Page 1

The Trolley™ E-Class

Personal Monitor Arm System

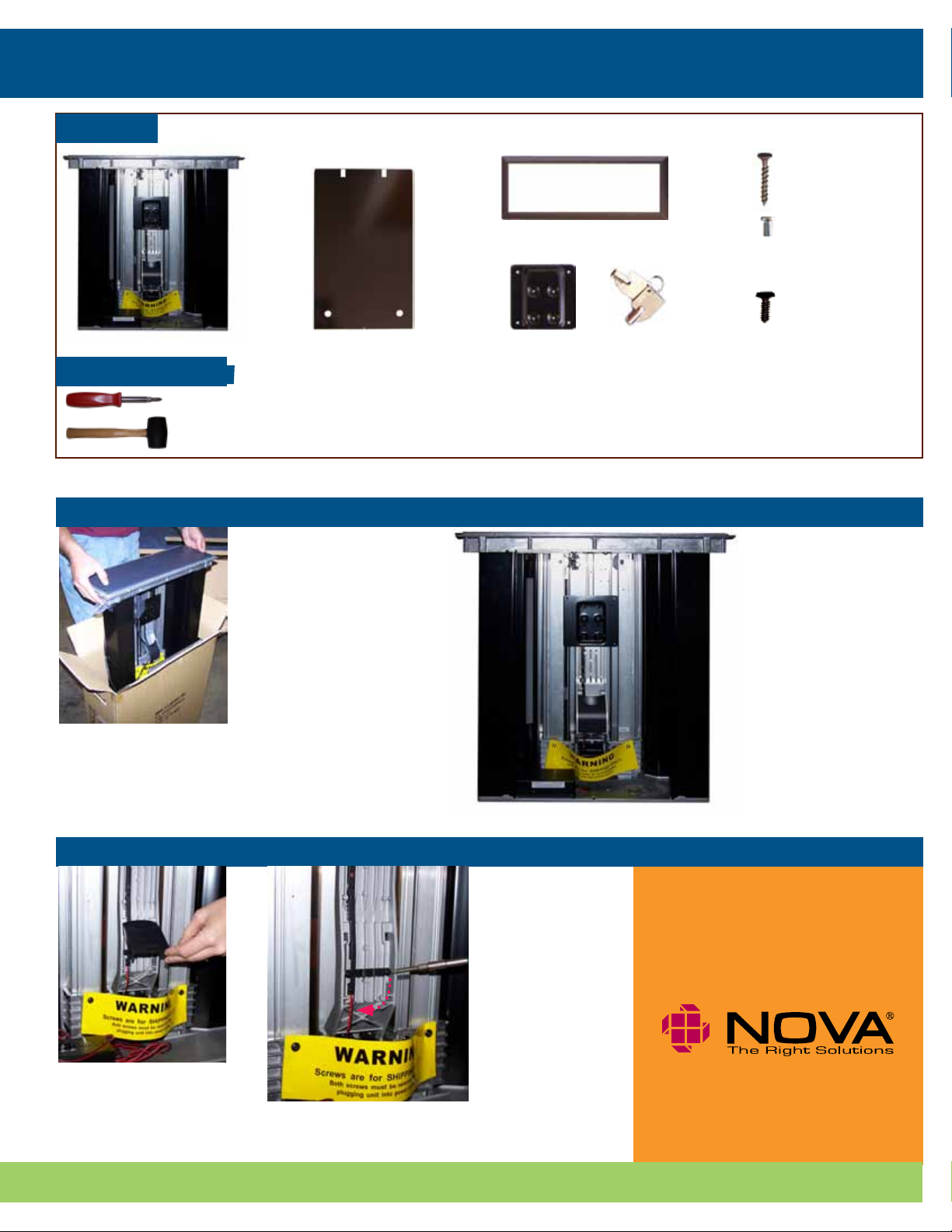

Parts List

Installation & Operating Instructions

Qty. 9

#6 x 3/4” screws

Qty. 4

Monitor screws

Phillips pan head

M4, length: 6mm

Qty. 2

Wire management

grommet screws

Phillips pan head

3mm, self-threading

screw, length: 10mm

The Trolley™ E-Class Removable Metal

Front Cover

Tools (not included)

Phillips Screwdriver

Power screwdriver may also be used,

if desired.

Rubber Mallet

(Ships with Flush Mount or Surface Mount)

75mm VESA

Trim Ring

Keys

Plate

(100mm

VESA Plate

Installed)

Note: Do NOT connect the Trolley E-Class to power source until Step 4.

Step 1:

1b. Place Trolley E-Class

in its upright, vertical

position with the open

interior side facing

you.

a.

1a. Remove Trolley E-Class

and parts from shipping

box.

Step 2:

a.

2a. With arm in down

position, remove black

cable management

cover.

b.

2b. Remove right

screw from cable

retention

clip on cable management channel. Then

loosen left screw

and rotate clip

downward.

b.

Need assistance? Call 1-800-730-6682 for NOVA Solutions Customer Support Page 1 of 4

Page 2

The Trolley

5c. If 75mm VESA plate required,

Personal Monitor Arm System

Step 3:

™

E-Class

Installation & Operating Instructions

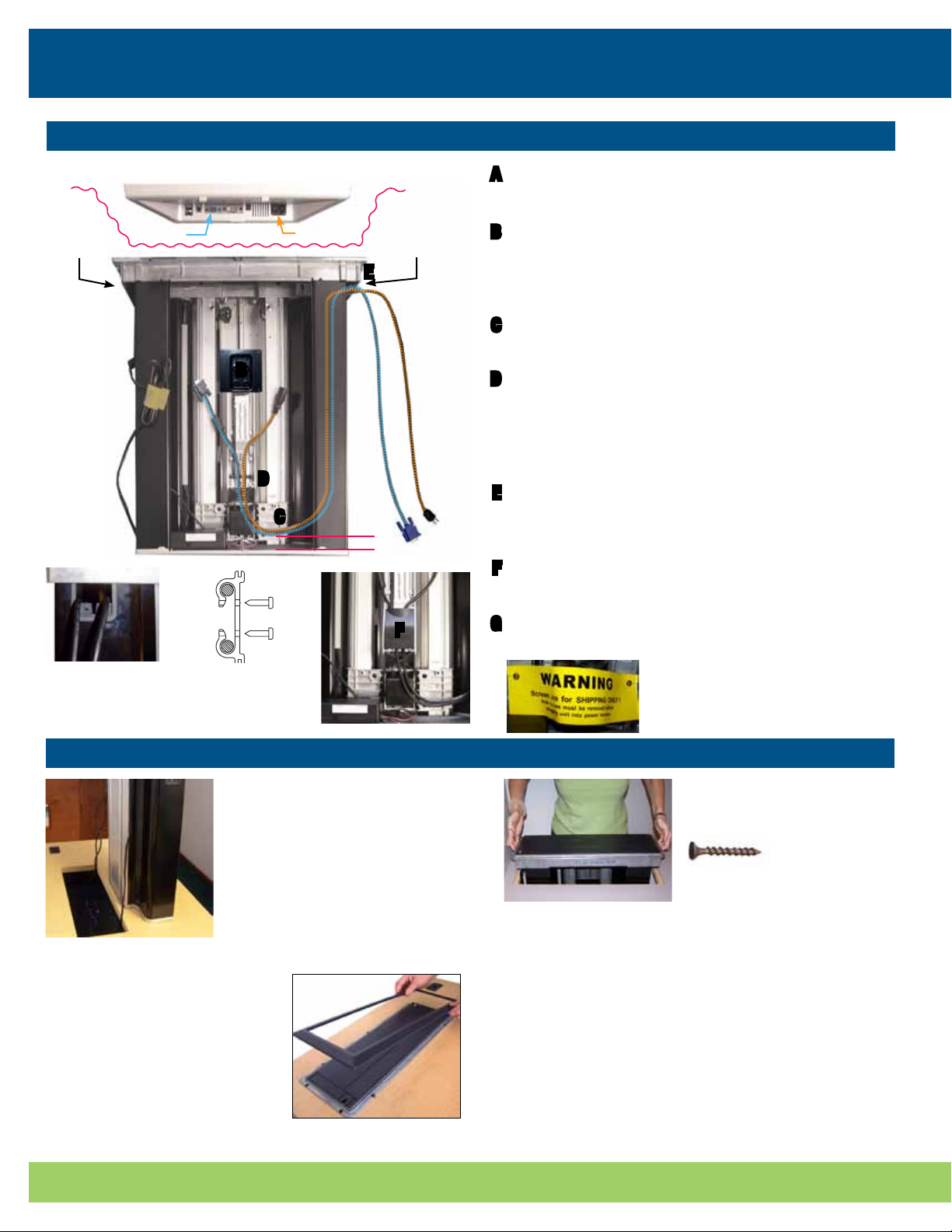

Flat panel monitor (bottom view. Dell monitor pictured here. Other brands may vary.

Video Port Power Port

Side Grommet

A

B

D

C

Side Grommet

E

1”

A

B

C

Step 7:

D

E

F

Feed monitor video and power cables through the

grommets on either side of The Trolley.

Align other end of video and power cables with ports on

monitor. Position the end of the cables even with the

center of the VESA plate on monitor arm. These cords

may need adjustment in Step 6a.

Leave about 1” of clearance between the video/power

cables and the bottom of The Trolley E-Class.

Place video/power cables in two center wire

management channels on monitor arm. Bring wire

clip (rotated downward in Step 3) back up over wires,

aligning right side over screw hole. Tighten left screw,

then reinstall and tighten right screw.

Place video and power cables in wire retention clamps

on side grommet. Secure screws in grommet. Make

sure all wires are clear of screw hole. See figs. 1 & 2.

Reinstall black cable management cover that was

removed in Step 2.

fig. 1 - Side grommet

with wire retention

clamps

fig. 2 - Top view

of wire retention

clamps

Step 4:

4a. With the open side of

The Trolley facing the user

side of the desk, place Trolley

on work surface adjacent to

work surface cutout.

Feed video and power cables

a.

through cutout.

4c. Using the palm of your hand

or a soft rubber mallet and a

block of wood, push or gently

tap the trim ring into place.

Start at one end and work your

way to the other. The NOVA logo

should be facing the user.

G

F

Completely remove two shipping screws indicated

by the yellow warning label.

Warning: After screws are removed and

before monitor is installed, arm may move

upward. If this happens, it should be

stopped by holding it with your hand.

4b. Lower Trolley into the

cutout and secure with nine

(#6 x 3/4”) screws provided.

Note: At this point, you can plug-in power

b.

and activate Trolley to open door and grip

the inside of unit while lowering into cutout, but unit must be in “Install Mode” to

allow door to stay open.

Make sure the PCU switch is in “Install Mode” before

completing Step 4d. Refer to Step 7a for location of PCU.

4d. Plug Trolley into power source. Insert and turn the key

to illuminate blue LED light. Wait 5 seconds to activate, then

push button and hold to open door and raise Trolley arm. The

power control module in the bottom of the Trolley housing is

normally shipped in “Install Mode.” The green LED does not

light when in “Install Mode.”

c.

Note: “Install Mode” only allows upward motion of arm and

access door will remain open.

Page 3

The Trolley™ E-Class

5c. If 75mm VESA plate required,

Personal Monitor Arm System

Step 5:

Installation & Operating Instructions

a.

5a. Select appropriate size VESA

plate for your monitor.

(100mm VESA plate installed)

Note: Once installed, the bottom of your

monitor should be 1 1/2” to 2” above the closed

Trolley door.

c.

remove four black screws on 100mm

VESA plate. Attach 75mm VESA plate

in correct position for monitor size.

5b. VESA plates can be detached and rotated to ensure a monitor

height clearance of 1 1/2” - 2” above closed Trolley door.

b.

5c. Depending on the depth of your monitor’s VESA plate mounting

area and/or the thickness of your monitor, different screw holes

can be used to adjust the space between the monitor and The

Trolley arm.

Using the flush screw holes

increases the space between the

monitor and the arm.

Using the indented screw holes

decreases the space between the

monitor and the arm.

Step 6:

6a. Attach the video and power cables

to your monitor. Allow enough slack in

cables for easy tilting of monitor, but do

not allow them to touch the work surface

or interfere with Trolley operation.

a. b.

Step 7:

a.

7a. Locate the power control

module at the bottom of The

Trolley E-Class and move the

switch to the right to “Operation

Mode.” The green LED will light.

Cables should allow for monitor tilt, but

should not touch work surface.

b.

7b. Push “Down” button for a few

seconds to activate unit. Once

the monitor is completely lowered

into the Trolley, the door will close

automatically.

Note: Pushing “Up” button will close door.

6b. Attach monitor

to VESA plate with

four monitor screws

provided.

Note: It may be helpful to have

another person assist in holding the monitor while attaching

it to the VESA plate.

7c. Remove the small

screw located at the bottom of Trolley (Ref. H). Slide

the top end of the removable metal front cover

into the upper front cover

slot. Note: Top of front

cover must slide inside the

groove of the top structure.

H

Slide bottom of cover into

c.

Trolley aligning with screw

hole. Reinstall the screw.

Need assistance? Call 1-800-730-6682 for NOVA Solutions Customer Support Page 3 of 4 Page 2 of 4 Need assistance? Call 1-800-730-6682 for NOVA Solutions Customer Support

Page 4

The Trolley™ E-Class

Personal Monitor Arm System

Intelligent Motion Technology

Overview

™

The Trolley

E-Class includes Intelligent Motion Technology.™ This feature reduces the risk of accidental damage and personal injury. Utilizing information from various different sensors, Intelligent Motion Technology™ continually monitors the Trolley’s operational

status and delivers information to the power control module.

If conditions create a “conflict” within The Trolley’s programming, the system will automatically take action to reduce damage or

injury. See below for some common operational conditions and how to resume normal operation.

Operational Guidelines

™

Power Failure

• In the event of a power failure during operation...

Operational Guidelines

Obstruction During Upward Motion

• If someone or something obstructs the upward

motion of the monitor (such as someone leaning

on or pushing down on the monitor)...

Monitor is Tilted During Operation

• If the monitor is moved out of vertical alignment

while Trolley is operating...

Access Door is Obstructed or Jammed

• If The Trolley senses an obstruction in the path of

the access door...

Operational StatusCondition

Unit will STOP

Unit will STOP

Unit will STOP

Unit will STOP

To Resume Operation...

Once power is restored, push the “Up” button to resume

normal operation. The Trolley will return to the “Up” position.

Once obstruction is cleared, push the “Up” button to resume

normal operation. The Trolley will return to the “Up” position.

Move monitor to fully vertical position. Push “Up” to resume

normal operation.

Note: The Trolley will not operate when the monitor is tilted.

The Trolley’s “Over-current Sensor” will stop the unit from

operating until the door obstruction is removed. Once the

path is clear, push either “Up” or “Down” buttons to resume

normal operation.

Page 4 of 4

For more information on installation and operation of The Trolley™ E-Class,

please contact Customer Support at 800-730-6682 or support@novasolutionsinc.com

© 2009, NOVA Solutions, Inc.

NOVA products are protected by various U.S. and foreign patents issued and/or pending.

INST_TR_E_01_11/10/09

Loading...

Loading...