the sequence is incorrect.

JR • Hitec • Futaba • New KO • Airtronics Z

JR, Hitec, Futaba, new KO, & Airtronics Z receivers

need to have the ESC’s input harness wire sequence changed

New Airtronics Z receivers have blue plastic cases & new KO

cases have tabs on the input harness openings as in Figure 1.

• Insert one end of the input harness into receiver with the

BLACK wire toward the outside edge of receiver case.

• Insert opposite end of input harness into ESC with the

WHITE wire toward the ‘S’ (signal) marking in the ESC’s case.

New KO Rx (with tabs) Old KO Rx (no tabs)

tabs

white

red

FIGURE 1

black

Old-style KO • Old-style Sanwa/Airtronics

If your receiver is an older KO or Sanwa/Airtronics, you must

change the sequence of the ESC’s input harness wires.

Old Sanwa/Airtronics cases are black in color & Old KO cases

do not have the tab openings, as in Figure 2 above.

• Insert one end of input harness into ESC with the WHITE

wire toward the ‘S’ (signal) marking in the ESC’s case.

• Interchange the red and black wires in the plug plastic at

the opposite end of the input harness as in Figure 3 below.

• Insert modified end of the harness into the receiver with

the RED wire toward the outside edge of receiver case.

FIGURE 3 With a small standard screwdriver, gently lift plastic

prong until wire and metal socket easily slide out of plastic housing.

CHANGING ESC’S INPUT HARNESS

con-

plastic connector

do not

.

no tabs

white

black

FIGURE 2

red

SUPER SPORT SET-UP

SUPER SPORT SET-UP

STEP 3

1. MOTOR CAPACITORS & SCHOTTKY NOT NEEDED

Novak brushless motors have built-in motor capacitors,

and like all reversible ESCs, does not use an external

Schottky diode--Schottky diodes damage reversible ESCs.

2. FACTORY-INSTALLED POWER CAPACITOR

WHY POWER CAPACITOR IS NEEDED: The Power Capacitor

drops ESC operating temperatures by 10-15°F and dissipates noise

& voltage spikes from the ESC’s high switching speed. You MUST

use Novak capacitors, because other capacitors with similar ratings

will not provide the same protection. We have done extensive

research to find capacitors with the very best Quality Factors.

Mount Power Capacitor using the included slide-mount

bracket or double-sided tape. To use slide mount bracket,

insert bracket into the channel on the back of the ESC,

and secure Power Capacitor with the included tie-wraps.

3. CONNECT SPEED CONTROL TO RECEIVER

Configure input harness wires and connect ESC to the

THROTTLE CHANNEL of receiver as described in Step 1.

4. CONNECT SPEED CONTROL TO BATTERY PACK

Connect Super Sport’s Tamiya-style JST battery connector

a charged 4 to 7 cell battery pack.

to

5. CHECK MOTOR SCREW LENGTH

Insert the M3 motor mounting screws that came with

your vehicle through the motor mounting plate in vehicle

You need to have about 1/8” (±1/32”) of the screw

extending past the mounting plate (2-4mm). Any less

can strip the threads in the motor’s end bell, and any

more will cause short-circuiting/damage inside the motor.

6.

INSTALL PINION GEAR

Install pinion gear on motor and position set-screw over

flat on end of shaft. Test fit motor in vehicle to align

pinion and spur gears, then tighten pinion gear on shaft.

7. INSTALL MOTOR IN VEHICLE

• Determine the best routing for sensor harness & motor

power

wire. Some off-road cars may require unsoldering

motor to route wires through the shock tower--refer to

Step 7, #3–”

• Using the M3 motor screws that came with your

vehicle, attach motor to vehicle’s motor mount using

one of the three sets of threaded mounting holes--

a mounting position that will avoid short-circuiting of solder

tabs on conductive surfaces such as aluminum or graphite.

• Check gear mesh for proper amount of play. You want

to have a small amount of free play between the pinion

and spur gears

free play at several positions around the spur gear.

• Avoid using excessive force when tightening motor

screws, as the threaded holes could become stripped.

8. USE SPIRAL WRAP TO BUNDLE/PROTECT WIRES

The included plastic spiral wrap can be used to protect

the 6 Teflon sensor harness wires between the ESC & motor

You can also use the included spiral wrap and tie-wraps to

bundle the sensor harness & power wires neatly together.

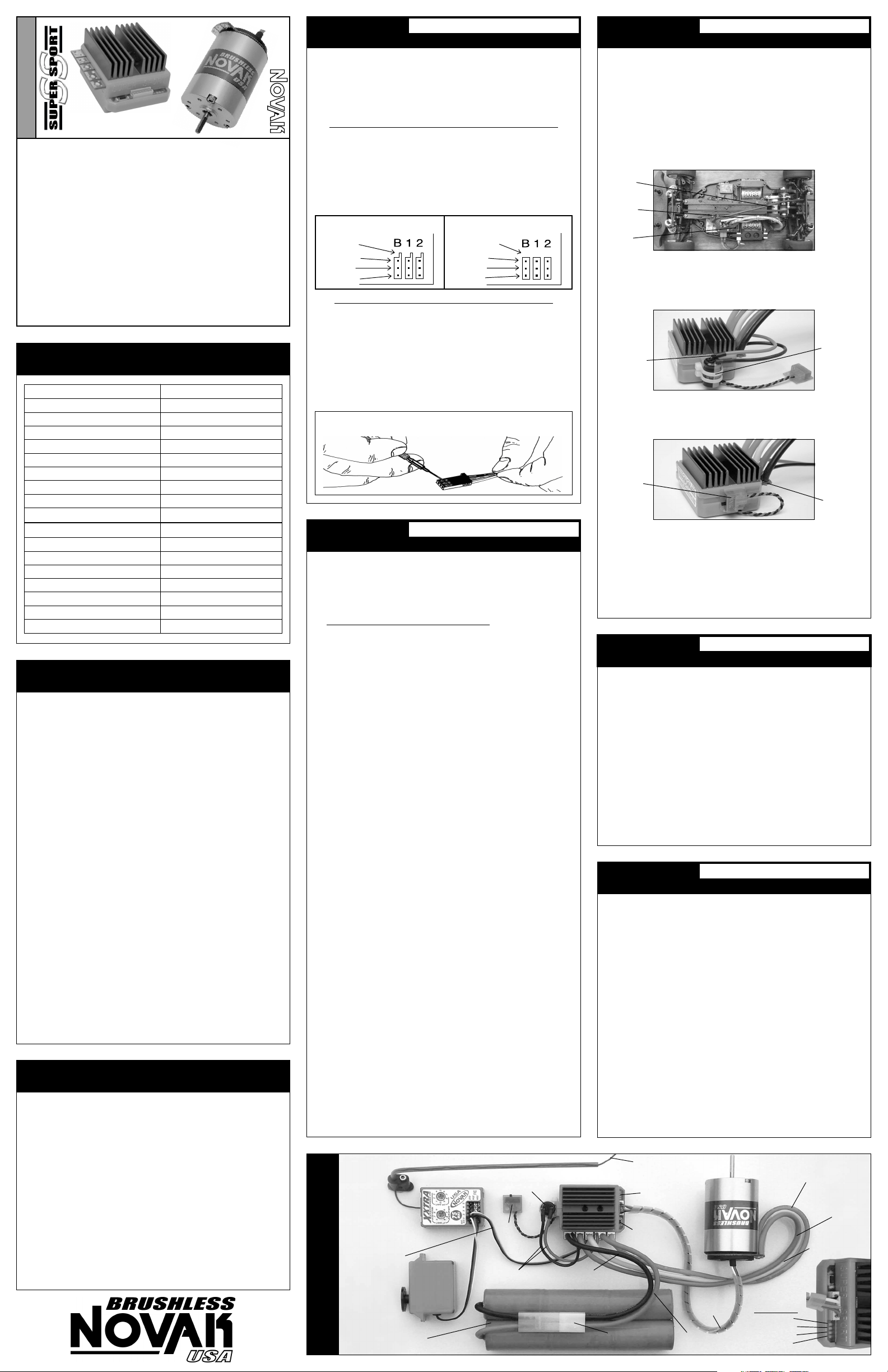

Keep receiver & antenna

as far from motor, servo,

battery, & power wires

as possible.

User-replaceable

input signal

harness plugged

into throttle

channel (#2).

SET-UP PHOTO

BASIC HOOK-UP INSTRUCTIONS

(see GEAR SELECTION on back)

SOLDERING POWER WIRES AT ESC & MOTOR”.

select

(about the thickness of piece of paper)--check

Power Capacitor

tie-wrapped to

slide-mount bracket

O

N

sw

/O

itch

FF

plugged

steering

ch. (#1)

4 to 7 cell

battery pack

Servo

into

PowerCap

(–)

(+)

wires

Black power wire

(battery negative)

.

.

STEP 2

1. DETERMINE BEST ESC MOUNTING LOCATION

Choose a mounting position that keeps power wires away

from the receiver and antenna, and will provide

maximum airflow over heat sinks for proper cooling.

The slide mount channel on the back of the Super Sport’s

case can hold the ON/OFF switch or power capacitor.

T

his slide mount lets you mount the power capacitor or the ON/OFF

switch against the side of ESC. The ON/OFF switch

facing any of four directions when held by the slide mount. The

switch also has a hole for attaching it with a 4-40 or smaller screw,

or you can use the included double-sided tape.

motor

phase wires

&

sensor harness

ESC

2. SLIDE-MOUNT POWER-CAP. BRACKET (optional)

To use the included P.Cap bracket to mount the capacitor on the back

of the ESC, be sure you have enough space in the desired location.

Slide the bracket into the channel on the ESC. Secure the

power capacitor to the bracket with the included tie-wraps.

heat shink

&

vinyl tubing

insulating

capacitor

leads

3. INSTALL THE SPEED CONTROL & SWITCH

If using the slide mount channel to hold ON/OFF switch,

slide switch into channel

Mount the ESC using the included double-sided tape.

slide-mount

switch

4. INSTALL THE RECEIVER AND ANTENNA

Mount receiver as far from ESC, motor, power wires,

battery, and servo as possible. These components all emit

RF noise when throttle is being applied. On graphite

aluminum, it may help to place receiver on edge with

crystal and antenna as far above chassis as possible.

Note: Mount the antenna as close to the receiver as possible, and trail

any excess wire off the top of the antenna mast––cutting or coiling the

excess antenna wire will greatly reduce radio range.

MOUNTING SPEED CONTROL

can be positioned

Super Sport

brushless

system

installed in

Tamiya

touring sedan

for first win

@ Tamiya

4 hour

Enduro Race

power

capacitor

tie-wrapped

to bracket

facing the desired direction.

solder tabs

or

SUPER SPORT SET-UP

SUPER SPORT SET-UP

STEP 4

For proper ESC operation, adjust transmitter as follows:

A. Set HIGH ATV or EPA to maximum setting.

[amount of throw at full throttle]

B. Set LOW ATV, EPA, or ATL to maximum setting.

[amount of throw at full brakes]

C. Set EXPONENTIAL to zero setting.

[throttle channel linearity]

D.

Set THROTTLE CHANNEL REV. SWITCH to either position.

E. Set THROTTLE CHANNEL TRIM to middle setting.

[adjusts neutral position/increases or decreases coast brakes]

F. Set ELECTRONIC TRIGGER THROW ADJUSTMENT to

70% throttle and 30% brake throw (or 7:3).

[adjusts trigger throw electronic/digital pistol-grip transmitters]

G. Set MECHANICAL TRIGGER THROW ADJUSTMENT

to position with 2/3 throttle and 1/3 brake throw.

[adjusts trigger throw on mechanical/analog pistol-grip transmitters]

TRANSMITTER ADJUSTMENTS

SUPER SPORT SET-UP

STEP 5

With ESC connected to receiver & a charged battery pack:

1. TURN ON THE TRANSMITTER’S POWER

2. PRESS & HOLD SPEED CONTROL’S SET BUTTON

3. TURN ON THE SPEED CONTROL’S POWER

With transmitter throttle at neutral, and still pressing the

SET button slide the ON/OFF switch to ON position.

4. HOLD ESC’S SET BUTTON UNTIL RED LED IS ON

Continue pressing SET button until the Super Sport’s red

status LED turns solid red.

5. RELEASE ESC’S SET BUTTON WHEN LED IS RED

6. PULL TRANSMITTER THROTTLE TO FULL-ON POSITION

Hold it there until the green status LED turns solid green.

Note: Motor will not run during programming even if connected.

7. PUSH TRANSMITTER THROTTLE TO FULL-BRAKES

Hold it there until the green status LED blinks green.

8. RETURN TRANSMITTER THROTTLE TO NEUTRAL

Amber, green, & red status LEDs will turn on solid,

indicating that

ESC returns to neutral and red status LED will turn on solid.

NOTE: If transmitter settings are changed, programming must be repeated

If you experience any problems, turn off ESC and repeat programming.

Trail excess wire off top

of antenna mast

Status LEDs

One-Touch

Set-Up

button

Tamiya-style

battery connector

ONE-TOUCH PROGRAMMING

proper programming has been completed.

Orange power wire

(motor phase ‘C’)

Blue power wire

(motor phase ‘A’)

Yellow power wire

(motor phase ‘B’)

Sensor

Harness

bundled with

Spiral Wrap

Red power wire

(battery positive)

ESC faceplate

close-up

Status LEDs:

Blue LED

Amber LED

Green LED

Red LED

•NOT ALL TRANSMITTERS HAVE THESE ADJUSTMENTS

•

.

STEP 6

The Super Sport is equipped with 6 user-selectable Throttle

Programs to choose from, as shown in the chart below.

THROTTLE PROGRAM SELECTION

THROTTLE PROGRAMS

OPTIONAL SET-UP

SS STANDARD

123456

RPM**

Acceleration* unlim. unlim. unlim. unlim. fixed fixed

Min.Brake

w/Reverse

**Unlimited RPM is based upon motor’s rating. 5800Kv motor produces

41760 RPM @ 7.2 volts DC.

*Unlimited acceleration refers to acceleration only being limited by the

quality of the batteries used. Fixed acceleration is accomplished by only

allowing a factory programmed acceleration rate--all Super Sport ESCs

are programmed with the same fixed acceleration rate for programs 5 & 6.

unlim. unlim. unlim. umlim. 24000 24000

low low high high low low

yes no yes no yes no

Selecting Throttle Program--TRANSMITTER ON

With transmitter ON & ESC connected to receiver and battery:

1. TURN ON THE SPEED CONTROL’S POWER

2. PRESS & HOLD SPEED CONTROL’S SET BUTTON

With transmitter throttle at neutral, press and hold SET

button on Super Sport until all 4 LEDs turn on.

3. RELEASE SPEED CONTROL’S SET BUTTON

All status LEDs will flash together. The number of times

the LEDs flash indicates the Throttle Program selected.

4. PRESS & RELEASE SET BUTTON TO SELECT PROGRAM

Each press will change to the next consecutive Program

number.

(After Program #6, the sequence begins again at Program #1)

5. WAIT FOR SPEED CONTROL TO EXIT PROGRAMMING

When SET button is not pressed for about 3 seconds, the

ESC loads the selected Program into memory and exits

programming--red status LED will turn solid red indicating

that the speed control is at neutral and ready to go.

Selecting Throttle Program--WITHOUT TRANSMITTER

With the transmitter power OFF (or input harness disconnected):

1. TURN ON THE SPEED CONTROL’S POWER

When speed control is powered on and no input signal

is being received from the receiver, the green and red

status LEDs will both turn on solid. This acts as a system

check at all times to let you know the condition of the

connection between your receiver and the Super Sport ESC.

2. PRESS & HOLD SPEED CONTROL’S SET BUTTON

Press and hold SET button on ESC until all 4 LEDs turn on.

3. RELEASE SPEED CONTROL’S SET BUTTON

All status LEDs will flash together. The number of times

the LEDs flash indicates the Throttle Program selected.

4. PRESS & RELEASE SET BUTTON TO SELECT PROGRAM

Each press will change to the next consecutive Program.

5. WAIT FOR SPEED CONTROL TO EXIT PROGRAMMING

SET button not pressed for 3 sec.--ESC exits programming.

STEP 7

1.

REPLACEMENT POWER CAPACITOR INSTALLATION

•

Insulate capacitor’s leads with the heat shrink tubing

included in the accessory kit.

• Solder capacitor’s NEGATIVE (–) lead {shorter lead on

capacitor} to the Super Sport’s BLACK PowerCap wire

that comes from the small hole on Super Sport’s Battery

Negative (–) solder tab.

Solder capacitor’s POSITIVE (+) lead to RED PowerCap wire

•

that comes from the small hole on Super Sport’s Battery

Positive (+) solder tab.

2. HARD WIRING ESC TO BATTERY PACK

•

Cut Super Sport’s BLACK power wire to desired length

and strip

battery NEGATIVE (–) of a charged 4 to 7 cell pack.

•

Cut RED power wire to desired length

of insulation off the end. Solder to battery POSITIVE (+)

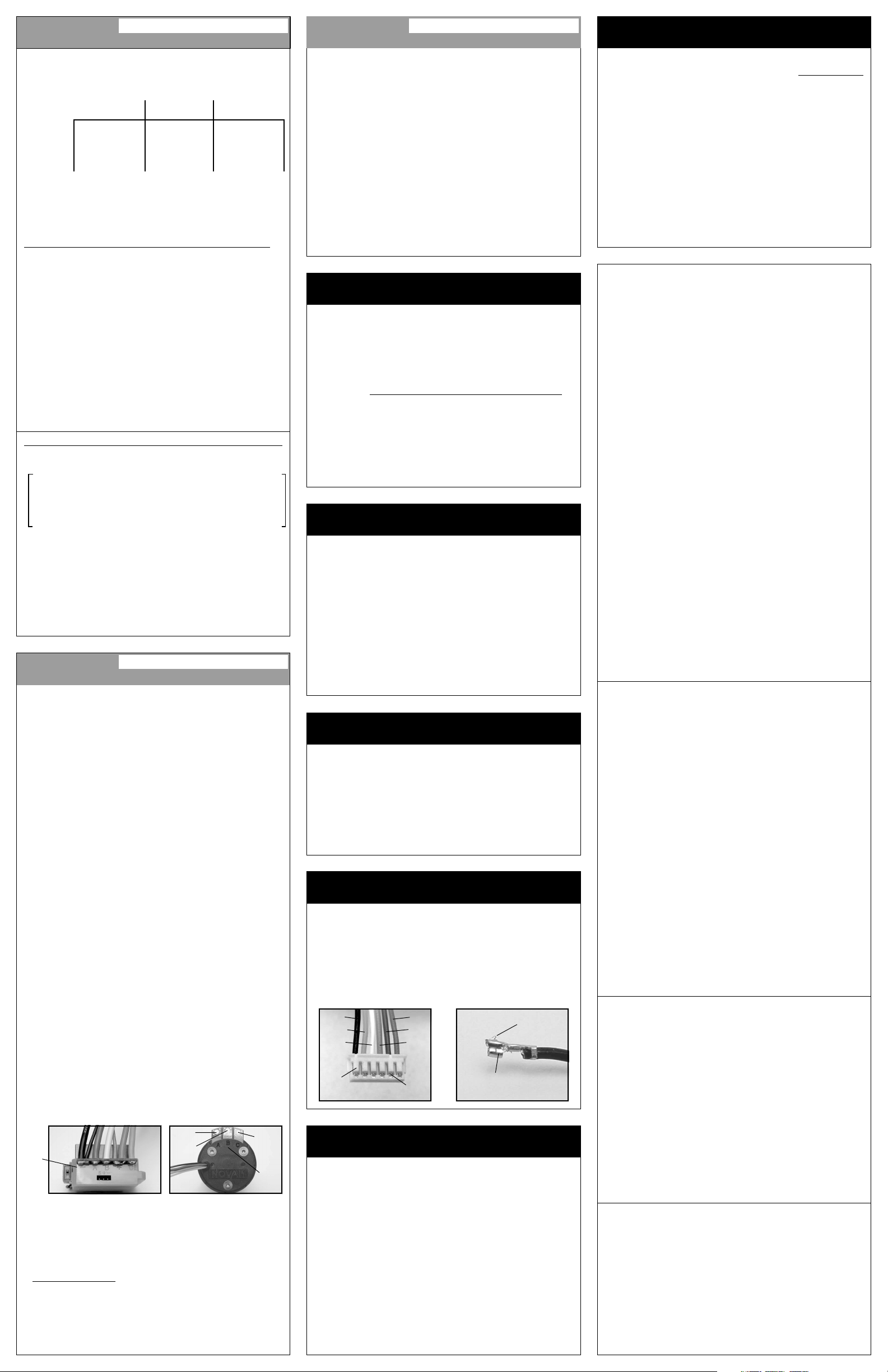

3. SOLDERING POWER WIRES AT ESC & MOTOR

The Super Sport ESC comes factory wired to the brushless

motor & battery connector. For custom installation or

for power wire replacement:

• Remove power wires from PCB solder tabs

be removed from the model so that you can get access to bottom

side of solder tabs). Use a soldering iron to apply heat to

the power wire’s solder joint on the bottom side of the

solder tab, while gently pulling up on the wire to

remove it from the hole in the PCB.

• Replace power wires by stripping 1/8-1/4” of

insulation from the end of the new wire. Tightly twist

strands of wire, and insert into proper solder tab’s hole

(tabs are identified by lettering that is engraved in the ESC

case and on the end cap of the motor--see photos

Use soldering iron to apply heat to exposed wire

extending past bottom of PCB, and begin adding solder

to tip of soldering iron and to wire. Add just enough

solder to form a clean & continuous joint from the plated

area of solder tab up

trim remaining

tab

strayed to an adjacent solder tab as this can result in short-circuiting

& damage to the electronics, which will void the product’s warranty

motor

&

battery

PCB tab

I.D. text

• Note: Power wires can also be soldered flat onto the

PCB solder tabs. Strip 3/16-1/4” of insulation from the

end of the new wire. Tightly twist strands of wire, and

tin with solder. Lay the stripped & tinned end of the

wire flat onto the PCB solder tab and use soldering

iron to heat the end of the wire, and add solder to

form a clean solder joint between the wire and the tab.

I

MPORTANT NOTE: DO NOT OVERHEAT SOLDER TABS

Prolonged/excessive heating of solder tabs will damage PCB.

4. CHANGING BATTERY CONNECTOR

If you are planning to change the ESC’s Tamiya-style

battery pack connector, we recommend using a highquality/low-resistance connector, such as Dean’s Ultra Plug

Always use a connector that can not be connected backwards!

1/8-1/4” of insulation off the end. Solder to

(now soldered)

(about 1/16” above PCB)

•Be sure to solder wires to matching tabs at ESC & Motor

SS HIGH

SPORTSMAN

OPTIONAL SET-UP

OPTIONAL HOOK-UP INSTR.

and strip 1/8-1/4”

(ESC must

below)

that is

onto the wire. Use side cutters to

wire from below the solder

--

make sure no strands of wire have

(A/B/C)

A

B

C

motor

phase

wire

tab I.D.

text

.

.

.

•

.

STEP 8

If you experienced any problems while performing the

One-Touch programming in Step 5, use the following

procedure to check that your transmitter has adequate throw.

With transmitter ON, ESC OFF & connected to receiver & battery:

1. PRESS & HOLD SPEED CONTROL’S SET BUTTON

2.

TURN ON SPEED CONTROL’S POWER

3.

HOLD SET BUTTON UNTIL BLUE, AMBER, & RED LEDs ON

4. RELEASE SPEED CONTROL’S SET BUTTON

Once blue, amber, & red LEDs (left 2 LEDs + right LED) turn on,

release the Super Sport’s SET button. Red LED will stay on.

5. PULL TRANSMITTER THROTTLE IN DRIVE DIRECTION

Slowly pull throttle toward full drive––blue LED blinks until 500µS of

throw is reached when it turns solid. (refer to Step 4/A to adjust throw)

6. PUSH TRANSMITTER THROTTLE IN BRAKE DIRECTION

Slowly push throttle toward full brake––amber LED blinks until 200µS of

throw is reached when it turns solid. (refer to Step 4/B to adjust throw)

Note: Without transmitter adjustments mentioned in Step 4/A & 4/B, ESC

will still program & operate normally with a minimum of ±90µS of throw.

GEAR SELECTION

As a general rule, you can start with the same gear ratio

that you previously had with a “stock” brush-type motor in

your vehicle. The difference is that you now have broad

power band, and can base your gear selection on application

instead of being limited to the narrow RPM range that your

brush-type motor produced its maximum

final drive ratios will give longer run time at the expense

speed, while

the ESC,

You will want the final drive ratio in the vehicle

{

If you had a modified brush-type motor in your

vehicle before switching to the Super Sport system

and you do not change the gearing, you will be

under-geared and the vehicle will appear slow!

ratios

and may result in overheating and thermal shut-down.

to be about 7.3:1 and not less than 6.5:1

CHECKING TRANSMITTER THROW

(while holding SET button)

(Important)

torque. Higher

of top

below 6.5:1 will cause excessive heating of

}

,

LOCKED ROTOR DETECTION

OPTIONAL SET-UP

The Super Sport system is equipped with Lock Rotor

Detection Circuitry that provides added protection against

overheat damage. Should the vehicle’s drive train become

locked or bound, or for any reason the motor shaft becomes

locked while the throttle is being applied for an extended

period, the Super Sport speed control will cut throttle power

to the motor. This situation could occur when the vehicle

becomes stuck against a tree or wall or jammed underneath

something where the wheels will not spin.

To indicate a locked rotor condition, the Blue & Green status

LEDs will flash six times and then remain on solid. The

transmitter’s throttle trigger must then be returned to the

neutral position before motor control is regained.

THERMAL SHUT–DOWN

The Super Sport system is equipped with temperature sensors

in both the ESC and motor to protect from overheating.

Should the ESC or motor become overheated for any reason,

the Super Sport ESC will cut throttle power to the motor.

To indicate thermal shut-down, the Blue status LED will flash

until the ESC or motor returns to within the normal operating

range, at which time throttle power is regained. The

transmitter’s throttle trigger must first be returned to the

neutral position before motor control is regained.

SENSOR HARNESS WIRING

Should any of the 26G Teflon wires pull out of the connector

on the end of the motor’s sensor harness, replace them into

the appropriate slot in the connector as shown below. The

connector has small plastic tabs that grab a small raised barb

on the back of the metal socket that is crimped onto the ends

of the Teflon wire. The plastic tab should be checked to make

sure it has not deformed excessively before inserting the

socket into the plastic connector housing.

harness become damaged, contact our Customer Service Department.

black

orange

white

plastic

tabs

red

blue

green

metal

barbs

If the motor’s sensor

raised

metal

metal socket

on end of Teflon

sensor harness wires

barb

MOTOR MAINTENANCE

• CHECK MOTOR SCREWS Check all motor screws for

loosening at regular intervals, just like other hardware on

your vehicle.

shaft end of the motor may become loose after a few runs of the

motor and will need to be tightened.

screws securing the end cap on the back of the motor.

• CHECK MOTOR BEARING WEAR After extensive use,

the ball bearings in the end bells of your brushless motor

may need to be replaced

will keep the majority of the debris out of the bearings, some

debris may get in, and eventually wear will occur. If the shaft

will not spin freely, you may need to replace the motor

bearings

kit #5900 and include bearing replacement instructions--If you do not

feel comfortable changing the bearing on your own, please contact

our Customer Service Dept. for assistance). A drop of light oil on

the bearings periodically can help extend bearing life.

Note: The 3 main 4-40 socket head screws on the

Also check the 3 flat head

. While the design of the motor

(replacement bearing sets are available in Novak accessory

ACCESSORIES

POWER CAPACITORS

An external power capacitor is included, and MUST BE USED

to maintain cool and smooth operation. Refer to Step 3

Replacement Power Capacitor is available in Novak kit #5677.

BATTERY/MOTOR 14G POWER WIRE

Replacement silicone power wires for your brushless motor

system

are available in Novak kits #5500 (36”red/36”black),

(36”red/36”blue), & #5510 (36”yellow/36”orange), or

#5505

(2 each of 9”red/black/blue/yellow/orange).

#5508

INPUT SIGNAL HARNESS

The user-replaceable input signal harness is available in both

short (4.5”) and long (9.0”) lengths to fit different applications.

4.5” harness in Novak kit #5315, and 9.0” harness in kit #5320.

MOTOR BALL BEARING SET

After extensive use, the ball bearings in the end bells of

your brushless motor may need to be replaced

Two replacement motor bearings are available in Novak kit #5900.

TROUBLE-SHOOTING GUIDE

This section describes possible ESC problems, causes, and solutions.

Steering Channel Works But Motor Will Not Run

• Make sure motor sensor harness is plugged into ESC––check

for damaged wires. Green & red status LEDs will be blinking fast.

•

Make sure input signal harness is plugged into throttle channel

of receiver & ESC. Check throttle channel operation with a

servo. Check wiring sequence of receiver signal harness. Green

& red status LEDs will be both be on solid.

• ESC may have shut down due to thermal overload or locked

rotor detection & ESC’s neutral point is too far off to sense

that throttle has been returned to neutral.

Blue & green status LEDs on solid indicates Locked Rotor

Detection. Blue LED blinking indicates thermal shut-down.

• Possible internal damage––Refer to Service Procedures.

Receiver Glitches/Throttle Stutters During Acceleration

• Receiver or antenna is too close to speed control, power wires,

or battery––Refer to Step 2.

• Bad connections––Check wiring and connectors.

• External Power Capacitor damaged/not installed––Refer to

Steps 3&7/Replace Power Capacitor (possible internal damage).

Motor and Steering Servo Do Not Work

• Check wires, receiver signal harness wiring and color

sequence, radio system, crystals, battery and motor

connectors, and battery pack.

• Possible internal damage––Refer to Service Procedures.

Speed Control Runs Hot

• Gear ratio too low––Increase ratio (see ‘GEAR SELECTION’).

Model Runs Slowly/Slow Acceleration

• Gear ratio too high––Reduce ratio (see ‘GEAR SELECTION’).

• Check battery connectors––Replace if needed.

Incorrect transmitter/ESC adjustment––Refer to Steps 4 & 5.

•

• External Power Capacitor damaged/not installed––Refer to

Steps 3&7/Replace Power Capacitor (possible internal damage).

•

Motor bearings worn––Refer to ‘

MOTOR MAINTENANCE

ESC Is Melted Or Burnt/ESC Runs With Switch Off

• Internal damage––Refer to Service Procedures.

*For more assistance call our Customer Service Department.

SERVICE PROCEDURES

Before sending in your Super Sport brushless system for service,

review the Trouble-Shooting Guide and instructions. The ESC or

motor may appear to have failed when other problems exist.

After reviewing the instructions, if you feel the system requires

service, please obtain the most current product

and pricing by one of the following methods:

WEBSITE: Print a copy of the PRODUCT SERVICE FORM from

the SERVICE section of the Novak website. Fill out the needed

information on this form and return it with the Novak product

that requires servicing.

PHONE/FAX/E-MAIL: If you do not have access to the internet,

contact our customer service department by phone, fax, or email as listed in the CUSTOMER SERVICE section below, and

they will supply you with current service options.

WARRANTY SERVICE: For warranty work, you MUST CLAIM

WARRANTY on the PRODUCT SERVICE FORM and include a valid,

itemized cash register receipt with purchase date on it, or an

invoice from previous service work. If warranty provisions have

been voided, there will be service charges.

ADDITIONAL NOTES:

• Super Sport ESC & Motor should be returned together.

• Hobby dealers or distributors are not authorized to replace

Novak products thought to be defective.

• If a hobby dealer returns your speed control & motor for

service, submit a completed PRODUCT SERVICE FORM to the

dealer and make sure it is included with the items.

• Novak Electronics, Inc. does not make any electronic

components (transistors, resistors, etc.) available for sale.

PRODUCT WARRANTY

The Super Sport brushless motor system is guaranteed to be free from defects

in materials or workmanship for a period of 120 days from the original date of

purchase (verified by dated, itemized sales receipt). Warranty does not cover

incorrect installation, components worn by use, damage from using fewer

than 4 or more than 7 cells (1.2 volts DC/cell) input voltage, cross-connection of

battery/motor power wires, overheating solder tabs, reverse voltage application

damage resulting from thermal overload, damage from incorrect installation

of FET servo or receiver battery pack, not installing or incorrect installation

of a Novak power capacitor on the ESC, splices to input harness, damage from

excessive force when using the One-Touch/SET button or from disassembling

case, tampering with

other foreign material to enter ESC or get onto the PC board, incorrect

installation/wiring of input plug plastic, allowing exposed wiring or solder

tabs to short-circuit, or any damage caused by a crash, flooding, or act of God.

In no case shall our liability exceed the product's original cost. We reserve

the right to modify warranty provisions without notice.

Because Novak Electronics, Inc. has no control over the connection and use

of the speed control & motor or other related electronics, no liability

assumed nor will be accepted for damage resulting from the use of

may be

this product. Every speed control & motor is thoroughly tested and cycled

before leaving

act of connecting/

internal electronics, allowing water, moisture, or any

our facility and is, therefore, considered operational. By the

operating speed control, the user accepts all resulting liability.

CUSTOMER SERVICE

NOVAK ELECTRONICS, INC.

Monday-Thursday: 8:00am-5:00pm (PST)

Friday: 8:00am-4:00pm

(949) 833-8873 • FAX (949) 833-1631

e-mail: cs@teamnovak.com

web: www.teamnovak.com

©2003 Novak Electronics, Inc. • All Rights Reserved • No part of these operating

instructions may be reproduced without the written permission of Novak

Electronics, Inc. • Super Sport Brushless ESC, Locked Rotor Detection Circuitry,

Variable Throttle Step Technology, Polar Drive Technology, Radio Priority Circuitry

& One-Touch Set-Up are all trademarks of Novak Electronics, Inc. • All Novak

speed controls & motors are designed & assembled in the U.S.A.

Printed in the U.S.A. 2/2003 • #IM-3005-1

(closed every other Friday)

.

’ section.

service options

,

,

Loading...

Loading...