Page 1

NNoovvaa DDaarrkkrroooomm

EEqquuiippmmeenntt LLttdd

UUnniitt 11AA HHaarrrriiss RRooaadd

WWeeddggnnoocckk IInndduussttrriiaall

EEssttaattee

WWaarrwwiicckk CCVV3344 55JJUU

TTeelleepphhoonnee

0011992266 440033009900

FFaaxx

0011992266 449999999922

EE--MMaaiill

ssaalleess@@nnoovvaaddaarrkkrroooomm..ccoomm

WWeebbssiittee

hhttttpp::////wwwwww..nnoovvaaddaarrkkrroooomm..ccoomm

Nova

Monochrome

B&W Print

Processor

OPERATING INSTRUCTIONS FOR THE

It’s packed with

hundreds of

products for the

serious darkroom

worker … and it’s

FFRREEEE!!

Just call, fax, write

or e-mail for your

own personal

copy.

HHAAVVEE YYOOUU GGOOTT

OOUURR LLAATTEESSTT

CCAATTAALLOOGGUUEE??

Washing Wash your finished print in your usual apparatus

ensuring that there are plenty of changes of water

throughout the wash time.

Note:- Nova manufacture vertical wash units ideal for this

purpose. Consult your Nova catalogue for further

information. Approximate wash times in all Nova washers are

as follows:-

Cold water 3 - 4 minutes 50 minutes

(15°C or less) (RC papers) (Fibre papers)

The clip needs only a rinse in clean water and a light shake

before re-use.

Replenishment Your Nova MONOCHROME system is

designed to allow you to keep stock/working chemicals in the

unit whilst not in use. Replenishment should take place at the

end of a printing session and also during the session if you are

doing a long print run.

It is recommended that you replenish each of the chemicals

after producing approximately 5 full size prints from

negatives or equivalent area. Actual times to replenish will

depend on what your subject matter consists of and how

particular you are about the actual density/contrast level of

your print.

To replenish, simply make use of the appropriate drain tap

into a suitable container (a measuring beaker is ideal for this

purpose). Top up each slot with fresh diluted stock solutions.

ALWAYS REPLENISH DEVELOPER, STOPBATH & FIXER

AT THE SAME RATE!

Replenishment rates:- (ILFORD MULTIGRADE)

Black & White only 15 ml per 10" x 8" print

(NOVA MULTISPEED BW)

10 ml per 10" x 8" print

Maintenance

After approximately 3 months, you should automatically clean

out all the slots. This should be done with the aid of a bottle

brush and warm water to flush them out. If the unit remains

badly stained, then the use of NOVA TARBUSTER Cleaner

will greatly reduce such staining.

NEVER ATTEMPT TO PUT ANY CHEMICAL OTHER THAN

STANDARD B&W WHITE CHEMICALS OR SPECIFIC

CLEANING FLUIDS IN THE MONOCHROME SLOTS..

NEVER USE WATER OR CHEMICALS AT TEMPERATURES

HIGHER THAN 30°C IN THE SLOTS

THE WARRANTY OF THE PRODUCT WILL BECOME NULL

AND VOID IN SUCH INSTANCES.

MONOCHROME MAST. ISSUE 2 01/04

Page 2

The Nova MONOCHROME system is a practical method of producing hand finished quality

BLACK & WHITE prints at 'room temperature'.

Our range is designed to meet the needs of modern processes and make printing a pleasure

not a chore. To enable you to obtain the best results from your new equipment, it is

important that you read the instructions carefully before you proceed.

Remember

All modern photographic materials are capable of excellent results.

Changing from one manufacturer to another will not correct any problems relating to

variables in technique or equipment. The only route to constant quality printing is to reduce

these variables to a minimum.

The following steps will assist you:i) Time the exposure and process sequence accurately.

ii) Use one type of film, paper and chemicals until you are confident enough to experiment.

Setting Up

With all Nova Processors it is important to begin by placing your MONOCHROME on a

table / bench as near to your enlarger as possible preferably stood in a shallow dish.

1) Mix up your chemistry to the manufacturers instructions. The 10” x 8” slots have a

chemical capacity of around 900 ml each, the 16” x 12” holds around 1800ml per slot. It is

therefore advisable to mix about one and two litres respectively of each chemical when

starting off, leaving you some chemical for replenishment (see Fig. 1).

2) To equalise the stresses in the processor, it is very important that you fill each slot with

500ml of chemistry at a time. This means that you will fill the first slot with 500ml of

Developer followed by 500ml of StopBath in slot two, and then 500ml of Fixer in slot

three. Continue in this way using until each slot is filled to the correct working level.

Note:- To measure the correct solution level, each slot must be filled to 5mm above the

top of the print when an agitation clip is suspended in the slot.

NEVER FILL EACH SLOT TO THE TOP IN ONE ATTEMPT OTHERWISE

PROCESSOR DAMAGE MAY RESULT!

3) Check the temperature in the developer slot and consult the time and temperature

chart in the chemical manufacturer's instructions- this will be your process time.

FIG. 1

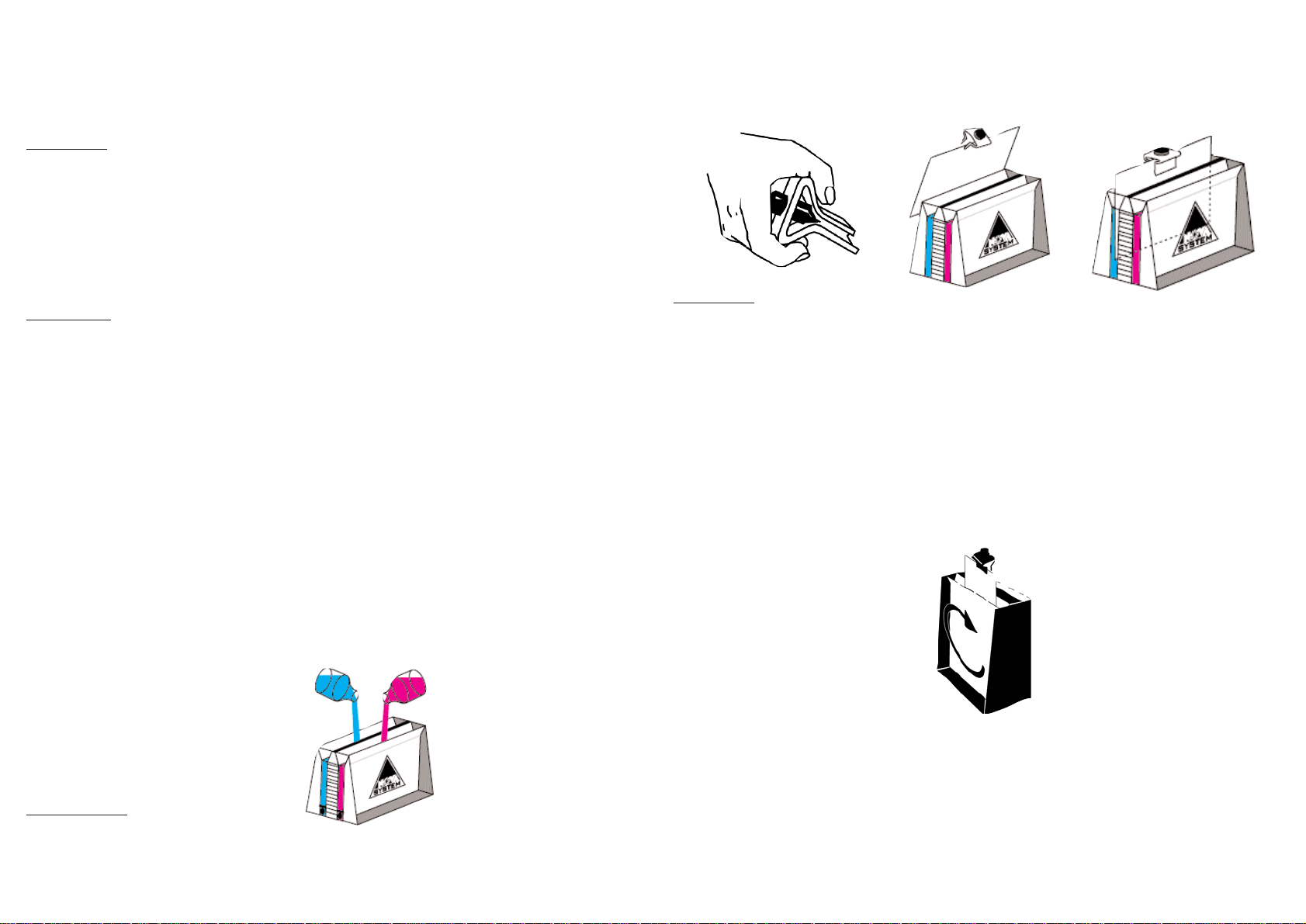

In Operation

4) Turn off your darkroom light and then expose your print onto the paper on the enlarger

baseboard. Take an agitation clip (supplied) and attach it to the print. Fig. 2

shows a simple and comfortable way of holding the clip.

5) Present the back of the exposed print to the edge of the developer slot (see Fig. 3).

Raise the print until you feel it locate in the slot and then gently lower it into the

chemical.(see Fig. 4)

Fig. 2 Fig. 3 Fig. 4

Developing

6) Agitation must be carried out in a gentle circular motion continuously for the first 30

seconds.(see Fig. 5). Once the print has been immersed in the chemical, do not be afraid to

raise the print half way out of the developer to help agitation. Thereafter, agitation need

only be done every 15 seconds throughout the rest of the development time. This should

last approximately 5 seconds and complete the sequence by raising the print halfway out of

the slot and then lowering back into place.

Note:- When producing small test prints, one may be tempted to make use of the increased

space for agitation. It is advised that this should be avoided and that test prints be

processed in a restricted area of the slot so as to simulate the same processing conditions

as the final print. Failing to do this may give a false indication of density and development

when the end print is produced.

Fig. 5

7) When your development time is complete, you must remove the print from the slot by

making use of the top edge. In curving the print on removal and scraping the back of the

print against this edge you will remove excess chemicals and minimise cross-over

contamination.

8) In the Stopbath:- Locate the print in the stopbath slot and agitate for about 15

seconds. Having done this, remove the print as previously stated.

9) Fixing:- Locate the print in the slot and agitate immediately for the first 20 seconds.

Note:- Room lights can be switched on at this stage.

Thereafter, agitate occasionally for the rest of the fixing time.

Loading...

Loading...