Page 1

Copyright © 2014 Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

Instruction Manual

for the Installation and Maintenance of

NovaSun Direct Freeze Resistant

High Pressure Solar Hot Water Systems

(October 2013)

For use by trained qualified personnel only. Applicable to the following models:

Novasun, Direct Freeze Resistant, 150l, 200l, 300l

We reserve the right to change the installation instructions.

Reproduction, even partial, is only allowed with written permission.

WE Geysers (Pty) Ltd ,7 Nelmapius Street,

Chamdor, Krugersdorp, 1754

novasun@solarassist.co.za

www.novasunsolar.co.za

Page 2

Copyright © 2014

Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

1

Contents

1. Introduction ............................................................................................................................... 2

2. System description ..................................................................................................................... 2

2.1 Configurations .................................................................................................................. 2

3. Health and safety ....................................................................................................................... 2

3.1 General ............................................................................................................................ 2

3.2 Installation considerations ................................................................................................. 2

4. System configurations ................................................................................................................ 3

4.1 Novasun Thermosiphon System .................................................................................. 3

4.2 Novasun Split-pumped System .................................................................................... 3

5. Frost, scaling and hail resistance, stagnation................................................................................ 4

5.1 Hail resistance ............................................................................................................... 4

5.2 Freeze protection .......................................................................................................... 4

5.3 Direct systems – Freeze resistant ................................................................................ 4

5.4 Scale resistance ............................................................................................................ 4

6. System placement and orientation............................................................................................... 4

6.1 Collector orientation .......................................................................................................... 4

6.2 Shading............................................................................................................................ 4

6.3 Tilt angle .......................................................................................................................... 5

6.4 Water supply / delivery ..................................................................................................... 5

6.5 Roof structural integrity .................................................................................................... 5

7. Mounting methods ..................................................................................................................... 5

7.1 Selection of appropriate mounting method ......................................................................... 5

7.2 System mounting methods ................................................................................................ 5

8. Mounting process ....................................................................................................................... 7

8.1 Suggested mounting method 1 .......................................................................................... 7

8.2 Suggested mounting method 2 .......................................................................................... 8

9. System Installation ..................................................................................................................... 8

9.1 General installation technique ............................................................................................ 8

9.2 Cylinder and System plumbing ........................................................................................... 8

9.3 Geysers ............................................................................................................................ 9

9.4 Electrical connection ......................................................................................................... 9

9.5 Installation Diagrams ........................................................................................................ 9

Pumped System – Installation Diagram........................................................................................ 9

10. System commissioning ............................................................................................................. 11

10.1 Commissioning direct systems ......................................................................................... 11

11. Installation checklist ................................................................................................................. 11

12. System Selection and Sizing ...................................................................................................... 12

12.1 Introduction ................................................................................................................... 12

12.2 System sizing ................................................................................................................. 12

12.3 System type ................................................................................................................... 12

13. Owners operating and maintenance instructions ........................................................................ 13

13.1 Introduction ................................................................................................................... 13

13.2 Operating and efficient use ............................................................................................. 13

13.3 Over-night temperature stabilisation ................................................................................ 14

13.4 High water temperature .................................................................................................. 14

13.5 Periods of reduced usage or holidays ............................................................................... 14

13.6 Freeze protection liquid ................................................................................................... 15

13.7 Setting the time clock ..................................................................................................... 15

13.8 Owner maintenance ........................................................................................................ 17

13.9 Troubleshooting .............................................................................................................. 18

14. Warranties ............................................................................................................................... 18

15. Contacts .................................................................................................................................. 18

16. Warranty Contact Centre .......................................................................................................... 18

17. Warranty Services: (log warranty services) ................................................................................ 19

Page 3

Copyright © 2014

Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

2

1. Introduction

All NovaSun solar hot water systems are high quality thermal solar

systems, using advanced technology to convert light into heat. This

installation manual must be read and understood before undertaking the

installation of a NovaSun solar hot water system. Should any aspect of the

installation process remain unclear a NovaSun Solar representative should

be contacted for advice prior to installation.

This manual does not seek to provide comprehensive guidance in terms of

the general plumbing and electrical connection of geysers, which is

assumed knowledge and required of any registered installer, but rather

sets out to provide guidance in terms of the correct installation of the solar

thermal components of the system.

Systems must be installed by suitably qualified and registered plumbers

and electricians, in accordance with relevant South African Norms and

Standards, National Building Regulations, Law and Regulations, Local ByLaws, including the following:

SANS 198 - Functional control valves and safety valves for domestic

hot and cold water supply.

SANS 10106 - The installation, maintenance, repair and replacement

of domestic solar water heating systems, edition three.

SANS10252 - Water supply and drainage for Buildings. Part 1 - Water

supply installations for buildings.

SANS 10254 - The installation, maintenance, replacement and repair

of fixed electric storage water heating systems.

SANS 10142 - The wiring of premises. Part 1 - Low-voltage

installations.

SANS 10400 - Parts A, B, L, XA.

Occupational Health and Safety Act (Act 85 of 1993)

National Buildings Regulations Act 103 of 1977

Water Services Act (Act N0 108 of 1977)

It is the responsibility of the installer to ensure that they and their staff

are familiar with and competent in respect of the above. Responsibility for

the safe and proper installation of a system rests with the installer.

The solar hot water systems referred to herein must be installed in

accordance with these instructions, local and national plumbing

regulations, municipal building codes and any other relevant statutory

regulations.

All intellectual property in this design and/or registrations and/or copyright

including any patent, patent application are the property of Novatherm CC

and/or WE Geysers (Pty) Ltd.

Observation of these instructions is most important and failure to do so

could void the benefits of the warranty.

The connection, attachment, integration or general association of other

equipment or parts which either directly or indirectly affect the operation

or performance of the solar system could void the warranty. Other such

equipment or parts not supplied by WE Geysers (Pty) Ltd, which may

affect its operation/performance must first be authorised by WE Geysers

(Pty) Ltd in writing if the full benefits of the warranty are to remain valid.

WE Geysers (Pty) Ltd does not accept liability or responsibility for the final

fitness of water for consumption from this water heater, as the water

quality is not affected by the system and is a function of the municipal

and/or other water supply.

This manual has been written with the intention of ensuring that the

system is correctly installed and that the owner/user is fully conversant

with the best methods of operation.

2. System description

2.1 Configurations

NovaSun solar hot water systems utilise state of the art technology and

perform with high efficiency in a wide range of weather conditions.

Collector output is directly related to the amount of incoming solar

radiation striking the collectors. This installation manual covers the

installation of the following systems:

Model Major System Components

NovaSun

150l

150 Litre Solartherm Direct Geyser

1 x 1.7sqm NovaSun Collector

NovaSun

200l

200 Litre Solartherm Direct Geyser

1 x 2 sqm NovaSun Collector

NovaSun

300l

300 Litre Solartherm Direct Geyser

2 x 2 sqm NovaSun Collectors

The models governed by this manual are pumped and thermo-siphon

systems. Thermisiphon systems may be installed in a close-coupled or split

system format whilst pumped systems are installed in split system format

and water is circulated using an applicable water circulation pump.

The NovaSun range of solar hot water systems are direct freeze resistant

systems.

System heating performance

Model Q-Factor*

Energy

Rating**

NovaSun 150l 11.8 TBA

NovaSun 200l 16.3 TBA

NovaSun 300l 27.5 TBA

*The thermal performance of the systems have been established by the South

African Bureau of Standards in terms of SANS 6211, at an incoming radiation of 16MJ

per m² per day, a temperature differential of 10°C and at an inclination of latitude

plus 10°.

**Q-factor is calculated in mega-joules whereas the energy rating is calculated in

kilo-watt hours. The energy rating is calculated by converting the q-factor into kwh.

The specific thermal capacity of the NovaSun collector is 4.39KJ/K m².

3. Health and safety

3.1 General

This appliance is not intended for use by young or infirmed persons

without supervision.

Scalding occurs at 50°C. This appliance is capable of providing hot water

over this temperature. In certain circumstances the system may expel hot

water and relieve pressure through the temperature pressure valve. Never

block this valve and always leave open to the atmosphere. Take care to

avoid contact with water when valve is in discharge.

This appliance is a water heating apparatus only and the final quality of

water and fitness for consumption is dependent on the quality of water

supplied to the system.

These systems are designed for the supply of hot water to domestic

household premises which have been constructed to the appropriate local

and national codes and regulations.

3.2 Installation considerations

All installations are to be carried out in accordance with the Occupational

Health and Safety Act (Act 85 of 1993) requirements and any relevant

local authority prescriptions. Some general points to take note of,

however, include the following:

Page 4

Copyright © 2014

Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

3

Assess site specific risks and eliminate or reduced to an acceptable

level so as to satisfy health and safety requirements, prior to

installation.

Water temperature can reach boiling point and the collector can reach

stagnation temperatures of over 70°C. Shade collectors during

installation to prevent heating.

Take care when handling collectors to prevent breakage to glass and

injury. Safety goggles, work wear and gloves must be used to reduce

risk of injury.

Be aware of overhead power lines coming in through roofs, as well as

electrical wiring running through ceilings.

Assess weather and postpone roof work if unsafe (e.g. high winds,

rain, lightning, etc.).

Scaffolding and safety equipment must be installed by certified

personnel and signed-off accordingly. Inspect before use.

Inform home owners or building occupants of time and place of work

to be carried.

Ensure occupants are aware of site access constraints and all health

and safety implications relevant to them. Cordon off the area, if

applicable, to prevent personal injury and ensure any pets are

secured.

Ensure personnel working on installation are competent and in suitable

physical condition. Installers must be trained and conversant with the

assessment of height hazards, working at height safety procedures,

assessment of safety equipment (e.g. scaffolding, harnesses, etc.) and

the use and wearing of safety equipment (e.g. goggles, hard hats,

gloves, etc.).

All personnel working on the installation of a solar hot water system

must be issued with the appropriate safety equipment and be trained

in their use.

Failure to observe

safe practices may

result in:

scalding /

burns;

electrical

shock;

and/or falling,

which can cause

serious injury or

death.

4. System configurations

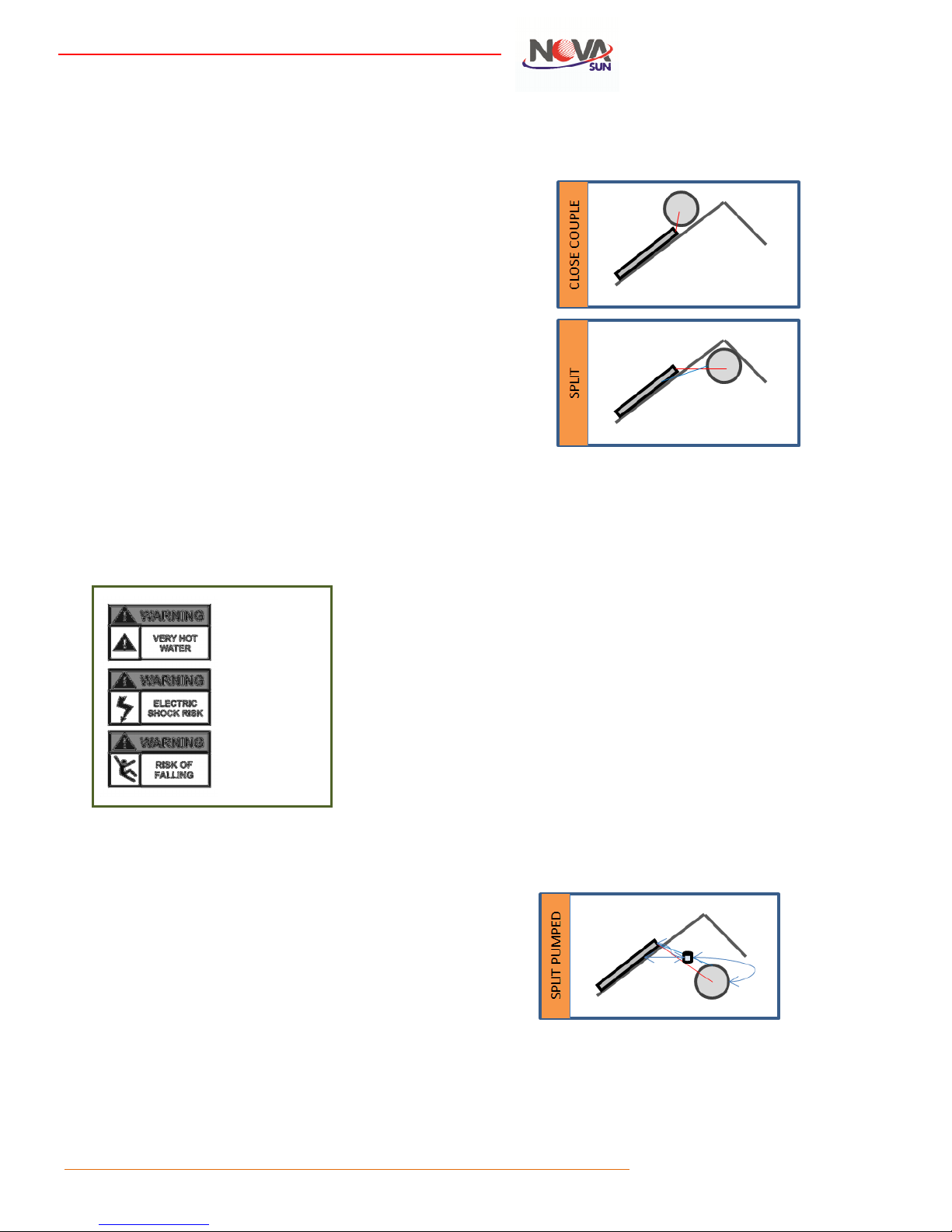

4.1 Novasun Thermosiphon System

For the purposes of the Eskom Rebate Program only thermo-siphon systems

can be installed and a rebate claimed.

A thermo-siphon system relies on the natural circulation of fluid between the

collector and the geyser. In order for the thermo-siphon process to occur

the geyser must be placed in a higher position than the solar collector. The

system operates according to the laws of thermal dynamics (i.e. a liquid,

when heated, becomes less dense and rises above the denser cooler liquid).

Heated water rises up through the collector and into the geyser, displacing

colder water therein, which sinks to the header pipe of the Novasun

collector. The process continues until the collector can add no more gain in

temperature or until the sun stops shining. Without sunlight the water in the

collector header pipe cools, becomes denser, preventing hotter liquid in the

geyser from being displaced.

A thermo-siphon can be close-coupled or split as illustrated below, provided

there is sufficient roof space.

4.2 Novasun Split-pumped System

• Where the solar water heater is installed in the roof, it must be

installed in compliance with SANS 10106 complete with a Safety Valve,

drain cock, Multi Pressure Control Valve 400kPa, Drip Tray and vacuum

breakers on the cold and hot water supply.

• When installed inside the roof minimum clearance must be allowed in

order to remove the element and thermostat.

• Roof structural integrity must be handled according to section 6.5.

• For Product warranty detail refer to the separate Warranty Agreement.

• Pump Circulation in the Novasun SWH system.

• When it is not convenient or possible to place the cylinder higher than

the collector, a circulating pump controlled by an electronic control unit

and two sensors is used to monitor the temperature of the manifold

and the cylinder, that enable the powering of the circulation pump

when the water in the panel manifold is hotter than the water in the

cylinder.

• When the temperature difference is less than the set point the pump

will stop

• When temperature of water in the cylinder reaches the highest set

point, the controller will stop the pump.

• The circulating pump used must be installed and maintained according

to the manufacturer’s instructions.

• A 12V circulating pump with a photovoltaic can also be used.

• A split-pumped system is illustrated below.

Page 5

Copyright © 2014

Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

4

5. Frost, scaling and hail resistance, stagnation

5.1 Hail resistance

NovaSun collectors are hail resistant with 4mm toughened glass and have

passed SABS hail tests.

5.2 Freeze protection

Solar hot water systems can be classified as (i) direct: freeze resistant, (ii)

direct: non freeze resistant or (iii) indirect.

5.3 Direct systems – Freeze resistant

In direct systems the water to be used in the household circulates through

the collector, transferring solar energy into the solar geyser.

The Novasun panel contains a fully insulated heat exchanger that acts as a

freeze resistant mechanism, as declared by the manufacturer. The pipework

connecting to the solar geyser must be insulated with Insulflex insulation

material.

When installed with a PEX-lined Solartherm Cylinder it can be used in all SA

climate locations (i.e in areas where frost occurs and areas, where ambient

temperature may fall below 5°C). Contact Solar Assist to discuss water

quality matters.

5.3.1Direct systems: non-Freeze Resistant

In direct systems the water to be used in the household circulates through

the collector, transferring solar energy into the solar geyser.

Direct systems are used in frost-free locations, where ambient

temperature never falls below 5°C and where water quality is good (i.e. less

than 600ppm total dissolved solids/minerals).

5.3.2Indirect systems

In indirect systems the potable water used in the household does not

circulate through the collectors, but remains in the geyser and is heated

indirectly by a heat exchanger.

There are two basic types of heat exchanger, namely a jacketed system

where an inner cylinder is surrounded by a secondary outer layer and an

internal heat exchanger where the solar geyser contains an internal copper

pipe structure.

In both cases the solar loop (i.e. the pipe work to and from the collectors)

contains a heat transfer medium (i.e. propylene glycol/water solution) which

is physically separated from the potable water.

Propylene glycol has a lower freezing point and prevents the liquid in the

collectors from freezing and damaging the collector through expansion that

occurs when ice forms. Only food grade glycol should be used.

Indirect systems are used in locations where frost occurs and the

ambient temperature drops below 5°C and/or where water quality is

poor (i.e. more than 600ppm total dissolved solids/minerals).

These collectors are resistant to freezing only when installed with an indirect

geyser and the solar loop filled with a solution of propylene glycol and

water. Water alone must not be used as a transfer fluid. The glycol / water

solution should be mixed in a glycol to water ratio of 1:3 (i.e. 33% glycol).

5.4 Scale resistance

Indirect systems containing a glycol solution also prevents scale build up

inside the collector in areas of poor water quality. It is important to note that

the geyser itself may still be affected by water quality as would be the case

with any conventional enamel-lined geyser unless a Solartherm PEX-lined

geyser is used.

If a direct system is used in areas of poor water quality the pipe work inside

the collector and solar loop may be subject to a build-up of scale. This may

be avoided through the use of a water softening system. This is good

practice regardless of type of system, as the water will affect other

household appliances in any event.

In the event collectors experience scale build-up the performance

of the system will decrease. Should this occur the system can be

flushed with a mildly acidic solution (e.g. vinegar solution) and in

the case of the Novasun collector, the Header Pipe should be

flushed. The pipe work should then be flushed with fresh water

after removal of scale prior to re-commissioning.

Ensure you are familiar with the relevant tank manufacturer’s warranty

terms and conditions in respect of water quality, particularly as it relates to

anode replacement in case of enamel-lined tanks.

6. System placement and orientation

A number of basic fundamentals need to be observed when installing any

solar hot water system.

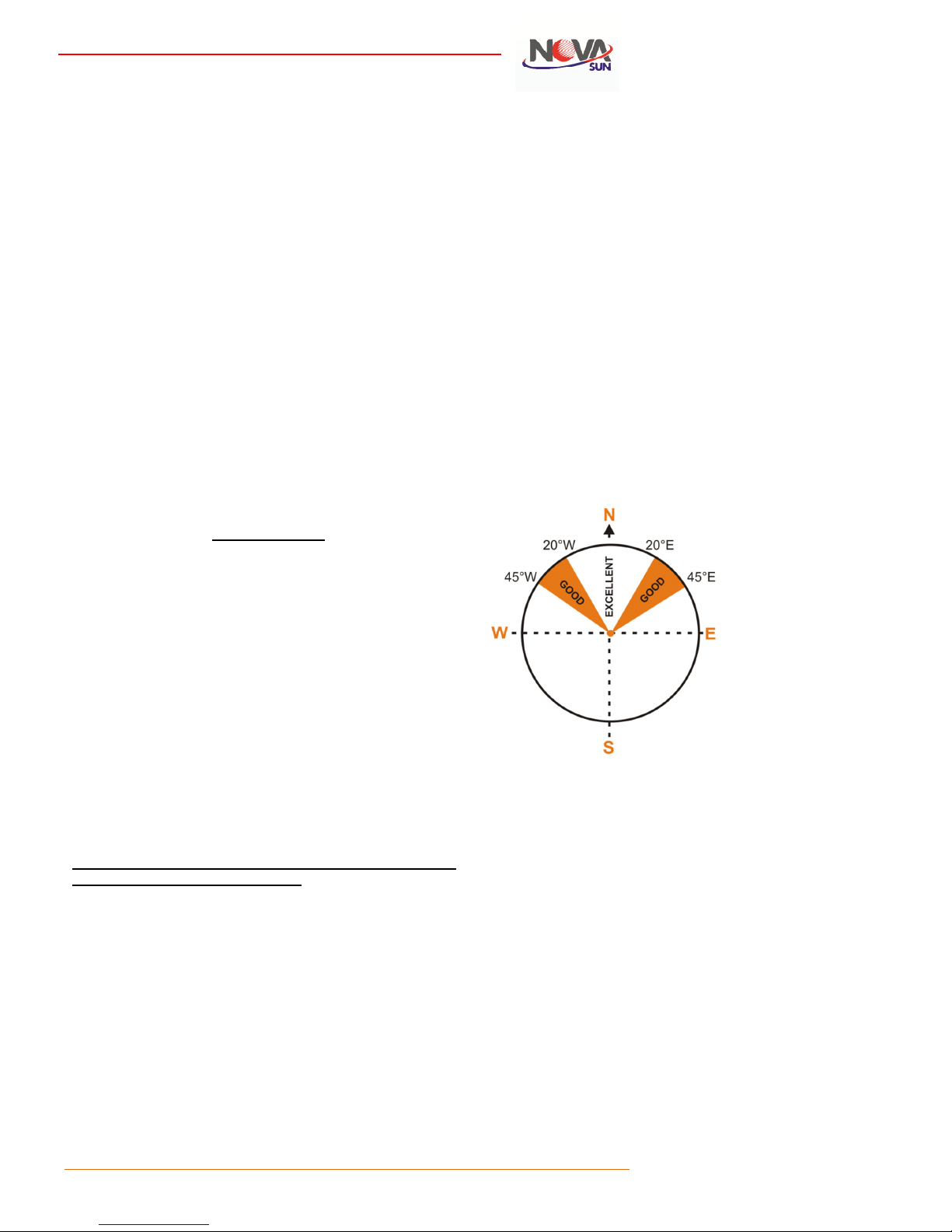

6.1 Collector orientation

Optimum system performance is achieved when the collectors face directly

North (i.e. true North) when installing in the Southern Hemisphere. The

closer the collector is to directly facing the equator the greater the amount

of solar radiation the collector will be exposed to and the greater the

potential for heating.

Angles up to 45° either side of North will not have a major effect on the

system performance given the state of the art technology used in the

construction of the NovaSun systems. Therefore, roofs that are orientated

away from North are also acceptable for installation.

Outside of the 45° range one could consider utilising more collector surface

area or using a mounting frame to adjust the orientation back to North.

6.2 Shading

With a system orientated to face North, the time period when the collector is

exposed to the most direct solar radiation is between 10h00 and 16h00.

Solar collectors with an East bias will achieve a greater gain in morning

hours and those with a West bias will do so in the afternoon.

Care should be taken to ensure that the collectors are not subjected to

excessive shading from trees or adjacent buildings, particularly between

09h00 and 16h00.

Also bear in mind that tree growth could lead to future shading issues.

If the installation takes place in summer, it is also important to take into

account the lower solar angles in winter, which result in longer shadows.

Page 6

Copyright © 2014

Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

5

6.3 Tilt angle

In respect of the optimum angle of inclination for a solar collector, the rule

of thumb provides that the latitude of the location is taken and then 10°

added thereto. Therefore, a location with latitude of 25° would indicate an

optimum collector tilt angle of 35°.

The angle of inclination, however, is also flexible and minimal loss of

performance occurs by installing at lower or higher angles of inclination.

The NovaSun collector can be installed as low as 10°. Below this, however,

the thermo-siphon process does not function effectively. Also, angles lower

than this would result in build-up of dust, as it is not able to be washed

away effectively by rainfall.

It must also be noted that installation angles over 30° will require additional

strapping to secure the geyser and collector during and after installation, as

at this angle the system will tend to move downward. Consideration should

be given to a split installation in these circumstances.

6.4 Water supply / delivery

The location of the installation should give as efficient a supply of hot water

to all areas of the residence as possible. If not possible, the system should

be placed as close to its main point of usage (e.g. master bathroom).

Discuss this with the client and confirm their understanding and

requirements.

6.5 Roof structural integrity

The area chosen for installation must be structurally capable of handling the

loading. Check load weights of applicable system and ensure that the weight

can be borne by the roof structure. Specialist advice should be sought if

required.

The system should be placed, such that the tank spans at least three main

trusses. It is good practice to brace all truss work that supports the

installation.

Strengthen rafters (or timbers or other structures) used for supporting the

panel and tank, for example by adding noggins between rafters or adding

thicker timbers alongside them or cross bracing them or adding additional

supporting struts to the truss to spread the additional load to a load bearing

point. Where ever possible the system should be installed over a supporting

wall of the building (i.e. on a truss resting on a supporting load bearing

wall). Never install a system on a roof with damaged or rotting timbers.

To prevent cracking of certain fibre cement and metal roof sheeting, a flat

mounting frame designed to spread the load of the geyser and its contents

should be designed by suitably qualified personnel and installed below the

geyser. Ensure that the roof covering material is structurally sound to

receive the weight of the system. In the case of a split system installation a

wooden frame should be constructed which raises the tank above the level

of the collectors. Care should be taken in the design and construction of this

frame so as to ensure it meets all relevant standards.

7. Mounting methods

7.1 Selection of appropriate mounting method

Please note that it is the installer’s responsibility to ensure that the means of

fixing the system to the roof such that it results in a safe and functional

installation.

The methods suggested are generic and will not necessarily be suitable in all

situations.

7.2 System mounting methods

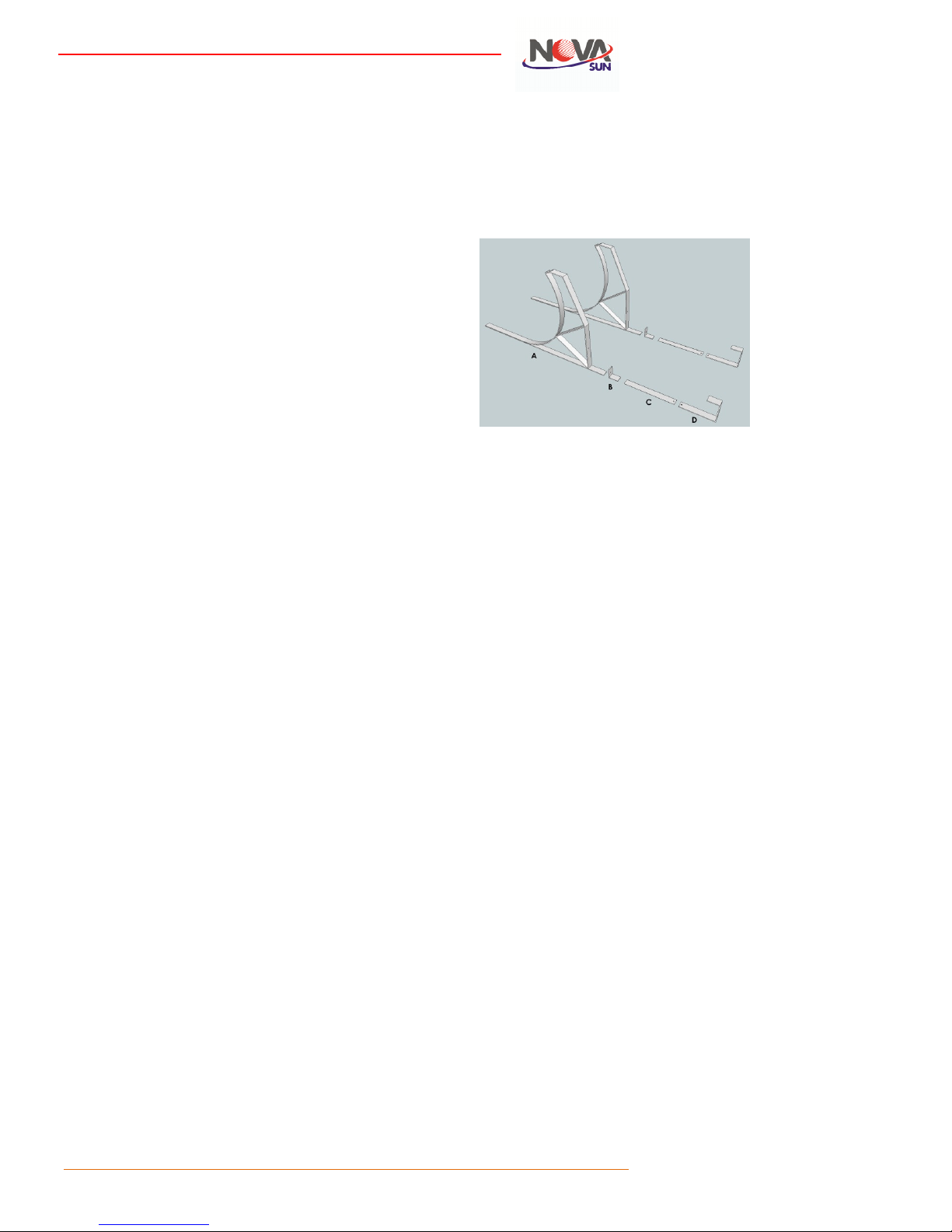

7.2.1Suggested method 1 - General purpose installation brackets

The image below depicts a typical bracketing system which could be used

with NovaSun solar hot water systems. This type of bracketing system is

suitable for tiled or corrugated roof structures with a pitch of less than 30

degrees. Typical kits would include the following pieces:

A (2 pieces) – Tank Cradle Bracket

B (2 pieces) – Collector Clamp

C (2 pieces) – Straps (not included*)

D (2 pieces) – Collector Hanger Bracket**

*Straps are not included as lengths required will differ from installation to installation.

These should be aluminium or stainless steel.

**Please note that two hanger brackets are required per collector. The 300 litre

system using two collectors require 4 hanger brackets (two per collector).

Please note that points of contact between the collector frame and mounting

brackets and between tank and mounting brackets are buffered by a foam

lining to prevent issues surrounding galvanic corrosion.

The installer must install the system in such a fashion to prevent long term

degradation of system materials through galvanic reaction.

7.2.2Suggested method 2 - Alternate installation brackets

As an alternative to the first bracketing system, straps could be used.

Collectors could be secured directly to the roof structure, at each of the four

corners of the collector, by means of aluminium strapping.

The straps should be securely fixed to the underside of the aluminium

collector frame using aluminium speed screws. The straps can then be

passed under the tiling and secured around the nearest truss and/or purlin.

In respect of the geyser, strapping can be hooped around the geyser, on

either end of the cylinder, using strap clamps available with commercially

available strapping systems, leaving enough length to pass the tail pieces

under the tiles and secured around the appropriate roof woodwork.

As indicated above the installer must install the system in such a manner so

as to prevent galvanic corrosion between system components and the

mounting brackets and/or straps.

Page 7

Copyright © 2014

Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

6

7.2.3Suggested method 3 alternate installation brackets

Geyser Brackets

a) Description: Profiled aluminium plating providing a solid footing

distributing the weight of the unit over the roof covering. Positioning of

bolts on brackets are off centre in order to allow the foot plate of the

geyser to rest squarely in the centre of the bracket once installed.

Easy to use wing nuts are supplied to minimise effort on installation.

The foot plate of the geyser has to be fitted to the geyser

before

the

bracket is fitted onto the foot plate.

b) Once the roof covering is moved away, the stainless steel strapping

attached to the bracket is then wrapped around timber roof structure

for anchoring the bracket. Be sure to secure the strapping onto the

timber using tech screws or similar. Roof covering is then placed back

into original position.

c) The bracket is placed underneath the geyser foot plate with the bolt

sliding through the slotted hole and tightened using the wing nut as

supplied.

d) Note the correct use of “left hand” and “right hand” bracket.

Attached strapping is then tightened onto the timber structure in the

same way as above.

NovaSun tanks are equipped with extra anchor points on the

tank in order for the tank to be installed on an angle of 31° if

so required on pitch roofs.

Panel Bracket

a) Description: Holding bracket attached to stainless steel strapping

.

b) The holding bracket is positioned underneath the panel in order to

hook onto the bottom lip of the panel. The stainless steel strapping is

then fastened onto the roof structure in the same way as the strapping

of the tank.

The holding brackets should be placed in position first and properly

fastened to the roof structure using tech screws or similar. The roof

covering can then be placed back into position and the panel positioned

and secured into the holding bracket.

Page 8

Copyright © 2014

Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

7

8. Mounting process

8.1 Suggested mounting method 1

Connect hanger bracket (D) to strapping (C), allowing enough length

strapping for the flexible strapping to fit under the roof tile and wrap around

the purlin/truss. Remove roof tiles and position hanger brackets.

The bracket should be secured in place by fixing to the purlin. Fixings (i.e.

screws, bolts, etc.) must be appropriate for the type of timber. Hard woods

and soft woods require particular fixings. Fix the bracket in place as shown

in the next image.

Replace tiles once the bracket is fixed in place as shown in the next image. 2

brackets are required per collector.

The hanger bracket should be positioned on the peak of the tile and not in

the valley. This helps prevent pooling of water and degradation to the

brackets and possible leaks.

The collector is positioned into the collector bracket as demonstrated in the

image above. A slight kick of 25mm from the cold inlet side to the hot outlet

side of the collector is recommended (i.e. cold side lower than hot side by

25mm).

In the case of sheet roofing, as depicted in the following image, a roof screw

can be removed, the strap placed over the existing hole and the roof screw

reinserted thereby securing the strap. In instances of sheet roofs,

appropriate waterproofing needs to be effected to the roof surface after

straps have been secured to the roof material.

The tank cradle (A) is positioned up against the top edge of the collector,

with the foot of the cradle slid underneath the collector.

The collector clamp (B) is fixed to the tank cradle to lock down the top of

the collector as depicted in the next image.

The tank cradles should also be placed on the peak of the roof tile. Once the

tank cradles are in place and the collector clamp fixed in place the geyser

can then be positioned into the cradles as pictured in the next image.

Page 9

Copyright © 2014

Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

8

Make sure that the tank is rotated to a position where the drain cock is at

the lowest point on the geyser as pictured above. This will ensure that the

maximum volume of water in the tank is available to be heated by the

collector.

The image below depicts the completed mounting of the system.

Larger tank sizes may require additional tank cradle brackets depending on

the roof pitch.

8.2 Suggested mounting method 2

As an alternate to collector hanger brackets, aluminium straps could be used

to secure the collector. Aluminium friendly speed screws can be used to

secure the strap to the back of the collector frame. A strap needs to be fixed

to each corner of the collector frame (i.e. four straps).

Straps should be long enough to be fed underneath the roof tiles and then

folded around the timberwork of the roof. The straps should be positioned

on the peak of the tile and not the valley to prevent water from pooling and

degrading the strap. The straps used should be of sufficient gauge to

provide for a secure mounting of the collector.

The image below depicts the view from below, with a tile removed. This

demonstrates the strap fixed to the frame of the collector and then folded

around the purlin. Fixings appropriate for the type of timber should be used

(i.e. hard woods and soft woods require particular fixings).

In respect of the geyser, stainless steel strapping can be hooped around the

geyser, on either end of the cylinder, using commercially available strap

clamping ystems or other secure means of completing the hoop, leaving

enough length to pass the tail pieces under the tiles and secured around the

appropriate woodwork with appropriate fixings.

As shown in the image below, the strap should fit closely around the body of

the tank. Make sure that the tank is positioned in such a way that the drain

cock is at the lowest point of the tank. Once the tank is in place, fix the

hoop in place and replace tiles.

9. System Installation

9.1 General installation technique

During fitting and prior to filling, the system must be protected against the

entry of dirt and water. After the system has been mounted, it must be

flushed in order to remove any debris (e.g. metal chips, packaging residue,

sawdust, etc.).

Shade panels until after connecting plumbing and installation is ready for

commissioning in order to prevent heating of empty collector.

Exercise caution during the lifting phase of installing the collector and tank

onto the roof. Ensure that adequate personnel are present to bear the

weight and that they are assisted with supportive lifting tethers and safety

rigging.

With reference to section 6 above, measure the size of the collector, and use

measurement to locate the best position on the roof to affix panels,

matching measurements to supporting roof trusses and purlins. Avoid

interference with coping or gutters.

A minimum distance between the top of the panel and the tank flow outlet is

300mm. In split system installations distances should be kept as short as

possible and generally should not exceed 3 metres.

For roof pitches above 30°, special and/or extra strapping or brackets may

be required to prevent downward movement of the tank and collector.

Measure the exact size of your tank and use this to locate the best position

on the roof at which to affix tanks to supporting roof trusses and purlins.

If necessary, strengthen rafters used for securing the panel and tank, for

example by adding noggins between rafters or adding thicker timbers

alongside them (refer section 6.5 above).

9.2 Cylinder and System plumbing

9.2.1General

Plumbing must conform to IOPSA code, SANS, PIRB and local regulations.

In a thermo-siphon the geyser is installed above the panel, but kept as close

as possible.

All piping runs should be kept as short as possible, both between the

collector and tank, as well as between the tank and the location of hot water

usage (i.e. bathrooms).

Page 10

Copyright © 2014

Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

9

All pipework must be properly insulated, including at least two metres of the

cold feed to and hot supply from the geyser. Insulation material must be

heat tolerant and UV resistant, nor must it unduly compress or cause

corrosion.

Installation Tip: For increased weatherability in harsh climate areas insulation can further be wrapped with aluminium duct

tape or covered by a product such as Flash Harry membrane and coating.

Piping from the flow of the tank to the inlet at the top of the collector must

have a continuous fall and from the top of the collector to the return must

have continuous rise.

Only hard-soldered connections or compression fittings are to be used in the

assembly of the solar heating circuit. No fluxing agents containing chloride

should be used.

Use copper pipe only. Plastic pipe must not be used due to the effects of

high water temperatures and pressures. The pipe work to and from the

geyser must also be copper for at least two metres below the hot water

outlet.

A temperature mixing valve must be used to control the temperature of

water delivered to the points of use. This is important in the prevention of

accidental scalding and is a SANS requirement.

9.3 Geysers

The Novasun Solar Water Heating systems make use of WE Geysers (Pty)

Ltd’s Solartherm geysers cylinders, depending on the model selected. The

manufacturers’ installation requirements that accompany each of these

products must be observed in the installation process. Failure to do so may

result in the warranty of these products becoming null and void.

WE Geyser tanks are fitted with SABS approved peripherals.

Geysers installed inside must have sufficient space for servicing thermostats

and elements (Note: there are no anodes in Solartherm cylinders which

require regular servicing) , as well as allowing for the required SANS height

of vacuum breakers above the tank

9.4 Electrical connection

All electrical work must be carried out by properly qualified and registered

electricians.

Novasun recommends the installation of a time switch when undertaking a

solar installation. This optimises the performance of the system and is

specifically required when a rebate is to be claimed in respect of the Eskom

incentive program.

The time clock is fitted to the distribution board and is used to set the time

periods that the thermostat and element receive electrical input. Time

settings will be dictated by patterns of consumption, but for example could

be set to activate from 3am to 5am and from 4pm to 6pm, taking care that

the times do not fall within Eskom peak periods.

Electric water heaters use 220 Volt AC power. The circuit breaker and

isolator should be switched off before working on the geyser. Verify that

power is off with a volt meter and ensure that load shedding or existing

timers are not active, which may cause the electrics to become live whilst

working on the system.

Power should not be applied to an empty electric water heater as heating

elements will be damaged. Tank warranties would be void in these

circumstances.

9.5 Installation Diagrams

Various installation diagrams are illustrated below in order to assist

installers with installation services. Prospective installers must

contact Solar Assist for system specific training and instructions

prior to installing the Novasun SWH range.

Thermosiphon System – Installation diagram

Acknowledgement: www.solarassist.co.za Note: For purpose of installation demonstration no insulation

has been shown here but Insulflex insulation must be installed according to standard on all open copper

piping as per paragraph 9.3.1

Pumped System – Installation Diagram

Note: For purpose of Pump controller installation and wiring instruction refer to the Geyserwise Installation

manual or go to www.geyserwise.co.za

Page 11

Copyright © 2014

Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

10

Pumped Controller – Geyserwise System

Acknowledgment: Geyserwise Installation Manual: For purpose of Pump controller installation and wi ring

instruction refer to the Geyserwise Installation manual or go to www.geyserwise.co.za

Page 12

Copyright © 2014

Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

11

10. System commissioning

10.1 Commissioning direct systems

Make sure that the solar radiation is low during

filling. In strong radiation it is possible for steam to

form in the collector. Keep the collector covered

throughout installation and commissioning.

Do not turn on the electric backup until the tank

has been filled with water.

Turn on at least one hot water outlet tap and open

the mains water supply to allow the water to fill the

tank and collector, expelling air from the tank. As

soon as water flows freely, without air sputter,

close the tap and allow the cylinder to pressurise.

Check all piping, joints and fittings for water leaks.

Check pressure relief valves to ensure correct

operation.

Turn on the electric backup element. Make sure the

tank is completely filled before turning on the

element. Ensure power is available to the backup

element.

Ensure the time clock has been correctly set.

11. Installation checklist

The following checklist should be observed by the

installer before handing the system over to the

owner/user.

All air bled from taps

System checked for water leaks

Cold and hot water pipes checked for leaks

Roof tiles back in position

Roof flashing watertight

Drain pipes free of obstruction

Pipework insulated

Electrical element, timer switch, isolator and

thermostat, controller and pump checked

Any protective plastic or packaging stickers

removed from tanks and/or collectors

Owner instructed on use

Page 13

Copyright © 2014

Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

12

12. System Selection and Sizing

12.1 Introduction

Individuals purchase solar hot water systems for

many reasons. Some buy to realise savings on their

energy spend, others out of concern for the

environment, others as they have no other means

of heating water or it could be a combination of the

above. Whatever the motivating factor is it is

important that the type and size of the system

selected are going to best meet the consumers’

needs and expectations.

12.2 System sizing

In deciding on the system required, apart from

conducting a site visit to ascertain the proposed

installation site and associated mounting, plumbing

and wiring considerations, the sales representative

should also consult with the prospective customer

as to their hot water requirements.

It is critically important that the prospective buyer

provide accurate information in this regard, as the

results of providing incorrect information can result

in a system that either over or under performs,

given the specific needs of the customer.

The onus is on the prospective buyer to provide the

sales consultant with an accurate disclosure of the

hot water requirements and usage patterns in order

that a load profile can be formulated.

A load profile would include information such as

how many showers are taken per day and how

many litres are used, how many baths are taken

and size of baths, how much hot water goes

towards washing dishes and doing laundry, etc.

Only once this information is analysed can a final

recommendation be made on system size.

12.3 System type

System type can relate to a number of system

characteristics as follows:

Direct vs. Indirect (refer section 5 above)

Close-coupled vs. Split (refer section 4 above)

The decision between direct versus indirect is

described in section 5 above, but basically this is

determined by whether or not frost or poor water

quality dictate an indirect system.

NOTE: THE DIRECT NOVASUN

(THERMOSIPHON/PUMPED) SOLAR

WATER HEATING SYSTEMS CAN BE

USED IN ALL CLIMATE AREAS OF SOUTH

AFRICA

The decision between close-coupled and split

system is largely an aesthetic decision based on

customer preference, but there is a cost implication

in that split system requires additional plumbing,

system controller, circulation pump and mounting

structures which translate into a greater installed

cost.

As the NovaSun systems have been SABS tested in

a thermo-siphon and pumped configuration and

registered with Eskom accordingly, a split system

installation can be claimed for on the rebate

programme if the system is a thermo-siphon or

pumped system. That is, even though the tank is

installed inside the roof there is enough space that

the tank is above the level of the collector/s,

allowing a thermo-siphon to operate or a pump to

force the circulation.

NOTE: Please visit www.novasunsolar.co.za for

more information on system.

Page 14

Copyright © 2014

Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

13

13. Owners operating and maintenance

instructions

13.1 Introduction

Dear Customer,

Thank you and congratulations on your purchase.

Your system is one of the most advanced available

and is proudly produced in South Africa.

It will provide years of service and savings. The

information below is provided to give guidance in

the effective use and maintenance of your system

and should be retained for future reference.

Yours sincerely,

WE Geysers (Pty) Ltd

13.2 Operating and efficient use

Savings in energy costs achieved is dependent

upon usage patterns and the extent to which

electrical backup is used. The following will assist in

understanding system performance:

Solar radiation is greater on clear, sunny

days, between 9am and 3pm. During periods

of use the system operates at approximately

twice the maximum ambient temperature and

during periods of non-use, it is possible to

achieve well over 90°C.

On days of high radiation schedule washing

loads as close as possible to mid-day.

On low solar radiation days avoid heavy hot

water usage.

Electrical backup, which is thermostatically

controlled and governed by a time-clock,

should be set at 55°C. The time-clock has

battery backup in order to prevent settings

being lost during general power failures. In

order to claim an Eskom rebate, a time-clock

is mandatory. We would advise the use of a

time-clock in any event, as this is the most

efficient method of operating a solar system.

Time-clock settings should, generally

speaking, be set for two hours in the morning

and two hours in the evening. For example, if

you bath at 06h30 and 18h00, set your timeclock for 04h00 to 06h00 and again for 15h00

to 17h00. Ensure backup time periods do not

coincide with localised load shifting by

municipalities employing ripple relay devices.

This will ensure that if there was not

sufficient solar gain during the day, you will

still have hot water in the evening and early

morning.

Solar systems without time-clocks rely on

thermostats to control when the element

switches on and off. This is not efficient or

cost-effective. An example of this would be,

using hot water in the morning which causes

the thermostat to automatically activate the

element to heat your water. However, this is

when the sun will start to heat your water.

Therefore, if you do not have a time-clock or

it is not programmed properly, you will not

save as much energy as you will use both

electricity and solar energy to heat your

water simultaneously.

An override function is provided on the time

clock so you can over-ride programmed

heating times and heat up your water

electrically. This should only be used when

strictly necessary (e.g. during periods of more

than normal usage when guests are in the

residence) and remembering to revert to preprogrammed settings. This will save you the

optimum amount of electricity and provide

the necessary reduction in peak-period use.

If you wish to set your timer differently, you

should discuss this with the dealer. However,

your timer must not come on during Eskom’s

peak electricity use periods. These may

change from time to time so please check

with your installer.

Page 15

Copyright © 2014

Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

14

Once you get used to the system and its

optimum performance pattern, you may

eventually completely switch the electrical

backup off, particularly in summer months.

An additional benefit of this is that it is the

fastest way to reduce the system’s payback

period.

Savings can be further maximised by using

hot water in the evening rather than in the

morning, maximising the free energy

harvested during the day.

Additional tips to enhance savings include:

To further optimise energy and hot water

savings, install aerated shower heads and

aerators in taps to reduce hot water

consumption.

Insulate hot water piping to minimise heat

losses.

Showering generally uses less water than

bathing.

For health reasons your hot water system

should provide water at 55ºC, but not much

warmer than that. Do not set your thermostat

backup temperature control for temperatures

in excess of this.

If shading of collectors is experienced

between 9am and 3pm then corrective action

should be taken. Annually prune or cut trees

that shade the system.

Partial shading by chimneys, TV antennas,

roof erected fixtures, etc. on buildings during

these hours is acceptable provided that it

does not exceed 10% of the area. Shading

from newly erected buildings should be

checked and if system performance is

affected, relocation of the system may be

necessary.

13.3 Over-night temperature stabilisation

Over-night temperature stabilisation is the

reduction in water temperature, as the hot

water at the top of the storage cylinder

transfers some of its heat to the cooler water

in the lower section of the cylinder.

This effect is often perceived as heat loss, but

is actually the redistribution of stored heat

more evenly over the entire contents of the

storage tank. This may make it necessary to

use the electric element to raise the water in

the top section of the cylinder back to an

acceptable temperature.

Over-night temperature stabilisation is most

evident in the morning if the time clock is left

off overnight.

13.4 High water temperature

Your solar water heater will generate hot

water quickly and efficiently. Under normal

family use, it will operate between 60ºC and

70ºC. However, the temperature can exceed

this and under certain circumstances may be

as high as 95ºC. This can occur during

prolonged periods of direct sunlight and

particularly in summer or long periods of

reduced water usage. Extreme care should be

taken in these circumstances.

Although every system is fitted with a mixing

valve that regulates temperature at points of

water use, check the water temperature

before use, such as when entering a shower

or filling a bath or basin, to ensure it is

suitable for the application and will not cause

scalding. It is required by SANS regulations,

that a temperature limiting device / mixing

valve be fitted to the system. This will limit

the water temperature to 50°C at the point of

use. The risk of scalding will be reduced, but

water should always be tested prior to use to

prevent injury in the case of a tempering

valve failure.

13.5 Periods of reduced usage or holidays

If the water heater is left unused for two weeks

or more a small quantity of hydrogen gas, which

is highly flammable may accumulate in the top of

the water cylinder. This is true of both

Page 16

Copyright © 2014

Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

15

conventional electric geysers and solar systems.

To dissipate this gas safely, it is recommended

that a sink hot tap be turned on for several

minutes. Do not use a dishwasher, clothes

washer or other appliance for this purpose.

During this procedure there must be no smoking,

open flames or any electrical appliance operating

nearby. If hydrogen is discharged through the tap

it will make an unusual sound like air escaping.

It is recommended that if the system is going to

be left unused for long periods of time, that the

backup element switched off at the distribution

board. Remember that when the geyser breaker

is reactivated the time clock may have to be reset

as it has a limited settings memory when

switched off (i.e. approximately 72 hours

depending on the model).

13.6 Freeze protection liquid

No freeze protection liquid is used in the Novasun

system.

13.7 Setting the time clock

WE Geysers (Pty) Ltd recommends that an SABS

approved time clock, with battery backup, be

installed on the distribution board. There are many

such time clocks on the market and the operation

of which are all relatively similar. A Samite QAT-RDM time clock has been selected to illustrate how

to program the time clock.

This time clock has four different screens. When it

is powered up screen 1 (main screen) appears.

SCREEN 1: Actual Time Indicator

This ON/OFF indicator indicates whether the time

clock is currently active or not. This screen also

displays the current actual time.

Press the green function button to cycle forward to

the next screen.

SCREEN 2: Set Actual Time

Press the Hour and Minute buttons to set the actual

time. Once the time is set press the function button

to advance to the next screen.

Page 17

Copyright © 2014

Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

16

SCREEN 3: Program Timer On/Off

To program the desired timer settings press the off

button to move the flashing segment to the time at

which power is made available to the geyser

thermostat/element. Once the segment is at the

desired time, press the on button repeatedly to

insert 30 minute backup segments until the time is

reached when you want the backup period to end.

These steps can be repeated if further backup

periods are required. For effective operation an

afternoon and an early morning backup period are

recommended.

EXAMPLE: Backup period from 3PM to 6PM

Press the Off button until the program time

indicates 15h00, then press the On button until the

program time indicates 18h00. As shown below.

SCREEN 4: Bypass on or off

The timer programme is bypassed using this

screen. Press the “Bypass On’’ button to bypass the

timer and provide the geyser with a constant

supply. The Bypass on display flashes.

Press the “Bypass Off” button for power to be

controlled by the timer and switch on according to

the set times.

Press the function button to return to screen one.

Note: When in “Bypass On” mode the display will

not revert to screen one after 60 seconds.

Should you be away from home for any extended

period and you wish to switch the geyser off at the

breaker on the distribution board, please remember

that you would have to re-programme the time

clock on your return as the on-board memory is

only stored for approximately 72 hours without

being connected.

The use of the electrical backup is very much

dependent on personal usage patterns of hot

water. The following, however, are a few tips:

During days with temperatures below 20°C,

water temperature may only reach 40°C to

50°C. It could be lower if these colder days

are coupled with overcast and rainy

conditions.

The human body generally prefers

temperatures of between 35°C to 40°C for

bathing during winter and therefore boosting

may be required at certain times.

Page 18

Copyright © 2014

Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

17

Backup heating is generally preferable during

late afternoon and early morning, so that

maximum use of solar energy during the day

is taken advantage of.

The backup should not be set that it is on

during periods when the water is being used.

This because an element cannot heat the

water with any efficiency when water is being

used.

If hot water use is heavy during the evening

then it is vital that a backup heating period

be set for the early morning if one desires hot

water first thing in the morning.

13.8 Owner maintenance

To ensure that the system will perform reliably,

some preventative maintenance should be

performed by the home owner/user. If the system

is in a position which is not easily accessible or the

owner is not in a position to effect the points

below, a service technician should be employed to

carry out the maintenance.

The following should be performed annually by the

owner/user or his appointed technician:

Wash the glass cover of the collector with a

mild household detergent. The collector glass

and seals should be inspected.

Mounting brackets and straps should be

checked for signs of wear.

Pipe insulation should be checked for signs of

degradation and/or damage. Please note that

although UV resistant insulation is used, the

harshness of the South African climate means

that the insulation will not last indefinitely.

There is no warranty on pipe insulation.

Visually inspect pipework for signs of leaks.

A periodic inspection of pressure reducing

valves, expansion valves, vacuum breakers,

temperature pressure valves and tempering

valves should be conducted on a solar geyser,

just as it should be done on any conventional

electrical geyser. These valves allow for the

safe operation of the geyser and should be

inspected twice yearly.

The temperature pressure (TP) valve is near

the top of the water heater and is essential

that this valve operates safely. It is possible

for the valve to release a little water through

the drain line during each heating period.

This occurs as heated water expands by

approximately 1L out of 50L of its volume. If

continuous leaking occurs this may indicate a

problem with the valve - please report this to

your installer immediately. WARNING - Never

block the outlet of this valve. TP valves

should be checked for performance at

intervals not exceeding 6 months, or more

frequently in areas of high incidents of water

deposits (such as Calcium or Magnesium).Be

advised that in areas or periods of high solar

radiation there will be greater frequency of

this valve opening. In order to check the TP

valve the easing gear should be operated.

This is a black knob on the TP valve that

needs to be turned in an anti-clockwise

direction and some water allowed to escape.

Be aware that this water may be at a high

temperature. Before opening the valve make

sure you are well clear and be advised that

the geyser will be under pressure so water

may be expelled at a high rate. Guard

carefully against exposure to the water

whether through direct contact or through

back splash. Be careful not to confuse the TP

valve with the solar relief valve fitted on

some indirect systems. Please contact your

installer for advice if unsure.

If at any point the temperature at point of

use (e.g. bathroom) appears to be increasing

or decreasing, the temperature mixing valve

may need to be set or adjusted accordingly.

Page 19

Copyright © 2014

Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

18

Warning

When inspecting your system please bear the

following in mind:

The removal of the electrical cover plate on the

solar geyser will expose 220 V wiring. It must

only be removed by an authorised electrician or

service person.

Care should be taken not to touch the pipe work

connecting the solar storage tank and the solar

collectors. Very high temperature hot water can be

generated by the solar collectors under certain

conditions, and will flow through the pipe work

from the solar collectors to the solar storage tank.

Working at heights should only be undertaken by

suitably qualified personnel, using the proper safety

equipment.

Failure to observe safe

practices may result

in:

scalding / burns;

electrical shock;

and/or falling,

which can cause

serious injury or

death.

13.9 Troubleshooting

Should your system not provide hot water please

check the following before requesting a service call:

Shading from trees is not excessive and is not

covering the collectors for all or part of the

day.

Hot water usage has not been excessive.

Hot water is not leaking from within the

plumbing system that feeds hot water to the

points of use.

The time clock is operational and has been

programmed correctly.

The electric meter and/or display light on the

time clock speeds up when the time clock is

active.

Power has been provided to the main board

(i.e. no electrical faults or load shedding).

The ripple relay has not become jammed in

the open position.

The water supply to the home has not been

interrupted (i.e. municipal shut-off)

Please contact your local dealer and/or installer if

all of the above have been checked and there is still

no hot water. A charge out fee may apply if the

system is found to be functioning correctly and the

matter relates to one of the above issues.

14. Warranties

Please refer to the NovaSun SWH Warranty

Document.

15. Contacts

WE Geysers (Pty) Ltd (Pty) Ltd

Physical Address 7 Nellmapius Road, Chamdor,

Krugersdorp, 1754

Postal Address PO Box 4060, Luipaardsvlei,

1743

Tel +27 11 769 1387

Fax +27 11 762 2200

email info@novasun.co.za

email novasun@solarassist.co.za

Website www.novasunsolar.co.za

16. Warranty Contact Centre

SolarAssist 0861 106 618 (24/7)

Website: www.solarassist.co.za

Email: info@solarassist.co.za

Page 20

Copyright © 2014

Ikhwezi Solar (Pty) Ltd, Novatherm CC, Solar Assist (Pty) Ltd

19

17. Warranty Services: (log warranty services)

Important Notice: Making use of a non-accredited Solar Installer to perform warranty work on your

Novasun SWH system will void your Warranty Agreement.

Date: Service Provider/Contact detail Services/Job performed.

Owner Notes:

Loading...

Loading...