Page 1

Model #

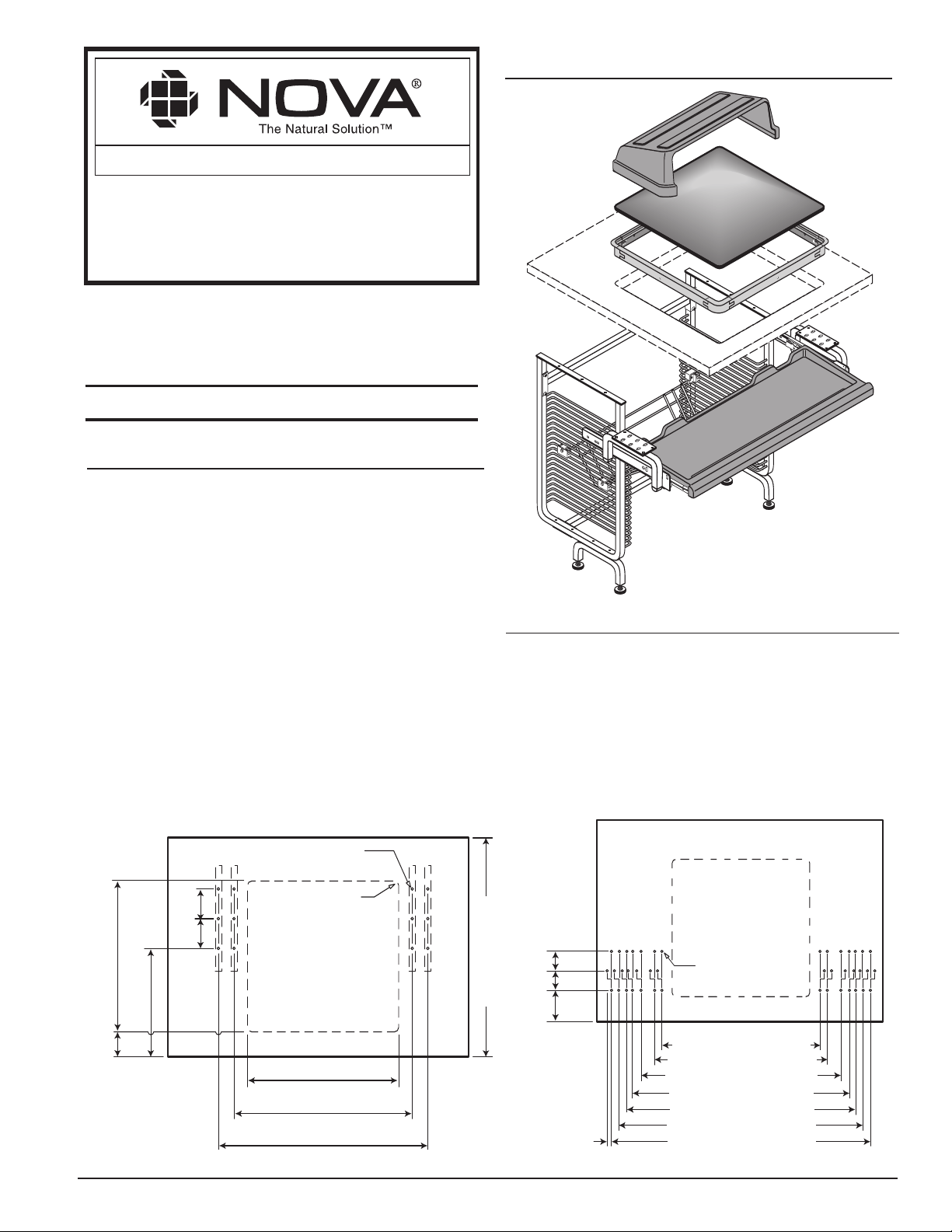

ASSEMBLED VIEW

Step 1

50-0-1818

If the worksurface is prepared for Retrofit Kit & Keyboard

Drawer Installation, skip to Step 3. Otherwise, please prepare your

worksurface to the specifications shown in Figure 1a for Viewport &

Side Assembly milling/drilling. If using a 24" Adjustable Keyboard

Drawer, please use separate hole pattern shown below.

The retrofit kit can be installed in almost any work surface. The kit is

designed to attach to a work surface that is 1-1/8" to 2" in thickness.

Thinner work surfaces may require some build-up of material for

proper installation. Glass work surfaces are not recommended. If

your countertop is a solid material such as natural granite or

marble or a fabricated solid surface such as Corian, you should use

a professional fabricator to create the opening and surface

mounting anchors required for your kit. Forward a copy of the

boring pattern and hole size cut out to a professional fabricator.

Step 2

FIGURE 1a

FIGURE 1b

Keyboard Drawer holes (as shown in Figure 1b) should be drilled

for the specific keyboard size. Care must be exercised to use the

specifications in Figure 1b regarding drill size and hole depth.

To offset the viewport and keyboard drawer, please call

Customer Support at 1-800-730-6682 for special instructions.

18-1/4"(464mm)

FRONT EDGE

14-

3

/

4

" min

.

(375

mm

)

1

/2"(12.7mm) R.

4 Places

25-

1

/16"(637mm)

21-1/4"(540mm)

UNDERSIDE OF TOP

3

/16"

Dia

.

5

/8"

Deep

6 Places

3-

9

/

16

"

(90

mm

)

3-

9

/

16

"

(90

mm

)

18-

1

/

4

"

(464)

mm

3"

(76

mm

)

Page 1

IIR002

50-0-1818 Asy. Instr. - Rev. 07/21/04, © Nova Solutions, Inc. 2002

Retrofit Kit

Assembly Instructions

P.O. Box 725 • 421 W. Industrial Avenue • Effingham, Illinois 62401 • Phone: (800) 730-6682 • Fax: (800) 940-6682 • E-mail: info@novasolutionsinc.com • Website: http://www.novasolutionsinc.com

The Natural Way to Look at a Computer™

-22, -24, -27, -28, -30, -33, -34

Min. 25-

1

/

2

" (648

mm

)

FRONT EDGE

2

1

/

2

"

(64

mm

)

2

1

/

2

"

(64

mm

)

4

"

(102

mm

)

1-1/4"(

Offset

32mm)

(Typ.)

3

/16" Dia.

5

/8" Deep

6 Places

321/8"(816mm)

34" Keyboard

311/4"(794mm)

33" Keyboard

281/16"(713mm)

30" Keyboard

261/8"(664mm)

28" Keyboard

255/16"(643mm)

27" Keyboard

2219/32"(574mm)

24" Keyboard

1813/16"(478mm)

22" Keyboard

for all other keyboards

for 24" Adjustable Keyboard Drawer

Page 2

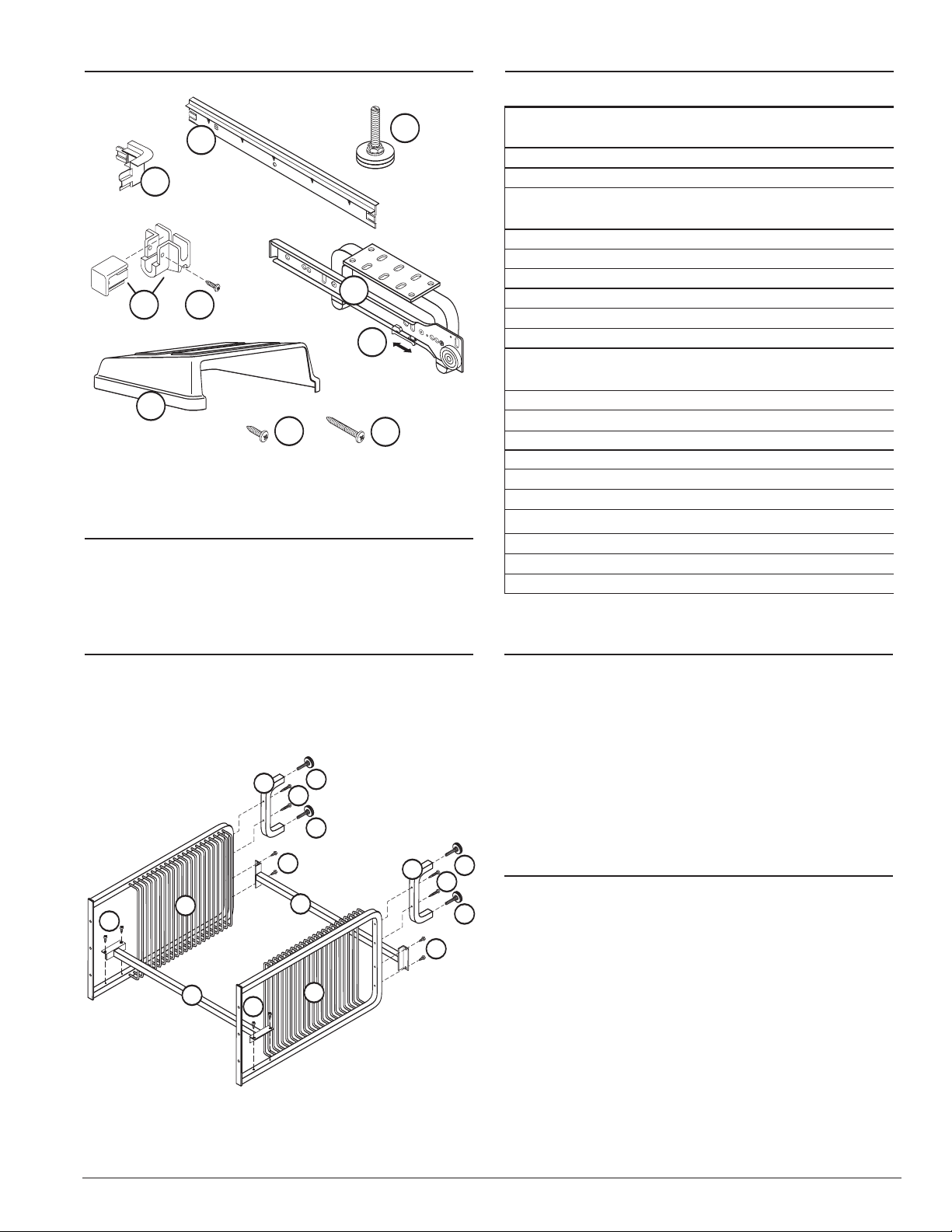

Review and identify Retrofit Kit parts listed above.

HARDWARE PACKING LIST

Ref. # Item # Qty. Description

1 20060126 1 Keyboard hanger with glide

– Left

2 20060105 2 Side Assembly

3 20060101 2 Cross Brace

4 20060127 1 Keyboard hanger with glide

– Right

5

Varies with Retrofit 1 Keyboard Drawer

6 10060127 1 Monitor Support

7 5081070 1 Viewport Glass

8 50900258 4 Leveler

9 1412APPBO 18 Screw - #14x3/4"

10 50900032 6 Screw - #14x1-1/2"

11 TB-M 4 Tracking Block

TB-F 4 Tracking Block

12 6N50TXPZ 8 Screw - Security, #6x5/8"

13 5011818 2 Leg

14 50900034 4 Trim Ring Corner

15 50900035 4 Trim Ring Straight - B

16 5081060 1 Visor

17 FR2020/Clip 2 Locking Tab

OPTIONS

5081120 1 Power Strip

5081066 1 CPU Holder

5081018 1 Anti-Reflective Glass

Step 3

Attach Cross Braces (Ref. #3) to Side Assemblies (Ref. #2) using

eight (8) Screws (Ref. #9). See Figure 2.

Step 4

If you are not using optional floor support legs (Ref. #13),

skip to Step #7. Otherwise, attach Leg (Ref. #13) to Side

Assembly (Ref. #2) using two (2) Screws (Ref. #10). Repeat

procedure for other side. Insert Levelers (Ref. #8) into

bottom of Leg (Ref. #13). Repeat procedure for other side.

See Figure 2.

Step 5

Step 6

9

10

12

8

11

14

15

16

FIGURE 2

10

13

8

8

13

8

8

3

9

9

9

9

2

2

3

10

Page 2

Turn Retrofit Assembly upright. Slide under viewport cutout

in worksurface. Align holes in top rails of Side Assemblies

(Ref. #2) with holes in worksurface. Attach Retrofit Assembly

to the worksurface securely using six (6) Screws (Ref. #9).

Optional: Adjust Levelers (Ref. #8).

50-0-1818 Asy. Instr., © Nova Solutions, Inc. 2002

17

4

Page 3

4

9

10

FIGURE 3

As shown in Figure 3, attach Left Keyboard Hanger securely

to t

he underside of the worksurface using three (3) Screws

(Ref. #9) and one (1) Screw (Ref. #10). Repeat procedure for

other side.

IMPORTANT: The longer of the screws (Ref. #10) passes

through the tubular section of the Keyboard Hanger allowing

the assembly to be leveled by either tightening or loosening

the screw. Adjusting the screws allows you to fine-tune the

action of the keyboard drawer.

Install Trim Ring by snapping pieces together (Ref. #14 and

#15), lowering into cutout, and attaching with four (4) screws

(Ref. #12).

Step 9

Adjusting Your Monitor: The Monitor Support adjusts three

ways — height (up/down), angle, and forward/backward.

Adjust it so that you have a comfortable viewing angle of the

monitor when you're in a normal working position. Push

Outward Locking Tabs back to unlock keyboard drawer. See

Figure 4. Remove the keyboard drawer and the glass. Lower

the monitor through the viewport opening while allowing the

wires to feed through the back of the monitor support. If the

monitor is too heavy, make sure you get assistance.

Step 10.1

EXPLODED VIEW

Page 3

9

10

Step 7

Outward

Locking

Tab

FIGURE 4

8

8

13

10

8

8

13

3

9

12

11

2

6

2

5

9

9

9

3

10

9

10

4

50-0-1818 Asy. Instr., © Nova Solutions, Inc. 2002

After installing the Keyboard Drawer, pull Outward Locking

T

ab forward to lock in place. See Figure 4.

Step 8

1

1

Angle Forward-Backward Up-Down

Page 4

1. Install monitor as high as possible without raising glass.

2. Screen should point slightly above user's face (bottom edge of

monitor is nearer to the eye than top edge).

3. Preferred position: top edge of monitor is at back edge of glass.

Determine the modification necessary to accomplish the

preferred viewing angle. To make angle adjustments, move

either the top or the bottom Tracking Block assemblies

independently of each other. For standard-size monitors, a good

starting point is 4 spaces up in front and 5 spaces up in back.

Monitor Adjustment

Maximum Monitor Dimensions:

17-1/2"D x 17"W x 18"H

Downward Gaze™ Monitor Installation

Step 10.2

Once the angle is adjusted, adjust the height by raising or

lowering both upper and lower Tracking Block assemblies the

same number of spaces.

Step 10.3

After you achieve the desired height and angle, you can fine

tune the viewing distance by sliding the carriage forward and

backward. Each time you make an adjustment, reinsert the Male

Tracking Blocks. When the adjustment is completed, install the

Security Screws. The bottom of the screen should always be

closer to your eyes than the top.

Step 10.4

Page 4

Too Low!

...Monitor is located too

far below glass so that

view is obstructed.

Wrong Angle!

...Top of monitor is closer

to the eye than the

bottom of the monitor.

PATENT INFORMATION: Nova products are covered by one or more of the following U.S. patents: Re. 34,266; 4,869,564; 5,125,727; 5,290,099; 5,294,193 & 5,408,939.

Other U.S. and foreign patents issued and pending.

Correct Installation

Incorrect Installation

50-0-1818 Asy. Instr. © Nova Solutions, Inc. 2002

K

eyboard drawer from

edge of top

79/16"(1st Stop)

10"(Last Stop)

3-5/8"

5-1/2" to

7-

5

/8"

22-7/8"

19-5/8"

12-11/16" 12-13/16"

14"

25-1/2"

LOWER

TRACKING

BL

OCK

UPP

ER

TRACKING

BLOCK

TR

ACKING

BL

OCK-F

SECURITY

SCREW

TRACKING

BLOCK-M

LOWER

TRACKING

BLOCK

UPPER

TRACKING

BLOCK

Loading...

Loading...