Page 1

52920 EN

Only

Stat Prole PRIME

®

CCS Analyzer

Instructions for Use

Manual

Page 2

Page 3

Nova Prime CCS Analyzer Quick Start Guide

Conrm the analyzer is

1

Ready for analysis.

Displays Ready, desired

test menu shows no Orange

Icons.

Login if necessary. Press

2

the Login icon then enter

or scan your User ID and

Password.

Select the Sample Container and the Panel.

3

Prepare the sample for analysis then press

4

to extend the sample probe.

Position the sample

5

over the sample probe

then press to

aspirate the sample.

Enter any additional

6

patient or sample

information needed

while the analysis is

completed.

Review results.

7

Page 4

LEVEL

REP

EC

SN

NOVA BIOMEDICAL SYMBOL DIRECTORY

In vitro diagnostic

medical device

Device for near-patient testing

Caution

Consult Instructions for Use

Biological risk

Catalog number

Manufactured by

Control

Level

YYYY - MM - DD

Only

Batch code

Serial number

Temperature limitation

Use by date

Electronic Waste

Authorized representative

in the European Commission

Laser radiation:

Do not stare into beam

Prescription use only

Page 5

Prime CCS Instructions for Use Manual

Revision History

PN52920 Prime CCS Instructions for Use Manual

Rev Release Description

H 05 – 2022 Update to meet IVDR requirements

J 01 – 2023 Hazardous Waste Disposal Advisory

Page 6

Preface

Ordering Information

The Stat Prole PRIME CCS Analyzer Instructions for Use Manual

can be ordered from Nova Biomedical Order Services. Call, fax, or

write to:

Nova Biomedical Corporation Phone: 1-800-458-5813

200 Prospect Street FAX: 1-781-893-6998

Waltham, MA 02454 (in the USA)

USA

The Stat Prole Prime CCS analyzer is manufactured in the USA

by Nova Biomedical Corporation.

REP

EC

Nova Biomedical GmbH Phone: + 49 (0) 61054505-0

Hessenring 13A, Geb. G FAX: + 49 (0) 61054505-37

64546 Mörfelden-Walldorf

Germany

Authorized Representative

+1-781-891-9718

(outside the USA)

Web: www.novabiomedical.com

Trademark

Stat Prole is a registered Trademark of Nova Biomedical

Corporation.

Stat Prole Prime is a registered Trademark of Nova Biomedical

Corporation.

®

®

Copyright

Printed in the U.S.A. Copyright 2023, Nova Biomedical Corporation,

Waltham, MA 02454.

i

Page 7

Prime CCS Instructions for Use Manual

T echnical Assistance

For technical assistance inside the United States, call Nova Biomedical

Technical Services:

1-800-545-NOVA (6682)

1-781-894-0800

FAX: 1-781-894-0585

For technical assistance outside the United States, call your local Nova

subsidiary or authorized distributor.

Nova Biomedical recommends users report any serious incidents/

adverse events to Nova Biomedical or Nova Biomedical’s Authorized

Representative, as well as to local Competent Authorities as required.

Nova Biomedical Canada Ltd.

17-2900 Argentia Road

Mississauga, Ontario L5N 7X9

Canada

Tel: 1 905 567 7700

Toll Free: 800 263 5999

Fax: 1 905 567 5496

ca-info@novabio.com

Nova Biomedical France

Parc Technopolis

Bât. Sigma 3 Avenue du Canada

91940 Les Ulis Courtaboeuf

France

Tel: (33) 1-64 86 11 74

Fax: (33) 1-64 46 24 03

Nova Biomedical UK

Innovation House

Aston Lane South

Runcorn, Cheshire,

WA7 3FY, UK

Tel: + 44 1928 704040

Fax: + 44 1928 796792

uk-info@novabio.com

Nova Biomedical Iberia, S.L.

c/Vic 17, Planta 3A

08173 Sant Cugat del Vallès

Barcelona

Spain

Tel: +34 935531173

es-info@novabio.com

or pt-info@novabio.com

Nova Biomedical Italia Srl

Via Como 19

20045 Lainate Milano

Italy

Tel: +39 02 87070041

Fax: +39 02 87071482

it-info@novabio.com

Nova Biomedical GmbH

Hessenring 13A, Geb. G

64546 Mörfelden-Walldorf

Germany

Tel: + 49 6105 4505-0

Fax: + 49 6105 4505-37

de-info@novabio.com

Nova Biomedical Benelux BV

Europalaan 4

5232 BC Den Bosch

The Netherlands

Tel: +31 (0) 733032701

NL-info@novabio.com

or BE-info@novabio.com

Nova Biomedical Switzerland

GmbH

Herostrasse 7

8048 Zürich

Switzerland

Tel: +41-41-521-6655

Fax: +41-41-521-6656

e-mail: ch-info@novabio.com

Nova Biomedical Brasil

Rua Massena, 107

Jardim Canadá

Nova Lima – MG Cep: 34007-746

Brasil

Tel: (55) 31 3360-2500

E-mail: sac@novabiomedical.com.br

Nova Biomedical KK

Harumi Island

Triton Square Ofce Tower X 7F

1-8-10 Harumi, Chuo-ku

Tokyo 104-6007

Japan

Tel: 03-5144-4144

Fax: 03-5144-4177

jp-info@novabio.com

ii

Page 8

Contents

1 Introduction 1-1

1.1 About This Manual .....................................................................1-1

1.2 Safety .........................................................................................1-2

1.3 Installation and Use ...................................................................1-5

1.4 Requirements ............................................................................1-5

1.5 Cleaning the Analyzer ................................................................1-6

1.6 Intended Use, Tests Performed, and Clinical Utility ...................1-6

1.7 The Sample ...............................................................................1-8

1.7.1 Handling Requirements..................................................1-8

1.7.2 Acceptable Anticoagulants .............................................1-9

2 Getting Started 2-1

2.1 Power Up Procedure .................................................................2-3

2.2 The Home Screen: Ready ........................................................2-4

2.2.1 Header Bar .....................................................................2-4

2.2.2 Selection Area ................................................................2-5

2.2.3 Sensor Status Screen ....................................................2-6

2.2.4 Menu Bar .......................................................................2-7

2.3 Login to the Analyzer .................................................................2-8

2.4 Automatic Calibrations ...............................................................2-8

2.4.1 Manual Calibrations

2.4.2 Air Detector Calibration

3 Sample Analysis 3-1

..........................................................2-9

.....................................................2-9

3.1 Analyzing Patient Samples ........................................................3-1

3.1.1 Analyzing Syringe Samples ...........................................3-1

3.1.2 Utilizing the Safety Sample Port ....................................3-3

3.1.3

Analyzing Sample from a Blood Collection Tube

3.1.4 Analyzing Sample from a Capillary Tube .......................3-6

3.2 The Sample Results Display ......................................................3-7

3.2.1 Sample Result Printout ..................................................3-8

3.3 Analyzing QC and Prociency Samples ...................................3-9

3.3.1 Analyzing Internal QC Samples ...................................3-10

3.3.2 Analyzing External QC Samples ..................................3-11

3.3.3 Analyzing Prociency Samples ....................................3-12

52920J EN 2023 – 01

.................3-5

iii

Page 9

Prime CCS Instructions for Use Manual

4 Reviewing Patient and QC Data 4-1

4.1 Reviewing Patient Data .............................................................4-1

4.2 Reviewing QC Data ...................................................................4-3

4.3 QC Statistics ..............................................................................4-4

4.4 Levey Jennings Graphs .............................................................4-4

5 Consumables Replacement 5-1

5.1

Calibrator Cartridge/Auto QC Cartridge Replacement

5.1.1 Replace the Calibrator Cartridge....................................5-3

5.1.2 Replace the Auto QC Cartridge......................................5-5

5.2 Replace the MicroSensor Card ..................................................5-6

5.3 Prime MicroSensor Card Warranty Process ..............................5-8

6 Periodic Replacements 6-1

6.1 Pump Tubing Harness Replacement .........................................6-1

6.1.1 Install the Pump Tubing .................................................6-3

6.2 Probe Replacement ...................................................................6-4

6.3 Reference Cartridge Replacement ............................................6-6

6.3.1 Install the Reference Cartridge .........................................6-7

6.4 Printer Paper Replacement .......................................................6-8

6.5 Safety Sample Port Replacement ..............................................6-9

7 Troubleshooting 7-1

.....................5-2

7.1 Event Log ...................................................................................7-2

7.2 Resolving Event Codes .............................................................7-2

7.2.1 Flow Event Codes .............................................................7-3

7.2.2 Printer Event Codes ..........................................................7-7

7.2.3 MicroSensor Card Event Codes .......................................7-8

7.3 Troubleshooting Flow Problems ..............................................7-14

7.3.1 The Flow Path Flush Tool ...............................................7-14

7.3.2 Flushing the Flow Path ...................................................7-15

7.3.3 Flushing the Sample Probe/S-Line .................................7-17

7.3.4 Flow T est ......................................................................7-18

7.4 Long-Term Shutdown ............................................................... 7-19

iv

Page 10

Contents

A Appendix A-1

A.1 Specications .............................................................................A-1

A.2 Quality Control and Calibration ..................................................A-3

A.2.1 Traceability of Calibrators, Controls, and Standards .......A-3

A.2.2 Quality Control ................................................................. A-3

A.2.3 Calibrator Cartridge ......................................................... A-4

A.3 Analytical Specicity, Human Whole Blood....................................A-4

A.4 Healthcare Professional Analytical Performance Studies ...........................

A.4.1 Method Comparison Study .............................................. A-8

A.4.2 Analytical Precision or Repeatability .............................A-16

A.4.3 Run-to-Run or Total Imprecision .................................... A-22

A.5 Point-of-Care/Near Patient Testing Performance Studies .......A-28

A.5.1 Within-Run Precision or Reproducibility ........................ A-29

A.5.2 Quality Control Total Imprecision ................................... A-34

A.5.3 Syringe Mode Method Comparison ............................... A-35

A.5.4 Capillary Mode Method Comparison ............................. A-36

A.6 Reference Values ....................................................................A-38

A.7 Cybersecurity ...........................................................................A-39

A.7.1 Cybersecurity Protection Overview .............................A-39

A.7.2 Software Updates .......................................................A-39

A.7.3 Operating System Patches .........................................A-39

A.7.4 Malware Control ..........................................................A-39

A.7.5 Creation of Software for Release ................................A-40

A.7.6 Security Related to the USB Port ................................A-40

A.8 Ordering Information ................................................................A-41

A.9 Warranty ..................................................................................A-42

A-8

B Principles of Measurement B-1

B.1 Measured Values .......................................................................B-1

B.1.1 Sodium, Potassium, Chloride, and Ionized Calcium .....B-1

B.1.2 pH Sensor .....................................................................B-2

B.1.3 Partial Pressure of Carbon Dioxide ...............................B-3

B.1.4 Partial Pressure of Oxygen ...........................................B-4

B.1.5 Hematocrit ..................................................................... B-4

B.1.6 Glucose ......................................................................... B-4

B.1.7 Lactate .......................................................................... B-5

B.2 Calculated Values ......................................................................B-6

B.2.1 Temperature Correction for Measured Values ..............B-6

B.2.2 Bicarbonate Concentration ...........................................B-7

B.2.3 Total Carbon Dioxide Content ....................................... B-7

B.2.4 Hemoglobin ................................................................... B-7

v

Page 11

Prime CCS Instructions for Use Manual

B.2.5 Base Excess of Blood ...................................................B-8

B.2.6 Standard Bicarbonate Concentration ............................B-8

B.2.7 Base Excess Extracellular Fluid ....................................B-9

B.2.8 Oxygen Content ............................................................B-9

B.2.9 Oxygen Saturation ......................................................B-10

B.2.10 Alveolar Oxygen .......................................................... B-10

B.2.11 Arterial Alveolar Oxygen Tension Gradient

B.2.12 Arterial Alveolar Oxygen Tension Ratio ........................B-11

B.2.13 P50 or PO2 (0.5) ......................................................... B-12

B.2.14 Ionized Calcium Normalized to pH 7.4 ........................ B-13

B.2.15 Anion Gap ................................................................... B-14

B.2.16 Oxygen Capacity of Hemoglobin (O2Cap) .................. B-14

B.2.17 PO2/FIO2 Oxygenation Index (PO2/FI) ....................... B-14

B.2.18 Respiratory Index (RI) ................................................. B-15

References

........................................................................................B-17

...................B-11

vi

Page 12

1 Introduction

1 Introduction

This manual provides all necessary instructions for the

routine operation and upkeep of the Stat Prole Prime

CCS Analyzer. Please read this manual carefully. It has

been prepared to help you attain optimum performance

from your Analyzer.

Throughout this manual: NOTE indicates especially

important information; CAUTION indicates information

that is critical to avoid instrument damage or incorrect

results; WARNING indicates possible hazard to the

operator.

WARNING: Blood samples and blood products

are potential sources of infectious agents.

Handle all blood products, ow path

components, and accessories (waste-line,

capillary adaptor, probe, MicroSensor Card,

clot catchers, ush tools/xtures, safety

sample port, etc.) with care. Gloves and

protective clothing are recommended. When

performing maintenance and troubleshooting

procedures, also use protective eyewear.

1.1 About This Manual

This manual is for the Stat Prole Prime CCS Analyzer.

This section introduces the Prime CCS Analyzer and

covers requirements, tests performed, procedural

limitations, clinical utility, and sample handling.

1. Intro.

1-1

Page 13

Prime CCS Instructions for Use Manual

1.2 Safety

Personnel operating this analyzer must be procient

in the operating and replacement procedures of the

analyzer. The following safety procedures must be

followed.

General Safety

1. Read the safety and operating instructions before

operating the analyzer.

2. Retain the safety and operating instructions for

future reference.

3. Observe all warnings on the analyzer and in the

operating instructions.

4. Follow all operating and use instructions.

5. Do not use the analyzer near water, for example

near a sink, etc.

6. Use only with a cart or stand that is

recommended by the manufacturer.

The analyzer and cart combination should be

used with care. Quick stops, excessive force, and

uneven surfaces may cause the analyzer and

cart combination to overturn.

7. Place the analyzer so that its location or position

does not interfere with its proper ventilation.

8. Place the analyzer away from heat sources.

9. Connect the analyzer to a power supply only of

the type described in the operating instructions or

marked on the analyzer.

10. Do not defeat the safety purpose of the polarized

or grounding type plug.

11. Route power cords so that they are not likely to

be walked on or pinched by items placed upon or

against them, paying particular attention to cords

at plugs, power sockets, and at the point where

they exit from the analyzer.

1-2

Page 14

1 Introduction

12. The analyzer should be cleaned only as

recommended by the manufacturer.

13. Take care not to let objects or liquids fall into the

analyzer.

14. The analyzer should be serviced by qualied

service personnel.

15. Do not attempt to service the analyzer beyond

that described in the operating instructions. All

other servicing should be referred to qualied

service personnel.

Electrical Safety

1. To reduce risk of electric shock, do not remove

the cover.

2. There are no user serviceable parts inside the

analyzer.

3. Servicing must be done by qualied service

personnel.

4. To reduce the risk of re or electric shock, do not

expose the analyzer to water.

5. Use Nova Part Number 52413 external power

supply to power up the analyzer.

6. Ensure that the wall outlet receptacle is properly

wired and earth grounded.

7. DO NOT use a 3-to-2 wire plug adaptor.

8. DO NOT use a 2-wire extension cord or a 2-wire

multiple-outlet power strip.

Chemical and Biological Safety

1. Observe all precautionary information printed on

the original solution containers.

2. Operate the analyzer in the appropriate

environment.

1. Intro.

1-3

Page 15

Prime CCS Instructions for Use Manual

3. Take all necessary precautions when using

pathologic or toxic materials to prevent the

generation of aerosols.

4. Wear appropriate laboratory attire, e.g., safety

glasses, gloves, lab coat, and breathing

apparatus, when working with hazardous

materials.

5. Dispose of all waste solutions according to

standard hospital procedures.

Barcode Scanner Safety

A Class 2 laser is incorporated into the bar code scanner.

WARNING: Do not stare into the laser beam.

Laser Specications:

• Wavelength: 650 nm

• Max Output: 1.9 mW

EN 60825-1: 2014

The laser complies with 21 CFR 1040.10 and

1040.11, except for deviations pursuant to Laser

Notice No. 50, dated June 24, 2007.

Disposal of Electronic Waste

This symbol ( ) on the product label indicates that the

product should not be treated as household waste.

Devices/Accessories: To ensure the product is disposed

properly, decontaminate the product according to the

instructions provided in section 1.5 of this manual and

hand over the product to the applicable collection point

for the recycling of electrical and electronic equipment.

1-4

Page 16

1 Introduction

1.3 Installation and Use

This section covers the installation requirements and

assembly procedures for the Stat Prole Prime CCS

Analyzer.

Prior to use of the analyzer, operators should be familiar

with Chapter 2 Operation and Chapter 3 Operating

Procedures.

NOTE: Under the Warranty, a Nova service

representative will install this equipment for you.

1.4 Requirements

Working Area Requirements (Environmental):

Keep the working area around the system free of dirt,

corrosive fumes, vibration, and excessive temperature

changes.

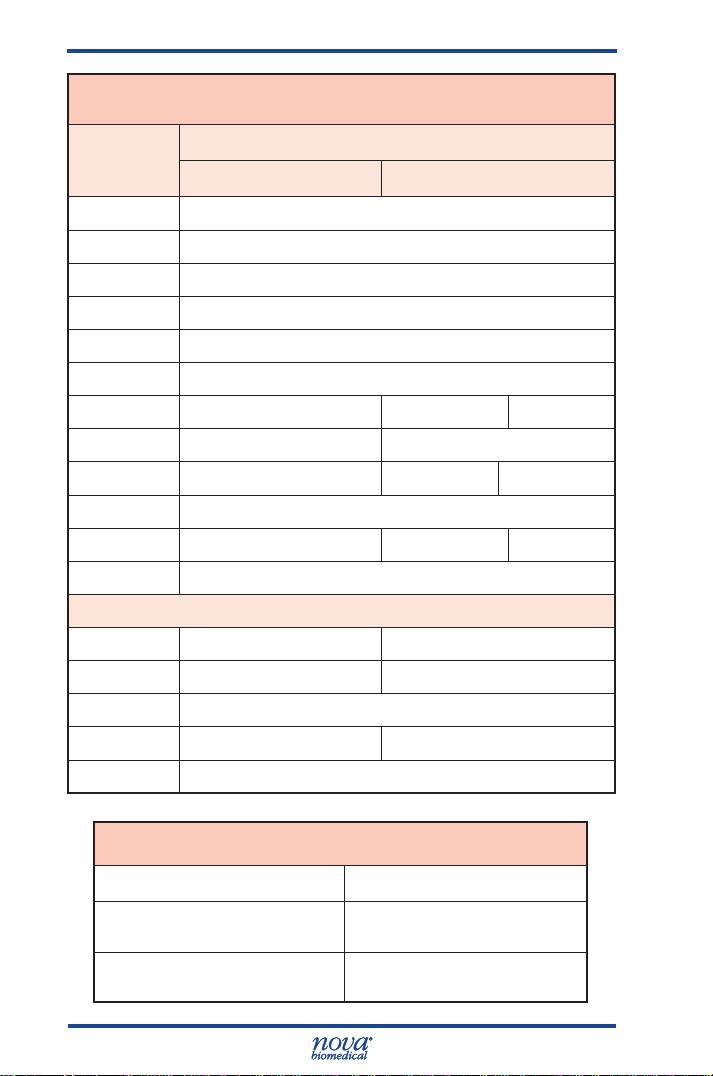

Table 1-1 Prime CCS Requirements

Electrical Requirements

Operating Voltage Range 100 – 240 VAC

Operating Frequency 50 – 60 Hz

Power Consumption Less than 100 W

Ambient Operating Temperature 15 °C – 32 °C (59°F – 89.6°F)

Operate at Humidity 20 to 85% without condensation

Operate at Altitude ≤ 12,000 feet (3650 meters)

Dimensions

Height 15.4 in (39.1 cm)

Width 12.0 in (30.5 cm)

Depth 14.4 in (36.2 cm)

Weight

17.5 lb (8.164 kg) without reagent pack

23 lb (10.45 kg) with full reagent pack

1. Intro.

1-5

Page 17

Prime CCS Instructions for Use Manual

Lifting the Analyzer:

1. One person is needed to lift the analyzer.

CAUTION: Never use the door (open or closed) to

assist you in lifting the analyzer. The door

cannot support the weight of the analyzer.

2. From the front of the analyzer, place your hands

under each side of the analyzer.

3. Lift the analyzer. Remember to bend your knees

and lift with your legs and not your back.

4. Place the analyzer onto a clean and at surface.

1.5 Cleaning the Analyzer

Nova Biomedical recommends using 70% Reagent

Alcohol (V/V) or Isopropyl Alcohol (IPA) for cleaning the

various analyzer surfaces or components when required.

Use a lint-free cloth lightly dampened with the cleaning

reagent to wipe down analyzer surfac es. Never spray

or pour reagent directly onto or into the analyzer. Once

wiped down, all residual uid should be dried with a lintfree cloth.

1.6 Intended Use, Tests Performed, and Clinical Utility

Intended Use

The Stat Prole Prime CCS Analyzer System is intended

for in vitro diagnostic use by health care professionals

in clinical laboratory settings and in Point-of-Care/NearPatient Testing settings for the quantitative determination

of pH, PCO2, PO

and Lac (Lactate) in heparinized whole blood.

Measured Parameters

Stat Prole Prime CCS Analyzer: pH, PCO2, PO

Na+, K+, Cl-, iCa, Glu (Glucose), and Lac (Lactate).

, Hct, Na+, K+, Cl-, iCa, Glu (Glucose),

2

, Hct,

2

1-6

Page 18

1 Introduction

Calculated Parameters

From the directly measured results, the calculated

results are shown in Table 1-2.

Table 1-2 Calculated Parameters

pH, PCO2, PO2

(corrected to patient temperature)

Bicarbonate level (HCO

Total Carbon Dioxide (TCO2)

Base Excess of the blood (BE-b)

Base Excess of extracellular uid

(BE-ecf)

Standard Bicarbonate Concentration

(SBC)

Oxygen Content (O2Ct)

Oxygen Capacity (O2Cap)

Alveolar Oxygen (A)

Clinical Utility

3

1

-

)

Arterial Alveolar Oxygen Tension

Gradient (AaDO

Arterial Alveolar Oxygen Tension

Ratio (a/A)

Respiratory Index (RI)

P50

PO2/FIO2 ratio

Oxygen Saturation (SO2%)

Hemoglobin (Hb)

Anion Gap

Normalized Calcium (nCa)

)

2

Table 1-3 provides the clinical utility information for each

of the analytes measured on the Stat Prole Prime CCS

Analyzer.

Table 1-3 Prime CCS Analyzer Clinical Utility

1. Intro.

pH

PCO

PO

Whole blood measurement of certain gases in Whole blood, or

pH of whole blood, is used in the Diagnosis and treatment of

2

life-threatening acid-base disturbances.

2

Whole blood measurements of the packed red cell volume of

Hct

a blood sample are used to distinguish normal from abnormal

states, such as anemia and erythrocytosis (an increase in the

number of red cells).

Na

+

Sodium measurement is used in the diagnosis and treatment of

electrolyte imbalance.

1-7

Page 19

Prime CCS Instructions for Use Manual

Table 1-3 Prime CCS Analyzer Clinical Utility

Potassium measurement is used to monitor electrolyte balance

in the diagnosis and treatment of disease conditions characterized by low or high potassium levels.

Chloride measurement is used in the diagnosis and treatment

of electrolyte and metabolic disorders.

Calcium measurements are used in the diagnosis and treatment of parathyroid disease, a variety of bone diseases, chronic

renal disease and tetany (intermittent muscular contractions or

spasms).

Glucose measurement is used in the diagnosis and treatment

of carbohydrate metabolism disturbances including diabetes

mellitus and hypoglycemia.

Lactate (lactic acid) measurement is used to evaluate the acidbase status of animals suspected of having lactic acidosis.

K

Cl

iCa

Glu

Lac

+

-

1.7 The Sample

Lithium heparin whole blood samples from syringes, open

tubes, small cups, and capillary tubes can be used on the

Stat Prole Prime CCS Analyzer. The minimum sample

size for analysis is 100 µL.

1.7.1 Handling Requirements

pH, PCO2, PO

Correct sample handling is critical to ensure that the

blood gas values obtained accurately reect the in vivo

state. Ensure that all samples have been obtained and

stored following consistent, clinically accepted protocols.

It is particularly important to ensure that samples are

well mixed before introduction into the analyzer. Nova

Biomedical recommends that you analyze the sample

within 15 minutes for blood gases. Storing samples on

ice is not recommended. Using iced samples may elevate

the PO

2

2

result.2

1-8

Page 20

1 Introduction

Potassium

Correct sample handling is critical to ensure whole

blood potassium values obtained accurately reect the

in vivo state. For example, a hemolyzed specimen of

50 mg/dL hemoglobin will increase the potassium blood

concentration by 3%.3

1.7.2 Acceptable Anticoagulants

• Lithium heparin is the acceptable anticoagulant

for use with the analyzer.

• EDTA, citrate, oxalate, sodium heparin, and

sodium uoride ARE NOT acceptable for use.

• Depending on the amount of heparin used in

the collection syringe and whether it is lled to

capacity with blood, heparin concentrations of 20

I.U. per mL to over 100 I.U. per mL may result.

• Liquid or dry heparin when present in excess

may cause errors. Ensure blood collection

devices are lled per manufacturer instructions.

• Ensure blood collection devices are lled per

manufacturer instructions.

• Our experience suggests that lyophilized lithium

heparin giving a nal concentration in blood of

not more than 20 I.U. per mL is acceptable.

1. Intro.

CAUTION:

1-9

Stat Prole Prime CCS Analyzer

users should take careful note of these

considerations when establishing reference

intervals and interpreting results.

Page 21

2 Getting Started

2 Getting Started

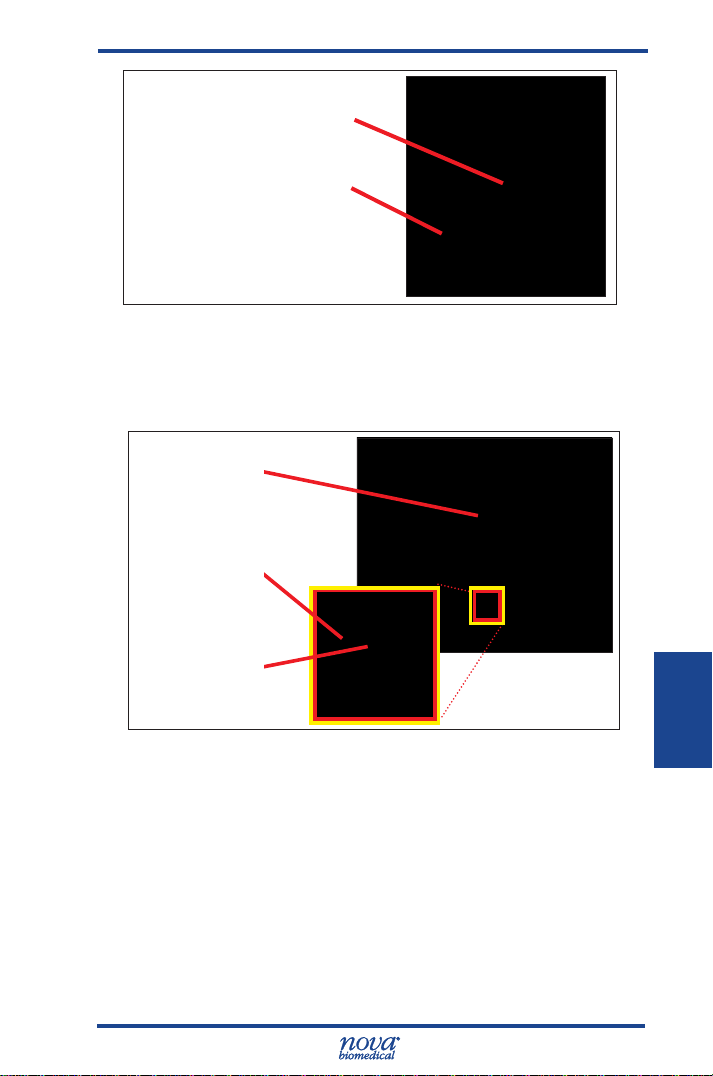

The Stat Prole Prime CCS Analyzer is pictured below.

1

4

1. Touch-screen Display

2. Printer

3. Sampler

4. Door/Front Panel

Figure 2.1 Nova Stat Prole Prime CCS

2

3

2. Started

2-1

Page 22

Prime CCS Instructions for Use Manual

1

3

8

9

7

4 5

1. Waste Line

2. Reference Line

3. Pump and Pump Tubing Cartridge

4. Calibrator Cartridge Opening

5. Control Cartridge Opening

6. Sampler

7. Air Detector

8. MicroSensor Card (under cover)

9. Reference Cartridge (under cover)

2

6

2-2

Figure 2.2 Analytical Compartment

Page 23

2 Getting Started

2.1 Power Up Procedure

When the analyzer is powered on, it displays the

Stat Prole Prime CCS logo. During this time, an

internal Power On Self Test (POST) is run. Any errors

encountered during the POST will display on the

analyzer's screen.

After successfully completing the POST, the Home

screen displays with Initializing. During initialization,

an internal diagnostic sequence is run: the MicroSensor

Card use life; the calibrator cartridge uid level; and the

internal auto QC cartridge uid level are checked.

Figure 2.3 Initializing Screen

2. Started

The Prime CCS performs a prime cycle. After completion,

the screen displays Not Ready.

Figure 2.4 Not Ready Screen

2-3

Page 24

Prime CCS Instructions for Use Manual

2.2 The Home Screen: Ready

The screen of the Prime CCS Analyzer is a Touch-screen.

The touch-screen display provides prompts, menus, status

information, sensor status, sample container and panel

selection, and date and time.

2.2.1 Header Bar

The Header Bar is the top section of the display. This

is where Ready or Not Ready, Date and Time, Login,

and MicroSensor Card, Calibrator Cartridge, and Control

Cartridge status are displayed.

Header Bar

Selection Area

Menu Bar

Figure 2.5 Home Screen: Ready

2-4

The current Date and Time is displayed.

When a timed operation is in process, the Date

and Time is replaced by a countdown timer.

Login using the Lock icon displayed in the

Header Bar. Press the Lock and proceed to

login with your Operator ID and password.

Only one person can be logged into the

analyzer at a time. When logged onto the

analyzer, an open lock is shown with the

logged in operator ID displayed under it.

Page 25

2 Getting Started

The analyzer can also be run with the login featured

turned off.

The upper right corner of the Home screen

(Header Bar) has the Status Graph which

when touched will display the status of the

MicroSensor Card, calibrator cartridge, and

QC cartridge.

2.2.2 Selection Area

The Selection Area is the middle of the display. Panel

selection, Sample container selection, and information

about sensor availability are found here.

Figure 2.6 Selection Area

• Analytes displayed in Orange are unavailable

for analysis. If you press the icon of the Orange

Analyte, the Sensor Status Screen with additional

information will display.

• Analytes displayed in Blue are available and

selected for analysis. If you press the icon of

a Blue Analyte, it turns Grey indicating it is not

selected for analysis.

• Analytes displayed in Grey are available but

not selected for analysis. If you press the icon

of a Grey Analyte, it turns blue, indicating it is

selected for analysis.

Use the Container button to select thetype

of conatiner and sample to be analyzed.

Use the Panel button to select from a

predened list of test panels.

2. Started

2-5

Page 26

Prime CCS Instructions for Use Manual

2.2.3 Sensor Status Screen

Analytes displayed in Orange are unavailable for

analysis. Press an orange analyte button to see the

Sensor Status Screen, which displays the status of that

analyte. Detected sensor errors or QC Lockout conditions

display on the screen.

• Touching the Calibrate button starts a Calibration

sequence then returns to the Home Screen.

• Touching the QC button displays the Analyze QC

Screen if more than one Internal QC is locked

out or an External QC is locked out for all the

sensors.

• Touching the QC button starts the QC Level

sequence for the QC Lockout, then returns to

the Home Screen if there is only 1 Internal QC

Locked out for all the sensors.

• Touching the Fix button starts a Calibration

sequence, then returns to the Home Screen.

• If all sensors pass Calibration from a Fix, all

Internal QCs that failed QC Lockout will be

executed.

• Touching the Right Arrow button displays the

status of the next sensor that is unavailable.

• Touching the Left Arrow button displays the

status of the prior sensor that is unavailable.

2-6

Figure 2.7 Sensor Status Screen

Page 27

2 Getting Started

2.2.4 Menu Bar

The Menu Bar is the bottom section of the screen. The

Tool Box icon (System Menu screens), Find Results icon,

QC icon (to run QC and QC Menu Screens), and the

Start (Run Test) or Calibrate icon.

The Home icon returns the analyzer to the Home

screen by touching this icon. This icon does not

display on the Home screen.

The Tool Box icon is located at the Menu Bar.

Press this icon to display Screen one of the

System Menus. The up/down arrow key is

pressed to display screen two. From the System

Menu, you can also navigate to the Setup Menu.

The recall results icon of the Menu Bar will

display all the patient results stored on the

analyzer.

The QC icon will display the QC Menu screen:

Run QC, Setup QC Levels, View QC Data, and

Setup QC Operations.

The Calibrate icon is displayed when all analytes

are not calibrated. Press Calibrate to initiate a

system calibration.

If one or more analytes are calibrated, the Start

icon displays. Press Start to begin an analysis.

The Prime icon is displayed in the footer after an

Auto QC Cartridge, a Control Cartridge, or tubing

is replaced. Press Prime to initiate a system

prime.

Pressing the Enter button moves the analyzer to

the next screen in the procedure.

Screens may contain other navigational icons including:

Press the Back icon to return to the previous

screen.

The Page Up and Page Down icons scroll

through the menus that have multiple pages.

2. Started

2-7

Page 28

Prime CCS Instructions for Use Manual

2.3 Login to the Analyzer

From the Home screen, login if you are prompted to login.

1. Press the Login icon to log into the analyzer.

2. Enter or scan your Operator ID then press the

Enter button.

3. If required, enter or scan your Password, then

press the Enter button.

2.4 Automatic Calibrations

The Stat Prole Prime CCS analyzer performs a 2-point

calibration 30 minutes after being powered on and

regularly thereafter to maintain optimal MicroSensor Card

and air detector performance.

Figure 2.8 Operator ID Screen and Operator Password Screen

A 1-point calibration is performed at regular intervals to

monitor MicroSensor Card performance between each

2-point calibration. If a calibration error occurs, an alert

is shown to notify the operator and the test button of the

affected analyte is displayed with an orange background

to indicate it is unavailable for testing.

Scheduled 2-point calibrations can be delayed once

for 10 minutes by pressing the Cancel button. After 10

minutes the rescheduled calibration begins and cannot

be cancelled.

2-8

Page 29

2 Getting Started

2.4.1 Manual Calibrations

A manually initiated 2-point calibration can be performed

whenever the analyzer displays Ready or Not Ready on

the header bar.

A Not Ready (Not Calibrated) status is displayed

after powering the analyzer on, after replacing some

consumable items or as a result of a system error. When

the analyzer displays Not Ready, samples cannot be run

until a 2-point calibration is performed that successfully

calibrates the air detectors and at least one analyte. To

initiate a calibration from the Not Ready state, press the

Calibrate button

A Ready status indicates the air detectors and one or

more analytes are calibrated and ready for analysis.

To manually calibrate the analyzer from the Ready

state select the Toolbox icon and then select the

Calibrate button .

Analytes that display an orange button may be

uncalibrated. Press the orange button and then select

the Calibrate button, if displayed, to initiate a 2-point

calibration.

CalibrateCalibrate

on the Menu Bar.

2. Started

Figure 2.9 Not Ready Screen and Ready Screen

2.4.2 Air Detector Calibration

The Air Detectors are automatically calibrated once a day.

An Air Detector calibration can be initiated manually, if

needed, as follows:

> > > .

2-9

Page 30

3 Sample Analysis

3 Sample Analysis

WARNING: While the probe is extended, do not open

or close the door.

When Ready is displayed on the Home screen the analyzer

is ready to analyze samples for any analyte not displaying an

Orange test button. The analyzer can measure whole blood

samples from capillary tubes, syringes, test tubes, and open

containers as well as external Quality Control material from

ampules and internal Quality Control material from an internal

auto QC cartridge.

3.1 Analyzing Patient Samples

Before running a patient sample verify the analyzer is

Ready to perform the analysis and that all the desired

analytes are available for selection. If necessary, refer to

Chapter 2 for additional information.

INTERFERENCE WARNING: Do not perform glucose

and lactate testing on patients taking the

drug hydroxyurea. Refer to section A.3 for

additional interference information.

3.1.1 Analyzing Syringe Samples

From the Home screen, log in if necessary.

1. Select the syringe button from the

container drop-down list.

2.

Select the desired Test Panel from the drop-down list

or select analytes to create a Custom Panel.

3. Analysis

Figure 3.1 Ready Screen: Container and Panel Drop-down Lists

3-1

Page 31

Prime CCS Instructions for Use Manual

3. Press the Start button to begin the

analysis.

4. If prompted, enter all Required Information and press

Start again to begin the analysis.

Figure 3.2

Sample Information Screen

5. Prepare the sample for analysis (mix well) then

position the sample over the probe and press the

Aspirate

The sample probe retracts automatically once sufcient sample

has been aspirated into the analyzer.

6. Enter any Required or Optional information while the

analysis is running.

button.

NOTE:

The Sample Information remains disabled until all

Required elds have been entered. The analysis can

be cancelled by pressing the X icon but results

will not be printed or transmitted.

Figure 3.3 Syringe Sample

3-2

Figure 3.4

Sample Information Screen

Page 32

3 Sample Analysis

3.1.2 Using the Safety Sample Port

The Safety Sample Port provides a means of attaching

a syringe to the analyzer instead of manually positioning

the sample probe in the sample.

When using the Safety Sample Port, Nova recommends

using the Nova Syringe Clot Catcher to ensure that

the sample is positioned correctly for aspiration and to

prevent clots from entering the ow path. If a clot catcher

is not used, syringes must be lled with sufcient sample

for the probe to travel approximately 1-inch (26 mm) into

the syringe.

Figure 3.5 Safety Sample Port

From the Home screen:

1. Select the appropriate syringe button

from the container drop-down list.

2. Select the desired Test Panel from the drop-down

list or select one or more analytes to create a

Custom Panel.

3. Analysis

Figure 3.6 Ready Screen: Container and Panel Drop-down List

3-3

Page 33

Prime CCS Instructions for Use Manual

3. Prepare the sample for analysis (mix well) then

attach the syringe to the Safety Sample Port.

4. Press the Start button to begin the

analysis.

5. If prompted, enter all Required Information and

press the Start button once more to begin the

analysis.

6. Press the Aspirate button to aspirate

sample into the analyzer. The sample probe

retracts automatically once sufcient sample has

been aspirated into the analyzer.

7.

Remove the syringe from the Safety Sample Port.

8. Enter any Required or Optional information while

the analysis is running.

NOTE: The

Required elds have been entered. The analysis can

be cancelled by pressing the X icon but results

will not be printed or transmitted.

Figure 3.7

Sample Information Screen

3-4

Sample Information screen will remain until all

Figure 3.8 Position Sample Screen:

Safety Sample Port

Page 34

3 Sample Analysis

3.1.3 Analyzing Sample from a Blood Collection Tube

From the Home screen:

1. Select the blood collection tube icon

from the container drop-down list.

2. Select the desired Test Panel from the dropdown list or select one or more analytes to

create a Custom Panel.

Figure 3.9 Ready Screen: Container and Panel Drop-down List

3. Press the button to begin the analysis.

4. If prompted, enter all Required Information

and press Start once more to begin the

analysis.

5. Prepare the sample for analysis (mix well)

then position the sample over the probe and

press Aspirate . The sample probe will

retract automatically once sufcient sample

has been aspirated into the analyzer.

6. Enter any Required or Optional information

while the analysis is running.

3. Analysis

Figure 3.10 Sample Information Screen

3-5

Figure 3.11 Position Sample Screen:

Page 35

Prime CCS Instructions for Use Manual

NOTE:

The Sample Information screen will remain until all

Required elds have been entered. The analysis can be

cancelled by pressing the X icon but results will

not be printed or transmitted.

3.1.4 Analyzing Sample from a Capillary Tube

From the Home screen:

1. Select the capillary icon from the

container drop-down list.

2. Select the desired Test Panel from the drop-down

list or select one or more analytes to create a

Custom Panel.

3. Press Start to begin the analysis.

4. If prompted, enter all Required Information and

press the Start button again to begin the analysis.

5. Prepare the sample for analysis (mix well).

Then position the capillary tube into the capillary

adaptor and press Aspirate .

6. When prompted, remove the capillary tube and

press .

7. Enter any Required or Optional information while

the analysis is running.

NOTE: The

3-6

Sample Information screen will remain until all

Required elds have been entered. The analysis can be

canceled by pressing the X icon but results will

not be printed or transmitted.

Figure 3.12 Ready Screen: Container and Panel Drop-down Lists

Page 36

3 Sample Analysis

Figure 3.13 Sample Information Screen

Figure 3.14 Position Sample Screen:

3.2 The Sample Results Display

Once the sample analysis is complete, results for the

selected and calculated analytes display (Figure 3.16).

Each analyte is shown with its measured value, the

unit of measure, and a 3-segment bar that provides a

visual indication of the sample concentration: Green

for normal results, Orange exceeds normal limits, and

Red exceeds panic limits. Sample results displayed as

-- were determined to be outside the analyzer's analytical

measurement range.

NOTE: Results can be displayed 2 different ways

(setup congurable).

The color bar consists of 3 segments:

1. The rst (left hand) segment indicates the

sample result is lower than the entered normal

range.

• The segment is displayed with a Orange

background if a sample result is between the

low Normal and low Alert range.

• The segment is displayed with a Red back-

ground when a sample exceeds the low Alert

range.

2. The middle segment indicates the sample result

is within the entered normal range.

• The segment is displayed with a Green

background when the sample result is within

the entered normal range.

3. Analysis

3-7

Page 37

Prime CCS Instructions for Use Manual

Figure 3.15

Blood Results Screens: Displayed in 1 Column (left) or 2 Columns

3. The last (right hand) segment indicates the

sample result is higher than the entered normal

range.

• The segment is Orange when a sample result is

between the high Normal and high Alert range.

• The segment is Red when a sample exceeds the

high Alert range.

Use the Page Up and Page Down buttons

to scroll through additional pages of result screens. The

number of pages is shown in the upper left corner of the

display, e.g., 1 of 3.

Press the Print button to print the results on the

analyzer’s thermal printer.

Press the Transmit button to transmit the results to

the LIS/HIS system.

Press the Home Button to return to Home screen.

3.2.1 Sample Results Printout

The Sample Results printout contains a customizable

header followed by the measured and calculated test

results. Each test result contains the test name, the

measured value and the unit of measure. A result

ag consisting of one or more up () or down () arrows

may also be displayed. Some event codes prevent a test

3-8

Page 38

3 Sample Analysis

result from being printed. Should this occur the event

code is printed in place of the test result. Results printed

as - - were determined to be outside the analyzer's

measurement range.

Flags

• A single up arrow is printed if the measured

value is above the upper end of the normal

range.

• A double up arrow is printed if the measured

value is above than the upper end of the critical

range.

• A triple up arrow

value is above than the upper end of the

measurement range.

• A single down arrow is printed if the measured

value is below the lower end of the normal

range.

• A double down arrow is printed if the

measured value is below the lower end of the

critical range.

• A triple down arrow

measured value is below the lower end of the

measurement range.

is printed if the measured

is printed if the

3. Analysis

3.3 AnalyzingQCandProciencySamples

Before running a QC sample, verify the analyzer is

Ready to perform the analysis and that all the desired

analytes are available for selection. If necessary, refer to

Chapter 2 for additional information.

3-9

Page 39

Prime CCS Instructions for Use Manual

3.3.1 Analyzing Internal QC Samples

From the Home screen:

1.

From the Home Screen, press the QC button .

2. Press the Analyze QC button .

3. Press the Select QC Level button.

Figure 3.16 Quality Control Screens

4. From the drop-down list, select the Internal

Control Level to be analyzed.

5. Enter a QC comment if desired.

6. Press Start to begin the analysis.

7. Wait until probe is fully extended.

8. Position the well-mixed sample over the probe.

Select the Aspirate button. The sample probe

retracts automatically when sufcient sample

has been aspirated. Tests are performed and the

QC results are displayed on the screen.

9. Once the analysis is complete press the Save

button to keep the QC results or press Delete to

discard the QC results.

3-10

Figure 3.17 Quality Control Results Screen

Page 40

3 Sample Analysis

3.3.2 Analyzing External QC Samples

From the Home screen:

1.

From the Home Screen, press the QC button

2. Press the Analyze QC button .

Figure 3.18 Quality Control Screens

3. From the drop-down list, select the External

Control Level to be analyzed.

4. Select the lot number to be analyzed.

5. Enter a QC Comment if desired.

6. Press Start to begin the analysis.

7. Wait for the Sample Probe to fully extend.

8. Prepare the sample for analysis (mix well), then

position the sample over the probe and press

the Aspirate button. The sample probe will

retract automatically once sufcient sample has

been aspirated into the analyzer.

9. Once the analysis is complete, press Save to

keep the QC results or press Delete to discard

the QC results.

3. Analysis

Figure 3.19 Position External QC Screen

3-11

Page 41

Prime CCS Instructions for Use Manual

3.3.3 AnalyzingProciencySamples

1.

From the Home Screen, press the QC button

2. Press the Analyze QC button .

3. From the drop-down list, press Select QC Level

to Analyze.

4. From the drop-down list select Prociency.

5. Press Start to begin the analysis.

6. Wait for the Sample Probe to fully extend.

Figure 3.20 Quality Control Screens

7. Prepare the sample for analysis (mix well) then

position the sample over the probe and press

Aspirate . The sample probe will retract

automatically once sufcient sample has been

aspirated into the analyzer.

8. Once the analysis is complete press Save to keep

the QC results or press Delete to discard them.

3-12

Figure 3.21 Prociency Sample Positioned on Probe

Page 42

4 Reviewing Patient and QC Data

4 Reviewing Patient and QC Data

Patient and QC Data are stored on the analyzer and

can be reviewed at any time. The following section will

demonstrate how to nd your data.

4.1 Reviewing Patient Data

To recall patient data, proceed as follows:

1. Press the Recall Results icon on the Menu

Bar to display the current date's patient results

2.

Select the patient result to review.(Figure 4.1)

3.

Then press to display

results (Figure 4.2).

the selected sample

4. Data

Figure 4.1 Results Screen

Figure 4.2 Patient Result Selected Data

4-1

Page 43

Prime CCS Instructions for Use Manual

4. If there is more than one page of data, up and

down arrow buttons will appear on the footer to

display all screens.

5. To view additional sample results, press the

"Start Date End Date" button.

6. Press the drop down menu for "Today, Yesterday,

Week, Month, Year, or All" for patient data; or

select the start and end dates on the screen.

7. Press the back button to display patient results

for the selected date range.

8. Select the desired patient result, then press

to display

9. To print the data, press the print icon on the

footer of the screen.

results.

4-2

Drop Down

Menu

Start and

End Date

Selection

Figure 4.3 Results Screens

Page 44

4 Reviewing Patient and QC Data

4.2 Reviewing QC Data

To recall any QC data on the analyzer, proceed as

follows:

1. Press the QC button on the Home screen

located in the footer of the screen.

2. The Quality Control screen displays: press the

"View QC Data" button.

3. The View QC Data screen displays. From this

screen, press the Start Date End Date button.

4. Press the drop down menu for "Today,

Yesterday, Week, Month, Year, or All" for QC

data; or select the start and end dates on the

screen.

5. Press the back button to display QC results.

6. A Level button is also available to select a QC

level from a drop down list.

7. A Lot button is available for choosing a QC lot.

8. Select a QC data date and press the to

display the data screen.

9. To print the data, press the print icon on the

footer of the screen.

4. Data

Figure 4.5 QC Results Screen

4-3

Figure 4.4 View QC Data Screen

Page 45

Prime CCS Instructions for Use Manual

4.3 QC Statistics

To view QC Statistics on the analyzer, proceed as

follows:

1. Press the QC button on the Home screen.

The Quality Control Screen displays.

2. Press the QC Statistics button to display the QC

Statistics screen.

Figure 4.6 Quality Control Screen

3. On this screen, press the Start Date End Date

button.

4. Press the drop down menu for "Today,

Yesterday, Week, Month, Year, or All" for patient

data; or select the start and end dates on the

screen.

5. Press the back button to display all the QC

Statistics for these selected dates.

6. To print the QC Statistics, press the print icon on

the footer of the screen.

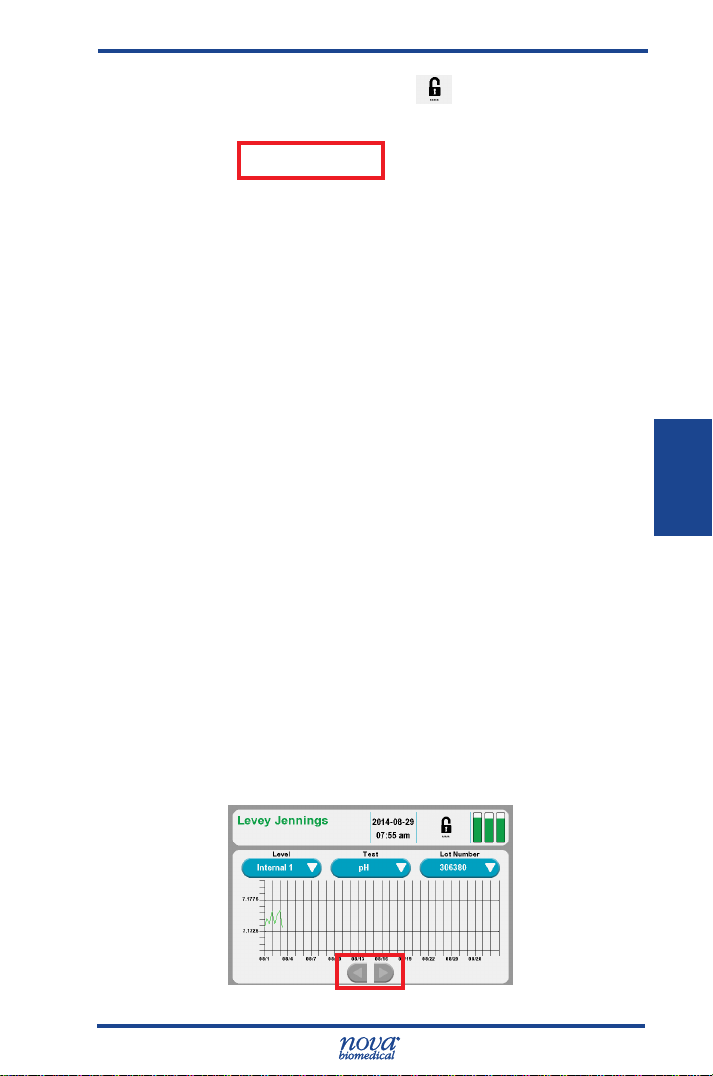

4.4 Levey Jennings Graphs

To generate a Levey Jennings graph on the analyzer,

proceed as follows:

1. Press the QC button on the Home screen.

The Quality Control Screen displays.

3. Press the Levey Jennings button to display the

Levey Jennings Graph screen.

4-4

Page 46

4 Reviewing Patient and QC Data

Figure 4.7 Quality Control Screen

4. Select the QC Level with the Level button for the

QC data. This displays a list of the levels that

have QC data.

5. Select the Test with the Test button. This

displays a list of the tests congured for the

analyzer.

6. Select the Lot Number with the Lot Number

button. This displays a list of the available lots

for the QC Level.

7. A graph dispays showing a Y-axis for the test

result and an X-axis for each day of a selected

level,lot, test, and month.

8. Touch the Right Arrow button to graph the QC

data of the next month that is available. Touch

the Left Arrow button to graph the QC data of

the prior month that is available.

9. To print the Levey Jennings Graph, press the

print icon on the footer of the screen.

4. Data

Figure 4.8 Levey Jennings Graph

4-5

Page 47

5 Consumables Replacement

5 Consumables Replacement

The following sections provide directions to operate and

maintain the Stat Prole Prime CCS Analyzer at peak

efciency. From the Home screen, press the Tool box icon

to display the System Menu screens (Figure 5.1). From

these screens, press the appropriate button to replace the

following consumables:

• MicroSensor Card

• Calibrator Cartridge

• Auto QC Cartridge

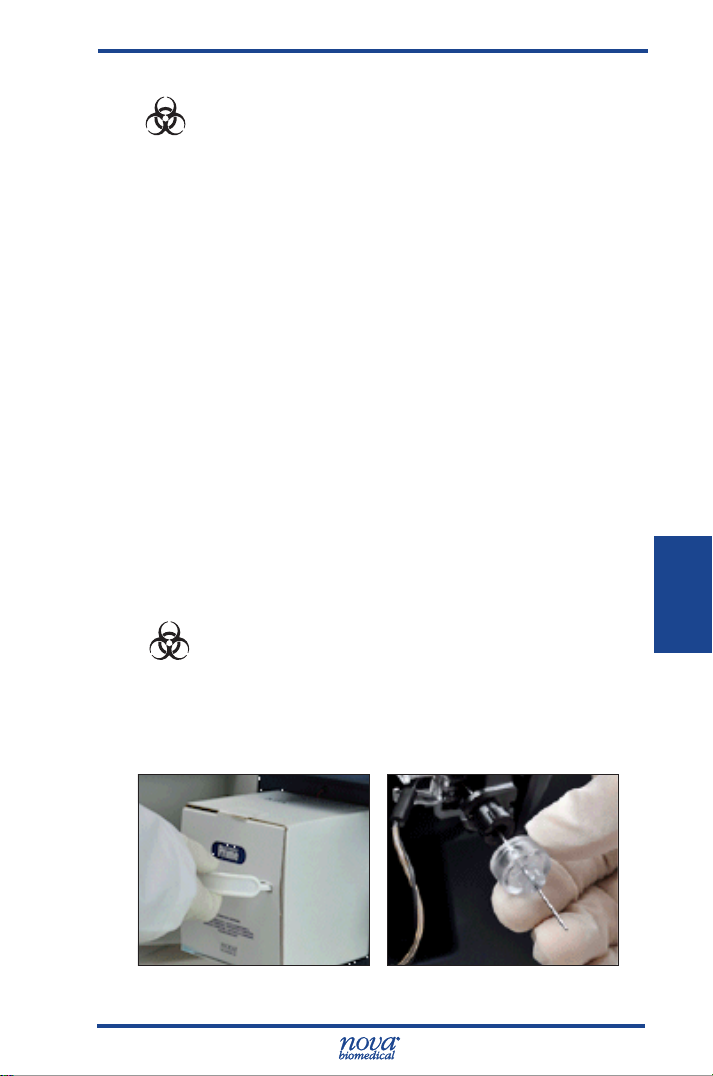

WARNING: Blood samples and blood products are

potential sources of infectious agents. Handle

all blood products, ow path components, and

accessories (waste-line, probe, MicroSensor

Card, clot catchers, ush tools/xtures, safety

sample port, etc.) with care. Gloves and

protective clothing are recommended. When

performing replacement and troubleshooting

procedures, also use protective eyewear.

5. Con Repl

Figure 5.1 System Menu Screens

The Cartridge Required screen (Figure 5.2) displays

when a new MicroSensor Card, Calibrator Cartridge, Auto

QC Cartridge, or Reference Cartridge has been removed

or requires replacement.

• The Sensor Card button displays if the

MicroSensor Card is not present, has zero

remaining life, or has not completed hydration.

5-1

Page 48

Prime CCS Instructions for Use Manual

Figure 5.2 Cartridge Required Screen

• The Calibrator Cartridge and/or Auto QC

Cartridge buttons display if the cartridge is not

present or has zero remaining life.

• The Reference Sensor button displays if the

Reference Sensor is not present.

Touching the button will bring you to the screen for

replacing this item.

5.1 Calibrator Cartridge and Auto QC Cartridge Replacement

The Calibrator Cartridge and/or Auto QC Cartridge should

be changed when the system indicates the cartridge

is empty. From the Home screen, press the Tool Box

icon . Then press Replace Calibrator Cartridge or

Replace Auto QC, as needed.

Mix the cartridge thoroughly by gentle inversions.

Then follow the directions on the screen to replace the

cartridge and the Capillary Adaptor.

WARNING: When the Calibrator Cartridge or Auto QC

Cartridge is removed, keep your ngers and

hands away from the back of the cartridge

compartment. Sharp needles can cause

injury, and the waste needle is a biohazard.

5-2

Page 49

5 Consumables Replacement

WARNING: Exposure to Blood Borne Pathogens.

Follow laboratory procedures.

NOTE: The Calibrator Cartridge and the Auto QC

Cartridge must be replaced through the Tool

Box screens. If you remove and replace a

cartridge (even if it is the same one) outside of

these screens, you will not be able to prime the

analyzer, and you will not be able to calibrate or

to analyze samples (Calibrator Cartridge) or to

analyze internal controls (Auto QC Cartridge).

If you have removed and replaced a cartridge

outside of these screens, go to the appropriate

screen and press Prime.

NOTE: The Capillary Adaptor comes in the Calibrator

Cartridge box. It is very important for the proper

operation of the analyzer that the Capillary

Adaptor be changed with every Calibrator

Cartridge change.

5.1.1 Replace the Calibrator Cartridge

WARNING: Exposure to Blood Borne Pathogens.

Follow laboratory procedures.

5. Con Repl

1. Press the Tool Box icon.

2. From the System Menu, press the Replace

Calibrator Cartridge button.

Figure 5.3 Remove Calibrator Cartridge and Capillary Adaptor

5-3

Page 50

Prime CCS Instructions for Use Manual

3. Open the door and remove the cartridge.

4. Slide in a new cartridge past the front

retaining lip.

CAUTION: Probe will move when Enter is pressed.

5. To replace the Capillary Adaptor, press the Enter

button. Slide off the used capillary adaptor.

Slide on the adaptor provided with Calibrator

Cartridge.

6. Close the analyzer door. Press the Prime button.

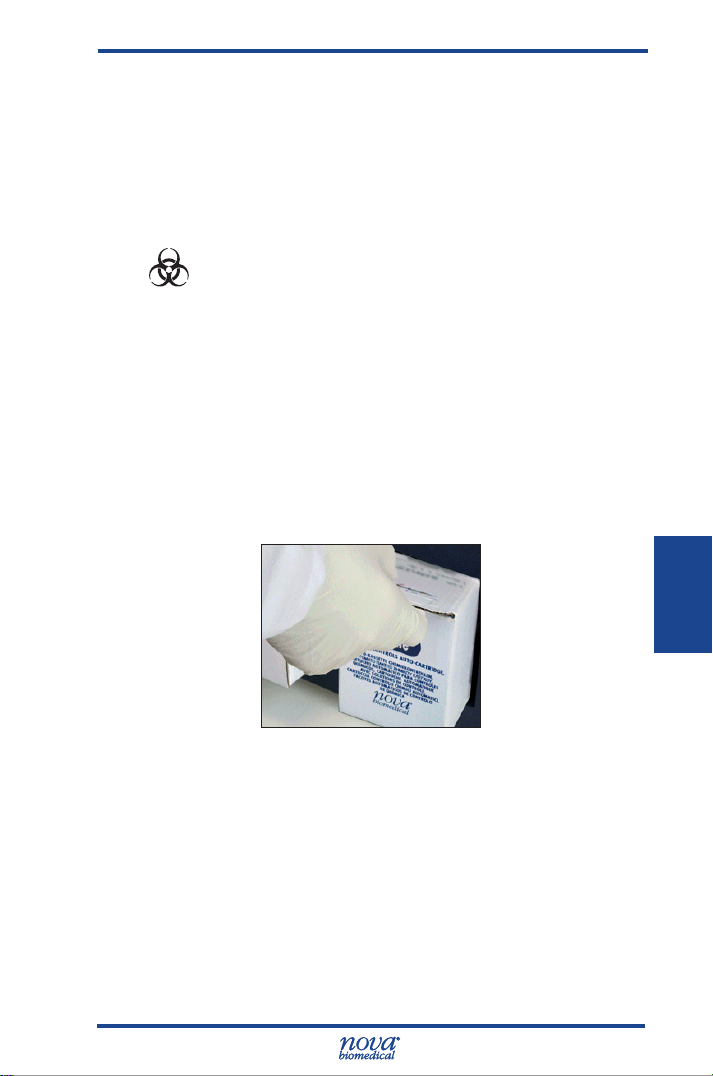

Calibrator Cartridge status can be viewed at any time by

pressing the Cartridge Status indicator icon at upper

right of the header bar.

5-4

Figure 5.4 MicroSensor Card Status

• The Calibrator status bar is empty (white) when

no Calibrator Cartridge is installed.

• The status bar is green and indicates the with

the remaining use life of the Calibrator Cartridge

when the use life remaining percentage is > 5%.

• The Calibrator status bar is orange when the

remaining use life is ≤ 5%.

• The screen displays the lot expiration date,

lot number, use life expiration date and time,

number of samples remaining, and percentage

use life remaining.

Page 51

5 Consumables Replacement

• When no cartridge is installed, all of the above

are blank.

• Press as appropriate the Install button or Replace

button.

5.1.2 Replace the Auto QC Cartridge

WARNING: Exposure to Blood Borne Pathogens.

Follow laboratory procedures.

1. Press the Tool Box icon.

2. From the System Menu, press the Replace

Auto QC button.

3. Open the analyzer door. Remove the Auto

QC Cartridge, if present.

4 Slide in a new cartridge, past the front

retaining lip.

5. Close the door. Press the Prime button.

5. Con Repl

Figure 5.5 Remove Auto QC Cartridge

Auto QC Cartridge status can be viewed at any time by

pressing the Status icon at upper right of the screen.

• The Auto QC status bar is empty (white) when

the Auto QC Cartridge is not installed.

• The Auto QC status bar is green when the

percentage remaining use life is > 5%.

5-5

Page 52

Prime CCS Instructions for Use Manual

Figure 5.6 Auto QC Cartridge Status

• The Auto QC bar is orange with the percentage

remaining use life of the Auto QC Cartridge if the

use life remaining percentage is ≤ 5%.

• The screen displays the lot expiration date,

lot number, use life expiration date, use life

expiration time, number of samples remaining,

and percentage use life remaining.

• If no pack is installed, all above is blank.

• There is either an install button to Install an Auto

QC Cartridge or a Replace button to replace an

Auto QC Cartridge.

5.2 Replace the MicroSensor Card

WARNING: Exposure to Blood Borne Pathogens.

Follow laboratory procedures.

1. Press the Tool Box icon.

2. From the System Menu, press the Replace

Sensor Card button. Wait for the pump to stop.

3. Open the analyzer door. Then open the

MicroSensor Card door. Remove the card.

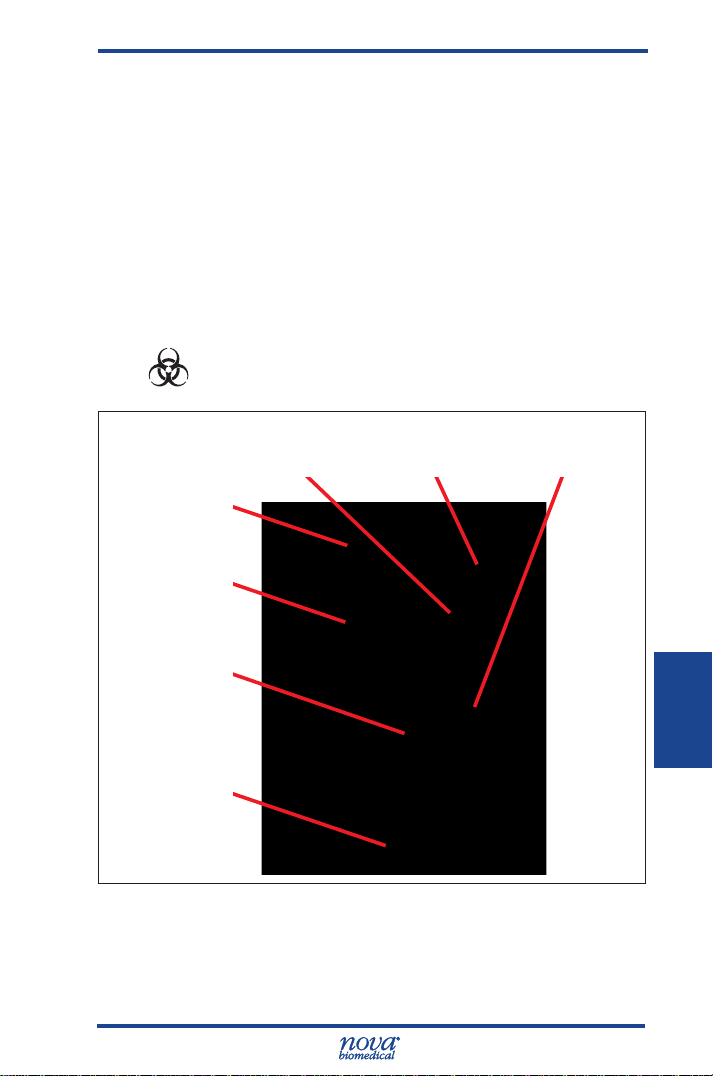

NOTE: Hold the MicroSensor Card as indicated in

Figure 5.7.

5-6

Page 53

5 Consumables Replacement

Hold by

Edges

Figure 5.7 MicroSensor Card

4 Insert the new card. Close the MicroSensor Card

door.

5. Close the analyzer door. Press the Prime button.

MicroSensor Card status can be viewed at any time by

pressing the Status icon on the upper right corner of

the screen.

• The sensor status bar is empty (white) when no

MicroSensor Card is installed.

• The bar is green and indicates the remaining use

life of the MicroSensor Card if the remaining use

life is greater than 5%.

• The status

remaining use life

use life

bar is orange

and indicates the

of the MicroSensor Card if the

remaining is less than or equal to 5%.

5. Con Repl

Figure 5.8 MicroSensor Card Status

5-7

Page 54

Prime CCS Instructions for Use Manual

• The screen displays the lot expiration date,

the lot number, the use life expiration date, the

use life expiration time, the number of samples

remaining, the percentage use life remaining.

• If no MicroSensor Card is installed, all above is

blank.

• There is either an Install button to install a

MicroSensor Card or a Replace button to replace

the Card.

5.3 Prime MicroSensor Card Warranty Process

If one or more analytes are unable to calibrate within the

MicroSensor Card warrantied use life, the analyzer will

generate a 16-digit warranty code that can be submitted

for credit towards a new MicroSensor card.

The scenarios described in Table 5-1 generate a warranty

code.

Warranty code generation depends upon the answers

to a series of questions the user is prompted to answer.

Following is a description of the screens and choices

presented to the user.

1. If a MicroSensor Card fails prior to its stated

warranty, the user is presented with the

following screen.

5-8

Figure 5.9 Warranty Screen

2. The user must select one of three options:

• Option 1: “Claim Sensor Card”. This option

provides the user with a warranty code which will

reimburse them for all of the available parameters

remaining on the MicroSensor Card to the end of

Page 55

5 Consumables Replacement

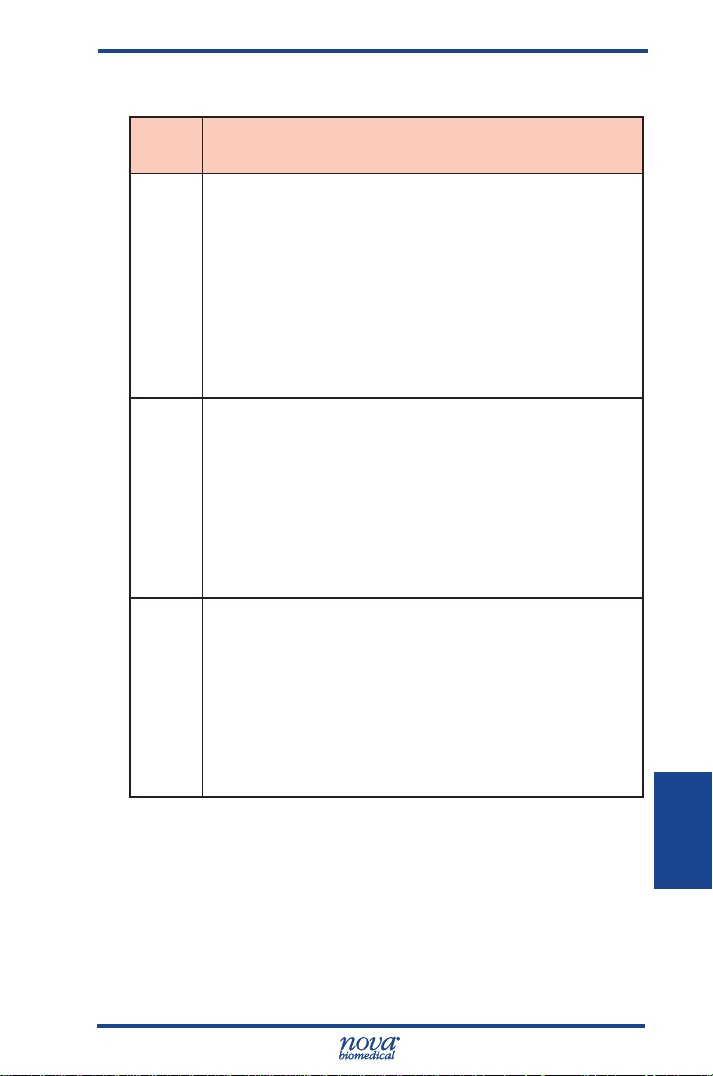

Table 5-1 Failures that Generate Warranty Codes

Failure Mode Action

Hydration Failure –

PCO

channel

2

Hydration Failure –

All other parameters

PCO

channel failure

2

during normal use

Any other channel

in normal use

the warranty period. If this option is selected, the

software will permanently deactivate the card.

• Option 2: “Claim Sensor”. This option

provides the user with a credit for only the failed

parameter but does not disable the remaining

parameters. The user is allowed to continue

using the remaining parameters on the card for

patient testing.

• Option 3: Choose to defer the choice

by selecting the cancel button . This only

defers the choice until the next time the failure is

detected.

The entire card is disabled. A single warranty

code is generated. The customer must install a

new card.

The sensor is automatically disabled and

a warranty code is generated and printed

automatically. The customer can continue using

the card or disable the remaining channels. To

disable the remaining channels and generate

a code for the rest of the card, the user must

select the disabled sensor – and follow the

prompts.

The PCO

a warranty code is generated and printed

automatically. The customer can continue using

the card or disable the remaining channels. To

disable the remaining channels and generate

a code for the rest of the card, the user must

select the white PCO

prompts.

The customer is presented with a popup that

allows disabling of the sensor or card.

is automatically disabled and

2

icon and follow the

2

5. Con Repl

5-9

Page 56

Prime CCS Instructions for Use Manual

3. Once the user has made a selection, the

appropriate conrmation dialogues are

presented.

Figure 5.10 Conrmation Dialogs

4. After conrmation, the Stat Prole Prime

analyzer will automatically print and save the

16-digit code. The code is stored in the analyzer

for future retrieval and is not lost.

5. The warranty codes can be retrieved at a later

time by pressing Menu > Service > Credits. The

codes are searchable by date range or printed

status. Note that the “Printed” status (right hand

column) refers to a reprint initiated from this

screen. It does not refer to the automatic printing

that occurs. This allows for easy identication of

any unclaimed codes.

6. Once the code is generated, the user must

provide it to customer support for a warranty

credit. Customers in the USA should contact

Nova Technical Support at 800-545–6682, In

Canada contact Nova Technical Support at

1-800-263-5999. Outside the USA or Canada

contact your local distributor.

5-10

Figure 5.11 Warranty Credits Screen

Page 57

6 Periodic Replacements

6 Periodic Replacements

Periodically the Pump Tubing Harness, Reference

Cartridge

replaced. This section gives procedures on replacements of

these consumable Items.

6.1 Pump Tubing Harness Replacement

The Pump Tubing Harness should be replaced at

intervals prescribed in the maintenance log. Replace the

tubing that goes around the pump as follows.

WARNING: Exposure to Blood Borne Pathogens.

, Sample Probe, or printer paper may need to be

Follow laboratory procedures.

Waste (W)

Line

Pressure

Plate

Tab of Tubing

Clip

Pump Tubing

Manifold; to

Reference

Cartridge

Pressure Plate

Release Button

Figure 6.1 Pump Tubing

Reference (R)

Line

Tubing Clip

6. Periodic

6-1

Page 58

Prime CCS Instructions for Use Manual

Figure 6.2 Replace and Install Pump Tubing Screens

1. From the Home screen, press the Tool Box icon.

2. From the System Menu, select Replace Pump

Tubing. Wait for the pump to stop.

3. Open the analyzer door. Then open the

MicroSensor Card door. Remove the

MicroSensor Card, if present.

4. Push the white button to release the Pump

Tubing Pressure Plate.

6-2

Figure 6.3 Release Pump Tubing Pressure Plate

5. Disconnect the W

and R tubes from the

analyzer.

6. Disconnect the tubing

connector from the

Reference Cartridge.

7. Remove the tubing

harness and discard.

8. Press the Enter

button to continue.

Figure 6.4

Disconnect Pump Manifold

Page 59

6 Periodic Replacements

Figure 6.5 Disonnect Tubing Connector from Reference Cartridge

6.1.1 Install the Pump Tubing

1. Install the tubing over the pump rollers.

2. Slide the tubing bracket under the locating tabs.

3. Connect the tubing connector to the Reference

Cartridge.

4. Connect the W and R tubes to the analyzer.

5. Close and latch the Pump Tubing Pressure

Plate.

6. Insert the MicroSensor Card.

7. Close the MicroSensor Card door.

8. Close the analyzer door.

9. Press the Prime button to continue.

6. Periodic

6-3

Page 60

Prime CCS Instructions for Use Manual

6.2 Probe Replacement

WARNING: Exposure to Blood Borne Pathogens.

Follow laboratory procedures.

If the Probe or Sample/Air Detector line become

damaged, replace the assembly. Use the following

procedure:

1.

From the Home screen, press the Tool Box

icon. From the System Menu select Replace S-Line

Probe and wait for the pump to stop.

2. Remove the capillary adaptor from the front of the

probe by gently pulling (Figure 6.6).

3. Disconnect the Air Detector Tube (Figure 6.7).

4. Disconnect the Air Detector Sample Line from the

Reference Cartridge module using the removal

Air Detector Tube

Connector

Figure 6.6

Remove Capillary Adaptor

6-4

Figure 6.7 Disconnect

Air Detector Tube

Page 61

6 Periodic Replacements

Removal Tool

Sample (S)-Line (connects to

Reference Cartridge)

Figure 6.8 Remove the S-line from the Reference Cartridge

tool (Figure 6.8).

5. Squeeze the white pinch clamp (Figure 6.9).

Remove the Probe, S-line, and Air Detector tube

Pinch

Clamp

S-Line (clear)

with Connection

to Reference

Cartridge

Air Detector

Line (gray) to

Analyzer

Figure 6.9 Remove Probe, S-line, and Air Detector Line

and discard.

6. Insert the new Probe assembly until it clicks into

place.

7. Install the Capillary Adaptor onto the probe.

8. Reconnect the S-line to the Reference Cartridge

9. Reconnect the Air Detector line into the analyzer.

10. Close the door.

11. Press the Calibrate button.

6-5

6. Periodic

Page 62

Prime CCS Instructions for Use Manual

6.3 Reference Cartridge Replacement

WARNING: Exposure to Blood Borne Pathogens.

Follow laboratory procedures.

1. From the Home screen, press the Tool Box icon.

2. From the System Menu, select the Replace Reference

button.

3. Open the door. Open the MicroSensor Card door.

4 Remove the MicroSensor Card, if present.

5. Disconnect the Sample (S)-line from the bottom of the

Reference Cartridge (Figure 6.10).

Pump Tubing

Manifold

Reference

Cartridge

MicroSensor

Card

6-6

S-Line

Figure 6.10 Reference Cartridge

6. Disconnect the Pump Tubing from the top of the

Reference Cartridge.

7. Slide the Reference Cartridge right to remove (Figure

6.11)..

8. Press the Enter button to continue.

Page 63

6 Periodic Replacements

Figure 6.11 Slide the Reference Cartridge Right to Remove

6.3.1 Install the Reference Cartridge

1. Position the new Reference Cartridge to the right of its

installed position.

2. Slide the Reference Cartridge left and into place.

3. Attach the S-Line to the bottom and Pump Tubing to

the top.

4. Insert the MicroSensor Card.

5. Close the MicroSensor Card door.

6. Close the analyzer door.

7. Press the Prime button to continue.

6. Periodic

6-7

Page 64

Prime CCS Instructions for Use Manual

6.4 Printer Paper Replacement

1. Open the printer cover.

2. Remove the depleted roll of paper.

3. Insert a new roll of paper. The loose end of the paper

should feed from the bottom of the roll.

4. Feed paper past the cover. Then close the printer

cover.

6-8

Figure 6.12 Replace the Printer Paper

Page 65

6 Periodic Replacements

6.5 Safety Sample Port Replacement

WARNING: Exposure to Blood Borne Pathogens.

Follow laboratory procedures.

1. Open the door.

2. Slide out the old Safety Sample Port.

3. Slide in a new Safety Sample Port.

4. Close the door.

Squeeze Pinch

Clamp to Remove

Safety Sample

Port

Figure 6.13 Replace the Safety Sample Port

6-9

6. Periodic

Page 66

Prime CCS Instructions for Use Manual

6-10

Page 67

7 Troubleshooting

7 Troubleshooting

This section describes the recommended troubleshooting

procedures for use with the Stat Prole Prime CCS

analyzer. The procedures use the most logical and

direct steps to resolve each problem and are written to

minimize the replacement of any unnecessary parts. If

the recommended solutions do not resolve the problem

please contact Nova Biomedical Technical Support for

troubleshooting assistance.

FOR TECHNICAL ASSISTANCE, CALL TOLL FREE:

USA 1-800-545-NOVA

Canada 1-800-263-5999

Other Countries Contact the local Nova

Biomedical Sales Ofce or

Authorized Nova Biomedical

Distributor

WARNING: Blood samples and blood products

are potential sources of infectious agents.

Handle all blood products, accessories,

and ow path components (waste-line,

capillary adaptor, probe, sensor cartridge,

etc.) with care. Gloves and protective

clothing are recommended. When

performing maintenance and troubleshooting

procedures, also use protective eyewear.

7. Trshoot.

7-1

Page 68

Prime CCS Instructions for Use Manual

7.1 Event Log

The Event Log displays a list of events that have

occurred during a selected time frame. To access the

Event Log: from the Home Screen, press:

> > >

The Event Log initially displays events that occurred on

the current date but may be changed to show events that

occurred during a specied time frame or that contain a

specic Event ID. Events are displayed chronologically,

with the most recent event at the top of the page.

Each event is shown with the date and time the event

occurred, the event ID and a description of the event.

To view additional details of a specic event, select

(highlight) the event of interest then press the Details

button . To print the Event Log press .

Figure 7.1 Event Screen

7.2 Resolving Event Codes

Event Codes are grouped into one of 5 categories,

Cartridge errors, Flow errors, Printer errors, MicroSensor

Card errors, and Hardware/Software errors. Use the

following troubleshooting steps to resolve the listed

codes.

If a displayed code is not listed, please contact Nova

Biomedical Technical Support for assistance.

7-2

Page 69

7 Troubleshooting

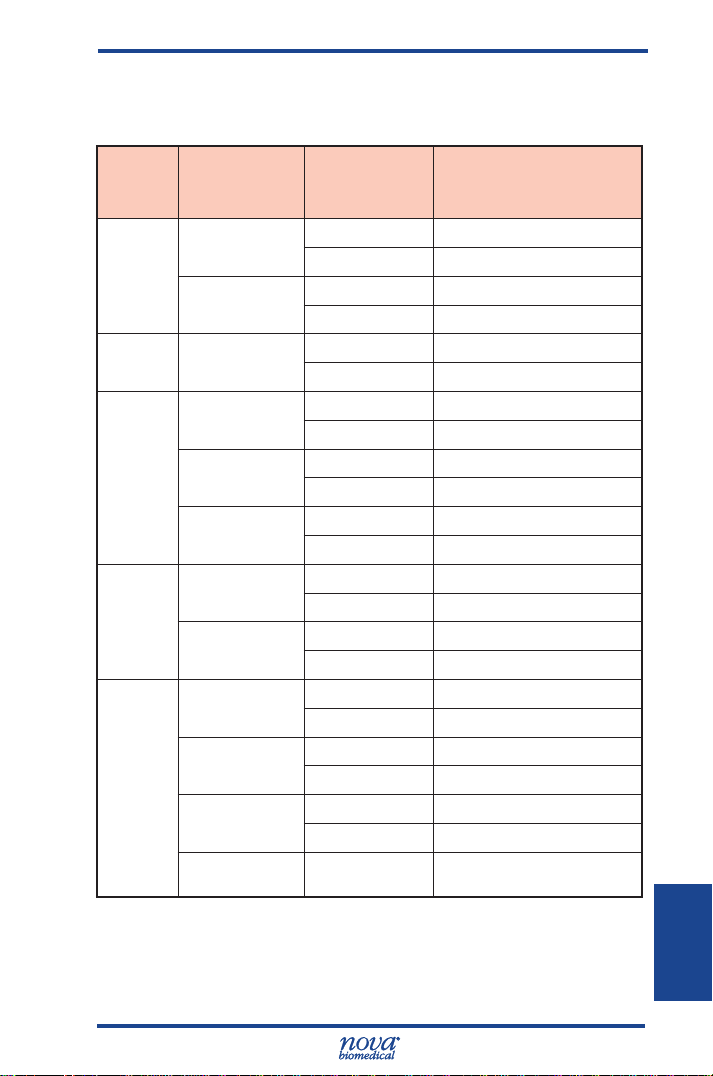

7.2.1 Flow Event Codes

Event

Code

Description and Corrective Action

602 Insufcient Sample – During the last sample

analysis, the leading edge of the sample was

not detected at the reference air detector when

expected.

Recommended Solution