PCI Bus

2/4-Axis Motor Control Board

MC8022P/MC8042P

Hardware Manual

2013-04-17 Ver. 1.0

NOVA electronics

NOVA electronics MC8022P/MC8042P - i

Prevent Electrostatic Discharge

ATTENTION: MC8022P/MC8042P is sensitive to electr ostati c di scharge, which can

cause internal damage and affect normal operation. Follow these guidelines when

you handle MC8022P/MC8042P:

・Touch a grounded object to discharge potential static.

・Wear an approved grounding wrist strap.

・Hold both ends of the boar d betwe en your fingers o r hold a mounting bracket.

・Do not touch connectors or pins on component boards.

・Do not touch circuit components on MC8022P/MC8042P.

・Store MC8022P/MC8042P i n appro pri ate static-safe p ackagi ng when not in use.

Safety Notice

WARNING: MC8022P/ MC8042P is not designed or intended to be fail-safe, or for

use in any application requiring fail-safe performance, such as in life-support or

safety devices or systems that could lead to death, personal injury or severe

property or environmental damage (individually and collectively, "critical

applications"). Customer must be fully responsible for the use of MC8022P/MC8 042P

in critical applications. Pr ovide adequate design and operating safe guards in order to

minimize risks associated with customer's applications when incorporating

MC8022P/MC8042P in a system.

Before you begin

ATTENTION: Before using MC8022P/MC8042P, read this manual thoroughly to

ensure correct usage and observe all the instructions given in this manual.

Checking the Contents

ATTENTION: When you unpack a package of MC 8022 P/MC 8042P, check f or the

following accessories. If something is missing or broken, co ntac t the plac e of

purchase.

The user’s manual and software are not with the package for resource-saving. If you

need additional manuals or software, contact the place of purchase or con tact us

to the following email address as "novaelec_info@novaelec.co.jp".

MC8042P or MC80222P 1

I/O Cable (CN2) 1

- i -

NOVA electronics MC8022P/MC8042P - ii

T

,

Consulting Other Manuals

ATTENTION: The circuit of MC8022P/MC8042P consists of mainly 4-axis motion

control IC “MCX304”, a PCI-bus interface ci rcuit and I/O interface circuits of each

axis. Basic functions of this board all depend on MCX304, so please refer to the

user’s manual of MCX304 regarding these functi ons. This manual describes about

Electric Specification of each axis I/O signal. R egarding the insta llation on Windows ,

API function for board control and sample program files for this board, see “MC8000P

Device Driver Manual.”

Environmental Conditions

ATTENTION: Use the following environmental conditions.

Operating Temperature 0~45°C(32~113°F)

Humidity 20~90% (no condensation)

Floating dust Not to be excessive

Corrosive gases None

Electric supply source DC+5V (±5%), external source: DC+24V

Inspection and Maintenance

ATTENTION: Perform inspection and maintenance periodically for correct use.

Cable connection

properly be connected.

Card-edge No dust and no corrosion.

Connector terminal area No dust and no corrosion.

On the IC and board No excessive dust and no foreign substance.

he connector of the board and a cable sh ould

Handling Precautions

ATTENTION:

・Do not use in any location subject to shock, vibration, magnetism and electricity.

Otherwise, the equipment may be damaged or malfunctioned.

・Do not disassemble, re pair or mo dify the equi pm ent.

・Do not connect or di sconnec t the bo ard or ca bles whi le power is appl ied.

Otherwise

breakdown or operation error may result.

・Information in this manual is subject to change without notic e.

・Windows are register ed trademark of Mi crosoft C orpo ration.

- ii -

NOVA electronics MC8022P/MC8042P - iii

1. Outline ................................................................... 1

1.1 MCX304 Functional Restriction ...................................................................................................... 2

1.2 PCI Bus Interface ........................................................................................................................... 2

1.3 Each Axis I/O Interface................................................................................................................... 2

2. I/O Address Setting and Register .......................... 3

3. I/O Signals ............................................................. 4

3.1 CN2 Connector (Rear connector)................................................................................................... 4

3.2 CN3, 4 Connector (Connector on the board).................................................................................. 6

3.3 Drive Pulse Output Signal (nP+P, nP+N, nP-P, nP-N) .................................................................... 8

3.4 General Output Signal and Deviation Counter Clear Output Signal (OUT1~14, nOUT0/DCC) ...... 8

3.5 Over Run Limit Input Signal (nLMT+, nLMT-)............................................................................... 10

3.8 Input Signals for Servo Motor (nINPOS, nALARM) ...................................................................... 13

3.10 Driving by External Signal (nEXOP+, nEXOP-) ............................................................................ 15

3.11 Emergency Stop Input Signal (EMG)............................................................................................ 15

3.12 External Power (VEX) .................................................................................................................. 15

4. Interrupt ............................................................... 16

5. Connection Example for Motor Driver.................. 17

5.1 Connection Example for Stepper Motor Driver ............................................................................. 17

5.2 Connection Example for AC servo motor driver............................................................................ 18

6. Input/Output Signals Timing................................. 19

6.1 Reset............................................................................................................................................ 19

6.2 Beginning of Driving ..................................................................................................................... 19

6.3 Input Pulse Timing........................................................................................................................ 19

6.4 Instant Stop Timing....................................................................................................................... 20

6.5 Decelerating Stop Timing ............................................................................................................. 20

7. Board Dimensions ...............................................21

8. Specifications ......................................................22

- iii -

NOVA electronics MC8022P/MC8042P - 1

1. Outline

MC8022P/MC8042P is a PCI-bus compliant circuit board equipped with 4-axis motion control IC “MCX304”. It can

independently control 2/4-axis of either stepper motor or pulse type servo drives for position and speed controls.

MC8022P/MC8042P functional block diagram is shown as follows. MC8022P/MC8042P consists of mainly 4-axis motion

control IC “MCX304”, a PCI-bus interface circuit and I/O interface circuits of each axis: X, Y, Z and U. Therefore, basic

functions of this board all depend on MCX304, so please refer to the user’s manual of MCX304 regarding these functions.

CN1

PCI Bus

Crystal Oscillator

16MHz

APIC21

PCI Interface

Adapter

EEPROM

93LC66

For multiple

Address SW

CLK

General Purpose

Input/Output IC

PIX132

CLK

XOUT0/DCC

XSTOP2~0

XINPOS

XALARM

MCX304

XPP

XPM

XLMTP

XLMTM

XECA

XECB

XEXPP

XEXPM

EMGN

X axis I/O Interface

Line Driver

26C31

AM

Output Buffer

TD62503

Photo Coupler

High-speed

Photo Coupler IC

Note: Input signals need an external electric supply 24V.

XP+P/N +direction pulse output

XP-P/N - direction pulse output

XOUT0/DCC general output

1 point/deviation C clear

XLMT+ +direction limit

CN2CN3

XLMT- -direction limit

XSTOP2~0 deceleration/

XINPOS servo in-position

XALARM servo alarm

XECAP/N encoder A-phase

XECBP/N encoder B-phase

XEXOP+ +direction driving

XEXOP- - direction driving

instant stop

Y axis I/O Interface

(same as X axis)

Z axis I/O Interface

(same as X axis) *Only for MC8042P

U axis I/O Interface

(same as X axis) *Only for MC8042P

EMG emergency stop for all axes

CN2

Output Buffer

TD62503

OUT1~14 general output

CN4

14 points

CN1: PCI card edge connector

CN2: PC rear connector

CN3, 4: Connectors on the board

MC8022P/MC8042P Circuit Block Diagram

- 1 -

NOVA electronics MC8022P/MC8042P - 2

1.1 MCX304 Functional Restriction

MC8022P/MC8042P does not support the following MCX304 general output signals. However, it is equipped with

PIX132(NOVA Electronics) on the board, so that it has fourteen general output signals and nOUT general output signals of

MCX304.

MCX304-nOUT1 output signal

nSTOP2/OUT1 pin of MCX304 is used as STOP2 input, so it cannot be used as general output nOUT1.

MCX304-nOUT2, 3 output signals

D15~D8 are used due to 16-bit data bus performance. Therefore, it cannot be used as nOUT2, 3 signals.

1.2 PCI Bus Interface

■ Occupied I/O Address

The board requires 24 I/O address locations for PCI bus. I/O addressing is determined by “plug and play” function of Windows.

■ Data Length

Data length is 16-bit. Read/Write access cannot be performed per byte.

■ Interrupt Signal

When using an interrupt to PCI bus, the board uses IRQ determined by “plug and play” function of Windows.

1.3 Each Axis I/O Interface

■ Drive Pulse Output (nP+P/N, nP-P/N)

Drive pulses in the +/- direction for motor driving are output a 50% duty cycle of from 1PPS to 4MPPS.

Drive pulse output signals of each direction are the differential line-driver output of AM26C31 line driver or equivalent.

■ General Output (OUT1~14, nOUT0)

General output signals (14points) from PIX132, output buffer uses TD62503 (Toshiba) and is the open collector output with

sustaining voltage 35V. These signals are placed in the connecto r CN4 on the board. nOUT 0 sig nal for each axis can be used a s a

deviation counter clear signal (DCC) for a servomotor in automatic home search executing. nOUT0 signal is placed in the rear

connector CN2.

■ Over Run Limit Input (nLMT+, nLMT-)

Input signal to disable output pulse for + and – direction respectively. Decelerating stop and instant stop for active can be

selected in mode setting. These input signals are isolated by photo coupler from internal circuit. external 24V power supply is

needed.

■ Decelerating Stop/Instant Stop Input (nSTOP2~0)

In automatic home search, this input signal is to stop drive pulse in deceleration or immediately from outside. Enable/Disable

and active logical level can be selected in mode setting and each axis has three inputs. For encoder Z-phase signal, input to

nSTOP2. The user can connect to the driver whose type of output circuit is open collector or differential line-driver. These input

signals are isolated by photo coupler from internal circuit.

■ Servo Motor Input (nINPOS, nALARM)

INPOS (in-position) signal and ALARM signal for servo motor drivers can be input, which can also be used as general input

signals. These input signals are isolated by photo coupler from internal circuit.

■ Encoder Input (nECAP/N, nECBP/N)

This signal inputs A/B phase signal from an encoder, which is placed in the connector CN3 on the board. nECAP/N, nECBP/N

signals are for an encoder A/B phase signal input and count up or down 32-bit real position counter inside MCX304. These input

signals are isolated by photo coupler from internal circuit and can easily be connected to a differential output line-driver.

■ Driving by External Input(nEXOP+, nEXOP-)

This signal externally controls driving in the + or – direction, which is placed in the connector CN3 on the board. In fixed

driving mode, the input signal triggers (the falling edge) to output specified drive pulse. In continuous driving mode, drive pulse

is output continuously while the input signal is low. This function can reduce the load of the host CPU, so the user can perform

jog feed of each axis speedy. These input signals are isolated by photo coupler from internal circuit.

- 2 -

NOVA electronics MC8022P/MC8042P - 3

■ Emergency Stop Input (EMG)

This signal is to perform the emergency stop for all axes. Active logical level can be set by selecting a jumper on the board. This

input signal is isolated by photo coupler from internal circuit.

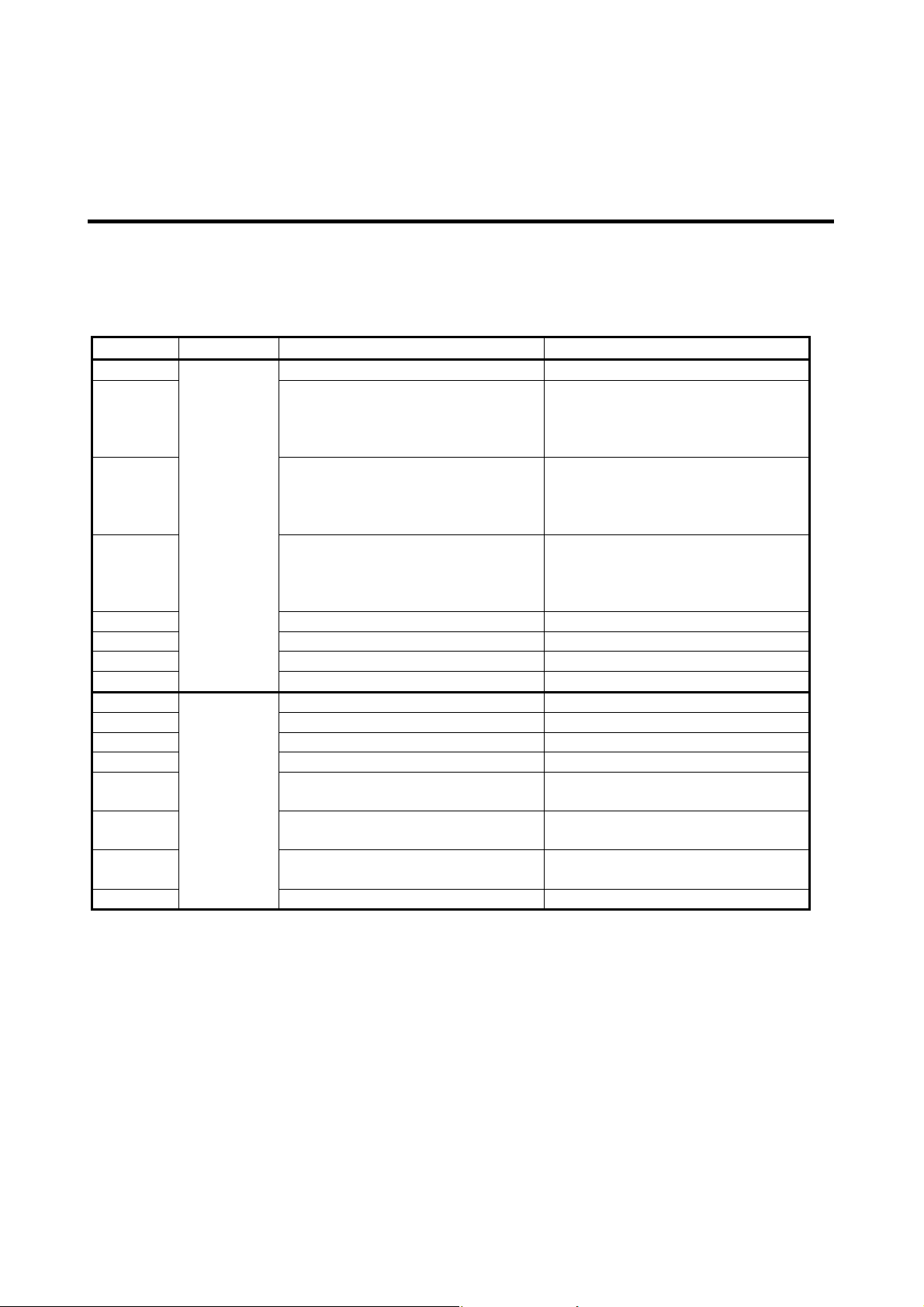

2. I/O Address Setting and Register

I/O port address of the board is automatically determined by the plug and play function (PnP function) of the PCI bus.

Read/Write registers of MCX304 on the board and ports of PIX132 can be accessed by API function which MC8000P device

driver provides. Each register and I/O port address are as shown in the table below.

For more details on each register, see chapter 4 of MCX304 user’s manual.

I/O Address IC Write Register Read Register

00 WR0 command register RR0 main status register

XWR1 X axis mode register 1

01

02

MCX304

03

04 WR4 output register 1 RR4 input register 1

05 WR5 output register 2 RR5 input register 2

06 WR6 write data register 1 RR6 read data register 1

07

10 write prohibit invalid

11 write prohibit invalid

12 write prohibit invalid

13 write prohibit invalid

14

15

16

17

PIX132

YWR1 Y axis mode register 1

ZWR1 Z axis mode register 1

UWR1 U axis mode register 1

XWR2 X axis mode register 2

YWR2 Y axis mode register 2

ZWR2 Z axis mode register 2

UWR2 U axis mode register 2

XWR3 X axis mode register 3

YWR3 Y axis mode register 3

ZWR3 Z axis mode register 3

UWR3 U axis mode register 3

WR7 write data register 2 RR7 read data register 2

Port A output data

(Set to D7~D0)

Port B output data

(Set to D7~D0)

Port C output data

(Set to D7~D0)

invalid invalid

XRR1 X axis status register 1

YRR1 Y axis status register 1

ZRR1 Z axis status register 1

URR1 U axis status register 1

XRR2 X axis status register 2

YRR2 Y axis status register 2

ZRR2 Z axis status register 2

URR2 U axis status register 2

XRR3 X axis status register 3

YRR3 Y axis status register 3

ZRR3 Z axis status register 3

URR3 U axis status register 3

Port A output data reading

(D7~D0)

Port B output data reading

(D7~D0)

Port C output data reading

(D7~D0)

- 3 -

NOVA electronics MC8022P/MC8042P - 4

3. I/O Signals

This chapter describes each I/O signals of the I/O connector. In the description, the signal name of each axis is described as

n○○○○.

3.1 CN2 Connector (Rear connector)

CN2 connector is equipped with external power (+24VDC) input, and inputs/outputs signals of each axis as shown below.

Connector Signal Type Signal Name

Drive pulse output signal in the +/– direction

Over run limit input signal in the +/– direction

CN2

Decelerating stop/Instant stop input signal 3 points

In-position and alarm input signal for servo motor

Deviation counter clear output signal for servo motor (shared with general

output 1 point)

Emergency stop input signal for all axis

CN2 Connector Pin Assignments

nP+P/N, nP-P/N

nLMT+, nLMT-

nSTOP0, nSTOP1, nSTOP2

nINPOS, nALARM

nOUT0/DCC

EMG

A2 A1

B2 B1

A1

B1

Pin 1 Mark

Cable (included, 1.2m)

A50

B50

When implemented in PC, the connector may be upside down occasionally.

A50 A49

B50 B49

The cable (included) is A1, A2, … A49, A50 from the right (red) of the upper cable to the left, and B1, B2,

… B49, B50 from the right (red) of the lower cable to the left when Pin 1 mark (▲) of the connector is

placed in the upper right.

Connector type: Board side FX2B-100PA-1.27DS (Hirose), Cable side FX2B-100SA-1.27R (Hirose)

- 4 -

NOVA electronics MC8022P/MC8042P - 5

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

CN2 Connector

Pin Signal I/O Content Chapter

*Note2

1 VEX External Power (+24V) 3.12 B1 EMG Input Emergency Stop (All

2 XLMT+ Input X axis Limit in + direction 3.5

3 XLMT- Input X axis Limit in – direction 3.5

4 XSTOP0 Input X axis Decelerating Stop /

Instant Stop

5 XSTOP1 Input X axis Decelerating Stop /

Instant Stop

6 YLMT+ Input Y axis Limit in + direction 3.5

7 YLMT- Input Y axis Limit in – direction 3.5

8 YSTOP0 Input Y axis Decelerating Stop /

Instant Stop

9 YSTOP1 Input Y axis Decelerating Stop /

Instant Stop

10 ZLMT+ Input Z axis Limit in + direction 3.5 MC8042P

11 ZLMT- Input Z axis Limit in – direction 3.5 MC8042P

12 ZSTOP0 Input Z axis Decelerating Stop /

Instant Stop

13 ZSTOP1 Input Z axis Decelerating Stop /

Instant Stop

14 ULMT+ Input U axis Limit in + direction 3.5 MC8042P

15 ULMT- Input U axis Limit in – direction 3.5 MC8042P

16 USTOP0 Input U axis Decelerating Stop /

Instant Stop

17 USTOP1 Input U axis Decelerating Stop /

Instant Stop

18 XSTOP2 Input X axis Encoder Z-phase 3.7

19 XINPOS Input X axis Inposition 3.8

20 XALARM Input X axis Alarm 3.8

21 YSTOP2 Input Y axis Encoder Z-phase 3.7

22 YINPOS Input Y axis Inposition 3.8

23 YALARM Input Y axis Alarm 3.8

24 ZSTOP2 Input Z axis Encoder Z-phase 3.7 MC8042P

25 ZINPOS Input Z axis Inposition 3.8 MC8042P

26 ZALARM Input Z axis Alarm 3.8 MC8042P

27 USTOP2 Input U axis Encoder Z-phase 3.7 MC8042P

28 UINPOS Input U axis Inposition 3.8 MC8042P

29 UALARM Input U axis Alarm 3.8 MC8042P

30 GND Internal Circuit GND

31 XOUT0/DCC Output X axis General Output/DCC

*Note1

32 YOUT0/DCC Output Y axis General Output/DCC 3.4

33 ZOUT0/DCC Output Z axis General Output/DCC 3.4 MC8042P

34 UOUT0/DCC Output U axis General Output/DCC 3.4 MC8042P

35 XP+P Output X axis Drive Pulse in + direction 3.3

36 XP+N Output X axis Drive Pulse in + direction 3.3

37 XP-P Output X axis Drive Pulse in – direction 3.3

38 XP-N Output X axis Drive Pulse in – direction 3.3

39 YP+P Output Y axis Drive Pulse in + direction 3.3

40 YP+N Output Y axis Drive Pulse in + direction 3.3

41 YP-P Output Y axis Drive Pulse in – direction 3.3

42 YP-N Output Y axis Drive Pulse in – direction 3.3

43 ZP+P Output Z axis Drive Pulse in + direction 3.3 MC8042P

44 ZP+N Output Z axis Drive Pulse in + direction 3.3 MC8042P

3.6

3.6

3.6

3.6

3.6 MC8042P

3.6 MC8042P

3.6 MC8042P

3.6 MC8042P

3.4

Pin Signal I/O Content Chapter

3.11

axes)

- 5 -

NOVA electronics MC8022P/MC8042P - 6

A

A

A

A

A

A

y

45 ZP-P Output Z axis Drive Pulse in – direction 3.3 MC8042P

46 ZP-N Output Z axis Drive Pulse in – direction 3.3 MC8042P

47 UP+P Output U axis Drive Pulse in + direction 3.3 MC8042P

48 UP+N Output U axis Drive Pulse in + direction 3.3 MC8042P

49 UP-P Output U axis Drive Pulse in – direction 3.3 MC8042P

50 UP-N Output U axis Drive Pulse in – direction 3.3 MC8042P

Note1: DCC (Deviation Counter Clear): Output to clear the deviation counter of a servo motor driver.

*

*Note2: MC8042P: The signals which only MC8042P has. MC8022P doesn’t.

Note: When connecting or disconnecting the cable into the CN2 connector, turn OFF PC first and turn OFF external

power (DC+24V), then connect or disconnect the cable. Otherwise, the destruction of the internal circuit may be

caused. Be careful about the connector direction and not to reverse it.

3.2 CN3, 4 Connector (Connector on the board)

CN3, 4 connectors on the board input/output signals of each axis as shown below.

Connector Signal Type Signal Name

CN3

Driving by external input signal in the +/– direction (can be used as general

input)

Encoder A/B phase input signal

nEXOP+, nEXOP–

nECAP/N, nECBP/N

CN4 General output signal OUT1~14

CN3, 4 Connector Pin Assignments

Mounting face

Rear face

1

29

30

Connector: HIF3FC-30PA-2.54DS (Hirose)

Socket (included): HIF3BA-30D-2.54R

(Optional accessor

49

2

50

CN3(50P)CN4(30P)

Connector: HIF3FC-50PA-2.54DS (Hirose)

Socket (included): HIF3BB-50D-2.54R

(Optional accessory)

1

2

CN2

- 6 -

NOVA electronics MC8022P/MC8042P - 7

X

Y

Z

X

X

Y

Y

Z

Z

CN3 Connector

Pin Signal I/O Content

1 VEX

3

EXOP+

5

EXOP+

7

EXOP+

9

UEXOP+

11

13

15

17

19

ECAP

21

ECBP

23

ECAP

25

ECBP

27

ECAP

29

ECBP

31

UECAP

33

UECBP

35

37

39

41

43

45

47

49

*Note2: MC8042P: The signals which only MC8042P has. MC8022P doesn’t.

External Power(+24V)

X axis Driving by External

Input

Signal in + direction

Y axis Driving by External

Input

Signal in + direction

Z axis Driving by External

Input

Signal in + direction

U axis Driving by External

Input

Signal in + direction

12

14

16

18

Input

X axis Encoder A phase (+) 3.9 20 XECAN Input X axis Encoder A phase (–) 3.9

Input

X axis Encoder B phase (+) 3.9 22 XECBN Input X axis Encoder B phase (–) 3.9

Input

Y axis Encoder A phase (+) 3.9 24 YECAN Input Y axis Encoder A phase (–) 3.9

Input

Y axis Encoder B phase (+) 3.9 26 YECBN Input Y axis Encoder B phase (–) 3.9

Input

Z axis Encoder A phase (+)

Input

Z axis Encoder B phase (+)

Input U axis Encoder A phase (+)

Input U axis Encoder B phase (+)

36

38

40

42

44

46

48

50

Chapter

Pin Signal I/O Content

3.12 2 VEX

3.10 4 XEXOP- Input

3.10 6 YEXOP- Input

3.10

8 ZEXOP- Input

*Note2

3.10

10 UEXOP- Input

*Note2

3.9

28 ZECAN Input Z axis Encoder A phase (–)

*Note2

3.9

30 ZECBN Input Z axis Encoder B phase (–)

*Note2

3.9

32 UECAN Input U axis Encoder A phase (–)

*Note2

3.9

34 UECBN Input U axis Encoder B phase (–)

*Note2

External Power(+24V)

X axis Driving by External

Signal in - direction

Y axis Driving by External

Signal in - direction

Z axis Driving by External

Signal in - direction

U axis Driving by External

Signal in - direction

Chapter

3.12

3.10

3.10

3.10

*Note2

3.10

*Note2

3.9

*Note2

3.9

*Note2

3.9

*Note2

3.9

*Note2

CN4 Connector

Pin Signal I/O Content

1 VEX

3 4

5 6

7 8

9 OUT1/PA6 Output General Output1 3.4 10 OUT2/PA7 Output General Output2 3.4

11 OUT3/PB0 Output General Output3 3.4 12 OUT4/PB1 Output General Output4 3.4

13 OUT5/PB2 Output General Output5 3.4 14 OUT6/PB3 Output General Output6 3.4

15 OUT7/PB4 Output General Output7 3.4 16 OUT8/PB5 Output General Output8 3.4

17 OUT9/PB6 Output General Output9 3.4 18 OUT10/PB7 Output General Output10 3.4

19 OUT11/PC0 Output General Output11 3.4 20 OUT12/PC1 Output General Output12 3.4

21 OUT13/PC2 Output General Output13 3.4 22 OUT14/PC3 Output General Output14 3.4

23 24

25 26

27 GND Internal Circuit GND 28 GND Internal Circuit GND

29 GND Internal Circuit GND 30 GND Internal Circuit GND

External Power(+24V)

Chapter

Pin Signal I/O Content

3.12 2 VEX

External Power(+24V)

Chapter

3.12

- 7 -

NOVA electronics MC8022P/MC8042P - 8

3.3 Drive Pulse Output Signal (nP+P, nP+N, nP-P, nP-N)

Drive pulse output signal outputs the drive pulse of +/– direction of MCX304 through a differential line-driver output

(AM26C31 or equivalent). nP+N is the reverse output of nP+P and nP-N is the reverse output of nP-P. At resetting, positive

output (nP+P, nP-P) becomes lo w level and reverse output (nP+ N, nP-N) becomes hi level. Drive pulse output is set to

independent 2-pulse type after resetting; however, the user can change to 1-pulse 1-direction type in mode setting. See chapter

2.6.2 and 4.5 of MCX304 user’s manual.

MCX304

nPP/PLS

AM26C31C or equivalent

nPM/DIR

nP+P

nP+N

nP-P

nP- N

Drive Pulse Output Signal Circuit

The following is the connection example of a motor driver with a photo coupler input and line receiver input.

MC8022P/MC8042P

AXP+P

AXP+N

AXP- P

AXP- N

CCW+

CCW-

Motor driver

CW+

CW-

Connection example of a motor driver with a photo coupler input

AXP+P

AXP+N

AXP- P

CW+

CW-

CCW+

+

-

AM26LS32

+

AXP- N

GND

CCW-

Twist Pair Shield

GND

Motor driver

Signal GND Line

-

AM26LS32

Connection example of a motor driver with a line receiver input

Note1: As shown above, when using a line receiver input circuit, connect MC8022P/MC8042P and a motor driver with GND

line. If there is the potential difference between MC8022P/MC8042P and motor driver, the malfunction and destruction of a

driver circuit and/or a motor driver circuit may be caused.

3.4 General Output Signal and Deviation Counter Clear Output Signal (OUT1~14, nOUT0/DCC)

General output signal outputs 14 points from PIX132 and one nOUT0/DCC output signal in MCX304 through buffer (TD62503).

nOUT0 signal is shared with deviation counter clear output (DCC) and is output from CN2 connector. Also other general output

signals: OUT1~14 are output from CN4 connector. At resetting, all the output signals (open collector output) will be OFF.

- 8 -

NOVA electronics MC8022P/MC8042P - 9

■ OUT1~14 Output

PIX132

Port Output

Port Output

・

・

・

・

・

TD62503

OUT1

・

・

・

・

・

OUT14

GND

Output voltage:35V(max)

Output current:100mA(max)

2.7K

in

10K

TD62503(Toshiba)internal circuit

out

General Output Circuit

OUT1~14 general output signals are output from CN4. ON/OFF of this signal can be controlled by writing to each port of PIX132

(NOVA electronics). Each port is set to output and becomes OFF when the PC system is started.

General Output Signal(CN4pin),Register Bit Table

CN4 PIX132

Pin # Output signal Port address Bit position

9

10

11

12

13

14

15

16

17

18

19

20

21

22

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

OUT8

OUT9

OUT10

OUT11

OUT12

OUT13

OUT14

0x14

0x14

0x15

0x15

0x15

0x15

0x15

0x15

0x15

0x15

0x16

0x16

0x16

0x16

6

7

0

1

2

3

4

5

6

7

0

1

2

3

ON/OFF of OUT1~14 output signals can be controlled by the following steps (1)~(4) on the program.

(1) Read current output data.

・Check the port address of the signal which the user wants to output and bit position according to the table above.

・Read the current output of the port.

Function: Nmc_InPort Current output data: mcb0pa

mcb0pa = Nmc_InPort(

Board number, Port address);

0x14, 0x15, 0x16

0x0~0xF

Example) Read the output data of the port which includes OUT1 output signal. mcb0pa = Nmc_In Port(0x0, 0x14);

(2) When turning ON the output.

・Set 1 to the bit corresponding to the signal which the user wants to turn ON.

・Example) When turning ON OUT1 output signal

mcb0pa = mcb0pa | 0x40;

(OUT1 is bit position 6, OR bit pattern is 0x40.)

(3) When turning OFF the output.

・Set 0 to the bit corresponding to the signal which the user wants to turn OFF.

・Example) When turning OFF OUT1 output signal.

mcb0pa = mcb0pa & 0xbf; (OUT1 is bit position 6, AND bit pattern is 0xbf.)

(4) Set the output data.

・Write the output data which is calculated by (2) or (3) to the port.

Function: Nmc_OutPort(Board number, Port address, Output data);

Example) Write the output data to the port Nmc_OutPort(0x0, 0x14, mcb0pa);

Examples of ON/OFF control of general output signals are described in sample program, so refer to it.

- 9 -

NOVA electronics MC8022P/MC8042P - 10

■ nOUT0/DCC Output

MCX304

nDRIVE/

OUT0/DCC

TD62503(Toshiba)

nOUT0/DCC

GND

nOUT0/DCC output is shared with general output signal (nOUT0) and deviation counter clear output (DCC), and is output to CN2.

At resetting, it will be OFF. Control of this signal is different from other general output, it can be performed by writing to the

register of MCX304.

When used as general output.

(1) To enable nOUT0 output, set the nOT0E bit of MCX304/WR5 to 1.

(2) Turn ON: Set the nOUT0 bit of MCX304/WR4 to 1. Turn OFF: Set the nOUT0 bit of MCX304/WR4 to 0.

When used as deviation counter clear output.

Deviation counter clear output is the output to clear a deviation counter in a servo motor driver. MCX304 has the function to

output this deviation counter clear signal during automatic home search.

For setting of a deviation counter clear enable, a logical level and pulse width, see chapter 2.4.3 of MCX304 user’s manual. And

for automatic home search details, see chapter 2.4. As shown in the figure above, TD62503 is used as buffer on the board, so that

the board output (open collector) turns ON when MCX304 output is active Hi.

3.5 Over Run Limit Input Signal (nLMT+, nLMT-)

It is the input signal to stop each drive pulse in the +/ – direction. This input signal is connected to the limit input of MCX304

through a photo coupler. After resetting, MCX304 becomes low active, so limit function works when electric current flows from a

signal pin (nLMT+, nLMT-). For more details on mode setting, see chapter 4.5 of MCX304 user’s manual.

To enable this signal, external power supply DC24V is needed. When the board is powered on, a built-in filter of this signal

becomes the setting of signal delay time 512μsec as default. This signal delay time can be changed for circumstances of system

noise. For more details, see chapter 2.6.9 and 4.6 of MCX304 user’s manual.

nLMTP

nLMTM

+5V

10K

TLP281 or equivalent

+5V

8.2K

VEX(+24V)

nLMT+

nLMT-

MCX304

Built-in fi lter

Built-in filter

Delay time: 512µSEC (default)

Over Run Limit Input Signal Circuit

The connection example of an over run limit input signal and a photo microsensor is shown below. When D3 bit of X axis mode

register 2 (XWR2) is set to 0 (the mode at reset), limit function becomes active at the light interception.

MC8022P/

MC8042P

VEX

+

DC24V Power

-

AXLMT+

MCX304 X axis mode register 2 WR2/D3 bit:0

Connection Example of Over Run Limit Input Signal and Photo Microsensor

When long wiring is needed, use the shield cable.

- 10 -

EE- SX670(Omron)

+

L

OUT

-

Active at the light interception

NOVA electronics MC8022P/MC8042P - 11

3.6 Decelerating Stop / Instant Stop (nSTOP0, nSTOP1)

Input signal to stop drive pulse output in deceleration or immediately. Generally, nSTOP0 signal is used a s a near home signal and

nSTOP1 signal is used as a home signal. MCX304 has three signals, STOP2~STOP0 for each axis as a home search input signal;

however, STOP2 is equipped with an interface circuit for encoder Z-phase. STOP1 signal is used as an input signal for home and

STOP0 is for near home.

[Enable/Disable and Logical setting]

Each input signal can be set enable/disable and logical level in mode setting. When enable is set in mode setting, and when this

signal becomes active during driving, drive pulse output stops. When during acceleration/deceleration driving, it stops in

deceleration and when during constant driving, it stops immediately. After resetting, all the signals are disabled. For instant, when

D1, D0 bit of XWR1 register is set to 1, 0 and set to low level and enable, and when current flows out from XSTOP0 signal pin

(CN2-A4) of this board, driving stops. For more details on mode setting, see chapter 4.4 of MCX304 user’s manual.

[Automatic Home Search]

MCX304 has automatic home search function. See chapter 2.4 of MCX304 user’s manual.

To perform high-speed home search → low-speed home search by only one signal, use nSTOP0 signal and switch JP3 jumper to

UPPER side as follows:

MCX304

Built-in filter

nSTOP0

+5V

VEX (+24V)

10K

Built-in filter

Delay time

:

512µSEC(Default)

nSTOP1

Factory setting

JP3

UPPER

LOWER

8.2K

TLP281 or equivalet

+5V

nSTOP0

nSTOP1

Decelerating Stop/ Instant Stop Input Signal Circuit

To enable this signal, external power supply DC24V is needed. When the board is powered on, a built-in filter in this signal

becomes the setting of signal delay time 512μsec as default. This signal delay time can be changed for circumstances of system

noise. For more details, see chapter 2.6.9 and 4.6 of MCX304 user’s manual.

This signal can read out the signal status by input register 1, 2 (RR4, 5) at any time, so it can be used as general input.

- 11 -

NOVA electronics MC8022P/MC8042P - 12

3.7 Encoder Z-phase Input Signal (nSTOP2)

nSTOP2 input signal is to stop drive pulse output during driving by connecting to the Z-phase output signal of an encoder or a

servo motor driver.

To enable this signal, external power supply DC24V is needed. When the board is powered on, a built-in filter in this signal

becomes the setting of signal delay time 512μsec as default. This signal delay time can be changed for circumstances of system

noise. For more details, see chapter 2.6.9 and 4.6 of MCX304 user’s manual.

[Enable/Disable and Logical setting]

nSTOP2 signal can be set enable/disable and logical level in mode setting as well as nSTOP1, 0 signal. For instant, when D5, D4

bit of WR1 register is set to 1, 0 and set to low and enable, and when current flows out from nSTOP2 signal pin of this board,

driving stops. For more details on mode setting, see chapter 4.4 of MCX304 user’s manual.

[Jumper setting]

This input signal can be adapted to either open collector output or line-driver output of the other output side by switching JP4

jumper. When the other side is open collector output, set JP4 to LOWER side (factory setting) and when is line-driver output, set

JP4 to UPPER side and connect nSTOP2 signal to one side of line-driver output.

MCX304

Built-in f ilter

nSTOP2

+5V

10K

1K

+5V

JP4

VEX (+24V)

8.2K

UPPER

LOWER

(Factory setting)

TLP281 or equivalent

Delay time: 512µSEC(default)

nSTOP2

Encoder Z-phase Input Signal Circuit

[Notes on Z-phase search]

Drive speed of Z-phase search

When this board is powered on, a built-in filter of nSTOP2 signal becomes the setting of signal delay time 512μsec as default. In

addition, TLP281 photo coupler (Toshiba) has approximately 100μsec delay time, so that the drive speed to search Z-phase must

be set for Z-phase signal to be active more than 1msec at least. When noise circumstances are good, search operation can be

performed at the higher speed by disabling the built-in filter of STOP2 signal.

Starting position for Z-phase search

In automatic home search of MCX304, the function stops search driving when the Z-phase signal (nSTOP2) changes from inactive

to active. Therefore, the starting position for Z-phase search must be completely away from this change point. Normally, adjust

mechanically so that this starting position becomes the 180°opposite side to the encoder Z-phase position.

The connection example of nSTOP2 input signal and open collector output of an encoder is shown below. When open collector

output is ON at Z-phase detected, set the D4 bit (SP2-L) of WR1 register to 0 (state of reset) for logical setting of MCX304.

MCX304

Built-in filter

JP4: Set to LOWER side

+5V

nSTOP2

10K

TLP281 or equivalent

MC8022P/

MC8042P

JP4

LOWER

nSTOP2

8.2K

VEX

+

DC24Vpower

-

Encoder

VCC

Open collector output

EC-Z

GND

Connection Example with Z-phase Output of open collector

The following is the connection example of nSTOP2 input signal and one pin of line-driver output of an encoder. When output is

low level at Z-phase detected, set the D4 bit (SP2-L) of WR1 register to 0 (state of reset) for logical setting of MCX304.

- 12 -

NOVA electronics MC8022P/MC8042P - 13

MC8022P/

MC8042P

JP4

UPPER

nSTOP2

GND

Encoder

EC- Z

GND

MCX304

Built-in filter

JP4:Set to UPPER side

+5V

nSTOP2

10K

TLP281 or equivalent

+5V

1K

Connection Example with Z-phase Output of line-driver

3.8 Input Signals for Servo Motor (nINPOS, nALARM)

nINPOS input signal is applied to the in-position output of a servo motor driver. Enable/disable and logical level can be set in

mode setting of MCX304. When enable is set and after completion of the driving, nDRV bit of main status register (RR0) returns

to 0 after this signal becomes active.

nALARM input signal is applied to the alarm output from a servo motor driver. Enable/disable and logical level can be set in

mode setting. When enable is set, nALARM input signal is monitored, and when nALARM is active, the ALARM bit of status

register 2 (nRR2) is set to 1. When the signal becomes active during driving, driving will stop immediately.

After resetting, both signals are disabled. For nINPOS input signal, set the D15, 14 bit of mode register 2 (nWR2) of MCX304 to

1,0 as low level active, and the n-DRV bit of RR0 register returns to 0 after waiting to flow current from nINPOS signal. For

nALARM input signal, set the D13, 12 bit of nWR2 register to 1,0 as low level active, and the signal becomes an alarm state when

current flows from nALARM signal pin. For more details, see chapter 2.6.5 and 4.5 of MCX304 user’s manual.

nINPOS

nALARM

+5V

10K

TLP281 or equivalent

+5V

8.2K

VEX (+24V)

nINPOS

nALARM

MCX304

Built-in filter

Built-in filter

Delay time: 512µSEC (default)

Input Signal Circuit for Servo Motor

To enable this signal, external power supply DC24V is needed. When the board is powered on, a built-in filter in this signal

becomes the setting of signal delay time 512μsec as default. This signal delay time can be changed for circumstances of system

noise. For more details, see chapter 2.6.9 and 4.6 of MCX304 user’s manual.

In addition, the input signal for a servo motor can read out the signal status by input register 1, 2 (RR4, 5) at any time, so it can be

used as general input.

- 13 -

NOVA electronics MC8022P/MC8042P - 14

3.9 Encoder A/B phase Input Signal (nECAP, nECAN, nECBP, nECBN)

nECAP/N, nECBP/N, input signals are the input to count a real position counter of MCX304 by connecting to the 2-phase output

signal of an encoder or a servo motor driver. For more details, see chapter 2.3.1, 2.6.3 and 4.5 of MCX304 user’s manual.

MCX304

nECA/PPIN

nECB/PMIN

+5V

750

+5V

TLP115A

220

1K

nECAP

nECAN

nECBP

nECBN

Encoder A/B phase Input Signal Circuit

As shown above, encoder A/B phase input signal circuit uses high-speed photo coupler IC TLP115A (Toshiba). Each input signal

can be directly connected to a differential line-driver output. As the figure below, when n***P/N signal is H/L, n*** signal of

MCX304 becomes Low and when is L/H, it becomes Hi. The delay time from input to the signal pin of MCX304 is under

100nSEC, so that the signal can count up to 4MHz in the case of 2-phase pulse input.

Input Signal

MCX304 Signal

n***P

n***N

n***

H

L

L

L

H

H

The connection example of an encoder A/B phase input signal and a differential line-driver output is shown as follows:

MC8022P/

MC8042P

XECAP

XECAN

CN3

Encoder

EC-A

AM26LS31

XECBP

EC- B

XECBN

Connection Example with Differential line-driver Output

The connection example of an encoder A/B phase input signal and an encoder with open collector output is shown as follows:

MC8022P/

MC8042P

XECAP

XECAN

XECBP

XECBN

CN3

R

R

Power Voltage(V)

12

24

R(Ω)

5

0

820 1/4W

2K 1W

+

-

DC Power

VCC

EC-A

EC-B

GND

Encoder

Connection Example with Open Collector Output

- 14 -

NOVA electronics MC8022P/MC8042P - 15

3.10 Driving by External Signal (nEXOP+, nEXOP-)

The signal externally controls driving in the + or – direction. In fixed driving mode, the falling edge of these signals trigger

outputs specified drive pulse. In continuous driving mode, drive pulse is output continuou sly while the input signals are low. This

function can reduce the load of the host CPU, so the user can perform jog feed of each axis speedy. External signal for driving can

be set in mode setting of MCX304. For more details, see chapter 2.6.1 and 4.6 of MCX304 user’s manual.

nEXPP

nEXPM

+5V

10K

TLP281 or equivalent

+5V

8.2K

VEX (+24V)

nEXOP+

nEXOP-

MCX304

Built- in filter

Built-in filter

Delay time: 512µSEC (default)

External Driving Signal(nEXOP+/-) Circuit

To enable this signal, external power supply DC24V is needed. When the board is powered on, a built-in filter in this signal

becomes the setting of signal delay time 512μsec as default. This signal delay time can be changed for circumstances of system

noise. For more details, see chapter 2.6.9 and 4.6 of MCX304 user’s manual.

3.11 Emergency Stop Input Signal (EMG)

All the drive pulse output stops when emergency stop signal becomes active. Active level can be switched by the JP2 jumper pin

on the board. When emergency stop signal becomes active during driving, driving for all axes stops instantly and 1 is set to the

error bit of all axes of main status register. For emergency stop of MCX304, see chapter 2.6.6 and 4.1.2 of MCX304 user’s

manual.

MCX304

Built-in filter

EMGN

1

3

JP2:EMG level switching

2

4

(1- 2 short-circuited

in factory default)

74HC14 or equivalent

JP2

+5V

10K

TLP281 or equivalent

8.2K

VEX (+24V)

EMG

Emergency Stop Input Signal Circuit

To enable this signal, external power supply DC24V is needed. When the board is powered on, a built-in filter in this signal

becomes the setting of signal delay time 512μsec as default. This signal delay time can be changed for circumstances of system

noise. For more details, see chapter 2.6.9 and 4.6 of MCX304 user’s manual.

JP2

1

34

Pin assignments of the JP2 jumper is shown on the left.

2

1-2 short circuit: When emergency stop signal (EMG) is short-circuited with GND of the external power, it becomes

active.

3-4 short circuit: When emergency stop signal (EMG) is open, it becomes active.

Factory default is 1-2 short-circuited.

3.12 External Power (VEX)

The power supplied externally is used for over run limit input signal (nLMT+, nLMT–) of each axis, decelerating stop/instant stop

(nSTOP0, nSTOP1, nSTOP2) input signal, input signal for servo motor (nINPOS, nALARM), external signal for driving

(nEXOP+, nEXOP–) and emergency stop input signal (EMG). DC24V is needed. Consumption current is 2.8mA per 1 input

signal.

- 15 -

NOVA electronics MC8022P/MC8042P - 16

4. Interrupt

This board has an interrupt signal generated by MCX304, which connect to the INTA# of four interrupt request signals in the

PCI bus. When an interrupt occurs in MCX304, the interrupt request signal of this board changes from Hi to Low. By reading

out the status register 3 (nRR3) of the axis generated the interrupt, the interrupt request signal returns from Low to Hi.

For the interrupt function of MCX304, please refer to the following.

Article Reference manual

Function of the interrupt Chapter 2.5 of MCX304 user’s manual

Setting of the interrupt enable / disable Chapter 4.4 of MCX304 user ’s manual

Interrupt notion to the application MC8000P User’s manual of device driver

When handling the interrupt by VC in Chapter 3.4.3

Chapter 4.13 of MCX304 user’s manual Reading out of the interrupt generation

MC8000P User’s manual of device driver

When handling the interrupt by VC in Chapter 3.4.3

[Notes for using interrupt]

IRQ number for the interrupt signal of this board is determined depending on PnP function.

In addition, it shares the same interrupt request signal with other devices by PnP function and Windows, competition is not

occurred because Windows generally controls it.

- 16 -

NOVA electronics MC8022P/MC8042P - 17

5. Connection Example for Motor Driver

5.1 Connection Example for Stepper Motor Driver

The figure shown below illustrates the connection example of MC8022P/MC8042P X axis and the 5-phase micro step driver of

TECHNO DRIVE KR535M.

MC8022P/

MC8042P

CN2 Connector

XP+P

XP+N

XP- P

XP-N

XOUT0

A35

A36

A37

A38

A31

Set JP4/AX

to UPPER.

+

DC5V Power

-

Source

CW pulse

CCW pulse

Hold OFF

5- phase micro step driver

KR-535M

F+

FR+

RH.O+

H.O-

XSTOP2

GND

A18

A30

Excitation timing

Z.P+

Z.P-

Note1: Wire hold OFF and excitation timing signals according to need. The hold off signal can be controlled by writing 0, 1 into

the D0 bit of MCX304 WR4 register after the D0 bit of WR5 register is 1 for enabling XOUT0 signal. The excitation timing

signal can perform a home search by the mode setting of WR1 register D4, 5 bit. In addition, the excitation timing signal can

directly read out the signal level through the RR4 register.

Note2: When the circumstances are affected by strong noise or there is long distance to the driver, the twist pair shield cable

shown above is recommended.

The figure shown below illustrates the connection example of MC8022P/MC8042P X axis and the stepper motor driver of

Oriental Motor UPK series.

MC8022P/

MC8042P

CN2 Connector

XP+P

XP+N

XP- P

XP- N

GND

XOUT0

GND

VEX

XSTOP2

XALARM

A35

A36

A37

A38

A31

A30

A1

A18

A20

Set JP4/AX

to LOWER

CW pulse

CCW pulse

2KΩ1W

Hold OFF

+

DC24V Power

-

.

Source

Excitation timing

Over heat

UPK series

Driver

CW+

CWCCW+

CCW-

H.OFF+

H.OFF-

TIMING

O.HEAT

COM

Note1: Wire hold OFF, excitation timing and over heat signals according to need. The hold off signal can be controlled by

writing 0, 1 into the D0 bit of MCX304 WR4 register after the D0 bit of WR5 register is 1 for enabling XOUT0 signal. The

excitation timing signal can perform a home search by the mode setting of the WR1 register D4, 5 bit. The over heat signal can

perform an alarm function by the mode setting of the WR2 register D12, 13 bit. In addition, the excitation timing and over heat

signals can directly read out the signal level through the RR4 register.

Note2: When the circumstances are affected by strong noise or there is long distance to the driver, the twist pair shield cable

shown above is recommended.

- 17 -

NOVA electronics MC8022P/MC8042P - 18

5.2 Connection Example for AC servo motor driver

The figure shown below illustrates the connection example of MC8022P/MC8042P X axis and the AC servo motor driver of

MINAS S series.

MC8022P/MC8042P

CN2 Connector

A35

XP+P

A36

XP+N

A37

XP- P

A38

XP- N

A1

VEX

GND

CN3

A18

A20

A19

A31

A30

19

20

21

22

XSTOP2

XALARM

XINPOS

XOUT0/DCC

XECAP

XECAN

XECBP

XECBN

CN4

XOUT1

XOUT2

GND

27

CW pulse

CCW pulse

Encoder Z- phase

Servo alarm

Positioning completion

Deviation counter clear

Encoder A- phase

Encoder B- phase

3

4

Servo on

Alarm reset

+

DC24V Power

-

Source

MINASSseries

CN I/F

23

PULS2

22

PULS1

25

SIGN2

24

SIGN1

21

CZ

14

GND

1

COM+

9

ALM

10

COIN

13

COM-

4

CL

15

OA+

16

OA-

17

OB+

18

OB-

2

SRV- ON

3

A- C L R

CN2

+

XLMT+

A2

L

OUT

CW direction

Limit

-

+

XLMT-

A3

L

OUT

CCW direction

Limit

-

+

XSTOP

A5

1

L

OUT

Home

-

+

XSTOP0

A4

L

OUT

Near home

-

EE-SX670 (Omron)

Note1: Set the mode of MINAS driver control to the position control mode and the pulse form to CW/CCW pulse mode. Do not

set the pulse form to Pulse/Sign mode because the lack of t6 time occurs.

Note2: Use encoder A/B phase signals when the user counts a real position counter in MCX3 04. If the real position data is not

necessary, no need to connect them. For other signals, connect them according to need.

Note3: In this example, encoder Z-phase uses the open collector output of driver side, so set JP4 to Lower side (default).

Note4: In this example, a near home signal and home signal are each connected for the home signal, so set JP3 to LOWER side

(default).

Note5: When the circumstances are affected by strong noise or the distance to the driver is long, the twist pair shield cable

shown above is recommended.

- 18 -

NOVA electronics MC8022P/MC8042P - 19

6. Input/Output Signals Timing

6.1 Reset

+5V

TRESET#

nP±P

nP±N

Read/Write to this board

Low

Hi

①

Disable

②

Enable

① Drive pulse output signals (nP±P, nP±N) are determined within a maximum of 250nSEC from ↓ of the target reset signal

(TRESET#) of APIC21 (ADTEC).

② Writing/Reading to this board can be performed after 500nSEC from ↑ of the target reset signal (TRESET#).

6.2 Beginning of Driving

*

IOW

nP±P

nP-P

(Direction Signal)

←

Writing of Drive Command.

Previous State

①

②

③

Valid Level

First Puls e Second Pulse

① First drive pulse is output within a maximum of 650nSEC after writing of drive command.

②③ When drive output pulse is 1-pulse type, a direction signal (nP-P) beco mes valid level within a maximum of 275nSEC

after writing of drive command. And first drive pulse is output after 375nSEC when the direction signal becomes valid level.

6.3 Input Pulse Timing

■ Encoder 2-phase Pulse Input

Count Up Count Down

nECAP

nECAN

nECBP

nECBN

①①①

① EC-A,EC-B phase difference time : 200nSEC min.

①

①①

①①

- 19 -

NOVA electronics MC8022P/MC8042P - 20

■ Up/Down Pulse Input

nECAP

nECAN

nECBP

nECBN

①

①

③

②

①

①

③

① UP/DOWN pulse width : 130nSEC min. ② UP⇔DOWN between the pulses : 260nSEC min.

③ UP/DOWN pulse cycle : 260nSEC min.

6.4 Instant Stop Timing

■ Instant Stop by External Signal

EMG,nLMT±

nSTOP2,1,0

nP±P

① When an external stop signal becomes valid level during driving, the driving stops after photo coupler delay time (100μsec

max.) + the delay time of IC built-in integral filter (512μsec default) + 1 drive pulse.

Valid Level

①

■ Instant Stop by Command

←

WRN

Writing of Stop Command

nP±P

②

② When stop command is written during drivin g, the driving stops after a maximum of 1 drive pulse.

6.5 Decelerating Stop Timing

■ Decelerating Stop by External Signal

nLMT±

nSTOP2,1,0

nP±P

① When an external decelerating stop signal becomes valid level during driving, the driving starts deceleration after photo

coupler delay time (100μsec max.) + the delay time of IC built-in integral filter (512μsec default) + 2 drive pulses.

Valid Level

①

■ Decelerating Stop by Command

←

WRN

nP±P

② When decelerating stop command is written during driving, the driving starts deceleration after a maximum of 2 drive

pulses.

Writing of Decelerating Stop Command.

②

- 20 -

NOVA electronics MC8022P/MC8042P - 21

7. Board Dimensions

21.6

17.2

11.4

(1.9)

176.5

174.6

unit:mm

2-φ3.2

CN3

B50

A50

UPPER

JP4

126.5

CN2

A1

B1

CN2

15 25.8

SW1

0

C

4

8

CN1 PCI bus connector

B1

APIC21

63.7

LOWER

B49

AXBXAYBYAZBZAU

JP1

B52

15.4

CN4

BU

AXAYAZAUBXBYBZ

B62

BU

UPPER

LOWER

JP3

JP2

2

1

4

3

Soldered surfaceA1 ~A49,A52 ~A62

PIX132

MCX304

5.1

89.5

106.7

3.8

8.3

JP1: Keep 1-2 short circuit (default).

JP2: Select active logical level for emergency stop signal (EMG).

1-2 short circuit (default): When the signal is short-circuited with GND, it becomes active.

3-4 short circuit: When the signal is open, it becomes active.

JP3: Select a home search signal. See chapter 3.6.

LOWER (default): Use STOP0 as a near home signal and STOP1 as a home signal.

UPPER: Use only STOP0 to perform high-speed home search → low-speed search.

*Axis assignment of MC8022P is executed by AX and AY, of MC8042P is executed by AX, AY, AZ

and AU.

JP4: Select STOP2 (Encoder Z-phase) input circuit. See chapter 3.7.

LOWER (default): For the open collector output.

UPPER: For the line-driver output.

*Axis assignment of MC8022P is executed by AX and AY, of MC8042P is executed by AX, AY, AZ

and AU.

SW1: Rotary switch to set the board number when multiple boards are used, which can be set from 0

to F (default setting: 0).

- 21 -

NOVA electronics MC8022P/MC8042P - 22

8. Specifications

Control Axis MC8022P: 2 axes (Independent, Simultaneous Control)

MC8042P: 4 axes (Independent, Simultaneous Control)

PCI Bus Interface

Data Bit Width 16 bit

Common Specifications of Each Axis

Drive Pulses Output

Pulse Output Circuit Differential line-driver (AM26C31) output

Pulse Output Speed 1PPS ~ 4MPPS

Pulse Output Speed Accuracy ± 0.1% (according to the setting speed)

477 x 10

Accelerating / Decelerating Speed 125 ~ 1 x 10

62.5×103 ~ 500 x 10

Initial Speed 1 ~ 8,000PPS (Multiple = 1)

500PPS ~ 4×10

Drive Speed 1 ~ 8,000PPS (Multiple = 1)

500PPS ~ 4×10

Output-pulse Number 0 ~ 268,435,455 (fixed drive)

Speed Curve Constant speed, linear acceleration/deceleration, parabola S-curve

Fixed Drive Deceleration Mode Auto (non-symmetrical trapezoidal acceleration is also allowed) / manual

Output-pulse numbers and drive speeds changeable during the driving

Logical levels of drive pulse selectable

Input Circuit High-speed photo coupler input. Connectable with differential line-driverr.

Pulse of each single, double and quad count edge evaluation is selectable (2-phase pulse style).

Position Counter

Logic Position Counter (for output pulse) range −2,147,483,648 ~ +2,147,483,647

Real Position Counter (for input pulse) range − 2,147,483,648 ~ +2,147,483,647

Comparison Register

COMP + Register Position comparison range −1,073,741,824 ~ +1,073,741,823

COMP − Register Position comparison range −1,073,741,824 ~ +1,073,741,823

Software limit functioned

Automatic home search

Enable/Disable of each step and search direction selectable

Interrupt

The factors of occurring interrupt:

..start / finish of a constant-speed drive

..end of the driving

..transition to “position counter ≥ COMP−”

..transition to “position counter < COMP−”

..transition to “position counter ≥ COMP+”

..transition to “position counter < COMP+”

Enable / disable for these factors selectable

External Signal for Driving

EXOP+ and EXOP- signals for fixed / continuous drive

Input Circuit Photo coupler + IC built-in integral filter

Occupied I/O Address 64 Determined by PnP.

Interrupt IRQ Determined by PnP.

Speed Multiplier 1 ~ 500

S-curve Jerk 954 ~ 62.5 x 10

acceleration/deceleration drive

Independent 2-pulse system or 1-pulse 1-direction system selectable

6

PPS/SEC2 (Multiple = 1)

3

~ 31.25 x 109PPS/ SEC

6

PPS/SEC (Multiple = 1)

6

PPS/ SEC (Multiple = 500)

6

PPS (Multiple = 500)

6

PPS (Multiple = 500)

2

(Multiple =500)

Encoder A/B phase Input

A/B phase pulse style or Up/Down pulse style selectable

To read / write data is always possible.

Automatic execution of Step 1 (high-speed near home search) → Step 2 (low-speed home search) → Step 3 (low-speed

encoder Z-phase search) → Step 4 (high-speed offset drive).

Deviation counter clear output : Clear pulse width within the range of 10μ~20msec and logical level selectable

- 22 -

NOVA electronics MC8022P/MC8042P - 23

External Deceleration / Instant Stop Signal

STOP0 ~ 2 3 points for each axis (STOP0:near home, STOP1:home, STOP2:encoder Z-phase input)

Enable / disable and logical levels selectable and can be used as general input.

Servo Motor Input Signal

ALARM (Alarm), INPOS (In Position Check)

Enable / disable and logical levels selectable

DCC (Pin shared between deviation counter clear output and OUT0)

General Output Signal

OUT1 ~ 14 14 points

1 point for each + and − direction

Logical levels and decelerating / instant stop selectable

Emergency Stop Signal Input

EMG 1 point for all axes

Stop the drive pulse immediately for all axes and logical levels selectable by jumper on the board.

Input Circuit Photo coupler + IC built-in integral filter

Input Circuit Photo coupler + IC built-in integral filter

Servo Motor Output Signal

Output Circuit TD62503 output (open collector output)

Output Circuit TD62503 output (open collector output)

Limit Signals Input

Input Circuit Photo coupler + IC built-in integral filter

Input Circuit Photo coupler + IC built-in integral filter

Electrical Characters

Temperature Range for Driving 0 ~ + 45°C (No condensation)

CN3: HIF3FC-50PA-2.54DS (Hirose)

CN4: HIF3FC-30PA-2.54DS (Hirose)

CN4: HIF3BA-30D-2.54R (Hirose) connector only

AB80411: Round cable with a shield for CN2 (3.5m)

AC80801: Extension board for CN3, CN4

Power Voltage for Driving +5V ± 5 %

Consumption current MC8022P: 300mA max / MC8042P: 400mA max

External Supply Voltage +24V

Board Dimensions 174.6×106.7mm (Connectors and brackets excluded)

I/O Connector Type CN2: FX2B-100PA-1.27DS (Hirose)

Accessories CN2: FX2B-100SA-1.27R (Hirose) with 1.2m cable

Optional accessories CN3: HIF3BB-50D-2.54R (Hirose) connector only

- 23 -

Loading...

Loading...