Page 1

Training Manual

Page 2

Page 3

Stat Profile pHOx Training Record

Instructor's Name: ___________________________________

Trainee's Name: ___________________________________

12

3

4

5

6

7

8

9

0

Date Completed/Initials

DWG #10-1016A

Handling and Running Patient Samples .............................................. ___________________

Handling and Running Controls ......................................................... ___________________

Replacing the Reagent Pack and Paper ............................................. ___________________

Identifying Flow Path and System Components .................................. ___________________

Calibrating the Analyzer ................................................................... ___________________

Daily Maintenance ........................................................................... ___________________

Troubleshooting ............................................................................... ___________________

Page 4

Page 5

Table of Contents Stat Profile pHOx Training Manual

QUICK REFERENCE

Key Facts (pHOx) ............................................................................. QR-1

Maintenance Planner ......................................................................... QR-2

Resolving Results Problems.............................................................. QR-3

Key Facts (BioProfile pHOx)............................................................ QR-4

Preface

Stat Profile pHOx Customer Training Programs ...................................... i

Learning Objectives .................................................................................ii

1 System Identification ............................................................ 1-1

1.1 System Overview .....................................................................1-1

1.2 Flow Overview......................................................................... 1-3

1.2.1 Reagents ......................................................................1-3

1.3 Flow Components ....................................................................1-3

1.3.1 Reagent Pack............................................................... 1-3

1.3.2 Reagent Harness..........................................................1-4

1.3.3 Pinch Valves................................................................1-4

1.3.4 Peristaltic Pump ..........................................................1-4

1.3.5 Sampler Assembly — Sample Probe.......................... 1-4

1.3.6 Sensor Module ............................................................1-5

1.3.7 Sensors ........................................................................1-5

1.3.8 Reference Electrode ....................................................1-6

1.3.9 Sensor Blanks..............................................................1-6

1.3.10 Interconnect Tubing ....................................................1-6

1.3.11 Barometric Pressure Module.......................................1-6

1.3.12 Pump Tubing............................................................... 1-7

2 Running an Analysis ...................................................................... 2-1

2.1 Is the Instrument Ready for Analysis?.....................................2-1

2.1.1 Home Screen ...............................................................2-1

2.2 Patient Samples — Acceptable Samples/Sample Handling ....2-1

2.2.1 Acceptable Samples ....................................................2-1

2.2.2 Acceptable Anticoagulants .........................................2-2

2.2.3 Syringe Handling Tips ................................................2-2

2.2.4 Capillary Handling Tips..............................................2-3

2.2.5 Sample is Presented and Analysis Occurs ..................2-3

2.3 Sample Information..................................................................2-4

2.4 Results Screen and Printout .....................................................2-4

2.5 Running an Analysis Exercise .................................................2-4

2.6 Standby Mode ..........................................................................2-4

PN 24302 Rev. B 7/2001 TOC-1

Page 6

Table of Contents Stat Profile pHOx Training Manual

3 Operational Status ............................................................... 3-1

3.1 Home Screen - Ready for Analysis..........................................3-1

3.2 Questionable Results................................................................ 3-1

3.3 System Status Screen ...............................................................3-1

4 Calibrating the Analyzer ....................................................... 4-1

4.1 Full 2-Point Calibration - all except Hb and SO

4.2 Calibration Timing ...................................................................4-1

4.3 Other Types of Calibration ......................................................4-2

4.3.1 SO2 and Hb Calibration ..............................................4-2

4.3.2 Single Point Calibration for Non-Gas Sensors ...........4-2

5 Using and Handling Controls ................................................. 5-1

5.1 Controls ....................................................................................5-1

5.1.1 Stat Profile pHOx Controls .........................................5-1

5.2 Handling Controls ....................................................................5-1

5.2.1 Storage Temperature ...................................................5-1

5.2.2 Stability of Opened Ampules......................................5-2

5.2.3 Altitude and Barometric Pressure Effects...................5-2

5.3 When to Use .............................................................................5-2

5.4 Using the Stat Profile pHOx's On-Board QC Features...........5-2

5.4.1 The QC Soft key .........................................................5-3

5.4.2 Automatic QC Analysis (Internal) ..............................5-3

5.4.3 Manual QC Analysis (External)..................................5-3

5.5 QC Data....................................................................................5-7

5.5.1 View Today's Data ......................................................5-7

5.5.2 View Daily Statistics...................................................5-7

5.5.3 View Monthly Statistics..............................................5-8

5.5.4 Printing Levey-Jennings Charts.................................. 5-9

.......................

2

4-1

6 Replacing Reagents and Paper .............................................. 6-1

6.1 When to Replace ......................................................................6-1

6.2 How to Replace ........................................................................6-1

6.3 Replacing the Reagent Pack.....................................................6-1

6.4 Replacing the Control Pack......................................................6-1

6.5 Replacing the Printer Paper......................................................6-1

7 Troubleshooting ................................................................... 7-1

7.1 Sensor Screens .........................................................................7-1

7.2 System Test .............................................................................. 7-1

7.3 Error Log ..................................................................................7-2

7.4 Flow Related Problems ............................................................ 7-2

7.5 Sensor Problems.......................................................................7-3

7.6 Results Related Problems.........................................................7-3

7.7 Miscellaneous Problems - Operational ....................................7-3

7.8 Call Nova..................................................................................7-3

TOC-2 PN 24302 Rev. B 7/2001

Page 7

Table of Contents Stat Profile pHOx Training Manual

8 Flow Test and Flushing ......................................................... 8-1

8.1 Manual Flow Test Lab ............................................................. 8-1

8.1.1 Water (Flow) Test .......................................................8-4

8.1.2 Pump Test....................................................................8-5

8.1.3 Flushing Sensor Module, Air Detector, and Probe.....8-7

8.1.4 Flushing the Reference Electrode ...............................8-8

8.2 Flushing the Entire Flow Path..................................................8-9

8.3 Reference Solution Test .........................................................8-12

9 Maintenance ........................................................................ 9-1

9.1 Logging Maintenance...............................................................9-1

9.1.1 Maintenance Log Sheets .............................................9-1

10 Routine Maintenance .......................................................... 10-1

10.1 Overview ................................................................................10-1

10.2 General Maintenance Procedures...........................................10-1

10.2.1 Suggested Daily Start-up Procedure .........................10-2

10.2.2 Flowpath Cleaning/Deproteinizing...........................10-2

10.2.3 Flow Cell Conditioning.............................................10-5

11 Maintaining Sensors ........................................................... 11-1

11.1 Overview ................................................................................11-1

12 Periodic Maintenance.......................................................... 12-1

12.1 Replacement of Pump Tubing, R-Line, and W-Line.............12-1

12.1.1 Pump Tubing Replacement.......................................12-2

12.1.2 Waste Line Replacement ..........................................12-3

12.1.3 Reference Line Replacement ....................................12-4

12.2 Probe and Air Detector Replacement ....................................12-5

13 Setup ................................................................................ 13-1

13.1 Adapting the Analyzer to Meet Your Requirements ............. 13-1

13.1.1 Data Input Display Options ......................................13-1

13.1.2 General Operating Options .......................................13-2

13.2 Inputting Selections................................................................13-2

13.3 Setup Menu Checklist ............................................................ 13-3

13.3.1 Results Configuration Menu Checklist.....................13-4

13.3.1.1 Reference & Alert Limits Setup Checklist 13-5

13.3.1.2 Electrode Offsets Setup Checklist............. 13-6

13.3.1.3 Results Units Setup Checklist ...................13-7

13.3.1.4 Results Suppression Checklist...................13-8

13.3.1.5 Remote Review..........................................13-9

13.3.1.6 Patient Name..............................................13-9

13.3.1.7 Mandatory Patient ID ................................13-9

PN 24302 Rev. B 7/2001 TOC-3

Page 8

Table of Contents Stat Profile pHOx Training Manual

13.3.2 Operation Configuration Checklist .........................13-10

13.3.2.1 Analysis Configuration Checklist ...........13-11

13.3.2.2 Calibration Configuration Checklist .......13-12

13.3.2.3 System Configuration Checklist..............13-13

13.3.2.4 Analysis Mode Checklist.........................13-15

13.3.2.5 Hb Type Checklist ...................................13-15

13.3.2.6 Stat Mode.................................................13-15

13.3.3 Communication Menu Checklist ............................13-16

13.3.4 Printer Checklist......................................................13-17

13.3.5 System Password Checklist ....................................13-18

13.3.6 Operator Password Checklist ..................................13-18

13.3.7 Language Checklist.................................................13-19

14 QC Setup ........................................................................... 14-1

14.1 QC Setup Checklist ................................................................14-1

14.1.1 Control Lot Checklist................................................14-3

14.1.2 Expiration Date Checklist .........................................14-3

14.1.3 Daily Analysis Time Checklist .................................14-4

14.1.4 QC Lockout Checklist...............................................14-5

14.1.5 Set Ranges Checklist.................................................14-5

15 Troubleshooting Lab ........................................................... 15-1

15.1 Troubleshooting Exercises .....................................................15-1

Problem #1 .............................................................................15-2

Problem #2 .............................................................................15-2

Problem #3 .............................................................................15-3

Problem #4 .............................................................................15-3

Problem #5 .............................................................................15-4

Problem #6 .............................................................................15-4

16 Examination/Evaluation ..................................................... 16-1

16.1 Certificate and C.E.U. Credits ...............................................16-1

Training Examination.............................................................16-3

Training Evaluation................................................................16-7

A Appendix ............................................................................. A-1

A.1 Technical Assistance............................................................... A-1

A.1.1 Telephone Technical Support (Hot Line) ..................A-1

A.1.2 Field Service Support .................................................A-2

A.2 Ordering Parts ......................................................................... A-3

A.2.1 Recommended Spare Parts......................................... A-3

A.3 Warranty Replacements .......................................................... A-4

A.4 Emergency (After Hours) Parts Shipments.............................A-4

A.5 Reaching your Nova Sales Representative ............................. A-4

TOC-4 PN 24302 Rev. B 7/2001

Page 9

Quick Reference Stat Profile pHOx Training Manual

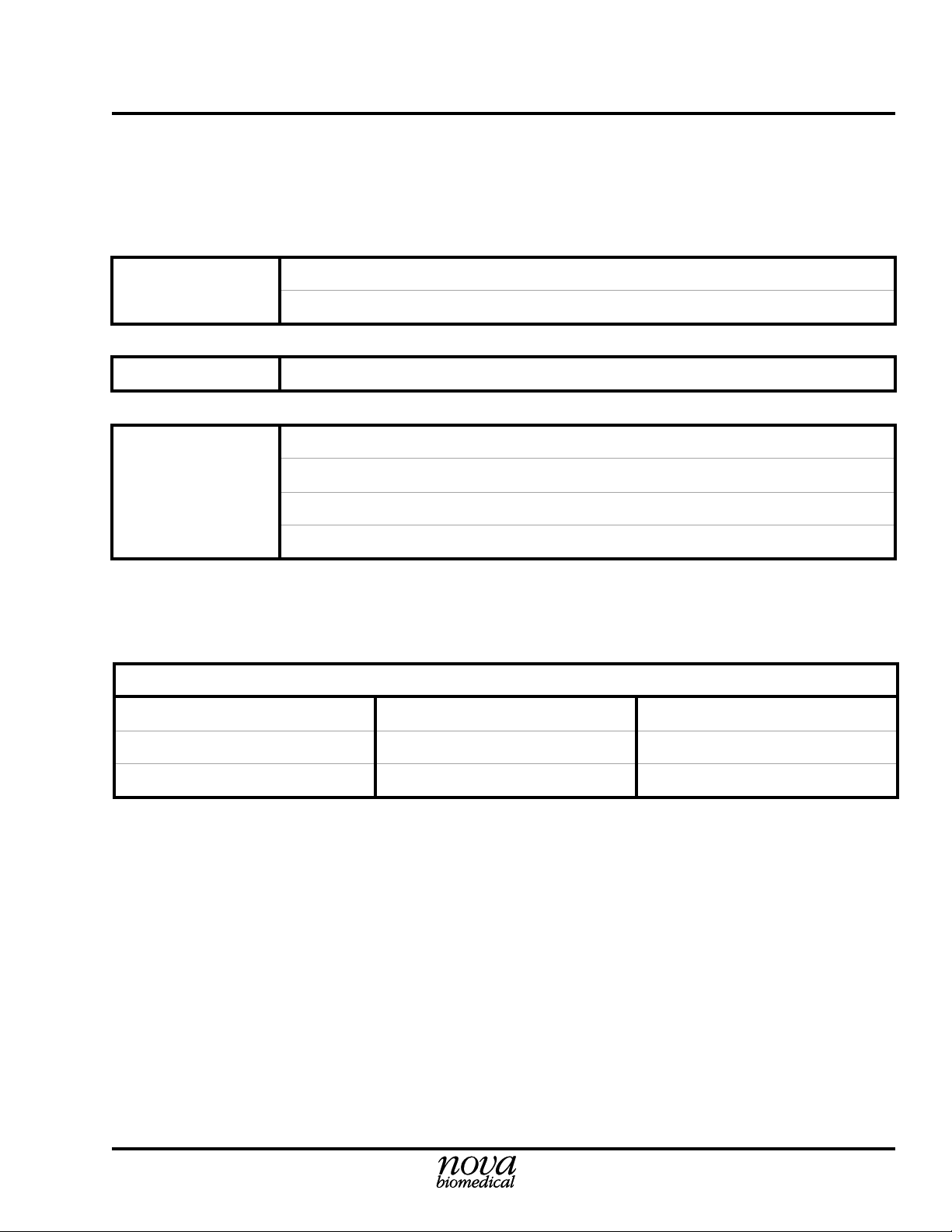

Key Facts (pHOx and pHOx Basic)

NOTE:

The pHOx Basic Analyzer measures only pH, PCO2, and PO2.

Sample Volume: 45 microliters whole blood (Micro sample)

70 microliters whole blood (Normal sample)

Slope Limits:

pH 9.1 - 11.6

PCO

PO

2

SO

2

+

Na

2

(-15.0) - ( -1.6)

7.9 - 12.6

6.9 - 18.2

8.8 - 11.5

Hct 12.0 - 50.0

Measurement Range:

pH 6.50 - 8.00 pH units H+ 316.23 - 10.00 nmol/L

PCO

PO

2

SO

2

2

3.0 - 200 mmHg 0.4 - 26.7 kPa

0 - 800 mmHg 0.0 - 106.7 kPa

0.0 - 100 % 0.0 - 1.0

Hb 4.0 - 24.0 g/dL 40.0 - 240.0 g/L 2.5 - 14.9 mmol/L

Hct 12 - 70 %

Dependency Rule and Information:

Hct Requires Na+ calibrated for calibration/results.

PCO

SO

2

2

Requires pH calibrated for results. (pH is checked on standards to assure bicarb is correct.)

Requires Hct and PO2 calibrated for results (uses calculated SO2 if measured SO2 is not

available).

Hgb Requires Hct and SO2 for reporting.

Priority:

1. If linked with the CO-Ox, then CO-Ox Hgb is reported.

2. If no CO-Ox or measured result, calculated result from Hct reading (Hct/3) is reported.

3. If no CO-Ox, no measured, and no Hct, analyzer reports Default Value (Hgb).

P50 Measured reported only with PO

between 30 and 75 mmHg.

2

P50c is reported when PO2 is outside above limits.

Also P50 requires calibrated SO2% and Hgb/Hct for reporting.

Qsp Qt Requires 2 separate blood samples for determination: mixed venous and arterial.

RI Utilizes input or default FIO2% for calculation.

Calculated Results Requires calibrated and proper results by measured tests used in calculation.

Suppression (Hgb) Only Hgb can be suppressed. Your option is to turn Hgb from measured to calculated (one

or the other will always appear). Option is done in the Setup Menu.

Update to PN 24302 Rev. B 3/2002

QR-1

Page 10

Page 11

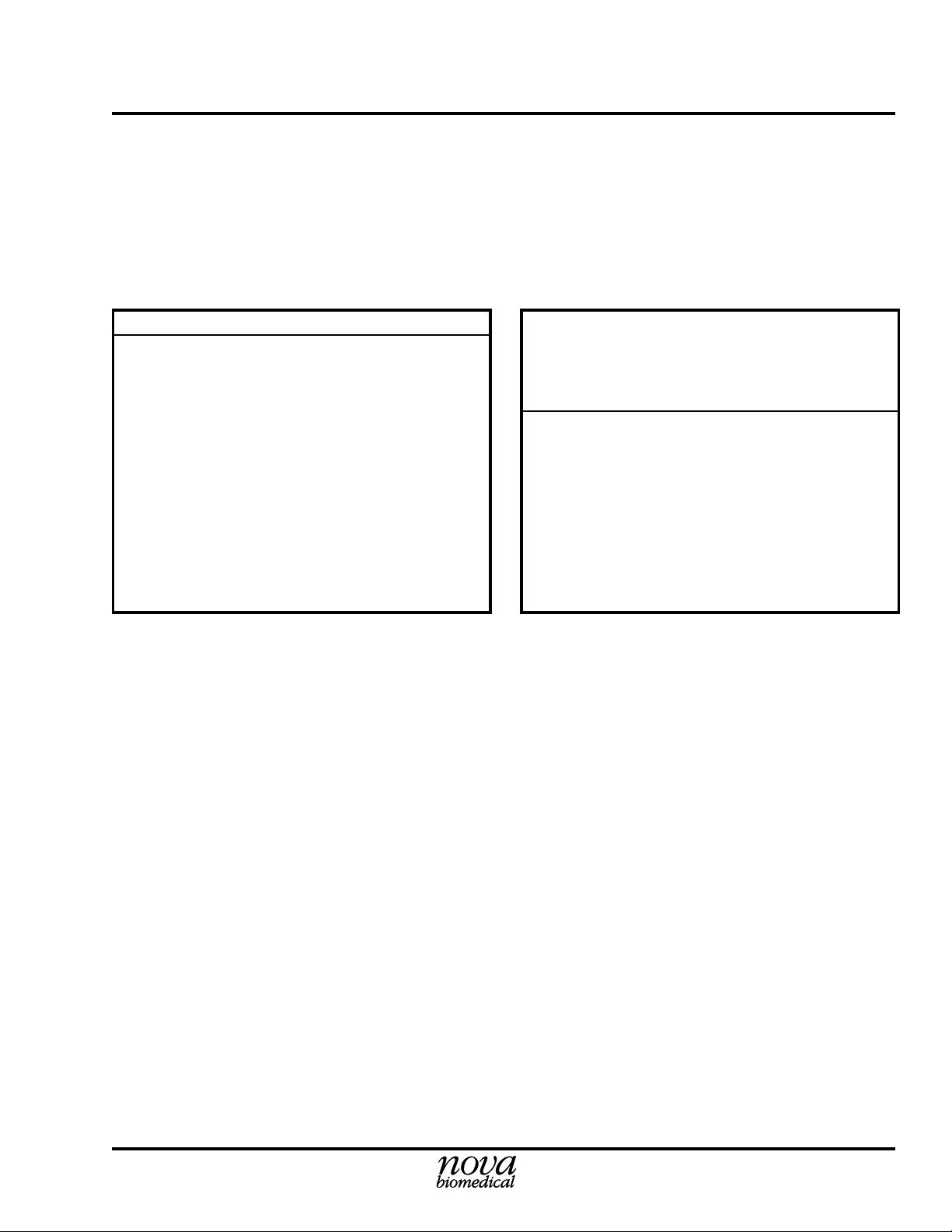

Quick Reference Stat Profile pHOx Training Manual

Maintenance Planner

Weekly

Monthly

Quarterly

NOTE:

For the BioProfile pHOx, SO2 is not applicable.

Reposition Tubing in Pinch Valves

Record Slopes

Calibrate SO2

Clean SO2 Sensor and Cuvette

Replace Pump Tubing

Replace W-line

Replace R-line

As Needed

Deproteinize Probe/Sensor Module Replace Probe Replace Reagent Pack

Replace PO2 Cap Condition pH Sensor Replace Control Pack

Replace PCO2 Cap Replace Sensors Replace Printer Paper

QR-2

Page 12

Page 13

Quick Reference Stat Profile pHOx Training Manual

Resolving Results Problems

Flow problems are often accompanied by sensor related problems. Do not change sensors or membranes until flow problems have been resolved first.

NOTE:

For the BioProfile pHOx, use protein solution instead of whole blood;

blood gases are just gases; SO2 is not applicable.

Blood Gases SO2

PO2/PCO2

Results High Verify controls are at room temperature

or Low

Check for low slope

Change membrane

Change sensor Results High Verify controls are at room temperature

Debubble sensor or Low Check for low sensor slope (<9.5)

Condition sensor module w/whole blood Condition w/pH Conditioning Solution

Calibrate

Check for air leak in system

Clean probe and preheater

Check waste line for restrictions Change reference electrode

Results High Recalibrate, clean cuvette and sensor,

or Low inspect or replace washer

pH

Condition sensor module w/whole blood

Verify reference solution delivery

Change pH sensor

QR-3

Page 14

Page 15

Quick Reference Stat Profile pHOx Training Manual

Key Facts (BioProfile pHOx)

Sample Volume: 300 microliters sample size for full panel

Slope Limits:

pH 9.1 - 11.6

PCO

2

PO

(-15.0) - (-1.6)

2

Measurement Range:

pH 5.00 - 8.00 pH units

PCO

2

PO

2

BarP 400.0 - 800.0 mmHg 53.3 - 106.7 kPa 15.7 - 31.5 inHg

7.9 - 12.6

3.0 - 200 mmHg 0.4 - 26.7 kPa

0 - 800 mmHg 0.0 - 106.7 kPa

Dependency Rule and Information:

PCO

2

Requires pH calibrated for results. (pH is checked on standards to assure bicarb is correct.)

Calculated Results Requires calibrated and proper results by measured tests used in calculation.

QR-4

Page 16

Page 17

Preface Stat Profile pHOx Training Manual

Stat Profile

Stat Profile® and pHOx® are registered trademarks of Nova

Biomedical.

Training on the Stat Profile pHOx Analyzer is intended to be carried

out by a Nova training specialist utilizing this training guide, the

reference manual shipped with the analyzer, training aids, and supplemental hands-on exercises as appropriate.

Training has been designed to be carried out in several stages

corresponding to the operator’s involvement level. When carried out

at your location, the time you make available per training session will

determine how much material can be covered.

Basic operator training requires approximately 1-2 hours, based on

analyzer features and the participants' prior experience. Key or

principal operator training requires an additional 2 hours of training.

See the following page for topics generally covered.

®

pHOx® Customer Training Programs

NOTES:

For additional information on training programs and materials, contact the Nova customer training department at:

(800) 545-NOVA ext. 571

i

Page 18

Preface Stat Profile pHOx Training Manual

NOTES:

Learning Objectives

Basic Operator Training is designed to provide a new (first line) operator

with skills to:

• Perform analyses of patient and QC samples

• Locate and use selected software screens and functions

• Identify major components

• Perform routine maintenance procedures

• Identify error conditions

• Carry out simple corrective procedures

• Use the reference manual or the Nova Hot Line as necessary

Key Operator Training adds those skills and information to:

• Perform all routine maintenance procedures

• Locate and utilize all necessary software screens and

functions

• Identify performance trends and patterns

• Introduction to Nova support service

• Customize maintenance schedules

• Apply advanced troubleshooting techniques to resolve

fluidic, calibration, and results-related problems

• Identify pre-analytical and other sources of sample handling

error

• Use troubleshooting guides to resolve results-related

problems

• Train additional operators in the workplace

Management Options will be discussed with the medical and/or

technical director. They include the following:

• Adapting the analyzer to the facility’s needs (setup options)

• Guidelines for analyzer performance verification

(See

Getting Your Nova Analyzer On Line

- Linearity

- Precision

- Correlation

• QA Program options

• CLIA compliance

ii

, PN 17361.)

Page 19

1 System Identification Stat Profile pHOx Training Manual

NOTES:

1 System Identification

1.1 System Overview

• The display is a backlit liquid crystal display (LCD) for

menus and messages. Menus allow use of operating options

and features.

• The keypad is the primary input device.

• The internal printer prints patient results, QC, setup information, error log, etc.

• The analytical compartment is where all calibration reagents enter and the sensor measurements take place.

• Reagents enter from the reagent pack. Waste materials

(samples and reagents) are expelled into the reagent pack

waste bottle.

• Sensors and air detectors are automatically calibrated periodically to insure accuracy.

1-1

Page 20

1 System Identification Stat Profile pHOx Training Manual

NOTES:

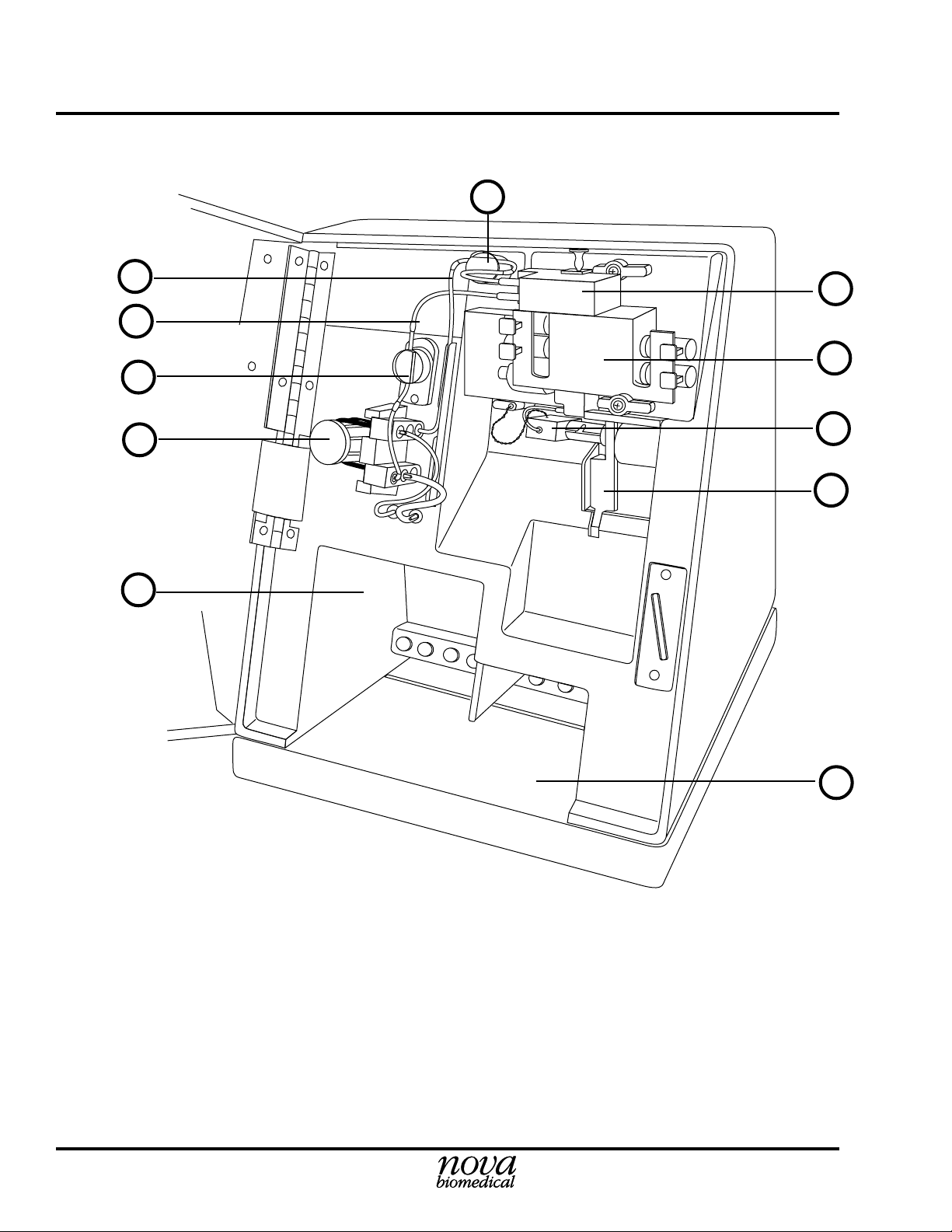

11

1

10

2

9

3

4

8

7

DWG #10-1017A

5

1-2

6

Figure 1.1 Analytical Compartment

1. Waste Line 7. Sampler

2. Reference Line 8. Air Detector

3. Pinch Valve (Reference) 9. Sensor Module with Sensors

4. Pump and Pump Tubing 10. Reference Electrode

5. Reagent Pack Opening 11. Pinch Valve (Waste)

6. Control Pack Opening

Page 21

1 System Identification Stat Profile pHOx Training Manual

NOTES:

1.2 Flow Overview

1.2.1 Reagents

Reagents are drawn from the reagent pack, through the reagent harness,

through the rotary valve, to the fluid fountain by way of the sample

tubing, where they are aspirated by the sample probe.

The sample probe can aspirate different reagents depending upon the

position of the rotary valve.

Aspirated fluids are drawn through the probe, the air detector, the

sensor module with sensors, reference electrode, around the pump and out

through the waste line to the waste container in the reagent pack.

1.3 Flow Components

1.3.1 Reagent Pack

The reagent pack contains 6 flexible bags in a cardboard carton. One

of these is a waste bag to collect the used reagents, controls, and

samples. The other 5 bags contain standard reagents: A, B, C, D, and

R. Each bag includes a polyethylene fitment with a septa seal. The

waste bag has a hydrophobic air vent.

Septa are arranged in a line along the rear of the pack. The septa are

pierced during insertion of the pack. The lot number and expiration

date are at the front of the pack.

The Reagent Management System (RMS) of the reagent pack automatically enters the calibration values, the lot number, the fluid

volumes, and the expiration date to the analyzer's computer after

insertion of the reagent pack.

Instructor shows all

these parts as they

are described.

Instructor points out

that the reagent pack

can be inserted and

removed a few times.

1-3

Page 22

1 System Identification Stat Profile pHOx Training Manual

NOTES:

1.3.2 Reagent Harness

The Reagent Harness transports reagents from the reagent pack to the

rotary valve. It is replaced as part of annual maintenance by Nova

Service.

1.3.3 Pinch Valves

There are 2 pinch valves: one is used to control the flow of the

reference fluid and the other one is used to control the flow of fluids

through the flow cell.

1.3.4 Peristaltic Pump

The pump is a 6-roller peristaltic pump driven by a stepper motor.

1.3.5 Sampler Assembly — Sample Probe

The sampler allows for the aspiration of the sample. The sampler has

2 sampling positions: horizontal for the aspiration of a sample from a

capillary tube and inclined for the aspiration of the sample from a

syringe. A capillary adapter automatically moves to the end of the

probe when the Capillary Analyze key is pressed. No special adapters

are required to aspirate a sample from a capillary tube. The capillary

or syringe positions are selected by pressing the Black Capillary key

or the White Syringe key.

1-4

Page 23

1 System Identification Stat Profile pHOx Training Manual

NOTES:

1.3.6 Sensor Module

The sensor module includes the preheater and flow cell. The preheater

preheats samples and controls to 37°C. In addition, it contains the

hematocrit impedance sensor and 2 air detectors. The sensor module

geometry is an interlaced configuration with the reference electrode

at the top of the sensor module, 3 sensors on the left side, 2 sensors on

the right side. In addition to the Hct sensor located in the preheater,

there are 6 sensors: Reference Electrode, Na+, PCO2, SO2 (optic), pH,

and PO2. A window in the door allows flow path visibility and is

augmented by a backlight.

1.3.7 Sensors

The Sensors housed in the sensor module are the core of the Stat

Profile pHOx Analyzer. The methodology used by each sensor are

Sensor Methodology

+

Na

Sodium ion-selective electrode

pH Hydrogen ion-selective glass electrode

PCO

PO

2

2

Severinghaus-type electrode

Polarographic Clark-type electrode

Hct Impedance electrode

Hb Impedance electrode/photometry

SO

2

Reflectance photometry (fiber optics)

The sensors clip into the sensor module, and an electrical contact is

automatically made.

1-5

Page 24

1 System Identification Stat Profile pHOx Training Manual

NOTES:

1.3.8 Reference Electrode

The Reference Electrode is mounted above the sensor module. It is a

solid-state Ag/AgCl electrode and provides the reference voltage for

comparison to sample voltages. The exit port of the flow path is

located on this electrode.

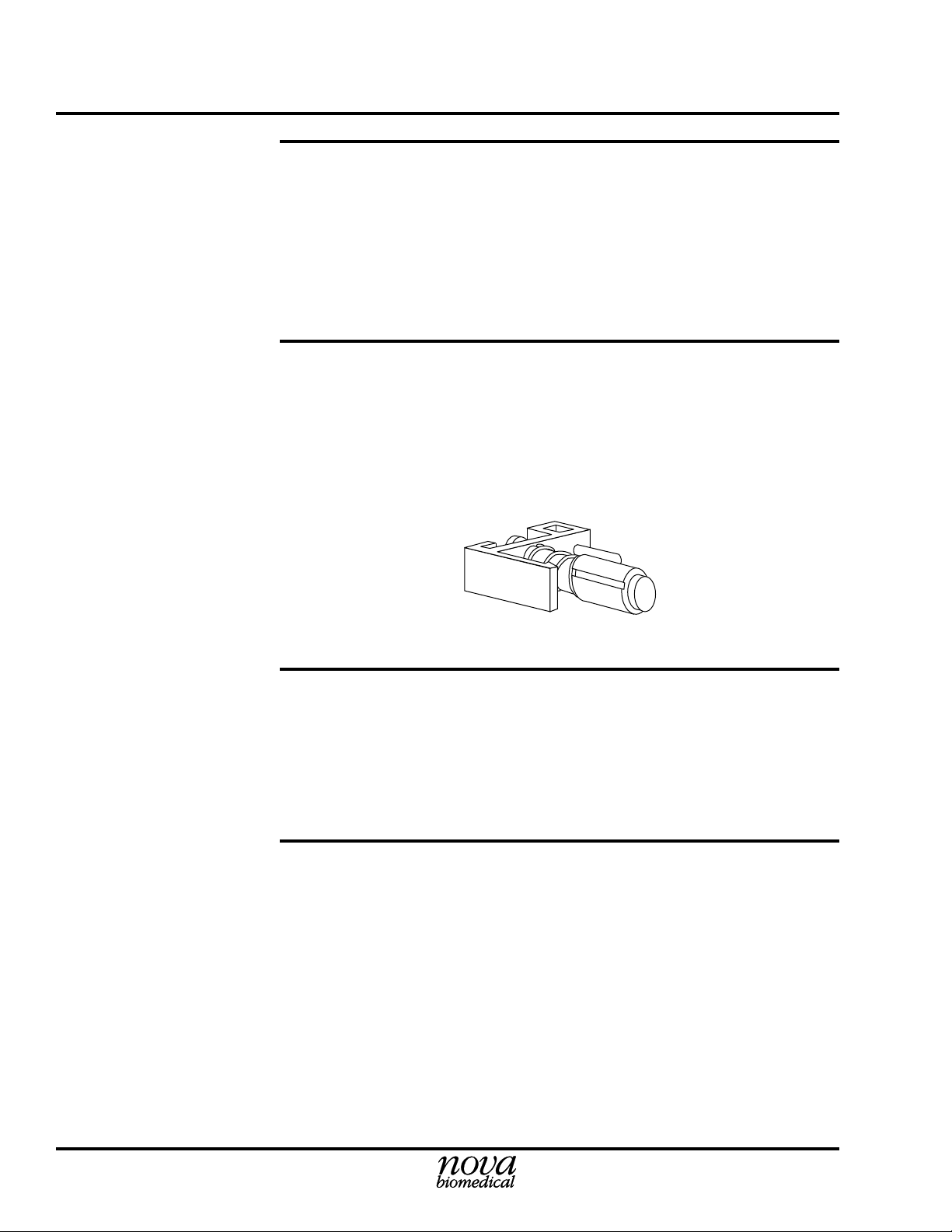

1.3.9 Sensor Blanks (PN 22507)

Sensor Blanks (see Figure 1.2) are used in place of sensors that are not

present on the analyzer or that are removed for certain maintenance and

troubleshooting procedures. Periodically (as needed) remove blanks

and clean the flow cell and tip of the blank with a cotton-tipped

applicator that is moistened with bleach.

DWG #7-0-039A

Figure 1.2 Sensor Blank

1.3.10Interconnect Tubing (PN 07161)

Interconnect Tubing is installed between the reference electrode and

the sensor module.

Required for the proper sealing of these components.

1.3.11Barometric Pressure Module

The Barometric Pressure Module, located on a printed circuit board,

continuously monitors the barometric pressure. This barometer can

be calibrated against an external barometer, if desired, through the

software.

1-6

Page 25

1 System Identification Stat Profile pHOx Training Manual

NOTES:

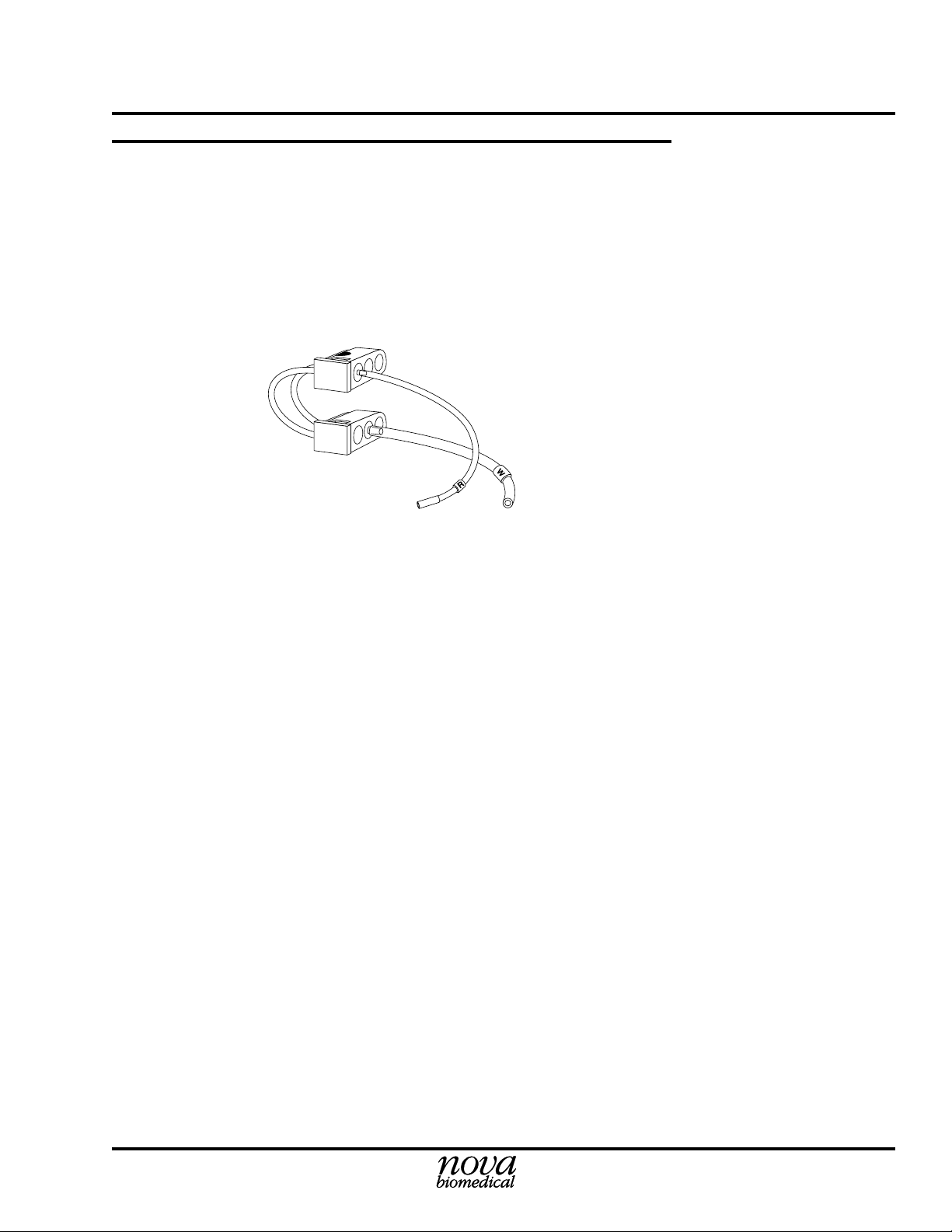

1.3.12Pump Tubing

The pump tubing has 2 manifolds (a top and bottom) and reference and

waste tubing, labelled R and W. The top manifold can be identified by

the half circle (right-sided). The R and W-pump tubing are connected

to the corresponding labeled outlets below the pump.

G #10-1007A

DW

Figure 1.3 Pump Manifolds and Tubing

1-7

Page 26

1 System Identification Stat Profile pHOx Training Manual

NOTES:

1-8

Page 27

2 Running an Analysis Stat Profile pHOx Training Manual

NOTES:

2 Running an Analysis

2.1 Is the Instrument Ready for Analysis?

2.1.1 Home Screen

Check the Home screen for Ready to analyze. The screen displays all

analytes with the uncalibrated ones x'd out. Also, the next QC and

Calibration times are displayed. A bar graph for the amount of

reagents and controls shows the approximate percent remaining.

For whole blood

2.2 Patient Samples — Acceptable Samples/Sample Handling

analysis only.

2.2.1 Acceptable Samples

The acceptable sample is heparinized whole blood.

Nova instruments are designed for clinical environments to analyze

actual patient specimens, not modified blood samples. Specimens

removed from the patient, anticoagulated appropriately, and promptly

analyzed are the only type of sample where the measurement results

will be reliable. Matrix effects/interferences can occur when patient

specimens are removed from the body, modified and then measured

on a Nova instrument. For example, matrix effects have been seen on

Nova analyzers when attempting to analyze samples collected from

cell savers used in various surgical procedures. Also, evaluation

laboratories run specimens from patients with a wide variety of

pathologies and from patients who are being treated with a broad

spectrum of therapeutic and pharmacological agents. Despite extensive clinical trials, it is not possible to anticipate every possible

combination of transfused blood products, crystalloids, and drugs (or

their metabolites) that may be present in a blood sample. As a result,

some users have found that their particular patient mix has necessitated making adjustments to maintenance. For example, a high

number of cardiopulmonary bypass pump or ECMO (extracorporeal

membrane oxygenation) samples result in a need for increased analyzer maintenance. If you are experiencing excessive downtime, you

may need to modify your own maintenance schedules. Nova’s Clinical Applications Group will assist you in tailoring a maintenance

program to meet these needs.

No serum or plasma

unless operator has

validated the system

for that purpose.

No urine, CSF,

cardioplegia solution,

or other body fluids.

Update to PN 24302 Rev. B 3/2002

2-1

Page 28

2 Running an Analysis Stat Profile pHOx Training Manual

NOTES:

This means no EDTA

(purple tops), NaF

(gray tops), or

uncentrifuged red

tops.

A general rule of thumb

for blood gas and

electrolyte analysis is

to run the sample

within 15 minutes of

the time it was

collected.

P

O2.... may increase in a

blood sample collected

into a plastic syringe

and stored on ice. The

NCCLS document

C32-P discusses

these increases.

2.2.2 Acceptable Anticoagulants

Sodium and lithium heparin resulting in a final concentration of not more

than 20 I.U. per mL in blood are the only acceptable anticoagulants.

2.2.3 Syringe Handling Tips

1. Remove air at time of collection.

2. Mix sample thoroughly by rolling between hands.

3. Run as soon as possible after collection. Do not ice plastic

syringes.*

4. Check for clots by expelling a drop of blood onto a gauze

pad.

5. For repeat samples, expel any air left in syringe.

6. Position sample so that probe tip stays deep in the syringe

but not touching the syringe plunger.

* NCCLS. Nov., 1993. Considerations in the simultaneous measurement of blood gases,

electrolytes and related analytes in whole blood., NCCLS document C32-P. Vol. 13, No. 17.

2-2

Page 29

2 Running an Analysis Stat Profile pHOx Training Manual

NOTES:

2.2.4 Capillary Handling Tips

• Collect in heparinized capillary tubes only.

• Place metal “flea” (stirring bar) in capillary prior to collecting sample.

• Sample must be collected without air spaces or gaps in

capillary.

• Using magnet, mix well after collection.

• Cover tube ends with removable caps (not clay seal) for

transportation to lab.

• See additional notes in Chapter 1 of the Reference Manual.

2.2.5 Sample is Presented and Analysis Occurs

Press the White Button (Syringe) or the Black Button (Capillary) to

run an analysis. The Aspirate screen displays. Wait until the sample

probe is in position. Present the sample to the probe.

Instructor

demonstrates

analysis.

Samples can be presented in a syringe, opened vacuum tube, sample

cup, or capillary.

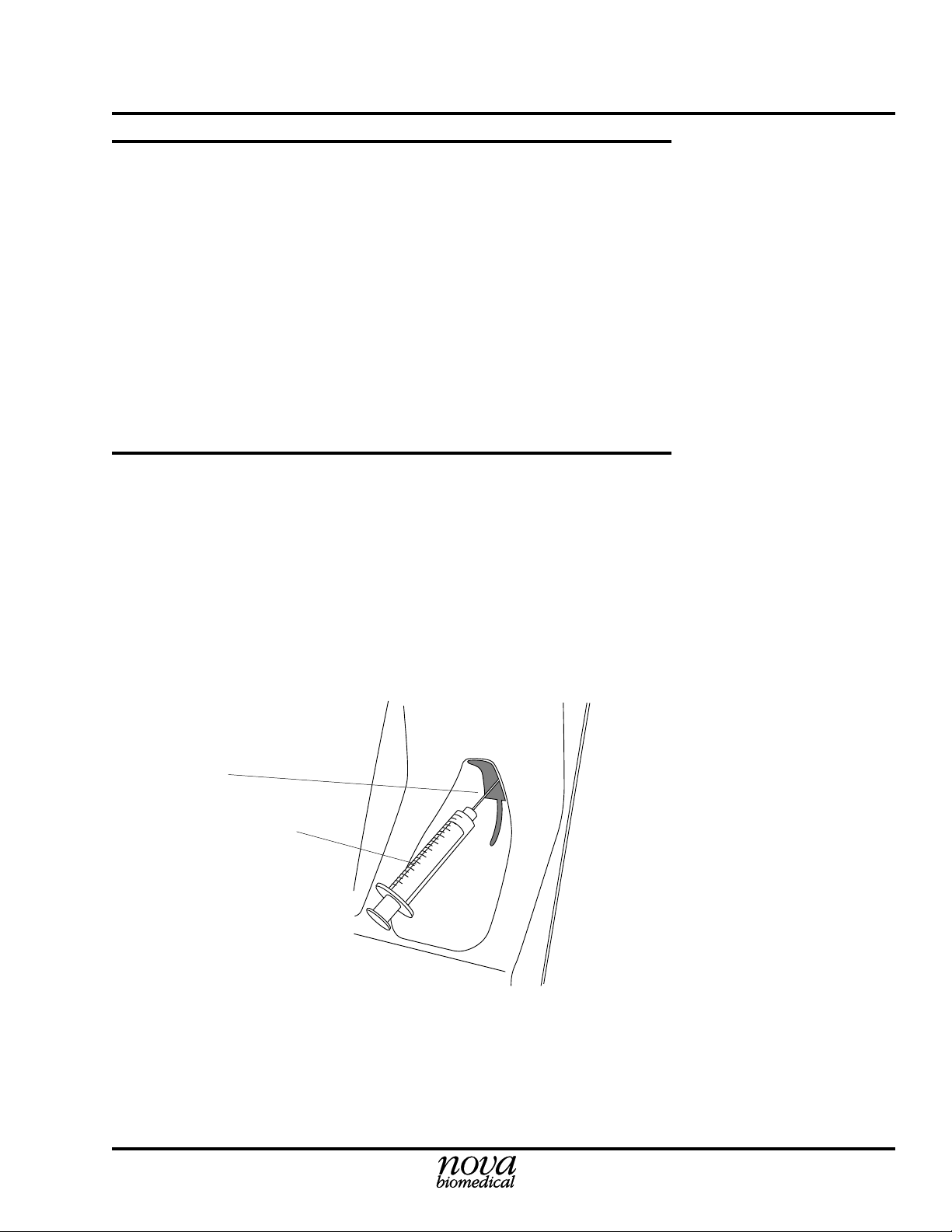

Probe

Syringe

G #10-1024A

DW

Figure 2.1 Syringe Sample Presentation

2-3

Page 30

2 Running an Analysis Stat Profile pHOx Training Manual

NOTES:

After the sample is positioned, press Continue (soft Key). (If not

pressed within 45 seconds, the analyzer returns to the Ready screen.)

In STAT Mode

Analysis, the Sample

Information screen is

not displayed. The

ABG ResultsMeasured screen is

displayed after

aspiration is

completed.

If the view results soft

key is not selected the

analysis will not go to

completion. No results

will be displayed or

printed out.

NOTE:

If you attach an

external key board,

alpha keys are

available.

2.3 Sample Information

2.4 Results Screen and Printout

The pump turns, pulling the sample through the probe, air detector

tubing, and sensor module. A pop-up screen appears. Remove the

sample from the probe. Press Analyze. (If Analyze -soft key- is not

pressed within 30 seconds, the probe will automatically move downward.) The probe moves downward.

The analyzer displays the Sample Information screen with a bar graph

until completion.

Input sample information, then press View Results to see the completed results.

The Sample information screen is displayed after aspiration has been

completed. This screen allows you to enter Accession number,

Operator ID, Patient ID number, Combine with CO-Oximeter, combine with last sample for A/V & Shunt results, Patient temperature,

and Sample Type. Use arrow keys to move to next option; Use the

number keys or the Enter key to toggle or get pop-up selection.

2-4

The ABG Results -Measured screen is displayed and results fill in the

table as they become available. The results on the screen can be

printed by pressing Print (soft key). Press Next Page (soft key) to go

to the next results screen, etc.

2.5 Running an Analysis Exercise

See Running an Analysis Checklist to perform the lab.

2.6 Standby Mode

See Standby Mode Checklist to perform the lab.

Page 31

2 Running an Analysis Stat Profile pHOx Training Manual

Running a Syringe Analysis Checklist

NOTES:

Step 1 Check the instrument for readiness.

• Check the display for the Home (Ready) screen.

Step 2 Present sample and begin analysis.

(Procedure for syringes)

• Press the White Syringe Button.

• Probe positions for sample aspiration.

Slide the syringe tip over the extended probe.

CAUTION:

the base of the syringe plunger or the bottom of the

sample cup or tube.

Do not allow the sample probe to touch

Step 3 Analysis begins.

• Press Aspirate Normal (soft key) to start the sampling. (Or,

press Aspirate Micro (soft key) for a smaller sample: 45µL

instead of 70µL.)

NOTE:

5 minutes of the time the probe extends, the probe

automatically starts to move down.

• When the system signals by an audible alarm, withdraw the

sample.

• Press Analyze. The probe moves down.

NOTE:

after the sample has been aspirated, the probe

automatically starts to move down.

If one of these soft keys is not pressed within

If Analyze is not pressed within 30 seconds

• The analysis begins.

• The Sample information screen is displayed.

Update to PN 24302 Rev. B 3/2002

2-5

Page 32

2 Running an Analysis Stat Profile pHOx Training ManualRunning a Syringe Analysis Checklist

NOTES:

Step 4 Enter patient information.

• The Sample information screen is displayed. (If in STAT

Mode, this screen does not display. Go to next step.)

• Enter patient data.

NOTE:

Press arrow keys to move through options.

Press number keys or Enter key to toggle or get

pop-up screen.

If the View Results

(soft key) is not

pressed, the analysis

will not go to

completion and will not

print out the results.

Step 5 Results are displayed and printed.

• Press View Results (soft key) to view the results.

• Measured results are displayed on the ABG Results Measured screen as they become available.

Selected calculated results can be viewed by pressing

Next Page (soft key) from the Results screen.

• To print the results, press Print (soft key).

• Results are transmitted to an optional external printer or

computer, if enabled.

• After transmission and/or printout, all patient information

becomes READ ONLY. They no longer can be changed or

combined.

• Press Home (soft key) to return to the Home (Ready) screen.

2-6

Page 33

2 Running an Analysis Stat Profile pHOx Training Manual

Running a Capillary Analysis Checklist

NOTES:

Step 1 Check the instrument for readiness.

• Check the display for the Home (Ready) screen.

Step 2 Prepare capillary.

(See Section 2.2.4, Capillary Handling Tips)

• Mix sample again by drawing magnet back and forth along

the length of the capillary.

• Keeping capillary level, remove cap (or caps) from the ends.

• Remove mixing flea by pulling it out one of the free ends

with the magnet.

Step 3 Present sample.

• Press the Black Capillary Button and wait for probe to

position.

• Holding one gloved finger over the open end of the capillary, carefully slide the tip of the capillary into the adapter

until it just touches the probe.

• The capillary should be in line with probe, not tilted horizontally.

Demo this before

trainees attempt it.

Skip this section if

they do not run

capillaries.

CAUTION: Do not

end of the capillary yet.

Step 4 Begin analysis.

• Press Aspirate Normal (soft key) to start the sampling. (Or,

press Aspirate Micro (soft key) for a smaller sample: 45µL

instead of 70µL.)

NOTE:

5 minutes of the time the probe extends, the probe

automatically starts to move down.

• As soon as the pump starts to turn, remove your finger from the

open end of the capillary, allowing the sample to be drawn up.

Update to PN 24302 Rev. B 3/2002

If one of these soft keys is not pressed within

remove your finger from the open

2-7

Page 34

2 Running an Analysis Stat Profile pHOx Training Manual

NOTES:

Running a Capillary Analysis Checklist

• When the system signals by an audible alarm, remove the

capillary from the probe and adapter.

• Press Analyze. The probe moves down.

NOTE:

after the sample has been aspirated, the probe

automatically starts to move down.

• The analysis begins.

• The Sample information screen is displayed.

If Analyze is not pressed within 30 seconds

Step 5 Enter patient information.

• The Sample information screen is displayed. (If in STAT

Mode, this screen does not display. Go to next step.)

• Enter patient data.

NOTE:

Press arrow keys to move through options.

Press number keys or Enter key to toggle or get

pop-up screen.

Step 6 Results are displayed and printed.

If the View Results

(soft key) is not

pressed, the analysis

will not go to

completion and will not

print out the results.

• Press View Results (soft key) to view the results.

• Measured results are displayed on the ABG Results Measured screen as they become available.

Selected calculated results can be viewed by pressing

Next Page (soft key) from the Results screen.

• To print the results, press Print (soft key).

• Results are transmitted to an optional external printer or

computer, if enabled.

• After transmission and/or printout, all patient information

becomes READ ONLY. They no longer can be changed or

combined.

• Press Home (soft key) to return to the Home (Ready) screen.

2-8

Page 35

2 Running an Analysis Stat Profile pHOx Training Manual

Running an AV Shunt Analysis Checklist

NOTES:

Step 1 Check the instruments for readiness.

NOTE:

This checklist can only be performed if a

Nova CO-Oximeter is in communication with the

pHOx Analyzer, so that the results can be combined. This checklist may be removed if not needed.

• Check the pHOx display for the Home (Ready) screen.

• Check the CO-Oximeter for readiness.

(See the Nova CO-Oximeter Reference Manual.)

Step 2 Present sample and begin analysis.

• Press the White Syringe Button.

Probe positions for sample aspiration.

• Press the AV Shunt (soft key).

• Position the mixed venous sample over the extended probe.

You must press soft

CAUTION:

the base of the syringe plunger or the bottom of the

sample cup or tube.

Do not allow the sample probe to touch

keys within 45

seconds or the cycle

will abort

automatically.

Step 3 Analysis begins.

• Press Aspirate (soft key).

• When the system signals by an audible alarm, withdraw the

sample.

• Press Analyze (soft key). The probe moves down.

• The analysis begins.

• The Sample information screen is displayed; enter patient

data.

NOTE:

Press arrow keys to move through options.

Press number keys or Enter key to toggle or get

pop-up screen.

If Analyze is not

pressed within 30

seconds after the

sample has been

aspirated, the probe

automatically starts

to move down.

2-9

Page 36

2 Running an Analysis Stat Profile pHOx Training Manual

NOTES:

Running an AV Shunt Analysis Checklist

Step 4 Continue Analysis on CO-Oximeter.

• Analyze the mixed venous sample on the CO-Oximeter.

Step 5 Run the Arterial Sample.

• When the message, Mixed Venous sample complete, position the arterial sample over the extended probe.

• Press Aspirate (soft key).

• After aspiration, remove arterial sample and press Analyze

(soft key).

Step 6 Continue Analysis on CO-Oximeter.

If the View Results

(soft key) is not

pressed, the analysis

will not go to

completion and will not

print out the results.

• Analyze the arterial sample on the CO-Oximeter.

Step 7 Results are displayed and printed.

• Press View Results (soft key) to view the results.

• Measured results are displayed on the ABG Results Measured screen as they become available.

Selected calculated results can be viewed by pressing

Next Page (soft key) from the Results screen.

• To print the results, press Print (soft key).

• Results are transmitted to an optional external printer or

computer, if enabled.

• After transmission and/or printout, all patient information

becomes READ ONLY. They no longer can be changed or

combined.

• Press Home (soft key) to return to the Home (Ready) screen.

2-10

Page 37

2 Running an Analysis Stat Profile pHOx Training Manual

Standby Mode Checklist

NOTES:

Step 1 Start the procedure.

NOTE:

This option allows you to place the analyzer

into a standby mode and allows you to reactivate

the analyzer out of the mode at a programmed time

and date. The standby mode will use less reagents

and controls because the analyzer will not run its

automatic calibration cycles. Calibration is lost

SO

except for

set time is elapsed, if you initiate a calibration, or if

you turn Standby off.

• From the Operational Menu, scroll down to the Standby

Mode.

• Press ENTER (once if mode is OFF or twice if Mode is ON).

and Hb. Standby mode ends after the

2

Step 2 Set the date.

• Press ENTER (again) - the date becomes blank.

• Key in the date that you want the analyzer to come out of

Standby Mode.

• Press ENTER to set the date. (DO NOT press OK.)

Step 3 Set the time.

• Press any Arrow key to go to the time field.

• Press ENTER - the time becomes blank.

• Key in the time that you want the analyzer to come out of

Standby Mode.

• Press ENTER to set the time. (DO NOT press OK.)

2-11

Page 38

2 Running an Analysis Stat Profile pHOx Training Manual

NOTES:

Standby Mode Checklist

Step 4a Start the Standby Mode.

• Now press OK (soft key) to initiate the Standby Mode.

• Another pop-up screen appears to verify that you want to go

into Standby Mode. Press OK (soft key) again and the

Standby Mode is officially ON.

Step 4b Cancel the Standby Mode.

• Press Cancel (soft key) to cancel the Standby Mode.

• The date and time fields revert to the previous settings.

• The Standby Mode is now OFF.

2-12

Page 39

3 Operational Status Stat Profile pHOx Training Manual

NOTES:

3 Operational Status

3.1 Home Screen - Ready for Analysis

Indicates readiness of the analyzer.

• All analytes are shown. Uncalibrated analytes are x'd out and

a — (a line through an analyte prefix) when the channel did

not pass QC and QC lockout is enable.

• The Next Cal and if programmed the Next QC is displayed.

• Two fluid gauges display the approximate remaining solutions for the reagent cartridge and control cartridge.

3.2 Questionable Results

Results with a problem display a symbol in the Alert column. There

are a number of symbols that can appear after the results. The symbols

have the following meanings:

• ↑ (single up arrow), ↓ (single down arrow) - The result is higher or

lower than the defined reference range for the parameter.

• ↑↑ (double up arrow), ↓↓ (double down arrow) - The result is higher

or lower than the defined alert range for the parameter.

• ↑↑↑ (triple up arrow), ↓↓↓ (triple down arrow) - The result is out of

the analyzer's operating range.

• X (an X through an analyte prefix) - The channel is uncalibrated.

• ? (question mark) - Insufficient sample is detected during sample

reading.

• * (asterisk) - The result is calculated using a default sodium

concentration.

• — (a line through an analyte prefix) - The channel did not pass QC and

QC lockout is enabled; or the results have been suppressed.

3.3 System Status Screen

This screen only appears if there are operational messages or status

codes.

3-1

Page 40

3 Operational Status Stat Profile pHOx Training Manual

NOTES:

3-2

Page 41

4 Calibrating the Analyzer Stat Profile pHOx Training Manual

NOTES:

4 Calibrating the Analyzer

4.1 Full 2-Point Calibration - all except Hb and

• Uses internal calibrators (standards)

• Calculates slopes for sensors and air detectors

• Occurs at regular intervals or can be manually initiated by

pressing Calibrate (soft key)

• Included as part of most maintenance routines

• Resets calibration timers

• Can generally be stopped by pressing Exit (soft key)

• Can be manually run by pressing the Calibration (soft key)

from the Ready (or Not Ready) screen.

1. The 2 pt. Calibration screen will display.

2. Select option 1: pH, PCO2, PO2, Hct Calibration (ABG).

3. Press Enter.

4.2 Calibration Timing

Auto calibration takes place at intervals of 2, 4, or 6 hours depending

on analyzer activity. See Chapter 3 of the Reference Manual for more

details.

S

O

2

4-1

Page 42

4 Calibrating the Analyzer Stat Profile pHOx Training Manual

NOTES:

4.3 Other Types of Calibration

4.3.1SO2 and Hb Calibration

• Uses external calibrators (2 levels)

• Initiated by the operator monthly or as needed

• Access from Ready screen: Calibrate (soft key)

Instructor shows

Calibration

Configuration screen

for calibration options.

Access the Setup

Menu (Password),

select Operation

Configuration Menu

(press Enter). Select

the Calibration

Configuration option

(press Enter). Discuss

the options.

CLIA regs. require 30

minutes.

4.3.2 Single Point Calibration for Non-Gas Sensors

• Values for calibration (standards) are lot specific and must

be verified or reentered at time of calibration.

S

O

See Calibrating

• Occurs with each gas Cal I (30-45 min. intervals) if Mode A

is selected

• Occurs with each analysis if Mode B is selected

• Uses a calibration standard (either C or A) and increases

time to appearance of results

• Checks for sensor drift

• Printing of drift is operator selected.

and Hb Checklist.

2

Mode A: One point

fluid & Gas Cal done

every 30-45 minutes.

Mode B: One point fluid

& Gas Cal done with

EACH analysis.

4-2

Page 43

4 Calibrating the Analyzer Stat Profile pHOx Training Manual

Calibrating SO2 Checklist

NOTES:

Step 1 Begin calibration.

• From the Home (Ready) screen, press Calibrate (soft key).

• Then select option 2: External two standard Hb,

Calibration then press ENTER.

• The External Standard Hb, SO2% Calibration screen appears.

SO

%

2

Step 2 Verify calibrator (standard) values.

• Consult insert sheet for this lot and compare to values on the

screen.

• Key in the assay value for Std. #1, if necessary.

Step 3 Prepare calibrator #1.

• Mix gently by inversion.

• Open the ampule carefully to avoid injury (glass edges).

• Position Calibrator #1 so that the extended probe tip is well

covered by the solution.

• Press Continue (soft key).

• When system signals by audible alarm, remove the ampule,

• Press Analyze (soft key).

Step 4 Prepare calibrator #2.

• Repeat procedure for calibrator #2.

• Enter/verify assay value for Std. #2. (Press ENTER after

entering the assay value.)

• Mix gently by inversion.

• Open the ampule carefully to avoid injury (glass edges).

• Position Calibrator #2 so that the extended probe tip is well

covered by the solution.

• Press Continue (soft key).

• When system signals by audible alarm, remove the ampule,

• Press Analyze (soft key).

4-3

Page 44

4 Calibrating the Analyzer Stat Profile pHOx Training Manual

NOTES:

4-4

Page 45

5 Using and Handling Controls Stat Profile pHOx Training Manual

NOTES:

5 Using and Handling Controls

5.1 Controls

CAUTION:

of controls other than Nova controls and will void warranty on

components that come into contact with them.

The Stat Profile pHOx Analyzer has on board QC and on board

controls. Controls can be analyzed either with the internal control

pack or with external Nova control ampules.

Performance of the analyzer may be affected by the use

5.1.1 Stat Profile pHOx Controls

• Monitor performance of all blood gases and electrolytes

• Contain no preservatives, dyes, or surfactants that can

damage sensors or other flow components

• Formulated at 3 clinically significant levels:

L1 Acidosis, with low pH, high PCO2, low PO2, low SO2,

low normal Hct and low normal Hb values

L2 Normal, with normal pH, PCO2 and PO2 values

L3 Alkalosis, with high pH, low PCO2, high PO2 high

SO

, and normal high Hct/Hb values

2

• Internal in a self-containing control pack (Auto- Cartridge

QC) or external in individual ampules

The Auto- Cartridge

QC has a use-life of 35

days.

5.2 Handling Controls

5.2.1 Storage Temperature

Store at 25°C (77°F). Warmer or colder controls affect gases and pH.

Hold vial between thumb and fingertip when shaking to avoid

changing temperature. For every 1°C

1%. The opposite effect is seen at temperatures

CAUTION:

sill or near a heating or air-conditioned duct.

Do not refrigerate. Avoid storing controls on a window

above

25°C, PO2 recovery drops

below

25°C.

5-1

Page 46

5 Using and Handling Controls Stat Profile pHOx Training Manual

NOTES:

5.2.2 Stability of Opened Ampules

Shake and analyze within 30 seconds of opening. Contamination with

room air will begin to affect PO2, PCO2, and pH results after that time.

PO

Room air has a

Exposure of controls to room air causes:

PCO

to decrease.

2

5.2.3 Altitude and Barometric Pressure Effects

Aqueous controls are assayed at sea level. Changes in altitude will affect

gas recovery. For every 1000 ft above sea level, PO2 recovery drops by

approximately 0.5%. An incorrect barometric pressure will also affect

gas recovery. System barometric pressure is displayed on the printout,

barometric pressure, or Status screen. If significantly different from a

known, accurate measurement, enter an offset by selecting Setup, enter

password, select Operations Configuration, press Enter, select System

Configuration Menu (use arrow keys to go to corrected Barometric

Pressure), enter mmHg, Press Home to exit to Home (Ready) screen.

of about 150 mmHg and a PCO2 of ~0 mmHg.

2

PO

and pH to increase,

2

5.3 When to Use

As of the date of publication of this guide, a minimum of one blood

gas control must be analyzed every 8 hour shift of lab operation. Also,

after maintenance or troubleshooting or as required by the laboratory’s

quality control program. All levels must be analyzed within a 24 hour

period.

5.4 Using the Stat Profile pHOx's On-Board QC Features

The analyzer's QC features allow you to:

• Set ranges and units for acceptable results.

• Store statistics.

• Program for internal or external control source.

• Display or print QC statistics in the form of reports.

• Remind or require operators to run QC at specific intervals.

• Analyze other forms of QC such as proficiency surveys or

linearity standards without “offsets”.

5-2

Page 47

5 Using and Handling Controls Stat Profile pHOx Training Manual

NOTES:

These features must be enabled or setup before they can be used. See

Quality Control Setup in the analyzer’s reference manual for details. If

you will be using them, the installer will have done at least a partial

setup so that you can learn how they work.

5.4.1 The QC Soft key

This key has more than one function:

• To run a QC analysis either internal or external

• To view or to print QC data

• To set up QC levels

• To turn automatic QC analysis on or off

5.4.2 Automatic QC Analysis (Internal)

To use the Automatic QC Analysis feature properly, the QC analysis

times need to be programmed under the Daily Analysis Times screen

during the QC Setup and the Automatic QC Analysis needs to be

turned on. QC is automatically performed at these programed times

with the controls from the Auto-Cartridge QC.

NOTE:

Internal QC can also be run manually: see the checklist.

5.4.3 Manual QC Analysis (External)

To use the Manual QC Analysis feature properly, the QC analysis

times need to be programmed under the Daily Analysis Times screen

during the QC Setup and the Automatic QC Analysis needs to be

turned on. When QC analysis is needed, a Pop up screen will appear

prompting you to run the required QC. Press OK (soft key). Then go

to the Analyze QC screen and select the appropriate QC.

GO TO CHECKLIST.

5-3

Page 48

5 Using and Handling Controls Stat Profile pHOx Training Manual

DWG #6010A

NOTES:

Analyzing Controls Checklist

Step 1 Preparing for Analysis

• Hold QC ampule between thumb

and forefinger and agitate vigorously for several seconds.

NOTE:

Do not warm ampule in hands.

Step 2 Initiating the QC Analysis

• Press QC (soft key) on the Home screen.

• With Analyze QC Highlighted, press ENTER.

• Select the QC to be analyzed, i.e., QC Level #1 External.

• Change if necessary by pressing Previous Control (soft key)

or Next Control (soft key).

• Press the White Button (Syringe) or Analyze (soft key).

Step 3 Completing the Cycle

Figure 5.1 Agitating the Ampule

5-4

• Once probe has extended, open the ampule while protecting

yourself from the sharp glass edges.

• Fully immerse the probe into the fluid of the ampule. Do not

allow the probe to touch the bottom of the ampule.

• Press Continue (soft key).

• When the system signals by an audible alarm, remove the

ampule and press Analyze (soft key). The probe moves

downward.

• Discard the ampule.

NOTE:

cause the system to

to the Quality Control screen.

Failure to press Continue (soft key) within 45 seconds will

time-out

canceling the cycle and returning you

Page 49

5 Using and Handling Controls Stat Profile pHOx Training Manual

Analyzing Controls Checklist

NOTES:

Step 4 Accepting or Rejecting Results

When results are ready, they appear on the screen along with

an indication of whether they have passed or failed the QC

range check. If one or more tests are out of range, the QC

Results screen flashes Exceed Limits.

• To save all data, press QC (soft key).

• To reject the data, press Delete (soft key). Then press

Continue to discard all the data.

• All data is either accepted or rejected.

Step 5 Repeat for next level

5-5

Page 50

5 Using and Handling Controls Stat Profile pHOx Training Manual

NOTES:

Analyzing Internal Controls Checklist

Step 1 Preparing for Analysis

• From the Ready screen, press QC (soft key) on the Home

screen.

Step 2 Initiating the QC Analysis

• With Analyze QC Highlighted, press ENTER.

• Select the QC to be analyzed, i.e., QC Select Internal L1.

• Change if necessary by pressing Previous Control (soft key)

or Next Control (soft key).

• Press Analyze (soft key).

Step 3 Accepting or Rejecting Results

When results are ready, they appear on the screen along with

an indication of whether they have passed or failed the QC

range check. If one or more tests are out of range, the QC

Results screen flashes Exceed Limits.

• To save all data, press QC (soft key).

• To reject the data, press Delete (soft key). A pop-up screen

appears: enter your password. Then press Continue to discard all the data.

• All data is either accepted or rejected.

Step 4 Repeat for next level

5-6

Page 51

5 Using and Handling Controls Stat Profile pHOx Training Manual

NOTES:

5.5 QC Data

To view QC data, select View or Print QC Data on the Quality Control

(QC) screen then press Enter. The QC Data screen for the selected

level is displayed. From this screen, you can view today's data, daily

statistics, monthly statistics, cumulative, or Levey-Jennings.

5.5.1 View Today's Data

From the QC Data screen, select View Today's Data then press Enter.

The QC Results screen is displayed. To view the next result, press

Next Page (soft key). For options, press Options (soft key). A pop-up

window appears. One option is for deleting this result. You can also

print or view other statistics.

5.5.2 View Daily Statistics

From the QC Data screen, select View Daily Statistics then press

Enter. This screen is the QC Daily Statistics for the selected level.

From this screen, you can view the next level, and/or print the

statistics.

5-7

Page 52

5 Using and Handling Controls Stat Profile pHOx Training Manual

NOTES:

5.5.3 View Monthly Statistics

The Monthly Statistics is a record of all QC accepted for the past month.

Print this record for your files at the end of each calendar month.

1. From the Quality Control screen, select View or Print QC Data.

2. From the QC Data screen select View monthly statistics.

3. Press Print (soft key).

=======Stat profile QC Statistics======

Date 6-23-98 Time 10:54

Analyzer ID 0 Operator ID 1

Lot#1234567890 Exp 7-31-98

----------------------------------------------------

DAILY (n=6)

Test Mean ±Range SD CV

pH 7.595 0.050 2.3 2.3

pCO223.0 10.0 2.3 2.3

pO

SO

Hb 7.5 10.0 3.5 3.5

Hct 18 10.0 2.3 2.3

----------------------------------------------------

Test Mean ±Range SD CV

pH 7.595 0.050 2.3 2.3

pCO223.0 10.0 2.3 2.3

pO

SO

Hb 7.5 10.0 3.5 3.5

Hct 18 10.0 2.3 2.3

----------------------------------------------------

QC CUMULATIVE (n=1,498 during163 days)

Test Mean ±Range SD CV

pH 7.595 0.050 2.3 2.3

pCO223.0 10.0 2.3 2.3

pO

SO

Hb 7.5 10.0 3.5 3.5

Hct 18 10.0 2.3 2.3

----------------------------------------------------

155 12.0 1.0 1.0

2

.... .... .... ....

2

MONTHLY (n=97 during 30 days)

155 12.0 1.0 1.0

2

.... .... .... ....

2

155 12.0 1.0 1.0

2

.... .... .... ....

2

5-8

Figure 5.2 QC Statistics Printout

Page 53

5 Using and Handling Controls Stat Profile pHOx Training Manual

NOTES:

5.5.4 Printing Levey-Jennings Charts

The Levey-Jennings data graph is displayed on screen. When printing, each graph will be rotated 90° with the date appearing on the long

axis of the chart.

1. From the Quality Control screen, select View or Print QC Data.

2. From the QC Data screen, select View Levey-Jennings.

3. Highlight the analyte using the arrow key.

4. Press enter to view data on the screen.

5. Press Print (soft key).

=======Stat profile QC Statistics======

LEVEY-JENNINGS CHARTS

Analyzer ID 0 Operator ID ...

Lot # 1234567890 Exp Date 07-31-98

Date Lower Limit Upper Limit

----------------------------------------------------

7.585 7.600 7.635

---------------------------------------------------11-23 *

11-24 *

11-25 *

11-26 *

11-27 *

11-28 *

11-29 *

11-30 *

12-01 *

12-02 *

Figure 5.3 Levey-Jennings Graphs Printout

5-9

Page 54

5 Using and Handling Controls Stat Profile pHOx Training Manual

NOTES:

5-10

Page 55

6 Replacing Reagents & Paper Stat Profile pHOx Training Manual

NOTES:

6 Replacing Reagents and Paper

6.1 When to Replace

Replace the fluid pack and/or the control pack when it has reached its

expiration date or when the graphic appears empty on the Home

screen. Also, replace the capillary adapter found in the reagent pack.

6.2 How to Replace

To install a new reagent pack and/or control pack, you will be using one

of the automated Operational Menu procedures: Change Reagent Pack

or Change Control Pack. These procedures come up as screens with

the steps necessary to carry out the changing of the pack. Because the

reminders are brief, you should refer to the complete illustrated procedures located in the maintenance section of the analyzer's reference

manual if you need additional details. To stop automated maintenance

procedures, press Cancel (soft key).

The on-board Reagent

Cartridge has a use-

life of 45 days.

The on-board QC

Cartridge has a use-

life of 35 days.

6.3 Replacing the Reagent Pack

See Replacing the Reagent Pack Checklist to perform the lab.

6.4 Replacing the Control Pack

See Replacing the Control Pack Checklist to perform the lab.

6.5 Replacing the Printer Paper

See Replacing the Printer Paper Checklist.

6-1

Page 56

6 Replacing Reagents & Paper Stat Profile pHOx Training Manual

NOTES:

Replacing the Reagent Pack/Capillary Adapter Checklist

WARNING: Blood samples and blood products are potential sources of

hepatitis and other infectious agents. Handle all blood products and

flow path components (waste-line, septum assembly, probe, flow cell,

etc.) with care. Gloves and protective clothing are recommended.

Dispose of the reagent waste bottle according to your laboratory's

biohazardous waste policies.

Step 1 Replace the capillary adapter.

• From the Home (Ready) screen, press Menu.

• Select Change Pack.

• Press Enter. A pop-up screen appears.

Change Reagent Pack

Change Control Pack

Exit

• Highlight Reagent Pack.

• Press Enter.

• Press Move Probe (soft key).

• Open the door.

• Remove the capillary adapter from the front of the probe by

pulling it off.

• Replace the adapter with a new one found in the reagent

pack. As you put on the adapter, make sure the probe goes

into the center hole of the adapter.

• Press Move Probe (soft key) when finished.

• Press Cancel then press Cancel again to return to the Home

screen.

6-2

Step 2 Remove old cartridge.

• Open the door.

• Remove the old cartridge - lift the cartridge up slightly to

clear the lip.

• Mix the new cartridge by gently inverting for several seconds.

DO NOT SHAKE THE PACK.

• Slide in the new cartridge.

• Close the door.

Update to PN 24302 Rev. B 3/2002

Page 57

6 Replacing Reagents & Paper Stat Profile pHOx Training ManualReplacing the Reagent Pack/Capillary Adapter Checklist

Step 3 Prime the analyzer.

• Press Prime (soft key): this primes and validates the cartridge.

Step 4 Calibrate the analyzer.

• After priming, a pop-up screen appears with a question, "Do

you want to recalibrate? Yes or No." Press Yes (soft key).

• Calibration takes place.

Step 5 Validate performance with QC.

• Run QC.

• Document the results.

NOTES:

6-3

Page 58

6 Replacing Reagents & Paper Stat Profile pHOx Training Manual

NOTES:

Replacing the Control Pack Checklist

WARNING: Blood samples and blood products are potential sources of

hepatitis and other infectious agents. Handle all blood products and

flow path components (waste-line, septum assembly, probe, flow cell,

etc.) with care. Gloves and protective clothing are recommended.

Dispose of the reagent waste bottle according to your laboratory's

biohazardous waste policies.

Step 1 Initiate the procedure

• From the Home (Ready) screen, press Menu.

• Select Change Pack.

• Press enter. A pop-up screen appears.

Change Reagent Pack

Change Control Pack

Exit

• Highlight Control Pack by using the down arrow key.

• Press Enter.

Step 2 Follow the screen directions.

• Open the cover.

• Remove the old cartridge - lift the cartridge up slightly to

clear the lip.

• Mix the new cartridge by gently inverting for several seconds.

DO NOT SHAKE THE PACK.

• Slide in the new cartridge.

• Close the door.

Step 3 Prime the analyzer.

• Press Prime (soft key).

Step 4 Calibrate the analyzer.

• After priming, a pop-up screen appears with a question, "Do

you want to recalibrate? Yes or No." Press Yes (soft key).

• Calibration takes place.

6-4

Step 5 Validate performance with QC.

• Run QC.

• Document the results.

Update to PN 24302 Rev. B 3/2002

Page 59

6 Replacing Reagents & Paper Stat Profile pHOx Training Manual

Replacement of the Printer Paper Checklist

NOTES:

Step 1 Open the printer cover.

Step 2 Lift print head.

• Open the printer platen.

• Gently pull the lever near the paper advance knob forward.

• Remove the depleted roll of paper.

Step 3 Remove paper holder from the old roll of paper.

Step 4 Install new roll of paper.

• Insert the paper holder into

a new roll of paper. The

loose end of the paper

should feed from the bottom of the roll.

• Install the paper holder with

paper into the support collars.

• Push the paper through the

back of the roller.

Step 5 Reposition print head.

DWG #10-1002B

Platen

Paper Advance

Knob

Figure 6.1 Paper Installation

• Center the paper and close the printer platen by moving the

lever back to the original position.

• Advance the paper by using the paper advance knob.

• Feed the paper through the cover. Then close the cover.

6-5

Page 60

6 Replacing Reagents & Paper Stat Profile pHOx Training Manual

Replacement of the Printer Paper Checklist

NOTES:

Step 6 Test printer (Optional).

• From the Home screen, press Menu (soft key); press Service

(soft key); use the down arrow key to select Printer Menu:

press ENTER; use the down arrow key to select Character

Set Test; finally press ENTER to obtain a character printout

to verify proper operation (see Figure 6.2).

• After the self test is completed, a pop-up screen appears.

Press OK.

• Press Home (soft key) to return to the Home screen

** TEST PRINT **

!”#$%&’()*+,-./01234567

89:;<=>?@ABCDEFGHIJKLMNO

PQRSTUVWXYZ[\]

hijklmnopqrstuvwxyz{|}~

^

‘abcdefg

—

ЗьйвдаезклипомДЕ

ЙжЖфцтыщяЦЬ¢£¥ ƒбнуъсСao

1

¿

αβΓπΣσµτΦθΩδ∞φ∈

≡±≥≤ ÷≈°.−

DWG #9-1000A

1

〈〈 〉〉

/

/

2

4

n2

§ßØø °

Figure 6.2 Sample Test Printout

¨

6-6

Page 61

7 Troubleshooting Stat Profile pHOx Training Manual

NOTES:

7 Troubleshooting

Instructor: Show

these screens as they

7.1 Sensor Screens

For a full description of these screens, turn to Chapter 6 of the Reference

Manual.

From the Home screen, press Menu (soft key). Then press Service

(soft key). Using the down arrow key, select Sensor Subsystem. Then

press ENTER.

Calibration and analysis data for each sensor, the SO2 LEDs, and the

air detectors are contained on the following screens.

7.2 System Test

For a full description of this screen, turn to Chapter 6 of the Reference

Manual.

From the Home screen, press Menu (soft key). Then press Service

(soft key). Using the down arrow key, select System Test then press

ENTER.

The System Test screen displays millivolt readings for all sensors.

From this screen, you can manipulate the pHOx Plus to perform many

actions, i.e., priming. It also allows you to check the sampler, rotary

valve, pump, waste valve, reference valve, ADTs, and SO2 LEDs.

Turn to Chapter 6 of the Reference Manual for procedures on how to

perform these tests.

The operator flow test is performed from the System Test screen by

pressing Operator Flow Test (soft key). The pump turns on, the probe

moves to the syringe position, and the waste valve opens. This allows

the user to present a cup of water to the probe and observe the flow of

water.

are discussed.

7-1

Page 62

7 Troubleshooting Stat Profile pHOx Training Manual

NOTES:

7.3 Error Log

From the Home screen, press Menu (soft key). Then press Service

(soft key). Using the down arrow key, select Error Log and press

ENTER.

This screen shows all errors displayed in chronological order followed by a short explanatory message - holds 96 errors.

For more detailed information, refer to the Reference Manual (Chapter 5,

Troubleshooting).

An index lists all the status messages by code with a symptom and

corrective action.

7.4 Flow Related Problems

The cause of flow problems are clots, hidden blockages, leaks, and

pumping problems.

The errors show up as flow status codes. Resolve by referring to

solutions described in the Reference Manual, Troubleshooting chapter, for

that status code.

NOTE:

Always fix flow problems first.

Flow problems are often accompanied by sensor related problems. Do

not change sensors or membranes until flow problems have been

resolved. Once flow problems are resolved, sensor problems often

disappear.

Diagnose with flow tests: Water Test, Pump Test, and Reference

Solution Test.

Water Test — Checks to verify that water can be pulled

through the system from the probe. If water cannot be

aspirated through the probe, a clog, leak, or a mechanical

pump problem exists in the system.

Pump Test — Checks to verify that the pump and waste valve

are functioning properly. Also verifies if the W-line from

the reference electrode to the waste bottle is free of blockages.

Reference Solution Test — Verifies reference solution is getting to the reference electrode.

7-2

Page 63

7 Troubleshooting Stat Profile pHOx Training Manual

NOTES:

7.5 Sensor Problems

Problems may be uncalibrated, overload, instability, slope, drift, out

of range, and dependency status codes.

Resolve by referring to solutions described in the Chapter 5, Trouble-

shooting, in the Reference Manual for that status code.

7.6 Results Related Problems

Problems may occur because sample results are either too high or too

low. Can be combination of two or more results problems.

See Resolving Results Problems in the Quick Reference section.

Resolve by referring to solutions described in the Chapter 5, Trouble-

shooting, in the Reference Manual for that error code.

7.7 Miscellaneous Problems - Operational

Problems may be related to lab temperature, incorrect barometric

pressure, open door, or reagent pack problems.

Resolve problems by lowering/raising temperature, correcting barometric pressure in the analyzer, closing door, and reinstalling/installing a new reagent pack.

7.8 Call Nova

For problems involving hardware, electronics, printer, or software

error messages.

Problems that cannot be resolved by you or at your site.

Resolve problems by calling Nova Technical Services at