Page 1

13"

PLANER

I·NSTRUCTION

MANUAL

Moder:

MB

1931

Page 2

CONTENTS

Ger8Al

WEfY'

lc::aE

MCllJt{Dt4C711-tE

~<:XJ<.

~~JOr.IS:

~

~a:F'

AD.JU.ST

~~

Q\lS'TAl.IJl'IG

SEm~

s.AfE1Y

~

P,l.,RTS

~."

Ra.l.ER,S

1HE

~

S\\IIT'O-I

DEI"ni

M.

niE

n-:IE

'DE

KJ'rrrlIFE

RULES

~

MB

PI.AI\IER

.................

MB

.............

a

-ruT'

[)EI'TH

~R

~ER

F~

POVtfER

1931

.....

....................................................

()I\ITO

**'1

..................................................

1931

..............

.................

....... " .•..

,.

••

".,

......

"'

..................................................................................................

".Il!

CJI=

CUT'

Kl'WES"

Kf\IIVEs

HElGI-IT''''+i-

•• , ••••

T(X)lS~

iIji

••

II!

•• , ...... ~ •••••••••

n-IE

wrx::t:J

11.+

••• " ••••••••••••••••

4

.........

1i.

.............

..............................................

SCAI.E

............

.......

,t."

.......................... _ ...........................

*

••

IfIi

••••••

Ii

••

*I

8AS.E

"

11

+

...

.,41

.............

*

....

III

..... " ••

........... , ...................................... " ............

...........................................................................................

'''

...........................................

tt

.............

................................................

•.•

u

''''

.................. " .........

.................

,,,

"

...

Ii

.......................................................

..........................................................

,.

......................................

,.

....... " ..........................

*

..................................

."

........................................................

....................

'''

.......

*.*1111

It

................

............................

111

,+u

"

••• " .......................

"""

.... " .............................

·.,.

.................

...

.,

.........

l1li

••••••••••••••••••••

11.4

............

"

...... , •••••

iII

.........

"

.................

11

••••••

+

••••

•••••••

11

••••••

1

..

1

3

411

•••

4

5

6

1'7

8

9

++.10

" ..

11

12

13

1~

ADJtJST

MAklf\lC;

~

1'tiE

T

A8lf:

11-IE

0J1l"ERHEAD

f()Il

FINiSH

EXrENSI~

AND

.............•........• _ ....•.......••.•........•••••••••

l.UBRJCA.~AAAI~

~

.........

.,

...............................................

P..A.RTS

u~,/DIA~.t.'Ii!

•••••••

4!

RalER.

•.

i

•••

..............

T.ABlE

P.ARAllEL

•••

U

......................................................................................

IIi*

.... I

.....

+

...... " .........

, ............................ u

•.•.•.•.•.

n

................................

*

..................................................

Ii

•••• " ....................

"'

•••• " ........

.,..~.1''''

••

-If!+

....

...................................

"

•••

~'I!

....

*

....

tI

•••

11

...........

it'

•••• , ..........

"

"

................

............

''.Ii

........

15

16-17

18

19

20-

22

23·31

Page 3

GENERAL

SAFETY

RULES

FOR

POWER

TOOLS

WARNING.

completely

...

ult I ••

owners manual and review frequently for continuous safe operatjon.

I.

laaw

application

machine~

2.

Ma'e

it

should

disable the third prong.

3.

K

••

p guards

maintenance

4

..

a

....

adjusting

5.1.,

Do

not

attempt

aU

instruc'tions. rules. etc. contained in

eeld

••

tllavolyll,

your

mach I

and

IVre

aU

be

v.

adlu.'111 keys aft

wrenches are removed from

work

are.

•••

limitations.

'eol,

aN

used

with a three-hole electrical socket.

I.

place aad

or

cleaning. make sure

d

.....

to

nre

for

your own safety.

prope'"

III

••

CJuttered

operate until

,

.Iectrlc "o.1e, or

as

well

as

specific potential hazards pertinent

IfOn

....

working or

it

is

property

nllcll

•••

the

areas

and

you

have read thoroughly

this

manuar.

..

rlDul

read

the

owner"s

1f

1he toots electrical plug has three

00

••

r.

If

a'

guard must

reattached before using the tool again.

Form the

machine before

hab't

of

workbenches increase the Ukelihood

F.II.,.

..

r

.......

manual carefully. learn its

not

remove

be

checking

tunling

accident

and

I.

lv'''.

or

otherwise

removed

to

see

it

on.

understand

co_..,

to

Keep

this

••

this

prongs.

for

that

keys and

of

an

6.

Do

locations,

7. K

••

I.

Male-

keys.

9.

Do

was

10. Use

were

abo,ul

1101

UN

or

p

'.11

..... away. All visitors should be kept

workshop

80t

force

designed.

.11.

right

not

Ule

III clangeroul Ilvlroaments.

expoae

t

••

designed. Con.tact the

tool~s

them

to

rmn.

Keep

childproof

lftac.I

tool

•• Do not force the machine

•••

..

With

It

wtU

padlocks.

do

the jab

manufacturer

suitability for a partlcu!ar job.

Do

not

usc

power

wor1<

area well illuminated.

at

a safe distance from work area.

master

better

or

switches.

and be safer at the rate for which it

attachments

or

distributor

1oo~s

in damp or

or

by

removing

to

do a Job

if

there

is

wet

starter

for

which

any Question

they

Page 4

GEIEUL

11

.......

jewelry which could be

protective hair covering to contain long

SAFE"

,.,

••

pateL

RULES

Avoid

cau&ht

FOR

loose

in

moving

POWER

clothing, gloves. neckties. rings,

parts.

hal,f.

TOOLS

Nonslip footwear is recommended.

bracelets.

or

Wear

12.....,.

eyeglasses

13.

SICUM

your

'1.

Do

15.

Mal.,.I

pedormance.

1:6.

Dlsc

accessories. or

17. Avo'.

power cord.

11.

Use

accessories.

CIIadI

19.

damaged should

perfonn its intended function. Check for alignment

parts. breakage

operation. Guards or other parts

.......

worlc.

hand and frees both

..

t

•••

....

•••• d ••

_cd.lllal

..

C

.....

........

.,

.....

only

have

Use

ctamps

ma,1t.

c

Keep proper footing and balance

•••••

follow Instructions for lubricating and changing accessories.

Il

a.op

cW

••

when

dartl

...

GIgssarles.

,.rt

..

be

of

parts. mounting.

L

Also

use face

impact

resistant lenses.

01

a vlse

hands

to

to operate

hold work

co.dltloll. Keep machine tlean

lrom

IIGwer

mounting

••

Make sure switch is in \he

Before

carefully checked to make sure

lou.el. Before

and

remounting motor.

Consuft

further use

and

that

are

replaced.

or

dust

the

mask

They

when

tool.

If

operation is dusty. Everyday

are

NOT

practical.

at

an

times.

for

servicing;

·off·

the

owner's

of

the machine. a guard

any

other

damaged

manual for

that

it

of

moving parts, binding

condition Ulat may affect its

should be properly repajred

safety glasses.

It

is

safer

than

uI,lng

best

and

safest

and

when

posttion before plugging in

win

operate

changing

recommended

or

other part that is

property

of

and

moving

or

20.

lnet'

untn

21."

.....

22.

...,.

.....

it

comes

•••••••

chips.

removal.

mac'."

to

tIOL

....

Always

Use a wood

ru

••

ll1l

a complete stop"

y

....

I

...

operate

r tools

r

_sl

the

tool

dust

collection system whenever possible.

••

all

••••

d.

Tum power off.

••

11.

un

••

, th

••

Recl.

.ask

if

operation

in

a well ventilated area and provide

2

creates

01

a

Do

tlrugs,

lot

of

not

alc

saw

leave

•••

dust

for

1,

proper

the fllachjne

or

••

,

and/or

wood

dust

Page 5

SAFETY

I.

Always

INSTRUCTIONS

wear

fOR

eye'

protection when operating any'machine+

MB

1931

2. Before starting

3.

Always

4.

Be sure all guards are in place before

5.

Read

attempting

6.

Do not force work through the

7.

Check

components. " rollers are

against

I.

Plane

9.

Use sound lumber. with no toose knots. and as few tight knots as possib1e.

1041

one side of the machine.

11.

12.

13.

14. Allow

stop

operators manual thoroughly and famillarize yourself with machine

fe(;,'.d

the

only

Never stand directly in line

Be

certain

which

Be

The

knives and cutterhead assembly.

could

sure

knives

the

UP.

motor

check

and disconnect from power source before making

to

make sure all holding screws are tight.

operaUng

to

operate.

machine~

rollers

wood boards.

the

occasionally

bad.

allowing

the workpiece

damage

knives are properly attached

an,~

sharp

the knives.

and

to

be

not

seated firmly. the feed rolls

kickback.

with

cither

is

free

can

easily

from

Allow the planer

sure

chips and

the

infeed or outfeed

nails.

as

cut

your

cutterhead to reuch full speed before

equipment.

sawdust

screws,

described

hand. Use

using.

to

apply

ere

not

will

not

'sides.

stonest and

in

the

instructions.

caution

the

lodged

holCl

Always

other foreign objects

when handling

any

adjustments.

b@fore

proper feed rate.

between

stock

stand off

any

finnly

to

the

3

Page 6

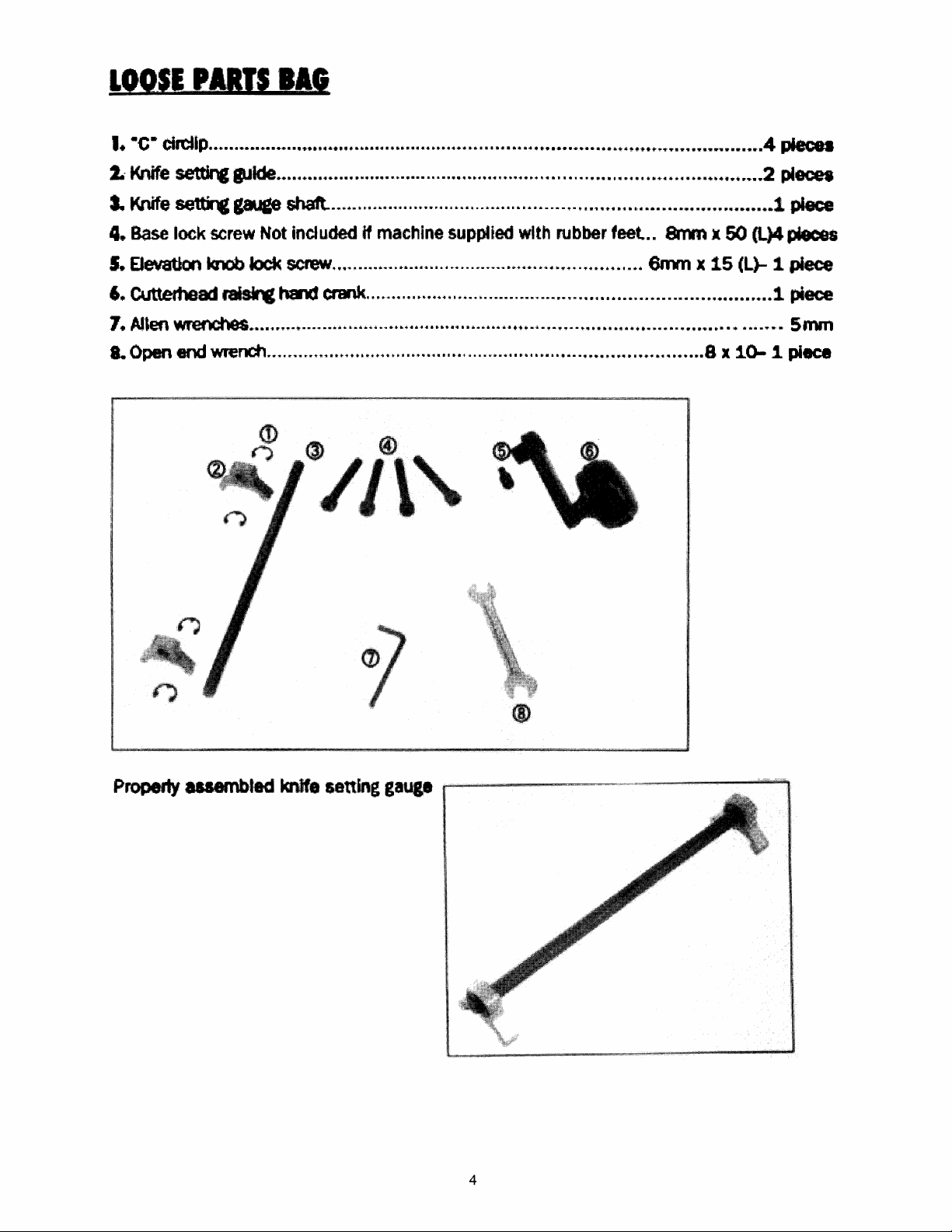

LOOSE

PARD

IIG

I. ·c·

11<rlife

cI..

4.

S.

circUp

set'tir\I:

t<rUfe

settir'C

Base

lock

EJevation

...............................................................................................

... Ide ............................... , ....•........ ····•········.·· ........... 0

&ace

screw

knob

Not included

lock

6. Cuttertleacll'8islrC,

7. AI'efl

L

Oper1

~

erM:I

...................................................... +

Wl'ef"dl

.......

staaft..

screw

t1alcI

r.+

'F

....................

.......................

............................................................................................... 1

if

machine

... -............................................................

CI'1IIlk.

......................................................................................

••••••••••••••••••••

supptied

~

•••••••

with

...................................................

+

••••••••••••••••••••••••••••••••••••••••••••

rubber

feet ..

8rrYn

6rnrn

x 50 (L)4 pieces

x

15

(L)-

8 x 1.0- 1 piece

4

pieces

2

pI~

piece

1 piece

1

,:Mace

SI'I"II'n

4

Page 7

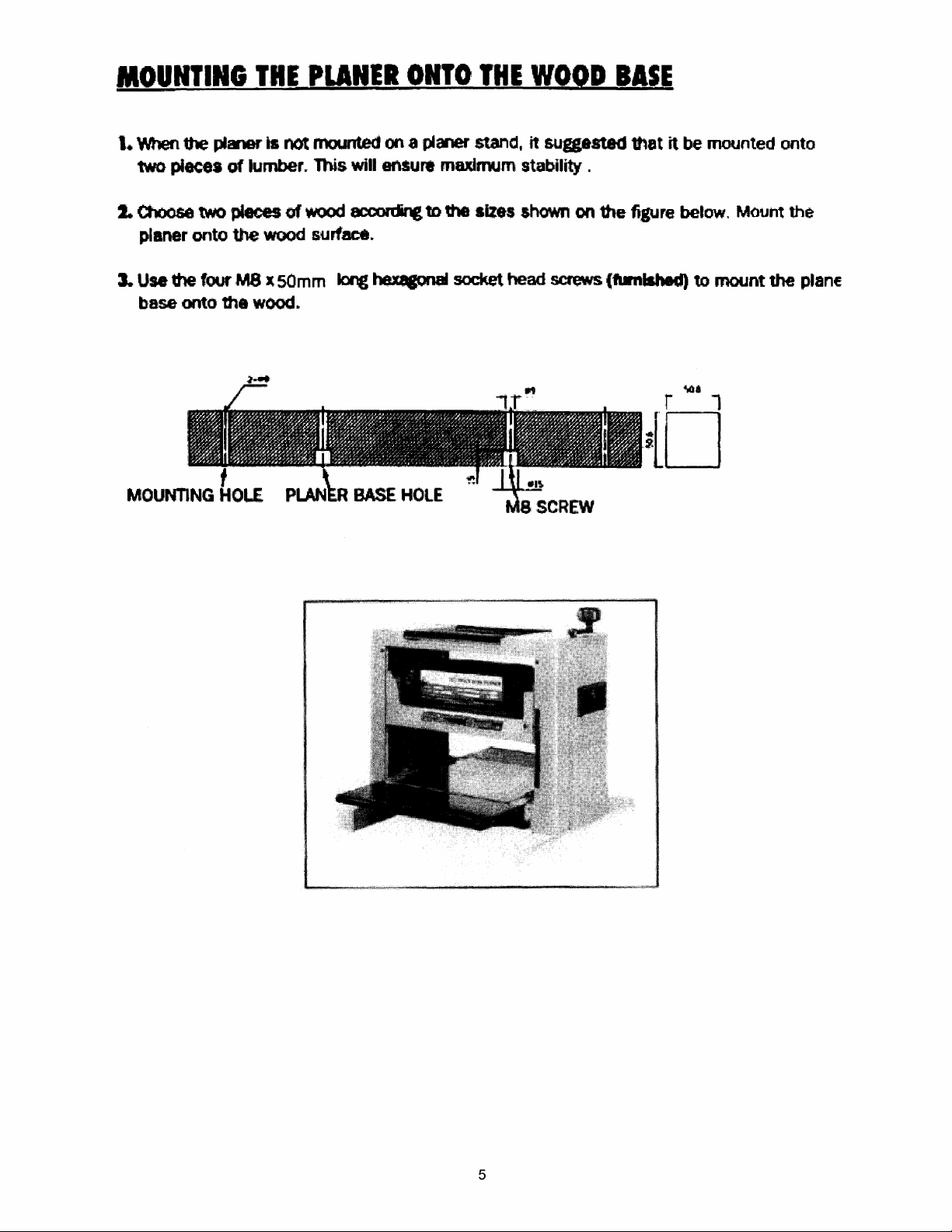

MOUNTING

1.

When

2..

Choose

3.

Ule pi

two pieces of lumber. This

t\YO

planer onto

Use 1he four

base

onto

I,HE

....

ts not

pieces

the

wood surface.

M8

x

SOmm

the

wood.

of

PLANER

mounted

will

WCXJd

eccordng

long

ONTO

on 8 planer stand.

ensure maximum stability .

heJtaIon8

to

the

siZes

socket

THE

it

sho\vn

head

WOOD

suggested lIlat it be mounted onto

screws

on

1he

(finished)

BASE

figure below, Mount the

to

mount

the

....

r 1

D

plane

5

Page 8

'lOCK

Two

consecutive

ROLLERS

rollers are built on

cutting operations.

top

of

the planer, providing convenient

handUng

of

stock for

SIod(

••

H.lly

pla,..I

011

pulled 10 ,11.

Ii,.

'.,1

0'

,It.

,.,.,.'or

madillne

for plall''',.

fall

6

Page 9

Motor:

Volts •••••••••••••••••••••••.••.••.••.•.•.•..•........••••.•.•••.•.••••••.•••. 220V

160Hz

Cvttl8, capacity:

Lengttl of stock (min) ...................................................................................... 5" (127mm)

Widtl1

Thickness

DepUl

Feed

of

stock (max) ...............................................................................

of

stock. .........................................................................

of

cut (max.) ...........••..•.••••

o.

•••

••••

................

•••••

...............

•••••••

0.2

•••••

rate ...........................................................................................

12-1/2·

..

-6-

••••••

26.2

(5

••••

fPM

(318mmJ

....

153mm)

2.5

mm

(8m/min)

Number of

Diameter ....................................................................................................

Idle

ruMing

knives.....

.••.•..

•..

....... ....................... .•.•... ........ .... .••......

••.

.......... 2.5lngJe

1.89·

speed .............................................................................................

9000

Cuts per minute .....................................................................................................

O

••

rall

dI

...

nsI08s:

LengUl

WidU1

Hci~lt

Net weigl1t ..............................................................................................

Gross weight ................................................................................ , .............

Packing size

......................................................................................................

22.8·

..........................................................................................................

......................................................................................................

(L

x W x

H)

.......................................................................

18.2·

67.6Ibs

70lbs

24· x 18.3· x 13.8"

22·

(58Omm)

(558mm)

(463rnfJl)

(30.7kg)

(31.8ke)

edged

(48n1m)

RPM

16000

7

Page 10

.VIII

the

planar can

extenIianI

THE

be

befcn

PUNER

moved

you

by

move

canylng

the

planer •

it

on

the right

and

left

of

the

frame. Qose the table

•

".1..

&fake

and

unplUUecJ

sute

the

plane

before

has

you

been

move

tum«l

the

8

oft

Planer

..

Page 11

ON/OFF

Your

planer

use.

If

yoU intend to be

chance

the

OFf position. Store

planer on, insen the

then

be

SWITCH

has a nx:ker style switch with a removable locklng

of

its

use

by

operable. To

away

from the machine

others, especially children, remove

it

in a

saf'e.

inconspicuous place in your workshop.

red

locking key and

tum

the

ptaner off, tum the switch

tum

for

a long period

the switch

the

to

to

locking

the

the

key

to prevent unauthorized

of

ON

OFF

time and

key

position.

positron.

there

with

the

To

The planer will

is

any

switch in

tum

the

SAFETY

SWITCH

WARNINGt

CIRCUIT

The

machine is

the sWltch

ON/OFF

Always be sure the switch is in

before connecting the planer to

BREAKER

win

pop out.

provided

tile

OfF

position

the

power source.

5WI,TCH

WlUl a breaker switch fur ovartoad protection. If an overtoad occurs.

tr

O.is

happens. walt sevC'ral rr

..

nutes.

and

press

the switch

to

reset.

BREAKER

SWITCH

9

Page 12

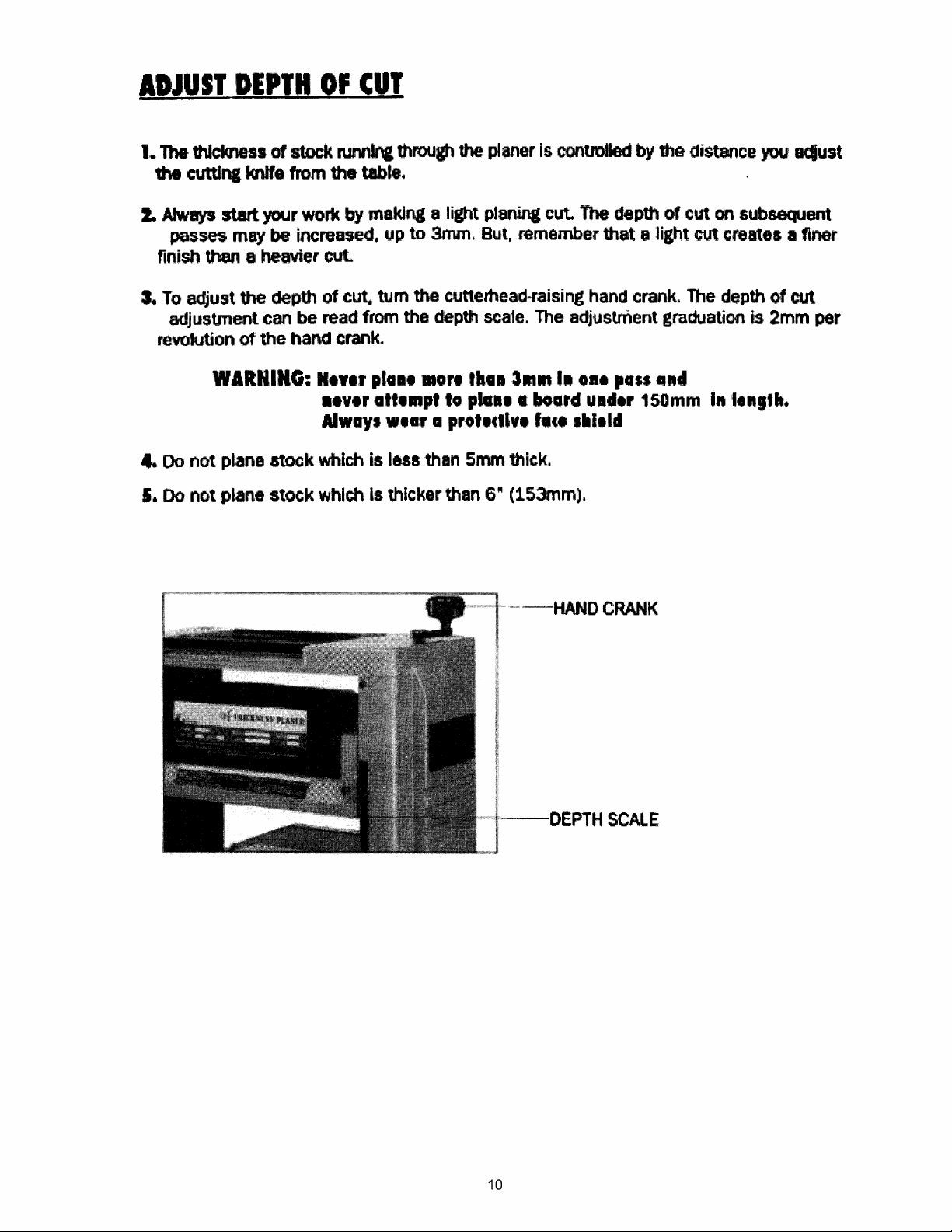

ADJUST

1.

The thickness of

the

cutting knife from

2.

Always

passes

finish then 8 heavier cut.

3.

To

adjust

adjustment can

revolution

DEPTH

stock

start

your work by making 8 light planing cut.

may

be increased.

the

depth of cut. rum

be

of

the

hand

OF

CUT

ruMIn&

the

read from the depth scale. The adjustment graduation

Crank4

through

tabl14

up

the

plener

to

3mm. But, remember that .. light cut creates a tiner

the

cuttemead-rajsing

Is

contmIled

The

hand

by

dep1h

crank.

lhe

distance

of

cut on subsequent

The

depth of cut

you

is,

adjust

2mm

per

4.00

5.

Do

WARNING:

not

plane stock which is less than

not

plane

stock

N.WII

••

vlr

Alway.

which

pla.1

att

wI.r

Is thicker than

.ort

...

pllo

.h

pla.l.

a protlctlve I.c

,5mm

••

31ft

II

Hard

thick.

6~

(153mm).

-~-HANO

I,

•••

0

••

uld.r

I.ld

CRANK

SCAlE

pass

150mm

and

I"'

••

gt".

10

Page 13

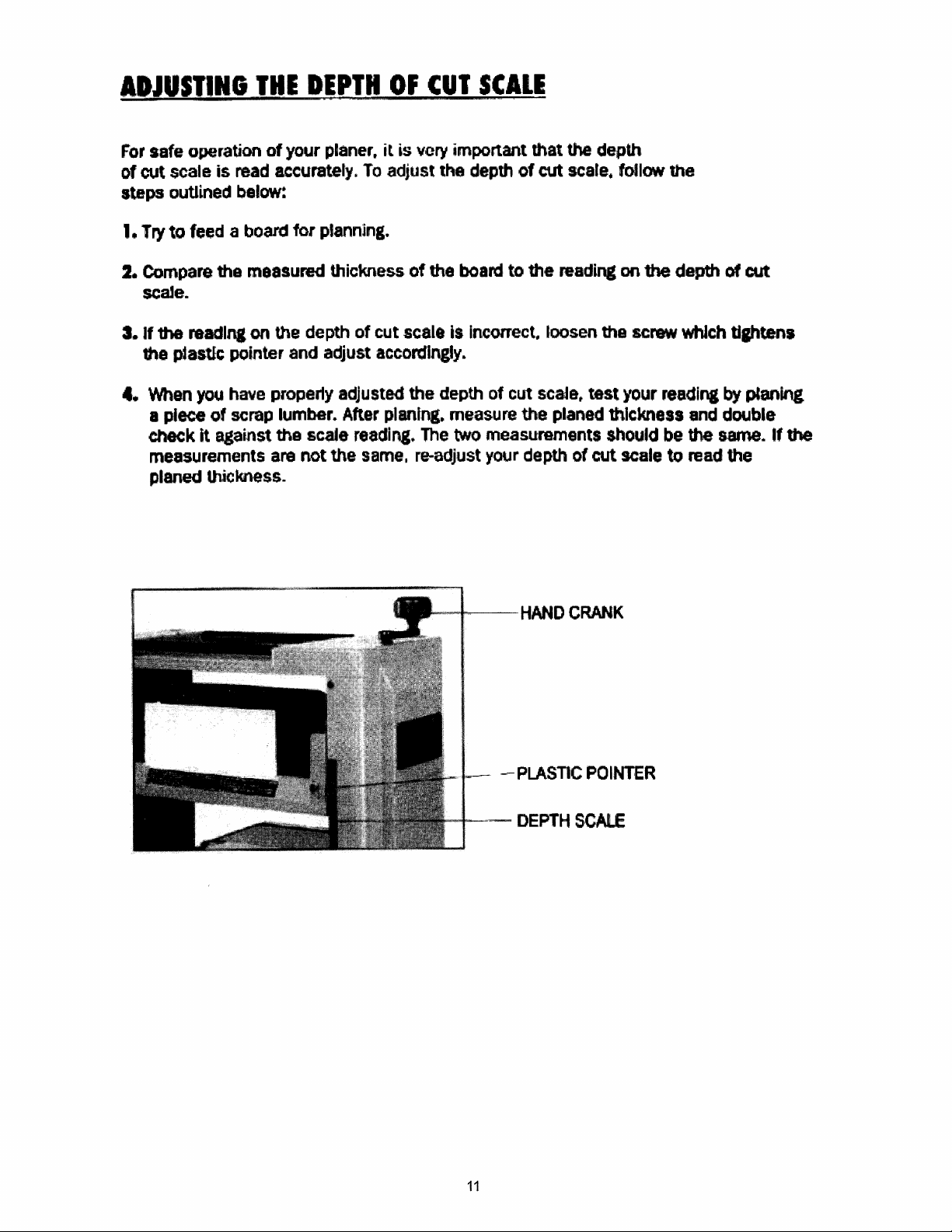

ADJUSTING

For

safe

operation

of

cut

scale

steps

2.

DutUned

I.

Try

to

Compare

feed a board

THE

of

is

read accurately.

below:

the

measured

scaJe.

3.

If

the

read1n&

the

p4astlc

4.

When

you

a piece of

Check

measurements are not

it

planed

on

the

pointer

have properly adjusted the depth

scrap

lumber.

against

the scale

U'tickness.

DEPT"

your

planer.

for

planning.

thickness

depth

and

adjust

After

the

OF

it

is

To

adjust

of

of

cut

scale is Incorrect. loosen

accordingly.

planing.

reading.

same.

CUT

very

the

The

re-adjust your depth

SCALE

important

the

depth

board

of

measure

two

measurements should be the same.

of

to

cut

the

that

cut

the

reading

scale.

planed

the depth

scare.

the

test

follow

on

the

screw

your

readina

thickness

of

cut scale to read

the

depth

whJch

and

of

cut

tllhtens

by

planing

double

the

If

the

I---~-

HAND

~

PLASTIC

CRANK

POINTER

11

Page 14

REMOVING

IHE

PLANEIINIVES,

WIIIIIICh

1.

Remove

Unplu,

belonJ

the chip

your

removing

guard

2. loosen the lock bar

are

spring loaded,

I.

Take

out

the

knife (e).

planer from

the

by

removing

(B)

and

and

will

and

the

power

planer

knife by tuming the lock screws

push

then

out

'the

knives.

the

Vlhcn

knife

source

screws

Ute

rock

SCREWS

CHIP

shown in figure.

assembty is loosened.

bar (9).

GUARD

fA)

clockWise.

The

knives

SCREW

12

Page 15

I_DALLING

THE

PLANER

KNIVES

Willi

1.

2.

3.

••

Remove

fit

the

At 1he knife

tumirC

direction

..

Set the knife

heit)lt

..

Be

sure 10 replace

Unplug your plan.r from Its

betote

1he

knife

the

must

I8mot11n1

Knives

lock bar (B)lnto the slot on the cutterhead.

Iota

screws

(See

be

accordlng to

th8

fig. below)

hel,&hts

reaet

the

or

slat

on

counterclockwise.

according to the Instructions

every

time

Chip

gu8ICI

power

InstaIll,."

the

th4t

the

the

Instructions,

euttemead, and tighten the Iockbar-kntfe

knlvel

after

source

planer kniwl

Make

sure the knife is facing

ant

taken out for

knives are

••

for

............

on

the following page.

any

instaUect

PIII

the

reason

..

r 1.1

as.setrmly

correct

The

•

...

knife

-.

by

WHIII...

Will

....

o

The

knife

edge

Is vel)' susceptible to chipping"

UN

caution when handling UHI'BUge

knIwIs

The

to

to

avoid

assembly

pre""

Clama,lltl

must

8Cddents

them.

be tlptened

dud",

securely

planing.

near

A

the

13

Page 16

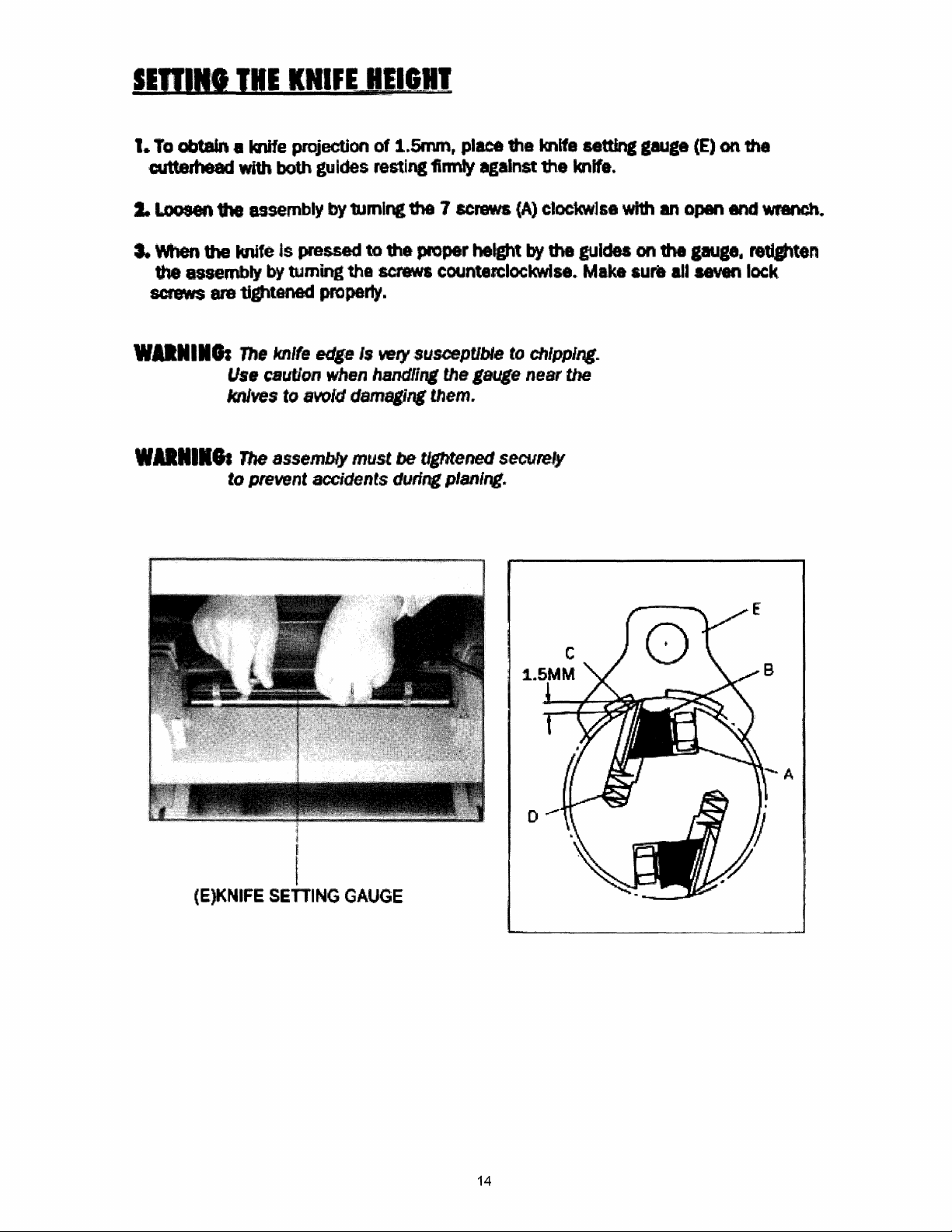

SEUIN'

1.

Ta

abtaIn.

cutterhead with both guides resting firmly

I.

Loosen the assembly by

a.

\\'hen

the assembly by tuming the

screws

THE

the

knife is pre,ued to

are

tightanad

KNIFE

knife projection

HEIGHI

of

1Umlng

screws

property.

1.5I'run. place the knife setting

the

the

proper height

against

7 screws

counterclockwise

the knife.

(A)

clockwlse with

by

the guides

..

Make

gauga

an

on

aura

(E)

open end

the

gauge.

all seven

on

1he

re1Wtten

lock

WNnCh..

WDIIIIII

WAIIIIe.

The

knife

edge

Is

wlf

susceptible

Us.

cauUon

knJves

The

assembly

to prevent accidents during planing.

to

when

svoid

handli", the lauge

damaging

must

them.

be

tightened

to

chipping.

near

securely

the

A

(E)KNIFE

SETTING

GAUGE

14

Page 17

1. The table extensions

are

mounted

at

the fronl and rear

ends

of

the main table.

2. Raise

the

cuttemead

assembly

so

that

adjusting the extensions.

3.

4.

Place

If

a straIght edge across the main table

1he

main

table and

table

extension

extension by loosening nut (8) and turning

touches the straight edge.

Adjust

the right

way.

5.

The roller

further adjustment.

has

been

factory

set

to

angn

you

can

get a clear view and work comfortably

and

table extension to

mller

are

not aligned. then adjust the table

screw

and

(A)

until the table extension

left s ide

of

with Ule table extension

be

adjusted

..

just

the table extension in this

and

t

,·equires

no

TABLE

EXTENSION

ROLLER

NUT(B)

SCREW(A)

15

Page 18

UKI"G

THE

CUllERHEAD

AND

WORKTABLE

PARALlEL

Plane

not

Adjust the cutter shaft

The

gauge

following

8 workptece and

the

same

tools used for checking

block

on

both sides of

accorcnng

procedures.

measure

and

the

are

to

the

figure

the

workpiece

the

workpiece.

worktable

shown

below.

shown

thickness after the cut.

perfonn the

so

they are parallel.

Please

size.

Make

use

the adjustment

following.

hardwood

If

the thickness

to

make a

as

per

is

toot

Ule

16

Page 19

JAIliNG

I.

Undemea1h

2.

Disengage the bevel

3.

Tum

tum counterclockwise

the

THE

the

bevel

CUlfERHEAD

main table. loosen

..

ar

next

to

gear to adjust the Mtght of that side of the cuttarheed.

lives

O.12mm

the

the

AND

·e· circllp

elrcllp.

raising

WORKtABLE

as

shown

See

f.gure 2 below.

thickness.

PAULLEL

in flIure 1

below+

One

tooth

of

4. After adjustment,

"C·circlip

re-engage

the

bfwal.,ar

and replace thII

·C·

clrcllp.

17

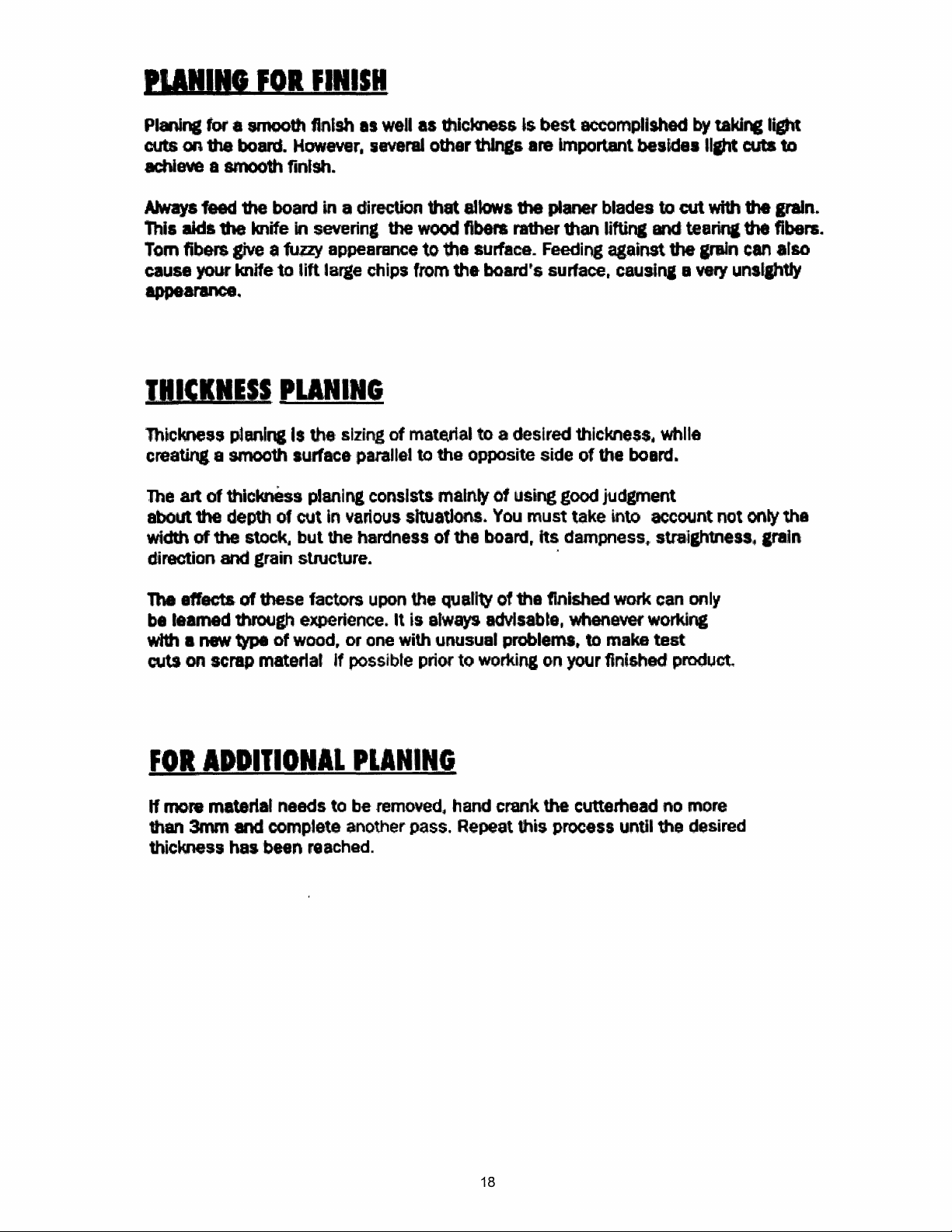

Page 20

PLIN'N'

FOR

FINISH

Planing

cuts on 1he board.

achieve a

AMaya feed 1he board in a direction

this

Tom

cause

for

• smooth finIsh

However.

arnoo1h

aids 1he knife in

fibers

gjve a fuzzy

your

knife

finish.

to

lift

IS

several other things are important besidea

severing

appearance

large

chips

well as thiclaless Is best

the

from

appearance.

JlleKNESS

Thickness

c.reating.

The

art

about

width of

direction

~anln&

a smooth surface parallel to the opposite side

of

thick.ni!ss planing consIsts mainly of using

the

deDth

the

and

PLANING

Is the

of

stock. but the

grain structure. .

cut

sizing

in

various

hardness

of

mate.rial

slWatJons,.

1hat

allows

wood

fibers rather than lifting

to

the

the board's surface.

the

surface.

planer blades

Feeding against the

to a deslred thickness. while

You

must

of the

board,

its dampness. straightness.

accomplished

CBUslnl

of

the board.

good

judgment

take

,nto account not

by

taking light

Ilaht

cuts to

to

cut

with

the

.-.d

tearifC the fibers.

pn

can

a

very

unsf&htIY

only

pin

grain

afso

the

..

Tha affects of these factors upon the quality

be

...

mad

1hrotJgh

with •

cuts

FOR

ff more materlar needs to be

than 3mm

thickness has

new

type

on

scrap material If possible prior to

ADDITIONAL

met

exPerience.

of

wood,

or

It is

always

one with unusual problema. to make

advisable.

working

PLANING

removed,

complete another pass. Repeat this process until

been reached.

hand crank

of

'the finished

on

the

work

whenever

your

cuttemead

working

finished product

can only

test

no

mora

the

desired

18

Page 21

LUBRICATION

1.

The recommended lubrication

operation

dust.

dkectly

tends

the

chain. This hastens

din

on

to

IS

to

simply

or

WOQd.shavings~

the

chain.

hasten

the

collection

Wipe

the chain clean.

coat chain

Over..ailing

WI

I'

speed reduction and height adjustment

2.

The

bearings on the cutterhead

further attention.

for

roller chains used in memum

defeats the purpose

of

dust, shavings. etc., and works

and

leads to premature

are

When

with

8 light film

,chains,

factory

there

of

of

replacement.

as well

as

1ubricated

to

slow speed

is

an appreciable bulld-up

oil

but

naver

the

rubrication. since

'them

'the

elevation screws.

end sealed.

pour

into members

This

applies

They

require

the oil

it

simply

to

of

of

the

no

PERIODIC

Bulldup

Periodic

of

cleaning is not

MAINTENANCE

sawdust and other debris can cause your machine to

p1anlna·

1.

Close-fittina

be

cleaned with a

replaced

2.

Remove

flammable

parts, such as thelockbars and

in

their

,.sln

solvent

only

rec1ommended.

brush

respective positions, slightly dampened with oil.

and

and

freed

other accumulations

fr'om

but

mandatory

the

clinging

from

feed rolls

for

accurate

planer cuttemead slots should

foreign

matter

and

labile with a

plane

and

inaccurately.

precision

then

n0n-

19

Page 22

'RoualISHOOTING

PIOBU.

FUZZY

TORN

GRAIN

GRAIN

'OS51IU

1..

PlaninI

moJsture

2.

Dull

I.

Too

2.

Knives

grain.

3.

Dull

CAUSE

wood

with high

content.

knives.

:'

he8\'Y

a cut

cutting against

knives.

the

IOUDY

I.

Dry

the

WOOd.

2.

Sharpen

1. Review proper depth

ofc~

.2.

Feed

Brain,

workpiece

3.

Sharpen

knlves~

wood

with

or tum

Bround.

kniVes.

1tIe

I

ROUGH/RAISED

GRAIN

1.

Dull

knives

2.

TOO

heavy

3.

Moisture content too

4.

Cuttemead

a cut.

bearings

damaged.

high.

I.

Sharpen mlvas.

t.

Review

of cut.

3.

Dry

4.

RePlace

proper

the wood.

bearings

depth

20

Page 23

TROUBLESHOOTING

PlOIUM

POOR

WORI<PIECE

FEEDING

LUMBER

JAMMED

OF

POS'SIIU

I.

Planer table

2. Feed roller dam8led

CAUSE

dirty,

3. Sprocket dam8led.

4.

Gear

box

malfunction.

1.lnadeQ1J8te

height.

knife

setting

IDIEDI

1.

C1ean

residue. and lubricate

planer table.

2.

Replace.

3.

Repface.

4.

Check lear box.

Set

1.

COlTeCt

off pitch

the

kr'INes

height.

to

and

the

21

Page 24

'ROUBlESIOOTING

PIOIUM

UNEVEN

CUT

BOARD

OOESNtT

DEPTH

CHAIN

MECHANICAL/

~

ELEcmlCAL

WON'T

DEPTH

$IDE

TO

SIDE

THICKNESS

MATCH

OF

CUT

SCALE

JUMPING

MACHINE

OF

START/RESTART

'OSSIIU

CIUSE

1. Knife projection not unifonn.

2. Cutterhead

planer

Depth

I

2. Sprockets wom.

1. Not

of

..

Sprockets misaligned.

ptuggad

not

levelled to

bed. table;

cut

scare

incorrect

In.

2. Circuit breaker/fUse.

3.

Motor

4.

Loose

5. Overload reset

failu,re.

wire.

I'las

not

reset.

IUIIDY

1.

Adju~

2. Level cutterhead

Adjust depth

I.

Align

2.

Replace sprockets.

1. Check power source.

2.

Check power

2.

Have

4.

Have

qualified electrician.

5.

Allow

down and restart.

knife proJection.

to

Df

cut

scale.

sprockets.

source~

motaf

motor

machine

cheeked.

checked by

to

c~

I

I

REPEATED

mlPPING

IN

MOTOR

RESULTING

STOPPAGE

CtRCUIT

6.

Motor

staner failure.

1. Extension cord too long

too thin.

2.

Knives too

3.

low

vo~tace

duU.

n.lMing. 3. Check voltage.

22

or

6.

Have

checked

electrician.

1.

Use

extension

2.

Sharpen

knives.

motor

starter

by

qualified

a shorter or thicker

corel.,

or

replace

I

Page 25

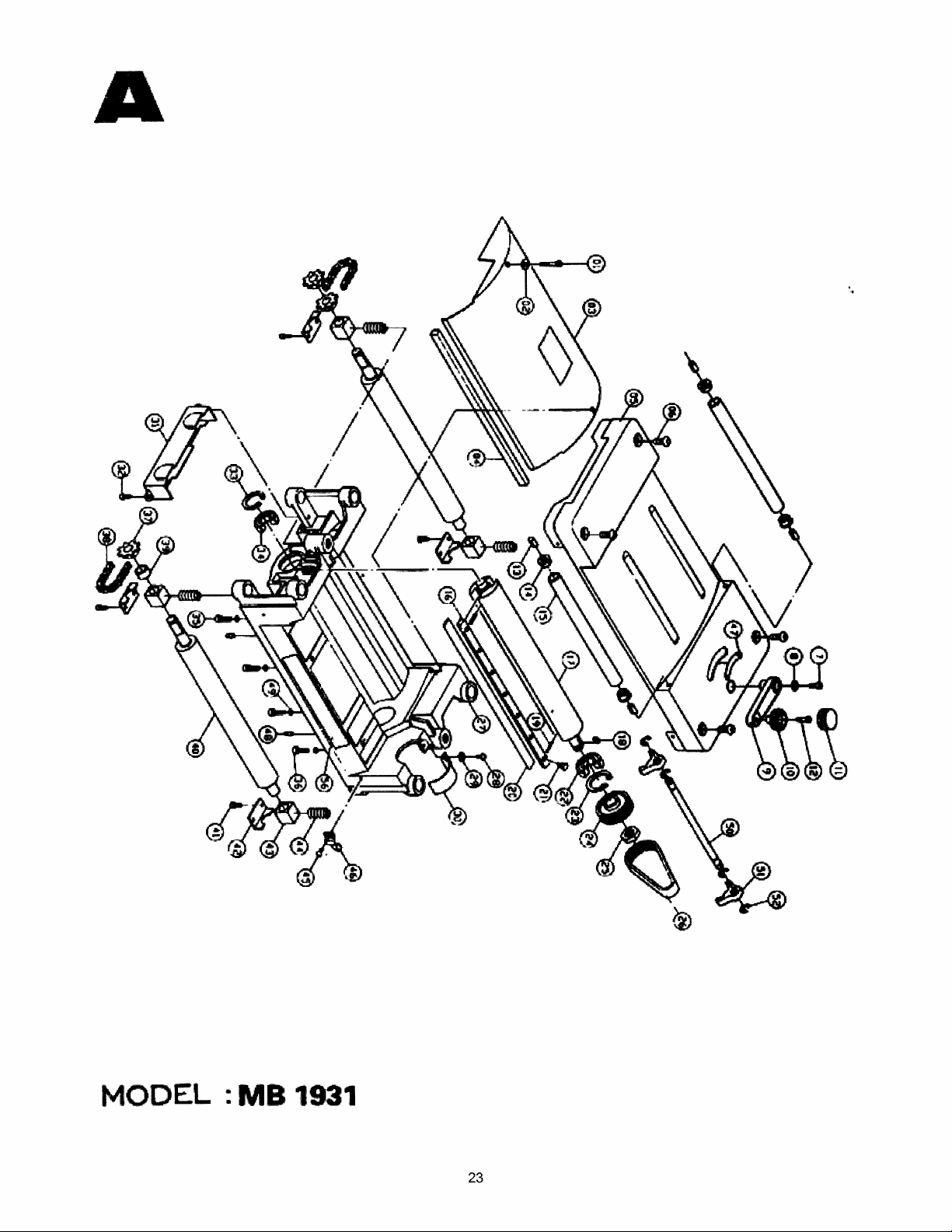

A

MODEL

:

MB

1931

23

Page 26

PARTS

liST

A

D

••

No.

1

2

3

4

5

6

7

8

crlptlon Speciftcatioft

Upper

Hexagonal

Spring

Chip

Chip guard

wamlng label 1

Sponge piece

Upper

Hexagonal

HexagonaJ

Spring

Mechanism

socket head

washer

guard

assembly

guard

socket

socket head

washer

head

screw

screw·

screw

MS40"SP*30

5.1-9.2·1.3

M8·1.2"·16

MS·l.0P·16

8.1·10.2*1.4

Hand'. set

9

10

11

12

Handle

Hand knob

Handle

Handle

crank

gu

ard

shaft

Quantity

2

2

1

1

1

1

4

1

1

1

1

1

1

1

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

Spring pin

Bush

RoUer

Glb

Cutterhead

Double

Spring

Knife

Gib

Bearing

·C·

Cunemead

Nut

Belt 135-J6

Upper

round

lock screw

clrcllp

pulley

frame

end

key

S-20

5·5*10

1/4-28UNF

6203-2NK

RlW-40

4

2

1

2

1

1

1

'2

14

1

1

1

1

1

1

I

24

Page 27

A

Cross

28

Plain washer

29

Pulley

30

Chain

31

Cross

32

33

34

35

36

37

38

39

40

41

42

43

round

head

screw

M4·0.7P*S

4"10·0.8

guard

guard

round

lie·

ctrclip

Bearing

Hexagonal socket head screw MS-1.OP·20

Self tappina

Chain sprocket

Chain

Spacing collar

Rubber

Cross

Bracket

Roller bracket

roller

round

p1ate

head

screw

head

screw

screw

M5·0~8P·8

I

RTW·35

6202-2NK

M8·1.59P*2Q

'41-26P

M5*O.8p·l0

2

2

1

1

2

1

1

2

:2

3

2

1

2

8

4

4

Bracket spring

44-

Cross

45

Indicator 1

46

Indication label

41

Pin

48

49

Spring

Gauge

50

Knife setting guide

51

-E- circlip

52

Waming label 1

56

round

washer

rod

head

screw

M4·0.7p·S

6.1·10.2*1.4

ETW,,9

4

,1

1

2

4

1

2

4

I

25

Page 28

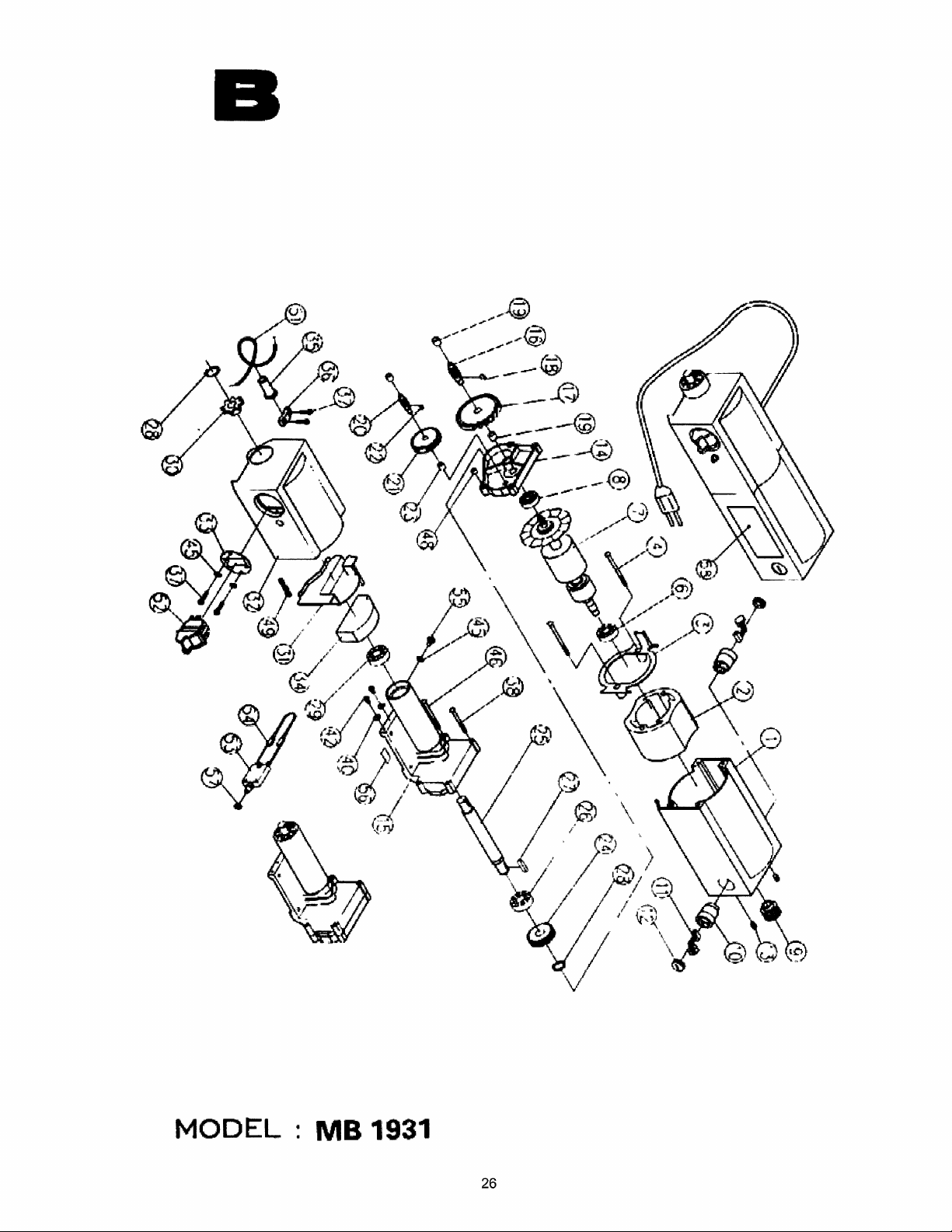

B

MODEL:

MB

1931

26

Page 29

PARTS

LIST

B

No.

1

1"'---"

2

3

4

·6

7

8

9

10

10

11

13

14

Description SpecIfication

Motor

Motor casing

Assembly

Stator assembly

Plate

Self

tapping screw

Bearing

Rotor

assembly

Bearing

Motor pulley

,

Carbon

Carbon

Carbon

Carbon brush

Set

Gear

brush 2

brush

bru

sh

screw

box

cover

bracket

cover

M4.8S·1.S9p·70

'6201·2NK

-

M~.8P·l0

Quantity

1

1

1

2

1

1

1

1

1

1

2

2

1

15

16

17

18

19

20

21

22

23

24

Gear

box

Gear

shaft

Gear

Double

Bronze

Gear

round

bush

shaft

Gear

Double round

Bush

Gear

end

end

key

key

8 1

70

4·4·8

8·11.13·10

8

46

343

.•

7

6-10*9

33

-

,1

2

25 Shaft 1

Bearing

26

Ooub~le

27

28

29

·e· cirelip

Bearing

round

end

key

'6202Z(A)

4*4·10

STW-15

116002Z,(A)

1

1

1

1

1

2

1

1

1

2

1

,

-

27

Page 30

B

30

31

134

32

36

i Self tapping

37

49

35

51

33

38

40

42

45

46

Chain

SwUch

SpacIng

Oust guard

Switch

Electrical wire

R type plug

Power

Safety wire ball

PowC!r

Switch

Self

sprocket

casqassembly

plate

guard (black) 1

wires

wi

res

plate 1

tappIn, screw

Plain

washer

Cross

Teeth

SeJf

round

washer

tapping screw

plug

screw

he,ad

clamp

screw

8

M4·16

SSP-1O

M4.85-1.59P* 50

4*10·0.8

M4*O.7P*S

BW-S

M4.8S·1.59P*SO

1

1

1

1

1

4

1

'1

,1

1

3

2

2

3

1

I

--

48

PositionIng pin

Safety swltch

52

53

Temperatu

57

Nut

54

Temperature control wire

55

Cross round head

MotOf label

56

58

MotO'f

re

name plate

contrQ~

switch

s~rew

-

5.6-7.1*5

2.0/1C·13em*2

MS·.OSP*S

2

1

1

1

1

1

1

1

1

28

Page 31

(2)

__

--;1--(*)

MODEL:

MB

1931

29

Page 32

PARTS

LIST

c

No.

1

2

3

4

5

16

1

18

9

10

11

12

13

14

DescrlptJon

Base

Assembly

Left

screw

Double round end

Bevel

gear

"E"

circlip

Double

Hexagonaf socket head

Axing

Transmission

Table extension bracket

Plain

Table extension bracket

T able extension roll

Depth scale

Hexagonal

round

piece

washer

head

end

shaft

er

screw

key

key

(seamless

screw

~

stee4

pipe)

, SpecEticatlon

4*4·8

ETW..a

4·4*8

MS*1.0P*10 4

6·19·3

M6*1.0P-S

20*350

MS·1.0P*25

Quantity

1

1

2

2

2

2

1

4

4

4

2

1

4

15

16

11

18

~

19

20

21

22

23

24

125

26

~'

27

128

Nut

Table

extension

Base

Plain washer

Hexagonal

Spring

Pad

Cross round

Guide plate

pin

Column

Double round

Right

-

' Hexagonal

screw

Fixing piece

socket

head

end

socket

head

screw

screw

key

head screw

Me·1.0P

5/16*23·2

MS IiIl.25P

0*20

~

~

M6·1.0P*10

4·4·8

MS*1.0p·l0

iii

20

4

2

1

4

4

4

1

4

2

4

1

1

4

2

30

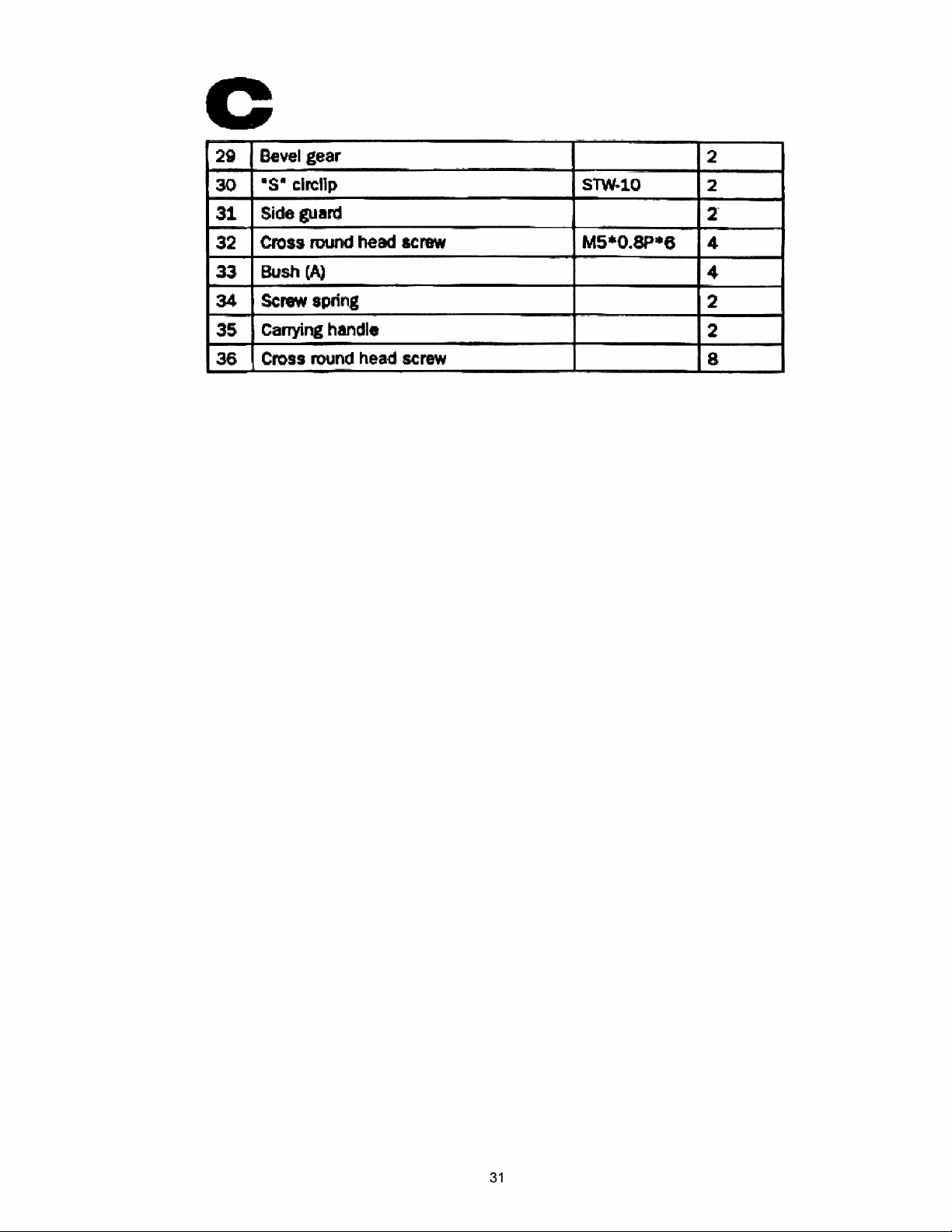

Page 33

c

Bevel

29

·S"

30

Side guard

31

gear

clrcllp

S'fW.10

2

2

7

32

33

34

35

36

Cross

Bush

Screw

Carrying

Cross

round tlead

CAl

spring

round

handle

head

screw

screw

M5*O.SP*6 4

4

2

2

8

31

Loading...

Loading...