Page 1

63438

Nova Primary

Glucose Analyzer

Only

Instructions for Use

Manual

Page 2

Page 3

Preface

Nova Primary Glucose Analyzer Instructions for Use Manual

Ordering Information

The Nova Primary Glucose Analyzer Instructions for Use Manual can be ordered from Nova

Biomedical Order Services. Write or call:

Nova Biomedical Telephone: 1-800-822-0911

200 Prospect Street FAX: 1-800-316-1178 (in the U.S.A.) or

Waltham, MA 02454 U.S.A. +1-781-891-9718 (outside the U.S.A.)

Website: www.novabiomedical.com

REP

EC

Nova Biomedical Deutschland GmbH Telephone: + 49 (0) 61054505-0

Hessenring 13A, Geb. G FAX: + 49 (0) 61054505-37

64546 Mörfelden-Walldorf

Germany

Authorized Representative

Trademarks

Nova Biomedical is a registered trademark of Nova Biomedical.

Copyright

Printed in the U.S.A. Copyright 2024, Nova Biomedical, Waltham, MA 02454.

T echnical Assistance

For technical assistance inside the United States and Canada, call Nova Biomedical T echnical

Services at:

U.S.A.: 1-800-545-NOVA (1-781-894-0800) or FAX: 1-781-894-0585

Canada: 1-800-263-5999

Page 4

T echnical Assistance

For technical assistance outside the United States and Canada, call your local Nova

subsidiary or authorized distributor.

Nova Biomedical recommends users report any serious incidents/adverse events back to

Nova Biomedical or Nova Biomedical's Authorized Representative as well as to their local

Competent Authority as required.

Nova Biomedical Benelux B.V.

Korenmolen 22

5281 PB, Boxtel, The Netherlands

Tel: + 31 (0) 733032701

benelux-support@novabio.com

Nova Biomedical Brasil

Rua Massena, 107, Jardim Canadá

Nova Lima – MG – Cep: 34007-746 Brasil

Tel: +55-31-3360-2500

supportec@novabiomedical.com.br

Nova Biomedical Canada, Ltd

17 - 2900 Argentia Road

Mississauga, Ontario L5N 7X9 Canada

Tel: +1-800-263-5999

+1-905-567-7700

Fax: +1-905-567-5496

ca-novaservice@novabio.com

Nova Biomedical France

Parc Technopolis

Bât. Sigma 3 avenue du Canada 91940

Les Ulis courtaboeuf, France

Tel: +33-1-64 86 11 74

Fax: +33-1-64 46 24 03

fr-support@novabio.com

Nova Biomedical GmbH, Deutschland

Hessenring 13 A, Geb. G

64546 Mörfelden-Walldorf, Germany

Tel: +49-6105 4505-0

Fax: +49-6105 4505-37

de-service@novabio.com

Nova Biomedical Iberia, S.L.

c/Vic 17

Planta 3A 08173

Sant Cugat del Vallès, Barcelona,

Spain

Tel: +34 935531173

es-soporte@novabio.com or

pt-suporte@novabio.com

Nova Biomedical Schweiz GmbH

Herostrasse 7

8048 Zürich, Switzerland

Tel: +41-41-521-6655

Fax: +41-41-521-6656

ch-support@novabio.com

Nova Biomedical U.K.

Innovation House

Aston Lane South

Runcorn, Cheshire WA7 3FY, UK

Tel: +44-1928 704040

Fax: +44-1928 796792

uk-support@novabio.com

Nova Biomedical ANZ Pty. Ltd.

5/372 Eastern Valley Way

Chatswood NSW, 2067 Australia

AU-info@novabio.com

Nova Biomedical Italia S.r.l.

Via Como, 19

20045 Lainate (MI) Italia

Tel: +39 02 87070041

Fax: +39 02 87071482

it-serviziotecnico@novabio.com

Nova Biomedical K.K.: Japan

Harumi Island Triton Square Ofce Tower X 7F

1-8-10 Harumi,

Chuo-ku, Tokyo 104-6007, Japan

Tel: 03-5144-4144

Fax: 03-5144-4177

jp-service@novabio.com

Page 5

NOVA BIOMEDICAL SYMBOL DIRECTORY

LEVEL

SN

REP

EC

In vitro diagnostic medical device

Caution

Consult instructions for use

Batch code

Serial Number

Temperature limitation

YYYY-MM-DD

Use by

Biological risk

Electronic Waste

Catalog number

Authorized Representative in the

Manufactured by

European Commission

Laser Radiation - Do Not Stare Into

Control

Level

Beam

Prescription Use Only

Only

Hazard

1

Page 6

Revision History

Rev. Release Description

A 12-2021 Initial Release

B 06-2023 FDA 510(k) review and IVDR compliance updates

C 09-2024 Updates to include latest software features

Page 7

Table of ConTenTs

Table of Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 About This Manual ...................................................................................................................... 1-1

1.2 Safety ..................................................................................................................................... 1-1

1.3 Installation and Use .................................................................................................................... 1-2

1.4 Requirements ............................................................................................................................ 1-3

1.5 Cleaning the Analyzer ................................................................................................................ 1-3

1.6 Intended Use, Tests Performed, and Clinical Utility ............................................................................. 1-4

1.7 The Sample ............................................................................................................................... 1-4

1.7.1 Handling Requirements ...........................................................................................................................................1-4

1.7.2 Acceptable Anticoagulants ........................................................................................................................................ 1-5

1.8 Warnings and Precautions ............................................................................................................ 1-5

2 Getting Started. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Analyzer Startup Procedure .......................................................................................................... 2-2

2.2 The User Interface ......................................................................................................................2-3

2.2.1 Log-In to the Analyzer ............................................................................................................................................. 2-3

2.2.2 The Status Bar .........................................................................................................................................................2-4

2.3 Destination Screens .................................................................................................................... 2-6

2.3.1 Logs ........................................................................................................................................................................2-7

2.3.2 Calibrate .................................................................................................................................................................2-8

2.3.3 Service ....................................................................................................................................................................2-9

2.3.4 Quality Control (QC) ................................................................................................................................................ 2-9

2.3.5 Configuration ........................................................................................................................................................2-10

2.3.6 Maintenance .........................................................................................................................................................2-10

2.3.7 Analysis ................................................................................................................................................................ 2-10

2.3.8 Results History ...................................................................................................................................................... 2 -11

2.3.9 Shut Down ............................................................................................................................................................ 2-11

2.4 System Calibration ....................................................................................................................2-11

3 Sample Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Analyzing a Whole Blood or Plasma Sample ..................................................................................... 3-1

3.2 Analyzing a QC Sample ............................................................................................................... 3-3

3.3 Recalling Sample Results .............................................................................................................3-4

3.4 Recalling QC Results ................................................................................................................... 3-5

63438 C 2024 - 09

TOC-1

Page 8

Nova Primary Glucose iNstructioNs for use maNual

4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Change Sensor and/or Membrane Cap ............................................................................................ 4-1

4.2 Change Calibrator Pack................................................................................................................4-2

4.3 Change Probe ............................................................................................................................ 4-3

4.4 Change Syringe..........................................................................................................................4-3

4.5 Change Pump Tubing ................................................................................................................... 4-5

5 Configuration and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 General ..................................................................................................................................5-1

5.2 Parameter ................................................................................................................................5-2

5.3 Operators ................................................................................................................................. 5-2

5.4 Enhanced Data Entry ................................................................................................................... 5-5

5.5 Quality Control Configuration ........................................................................................................5-6

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 Status Overlay ...........................................................................................................................6-1

6.2 Event Log .................................................................................................................................6-2

6.3 Troubleshooting Procedures ..........................................................................................................6-3

6.3.1 Event Codes .............................................................................................................................................................6-3

7 Advanced User Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1 Installing Software ..................................................................................................................... 7-1

7.2 Flowpath Service ........................................................................................................................ 7-1

7.3 System Backflush .......................................................................................................................7-2

7.4 Clear Data ................................................................................................................................ 7-3

7.5 Long Term Shutdown ................................................................................................................... 7-3

7.6 Auditable Actions ....................................................................................................................... 7-4

7.7 Resource Issues .........................................................................................................................7-5

7.8 Installing 3rd Party Software ........................................................................................................ 7-5

TOC-2

Page 9

Table of ConTenTs

A Appendix..............................................A-1

A.1 Specifications ............................................................................................................................A-1

A.2 Quality Control ..........................................................................................................................A-1

A.3 Analytical Specificity ..................................................................................................................A-2

A.4 Analytical Performance Studies ...................................................................................................... A-4

A.4.1 Method Comparison ................................................................................................................................................ A-4

A.4.2 Precision ................................................................................................................................................................ A-6

A.4.2.1 Within-Run Precision Performance ..........................................................................................................A-6

A.4.2.2 Whole Blood Run-to-Run Precision Performance .......................................................................................A-9

A.4.2.3 Quality Control and Plasma Run-to-Run Precision Performance .............................................................A-10

A.5 Calibrator Pack ........................................................................................................................ A -12

A.6 Traceability of Calibrators, Controls, and Standards .......................................................................... A-12

A.7 Reference Values ..................................................................................................................... A-12

A.8 Cybersecurity ......................................................................................................................... A-12

A.8.1 Cybersecurity Protection Overview .........................................................................................................................A-12

A.8.2 Software Updates .................................................................................................................................................A-12

A.8.3 Operating System Patches ......................................................................................................................................A-13

A.8.4 Anti-Malware Updates ...........................................................................................................................................A-13

A.8.4.1 Malware Control ................................................................................................................................... A -14

A.8.5 Creation of Software for Release ..........................................................................................................................A-14

A.8.6 Security Risks Related to Ethernet Connectivity .......................................................................................................A-14

A.8.7 Security Risks Related to USB Ports ......................................................................................................................A-14

A.8.8 Physical Protection ................................................................................................................................................A-14

A.8.9 Driver Level Protection ...........................................................................................................................................A -14

A.8.9.1 Data Import ........................................................................................................................................... A-15

A.8.9.2 Data Export ........................................................................................................................................... A-15

A.8.10 Firewall Setup and Maintenance ............................................................................................................................A -15

A.9 Emission and Immunity Testing .................................................................................................... A -15

A.10 Ordering Information ................................................................................................................ A-16

B Theory ...............................................B-1

B.1 Two-Point Calibration .................................................................................................................. B-1

B.2 One-Point Calibration ................................................................................................................. B-1

B.3 Principle of Measurement ............................................................................................................. B-1

B.3.1 Glucose ...................................................................................................................................................................B-1

B.4 Warranty ................................................................................................................................. B-2

TOC-3

Page 10

Nova Primary Glucose iNstructioNs for use maNual

TOC-4

Page 11

IntroductIon

1 IntroductIon

This manual provides all necessary instructions for the routine operation and upkeep of the

Nova Primary Glucose Analyzer. Please read this manual carefully. It has been prepared to

help you attain optimum performance from your analyzer.

WARNING: Blood samples and blood products are potential sources of infectious

agents. Handle all blood products and ow path components (waste-line,

sample probe and adaptor, sensor, membrane cap, etc.) with care. Gloves

and protective clothing are recommended. When performing maintenance

and troubleshooting procedures, also use protective eyewear.

1.1 about thIs Manual

This manual is for the Nova Primary Glucose Analyzer.

This section introduces the Primary Glucose Analyzer and covers requirements, tests

performed, procedural limitations, clinical utility, and sample handling.

Throughout this manual:

IntroductIon

1

NOTE indicates especially important information;

CAUTION indicates information that is critical to avoid instrument damage or incorrect results;

WARNING indicates a possible hazard to the operator.

1.2 safety

Personnel operating this analyzer must be procient in the operating and replacement

procedures of the analyzer. The following safety procedures should be followed.

General Safety

1. Read the safety and operating instructions before operating the analyzer.

2. Retain the safety and operating instructions for future reference.

3. Observe all warnings on the analyzer and in the operating instructions.

4. Follow all operating and use instructions.

5. Do not use the analyzer near water, for example near a sink, etc.

6. Use only with a cart or stand that is recommended by the manufacturer . The analyzer and

cart combination should be used with care. Quick stops, excessive force, and uneven

surfaces may cause the analyzer and cart combination to overturn.

7. Place the analyzer so that its location or position does not interfere with its proper ventilation.

8. Place the analyzer away from heat sources.

9. Connect the analyzer to a power supply only of the type described in the operating

instructions or marked on the analyzer.

10. Do not defeat the safety purpose of the polarized or grounding-type plug.

11. Route power cords so that they are not likely to be walked on or pinched by items placed

upon or against them, paying particular attention to cords at plugs, power sockets, and

at the point where they exit from the analyzer.

12. The analyzer should be cleaned only as recommended by the manufacturer.

13. Take care not to let objects or liquids fall into the analyzer.

14. The analyzer should be serviced by qualied service personnel.

15. Do not attempt to service the analyzer beyond that described in the operating instructions.

All other servicing should be referred to qualied service personnel.

1-1

Page 12

Nova Primary Glucose iNstructioNs for use maNual

Electrical Safety

1. To reduce the risk of electric shock, do not remove the cover.

2. There are no user-serviceable parts inside the analyzer.

3. Servicing must be done by qualied service personnel.

4. To reduce the risk of re or electric shock, do not expose the analyzer to water.

5. Use Nova Part Number 64118 external power supply to power up the analyzer.

6. Ensure that the wall outlet receptacle is properly wired and earth grounded.

7. DO NOT use a 3-to-2 wire plug adapter.

8. DO NOT use a 2-wire extension cord or a 2-wire multiple-outlet power strip.

Chemical and Biological Safety

1. Observe all precautionary information printed on the original solution containers.

2. Operate the analyzer in the appropriate environment.

3. Take all necessary precautions when using pathologic or toxic materials to prevent the

generation of aerosols.

4. Wear appropriate laboratory personal protective equipment (PPE), e.g., safety glasses,

gloves, lab coat, and breathing apparatus, when working with hazardous materials.

5. Dispose of all waste solutions according to standard hospital procedures and local

regulations.

Disposal of Used Analyzers for Customers in Europe

This symbol (

household waste.

Device/Accessories: T o ensure the product is disposed of properly, clean all analyzer surfaces

and components and hand over the product to the applicable collection point for the recycling

of electrical and electronic equipment.

) on the product label indicates that the product should not be treated as

1.3 InstallatIon and use

This section covers the installation requirements and assembly procedures for the Nova

Primary Analyzer . Before using the analyzer , operators should be familiar with the Operation

and Operating Procedures described in this manual.

Federal Communications Commission (FCC) Notice

The Nova Primary Analyzer complies with Part 15 of the FCC Rules: Operation is subject

to the following conditions:

1. The Nova Primary may not cause harmful interference.

2. The Nova Primary must accept any interference received, including interference that

may cause undesired operation. Changes and Modications not expressly approved by

Nova Biomedical Corporation can void your authority to operate this equipment under

the Federal Communications Commission rule.

NOTE: Under the warranty, a Nova factory trained service representative will install

this equipment for you.

1-2

Page 13

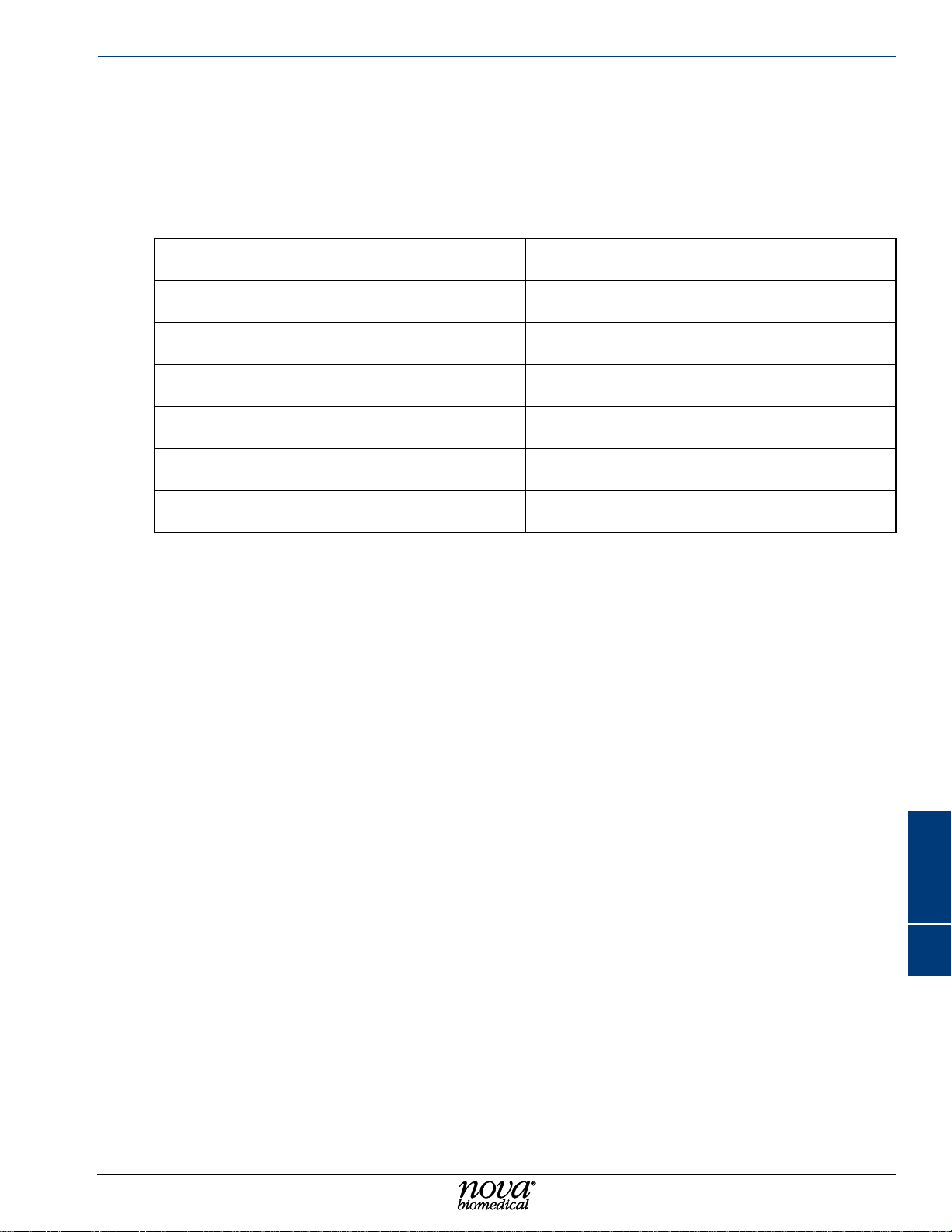

1.4 requIreMents

Working Area Requirements (Environmental):

Keep the working area around the system free of dirt, corrosive fumes, vibration, and

excessive temperature changes.

Electrical Requirements

Operating Voltage Range 100 – 240 VAC

Operating Frequency 47 – 63 Hz

Power Consumption Maximum: 180 W, Typical Load: Less than 100 W

Heat Load Maximum: 614BTU/hr., Typical: Less than 340 BTU/hr.

Ambient Operating Temperature 15 °C – 32 °C (59°F – 89.6°F)

Operate at Humidity 20 to 85% (noncondensing)

Operate at Altitude up to 10,000 feet (3050 meters)

IntroductIon

IntroductIon

1

Table 1-1 Nova Primary Requirements

Dimensions

Height 17.2 in (43.8 cm)

Width 11.3 in (28.8 cm)

Depth 17.8 in (45.3 cm)

Weight

26.5 lb (12.0 kg) without reagent pack

31.9 lb (14.5 kg) with full reagent pack, power supply and wireless keyboard

Lifting the Analyzer:

1. One person is needed to lift the analyzer.

CAUTION: Never use the door (open or closed) to assist you in lifting the analyzer. The

door cannot support the weight of the analyzer.

2. From the front of the analyzer, place your hands under each side of the analyzer.

3. Lift the analyzer . Remember to bend your knees and lift with your legs and not your back.

4. Place the analyzer on a clean, at surface.

1.5 cleanIng the analyzer

Nova Biomedical recommends using 70% reagent alcohol (v/v) or isopropyl alcohol (IP A) for

cleaning the various analyzer surfaces or components when required. When using alcohol,

use a lint-free cloth lightly dampened with the cleaning reagent to wipe down the analyzer

surfaces. Never spray or pour reagent directly onto or into the analyzer. Once wiped down,

dry all residual uid with a lint-free cloth.

1-3

Page 14

Nova Primary Glucose iNstructioNs for use maNual

1.6 Intended use, tests PerforMed, and clInIcal utIlIty

Intended Use

The Nova Primary Glucose Analyzer System is indicated for in vitro diagnostic use by health

care professionals in clinical laboratory settings for the quantitative determination of Glucose

in lithium heparinized venous whole blood and plasma.

Measured Parameter

Glucose

Clinical Utility

Glucose measurement is used in the diagnosis and treatment of carbohydrate metabolism

disturbances including diabetes mellitus, neonatal hypoglycemia, and idiopathic hypoglycemia,

and of pancreatic islet cell carcinoma.

1.7 the saMPle

• Lithium heparin venous whole blood and plasma samples from syringes, blood

collection tubes, and small cups.

• The minimum sample size for analysis is 25 μL.

1.7.1 handlIng requIreMents

Correct sample handling is critical to ensure that the values obtained accurately reect the

in vivo state. Ensure that all samples have been obtained and stored following consistent,

clinically accepted protocols.

Whole Blood

Venous blood samples should be collected with minimal stasis, without the exercise of the

arm. Collect blood for analysis in vacuum tubes containing lithium heparin. It is particularly

important to ensure that samples are well mixed before introduction into the analyzer. Nova

Biomedical recommends that you analyze the sample within 15 minutes for glucose to

minimize the clinical impact of glycolysis on the measured glucose result. Measurement

delays greater than 15 minutes may impact the clinical accuracy of the whole blood glucose

measurement.

Plasma

The Current CLSI Guideline is GP44-A4 Vol. 30 No. 10 (replaces document H18) indicates

that plasma should be physically separated from contact with cells as soon as possible to

a maximum time limit of 2 hours from the time of collection.

Collect plasma samples with minimal stasis, without the exercise of the arm, in vacuum tubes

containing lithium heparin. Obtain plasma by centrifuging heparinized whole blood within 1

hour of collection. Following centrifugation at 1000 RCF for 10 to 15 minutes, remove the cap

and use a syringe or bulb pipette to obtain a plasma sample. Take the sample from the area

close to the cells. Plasma samples more than 1 hour old should be centrifuged immediately

before analysis to remove any brin clots. If assays will not be completed within 8 hours,

the plasma sample should be stored refrigerated at 2 to 8˚C. If assays will not be completed

within 48 hours or if the plasma sample is to be stored beyond 48 hours, the samples are

to be stored frozen at -20˚C.

1-4

Page 15

References

1. CLSI Guideline GP44-A4. Procedures for the Handling and Processing of Blood Specimens

for Common Laboratory Tests; Approved Guideline - Fourth Edition.

2. CLSI Guideline GP41, 7th Edition. Collection of Diagnostic Venous Blood Specimens.

3. Jacobs., Kasten, DeMott, and Wolfson, ed. 1990. Laboratory T est Handbook. Lexi-Comp

Inc.

4. Tietz, N.W., ed. 1986. Textbook of Clinical Chemistry. W.B. Saunders Co.

1.7.2 accePtable antIcoagulants

• Lithium heparin is the acceptable anticoagulant for use with the analyzer.

• EDTA, citrate, oxalate, sodium heparin, and sodium uoride have not been evaluated

for use.

• Depending on the amount of heparin used in the collection syringe and whether it

is lled to capacity with blood, heparin concentrations of 20 I.U. per mL to over 100

I.U. per mL may result.

• Liquid or dry heparin when present in excess of 100 IU/mL may cause errors. Ensure

blood collection devices are lled per manufacturer's instructions.

• Our experience suggests that lyophilized lithium heparin giving a nal concentration

in blood of not more than 20 I.U. per mL is acceptable.

IntroductIon

IntroductIon

1

1.8 WarnIngs and PrecautIons

• T o ensure optimal system performance, the Use By symbol printed on the glucose

membrane, glucose sensor, syringe, sample probe, and pump tubing packaging

indicates the last date they should be installed on the analyzer.

• Operators should periodically inspect the sample owpath for signs of uid leakage.

This includes the syringe, sample probe, waste pump, and all tubing connections to

these components. If a potential leak is observed, please contact Nova Technical

Support or your authorized Nova distributor for assistance.

• Whole blood samples with Hematocrit values below 17% or above 62% have not

been evaluated for use on the system.

1-5

Page 16

Nova Primary Glucose iNstructioNs for use maNual

1-6

Page 17

2 gettIng started

The Nova Primary Glucose Analyzer is pictured below.

GettinG Started

GettinG Started

2

2

1

1. Touch-screen Display

2. Printer

3. Sampler

4. Door/Front Panel

4

3

2-1

Page 18

Nova Primary Glucose iNstructioNs for use maNual

1. Sampler Assembly

2. Sensor/Well Assembly

3. Syringe Assembly

4. Waste Pump

5. Calibrator Cartridge

4

1

2

5

3

2.1 analyzer startuP Procedure

The Nova Primary Glucose Analyzer is a semi-automated instrument. When the Nova

Primary Analyzer is powered on, it automatically loads the required operating sequences

and launches the Graphical User Interface (GUI) on the touch screen display. When the

power-up procedure is complete, the User Account Login window will be displayed.

To navigate the User Interface and to enter alphanumeric text, the operator can use a

combination of the touchscreen display , a popup keyboard overlay on the display, an external

wireless keyboard, and the wireless barcode scanner.

To use the keyboard overlay, press the keyboard icon

and use it as you would any keyboard. Use the arrows in each corner to move the keyboard

to a desired corner of the screen, or touch and drag the keyboard to the desired location.

Press any arrow key to display additional special characters. Press the red X to remove the

keyboard from the screen.

NOTE: If the active screen does not support special characters, the additional characters

are not shown.

when displayed on the screen

2-2

Page 19

2.2 the user Interface

GettinG Started

During the initial installation, an Administrator User Account and Password must be created

to log into the analyzer’s User Interface. This Administrator account is then used to create

any additional Administrator or User accounts and passwords required for other operators.

User Names must be a minimum of 3 alphanumeric characters and are not case sensitive.

User Passwords must be a minimum of 8 and a maximum of 25 alphanumeric characters

and must contain at least one capital letter and one number . Passwords are case sensitive

and should not include spaces or special characters (!,@,#,$,%,^,&,*,/,<).

The default Administrator account User Name is Flex2admin. The password is Password1.

Once logged in, you will be prompted to change the password.

2.2.1 log-In to the analyzer

Pressing the Destination Screen

button in the lower-left corner of

the touchscreen will display the

Destinations Overlay used to

navigate through the user interface.

The operator is prompted to enter their Username and Password. The operator can also

choose to power down the analyzer by selecting the plug icon in the lower left-hand corner

of the log-in window.

Once a valid Username and Password is entered, the checkmark to the right of the Username

will turn green . Press Enter on the keyboard or tap the green check mark to access the

User Interface.

GettinG Started

2

When rst logging into the analyzer, the Sample Analysis screen is displayed. On this screen,

the operator can see the current system status and access the remainder of the user interface

features. The display contains two sections, the Status Bar, and the Destination Screen.

Status Bar

Destination

Screen

2-3

Page 20

Nova Primary Glucose iNstructioNs for use maNual

2.2.2 the status bar

The Status Bar at the top of the screen shows the current Analyzer Status, Date and Time,

next Scheduled Event, Calibrator Pack status, System Events, the currently logged in

Operator (when login is required), and time to completion.

Analyzer

Status

Analyzer Status – indicates if the analyzer is Ready for analysis or Busy with a blue

background. If the analyzer is Not Ready for analysis, Not Ready is displayed with a yellow

background.

Press on any open area on the Status Bar

to display the Analyzer Status Overlay . The

overlay provides additional information

about the Calibration Status, Calibrator

Pack Status, and other system status data.

Operators are also able to Flush the waste

well and Prime the Calibrator Pack from

the overlay as required.

Date/Time

Scheduled

Events

Calibrator Pack

Status

System

Events

Operator

Time to

Completion

2-4

Date/Time – displays the current system

date and time.

Press the Date/Time on the status bar to

display the Date/Time overlay . Operators

can update the current system date and

time from the overlay.

Page 21

GettinG Started

Scheduled Events – press the Scheduled Events icon to display the next scheduled

event’s date and time. If a scheduled calibration is due in less than 5 minutes the icon will

be displayed with a yellow background and a countdown timer indicating how much time is

left before the calibration will begin.

Calibrator Pack Status - displays the estimated number of samples remaining in the

Calibrator Pack. When less than 10% of the pack is remaining, < 10% is displayed with a

yellow background. If the Calibrator Pack is Empty, Expired, or Not Installed, the status

is displayed with a red background.

GettinG Started

2

System Events – press the System

Events icon to display the Event overlay .

This will provide additional information to

help the operator identify any problems

with the system. T ouch the display to clear

the event overlay.

Operator – press the Operator icon to Logout of the User Interface or to update the loggedin user’s password.

Operator Logout/Change Password Overlay

Time to Completion – a countdown timer is displayed whenever an active process is running

on the analyzer. The timer displays the amount of time left until the process is completed.

2-5

Page 22

Nova Primary Glucose iNstructioNs for use maNual

2.3 destInatIon screens

The Destination Screens are accessed to analyze patient and Quality Control samples, review

test results, and to congure, maintain, and service the Nova Primary Analyzer. Destination

Screens are displayed below the Status Bar on the touchscreen display and change to the

selected Destination.

Pressing the Destination Screen button

in the lower-left corner of the touchscreen

will display the Destinations Overlay used

to navigate through the user interface.

Destination screens include:

• System Logs - Audit Log, Error Log,

Calibration Log, and Maintenance

Log

• Calibrate the system manually.

• Service level features

• QC conguration and testing menu

• System Conguration options

• System Maintenance procedures

• Sample Analysis testing menu

• Previous Results History

• Shut Down the analyzer if needed.

2-6

Page 23

2.3.1 logs

The Logs screen provides access to the analyzer Audit, Error , Calibration, and Maintenance

Logs. Select the button of the log to display to show any entries for the current date.

GettinG Started

GettinG Started

2

The Set Dates button on the bottom of each log screen allows the operator to enter a date

range of the log entries to display.

To Print reports, use the Select All button or select individual entries in the displayed list,

then press the Print button.

To Export log entries as a comma separated values (.csv) le, insert a compatible USB drive

in the USB port on the back of the analyzer. Use the Select All button or select individual

entries in the displayed list, then press the Export button.

The analyzer will create a le name based on the log being displayed and current date and

time. Select the green checkmark to copy the le to the USB drive, or press the red X to

cancel.

2-7

Page 24

Nova Primary Glucose iNstructioNs for use maNual

Audit Log – the Audit Log contains

the date and time and the operator

ID that an auditable action was

performed. For a list of recorded

activities, see Section 7.6 Auditable

Actions.

Event Log - The Event Log will

display the date and time an event

occurs and a brief description

of the event. Refer to Chapter 6

Troubleshooting for more information

on system events. Operators cannot

delete or modify the Event Log.

Calibration Log - The Calibration

Log displays the date and time

of each system calibration, the

calibration status, and the slope of

the glucose sensor.

Maintenance Log - The Maintenance

Log displays the date and time each

maintenance activity was performed,

the operator that performed the

maintenance, and the maintenance

activity performed.

2.3.2 calIbrate

Press the Calibrate button to initiate a 2-point calibration of the Glucose sensor/membrane

and air detectors.

2-8

Page 25

2.3.3 servIce

The Service screen contains advanced user and service only functions. Please refer to

Chapter 7 Advanced User Functions.

Install Software – used by your local

Nova Service representative to update

analyzer software when a new release

is made available.

GettinG Started

GettinG Started

Flowpath Service – provides

manual control of the analyzer’s

electromechanical components for use

in troubleshooting system errors.

Clear Data – provides a means of

permanently clearing patient and QC

data as well as selected log les from

the analyzer's database.

System Backush – used to clear any obstructions within the sensor/dilution well assembly .

Long Term Shutdown – used to shutdown the analyzer for extended periods of time.

Resource Issues – contains additional information on errors logged by the analyzer. Used

by Technical Support and Service representatives for troubleshooting purposes.

Clear Print Queue – tool to purge any queued printer les if needed.

Tools – used by your local Nova Service representative as a troubleshooting aid.

Auto Log – provides a means of downloading analyzer log les for review by Nova’s software

development team if needed.

PSoC’s – (Programmable System on Chip) Displays the status and software version of the

analyzer Controller and Sensor Well assemblies.

2

2.3.4 qualIty control (qc)

The QC screen provides the ability to

congure and analyze Quality Control

(QC) samples on the analyzer.

Analysis – select the Analysis button

then select the desired QC, Linearity, or

Prociency Level to analyze.

Results – select the Results button to

review past QC sample results.

Conguration – select the Conguration

button to add new QC, Linearity, or

Prociency lot numbers and expected

ranges.

2-9

Page 26

Nova Primary Glucose iNstructioNs for use maNual

2.3.5 confIguratIon

The Conguration screen provides a way

to customize the analyzer for the location

where it will be used.

General – select the General button to

enter an analyzer ID and location and

select from several options to customize

the analyzer as desired.

Parameter – select the Parameter

button to choose the unit of measure,

measurement resolution, and modify

the reportable analytical measurement

range.

Operators – select the Operators button to add new or edit existing operators.

Network – for future connectivity options.

Enhanced Data Entry - displayed when enabled in the General Conguration menu. Allows

custom text or list elds to be added by the end user.

Import – import an analyzer conguration le from a USB device.

Export – export the current analyzer conguration le to a USB device.

2.3.6 MaIntenance

The Maintenance screen provides a means

of replacing the consumables used on the

analyzer, ushing the system if necessary,

placing the analyzer in Standby , and taking

it out of Standby. Step-by-step instructions

for these maintenance procedures can be

found in Chapter 4.

2.3.7 analysIs

The Analysis screen is displayed when

preparing to run patient samples. The

operator selects the Sample Type if

necessary , enters a sample ID, and presses

Analyze to begin the sample analysis.

Results are posted as soon as they are

available.

2-10

Page 27

2.3.8 results hIstory

The Results History screen displays all samples for the current date. The date range can

be modied to show additional samples. Selected samples can be printed or exported to a

USB device.

2.3.9 shut doWn

GettinG Started

GettinG Started

2

Press Shut Down to shut down the analyzer. An "Are You Sure?" popup will be displayed,

select Yes to shut down the analyzer. Select No to cancel the shut down process.

2.4 systeM calIbratIon

The Nova Primary performs a 2-point calibration of the glucose sensor and membrane

and the system’s air detectors every two hours to maintain optimal sensor performance. A

1-point calibration is run during each whole blood sample analysis to conrm the current

sensor/membrane calibration has not changed. Due to differences in the sample matrix, a

1-point calibration is run on Plasma samples every 30 minutes or after every 10 samples,

whichever occurs rst.

2-Point calibrations also occur more frequently after a sensor or membrane is changed. For

the rst two hours, calibrations are run every 30 minutes. For the next two hours, calibrations

occur every hour. After four hours, the analyzer returns to its normal 2-hour calibration

frequency.

2-11

Page 28

Nova Primary Glucose iNstructioNs for use maNual

2-12

Page 29

3 saMPle analysIs

The Nova Primary Glucose Analyzer System was designed for in vitro diagnostic use by

health care professionals in clinical laboratory settings for the quantitative determination of

Glucose in lithium heparinized venous whole blood and plasma samples.

Sample analySiS

3.1 analyzIng a Whole blood or PlasMa saMPle

To analyze a whole blood or plasma sample:

1. Verify the analyzer is READY to analyze the sample.

2. If necessary, press the Destinations button then select Analysis to display the Sample

Analysis screen.

3. Select Sample Type, Whole Blood or Plasma, if necessary. The default Sample Type is

displayed automatically.

4. Enter a Sample ID of up to 40 alpha-numeric characters, if desired.

5. Press Analyze to extend the sample probe.

Sample analySiS

3

6. Position the sample container so the sample probe is immersed in the sample, then

press Aspirate.

7. The analyzer aspirates the sample into the owpath, the sample probe retracts, and the

analysis starts. If desired, press Cancel to terminate the analysis.

3-1

Page 30

Nova Primary Glucose iNstructioNs for use maNual

8. The analyzer displays the sample results on the screen. If enabled, the on-board thermal

printer prints the results. If not enabled, press the Print button to print the results, if desired.

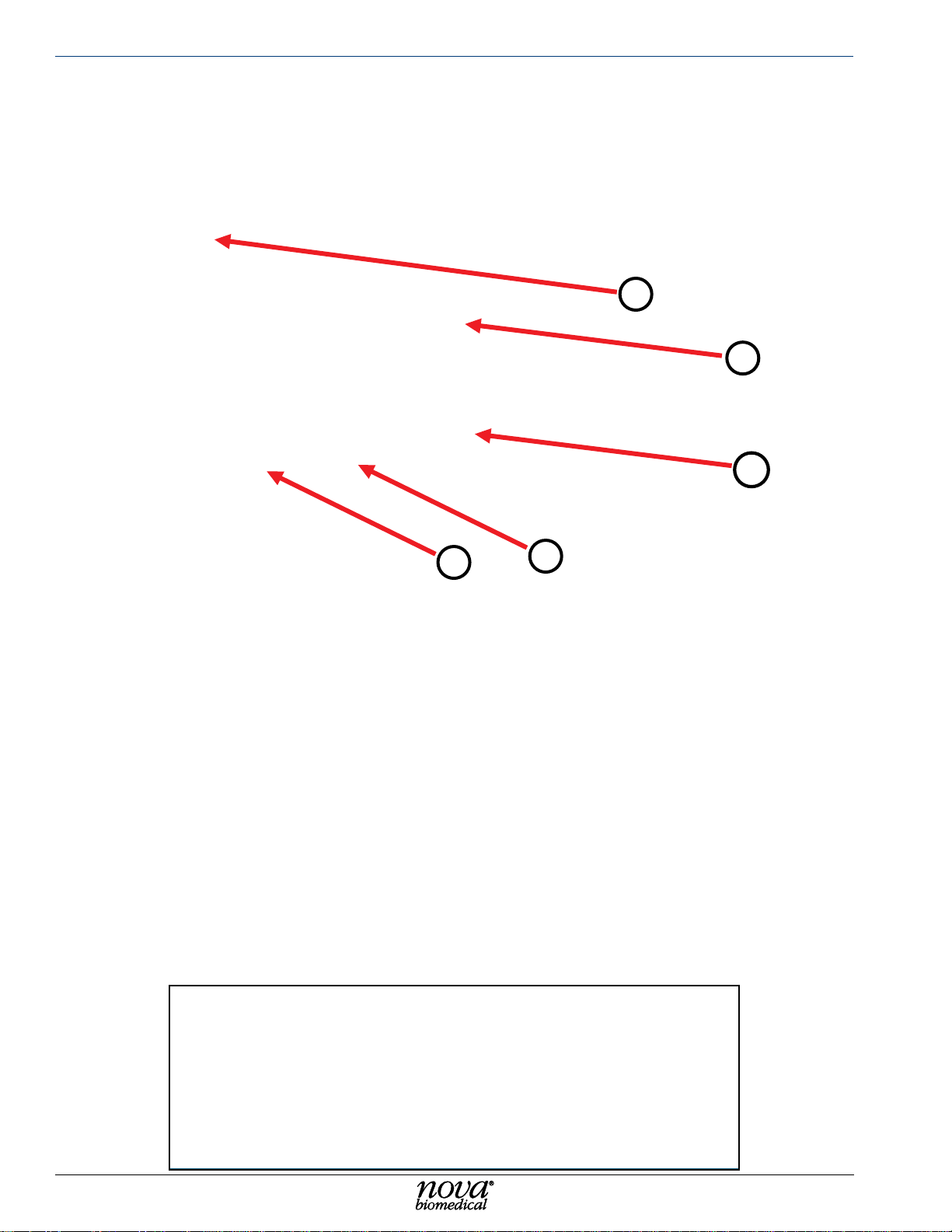

9. Results within the expected normal range are displayed with a green checkmark

Results below the expected range are displayed with a red down-arrow

the expected range are displayed with a red up-arrow

.

, results above

.

NOTE: Sample IDs, and any additional sample information elds, are blank when the

Analysis screen is rst accessed from the Destinations button. After the initial

sample analysis, these elds are left lled in to minimize reentry of sample

information when repeating an analysis on the same sample multiple times.

The elds are editable if any changes are needed.

NOTE: If desired, press the Rerun button to

display a free text entry popup to describe

the reason the sample was rerun. Press

the green checkmark to save the entry

and close the popup window, or press

the red X to discard any changes and

close the window.

3-2

Page 31

3.2 analyzIng a qc saMPle

To analyze a Quality Control sample:

1. Verify that the analyzer is READY for a QC sample analysis.

2. If necessary, press the Destinations button then, select QC to display the QC screen.

3. Select Analysis, then select the button for the desired QC, Linearity, or Prociency sample.

4. Press Analyze to extend the sample probe.

5. Position the QC vial so the sample probe is immersed in the sample, then press Aspirate.

6. The analyzer aspirates the sample into the owpath, the sample probe retracts, and the

analysis starts. If desired, press Cancel to terminate the analysis.

7. The analyzer displays the sample results on the screen. If enabled, the on-board thermal

printer prints the results.

Sample analySiS

Sample analySiS

3

8. Results within the expected range are displayed with a green checkmark . Results

below the expected range are displayed with a red down-arrow

expected range are displayed with a red up-arrow .

, results above the

3-3

Page 32

Nova Primary Glucose iNstructioNs for use maNual

3.3 recallIng saMPle results

Previously analyzed sample results are retained indenitely in the analyzers database.

These samples can be recalled for review, printed, and exported to a USB device as a .csv

le for use in an ofine spreadsheet. Samples can also be rerun by rst selecting a sample,

then pressing the Rerun button. The sample analysis screen is displayed with the sample

information from the selected sample entered.

NOTE: Use the left/right and up/down scrollbars to view additional sample details.

To recall sample results:

1. If necessary, press the Destinations button, then select Results History to display the

Results History screen. Samples analyzed on the current date are shown automatically .

2. To expand the date range of the displayed samples, press the Set Dates button and

enter the starting and ending date range for samples to be displayed. Press the green

checkmark to display the results or press the red X to cancel.

3. An individual result’s Sample ID can be edited by rst selecting the sample ID to edit,

then pressing Edit. The Sample ID is displayed and can be updated by the user. Press

the green checkmark to save any changes or press the red X to cancel without saving.

4. To print a sample result, rst select the sample to print then press the Print button. Select

multiple samples or select all samples, then press Print to print the selected sample

results. If the Print button is inactive (greyed out) no results have been selected.

3-4

Page 33

Sample analySiS

5. To export samples to a USB drive,

a. Insert a USB drive in the USB connector on the back of the analyzer.

b. Select the sample data to export. Use the Set Dates button to recall data from a

specic time frame then select the data to export.

c. Press the Export button to display the

destination drive and timestamped le

name that will be created. If the Export

button is inactive (greyed out) no results

have been selected.

d. If le encryption has been enabled in the

Conguration Menu, a blank Password

eld is displayed. Enter a case sensitive

password that will be required to open

the le.

e. Press the green checkmark to export the

le or press the red X to cancel. If the destination is blank and the checkbox remains

grey, a USB drive was not found.

Sample analySiS

3

3.4 recallIng qc results

Previously analyzed QC results are retained indenitely in the analyzers database. These

samples can be recalled for review, printed, and exported to a USB device as a .csv le for

use in an ofine spreadsheet.

To recall QC results:

1. If necessary, press the Destinations button, then select QC to display the QC Analysis

screen.

2. Select the Results button. All QC samples analyzed on the current date are shown

automatically.

3. To narrow the list of displayed results,

select the Level dropdown list and select

the desired level to display . Deselect the

Current lots only checkbox to include

inactive lots of QC.

3-5

Page 34

Nova Primary Glucose iNstructioNs for use maNual

4. To expand the date range of the displayed samples, press the Set Dates button and

enter the starting and ending date range for samples to be displayed. Press the green

checkmark to display the results or press the red X to cancel.

5. To print a sample result, rst select the sample or samples to print then press the Print

button. Select multiple samples or select all samples, then press Print to print the selected

sample results.

6. To export samples to a USB drive:

a. Insert a USB drive in the USB connector on the back of the analyzer.

b. Select the sample data to export. Use the Set Dates button to recall data from a

specic time frame then select the data to export.

c. Press the Export button to display the destination drive and timestamped le name

that will be created. If the Export button is inactive (greyed out) no results have been

selected.

d. Press the green checkmark to export the results or press the red X to cancel.

3-6

Page 35

4 MaIntenance

The following section provides detailed information and directions for maintaining the Nova

Primary Analyzer . T o access the maintenance functions from the Destinations overlay , press

the Maintenance button to display the available system maintenance functions.

From the Maintenance Menu, the operator can change the Glucose membrane cap and

sensor, Calibrator Pack, Sample Probe, Syringe Assembly, and Pump Tubing. The system

can also be placed in a Standby state to conserve uids when not in use and taken out of

Standby when ready for use.

Maintenance

Maintenance

4.1 change sensor and/or MeMbrane caP

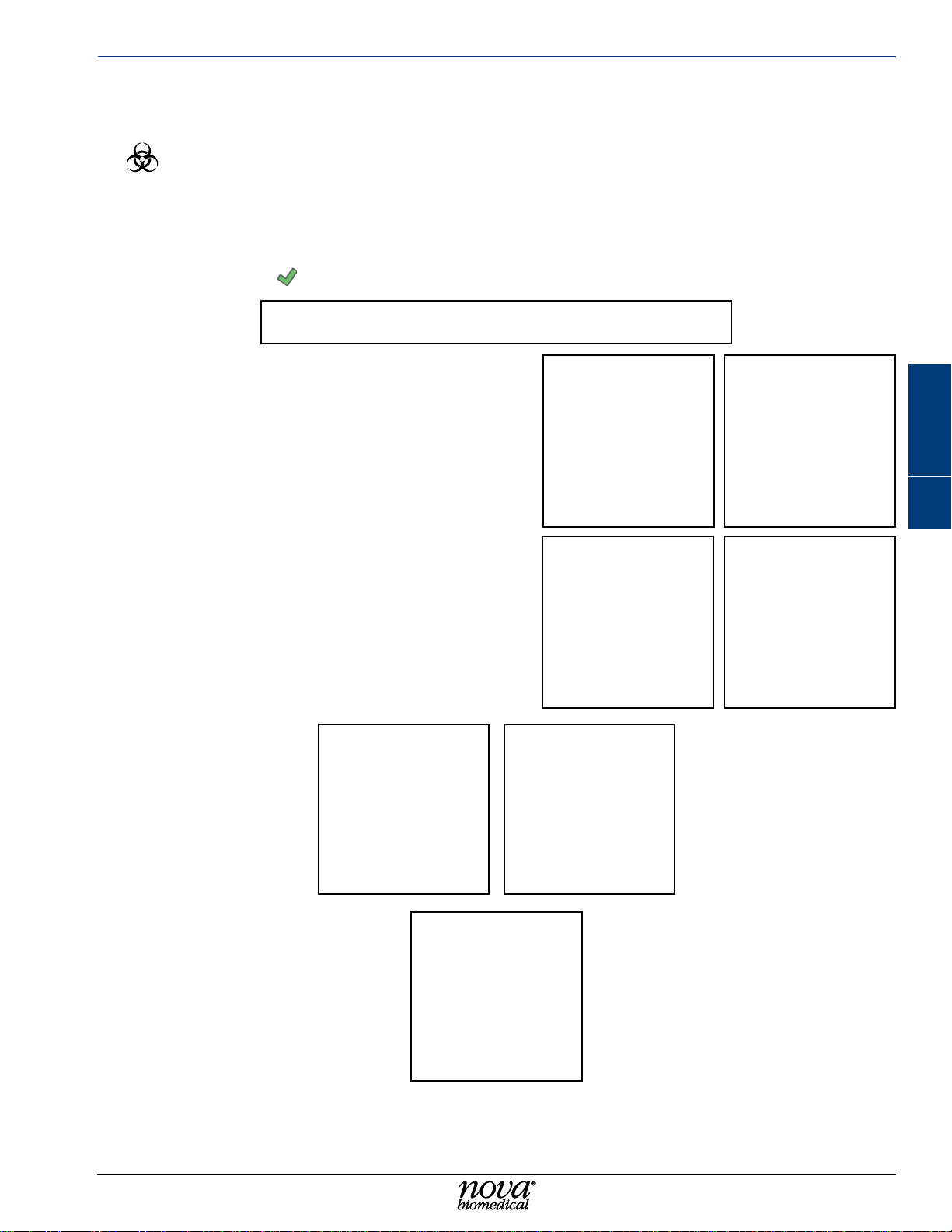

WARNING: Exposure to Blood Borne Pathogens. Follow established Good Laboratory

Practices (GLP). Gloves and protective clothing are recommended.

To replace the Glucose sensor or Membrane Cap

1. From the Destinations overlay, select Maintenance, then select Change Sensor and/

or Membrane Cap.

2. Press Start to display the Lot Number overlay.

3. If desired, enter the Lot Number of the sensor or membrane. If changing the glucose

sensor, rst select the Sensor Lot Number checkbox, then enter the Lot Number . Press

the green checkmark

owpath.

to continue. The pump will run briey to remove uid from the

4

4-1

Page 36

Nova Primary Glucose iNstructioNs for use maNual

4. Unlock the Glucose sensor from the chamber.

5. Remove the sensor from the chamber.

6. Remove the old membrane cap and discard it.

7. Wipe the tip of the glucose sensor with a

lintless tissue dampened with deionized water

to remove any residue from the old membrane

cap, then dry the sensor with a lintless tissue.

8. Press the Install Sensor button

in the upper right hand corner of the screen.

9. Install a new Glucose membrane cap onto

the sensor.

10. Install the sensor into the sensor chamber.

4

5

6

7

9 10

11. Press Continue to prime the owpath and recalibrate the sensor.

4.2 change calIbrator Pack

WARNING: Exposure to Blood Borne Pathogens. Follow established Good Laboratory

Practices (GLP). Gloves and protective clothing are recommended.

To replace the Calibration Pack

1. From the Destinations overlay , select Maintenance then select Change Calibrator Pack

and Adapter.

2. Press Start.

The Sample Probe will reposition itself so

the adapter can be accessed.

3. Remove the old Calibrator Pack.

4. Remove the old adapter and install the new

adapter.

5. Press Install Calibrator Pack

6. Mix the new calibrator pack by gentle inversion for 10 seconds.

7. Install the new Calibrator Pack in the analyzers uid bay.

3 4

.

4-2

6 7

8. Press Continue to prime the Calibrator pack and calibrate the analyzer.

Page 37

Maintenance

4.3 change Probe

WARNING: Exposure to Blood Borne Pathogens. Follow established Good Laboratory

Practices (GLP). Gloves and protective clothing are recommended.

To change the Sample Probe

1. From the Destinations overlay, select

Maintenance then select Change Sample

Probe.

2. Press Start to display the Lot Number

overlay.

3. If desired, enter the Lot Number of the

Sample Probe being installed. Press the

green checkmark

to continue.

4 5

6 7

The Sample Probe will be repositioned for

replacement.

4. Remove the adapter from the sampler

assembly.

5. Disconnect the sample line connecting the

sample probe to the syringe assembly.

6. Disconnect the Air Detector cable from the

chassis.

7. Pinch the probe tabs to release the probe

from the sampler assembly , then gently pull

the probe to the left to remove it.

8. Press Install Probe

9. Slide the new Probe onto the sampler

assembly, ensuring the locking tabs click

into place securely.

10. Install the adaptor by sliding it over the probe

and onto the sampler assembly.

11. Connect the air detector cable to the chassis.

12. Attach the sample line to the syringe

assembly. Conrm all connections are

secure, then press Continue

.

.

9 10

11

12

Maintenance

4

4.4 change syrInge

WARNING: Exposure to Blood Borne Pathogens. Follow established Good Laboratory

Practices (GLP). Gloves and protective clothing are recommended.

To change the Syringe

1. From the Destinations overlay, select Maintenance then select Change Syringe.

2. Press Start to display the Lot Number overlay.

3. If desired, enter the Lot Number of the Syringe being installed. Press the green checkmark

to continue.

4-3

Page 38

Nova Primary Glucose iNstructioNs for use maNual

The syringe will retract.

4. After the syringe fully retracts, loosen the plunger thumbscrew.

5. Push the plunger up into the syringe.

6. Unscrew the syringe by turning the barrel counterclockwise.

4 5

6

7. Press Install Syringe .

8. Attach the syringe barrel by turning the barrel clockwise.

9. Extend the syringe plunger

10. Tighten the thumbscrew.

8

9

10

11. Press Continue .

4-4

Page 39

Maintenance

4.5 change PuMP tubIng

WARNING: Exposure to Blood Borne Pathogens. Follow established Good Laboratory

Practices (GLP). Gloves and protective clothing are recommended.

To change the Pump Tubing

1. From the Destinations overlay, select Maintenance then select Change Pump Tubing.

2. Press Start to display the Lot Number overlay.

3. If desired, enter the Lot Number of the Pump Tubing being installed. Press the green

checkmark

to continue.

4. Disconnect the waste tubing from the well

assembly.

5. Disconnect the waste tubing line connected

to the analyzer chassis.

6. Press the pump pressure plate release

button and lower the pressure plate.

7. Slide the old pump tubing off the pump

rollers.

8. Press Install Tubing

9. Slide the new pump tubing onto the pump

roller cage and close the pump pressure

plate. Ensure the plate clicks into place

securely.

10. Connect the waste line to the chassis.

11. Connect the waste tubing to the well

assembly.

.

9 10

4 5

76

Maintenance

4

12. Press Continue .

11

4-5

Page 40

Nova Primary Glucose iNstructioNs for use maNual

4-6

Page 41

5 confIguratIon and setuP

The Nova Primary conguration and setup options are used to customize the analyzer’s

User Interface to meet each location’s operating requirements. This section explains the

available options and their function.

5.1 general

General conguration settings include the following options:

• Language – select the desired display

language from the drop-down list of

available languages.

• Analyzer ID – enter an analyzer ID of up

to 25 alpha-numeric characters.

• Location – enter a location for the analyzer

of up to 50 alpha-numeric characters.

• Use Network Time – when selected, the

analyzer will synchronize with the network

time server when connected to the local

network. When not selected, the analyzer

will use its internal clock.

• Default Sample Type – select the default sample type used on the analyzer. The sample type

is shown on the analysis screen and can be changed there if needed.

• 24 Hour/12 Hour Time Format – select the time format to use. Choose 24 hour (0 to 24) or 12

hour (0 to 12 AM/PM).

• Date Separator – select the date separator to use. Choose backslash (/), dash (–) or decimal

(.) from the drop-down list.

• Date Format – select the date format to use. Choose MM DD YYYY, DD MM YYYY, or YYYY

MM DD from the drop-down list.

• Enable Standby – when enabled, the analyzer will go into Standby mode at the Enter time and

exit Standby mode at the Exit time. Standby mode conserves calibrator uids by pausing the

normal calibration cycle and running a brief maintenance sequence occasionally to prevent any

blockages in the sample owpath.

• Enable Auto Logoff – if Users are congured in the system, enabling Auto Logoff will log off the

currently logged in user after the entered number of minutes.

• Enable QC Lockout – when enabled, the analyzer will not report a sample result if a Quality

Control result is outside the expected range. QC lockout can be cleared by running a QC sample

that recovers a value within the expected range.

• Enable Auto Print – when selected, sample results are automatically printed on the local printer .

• Require Login – when individual Users are congured in the system, enabling Require Login

prevents use of the analyzer unless a valid User has logged into the analyzer.

• Encrypt Exported Sample Results – when enabled, sample results uploaded to an external

drive are encrypted. If not selected, results are sent as an unencrypted .csv le.

• Display Sample ID – when enabled, a sample ID eld is displayed

• Enable Enhanced Data Entry – when enabled, operators have access to a congurable,

enhanced data entry menu.

• Numeric Format – Select either a decimal point or a comma numeric separator.

Configuration and Setup

Configuration

and Setup

5

NOTE: Use this feature when a regular Standby schedule is expected. The analyzer

can be put into and brought out of Standby mode at any time if desired.

5-1

Page 42

Nova Primary Glucose iNstructioNs for use maNual

5.2 ParaMeter

Parameter settings include the following options:

• Lower Limit – enter the lower limit of

expected values. Results that fall below

this limit are agged with a red down

arrow.

• Upper Limit – enter the upper limit of

expected values. Results that fall above

this limit are agged with a red up arrow.

• Units of Measure – select the desired

unit of measure from the available

options.

• Decimal Places – select no decimal

(X.) or 1 decimal place (X.x) for results

less than 100 mg/dL.

Press Save to save any changes.

5.3 oPerators

The Nova Primary allows an operator with Administrator privileges to create and edit Operator

Accounts for other system operators. Each Operator Account must have a unique User Name

and an associated Password. Once an Operator Account is created, it can be activated

or deactivated, but it cannot be deleted or removed from the system database. Operator

Accounts are assigned a specic privilege level (Basic, Intermediate, or Administrator) based

on the desired level of system access. A system administrator can set a password expiration

date for individual Operator Accounts and can also set a limit for the number of failed log-in

attempts for each operator.

To add a new operator or change the conguration of an existing user:

1. Select Operators, then press Add to add a new operator or highlight an existing operator

and press Change to update the conguration of an existing operator.

5-2

Page 43

2. Enter an Operator Name in the box

provided. User Names must be 3-25

alphanumeric characters and are

not case-sensitive. User names can

include dashes (-) and underscores (_)

but no spaces or special characters

(!,@,#,$,%,^,&,*,/,<).

3. Enter a Password for the User Account.

Passwords must be 8-25 alphanumeric

characters and are case-sensitive. The

password must include at least 1 capital

letter, 1 lowercase letter, and 1 number.

Passwords can include dashes (-) and

underscores (_) but no spaces and no

special characters (!,@,#,$,%,^,&,*,/,<).

Configuration and Setup

NOTE: The alert icon will appear and ash

next to the User Name and Password

entry boxes when entering in these

items. The alert icon will be visible until

the User Name and Password criteria

have been met. When adding a new

User Account, the system will not let

the operator enter any information into

the next section until the criteria for

the previous section have been met.

4. Select the Status for the User Account (Active or Inactive). Only active User Accounts can

login to the system. If a User Account has been made inactive or has been deactivated

as a result of too many failed login attempts, the account must be made active again by

a system administrator.

Configuration

and Setup

5

5-3

Page 44

Nova Primary Glucose iNstructioNs for use maNual

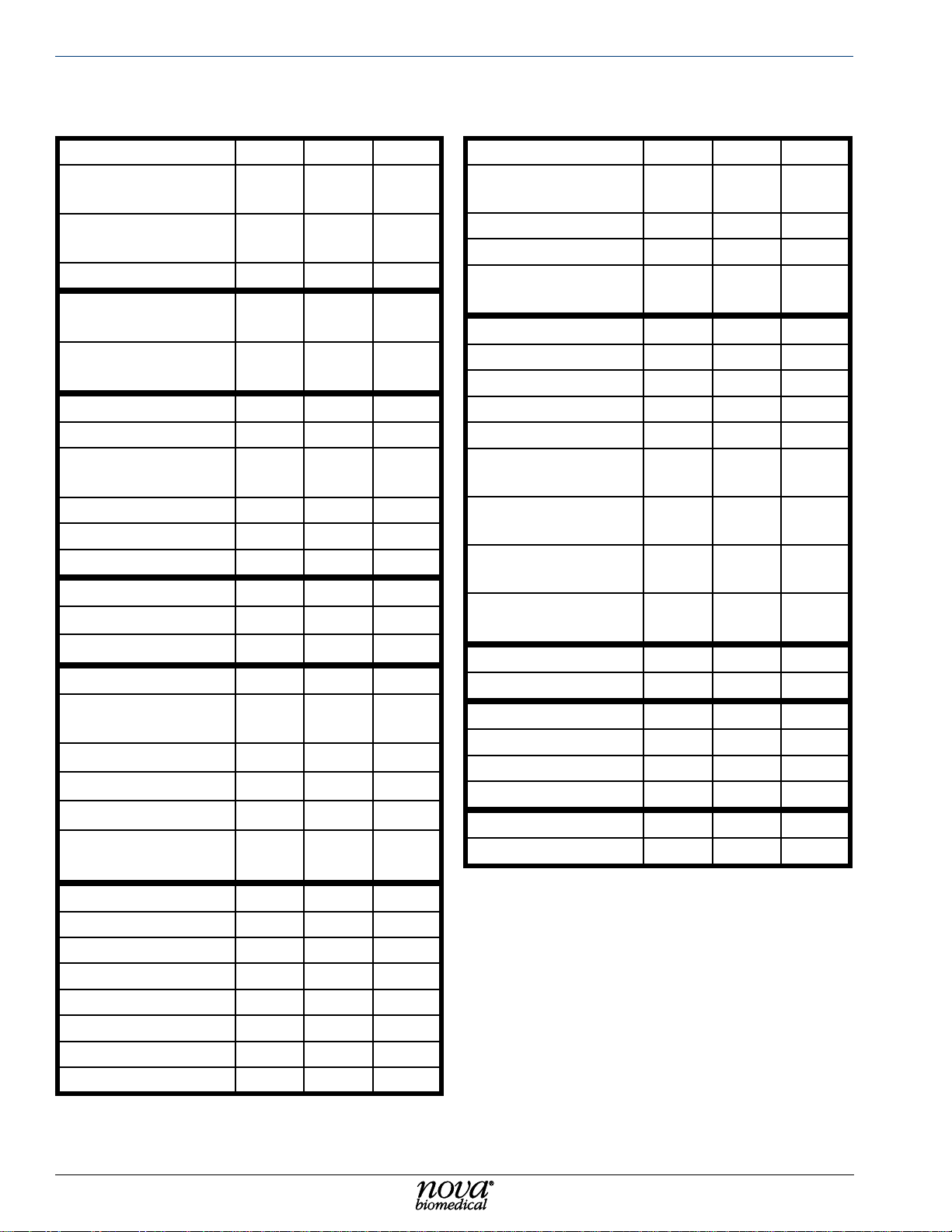

5. Select the Privilege Level for the User Account (Basic, Intermediate, or Administrator).

Refer to the chart below for detailed user functionality.

Analysis Menu

Run Sample

Analysis

Cancel Sample

Analysis

Enter Sample ID X X X

Historical Results

Menu

Export/Print

Historical Results

QC Menu

Run External QC X X X

Export/Print QC

Results

View QC Results X X X

Cancel QC Analysis X X X

Congure QC X X X

User Menu

Change Password X X X

Log Out Current User

Maintenance Menu

Change Sensor/

Membrane Cap

Change Syringe X X X

Change Probe X X X

Change Pump Tubing

Calibrate Air

Detectors

Basic Interm. Admin

X X X

X X X

Basic Interm. Admin

X X X

Basic Interm. Admin

X X X

Basic Interm. Admin

X X X

Basic Interm. Admin

X X X

X X X

X X X

Conguration

Modify General

Settings

Create/Edit Users X

Modify Parameters X

Modify Network

Settings

Logs Menu

View Audit Logs X X X

Export Audit Logs X X X

View Error Logs X X X

Export Error Logs X X X

View Calibration

Logs

Export Calibration

Logs

View Maintenance

Logs

Export Maintenance

Logs

Shutdown Button

Shutdown Analyzer X X X

Status Window

Run Calibration X X X

Run Flush Wells X X X

Run Prime X X X

Time/Date Window

Change Date/Time X X

Basic Interm. Admin

X

X

Basic Interm. Admin

X X X

X X X

X X X

X X X

Basic Interm. Admin

Basic Interm. Admin

Basic Interm. Admin

Service Menu

Install Software X

Flowpath Service X

System Backush X

Archive Data X

Long Term Shutdown

Resource Issues X

Clear Print Queue

5-4

Basic Interm. Admin

X X X

X X X

Page 45

6. Set the number of days after which the password will expire. For example, if this

number is set to 30 days, the password will expire every 30 days. The end user will

be required to create a new password every 30 days upon logging in to the system.

The same password cannot be used twice. If this number is set to 0, the password

will have no expiration for this User Account.

7. Set the failed Login Attempts number . For example, if this number is set to 3, the User

Account will be made inactive after 3 failed login attempts by the end user. A system

administrator would then need to make the User Account active again. If this number

is set to 0, the User Account will have no limit to the number of failed login attempts.

8. When all User Account information is correctly entered, select the green checkmark

to add the User Account to the system database. Selecting the red X will cancel the

process.

5.4 enhanced data entry

When enabled in General settings, Enhanced Data Entry allows the end user to customize

default data elds as required or optional and to create up to 6 additional free text entry elds

or drop-down lists. The Priority Field can be either a text or a list eld and will be displayed

as the rst eld on the sample analysis screen.

Configuration and Setup

Configuration

and Setup

To congure the Priority and Other Fields:

1. Select the eld type to add, either Add Text or Add List.

2. When adding a Text eld, a popup window is displayed to add a eld Name of up to

20 alphanumeric characters including space, dash -, and underscore _. If Required is

selected, a sample analysis cannot begin until the eld has a valid entry.

3. If the name contains illegal characters or is too long, a red exclamation icon

at the end of the eld. Hover over the icon to see a description of the problem. Select

to save the eld name or click X to cancel and discard any changes.

is displayed

5

5-5

Page 46

Nova Primary Glucose iNstructioNs for use maNual

4. When adding a List eld, a popup window is displayed to add a eld Name of up to 20

alphanumeric characters including space, dash -, and underscore _. If Required is

selected, a sample analysis cannot begin until the eld has a valid entry. If the name

contains illegal characters or is too long, a red exclamation icon is displayed. Hover over

the icon to see a description of the problem.

5. Next, add entries to select in the dropdown

list. Entries names can be up to 20

alphanumeric characters including space,

dash -, and underscore _. One entry can

be selected as a default entry by checking

the Default checkbox.

6. Press Add to add the current Entry to the list.

7. When all Entries have been completed select

to save the list eld or click X to cancel

and discard any changes.

8. Remember to press Save

the Enhanced Data Entry screen to save

any changes that were made.

5.5 qualIty control confIguratIon

before exiting

The Nova Primary has 2 levels of external Quality Control material for monitoring. Results

that exceed the entered ranges are agged for easy identication. There are additional

selections for Linearity and Prociency testing materials.

To congure a lot of QC material:

1. From the Destinations Overlay, select the QC button to display the QC screen.

2. Select Conguration then select the desired QC Level 1 or Level 2.

3. Enter the Lot Number of the QC material.

4. Enter the Expiration Date. Select the Year and Month from the dropdown list.

5. Enter the Lower Limit and Upper Limit for the selected level of Quality Control, Linearity,

or Prociency material. Test results lower than the Lower Limit are agged with a red

down arrow; results above the upper limit are agged with a red up arrow. Results within

the entered range are displayed with a green checkmark.

6. Press Save to save the QC lot entries.

5-6

Page 47

6 troubleshootIng

The Nova Primary continuously monitors the status of all electromechanical components,

consumables, and software processes to ensure the analyzer is operating correctly. In the

event an error condition is identied, the analyzer will display a system event icon

Header Bar to notify the user of the problem. This section explains the meaning of each

event code and lists troubleshooting steps that you can take to resolve the problem.

6.1 status overlay

The Status Overlay provides a quick summary of the overall status of the analyzer. T o display

the Status Overlay, touch an open section of the blue header bar at the top of the screen.

To clear the Status Overlay, touch the screen a second time.

The Status Overlay contains the:

Calibration Status of the glucose sensor.

Calibrated (Cal) or Uncalibrated (UnCal), the

glucose sensor slope, and the programmed

analytical measurement range (Lower and

Upper Limits).

TroubleshooTing

in the

Calibrator Pack Status shows the lot number

of the installed calibrator pack, the expiration

date, the date the pack was installed, and the

estimated number of samples remaining in the

pack.

Flow Time displays the measured owtime from

the last calibration sequence and the expected

owtime range programmed into the analyzer.

Primed indicates if the analyzer is primed with the required reagent. The analyzer must be

primed to be available for sampling. If the module is primed, the prime status will read T rue.

If the module is not primed, the status will read False.

Connected indicates if the analyzer is connected to the internal onboard computer. The

analyzer must be connected to be available for sampling. If the analyzer is connected, the

connected status will read True. If the analyzer is not connected, the status will read False.

Well shows the status (Blocked or Clear) of the sample dilution well. This well must be clear

for the analyzer to be available for sampling. If the well status indicates that is blocked,

additional troubleshooting is required.

Three functions are available on the bottom of the overlay for use as a rst step to correct

specic problems. If these do not correct the issue, additional troubleshooting procedures

are detailed later in this section.

TroubleshooTing

6

Calibrate will initiate a 2-point calibration for the glucose sensor and air detectors to address

an UnCal status.

Flush Well will initiate an automated process that will attempt to clear any blockages that

may exist in the dilution well.

Prime will initiate a system priming sequence to address ow issues that may exist when

the Primed status is False.

6-1

Page 48

Nova Primary Glucose iNstructioNs for use maNual

6.2 event log

All system events that have occurred are recorded in the analyzer’s Event Log. To access

the event log:

1. Press the Destinations button then select the Logs button.

2. Press the Event button to display the Events screen.

3. Any system events that occurred on the current date are displayed with the Date/Time the event

occurred and a Description of the event. Refer to Section 6.3 Troubleshooting Procedures.

4. To expand the date range of the displayed events, press the Set Dates button and enter

the starting and ending date range for events to be displayed. Press the green checkmark

to display the events or press the red X to cancel.

To Print reports:

1. Use the Select All button or select individual entries in the displayed list.

2. Press the Print button.

To Export log entries as a comma separated values (.csv) le:

1. Insert a compatible USB drive in the USB port on the back of the analyzer.

2. Use the Select All button or select individual entries in the displayed list.

3. Press the Export button.

The analyzer will create a le name based on the log being displayed and current date

and time. Select the green checkmark to copy the le to the USB drive, or press the red

X to cancel.

6-2

Page 49

6.3 troubleshootIng Procedures

These troubleshooting procedures use the most logical and direct steps to resolve an event

code. The solutions are set up in a block format that lists steps to perform to restore correct

operation. These steps are also organized to prevent unnecessary consumable replacement.

If the recommendations given here do not resolve the problem, contact Nova Technical

Services for troubleshooting assistance.

FOR TECHNICAL ASSISTANCE CALL:

USA: 1-800-545-NOVA

CANADA: 1-800-263-5999

OTHER COUNTRIES: Contact the local Nova Biomedical Sales Ofce or authorized Nova

Biomedical Distributor.

6.3.1 event codes

Slope Error

The sensor slope is calculated during each calibration sequence. A Slope Error is generated

when the calculated slope is lower than the slope low limit or above the slope high limit.

TroubleshooTing

Recommended Solutions:

1. Recalibrate the analyzer.

2. Install a new Glucose Membrane Cap.

3. Install a new Glucose Sensor.

4. Contact Nova Biomedical Technical Support.

Slope Drift Error

A slope drift check is performed during each calibration sequence. A Slope Drift Error is