Page 1

Reference Manual

Page 2

Page 3

EC Declaration of Conformity

Issued by

Nova Biomedical Corporation

200 Prospect Street

Waltham, MA 02454, U.S.A.

Equipment Description: Model - Stat Profile® pHOx® Analyzer

Laboratory Equipment

100 - 120 / 220 - 240 V, 130 W, 50/60 Hz

Protection Class I

Year of Manufacture: See serial number showing date.

Applicable Directives: 73/23/EEC, Low Voltage Directive

Laws for electrical equipment within certain voltage limits

89/336/EEC, EMC Directive

Laws relating to electrical magnetic compatibility

Applicable Standards: EN 61010-1/A2:1995, EN 61010-2-010/A1:1996

Equipment for Measurement, Control and Laboratory use

EN 50081-1:1992

Electromagnetic Compatibility. Generic Emission Standard

EN 50082-1:1992

Electromagnetic Compatibility. Generic Immunity Standard

Type Examination Certificate: GS-mark License Number AL 01 06 20747 011

TUV Product Service, Munich/Germany

Authorized by : ________________________ 3/15/99

Francis C. Manganaro Date

President

Nova Biomedical Corporation

Page 4

Page 5

Preface Stat Profile pHOx Reference Manual

Nova Stat Profile

®

pHOx® Reference Manual

Part Number and Ordering Information

The Stat Profile® pHOx® Reference Manual (PN 22363) can be ordered from Nova Biomedical

Order Services. Write or call:

Nova Biomedical

200 Prospect Street

Waltham, MA 02454-9141

U.S.A.

Telephone: 1-800-458-5813

FAX: (781) 893-6998 (in the U.S.A.) or

(781) 899-0417 (outside the U.S.A.)

Technical Assistance

For technical assistance, call Nova Biomedical Technical Services at:

Telephone: 1-800-545-NOVA or

FAX: (781) 894-0585

Trademarks and Patents

Stat Profile® and pHOx® are registered trademarks of Nova Biomedical.

The Stat Profile pHOx Analyzer is covered by the following patents:

U.S. Patent No. 4,686,479, U.S. Patent No. 5,578,194.

Copyright

(781) 894-0800

Printed in the U.S.A. Copyright 2001, Nova Biomedical, Waltham, MA 02454-9141.

i

Page 6

Preface Stat Profile pHOx Reference Manual

Note: U.S. Legislative Requirements — Nova Analyzers

The new legislative requirements for clinical laboratories have established a new regulatory

environment and have changed the responsibility that Nova Biomedical has regarding the

proper operation and control of Nova analyzers. With the advent of the requirements that the

end user specifically follows all directions for use from the manufacturer, Nova becomes a

partner with the user and becomes responsible for providing instructions that will virtually

guarantee that the analyzer is in control. This requires Nova to provide instructions on

maintenance and control which are virtually foolproof in regards to assuring that an analyzer

is in control.

In addition to asking that all operators perform the maintenance and calibration procedures

described in this manual, we also recommend that only Nova reagents, calibrators, cleaning

agents, and controls be run through the analyzers. These are the only materials that we have fully

characterized and tested. We have neither tested the performance nor determined the long term

effects of products provided by others for use on our instruments. Confirming that an analyzer

is in control by using reagents and controls not certified by Nova Biomedical can not be

guaranteed by Nova, and Nova will not be responsible for the consequences. Users who elect

to use reagents, standards and/or controls from other producers should confirm by the

appropriate testing protocols from those other manufacturers that Nova’s instrumentation is in

control and in compliance with all legislative requirements. This testing verification should

also include a means of troubleshooting when the instrument is not in control, since Nova

Biomedical cannot, in the present environment, provide that service. Since Nova Biomedical

does not know the formulations of the reagents and controls used by other manufacturers,

including the levels of surfactants, preservatives, viscosity adjusters, and other additives that

may be used, there is no way for Nova to be certain that the results obtained on controls or

patient samples will be correct when these products are used. There is also no way to tell

whether there will be long term or short term adverse effects on sensor performance, sensor

life, tubing or flow cell degradation, or on data quality/accuracy or reliability.

Nova Biomedical manufactures totally integrated systems to assure proper analyzer performance. We cannot characterize all products that might be used on Nova analyzers, nor can we

control changes that other manufacturers might choose to make to their products. Therefore,

use of these products with a Nova analyzer must be the responsibility of the individual end user

and of that manufacturer rather than Nova.

Under these new legislative requirements, user modification of an in vitro diagnostic device,

is also regulated. Modification of the product includes use of untested products or products

which have not been tested to determine substantial equivalency and safety and effectiveness

in use with Nova analyzers.

Nova Biomedical’s Reference Manuals include the specific information needed for the proper

maintenance, qualification, and operation of Nova Biomedical Analyzers. If the user follows

the directions in those manuals, they should have very few problems. In the case where they

need assistance from Nova Biomedical in troubleshooting their systems, we will stand ready

to assist them in any and all ways necessary.

ii

Page 7

NCCLS Cross-Reference Stat Profile pHOx Reference Manual

Cross-Reference Table for NCCLS Guideline

NCCLS Guideline Stat Profile pHOx Reference Manual

1. Principle of Test Appendix B: Sections B.2 to B.2.6

2. Specimen required Chapter 1, Sections 1.3, 1.3.1, 1.3.2

3. Reagents, Standards, and Controls Appendix A: Sections A.2 to A.2.3.1

4. Calibration procedures and schedule Chapter 3: Sections 3.16, 3.16.1 to 3.16.4

5. Step-by-Step Directions

Analysis Chapter 3: Sections 3.18, 3.18.1 to 1.18.4

Maintenance Chapter 4

Troubleshooting Chapter 5

6. Calculations Appendix B: Sections B.3 to B.3.2

7. Frequency, Control Tolerance Chapter 3: Sections 3.17, 3.17.1, 1.17.2

8. Expected values Appendix A: Section A.3

9. Linearity limits Appendix A: Section A.1

10. Limitations (interferences) Chapter 1, Sections 1.3.2, 1.3.3, 1.3.4

11. References Chapter 1: Page 1-3; Appendix B: Page B-9

12. Effective Date Table of Contents

13. Distribution Nova pHOx Customers

14. Author Alan J. Mannarino

NOTE:

This manual complies with the NCCLS guidelines Vol. 4, Section 2.1. As a user, you

can copy and compile these above sections into one compact NCCLS Nova pHOx Manual or

use the cross-reference to find the appropriate section in the Nova Stat Profile pHOx

Reference Manual.

Page 8

Page 9

Nova Stat Profile pHOx Reference Manual

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Installation ............................................................................................................ 1-1

1.1.1 Requirements ............................................................................................ 1-1

1.2 Intended Use, Tests Performed, and Clinical Utility ............................................ 1-2

1.3 The Sample ........................................................................................................... 1-4

1.3.1 Handling Requirements ............................................................................ 1-4

1.3.2 Acceptable Anticoagulants ....................................................................... 1-4

1.3.3 Interfering Substances .............................................................................. 1-5

1.3.4 Matrix Effects ........................................................................................... 1-5

1.4 About This Reference Manual.............................................................................. 1-5

2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Installing the Stat Profile pHOx ........................................................................... 2-1

2.2 Power Up Procedure............................................................................................. 2-1

2.3 Using the Keypad and Display ............................................................................. 2-1

2.3.1 General Keypad Entry .............................................................................. 2-3

2.4 Overview of the Displays (User Interface)........................................................... 2-4

2.5 Adapting the Program to Your Clinical Requirements with the Setup Menu....... 2-4

2.6 Setup Options ....................................................................................................... 2-5

2.6.1 Password................................................................................................... 2-6

2.6.2 Results Configuration Menu..................................................................... 2-7

2.6.2.1 Remote Review............................................................................ 2-7

2.6.2.2 Results Suppression..................................................................... 2-8

2.6.2.3 Mandatory Patient ID .................................................................. 2-8

2.6.3 Operation Configuration Menu ................................................................ 2-9

2.6.4 Communications....................................................................................... 2-9

2.7 QC Setup .............................................................................................................. 2-9

2.7.1 QC Lockout .............................................................................................. 2-9

2.8 Remote Control .................................................................................................. 2-11

PN 22363 Rev. D 6/2001 TOC-1

Page 10

Table of Contents

3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Display and Door.................................................................................................. 3-3

3.2 Keypad.................................................................................................................. 3-3

3.3 Printer (Optional).................................................................................................. 3-3

3.4 Sampler................................................................................................................. 3-3

3.5 Sensor Module...................................................................................................... 3-4

3.6 Sensors.................................................................................................................. 3-4

3.7 Reference Electrode.............................................................................................. 3-4

3.8 Barometric Pressure Module ................................................................................ 3-5

3.9 Pinch Valves.......................................................................................................... 3-5

3.10 Peristaltic Pump.................................................................................................... 3-5

3.11 Reagent Pack ........................................................................................................ 3-5

3.12 Auto-Cartridge QC ............................................................................................... 3-6

3.13 Movement Of Fluids............................................................................................. 3-6

3.14 Operational Overview........................................................................................... 3-7

3.15 Ready to Analyze.................................................................................................. 3-7

3.16 Calibrating the Analyzer....................................................................................... 3-8

3.16.1 Two-Point Calibration (Automatic and Manual)...................................... 3-8

3.16.2 Manual Calibration................................................................................... 3-8

3.16.3 SO2/Hb Calibration.................................................................................. 3-8

3.16.4 One-Point Calibration............................................................................... 3-9

3.17 Quality Control ..................................................................................................... 3-9

3.17.1 Running QC Samples ............................................................................. 3-10

3.17.2 Running Linearity Solutions/Proficiency Samples................................. 3-10

3.18 Analyzing Samples ............................................................................................. 3-10

3.18.1 Analyzing from a Syringe or an Ampule................................................. 3-11

3.18.2 Analyzing from a Capillary Tube ........................................................... 3-12

3.18.3 Analyzing in AV Shunt Mode................................................................. 3-13

3.18.4 Stat Mode................................................................................................ 3-13

3.19 Results Recall ..................................................................................................... 3-14

4 Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Sample Number Counter ...................................................................................... 4-1

4.2 Scheduled Maintenance........................................................................................ 4-1

4.2.1 Reagent Pack and Control Pack Changing ............................................... 4-2

4.2.2 Flowpath/Probe Maintenance ................................................................... 4-3

4.2.3 Standby Mode........................................................................................... 4-3

4.2.4 pH and Sodium Sensors Replacement...................................................... 4-3

4.2.5 PCO2 Sensor or Membrane Replacement................................................ 4-4

4.2.6 PO2 Sensor Polishing and Membrane Replacement................................. 4-6

4.2.7 Reference Electrode Replacement............................................................ 4-7

TOC-2 PN 22363 Rev. D 6/2001

Page 11

Nova Stat Profile pHOx Reference Manual

4.2.8 SO2 Sensor Maintenance........................................................................... 4-9

4.2.9 Pump Tubing Replacement..................................................................... 4-10

4.2.9.1 Waste Line Replacement ........................................................... 4-11

4.2.9.2 Reference Line Replacement..................................................... 4-12

4.2.10 Sensor Module Conditioning.................................................................. 4-13

4.2.11 Flowpath Cleaning/Deproteinizing......................................................... 4-13

4.2.12 Printer Paper Replacement ..................................................................... 4-14

4.2.13 Probe and Air Detector Replacement ..................................................... 4-15

4.2.14 Sensor Module Replacement.................................................................. 4-17

4.3 Display/Cabinet Cleaning................................................................................... 4-19

5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Troubleshooting Procedures ................................................................................. 5-1

5.2 Stat Profile pHOx 2-Point Calibration Sequence ................................................. 5-2

5.3 Status Codes ......................................................................................................... 5-4

5.4 pH Conditioning ................................................................................................... 5-7

5.5 Troubleshooting Flow Problems........................................................................... 5-7

5.5.1 Operator Flow Test ................................................................................... 5-7

5.5.2 Flushing the Reference Electrode........................................................... 5-10

6 Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 Sensor Subsystem Screens.................................................................................... 6-1

6.1.1 Running a Flow Test and Checking the Rotary Valve Operation ............. 6-1

6.1.2 Checking the Sampler............................................................................... 6-2

6.1.3 Checking the Pump................................................................................... 6-2

6.1.4 Checking the Waste Valve......................................................................... 6-2

6.1.5 Checking the Reference Valve.................................................................. 6-2

6.1.6 Checking the SO2 LEDs........................................................................... 6-3

6.1.7 Checking the Air Detectors....................................................................... 6-3

6.2 Analog Input ......................................................................................................... 6-3

6.3 System Test ........................................................................................................... 6-3

6.4 Printer Menu ......................................................................................................... 6-4

6.5 Error Log .............................................................................................................. 6-4

6.6 Communications Test ........................................................................................... 6-4

6.7 RS-232 Serial Ports .............................................................................................. 6-5

6.7.1 CO-Oximeter Interface ............................................................................. 6-6

6.7.2 PDM/Computer Interface ......................................................................... 6-6

6.7.3 Bar Code Scanner Port ............................................................................. 6-6

6.7.4 External Keyboard.................................................................................... 6-6

PN 22363 Rev. D 6/2001 TOC-3

Page 12

Table of Contents

7 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1 High-Level Protocol ............................................................................................. 7-1

7.1.1 Header Record .......................................................................................... 7-2

7.1.2 Patient Information Record ...................................................................... 7-3

7.1.3 Test Order Record..................................................................................... 7-5

7.1.4 Result Record ........................................................................................... 7-7

7.1.5 Comment Record...................................................................................... 7-9

7.1.6 Message Terminator Record .................................................................... 7-9

7.1.7 Parameter Names.................................................................................... 7-10

7.2 Examples ............................................................................................................ 7-16

7.2.1 pHOx Only Patient Sample .................................................................... 7-16

7.2.2 pHOx Only QC Sample.......................................................................... 7-17

7.2.3 pHOx ABG Calibration .......................................................................... 7-18

7.2.4 pHOx SO2% Calibration ......................................................................... 7-19

7.2.5 Combined Patient Sample ...................................................................... 7-19

7.2.6 pHOx Only QC Sample.......................................................................... 7-21

A Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.1 Stat Profile pHOx Specifications......................................................................... A-1

A.2 Reagents and Solutions........................................................................................ A-5

A.2.1 Reagents and Solutions............................................................................ A-5

A.2.2 Reagent Pack ........................................................................................... A-6

A.2.3 Verifying the Analyzer's Performance ..................................................... A-6

A.2.3.1 Nova Stat Profile pHOx Controls Levels 1, 2, 3: QC................ A-7

A.3 Reference Values ................................................................................................. A-8

A.4 Ordering Information........................................................................................... A-9

A.5 Shutdown Procedure.......................................................................................... A-11

A.5 Warranty ............................................................................................................ A-11

TOC-4 PN 22363 Rev. D 6/2001

Page 13

Nova Stat Profile pHOx Reference Manual

B Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.1 Sensor Calibration ................................................................................................B-1

B.1.1 Two-Point Calibration ..............................................................................B-1

B.1.2 One-Point Calibration ...............................................................................B-1

B.2 Parameter Definitions ...........................................................................................B-2

B.2.1 pH Sensor .................................................................................................B-2

B.2.2 Partial Pressure of Carbon Dioxide (PCO2) .............................................B-2

B.2.3 Partial Pressure of Oxygen (PO2) .............................................................B-3

B.2.4 Hematocrit ................................................................................................B-3

B.2.5 Hemoglobin (Measured) ...........................................................................B-3

B.2.6 SO2 % Concentration ................................................................................B-4

B.3 Calculated Values..................................................................................................B-4

B.3.1 Temperature Correction for Measured Values* ........................................B-4

B.3.2 Calculated Parameters ..............................................................................B-5

C Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

C.1 pHOx Installation .................................................................................................C-2

C.1.1 Printer Paper Installation ..........................................................................C-2

C.1.2 SO2 Sensor Installation .............................................................................C-3

C.1.3 Reference Electrode Installation...............................................................C-3

C.1.4 Pump Tubing Harness Installation............................................................C-4

C.1.5 Reference Line (R-line) Installation .........................................................C-5

C.1.6 Waste Line (W-line) Installation...............................................................C-6

C.1.7 Sodium and pH Sensor Installation ..........................................................C-6

C.1.8 PO2 and PCO2 Sensor installation ............................................................C-7

C.1.9 Probe and Air Detector Installation ..........................................................C-8

C.1.10 Reagent Pack Installation .........................................................................C-9

C.1.11 Auto-Cartridge Quality Control Pack Installation....................................C-9

C.1.12 Calibration ..............................................................................................C-10

PN 22363 Rev. D 6/2001 TOC-5

Page 14

Table of Contents

TOC-6 PN 22363 Rev. D 6/2001

Page 15

1 Introduction

This manual provides all necessary instructions for the routine operation and maintenance of

the Stat Profile pHOx Analyzer. Please read this manual carefully. It has been prepared to help

you attain optimum performance from your Stat Profile pHOx Analyzer.

1 Introduction

1. Intro.

WARNING: Blood samples and blood products are potential sources of hepatitis and

other infectious agents. Handle all blood products and flow path components (wasteline, capillary adapter, probe, sensor module, etc.) with care. Gloves and protective

clothing are recommended.

!

This section introduces the Stat Profile pHOx Analyzer and covers requirements, tests

performed, procedural limitations, clinical utility, and sample handling.

1.1 Installation

This section covers the installation requirements and assembly procedures for the Stat Profile

pHOx Analyzer.

1.1.1 Requirements

Working Area Requirements:

Keep the working area around the system free of dirt, corrosive fumes, vibration, and excessive

temperature changes. Ambient operating temperature is 15 °C to 30 °C (59°F to 86 °F). Operate

at humidity of 0 to 95% without condensation.

NOTE:

Analyzer and means refer to the manual.

NOTE:

equipment for you.

This International Caution Label appears on the rear of the pHOx

Under the Warranty, a Nova service representative will install this

Electrical Requirements:

A grounded, 3-wire receptacle within 5 feet of the system is required for operation. The U.S.

models require a 120 Volt AC line at 50/60 Hz frequency. The analyzer can be operated at

100 - 120; 220 - 240 Volt AC 50/60 Hz.

Fuse requirements:

• 2 Amp Time Delay (SB 2A or T2A) at 100 - 120 Volt AC line.

• 1 Amp Time Delay (T1A) at 220 - 240 Volt AC line.

1-1

Page 16

Stat Profile pHOx Reference Manual

1.2 Intended Use, Tests Performed, and Clinical Utility

1. Intro.

Intended Use

The Stat Profile pHOx Analyzer is intended for in vitro diagnostic use by health care

professionals in the quantitative determination of pH,

hematocrit (Hct), hemoglobin (Hb) in heparinized whole blood.

Measured Parameters

pH, PCO2, PO2, SO2%, Hct, (Na+ required for Hct), Hb, and barometric pressure

Calculated Parameters

From the directly measured results, the calculated results are

• Base Excess of the blood (BE-b)

• Base Excess of extracellular fluid (BE-ecf)

• Bicarbonate level (HCO

• Standard Bicarbonate Concentration (SBC)

• Total Carbon Dioxide (TCO2)

• Oxygen Content (O2Ct)

• Oxygen Saturation (SO2%) - (If measured result not available)

• Alveolar Oxygen (A)

• Arterial Alveolar Oxygen Tension Gradient (AaDO2)

• Arterial Alveolar Oxygen Tension Ratio (a/A)

• Oxygen Capacity (O2Cap)

• Hemoglobin (Hbc) - (If selected or measured result not available)

• P50 (measure single point)

• pH, PCO2, PO2 (corrected to patient temperature)

˙

•

˙

/

Qsp Qt

(physiological shunt - requires 2 samples: mixed venous and arterial)

• Respiratory Index (RI - uses entered %FIO2 or default value of 20.9)

• PO2/FIO2 ratio

-

)

3

PCO

, PO2, oxygen saturation (SO2%),

2

1-2

With the Nova CO-OXIMETER inputs of Oxygen Capacity of hemoglobin (O2Cap) and

Oxygen Content of hemoglobin (O2Ct), the additional combined CO-Oximeter/Stat Profile

pHOx calculated results are

• CcO

• CaO

• Cv- O

• a-v- DO

2

2

2

2

• P50

Page 17

1 Introduction

Test Dependencies

• If O2Cap from the Nova CO-OXIMETER is available, that value is displayed.

• If O2Ct from the Nova CO-OXIMETER is available, that value is displayed instead

of the calculated O2Ct value.

• If SO2% from the Nova CO-OXIMETER is available, that value is displayed instead

of the SO2% measured by the reflectance method.

• If Hb from the Nova CO-OXIMETER is available, that value is displayed instead of

the Hb measured by the conductivity and photometric methods.

1. Intro.

Clinical Utility

1

The following list includes the clinical utility information for each of the analytes measured

on the Stat Profile pHOx Analyzer.

Blood Gases: Whole blood measurement of blood gases is used in the diagnosis

(PCO2, PO2, and treatment of life-threatening acid-base disturbances in critically ill

and pH) patients with numerous metabolic and pulmonary diseases.

Oxygen Used to assess the oxygenation of hemoglobin and the adequacy of tissue

Saturation oxygenation in the evaluation of pulmonary function. Also used in the

diagnosis and treatment of cyanosis.

Hematocrit Whole blood measurement of hematocrit is used to estimate that red blood

cells are present in sufficient quantity to carry oxygen and carbon dioxide.

Hemoglobin Oxygen is carried from the lungs throughout the body by hemoglobin present

in red blood cells. Measurement of hemoglobin provides the clinician with

information regarding the evaluation of chronic and acute anemias and also

with information pertaining to the potential oxygen transport capability of the

hemoglobin.

Physiologic The physiologic shunt or AV Shunt calculation relates to the small fraction

Shunt of the cardiac output which goes to the lungs that does not come into contact

with oxygen exchange units (alveoli). In health, this shunt fraction is less than

5%. Increased shunt fraction is seen in cases where there is a pathophysiologic process that reduces the number of functional gas exchange alveoli or

blood is directed away from functional alveoli.

Ref. 1.Tietz, N.W. ed. 1986. Textbook of Clinical Chemistry. W. B. Saunders Co.

1-3

Page 18

Stat Profile pHOx Reference Manual

1.3 The Sample

1. Intro.

1.3.1 Handling Requirements

Sodium or lithium heparin whole blood sample from syringes, open tubes, small cups, and

capillary tubes can be used on the Stat Profile pHOx Analyzer. The sample size is 70 µL for

normal mode and 45 µL for micro mode (blood gases only).

Correct sample handling is critical to ensure that the blood gas values obtained accurately

reflect the in vivo state. Ensure that all samples have been obtained and stored following

consistent, clinically accepted protocols. It is particularly important to ensure that samples are

well mixed before introduction into the analyzer. Nova Biomedical recommends that you

analyze the sample within 15 minutes for blood gases. Storing samples on ice is not

recommended. Using iced samples may elevate the PO2 result.

1. National Committee for Clinical Laboratory Standards. Considerations in the Simultaneous Mea-

surement of Blood Gases, Electrolytes, and Related Analytes in Whole Blood; Proposed Guideline.

NCCLS Document C32-P. Vol. 13, No. 17.

1

1.3.2 Acceptable Anticoagulants

Sodium and lithium heparin are the recommended anticoagulants for use with the Stat Profile

pHOx Analyzer. EDTA, citrate, oxalate, or sodium fluoride are not recommended for use.

Depending on the amount of heparin used in the collection syringe and whether it is filled to

capacity with blood, heparin concentrations of 20 I.U. per mL to over 100 I.U. per mL may be

obtained. Liquid heparin when present in excess may cause errors by dilution in pH, PCO2, and

PO

.

2

Our experience suggests that lyophilized lithium heparin giving a final concentration in blood

of not more than 20 I.U. per mL is acceptable in the critical care laboratory. Stat Profile pHOx

Analyzer users should take careful note of these considerations when establishing reference

intervals and interpreting results.

1-4

Update to PN 22363 Rev. D 3/2002

Page 19

1.3.3 Interfering Substances

S

O2% Interferences:

High levels of COHb and MetHb will increase the reported SO2% value.

MetHb values above 15% will interfere with the SO2% value.

10% Intralipid solutions will interfere with the

Intralipid are >500 mg/dL.

Hemolyzed samples will interfere with the SO2% value.

Hematocrit (Hct) Interference:

White Blood Count (WBC) greater than 50,000 WBC/µL may increase the hematocrit value.

1.3.4 Matrix Effects

Nova instruments are designed for clinical environments to analyze actual patient specimens,

not modified blood samples. Specimens removed from the patient, anticoagulated appropriately, and promptly analyzed are the only type of sample where the measurement results will

be reliable. Matrix effects/interferences can occur when patient specimens are removed from

the body, modified and then measured on a Nova instrument. For example, matrix effects have

been seen on Nova analyzers when attempting to analyze samples collected from cell savers

used in various surgical procedures. Also, evaluation laboratories run specimens from patients

with a wide variety of pathologies and from patients who are being treated with a broad

spectrum of therapeutic and pharmacological agents. Despite extensive clinical trials, it is not

possible to anticipate every possible combination of transfused blood products, crystalloids,

and drugs (or their metabolites) that may be present in a blood sample. As a result, some users

have found that their particular patient mix has necessitated making adjustments to maintenance. For example, a high number of cardiopulmonary bypass pump or ECMO (extracorporeal membrane oxygenation) samples result in a need for increased analyzer maintenance. If

you are experiencing excessive downtime, you may need to modify your own maintenance

schedules. Nova’s Clinical Applications Group will assist you in tailoring a maintenance

program to meet these needs.

1 Introduction

SO

% when the blood concentrations of

2

1. Intro.

1.4 About This Reference Manual

This manual is for Stat Profile pHOx Analyzer.

Throughout this manual,

information that is critical to avoid instrument damage or incorrect results, and

indicates possible hazard to the operator.

NOTE:

indicates especially important information,

CAUTION:

indicates

WARNING:

1-5

Page 20

Stat Profile pHOx Reference Manual

1. Intro.

1-6

Page 21

2 Setup

This section describes how to setup the Stat Profile pHOx Analyzer.

2.1 Installing the Stat Profile pHOx

The analyzer is initially installed by a factory authorized representative.

2 Setup

2. Setup

CAUTION:

at all times. This is necessary to prevent crystallization of salts in the fluid

lines and cuvette. If it is to be shut down indefinitely, purge all fluid lines

with distilled water and then with air. The purge sequence is selected from

the Operational Menu.

2.2 Power Up Procedure

After power up, the analyzer checks the error condition status of the instrument by the Power

On Self Test (POST). The bicolor LED on the front panel will be a solid yellow if the analyzer

has passed this test.

NOTE:

than 1 minute, the Not Ready screen will appear with the LED at solid

yellow. The analyzer will need to be calibrated.

The pHOx analyzer is designed to be left on with adequate fluids

After power up, the analyzer displays the pHOx logo screen. In less

2.3 Using the Keypad and Display

Overview The keypad, display, and status lights are located on the front panel.

Display The display provides prompts, menus, status information, error messages,

patient results, etc. The top line gives the screen's name (i.e., Setup Menu) and

in some screens the date and the time. The second line displays directions for

the screen or additional information about the displayed data. The middle of the

screen is for the menu items that you can select, detailed direction for

procedures, patient information, or electrode statuses. The bottom line defines

the soft keys.

2-1

Page 22

Stat Profile pHOx Reference Manual

Soft Keys The 4 soft keys are defined by the labels currently shown on the lower line

of the display. The keys cause system action, such as selection of menus,

initiation of maintenance procedures, and other displays.

Some common soft keys are

Home returns you back to the READY screen.

Next Screen moves you to the next screen in the sequence.

Cancel returns to the previous screen or cancels a sequence.

2. Setup

Status Lights The 2 status lights on the front panel reveal the system status as follows:

Steady Green - All air detectors and one or more channels are calibrated. The

analyzer is ready for analysis or input.

Flashing Green - All air detectors and one or more channels are calibrated, but

the analyzer is busy analyzing, priming, accepting external data, etc. The

analyzer will not allow any analytical or any other sequence to be started until

it becomes not busy.

Steady Yellow - One or more air detectors or all channels are not calibrated.

Flashing Yellow - One or more air detectors or all channels are uncalibrated and

the analyzer is busy.

Status Symbols There are a number of symbols that can appear after the results. The symbols

have the following meanings:

↑ (single up arrow), ↓ (single down arrow) - The result is higher or lower that the

defined reference range for the parameter.

↑↑ (double up arrow), ↓↓ (double down arrow) - The result is higher or lower that

the defined alert range for the parameter.

↑↑↑ (triple up arrow), ↓↓↓ (triple down arrow) - The result is out of the

analyzer's operating range.

X (an A through an analyte prefix) - The channel is uncalibrated.

? (question mark) - Insufficient sample is detected during sample reading.

* (asterisk) - The result is calculated using a default sodium concentration.

— (a line through an analyte prefix) - The channel did not pass QC and QC

lockout is enabled; or the results have been suppressed.

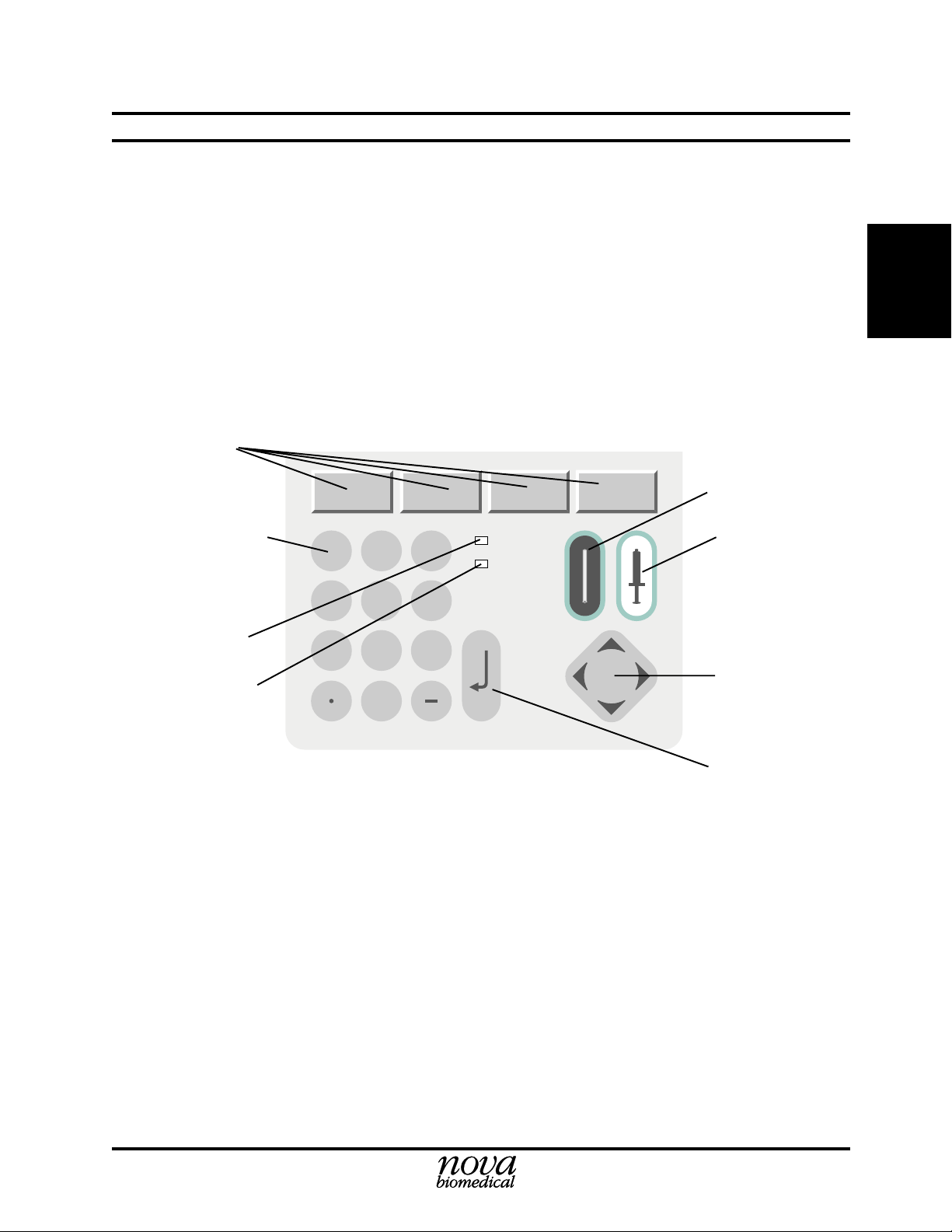

Keypad The keypad allows you to enter information into memory. It consists of 12

number keys (including a decimal point key and a dash key), up (↑), down

(↓), left (←), and right (→) arrow keys, and an ENTER (↵) key. The arrow

keys move the cursor on the display. Also, the left arrow key can be used as

a backspace when entering numerical information. The ENTER (↵) key

places data on the display into memory.

2-2

Analyze Keys There are 2 keys to initiate an analysis: one key has an icon of a capillary tube

and the other key has an icon of a syringe. To perform an analysis with a

capillary sample, press the capillary key. To perform an analysis with a

syringe sample, press the syringe key. These 2 keys are only active when the

Home screen or the Result screen are displaying.

Page 23

2.3.1 General Keypad Entry

Entering numbers:

1. In general, press the arrow keys to select a character entry field or option. Then follow

the screen instructions.

2. For numeric ID entry, press a key to add a character, and the cursor moves to the right.

Up to 20 characters are accepted. If editing an entry, press the left arrow (←) to erase

the last character.

3. After data has been entered correctly, press ENTER (

information into memory.

Soft Keys

2 Setup

↵

) as a final step to store the

Analyze Capillary

2. Setup

Number Keys

Green LED

Yellow LED

1

4

7

2

5

8

0

Figure 2-1. Stat Profile pHOx Keypad

3

6

9

ENTER

Analyze Syringe

Up, Down, Left,

Right Keys

Enter Key

2-3

Page 24

Stat Profile pHOx Reference Manual

2.4 Overview of the Displays (User Interface)

The format that allows the operator to change displays, enter data, and perform functions is

generally referred to as the user interface (controlled by software).

Here are some general rules for the user interface:

2. Setup

• To perform any operation, use the screen instructions to guide you.

• To go back to the Ready screen or the menu for a selected section (i.e., QC, Setup,

etc.), press Home.

• To move back to the previous display, press Previous Page (soft key), if applicable.

• Press Cancel (soft key) to terminate the current operation or sequence or to return to

previous display.

• Press Exit (soft key) to return to the previous display.

• Analyzing a sample and performing calculations take precedence over the user

interface. Therefore, you are temporarily locked out of accessing displays that can

interfere with an ongoing sequence or operation.

• A status message indicates an error condition.

2.5 Adapting the Program to Your Clinical Requirements with the Setup Menu

Use the Setup Menu to adapt the analyzer to your requirements.

2-4

Page 25

2.6 Setup Options

The Setup Menu has the following setup options:

• Results Configuration Menu

• Operation Configuration Menu

2 Setup

- Reference and Alert Limits Setup

PCO

pH,

- Electrode Offsets Setup

pH,

PCO

- Results Units Setup

Temperature: °C or °F

Blood Gas: mmHg or kPa

pH/H+: pH or H

Hb: g/dL or mmol/L or g/L

- Results Suppression: Suppress or not suppress

- Remote Review: ON or OFF

- Patient Name: ON or OFF

- Mandatory Patient ID: ON or OFF

- Analysis Configuration

Analysis Transmit Mode Manual/Auto

Transmit Diagnostic Data Off/ON

Analysis Print Mode Manual/Auto

Print Diagnostic Data OFF/ON

CO-Ox Data Merge Accession nbr/Patient ID

Set Analyzer ID Number:

- Calibration Configuration

Set 1 Point Calibration Frequency 30, 45 min.

Set 2 Point Calibration Frequency 2, 4, 6 hr.

Transmit Diagnostic Data OFF/ON

Print Diagnostic Data OFF/ON

Transmit Drift Data OFF/ON

Print Drift Data OFF/ON

- System Configuration

Set Date Format DD/MM/YY, MM/DD/YY, YY/MM/DD

Set Time Mode 24/12 hr. Mode

Date and Time Set

Measured Barometric Pressure 760 mmHg

Corrected Barometric Pressure 0.0 mmHg

Set Default Hb Used in Calculations: 14.3 g/dL

Set Tone Frequency (100-500Hz): 3500 Hz

- Analysis Mode: A or B

- Hb Type: Measured or Calculated

- STAT Mode: ON or OFF

, PO2, SO2%, Hct, Hb

2

, PO2, SO2%, Hct, Hb

2

+

2. Setup

2-5

Page 26

Stat Profile pHOx Reference Manual

• Communications Menu

- Baud (4800, 9600, 19200)

- Data Bits (7, 8)

- Stop (1,2)

- Parity (None, Even, Odd)

- External Keyboard: Yes or No

- Co-oximeter attached: Yes or No

2. Setup

2.6.1 Password

• Printer Installed or Not Installed

• Passwords: System or Operator

• Operator Passwords: ON or OFF

• Language: English, Chinese, French, German, Italian, Japanese, and Spanish

The first option you should call up is Set Password: either System or Operator.

The System Password, which safeguards the setup parameters, is required to enter the Setup

Menu. Set up System Passwords as follows:

1. Press Menu on the Ready screen to display the Operational Menu screen.

2. Press Setup to display the Setup Menu screen.

3. A pop-up Password screen appears. Enter the default password, 0. This is the

password until one is officially entered.

4. Scroll down with the arrow keys to the Password option and press Enter. A pop-up

screen appears: select System Password.

5 Key in a password number between 1 and 9999 (up to 4 numeric characters) then

press ENTER.

6. Proceed to the next setup option or return to the Operational Menu.

2-6

The Operator Passwords allows you the ability to enable and to enter 200 unique passwords

with privilege levels. When enabled, password entry will be required whenever any of the

home screen soft keys, syringe key, or capillary key are pressed. Entry into any one of the

protected areas depends on the privilege level assigned to the operator of the analyzer.

There are 3 privilege levels: Privilege Level 1 is the most privileged operator and Privilege

level 3 is the default level.

• Privilege Level 1 operators have access to all areas of the analyzer except those

protected by the existing System Password. Level 1 operators do not require PDM

review and may override this feature. Level 1 operators can override QC lockout.

• Privilege Level 2 operators have access to all areas of the analyzer except those

protected by the existing System Password. Level 2 operators will require PDM

review, but may override this feature. Level 2 operators cannot override QC lockout.

• Privilege Level 3 operators have access to analysis only. Level 3 operators will

require PDM review before the results are released. Level 3 operators cannot override

QC lockout.

Page 27

Set up Operator Passwords as follows:

1. Press Menu on the Ready screen to display the Operational Menu screen.

2. Press Setup to display the Setup Menu screen.

3. A pop-up Password screen appears. Enter the default password, 0. This is the

password until one is officially entered.

3. Scroll down with the arrow keys to the Password option and press Enter. A pop-up

screen appears: select Operator Password.

4. Key in a password number, up to 4 numeric characters, and press ENTER.

5. To enable Operator Passwords, scroll down to Operator Passwords then press the

Enter key: Off will turn to On.

6. Proceed to the next setup option or return to the Operational Menu.

2.6.2 Results Configuration Menu

The Results Configuration Menu screen allows you to set reference and alert limits (Low and

High) for all analytes; to adjust electrode offsets for slope and intercept for all analytes; to select

units for temperature, pH, blood gas, and hemoglobin; to turn Remote Review On or Off

(operator Password is enabled when On); Mandatory Patient ID (On or Off); Patient Name (On

or Off); Global Suppression (Test Results).

2 Setup

2. Setup

2.6.2.1 Remote Review

The operator passwords are enabled whenever Remote Review is enabled. To enable Remote

Review (password required), go to the Results Configuration screen, select Remote Review,

then press the Enter key to enable (On) - disable is Off.

Features of Remote Review are as follows:

• Send Results Data to PDM for Review: When all results and calculated parameters are

available, the pHOx Analyzer transmits all this data to the PDM. The analysis cycle

is suspended indefinitely until the PDM returns record or the review is bypassed or

cancelled.

• Suppress Results Data: The PDM will return a reviewed data record to the pHOx

Analyzer. The analyzer will suppress test results based on the information received

from PDM.

• Bypass Review: A pHOx operator with password level 1 or level 2 can bypass a remote

review session. When the session is bypassed, the results are saved, displayed, and

printed (if automatic printing is on). A reviewed data record sent by PDM is ignored

if the review session is bypassed.

2-7

Page 28

Stat Profile pHOx Reference Manual

• Cancel Review: A pHOx operator can cancel a remote review session. When the session

is cancelled, the results are saved, but the results will not be displayed or printed. A

reviewed data record sent by PDM is ignored if the review session is cancelled.

• Review Patient Name: PDM can return a patient name with the suppressed test results.

The patient name will be displayed and printed with the result data if the patient name

entry feature is ON.

• Review Accession Number: PDM can return an accession number with the suppressed

2. Setup

2.6.2.2 Results Suppression

In the Results Configuration screen, test results can be suppressed: will not be displayed,

printed, or transmitted. The suppressed results will only affect analysis results: it will still

calibrate.

Measured tests that depend on the results from a suppressed test will not be displayed. A

dependency error is displayed.

Calculated parameters that depend on suppressed results are not calculated.

Suppress results as follows:

test results. The accession number will overwrite the existing accession number. The

accession number will be displayed and printed with the result data.

1. In the Results Configuration screen, scroll down to Results Suppression.

2. Press the Enter key to get a pop-up screen of the tests.

3. Scroll to the test that you want to suppress then press the Enter key.

4. Scroll to the next test or exit from screen.

5. On the Home screen, the suppressed test will have a strike through the test;

no results will be reported on this test.

2.6.2.3 Mandatory Patient ID

In the Results Configuration screen, the Mandatory Patient ID is enabled or disabled. If

enabled, the Sample Information screen will prompt for Patient ID before the sample analysis

can continue.

A patient ID can be sent from PDM as part of a remote review session.

A patient ID can also be received from a bar code device or external keyboard through the bar

code port.

2-8

Page 29

2.6.3 Operation Configuration Menu

The Operation Configuration Menu screen allows you to setup the analysis output options, to

configure calibration frequency, and to set date, time, barometric pressure, analyzer ID

number, and to change the analysis mode (A or B); to select Hb Measured or Calculated; to

select STAT Mode.

2.6.4 Communications

The Communication screen allows you to setup the communication ports: Baud, Stop, Data, and

Parity. Also, the External Keyboard and CO-Oximeter attached (Yes or No) is selected here.

2.7 QC Setup

2 Setup

2. Setup

To access the QC Setup screen, press QC (soft key) on the Ready screen. Then use the down

arrow key to select QC Setup and press the ENTER key to display the QC Setup screen.

For External Controls, enter the Lot Number, the Expiration Date, the Daily Analysis Times

(up to 3 times per control per day), and the Ranges of each control.

For Internal Controls, the Lot Number, the Expiration Date, and the Control Ranges are

automatically read from the control pack when the QC Auto Cartridge is installed. The Daily

Analysis Times (up to 3 times per control per day) must be manually entered.

2.7.1 QC Lockout

QC Lockout can be enabled (ON) in one of 2 modes or disabled (OFF) from the QC Setup

screen (a password protected screen). When QC Lockout is selected from this screen, a popup screen appears. Lockout OFF, Mode A, and Mode B are the choices. When QC Lockout is

ON (Mode A or Mode B) and QC is due, all test that are scheduled for QC will be lock out. A

QC analysis must be done for a locked out test before an analysis can be performed.

Channel Lockout

A channel will be locked out when it does not pass a QC level. The channel appears with a

strike-through it. This channel will not report results unless a password overrides it. When all

channels become locked out, the analyzer displays the Not Ready screen.

NOTE:

track (Mode A) of the channels that would be locked out if the QC Lockout

feature was ON. If the QC Lockout feature is now turned ON, all those

channels will now become locked out.

If the QC Lockout feature is OFF, the analyzer will internally keep

2-9

Page 30

Stat Profile pHOx Reference Manual

Level Lockout

QC level lockout is enforced for both Mode A and Mode B. If a QC level is not run and QC

Lockout is enabled, all channels in that QC level will become locked out. These channels

remain locked out until the QC analysis cycle of that level is run. A message is displayed on

the Ready/Not Ready screen that a QC analysis is due for a particular level.

2. Setup

NOTE:

track of all channels in this level that would be locked out if the QC Lockout

feature was ON. If the QC Lockout feature is now turned ON, all those

channels will now become locked out.

QC Lockout is activated by selecting either Mode A or Mode B.

Mode A QC lockout locks or unlocks channels based on the last QC level run. A lockout

channel is displayed with a strike-through the channel name. Results for a locked out channel

are not calculated. If more than one QC level is run for the QC cycle, only the last QC level

that a channel is in determines whether the channel will be locked or unlocked. If 3 levels were

run and the channel passed the first 2 levels but failed the last, the channel will be locked out.

To be unlocked, this channel must pass that last level: passing the first 2 does not count. If the

reverse happened and the channel failed the first 2 levels but passed only the last level, the

channel will not be locked out.

Mode B QC lockout locks or unlocks channels based on the last QC run for all levels. A

lockout channel is displayed with a strike-through the channel name. Results for a locked out

channel are not calculated. If a channel fails any level run in a QC cycle, the channel will be

locked. To be unlocked, the channel must pass all levels that it failed.

If the QC Lockout feature is OFF, the analyzer will internally keep

2-10

QC Lockout OFF

When the QC lockout mode is set to OFF, the analyzer internally tracks the lockout state for

each channel. The tracking uses the Mode A lockout. If QC lockout is enabled by selecting

either Mode A or Mode B, any number of the tracked channel can now become locked out.

QC Lockout is password protected, and a password override (Level 1 operators only) is

provided with a pop-up screen. Analysis can be initiated for all channels in a lockout state, but

results will be displayed with the message "Scheduled QC Not Run" and printed with this error

message.

For Automatic QC mode to perform, turn Automatic QC Analysis ON in the Quality Control

screen.

Messages displayed on the Ready/Not Ready screen detail the reason for the QC lockout. These

message are only displayed if QC lockout is enabled (Mode A or Mode B). The following are

the messages and their meanings.

Page 31

2 Setup

Level Lockout Ready/Not Ready Screen Messages

Internal L(n) Not Run Internal L(n) missed a scheduled QC cycle. All channels are locked

out for that level. Results for the locked out channels will not be

reported. Internal QC level (n) must be run to unlock the channels.

External L(n) Not Run External L(n) missed a scheduled QC cycle. All channels are locked

out for that level. Results for the locked out channels will not be

reported. External QC level (n) must be run to unlock the channels.

Mode A Ready/Not Ready Screen Messages

QC Lockout All channels are locked out. Analysis cannot be run without a

password override. Any QC level that is run will unlock the

channels.

Mode B Ready/Not Ready Screen Messages

QC Lockout Internal L(n) Internal L(n) has channels that are locked out. Results for locked out

channels will not be reported. Internal QC level (n) must be run to

unlock the channels.

QC Lockout External L(n) External L(n) has channels that are locked out. Results for locked

out channels will not be reported. External QC level (n) must be run

to unlock the channels.

2. Setup

2.8 Remote Control

Remote control is enabled on the PDM side. See the PDM Manual for information. The

analyzer's system ready status information is sent to the PDM upon each change of status:

barometer, temperature, reagent pack, control pack, minimum calibration, QC test lockout, QC

level lockout, and standby mode state.

The system test status information is sent to the PDM after calibration and QC are completed.

This test status information includes the calibration status and QC lockout status of each test

and the performance status of glucose.

Remote control from the PDM can do the following:

• Initiate a 2-point calibration sequence

• Run an internal QC (any level)

• Turn global suppression on or off

• Enter or delete passwords

• Maintain a maintenance activity record that is sent to the PDM at the completion of

the maintenance. The maintenance status information includes an operator ID, an

activity ID, and the date and time of the maintenance.

2-11

Page 32

Stat Profile pHOx Reference Manual

2. Setup

2-12

Page 33

3 Operation

The Stat Profile pHOx Analyzer is pictured below with its components.

1

4

7

8

0

3 Operation

3

3. Operation

1

2

3

5

2

6

9

4

5

Figure 3.1 Nova Stat Profile pHOx Components

1. Display

2. Keypad

3. Printer

4. Sampler

5. Door/Front Panel

DWG #10-1016A

3-1

Page 34

Stat Profile pHOx Reference Manual

11

1

2

3

4

3. Operation

5

10

9

8

7

DWG #10-1017A

3-2

Figure 3.2 Analytical Compartment

1. Waste Line

2. Reference Line

3. Pinch Valve (Reference)

4. Pump and Pump Tubing

5. Reagent Pack Opening

6

6. Control Pack Opening

7. Sampler

8. Air Detector

9. Sensor Module With Sensors

10. Reference Electrode

11. Pinch Valve (Waste)

Page 35

3.1 Display and Door

The display is a liquid crystal display (LCD). To adjust the display intensity, use the right

(darker) or left (lighter) arrow key while displaying the Ready or Not Ready screen. Prompts,

menus, status information, error messages, patient results, etc. are displayed on the screen. The

default language is English. (Other languages can be selected through the setup menu.)

The door may be opened to access the analytical compartment of the system. There is an inside

latch that is easily released when you pull at the bottom right side of the door.

3.2 Keypad

The primary input device is the keypad. It has the digits (0 thru 9), a decimal point, a dash, an

ENTER key, arrow keys (up, down, left, and right), and analyze keys (syringe and capillary

icons). There are also 4 Soft Keys whose function is determined by the legend displayed just

above it on the LCD display: Print, Exit, Cancel, Menu, etc.

3 Operation

3. Operation

3.3 Printer (Optional)

The internal printer (optional) will be able to print patient results, list the analyzer's setup

information, error log, etc.

3.4 Sampler

The sampler allows for the aspiration of the sample. The sampler has 2 sampling positions:

horizontal for the aspiration of a sample from a capillary tube and inclined for the aspiration

of the sample from a syringe. No special adapters are required to aspirate a sample from a

capillary tube. The capillary or syringe positions are selected by pressing the Black Capillary

key or the White Syringe key.

3-3

Page 36

Stat Profile pHOx Reference Manual

3.5 Sensor Module

The sensor module includes the preheater and flow cell. The preheater heats samples and

controls to 37°C. In addition, it contains the hematocrit impedance electrode and 2 air detectors.

The sensor module geometry is an interlaced configuration with the reference electrode at the

top of the sensor module, 3 sensors on the left side, 2 sensors on the right side. In addition to

the Hct sensor located in the preheater, there are 6 sensors: Reference electrode, Na+, PCO2,

SO

(optic), pH, and PO2. A window in the door allows flow path visibility and is augmented

2

by a backlight.

3.6 Sensors

3. Operation

The Sensors housed in the sensor module are the core of the Stat Profile pHOx Analyzer. The

methodology used by each sensor are

Electrode Methodology

+

Na

pH Hydrogen ion-selective glass electrode

PCO

2

PO

2

Hct Impedance electrode

Hb Impedance electrode/photometry

SO

2

The sensors clip into the sensor module, and electrical contact is automatically made.

3.7 Reference Electrode

The Reference Electrode is mounted above the sensor module. It is a solid-state Ag/AgCl

electrode and provides the reference voltage for comparison to sample voltages. The exit port

of the flow path is located on this electrode.

Sodium ion-selective electrode

Severinghaus-type electrode

Polarographic Clark-type electrode

Reflectance photometry (fiber optics)

3-4

Page 37

3.8 Barometric Pressure Module

The Barometric Pressure Module, located on a printed circuit board, continuously monitors the

barometric pressure. This barometer can be calibrated against an external barometer, if desired,

through the software.

3 Operation

3.9 Pinch Valves

There are 2 pinch valves: one is used to control the flow of the reference fluid and the other one

is used to control the flow of fluids through the sensor module.

3.10 Peristaltic Pump

The pump is a 6-roller peristaltic pump driven by a stepper motor.

3.11 Reagent Pack

The reagent pack contains 6 flexible bags in a cardboard carton. One of these is a waste bag

to collect the used reagents, controls, and samples. The other 5 bags contain standard reagents:

A, B, C, D, and R. Each bag includes a fitment with a septa.

The exposed bag fitments are arranged in a line along the rear of the pack. The septa are pierced

during insertion of the pack. The lot number and expiration date are printed on the front of the

pack.

The Reagent Management System (RMS) of the reagent pack automatically enters the

calibration values, the lot number, the fluid volumes, and the expiration date to the analyzer's

computer after insertion of the reagent pack.

3. Operation

3-5

Page 38

Stat Profile pHOx Reference Manual

3.12 Auto-Cartridge QC

Nova Biomedical's Auto-Cartridge QC is a total automated control system contained within

a single on-board reagent cartridge. This system allows any level of quality control to be run

at any time: either on a programmed schedule or on demand. The Auto-Cartridge QC system

reduces costs by eliminating the time and labor required to manually perform quality control.

Each Nova Auto-Cartridge contains 3 levels of blood gas controls, 2 levels of hematocrit,

SO

%, and hemoglobin controls, plus software that automates running controls and storing

2

quality control data. When the cartridge is installed, all quality control target ranges, lot code,

and expiration date information is automatically downloaded to the analyzer. The user then

programs the pHOx Analyzer to automatically analyze up to 3 quality control levels, 3 times

3. Operation

per day (a total of 9 analyses per day). If any analyte is outside the target range, it is

automatically reanalyzed. If a control value remains out of range, the user is notified.

All quality control data is automatically stored. Daily and cumulative statistical reports and

Levey-Jennings graphs can be printed at any time. This automation assures that quality control

is always performed accurately and on schedule, thereby guaranteeing regulatory compliance.-

3.13 Movement Of Fluids

To begin an analysis, press the Capillary or Syringe key to move the sampler to either the

capillary or syringe position. Present the sample to the probe and press either Aspirate Normal

or Aspirate Micro (soft keys). The Aspirate Normal soft key allows for the aspiration of 70 µL

of sample, and the Aspirate Micro soft key allows for the aspiration of 45 µL of sample. The

sample is aspirated by the peristaltic pump until the leading edge is detected by either the 45 µL

or 70 µL air detector. After the aspiration is completed, there is an audible beep and a pop-up

display that prompts you to press Analyze after removing the syringe or capillary. The sample

is advanced until the leading edge is properly located in front of the electrodes. Once all

measurements have been completed, the sample is pumped to the waste and the flow path is

washed.

3-6

Update to PN 22363 Rev. D 3/2002

Page 39

3.14 Operational Overview

The Stat Profile pHOx Analyzer is a stand-alone, microprocessor-based instrument for

analyzing blood samples. The analyzer measures pH, PCO2, PO2, SO2%, Hct, and Hb in

heparinized blood. The analyzer additionally calculates the parameters listed in Section 1.2.

The software allows the control of the following functions:

3 Operation

• Calibration

• Sample analysis

• Quality Control

• Diagnostic and maintenance functions

• System configurations

• Communication interface with external devices

• Storage and retrieval of patient records

After the analyzer is set up and calibrated, it is ready to begin analyzing samples. Samples can

be aspirated from syringes, capillaries, open tubes, small sample cups, or ampules. After

sample acceptance, patient data can be entered. A limited number of patient records (18) is

stored in a "circular" buffer. Once the buffer is full, each new saved record overwrites the oldest

record.

3.15 Ready to Analyze

When the Ready to Analyze screen is displayed, the analyzer is ready to run samples.

The following information is displayed on the screen:

3. Operation

• All calibrated analytes - Uncalibrated analytes are X'd out.

• Next QC time (if selected in Setup)

• Next Calibration time

• Amount remaining for reagents (A bar graph is displayed for fluid volumes greater

than 10% of the original volume.)

• Soft keys

- Results - Patient

- QC - Run Quality Control Samples

- Calibrate

- Menu (Operational)

3-7

Page 40

Stat Profile pHOx Reference Manual

3.16 Calibrating the Analyzer

The analyzer uses a 2-point calibration to measure pH, PCO2, PO2, Hct, Na+ electrode slopes

and to verify electrode performance. This 2-point calibration occurs automatically at regular

intervals, or, if desired, calibration can be manually initiated. The options are listed in the

Calibration screen. If an electrode fails to calibrate for any reason, an appropriate error code

is generated. An operator can cancel a calibration in progress from the keypad to run a stat

analysis. If this is done, the previous calibration slopes are used for the analysis calculations.

3.16.1Two-Point Calibration (Automatic and Manual)

3. Operation

The analyzer performs an automatic 2-point calibration at 2, 4 or 6 hour intervals (as selected

in Setup). These Auto-Cal intervals can be extended as follows:

Auto-Cal Extension: System Busy when Auto-Cal scheduled to run

If the system is busy when an Auto-Cal is scheduled to run, the request is held in a queue until

the current sequence is completed. The system presents the operator with a pop-up that allows

the delay of a 2-point calibration sequence for an additional 10 minutes. The 2-point calibration

sequence may be delayed indefinitely.

3.16.2Manual Calibration

Manual calibrations may be initiated to calibrate any uncalibrated electrodes or calibrate the

system after maintenance. Press the soft key for Calibrate on the Home screen. The 2-point

Calibration screen is displayed with options for calibration. Use the arrow keys to go to the

desired option. Then press ENTER.

3.16.3SO2/Hb Calibration

O2 and Hb must be manually calibrated with 2 external calibrators. To calibrate SO2 and Hb,

S

press Calibrate on the Home screen. Then go to option 2 and press Enter. Follow the directions

on the screen. You will be asked to enter the assay values for each level of calibrator. These

2 values can be verified on the SO2 Sensor Subsystem screen.

3-8

Page 41

3.16.4One-Point Calibration

All analytes are checked for calibration every 30 or 45 minutes if analysis Mode A was selected in

the setup options. This check is done by exposing the electrodes to a known standard and comparing

the new value to the value obtained during the 2-point calibration. A calibration drift error is generated

if the difference exceeds the internally set limits. The flagged sensor will revert to an uncalibrated state.

3 Operation

3.17 Quality Control

The Quality Control screen is accessed from the Home screen by pressing QC (soft key). Times

for running QC can be set through the QC Setup. This menu also allows access to reports and

manipulation of daily, monthly, cumulative data, and Levy Jennings graphs.

Definitions:

Daily Statistics - All QC samples stored since the last Move Daily Data to Month-to-Date was

performed. Daily data accumulation begins at midnight of the current day.

Monthly Statistics - Cumulative statistics for the last 32 days. Monthly statistics are simply

cumulative statistics.

Cumulative Statistics - A running accumulation of mean, SD (standard deviation), and CV%

(coefficient of variance in percent) for all stored QC samples. Although these statistics are

based on the total number of samples, the n on the screen and on the printout indicates the

number of days. The Cumulative Statistics cannot be reset except by changing to a control with

a new lot number.

NOTE:

30 or 45 minutes, instead the 1-point calibration is automatically performed

with each sample analysis..

If Mode B is selected, a 1-point calibration does not take place every

3. Operation

NOTE:

that analyte, the SD result for that analyte is not displayed (blank screen).

When a new Auto-Cartridge QC with a new lot number is installed, the data from the previous

lot number is erased from the memory of the analyzer. Thus, you are unable to run lots in

parallel to validate the new lot to the old by alternating packs on the same unit.

Nova Recommendation: All Nova controls ship with a product insert sheet. This product insert sheet

contains the target value ranges for each level of QC contained in the pack. Nova’s recommendation for conversion to a new lot number is to use the product insert sheet range levels for the

first 30 days or until sufficient data is collected to establish the new target values. After sufficient

data is collected, the established values and ranges can be entered into the analyzer.

Alternate Method: If this method is inadequate, Nova recommends the use of the external

controls run in parallel and overlapping with the on-board product change over. This method

offers continuity in monitoring performance during the change over period, but it does add

cost. The external QC monitoring can be done using the QC program on the analyzer.

When the SD approaches zero and is smaller than the display range of

3-9

Page 42

Stat Profile pHOx Reference Manual

3.17.1Running QC Samples

From the Home screen, press QC (soft key) to display the Quality Control (QC) screen. Follow

the instructions on the screen.

3. Operation

NOTE:

entered) and you choose to delay or not run the QC, a message is displayed

indicating that QC was not run. If the QC lockout mode is selected and a

scheduled QC is not allowed to run, the analyzer becomes Not Ready.

If you power up without QC scheduled and QC Lockout off, the analyzer

will boot up in control.

NOTE:

Setup QC Levels screens, then turn Automatic QC Analysis ON in the

Quality Control (QC) screen.

If the mandatory QC mode is selected (i.e., QC times have been

To use the Auto QC mode, set the times for the 3 control levels in the

3.17.2Running Linearity Solutions/Proficiency Samples

From the Home screen, press QC (soft key) to display the Quality Control (QC) screen. Then

select Proficiency. Follow the instructions on the screen.

NOTE:

When a sample is run in this mode, slopes and offsets do not apply.

3.18 Analyzing Samples

Samples can be analyzed from capillaries of various sizes and glass or plastic syringes from

1 cc to 10 cc. Samples are aspirated from a horizontal position for capillary tubes through a

built-in adapter or at a 30° angle from the horizontal for syringes and ampule control samples.

1. Once the Capillary or Syringe button is pressed, the Aspirate screen is displayed.

2. Press one of the soft keys: Aspirate Micro or Aspirate Normal.

3. Then press Aspirate (soft key). The Sample Information screen is displayed.

4. The Sample Information screen is 2 screens. Screen 1 has Accession number, Patient

ID number, Patient Temperature, Combine CO-Ox Data (yes/No), Operator ID, and

Patient Name.

Screen 2 has Sample Type (Arterial, etc.), Puncture Site (Radial Artery, Brachial

Artery, Femoral Artery, Arterial Catheter, or Unspecified), Ventilator Rate/Min,

Tidal Volume, PEEP/CPAP, and Mode of Therapy (Unspecified, CMV, ACV,

SMV, PEEP, CPAP, PSV, PCV).

5. Press View Results (soft key) to display the Results - Measure screen. To view all

results (measured and calculated), continually press Next Page (soft key).

3-10

Page 43

3.18.1 Analyzing from a Syringe or an Ampule

From the Home screen (Ready for Analysis), press the syringe key (for syringe or ampule

samples) to position the probe. To aspirate the sample, press Aspirate Normal (soft key).

Follow the directions on the screen.

3 Operation

NOTE:

To run in micromode, press Aspirate Micro (soft key). The time is

typically longer than normal mode. For other functions, follow the screen

instructions.

Syringe

#10-1024A

G

DW

Figure 3.3 Analyzing from a Syringe

3. Operation

3-11

Page 44

Stat Profile pHOx Reference Manual

3.18.2Analyzing from a Capillary Tube

From the Home screen (Ready for Analysis), press the Capillary key to position the probe. To

aspirate the sample, press Aspirate Normal (soft key). Follow the directions on the screen.

3. Operation

NOTE:

typically longer than normal mode. For other functions, follow the screen

instructions.

Capillary Tube

To run in micromode, press Aspirate Micro (soft key). The time is

G #10-1070A

DW

Figure 3.4 Analyzing from a Capillary Tube

3-12

Page 45

3.18.3Analyzing in AV Shunt Mode

The AV Shunt sample analysis combines both the pHOx and the CO-Oximeter results for 2