Page 1

Vehicle Restraint

Owner’s Manual

© 2013 Nova Technology International, LLC

MF2-012-000 October 2013

Page 2

TABLE OF CONTENTS

SAFETY WARNINGS …………………………………………………………………

COMPONENTS DESCRIPTION …………….…………………………………………

OPERATING PROCEDURES …………………………………………………………

ROUTINE MAINTENANCE ……………………………………………………………

TROUBLESHOOTING …………………………………………………………………

CONTROL HARNESS …………………………………………………………………

ELECTRICAL SCHEMATIC …………………………………………………………..

OUTSIDE LIGHT BOX WIRING ……………………………………………………….

PARTS …………………………………………………………………………………..

NOTES …………………………………………………………………………………….

WARRANTY……………………………………………………………………………..

3

4

5

9

11

13

14

15

16

21

23

2

NOVA Lock & LoadTM Owner’s Manual

Page 3

SAFETY WARNINGS

You will find the safety alerts DANGER, WARNING, CAUTION or IMPORTANT used throughout this

manual. Their meaning is listed below:

This is the highest level statement. Failure to

follow the listed instructions will most likely

result in severe injury or death.

This is a statement of serious hazard. Failure

to follow the listed instructions could place

the individual at risk of serious injury or

death.

DO NOT OPERATE THIS PRODUCT UNTIL YOU HAVE READ AND UNDERSTAND THE SAFETY

PRACTICES, WARNINGS AND OPERATING INSTRUCTIONS CONTAINED WITHIN THIS MANUAL.

IMPROPER USE OF THE LOCK & LOAD VEHICLE RESTRAINT COULD RESULT IN SERIOUS

INJURY OR DEATH.

If the Lock & Load vehicle restraint does not operate properly using the procedures in this manual, BE

CERTAIN TO CHOCK THE VEHICLE WHEELS BEFORE LOADING OR UNLOADING. Contact NOVA

or your local representative for service.

DANGER

!

WARNING

!

The statements used with this level of

warning deal with a safe operating

procedure. If the procedure is ignored the

possibility of personal injury may exist.

IMPORTANT is used to draw attention to a

procedure that needs to be followed

to prevent machine damage.

CAUTION

!

IMPORTANT

3 NOVA Lock & LoadTM Owner’s Manual

Page 4

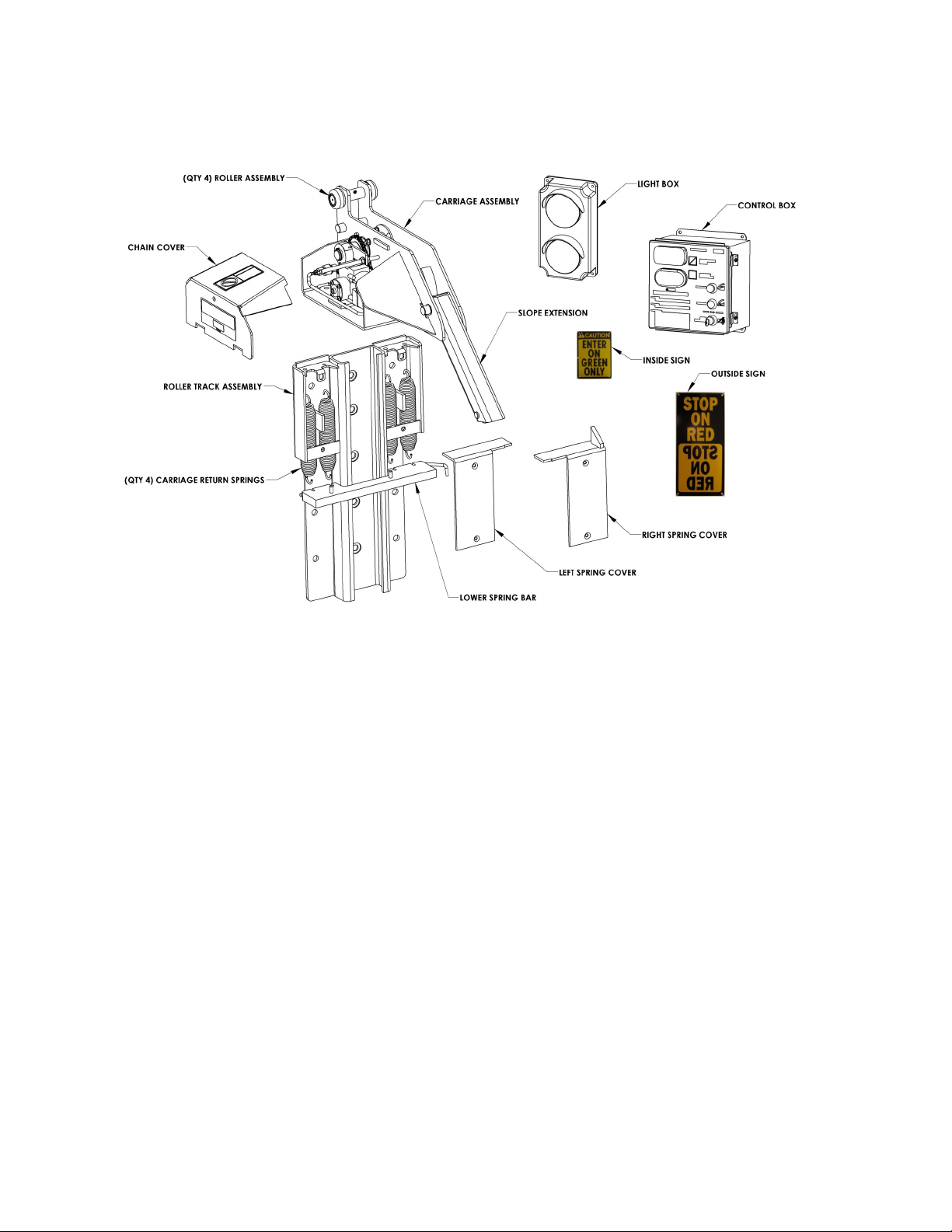

COMPONENTS DESCRIPTION

Figure A—Lock & Load Components Description

4

NOVA Lock & LoadTM Owner’s Manual

Page 5

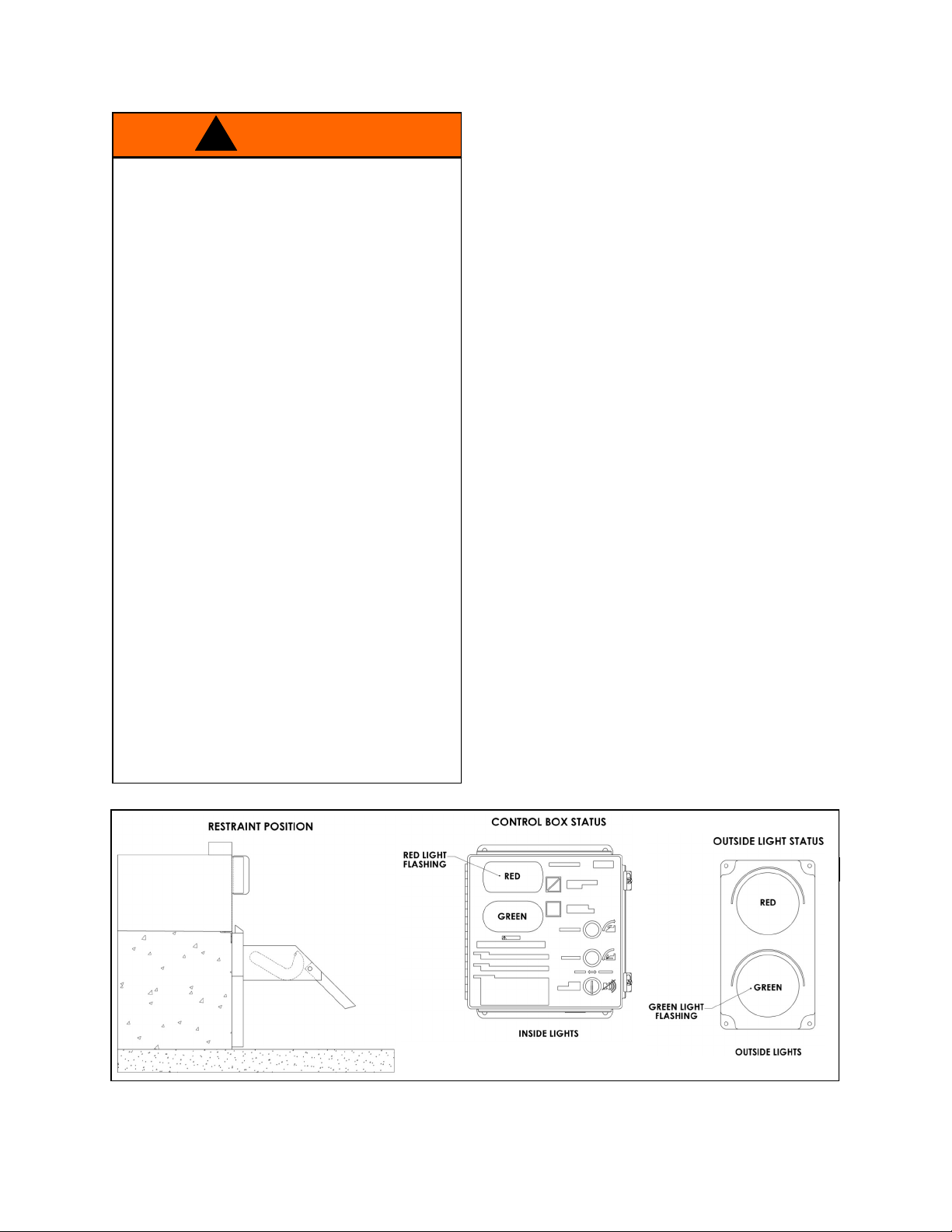

OPERATING PROCEDURE

Before loading or unloading a vehicle at

your loading dock while using a Lock & Load

vehicle restraint, always visually inspect to

be sure that the restraint is engaged with the

Rear Impact Guard (RIG). If the restraint is

still not engaged after backing the trailer

firmly against the dock bumpers, secure the

trailer by other means.

Be sure that the area around the RIG

assembly is clear of obstructions.

Always operate the Lock & Load vehicle

restraint from the top of the dock.

Inspect all restraint lights daily to make

certain they work properly.

Perform maintenance on restraints in

accordance with Maintenance on page 11 of

this manual.

Lock & Load vehicle restraints should be

operated only by authorized personnel who

have read and understand the Owner’s

Manual.

If you have questions, Call your local

representative or NOVA at (800) 236-7325.

FAILURE TO FOLLOW THESE PROCEDURES

COULD RESULT IN SERIOUS INJURY OR

DEATH.

WARNING

!

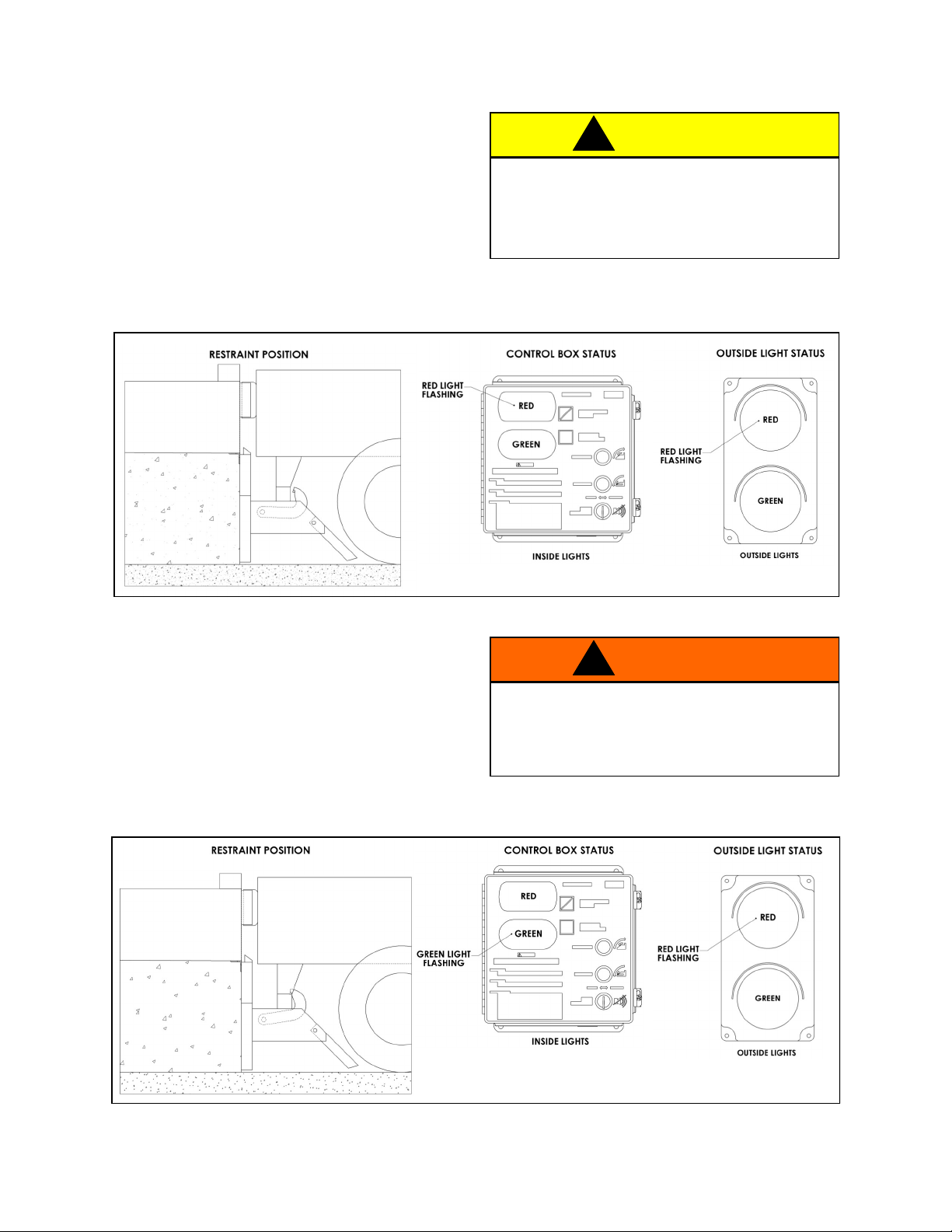

Stored Position / Restraint UNLOCKED

Hook is in the STORED position. Inside light is

flashing red alerting forklift operator unsafe

condition exists. Outside light is flashing green

alerting truck driver it is safe to back in.

Refer to Figure B.

FIGURE B—STORED POSITION

NOVA Lock & LoadTM Owner’s Manual 5

Page 6

OPERATING PROCEDURE continued

RESTRAIN Button Pressed Restraint ENGAGING

Trailer has backed into loading dock and is

parked firmly against dock bumpers. Hook

rotates from stored position to engage RIG.

Outside light is flashing red alerting truck driver

not to move. Refer to Figure C.

If horn sounds, proceed to FAULT, otherwise

proceed to Restraint ENGAGED.

If trailer can not be restrained due to a lift

gate or other obstruction that could become

damaged, proceed to OVERRIDE.

CAUTION

!

FIGURE C—RESTRAINT LOCKING

Restraint ENGAGED

Once the RIG is engaged by the hook, an

ENGAGED condition exists. Inside light is flashing green alerting the forklift operator a safe condition exists. Outside light is flashing red alerting

truck driver not to move. Refer to Figure D.

If during loading/unloading the inside light turns

red and the horn sounds, press RESTRAIN

button to secure the RIG.

Visually inspect to ensure that the Lock &

Load vehicle restraint hook securely engages

the RIG of the trailer before operating the

dock leveler.

WARNING

!

6

FIGURE D—RESTRAINT LOCKED

NOVA Lock & LoadTM Owner’s Manual

Page 7

OPERATING PROCEDURE continued

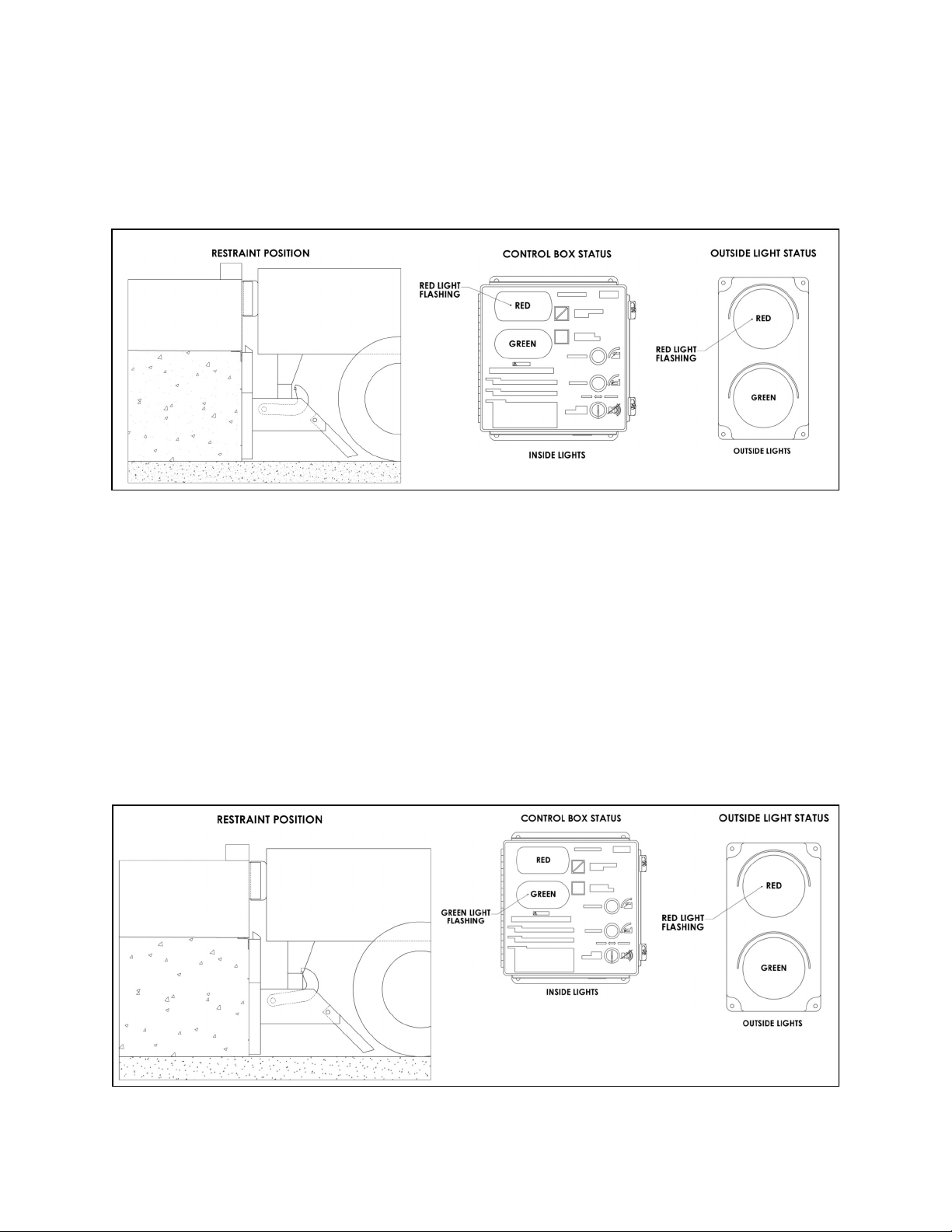

RELEASE Button PressedRestraint DISENGAGING

Hook travels from the ENGAGED position to the

STORED position. Outside light is flashing red

alerting truck driver not to move. Refer to Figure E.

FIGURE E—RESTRAINT UNLOCKING

FAULT from ENGAGING State

Hook cannot engage the RIG. This could be due

to a RIG that is located too far toward the rear

axle, bent, obstructed or missing. Inside light is

flashing red and horn is pulsing, alerting the forklift operator that the trailer is not locked. Outside

light is flashing red alerting the truck driver not to

move. See Figure F.

If the trailer is parked firmly against the dock

bumpers proceed to HORN OVERRIDE. If not,

press RELEASE to clear the fault, have trailer

back up and repeat Restraint ENGAGING.

NOVA Lock & LoadTM Owner’s Manual

FIGURE F—FAULT STATE

7

Page 8

OPERATING PROCEDURE continued

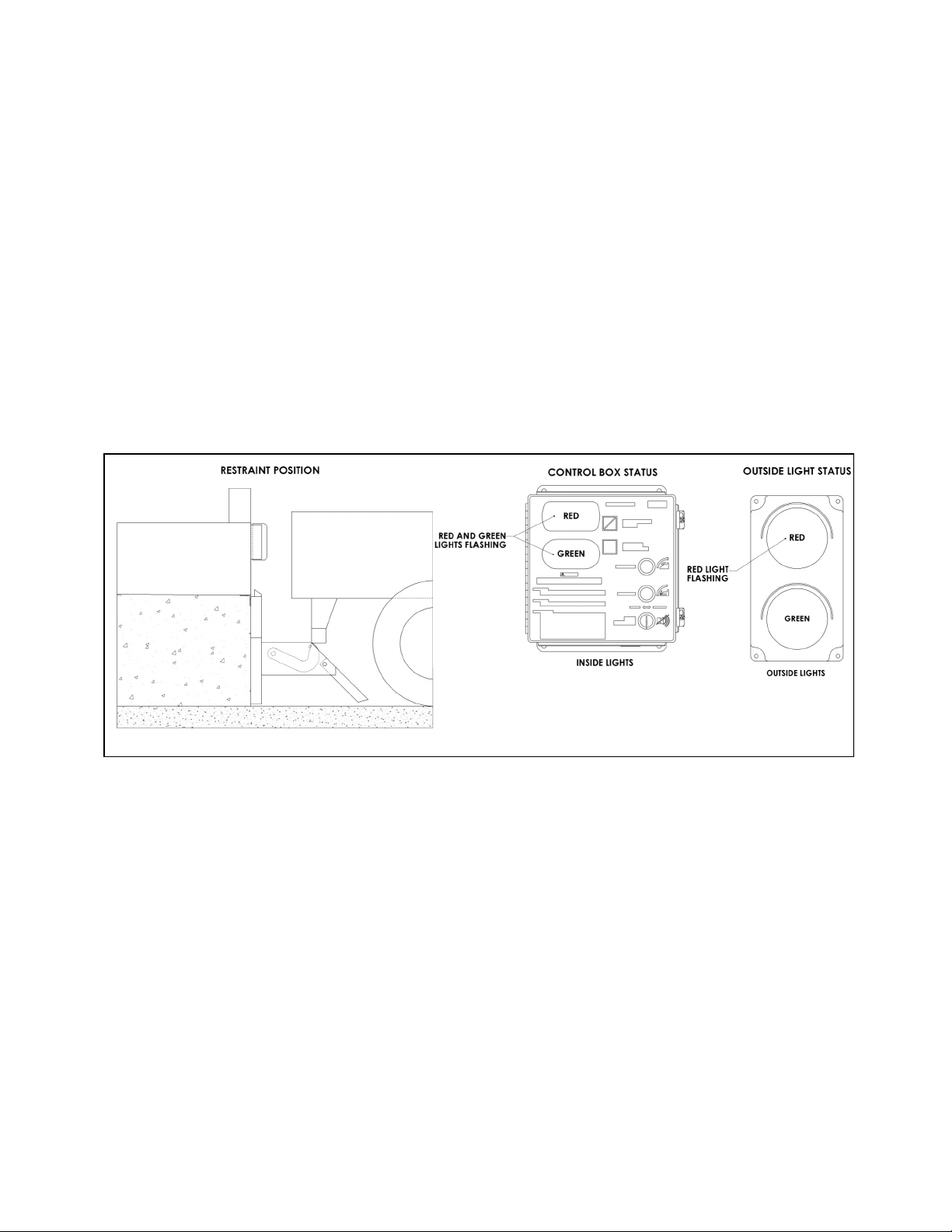

HORN OVER-RIDE State, KEY

SWITCH TURNED TO OVER-RIDE

after Securing Trailer by Alternate

Means

An alternate means of securing the truck must be

used (e.g. wheel chocks) if the hook can not

capture the RIG. Inside lights are flashing red

and green alerting the forklift operator the trailer

is secured by other means. Outside light is

flashing red alerting the truck driver not to move.

See Figure G.

To return to STORED, turn the HORN OVERRIDE key and press the RELEASE button.

FIGURE G—HORN OVER-RIDE STATE

NOVA Lock & LoadTM Owner’s Manual 8

Page 9

ROUTINE MAINTENANCE

When working with electrical or electronic

controls, make sure that the power source

has been locked out and tagged according to

OSHA regulations and approved local

electrical codes.

Post safety warnings and barricade work area, at dock level and at ground level, to prevent unauthorized use of the dock.

Safe operation of the Lock & Load truck

restraint requires all lights and the

horn to be working properly. DO NOT use

Lock & Load vehicle restraint if parts are

broken or missing.

Use lifting device (e.g. crane, jack) when

lifting carriage (approx. 110 lbs.). Lifting by

hand may cause back injury.

Maintenance may be required more

frequently at loading docks exposed to harsh

environments (extreme climates, corrosive

chemicals, frequency of usage, etc.). If these

conditions exist, consult NOVA for

accelerated maintenance requirements.

NOTE: If a leveler is installed at the Lock & Load

vehicle restraint location, it may be necessary to

raise the leveler before performing maintenance.

Raise the leveler, insert and secure the maintenance strut, and LOCKOUT/TAGOUT the power

source.

DANGER

!

WARNING

!

CAUTION

!

IMPORTANT

DAILY

Remove debris around Lock & Load vehicle

Verify that restraint operates smoothly and

Replace damaged or missing light bulbs and

Repair, remount, or replace outside and

Inspect dock bumpers. Missing bumpers must

180 DAYS

Perform all Daily maintenance.

Grease rollers at fittings located on the top

Verify brake torque is greater than 500 in-lbs,

Inspect the outside electrical connections

Check that all concrete anchor bolts are

Perform operational test after all maintenance

Inspect dock bumpers. Four inches (4") of

360 DAYS

Perform all Daily and 180 Day maintenance.

Check and tighten, if necessary, motor drive

Lube chain using chain lube.

Lubricate limit switch mounting bracket

restraint.

inside, outside lights and horn are working.

lenses.

inside signs and labels as required.

be replaced.

and bottom axle with a synthetic oil-base moly grease with a temperature range of

–40° to 170° F.

and less than 700 in-lbs at the hook shaft,

rotating the hook from ENGAGED to

STORED.

(junction box, conduit, power harness) and

outside communication light. Loose or

damaged components must be repaired or

replaced.

torqued to 100 ft-lbs.

repairs and adjustments are complete.

protection is required. Worn, torn, loose or

missing bumpers must be replaced.

chain. To tighten see Figure H, page 10.

between drive sprocket and cam with a

synthetic oil-base moly grease with a

temperature range of –40° to 170° F .

NOVA Lock & LoadTM Owner’s Manual

9

Page 10

ROUTINE MAINTENANCE

DRIVE CHAIN ADJUSTMENT

Inspect the drive chain periodically for dirt and

chain slack. Open the motor enclosure and clean

the chain with solvent. After cleaning, spray with a

high quality chain spray type lubricant.

The drive chain should not have more than 1/4"

slack. Refer to Figure H. To tighten chain:

Open motor enclosure and loosen the four (4)

motor mounting bolts.

Pry the motor assembly forward, in the

slotted holes, until the chain is tight with proper alignment between sprockets.

Hold in this position and tighten the four (4)

motor mounting bolts to 75 in-lbs.

When working with electrical or electronic

controls, make sure that the power source

has been locked out and tagged according to

OSHA regulations and approved local

electrical codes.

DANGER

!

BRAKE TORQUE ADJUSTMENT

(Refer to Figure H.)

Loosen brake adjuster locknut while holding

the adjuster screw to prevent inadvertent

adjustment.

Turn adjuster screw clockwise to increase

brake torque as needed.

Tighten adjuster locknut while holding the

adjuster screw to prevent inadvertent

adjustment.

Verify brake torque is in the range of 500 to

700 in-lbs at the hook shaft; readjust as required.

10

FIGURE H—MAINTENANCE AND LUBRICATION

NOVA Lock & LoadTM Owner’s Manual

Page 11

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE RESOLUTION

Lock & Load vehicle restraint

lights do not flash and the

hook does not raise.

Lock & Load vehicle restraint

lights are flashing, but the

hook does not raise or lower to

full extent.

Lock & Load vehicle restraint

is operational, but hook drops

causing lights to change and/

or horn to sound while trailer is

being serviced.

Lock & Load vehicle restraint

is operational but all lights are

out.

Power source malfunction.

Incorrect wiring.

Chain is loose or broken.

Low incoming voltage.

Drive motor defective.

Incorrect wiring.

Verify brake torque.

Drive motor defective

Bulbs burnt out, loose or missing.

Incorrect wiring.

Check power source, including facility

circuit breaker and 1A fuse. and

circuit breaker on power module.

Verify wiring per Electrical Schematic,

Figure K page 14.

Adjust or replace as required.

Verify incoming voltage at L1 and L2

is a minimum of 110V. Do not power

off a control transformer from other

equipment unless properly sized for

load.

Check motor. Repair or replace as

needed.

Verify wiring per Electrical Schematic,

Figure K page 14.

If brake torque is less than 500 in lb or

chain is loose or broken, adjust or

replace as required.

Check motor. Repair or replace as

needed.

Check all bulbs and replace as re-

quired.

Verify wiring per Electrical Schematic,

Figure K page 14.

Lock & Load vehicle restraint

horn does not sound but hook

and lights are operational.

Lock & Load vehicle restraint

hook is in stored position with

an inside green light.

Lock & Load vehicle restraint

carriage does not return to a

full up position

Horn is defective.

Incorrect wiring.

Power horn using 12V DC power. If

horn does not sound, replace as required.

Verify wiring per Electrical Schematic,

Figure K page 14.

Incorrect wiring. Verify wiring of SW1 and SW2 at the

control box and outside junction box.

Carriage binding in track.

Damaged roller track plate.

Broken or weak springs.

Check to see if roller track plate is

clean and rollers are clean, full of debris and lubricated. Use only approved grease to lubricate rollers.

Verify that the roller track plate is

straight and not damaged.

Remove spring cover and replace as

required

NOVA Lock & LoadTM Owner’s Manual

11

Page 12

TROUBLESHOOTING CONTINUED

LIMIT SWITCH TEST PROCEDURE

Set multimeter to “RX1” scale for “Continuity

Test”.

Attach multimeter leads to pins “B” and “C” of

limit switch connector. You should have:

- plunger released - no meter reading.

- plunger depressed - a “Full Scale” meter

reading.

NOTE: The green (ground) wire of the limit switch

does not have to be tested. A continuity test lamp

may be used instead of a multimeter.

FIGURE I—LIMIT SWITCH AND HOOK POSITION CHART

12

NOVA Lock & LoadTM Owner’s Manual

Page 13

CONTROL HARNESS

NOVA Lock & LoadTM Owner’s Manual

FIGURE J—CONTROL HARNESS

13

Page 14

ELECTRICAL SCHEMATIC

WIRING PROVIDED BY OTHERS

WIRING PROVIDED BY NOVA TECHNOLOGY

14

LOCK MOTOR

1/10 HP

3.5 FLA

MOTOR HAS AUTOMATIC

THERMAL OVERLOAD

FIGURE K—ELECTRICAL SCHEMATIC

NOVA Lock & LoadTM Owner’s Manual

Page 15

OUTSIDE LIGHT BOX WIRING

FIGURE L—OUTSIDE LIGHT BOX WIRING

NOVA Lock & LoadTM Owner’s Manual

15

Page 16

CARRIAGE ASSEMBLY DRAWING

PARTS

FIGURE M —CARRIAGE ASSEMBLY

CARRIAGE ASSEMBLY PARTS LIST

ITEM NO. PART NUMBER DESCRIPTION

1 MF2-015-000 3/8"-16 X 1 1/2" HH CAP SCREW

2 MF2-061-000 SNAP RING

3 MF2-047-000 ROLLER ASSEMBLY

4 MF2-034-000 3/4" CONDUIT NIPPLE

5 MF2-038-000 LIMIT SWITCH, LS1

6 MF2-039-000 LIMIT SWITCH, LS2

7 MF2-094-000 CAM DECAL

8 MF2-028-000 CAM

9 MF2-024-000 LIMIT SWITCH MOUNTING PLATE

10 MF2-042-000 CHAIN COVER

QTY.

2

1

4

1

1

1

1

1

1

1

16

NOVA Lock & LoadTM Owner’s Manual

Page 17

PARTS continued

CARRIAGE ASSEMBLY PARTS LIST continued

ITEM NO. PART NUMBER DESCRIPTION QTY.

11 MF2-026-000 7/16”-14 SERRATED FLANGE LOCK NUT 2

12 MF2-016-000 3/8"-16 SERRATED FLANGE WHIZ NUT 8

13 MF2-041-000 1/4"-20 X 1 1/2" SOCKET HEAD CAP SCREW 2

14 MF2-018-000 1 3/4" OD, 1 1/4" ID, 1/8" THK, MACHINERY BUSHING 2

15 MF2-040-000 1/4" LOCK WASHER 2

16 MF2-095-000 NO STEP DECAL 1

17 MF2-021-000 1/4" X 1/4" X 1 1/4" HOOK KEY 1

18 MF2-023-000 1/4" X 1/4" X 1" KEY, SPROCKET & CAM 2

19 MF2-020-000 HOOK SHAFT 1

20 MF2-037-000 3/4" CONDUIT LOCK NUT 2

21 MF2-022-000 HOOK DRIVE SPROCKET W/SET SCREW 1

22 MF2-019-000 5/16"-18 X 1/2" SK SET SCREW 1

23 MF2-014-000 3/8"-16 X 1" CARRIAGE BOLT 6

24 MF2-117-000 5/16”-18 X 5/8” FLANGE HEAD SCREW 4

25 MF2-033-000 CORD GRIP 1

26 MF2-003-000 STRAIGHT HOOK 1

27 MF2-004-000 CARRIAGE WELDMENT 1

28 MF2-005-000 WIRE HARNESS 1

29 MF2-017-000 LOCK & LOAD BEARING ASSEMBLY 2

30 MF2-017-002 SET SCREW 4

31 MF2-064-000 "LOCK & LOAD" HORIZONTAL DECAL 1

32 MF2-066-000 5/16"-18 X 5/8" SET SCREW 1

33 MF2-068-000 SERIAL NUMBER DECAL 1

34 MF2-080-000 "LOCK & LOAD" LARGE HORIZONTAL DECAL 1

35 MF2-107-000 CHAIN 1

36 MF2-110-000 MF2 MOTOR ASSEMBLY 1

37 MF2-027-000 7/16-14 NYLOCK NUT 1

38 MF2-013-000 GREASE FITTING 2

NOVA Lock & LoadTM Owner’s Manual

17

Page 18

PARTS continued

ROLLER TRACK ASSEMBLY DRAWING and PARTS LIST

FIGURE N—ROLLER TRACK ASSEMBLY

ITEM NO. PART NUMBER DESCRIPTION QTY.

1 MF2-052-000 SPRING COVER RIGHT HAND 1

2 MF2-048-000 ROLLER TRACK 1

3 MF2-049-000 5/16"-18 CAGE NUT 4

4 MF2-050-000 EXTENSION SPRING 4

5 MF2-054-000 5/8" X 4" CONCRETE ANCHOR 15

6 MF2-051-000 LEFT SPRING COVER 1

7 MF2-060-000 5/16"-18 X 1 1/4" FLAT HEAD SOCKET SCREW 4

18

NOVA Lock & LoadTM Owner’s Manual

Page 19

PARTS continued

SLOPE EXTENSION DRAWING AND PARTS LIST

FIGURE O—SLOPE EXTENSION ASSEMBLY

ITEM NO. PART NUMBER DESCRIPTION QTY.

1 MF2-045-000 1" X 18 GAUGE FLAT WASHER 2

2 MF2-046-000 COTTER PIN 1

3 MF2-044-000 SLOPE EXTENSION PIVOT PIN 1

4 MF2-043-000 SPRING MOUNTING PLATE ASSEMBLY 1

5 MF2-026-000 7/16"-14 SERRATED FLANGE LOCK NUT 2

6 MF2-002-000 SLOPE EXTENSION 1

7 MF2-007-000 LOCK & LOAD CARRIAGE ASSEMBLY 1

8 MF2-132-000 ROLLER SLOPE EXTENSION 1

9 MF2-143-000 5/8” X 3” CLEVIS PIN 1

10 MF2-142-000 COTTER PIN 1

11 MF2-130-000 5/8” SAE FLAT WASHER 1

12 MF2-136-000 ROLLER ASSEMBLY 1

NOVA Lock & LoadTM Owner’s Manual

19

Page 20

ELECTRICAL PARTS

PARTS continued

20

FIGURE P —ELECTRICAL PARTS

NOVA Lock & LoadTM Owner’s Manual

Page 21

PARTS continued

ELECTRICAL REPLACEMENT PARTS LIST

ITEM NO. PART NUMBER DESCRIPTION

1 MF2-082-000 TIMER

2 MF2-083-000 FLASHER

3 MF2-084-000 TRANSFORMER

4 MF2-085-001 RED RECTANGULAR LENS

5 MF2-085-002 RECTANGLE BASE

6 MF2-085-003 RED LED WEDGE

7 MF2-086-001 GREEN OVAL LENS

8 MF2-086-002 OVAL BASE

9 MF2-086-003 GREEN LED WEDGE

10 MF2-087-000 OUTSIDE RED LED LIGHT MODULE

11 MF2-088-000 OUTSIDE GREEN LED LIGHT MODULE

12 MF2-089-001 GREEN PUSH BUTTON

13 MF2-089-002 NO CONTACT

14 MF2-089-003 CONTACT BASE

15 MF2-090-001 YELLOW PUSH BUTTON

16 MF2-091-001 KEY SWITCH

17 MF2-091-002 NC CONTACT

18 MF2-091-003 NO CONTACT

19 MF2-091-004 CONTACT BASE

20 MF2-092-000 KEY

21 MF2-156-000 FUSE

22 MF2-157-000 FUSE

23 MF2-158-000 FUSE

QTY.

1

1

1

1

1

2

1

1

2

1

1

1

2

2

1

1

1

1

1

1

1

1

1

NOVA Lock & LoadTM Owner’s Manual

21

Page 22

MISCELLANEOUS PARTS

PARTS continued

FIGURE Q —MISCELLANEOUS PARTS

MISCELLANEOUS REPLACEMENT PARTS LIST

ITEM NO. PART NUMBER DESCRIPTION QTY.

1 MF2-011-000 CONTROL BOX 1

2 MF2-012-000 OWNERS MANUAL 1

3 MF2-057-000 CAUTION SIGN 1

4 MF2-056-000 STOP ON RED SIGN 1

5 MF2-055-000 OUTSIDE TRUCK LIGHT ASSEMBLY 1

6 MF2-093-000 INSTALLATION MANUAL 1

22

NOVA Lock & LoadTM Owner’s Manual

Page 23

WARRANTY

NOVA STANDARD PRODUCT WARRANTY

Nova Technology International, LLC (“Nova”) warrants that its products will be free from defects in

design, materials and workmanship for a period of one (1) year from the date of shipment. All claims for

breach of this warranty must be made within 30 days after the defect is or can with reasonable care, be

detected. In no event shall any claim be made more than 30 days after this warranty has expired. In

order to be entitled to the benefits of this warranty, the product must have been properly installed,

maintained and operated in accordance with all manufacturer’s recommendations and/or specified

design parameters and not otherwise have been subject to abuse, misuse, misapplication, acts of

nature, overloading, unauthorized repair or modification, application in a corrosive environment or lack of

maintenance. Periodic lubrication, adjustment and inspection in accordance with all manufacturers’

recommendations are the sole responsibility of the Owner/User.

In the event of a defect, as determined by Nova, covered by this warranty, Nova shall remedy such

defect by repairing or replacing any defective equipment or parts, bearing the cost for the parts, labor

and transportation. This shall be exclusive remedy for all claims whether based on contract, negligence

or strict liability.

PRODUCT SPECIFIC WARRANTY

Lock & Load Vehicle Restraint

In addition to the “Standard Product Warranty” provided with all Nova Products, Nova guarantees

materials, components and workmanship to be free of defects for the following extended periods:

Extended 2-year General Warranty– For a period of two (2) years from date of shipment, this

warranty specifically applies to: the roller track assembly, carriage assembly, and control box only.

Extended 5-year Structural Warranty – For a period of five (5) years from the date of shipment,

product will carry a prorated structural warranty. This warranty specifically applies to: the roller

track, carriage weldment, chain cover, straight hook, and lower spring bar only.

NOT COVERED UNDER WARRANTY

Routine maintenance, lubrication, adjustments, including initial field set-up.

Repairs required as a result of failure to follow routine maintenance procedures specified in the

owner’s manual, abuse, accident, willful damage, neglect, improper installation, submersion, or

shipping damage.

WARRANTY LIMITATIONS

The above warranties are in lieu of any other warranties, whether expressed or implied, including but not

limited to and implied warranty of merchantability for a particular purpose. Nova and its subsidiaries

shall not in any event be liable to anyone, including third parties, for incidental, consequential or special

damages of any kind including but not limited to, breach of warranty, loss of use, loss of profit,

interruption of business or loss of goodwill.

NOVA Lock & LoadTM Owner’s Manual

23

Page 24

N90W14507 Commerce Drive Menomonee Falls, WI 53051

Phone 262-502-1591 | 800-236-7325 | fax 262-502-1511

www.novalocks.com

© 2011 Nova Technology International, LLC

Loading...

Loading...