Nova controls NEPTUNE User Manual

Neptune

WATER TREATMENT SYSTEM

Fourth & Fifth Pump

Option (Sprite WT)

Neptune Controller

Reference Manual

CM-700 Series

Copyright 2004 Nova Controls, Inc. P/N 20-07788-00 Rev. H

i P/N 20-07788-00 Rev. H

ii P/N 20-07788-00 Rev. H

Table of Contents

1 Theory of Operation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Starting the Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

System Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Pump Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Mounting the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Bulkhead Fitting Installation (3 Fittings) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Supply and Discharge Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Solenoid Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Trigger Output for Optional Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Probe Float Assembly Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Float Adjustment After Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Adjust Probe Floats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Adjust Water Tank Float Ball . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Probe Float Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Run a Test Cycle (after Set up) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Page

3 Description of Controls

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Run Mode Operation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Run Mode Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Select Formula / Home Screen (

Prime Pump/Fill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operating Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Tank at Low Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Tank Fill / Formula in Progress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pump(s) Running / Formula in Progress. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Error Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Time-To-Fill Error (

P/N 20-07788-00 Rev. H iii

t.Err) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Fr-A ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Formula Error (F.Err) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Calibration Error (

Probe Float Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Setup Mode Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

C.Err). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5 Setup Mode

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setup Mode Menu Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Password Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Prime Pump/Fill (

User Prime Enable (

Installer Formula Select (

User Formula Select (

Formula Time Edit (

Pump Volume vs. Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Fill Time Limit (

AutoStart on Power Up (

Fill Solenoid Type Identification (

Pump/Fill Sequence Edit (

Password Edit (

Exit Setup Mode (

Pr) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

UPr) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Fr-A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

UFr) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

FE) — (Create/Change a Formula) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

FILL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

ASt.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

FC.AC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

S.1-F) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

PASS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

END) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6 Troubleshooting

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Power Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Calibrating the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Probe Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

In Tank Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Out of Tank Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7 Maintenance and Service

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Every Maintenance Visit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Pump Tube Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Neptune Replacement Parts & Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Neptune System Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Probe Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8 Specifications

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Limitation of Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Index

iv P/N 20-07788-00 Rev. H

Theory of Operation

Overview

This chapter describes the theory of operation and the features of the Neptune Water Treatment Controller. The Neptune, with probe, detects the tank solution level. When the probe indicates a low solution level in the tank, Neptune automatically doses up to three chemicals into the tank and fills it with

water up to the appropriate level. When the probe indicates a high solution level in the tank, the solenoid closes and shuts off the water fill. In the unlikely event that the solenoid switch should fail, a tank

float ball switch (positioned at the makeup waterline) mechanically stops the fill to prevent overflow.

Once a high-level indication is reached, no programs can begin to run until a new, low-solution level

signal is received.

The three chemical pumps, and the solenoid water fill, can be set up to dispense in three different formulas (programs). An installer’s test formula is shipped with all new Neptune units.

The easy-to-read LCD screen displays information about the current cycle and any system errors in

formula, fill or calibration that may occur.

1

Starting the Cycle

AutoStart—The Neptune is factory set to automatically begin probe float operation and run a for-

mula–if the tank is low–when the power is turned on. It is recommended that the Neptune system be

run in AutoStart mode.

Manual Start—The installer can choose to disable AutoStart during setup. With AutoStart disabled,

the display flashes “

will not detect low or high water levels and no formula will run). To enable system operation, the

operator must manually press and release the

Fr-A” to indicate that the power is on but the system is not yet operational. (probe

ENTER key to start functional operation of the unit.

Normal Operation

With AutoStart enabled (or after the operator has pressed and released ENTER in Manual Start), a

cycle starts and runs the displayed formula if all of the following conditions are met:

• At least one formula is programmed into the Neptune.

On new Neptune units, the factory test formula displays as Formula A .

• The probe senses a low solution level for 20 continuous seconds, indicating that the tank needs to

be refilled. A low solution level is indicated by a “dot” added to the displayed formula .

• No cycle is currently in progress.

Chemical pumps run (either sequentially or simultaneously) and the solenoid initiates a water fill that

remains on until the tank is full. After the selected formula has run and the tank has filled with water,

the system resets itself automatically to the “ready” stage.

P/N 20-07788-00 Rev. H 1

System Error

A system error displays on the screen if there is a problem with the probe, the water fill solenoid, the

formula, or system calibration. Based upon the Troubleshooting Guide and the error message

displayed, the operator can correct the problem and restart the cycle. For more information, see “Error

Messages” on page 24 of the Troubleshooting chapter in this manual.

Note

"

The error must be cleared before the next formula can be run.

Pump Sequence

When tank conditions trigger the start of a cycle, the unit dispenses a formula that causes the pumps

and the water fill to run in a preset order. More than one pump, or the fill solenoid, can be set to run

simultaneously. The last used formula will run, unless the user selects a different formula (only

allowed when the installer has enabled User Formula Select). For more information on setting User

Formula Select or the pump sequence, see “User Formula Select (UFr)” on page 19 or “Pump/Fill

Sequence Edit (S.1-F)” on page 21.

Features

Additional Neptune features include:

• Factory-Set Test Formula

Neptune is shipped with a pre-programmed test formula that allows quick and easy system testing during installation.

• Advanced Design

The Neptune uses miniaturized electronics to provide powerful features in a small package.

A four-position digital readout allows simple, three-button operation and set up of all options.

• Reliability

The gasket-enclosed Neptune controller is highly water resistant. The readout displays formula

and pump information, including easy-to-understand error messages.

• Easy Service and Repair

The Neptune features convenient front access for all servicing. No internal access to the cabinet

is required for installation or routine maintenance. In the unlikely event that repairs are needed,

spare parts are available in modular form for fast and convenient service.

• Versatility

Up to three formulas may be programmed to operate a combination of pumps and fill.

• Upgradable and Expandable

Extend Neptune’s capabilities by connecting an auxiliary one or two-pump unit, the

Sprite WT. Triggered by Neptune’s controller, the 4th and 5th pumps give you the flexibility to increase doses of currently used chemicals or to add up to two more chemicals.

2 P/N 20-07788-00 Rev. H

Installation

Overview

This chapter describes the hardware installation of the Neptune. In this chapter, you will:

• Mount the unit on the bracket

• Install Bulkhead Fittings

• Connect Supply and Discharge Tubing

• Connect External Solenoid

• Install Probe Float Assembly

• Adjust Probe Floats After Mounting

• Make Probe Float Electrical Connections

• Power On

• Run a Test Cycle

2

Caution

,

The Neptune system is intended to be installed by experienced installers, in

accordance with all applicable electrical and plumbing codes.

All dispenser power must be disconnected during installation and/or any time

the dispenser cabinet is opened.

Mounting the Unit

The Neptune is a vertical surface mount water

treatment controller. When choosing an installation

location, make sure to install it close to the product

containers and at a reasonable height for easy service

access.

To mount the Neptune on the bracket:

1. Drill one hole in wall for upper mounting

bracket screw wall anchor.

2. Install wall anchor and temporarily attach

bracket to the wall (do not fully tighten screw).

3. Level bracket using built-in level and mark drill

locations for lower mounting screw holes.

4. Swing bracket out of the way, drill lower holes, and install lower wall anchors.

5. Screw bracket into place.

6. Lower unit onto wall mount bracket and press down until unit locks into place.

Figure 1 Neptune Controller

Mounting

bracket

7. To remove unit from bracket, depress lock button on top of bracket as you lift the unit.

P/N 20-07788-00 Rev. H 3

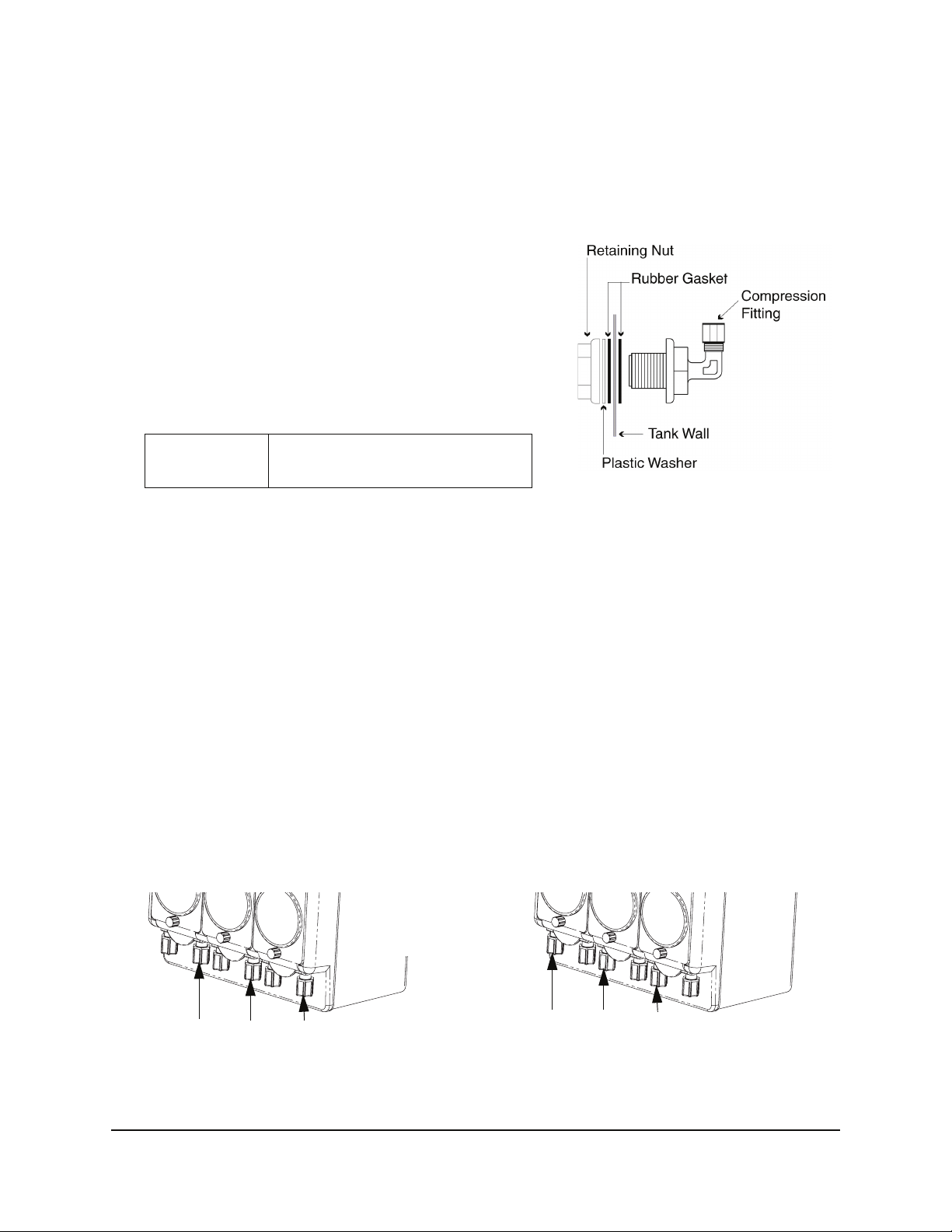

Bulkhead Fitting Installation (3 Fittings)

Correct bulkhead fitting placement is critical for accurate chemical delivery.

Installation requirements are:

• All bulkhead fittings must be mounted above the maximum water level in the tank.

• Chemicals must not discharge on top of the probe assembly.

When mounting the bulkhead fittings, you may use previously

punched holes, if they meet the location criteria above. If a

hole is present and confirmed suitable, skip to Step 2.

1. Drill a 3/8" hole in the center of the product inlet location. Use a Greenlee (or similar) 7/8" hole punch to cut

the final hole.

2. Remove bulkhead fitting retaining nut and, working

from inside tank, insert nut and rubber gasket into hole.

Warning

,

3. From the outside of the tank, install rubber gasket,

Do not over-tighten the retaining nut!

Figure 2 Bulkhead Fitting

Assembly

plastic washer and plastic retaining nut. Tighten finger-tight plus 1/4 turn only.

Supply and Discharge Tubing

Installation requirements are:

• The maximum combined distance for supply and discharge tubing must not exceed 50 feet.

• The maximum supply side tubing distance must not exceed 15 feet.

• The maximum vertical height from product container to pump must not exceed 10 feet.

• The supply container must be installed below the pump.

To install tubing:

1. Locate the compression fitting on the correct side of each pump. (See Figure 3 “Supply and Dis-

charge Hose Connections.”)

• Discharge Tubing = Right side of each pump

• Chemical Supply Tubing = Left side of each pump

2. Cut tubing to the appropriate length route to correct product container.

Discharge Tubing Connections Supply Tubing Connections

Discharge Compression Fittings—Right Side

(Pump Outputs)

Figure 3 Supply and Discharge Hose Connections

4 P/N 20-07788-00 Rev. H

Supply Compression Fittings—Left Side

(Pump Inputs)

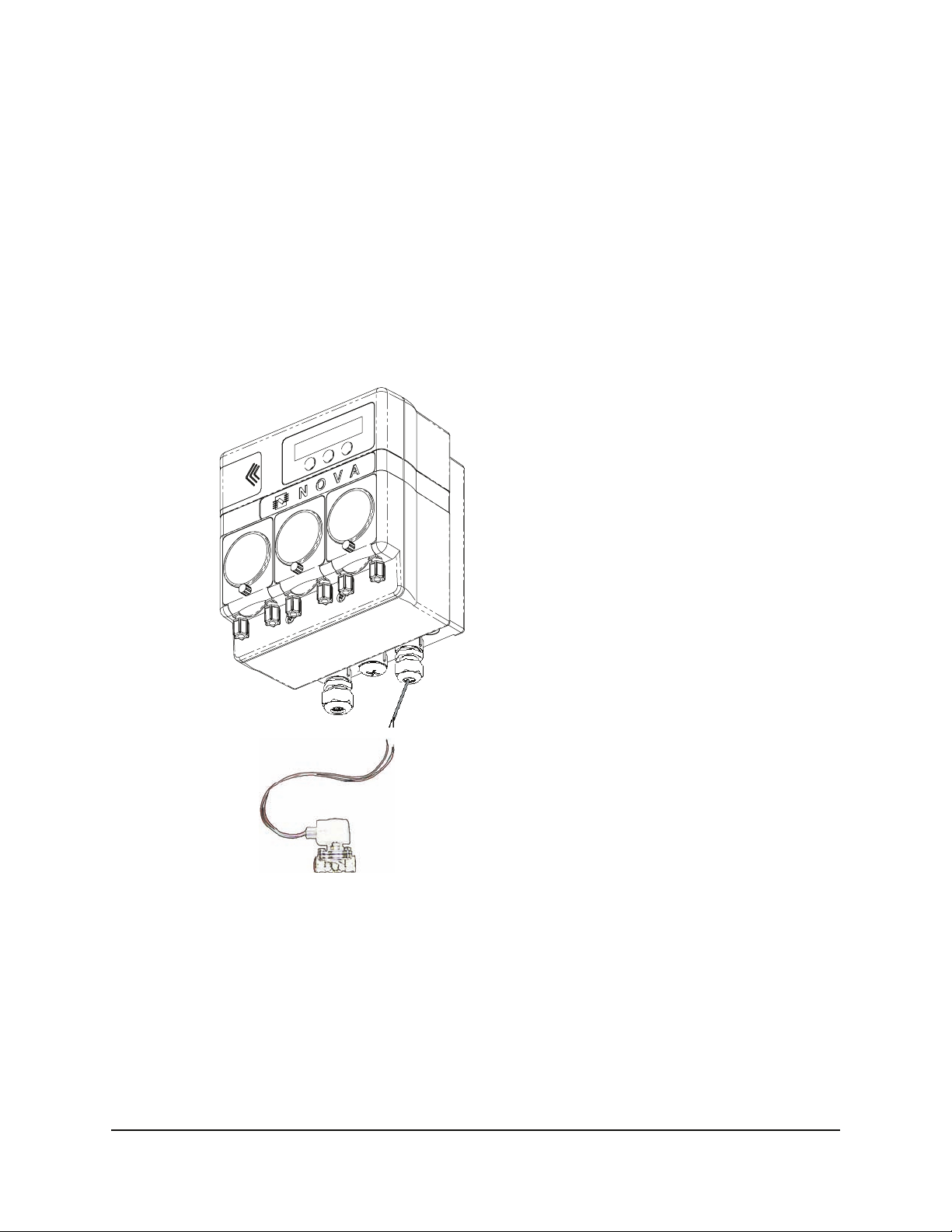

Solenoid Connections

1. Locate the external solenoid at the fill water source. Plumb it into the input water system, verifying that the water flow through the solenoid is correct.

2. Facing the front of the Neptune, find the Fill Solenoid two-conductor cable

(marked “solenoid”) that is protruding from the far-right seal-tight fitting.

3. Separate the two red wires from the green wire on the external solenoid.

4. Attach the wires from the two-conductor cable (marked “solenoid”) to the red wires on solenoid,

as shown in Figure 4.

5. Do not attach the green solenoid wire; this is the solenoid Frame Ground. The solenoid is low

voltage and therefore does not require grounding. Safely secure the green wire (i.e., with a wire

nut or tape).

Fill Solenoid Two-conductor Cable

Red Wires

Water Fill Solenoid Valve

Figure 4 Solenoid Connections

Trigger Output for Optional Pumps

A logic 5VDC output is provided in the Neptune to trigger additional external options, such as the

Sprite WT 2-Pump Auxiliary Water Treatment Controller. For information about installing or using

this option, refer to the Sprite WT Reference Manual, p/n 20-08067-00.

P/N 20-07788-00 Rev. H 5

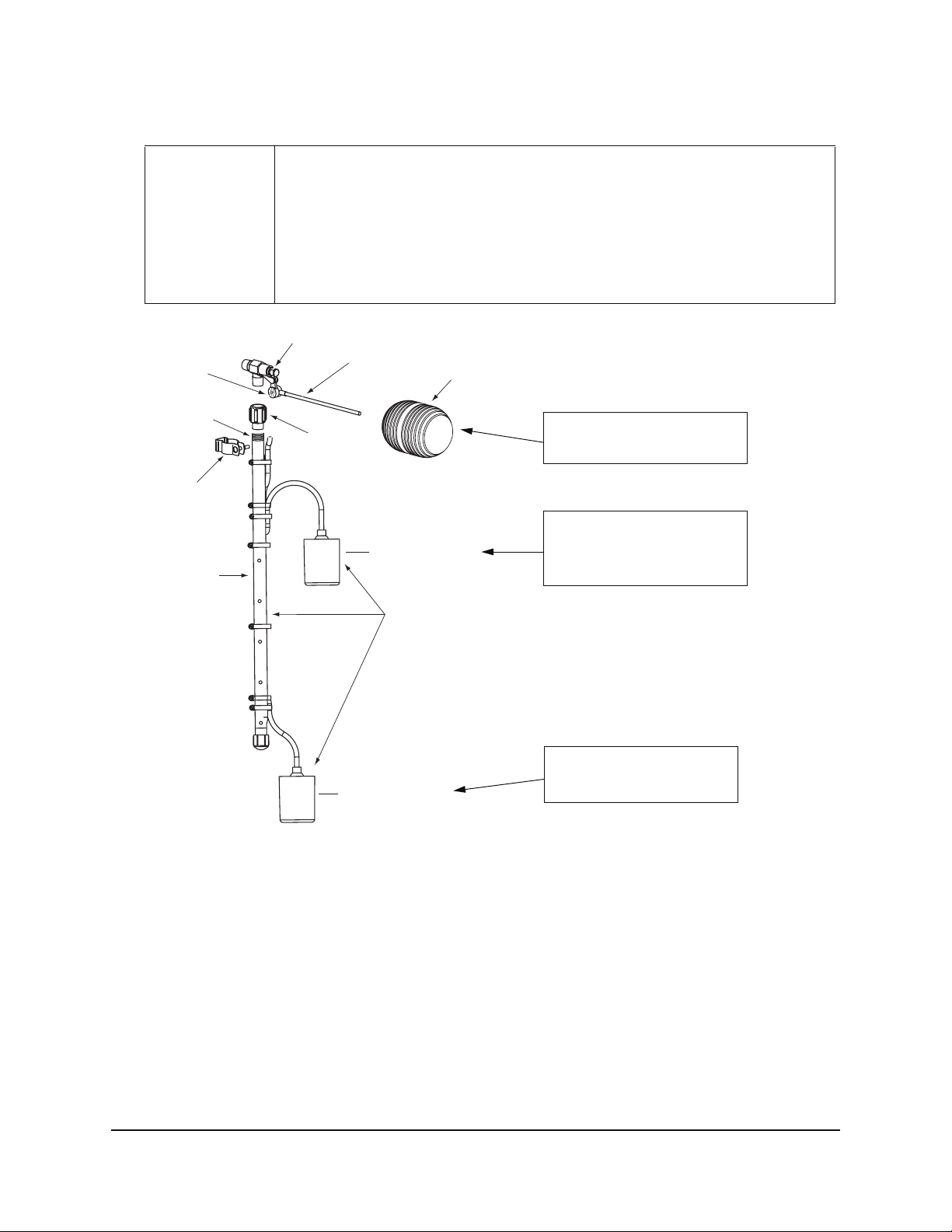

Probe Float Assembly Installation

T

The Neptune has two electrical probe floats and one mechanical water tank float:

1. The probe floats measure the solution level in the tank. The lower probe float engages

Note

"

Float

Adjustment

humb Screw

Stir-stick

Threads

Mounting

Bracket

Stir Stick

when the tank solution level is low. It initiates the formula start (pumps and water fill).

The upper probe float shuts off the water fill when it has reached the optimal level.

When either probe float engages, you can hear an audible “clacking” sound.

2. The water tank float ball provides a safety shut off if the upper probe float fails to

operate. In typical Neptune operation, the water tank float ball remains in the open

position (as s shown in Figure 6 on page 7).

Float Valve

Float Lever

Water Tank Float Ball (Safety Shut-off)

Coupler

Upper Probe Float

Shuts off water

if probe float fails.

Stops water fill and

prevents Fill Time

Error (T.Err).

Probe Assembly

Triggers water fill

Figure 5 Probe Float Assembly Diagram

Lower Probe Float

and pumps.

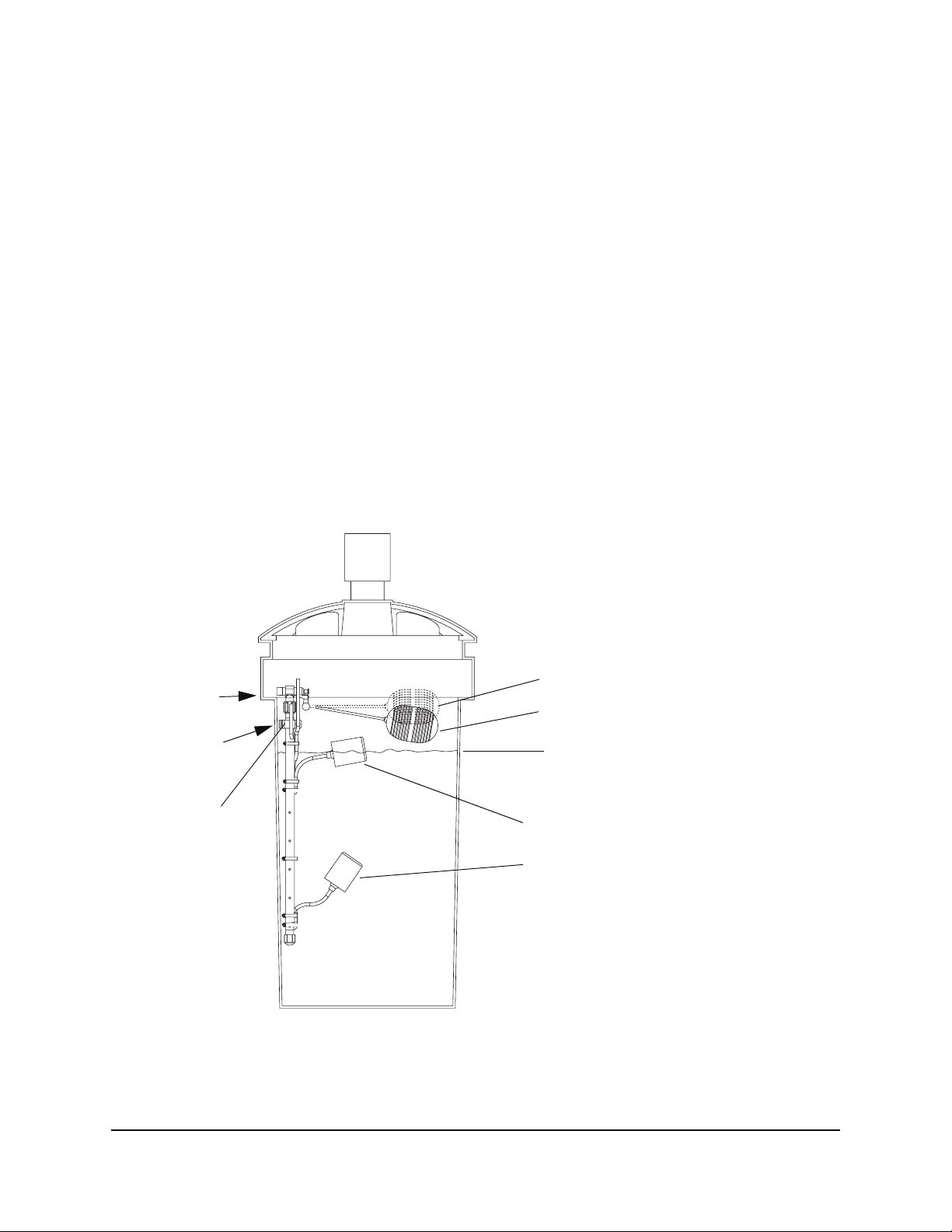

1. Identify the high (maximum) water level on the tank and mark it.

2. Locate the following (refer to Figure 5 for help in identifying each part): Probe Assembly

(includes upper and lower electric floats); Mounting Bracket with hardware; Coupler; Water

Tank Float Valve, Float Lever, and Float Ball.

3. Position the Probe Assembly (as in Figure 6 on page 7) so that, during operation:

• The upper probe float engages (points upward at an about a 15° angle when half immersed at

the maximum water level) and initiates water shut off before the water tank float engages.

• There is enough room at the top of the tank for the water tank float to fully rise and initiate

water shut off. The water tank lid must not inhibit the full rise of the float.

• The mounting bracket will be above the maximum water level.

6 P/N 20-07788-00 Rev. H

4. Place the bracket over the stir-stick portion of the probe, just below the threads of the stir-stick.

With the probe properly positioned, mark the location of the mounting hole (making sure it is

above the maximum water level).

5. Drill the mounting hole.

6. Place mounting screw through bracket and secure it just below the threads on the stir-stick.

7. Install the coupler to the top of the stir stick.

8. Install the float valve onto the coupler. Position the valve so it is aligned with the probe floats and

the float lever (the ball will extend in the same direction as the probe floats). Make sure that

joints are water tight.

9. Position the probe and mark the location for the water inlet connection to the valve.

10.Drill the water inlet hole, making sure that it is large enough to accept all of the fittings required

to plumb the probe.

11.Install the float lever and float ball onto the valve. Using the float adjustment thumb screw, adjust

the water tank float ball so that it engages approximately 1.5 to 2 inches above the high water

level and prior to tank overflow.

12.Mount the Probe Float Assembly to the tank.

13. Plumb the float valve to the water fill solenoid valve.

Drill hole for

water inlet

(step 10)

Drill hole

for mounting

bracket

(step 5)

Mounting Bracket

Figure 6 Probe Float Assembly, Mounted in Water Tank

Water Tank Float in closed position

Water Tank Float in open position

Maximum water level

Upper Probe Float

Lower Probe Float

P/N 20-07788-00 Rev. H 7

Float Adjustment After Mounting

Adjust Probe Floats

Note

"

The probe is set for a 36 inch (55 gallon) tank. Probe floats may be adjusted to

accommodate various sizes of water tank or preferred water levels.

When adjusting electric probe floats, be sure to maintain a 4” service loop between

the float and the tie wrap.

Upper and lower probe floats are easily adjustable by sliding the cable up or down and making the

loop larger or smaller, as needed. A “clacking” sound indicates that the float has engaged. To adjust

the probe floats after installation, cut the tie wraps, slide the cable, and attach new tie wrap s .

The lower electric probe float should be set so that, during operation, the float engages at the lowest

(minimum) water level that is acceptable for your installation. See Figure 7 “Electric Probe Float

Adjustment (Low Water Level).”

Tie Wraps

Float Cable

Tie Wraps

(to adjust float cable)

Float Cable

Cable Loop

Figure 7 Electric Probe Float Adjustment (Low Water Level)

Lower Probe Float

Low Water Level

Adjust Water Tank Float Ball

You must also adjust the water tank float ball that provides the safety water shut off. Using the float

adjustment thumb screw (see Figure 5“Probe Float Assembly Diagram” on page 6), adjust the float

ball so that, during operation, it does not engage before

Set the water tank float to engage approximately 1.5 to 2 inches above the high water level and prior to

tank overflow.

Caution

,

8 P/N 20-07788-00 Rev. H

There must be enough room at the top of the tank for the water tank float ball to fully

rise and initiate water shut off. Make sure that the water tank lid does not inhibit the

full rise of the float ball.

the electric probe float has shut off the water.

Loading...

Loading...