Page 1

Application Note 86

January 2001

A Standards Lab Grade 20-Bit DAC with 0.1ppm/°C Drift

The Dedicated Art of Digitizing One Part Per Million

Jim Williams

J. Brubaker

P. Copley

J. Guerrero

F. Oprescu

INTRODUCTION

Significant progress in high precision, instrumentation

grade D-to-A conversion has recently occurred. Ten years

ago 12-bit D-to-A converters (DACs) were considered

premium devices. Today, 16-bit DACs are available and

increasingly common in system design. These are true

precision devices with less than 1LSB linearity error and

1ppm/°C drift.1 Nonetheless, there are DAC applications

that require even higher performance. Automatic test

equipment, instruments, calibration apparatus, laser trimmers, medical electronics and other applications often

require DAC accuracy beyond 16 bits. 18-bit DACs have

been produced in circuit assembly form, although they are

expensive and require frequent calibration. 20 and even

23+ (0.1ppm!) bit DACs are represented by manually

switched Kelvin-Varley dividers. These devices, although

amazingly accurate, are large, slow and extremely costly.

Their use is normally restricted to standards labs.2 A

useful development would be a practical, 20-bit (1ppm)

DAC that is easily constructed and does not require

frequent calibration.

20-Bit DAC Architecture

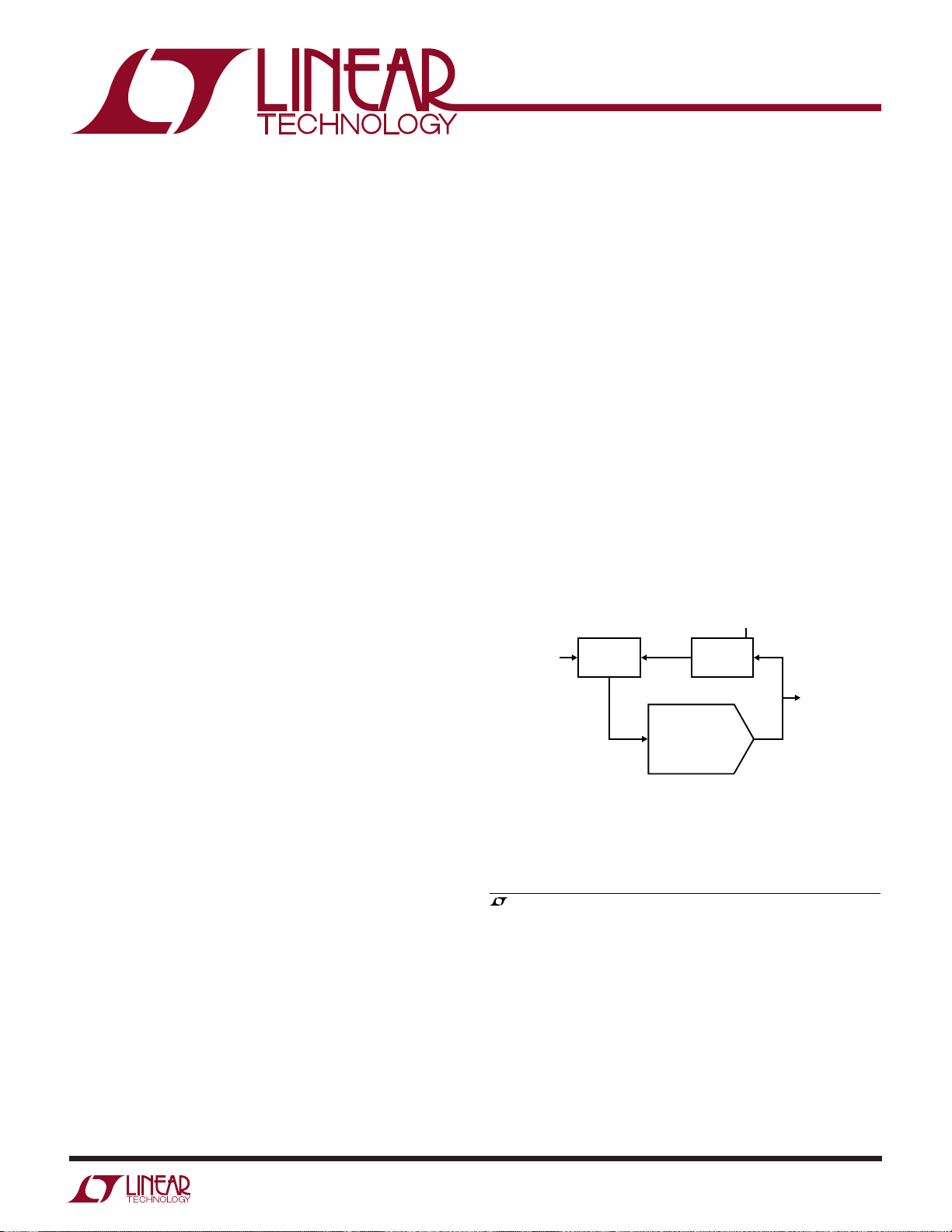

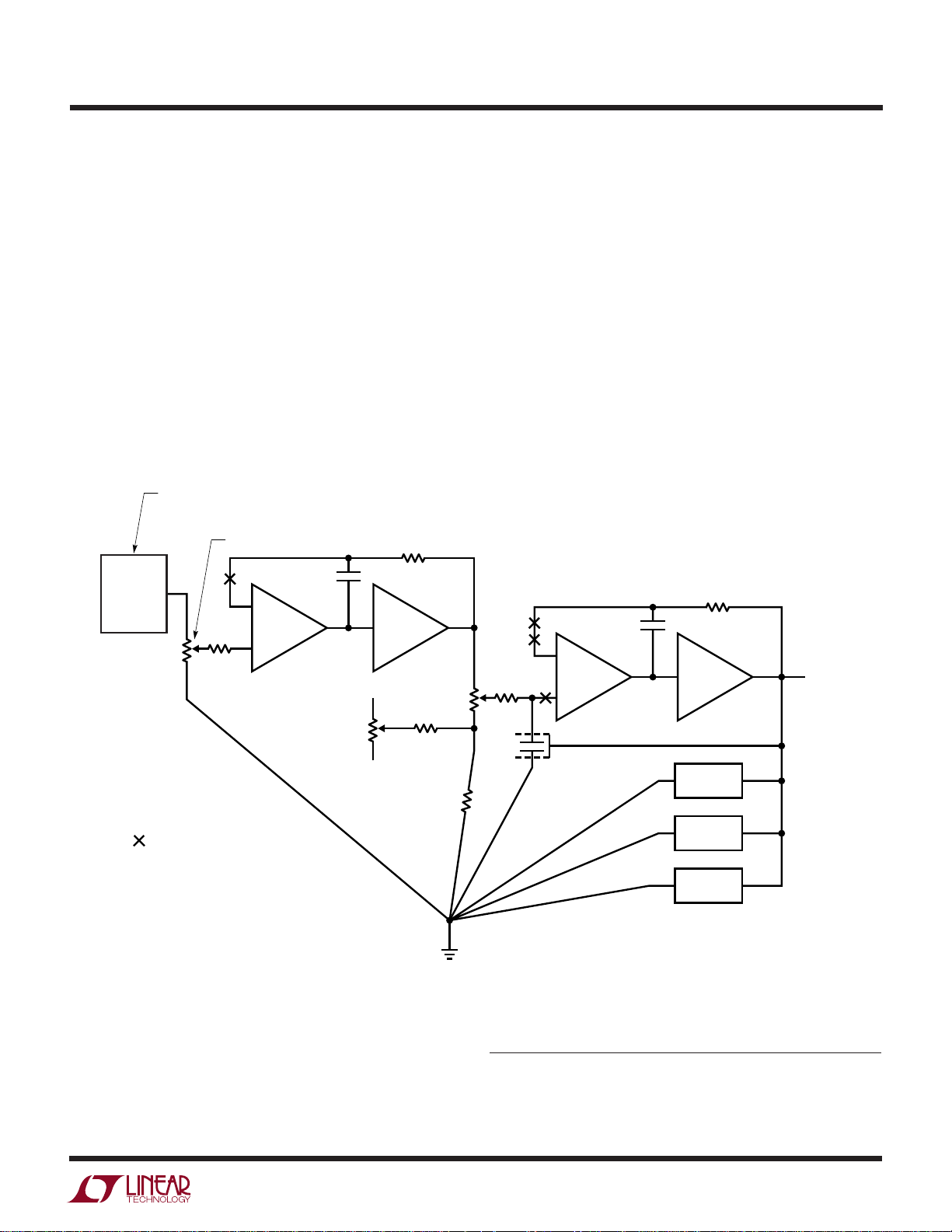

Figure 1 diagrams the architecture of a 20-bit (1ppm) DAC.

This scheme is based on the availability of a true 1ppm

analog-to-digital converter with scale and zero drifts below 0.02ppm/°C. This device, the LTC®2400, is used as a

feedback element in a digitally corrected loop to realize a

20-bit DAC.

3

In practice, the “slave” 20-bit DAC’s output is monitored

by the “master” LTC2400 A-to-D, which feeds digital

information to a code comparator. The code comparator

differences the user input word with the LTC2400 output,

presenting a corrected code to the slave DAC. In this

fashion, the slave DAC’s drifts and nonlinearity are continuously corrected by the loop to an accuracy determined

by the A-to-D converter and V

4

. The sole DAC require-

REF

ment is that it be monotonic. No other components in the

loop need to be stable.

V

REF

20-BIT

USER

INPUT

CODE

COMPARATOR

CORRECTED

CODE

DIGITAL

CODE

Figure 1. Conceptual Loop-Based 20-Bit DAC. Digital

Comparison Allows A-to-D to Correct DAC Errors. LTC2400

A-to-D’s Low Uncertainty Characteristics Permit 1ppm

Output Accuracy

, LTC and LT are registered trademarks of Linear Technology Corporation.

Note 1: See Appendix A, “A History of High Accuracy Digital-to-Analog

Conversion,” for a review of high accuracy digital-to-analog conversion.

Note 2: Consult Appendix C, “Verifying Data Converter Linearity to

1ppm,” for discussion on Kelvin-Varley dividers. Also, see Appendix A,

“A History of High Accuracy Digital-to-Analog Conversion.”

Note 3: The LTC2400 analog-to-digital converter is profiled in

Appendix␣ B, “The LTC2400—A Monolithic 24-Bit Analog-to-Digital

Converter.”

Note 4: D-to-A converters have been placed in loops to make A-to-D

converters for a long time. Here, an A-to-D converter feeds back a loop

to form a D-to-A converter. There seems a certain justified symmetry

to this development. Turnabout is indeed fair play.

FEEDBACK

CODE

20-BIT

“SLAVE”

DAC

LTC2400

“MASTER”

A-TO-D

V

IN

20-BIT

(1PPM)

ANALOG

OUTPUT

V

OUT

AN86 F01

AN86-1

Page 2

Application Note 86

This loop has a number of desireable attributes. As mentioned, accuracy limitations are set by the A-to-D converter and its reference. No other components need be

stable. Additionally, loop behavior averages low order bit

indexing and jitter, obviating the loop’s inherent smallsignal instability. Finally, classical remote sensing may be

used or digitally based sensing is possible by placing the

A-to-D converter at the load. The A-to-D’s SO-8 package

and lack of external components makes this digitally

incarnated Kelvin sensing scheme practical.

5

Circuitry Details

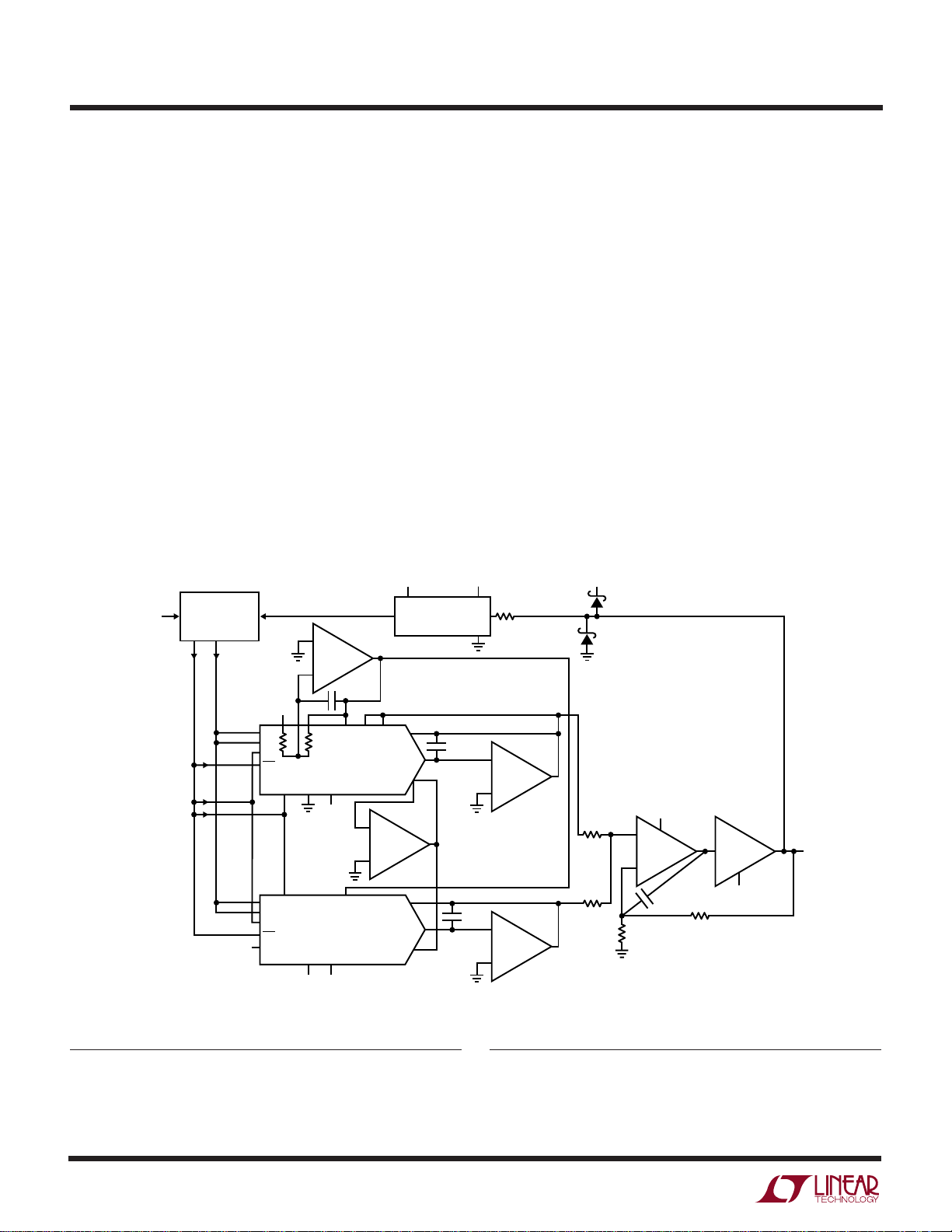

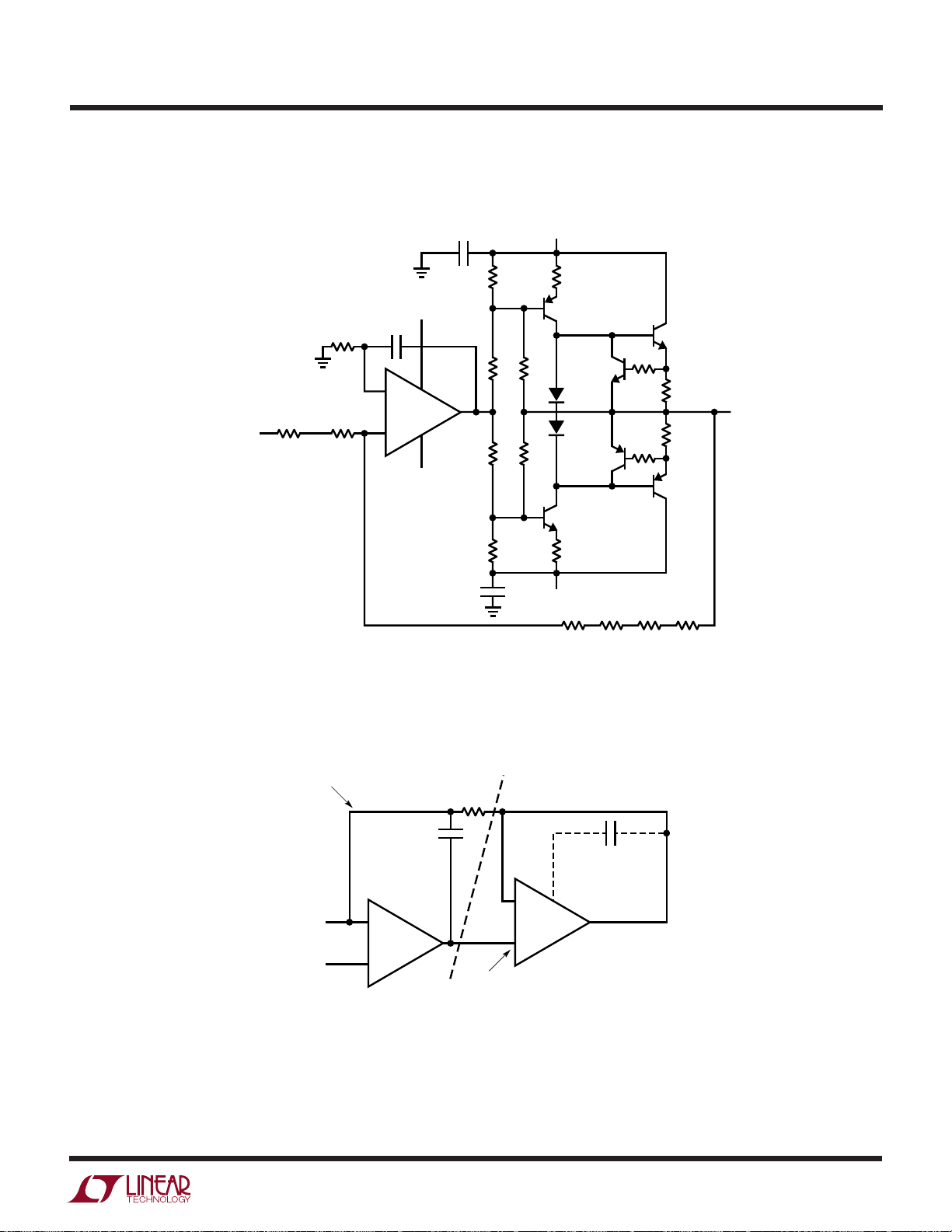

Figure 2 is a detailed schematic of the 1ppm DAC. The

slave DAC is comprised of two DACs. The upper 16 bits of

the code comparator’s output are fed to a 16-bit DAC

(“MSB DAC”), while the lower bits are converted by a

separate DAC (“LSB DAC”). Although a total of 32 bits are

presented to the two DACs, there are 8 bits of overlap,

assuring loop capture under all conditions. The composite

20-BIT

USER

INPUT

CODE

COMMAND

INPUTS FROM

CODE COMPARATOR

CODE

COMPARATOR

(SEE APPENDIX D

FOR DETAILS)

CORRECTED

CODE OUT—

24-BIT WORD

+

LT1001

–

A4

24-BIT

FEEDBACK

CODE

5V 5V

SERIAL

DIGITAL

OUT

LTC2400

A-TO-D

5V

DACs’ resultant 24-bit resolution provides 4 bits of indexing range below the 20th bit, ensuring a stable LSB of

1ppm of scale. A1 and A2 transform the DAC’s output

currents into voltages, which are summed at A3. A3’s

scaling is arranged so that the correction loop can always

capture and correct any combination of zero- and fullscale errors. A3’s output, the circuit output, feeds the

LTC2400 A-to-D. The LT®1010 provides buffering to drive

loads and cables. The A-to-D’s digital output is differenced

against the input word by the code comparator, which

produces a corrected code. This corrected code is applied

to the MSB and LSB DACs, closing a feedback loop.6 The

loop’s integrity is determined by A-to-D converter and

voltage reference errors.7 The resistor and diodes at the

5V powered A-to-D protect it from inadvertent A3 outputs

(power up, transient, lost supply, etc.). A4 is a reference

inverter and A5 provides a clean ground potential to both

DACs.

(SEE APPENDIX I

REF

FOR OPTIONS)

REF

IN

CS

1k

1N5817

1N5817

100pF

5V

LD

WR

ML

BYTE

REF

R

R

LTC1599

CLVL CLR

5V

REF R

OSRFS

–

A5

LT1001

FB

I

OUT

–

I

* = 1% METAL FILM

DATA

INPUTS

+

DATA

INPUTS

BYTE

LD

WR

5V

CLVL

LTC1599

ROSCLR

V

REF

REFML

5V

R

FB

I

OUT

–

I

Figure 2. Detail of 1ppm DAC. Composite DAC Is Comprised of Two DAC Values Summed

at Output Amplifier. LTC2400 A-to-D and Code Comparator Furnish Stabilizing Feedback

Note 5: One wonders what Lord Kelvin’s response would be to the

digizatation of his progeny. Such uncertainties are the residue of progress.

Note 6: The code comparator is detailed in Appendix D, “A Processor

Based Code Comparator.”

MSB DAC

100pF

–

A1

LT1001

+

2k*

+

LT1001

15V

A3

OUTPUT

AMPLIFIER

LT1010

–

LSB DAC

100pF

–

LT1001

4.12M*

A2

0.1µF

4.12M*

–15V

2k*

+

Note 7: Voltage reference options are discussed in Appendix I,

“Voltage References.” For tutorial on the LTC2400, refer to

Appendix␣ B.

OUTPUT

AN86 F02

AN86-2

Page 3

Application Note 86

Linearity Considerations

A-to-D linearity determines overall DAC linearity. The

A-to-D has about ±2ppm nonlinearity. In applications

where this error is permissible, it may be ignored. If 1ppm

linearity is required, it is obtainable by correcting the

residual linearity error with software techniques. Details

on LTC2400 linearity and this feature are presented in

Appendices D and E.

DC Performance Characteristics

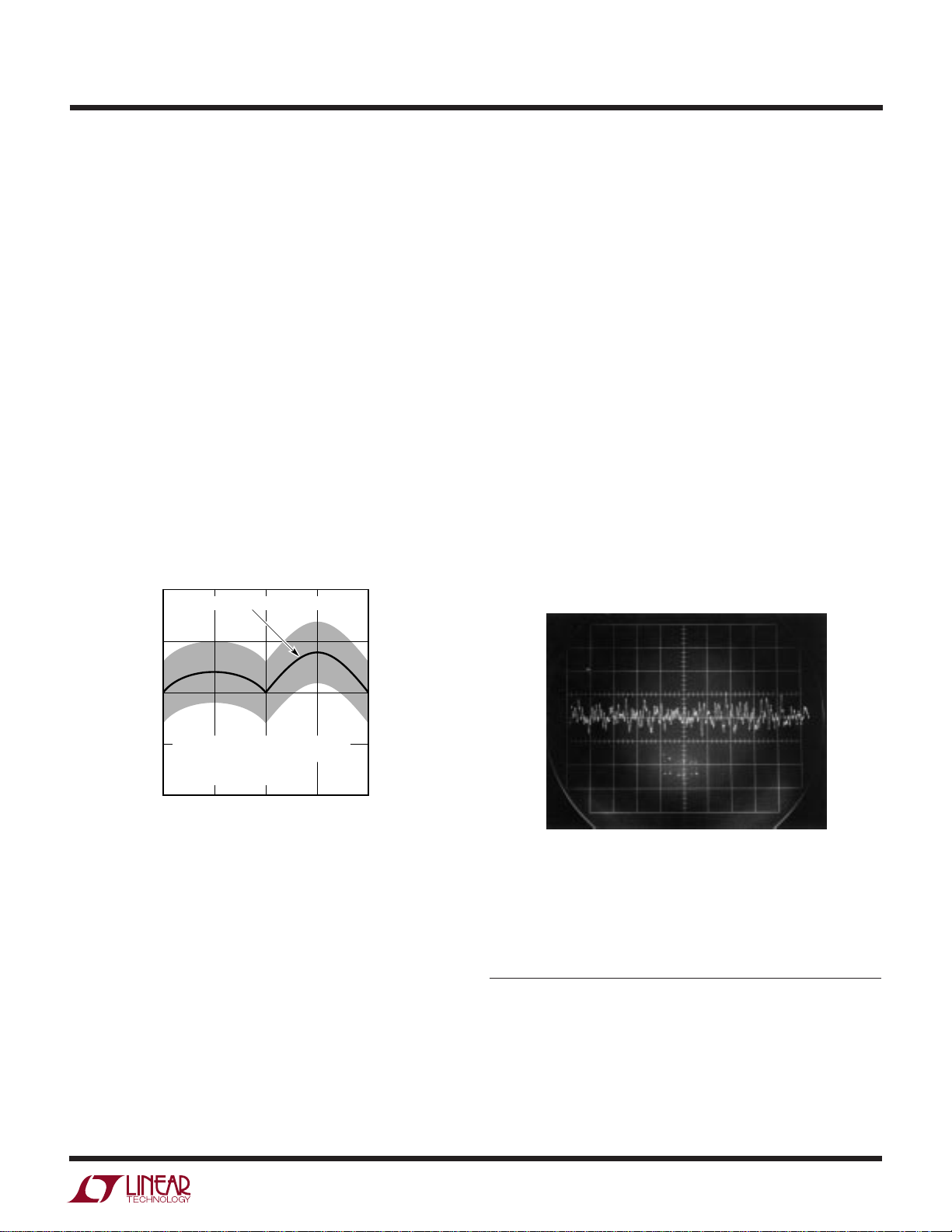

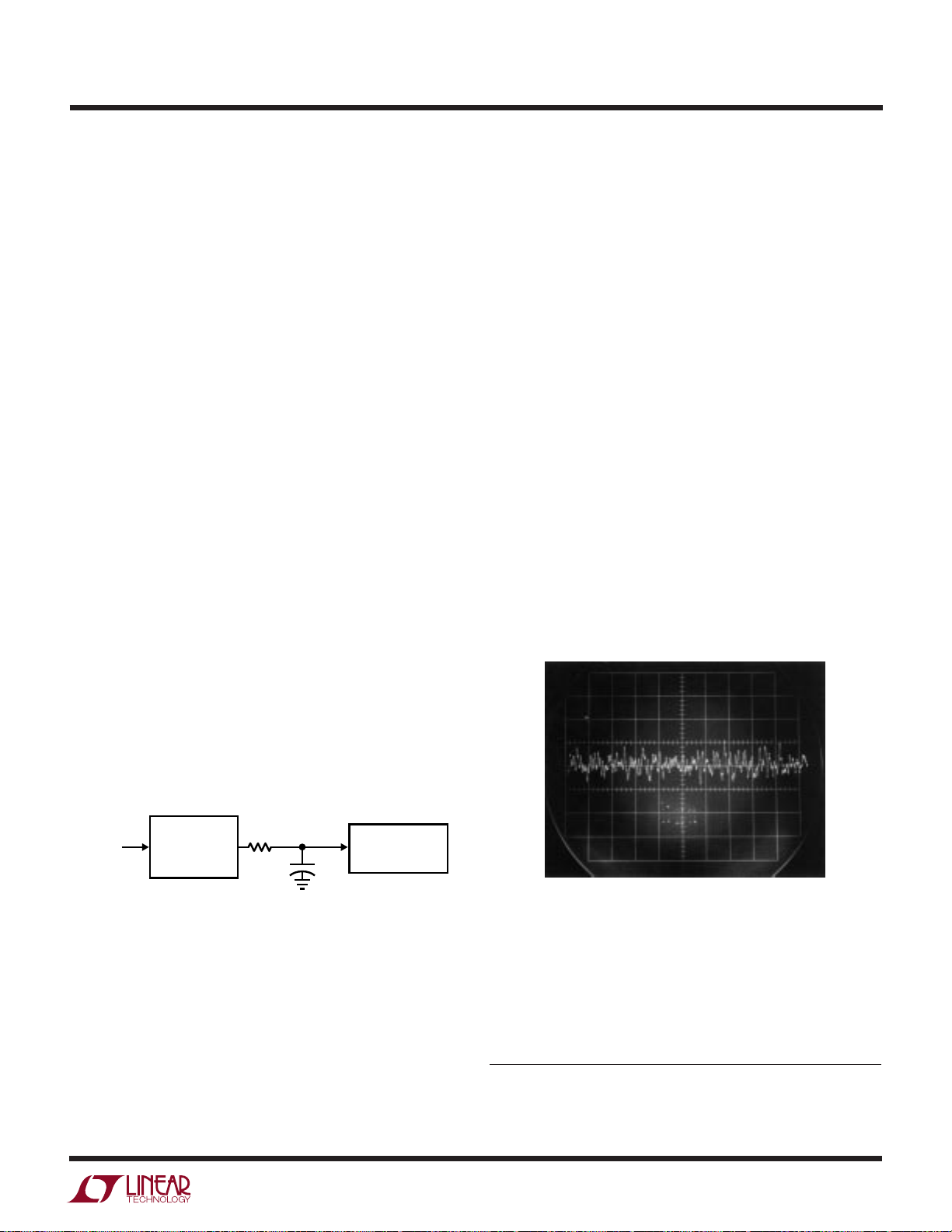

Figure 3 is a plot of linearity vs output code. The data

shows linearity is within 1ppm over all codes.8 Output

noise, measured in a 0.1Hz to 10Hz bandpass, is seen in

Figure 4 to be about 0.2LSB.9 This measurement is

somewhat corrupted by equipment limitations, which set

a noise floor of about 0.2µV.

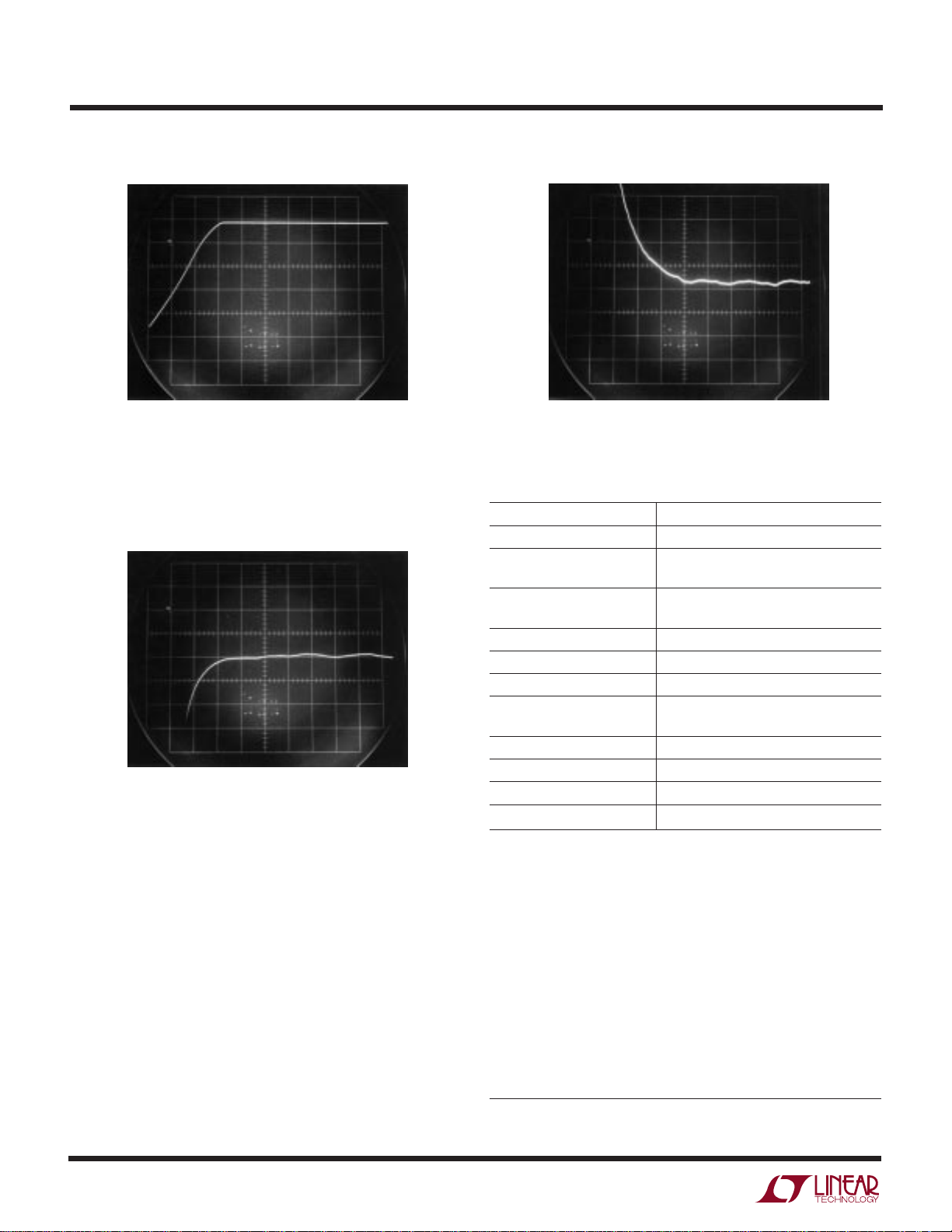

Dynamic Performance

The A-to-D’s conversion rate combines with the loop’s

sampled data characteristic and slow amplifiers to dictate

relatively slow DAC response. Figure 5’s slew response

requires about 150 microseconds.

Figure 6 shows full-scale DAC settling time to within 1ppm

(±5µV) requires about 1400 milliseconds. A smaller step

(Figure 7) of 500µV needs only 100 milliseconds to settle

within 1ppm.

10

Conclusion

Summarized 1ppm DAC specifications appear in Figure 9.

These specifications should be considered guidelines, as

the options and variations noted will affect performance.

Consult the appropriate appendices for design specifics

and trade-offs.

1.0

INDICATED MEASUREMENT RESULTS

0.5

0

SHADED REGION DELINEATES

LINEARITY ERROR (ppm)

–0.5

MEASUREMENT UNCERTAINTY DUE TO

DAC OUPUT NOISE AND

INSTRUMENTATION LIMITATIONS

–1.0

0

262,144 524,288 786,432 1,048,576

DIGITAL INPUT CODE

Figure 3. Linearity Plot Shows No

Error Outside 1ppm for All Codes

AN86 F03

500nV/DIV

2s/DIV AN86 F04.tif

Figure 4. Output Noise Indicates Less Than 1µV,

About 0.2LSB. Measurement Noise Floor, Due

to Equipment Limitations, Is 0.2µV

Note 8: Establishing and maintaining confidence in a 1ppm linearity

measurement is uncomfortably close to the state of the art. The

technique used is shown in Appendix C, “Verifying Data Converter

Linearity to 1ppm.”

Note 9: Noise measurement considerations appear in Appendix H,

“Microvolt Level Noise Measurement.”

Note 10: Measuring DAC settling time to 1ppm is by no means

straightforward, even at the relatively slow speed involved here. See

Appendix G, “Measuring DAC Settling Time.”

AN86-3

Page 4

Application Note 86

1V/DIV

50µs/DIV AN86 F05.tif

5µV/DIV

500ms/DIV AN86 F06.tif

Figure 5. DAC Output Full-Scale Slew Characteristics Figure 6. High Resolution Settling Detail After a Full-Scale Step.

Settling Time Is 1400 Milliseconds to Within 1ppm (±5µV)

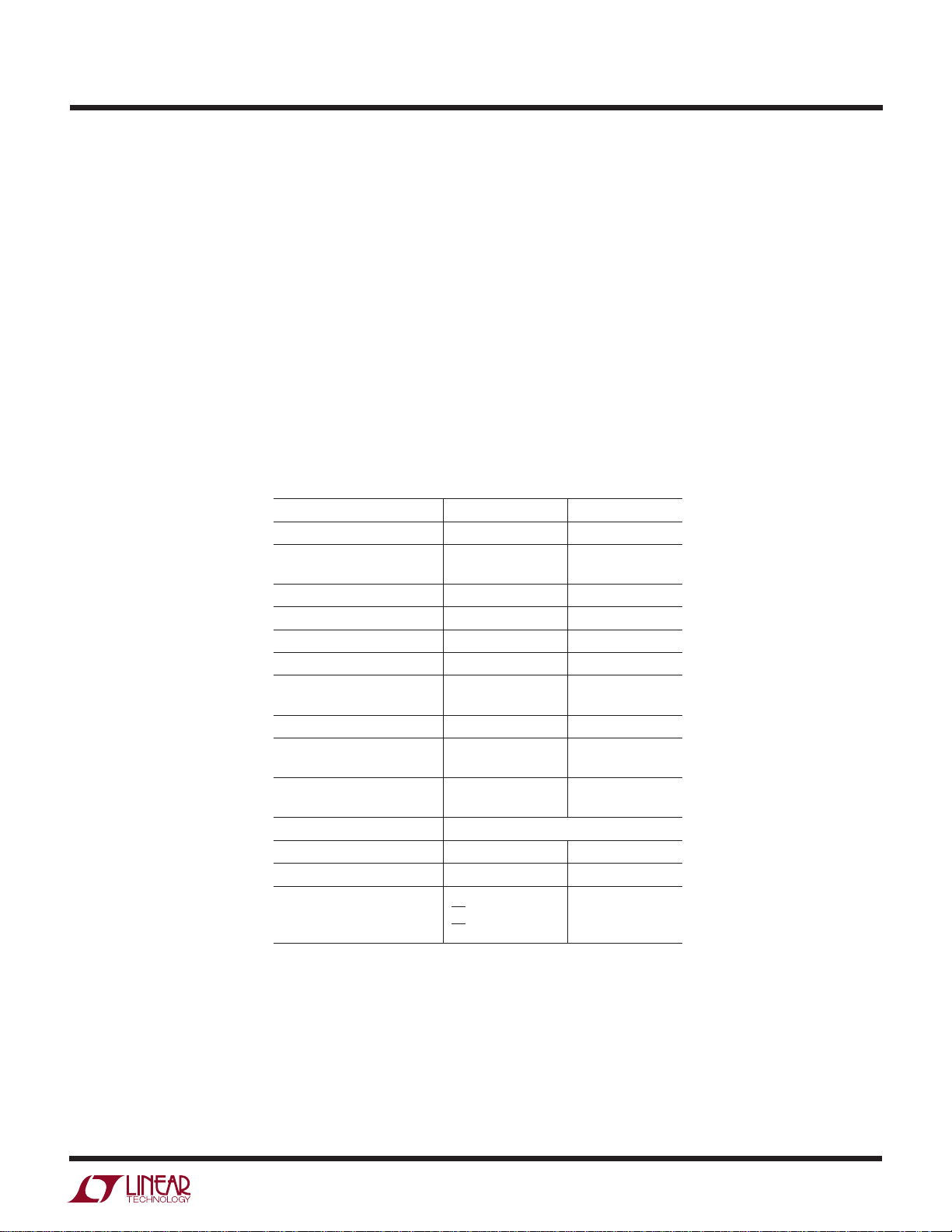

PARAMETER SPECIFICATION

Resolution 1ppm

5µV/DIV

50ms/DIV AN86 F07.tif

Figure 7. Small Step Settling Time Measures 100

Milliseconds to Within 1ppm (±5µV) for a 500µV

Transition

Full-Scale Error 4ppm of V

(Trimmable to 1ppm by V

Full-Scale Error Drift 0.04ppm/°C Exclusive of Reference

(0.1ppm/°C with LTZ1000A Reference

Offset Error 0.5ppm

Offset Error Drift 0.01ppm/°C

Nonlinearity ±2ppm, Trimmable to Less Than 1ppm

Output Noise 0.2ppm

(≈0.9µV, 0.1Hz to 10Hz BW)

Slew Rate 0.033V/µs

Settling Time—Full-Scale Step 1400 Milliseconds

Settling Time—500µV Step 100 Milliseconds

Output Voltage Range 0V to 5V. For Other Ranges See Note 3

Note 1: See Appendix I

Note 2: See Appendix E

Note 3: See Appendices E and F

REF

Adjustment)

REF

1

)

2

AN86-4

Figure 8. Summarized Specifications for the 20-Bit DAC

Note: This Application Note was derived from a manuscript originally

prepared for publication in EDN magazine.

Page 5

Application Note 86

REFERENCES

1. Linear Technology Corporation, “LTC2400 Data Sheet,”

Linear Technology Corporation, January 1999.

2. Linear Technology Corporation, “LTC2410 Data Sheet,”

Linear Technology Corporation, April 2000.

3. Keithley Instruments, “Low Level Measurements,”

Keithley Instruments, 1984.

4. Williams, J., “Testing Linearity of the LTC2400 24-Bit

A/D Converter,” Linear Technology Corporation, Design Solution 11, November 1999.

5. Seebeck, T. Dr., “Magnetische Polarisation der Metalle

und Erze durch Temperatur-Differenz,” Abhaandlungen

der Preussischen Akademic der Wissenschaften

(1822–1823), pp. 265–373.

6. Williams, J., “Component and Measurement Advances

Ensure 16-Bit DAC Settling Time,” Linear Technology

Corporation, Application Note 74, July 1998.

7. Lee, M., “Understanding and Applying Voltage References,” Linear Technology Corporation, Application

Note 82, November 1999.

8. Williams, J., “Applications Considerations and Circuits for a New Chopper-Stabilized Op Amp,” Linear

Technology Corporation, Application Note 9, August

1987.

9. Huffman, B., “Voltage Reference Circuit Collection,”

Linear Technology Corporation, Application Note 42,

June 1991.

10. Spreadbury, P. J., “The Ultra-Zener—A Portable Replacement for the Weston Cell?” IEEE Transactions on

Instrumentation and Measurement, Vol. 40, No. 2,

April 1991, pp. 343–346.

11. Williams, J., “Thermocouple Measurement,” Linear

Technology Corporation, Application Note 28, February 1988.

12. Hueckel, J. H., “Input Connection Practices for Differential Amplifiers,” Neff Inst. Corporation, Duarte, California.

13. Gould Inc., “Elimination of Noise in Low Level Circuits,” Gould Inc., Instrument Systems Division, Cleveland, Ohio.

14. Williams, J., “Prevent Low Level Amplifier Problems,”

Electronic Design, February 15, 1975, p. 62.

15. Pascoe, G., “The Choice of Solders for High Gain

Devices,” New Electronics (Great Britain), February 6,

1977.

16. Pascoe, G., “The Thermo-E.M.F. of Tin-Lead Alloys,”

Journal Phys. E, December 1976.

17. Brokaw, A. P., “Designing Sensitive Circuits? Don’t

Take Grounds for Granted,” EDN, October 5, 1975,

p.␣ 44.

18. Morrison, R., “Noise and Other Interfering Signals,”

John Wiley and Sons, 1992.

19. Morrison, R., “Grounding and Shielding Techniques

in Instrumentation,” Wiley-Interscience, 1986.

20. Vishay Inc., “Vishay Foil Resistors,” Vishay Inc., 1999.

AN86-5

Page 6

Application Note 86

APPENDIX A

A HISTORY OF HIGH ACCURACY

DIGITAL-TO-ANALOG CONVERSION

People have been converting digital-to-analog quantities

for a long time. Probably among the earliest uses was the

summing of calibrated weights (Figure A1, left center) in

weighing applications. Early electrical digital-to-analog

conversion inevitably involved switches and resistors of

different values, usually arranged in decades. The application was often the calibrated balancing of a bridge or

reading, via null detection, some unknown voltage. The

most accurate resistor-based DAC of this type is Lord

Kelvin’s Kelvin-Varley divider (Figure, large box). Based

on switched resistor ratios, it can achieve ratio accuracies

of 0.1ppm (23+ bits) and is still widely employed in

standards laboratories.1 High speed digital-to-analog conversion resorts to electronically switching the resistor

network. Early electronic DACs were built at the board level

using discrete precision resistors and germanium transistors (Figure, center foreground, is a 12-bit DAC from a

Minuteman missile D-17B inertial navigation system, circa

1962). The first electronically switched DACs available as

standard product were probably those produced by

Pastoriza Electronics in the mid 1960s. Other manufacturers followed and discrete- and monolithically-based modular DACs (Figure, right and left) became popular by the

1970s. The units were often potted (Figure, left) for

ruggedness, performance or to (hopefully) preserve proprietary knowledge. Hybrid technology produced smaller

package size (Figure, left foreground). The development of

Si-Chrome resistors permitted precision monolithic DACs

such as the LTC1595 (Figure, immediate foreground). In

keeping with all things monolithic, the cost-performance

trade off of modern high resolution IC DACs is a bargain.

Think of it! A 16-bit DAC in an 8-pin IC package. What Lord

Kelvin would have given for a credit card and LTC’s phone

number.

Note 1: See Appendix C, “Verifying Data Converter Linearity to 1ppm,”

for details on Kelvin-Varley Dividers.

Figure A1. Historically Significant Digital-to-Analog Converters Include: Weight Set (Center Left), 23+ Bit Kelvin-Varley Divider

(Large Box), Hybrid, Board and Modular Types, and the LTC1595 IC (Foreground). Where Will It All End?

AN86-6

AN86 FA01.tif

Page 7

APPENDIX B

THE LTC2400—A MONOLITHIC 24-BIT

ANALOG-TO-DIGITAL CONVERTER

Application Note 86

The LTC2400 is a micropower 24-bit A-to-D converter

with an integrated oscillator, 4ppm nonlinearity and 0.3ppm

RMS noise. It uses delta-sigma technology to provide

extremely high stability. The device can be configured for

better than 110dB rejection at 50Hz or 60Hz ±2%, or it can

be driven by an external oscillator for a user defined

rejection frequency in the range 1Hz to 120Hz.

PARAMETER CONDITIONS

Resolution (No Missing Codes) 0.1V ≤ V

Integral Nonlinearity V

Offset Error 2.5V ≤ V

Offset Error Drift 2.5V ≤ V

Full-Scale Error 2.5V ≤ V

Full-Scale Error Drift 2.5V ≤ V

Total Unadjusted Error V

Output Noise 1.5µV

Normal Mode Rejection 110dB (Min)

60Hz ±2%

Normal Mode Rejection 110dB (Min)

50Hz ±2

Input Voltage Range 0.125V • V

Reference Voltage Range 0.1V ≤ V

Supply Voltage 2.7V ≤ VCC ≤ 5.5V

Supply Current

Conversion Mode CS = 0V 200µA

Sleep Mode CS = V

Figure B1. Key Specifications for LTC2400 A-to-D Converter.

High Linearity and Extreme Stability Allow Realization of 1ppm DAC

REF

V

REF

REF

V

REF

This ultraprecision A-to-D converter in an SO-8 pin package forms the heart of the 20-bit DAC described in the text.

It is significant that the device is used here as a circuit

component

rather than in the traditional standalone role

accorded precision A-to-D converters. This freedom, in

keeping with the IC’s economy and ease of use, is a

noteworthy opportunity. Alert designers will recognize

this development and capitalize on it. Key specifications

for the A-to-D are given in Figure B1.

≤ V

REF

CC

= 2.5V 2ppm of V

= 5V 4ppm of V

≤ V

REF

CC

≤ V

REF

≤ V

REF

≤ V

REF

= 2.5V 5ppm of V

= 5V 1ppm of V

CC

CC

CC

CC

0.01ppm of V

0.02ppm of V

to 1.125V • V

REF

24 Bits

0.5ppm of V

REF

4ppm of V

REF

≤ V

REF

20µA

REF

REF

REF

/°C

REF

/°C

REF

REF

RMS

REF

CC

AN86-7

Page 8

Application Note 86

APPENDIX C

VERIFYING DATA CONVERTER LINEARITY TO 1PPM

Help from the Nineteenth Century

INTRODUCTION

Verifying 1ppm linearity of the DAC and the analog-todigital converter used to construct it requires special

considerations. Testing necessitates some form of voltage source that produces equal amplitude output steps for

incremental digital inputs. Additionally, for measurement

confidence, it is desirable that the source be substantially

more linear than the 1ppm requirement. This is, of course,

a stringent demand and painfully close to the state of the

art.

The most linear “D to A” converter is also one of the oldest.

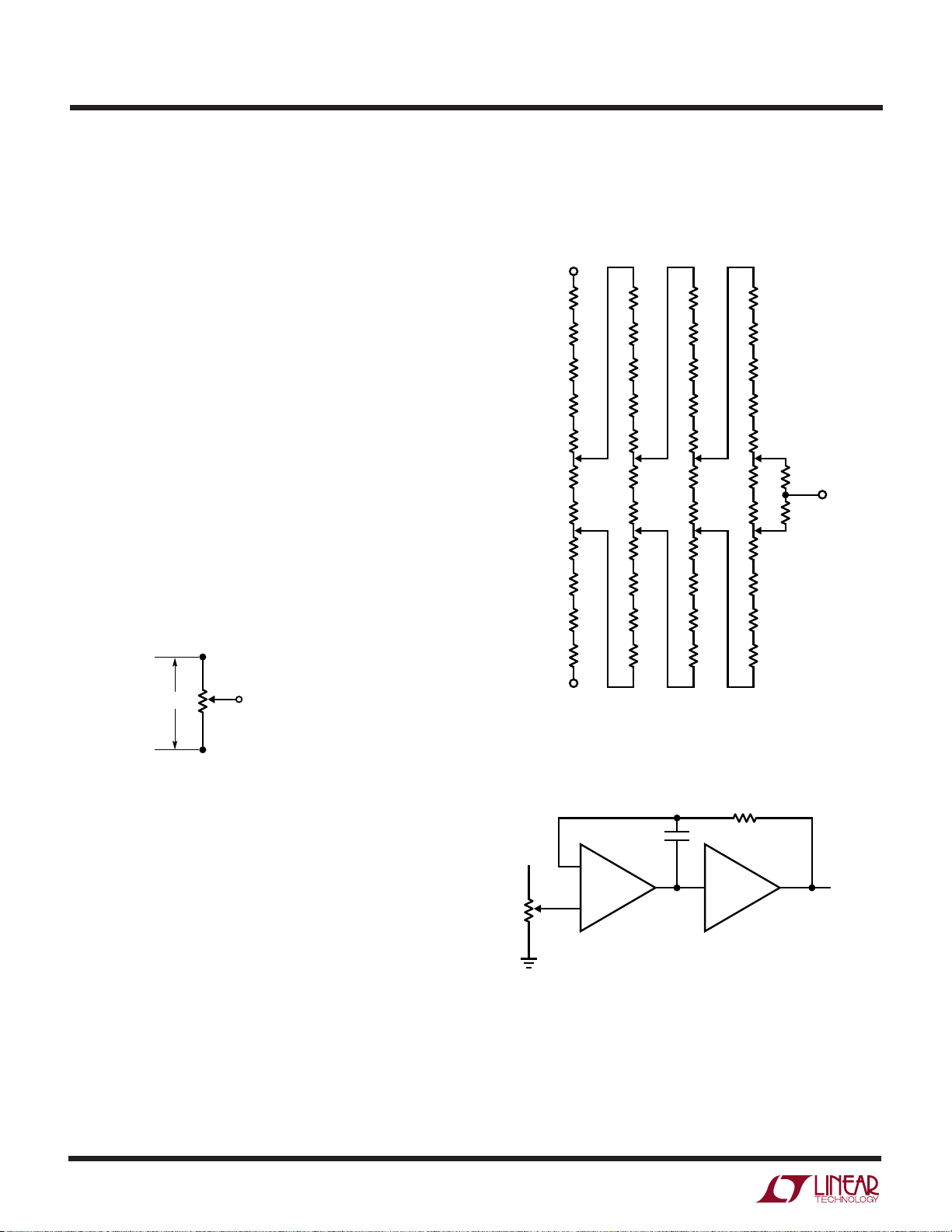

Lord Kelvin’s Kelvin-Varley divider (KVD), in its most

developed form, is linear to 0.1ppm. This manually switched

device features ten million individual dial settings arranged in seven decades. It may be thought of as a

3-terminal potentiometer with fixed “end-to-end” resistance and a 7-decade switched wiper position (Figure C1).

SEVEN-DECADE SWITCHED

R = 100k

WIPER POSITION PERMITS

SETTING TO 0.1ppm LINEARITY

AN86 FC01

10k 2k 400Ω 80Ω

INPUT

80Ω

OUT

80Ω

COMMON

Figure C2. A 4-Decade Kelvin-Varley Divider. Additional

Decades Are Implemented By Opening Last Switch, Deleting

Two Associated 80Ω Values and Continuing ÷ 5 Resistor Chains

AN86 FC02

Figure C1. Conceptual Kelvin-Varley Divider

The actual construction of a 0.1ppm KVD is more artistry

and witchcraft than science. The market is relatively small,

the number of vendors few and resultant price high. If

$13,000 for a bunch of switches and resistors seems

offensive, try building and certifying your own KVD. Figure

C2 shows a detailed schematic.

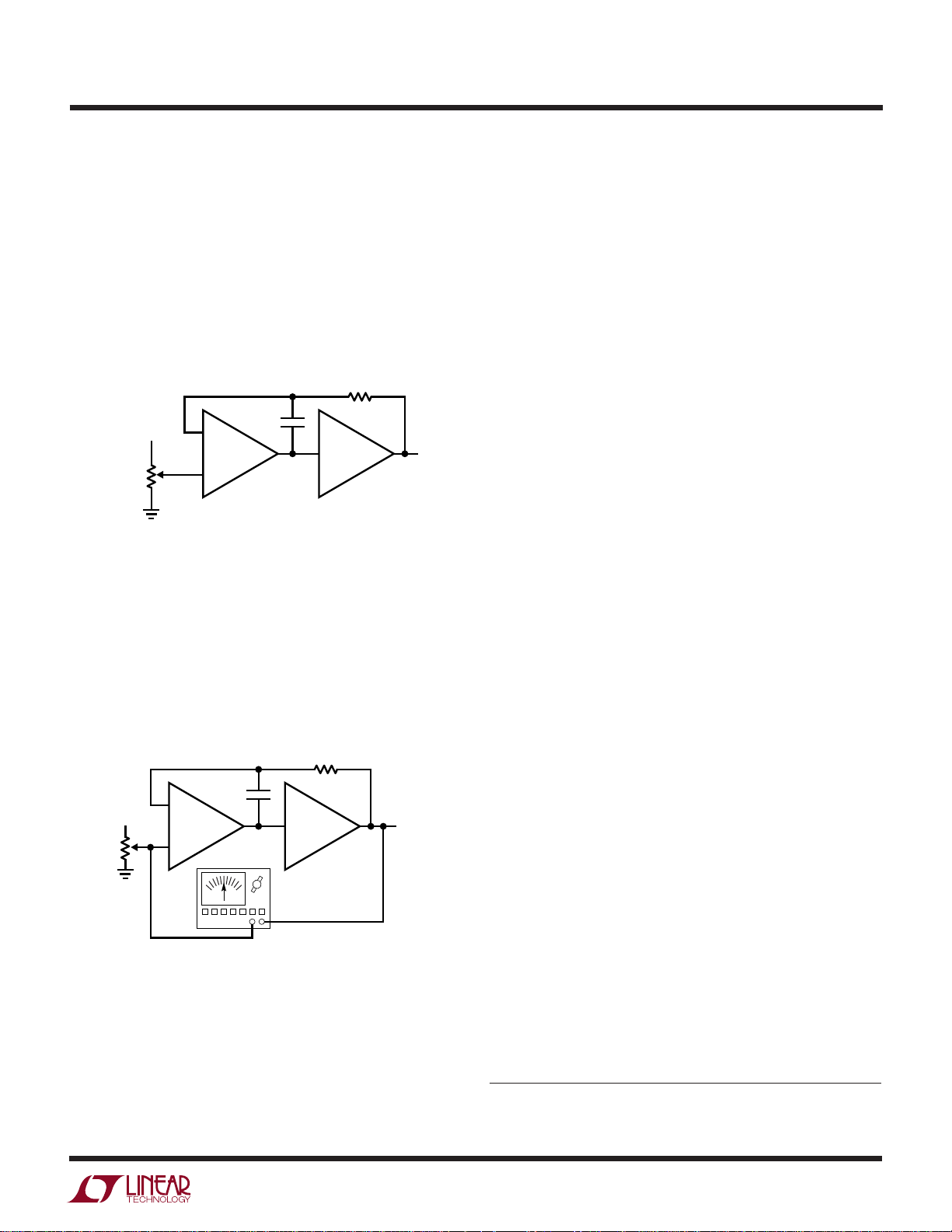

The KVD shown has a 100kΩ input impedance. A consequence of this is that wiper output resistance is high and

varies with setting. As such, a very low bias current

follower is required to unload the KVD without introducing

significant error. Now, our KVD looks like Figure␣ C3. The

LT1010 output buffer allows driving cables and loads and,

more subtly, maintains the amplifier’s high open-loop

gain.

AN86-8

10k

0.1µF

E

INPUT

KVD

Figure C3. KVD with Buffer Gives Output Drive Capability

–

LT1010LTC1152

+

KVD = ELECTRO SCIENTIFIC INDUSTRIES RV-722,

FLUKE 720A OR JULIE RESEARCH LABS VDR-307

OUTPUT

AN86 FC03

Page 9

Application Note 86

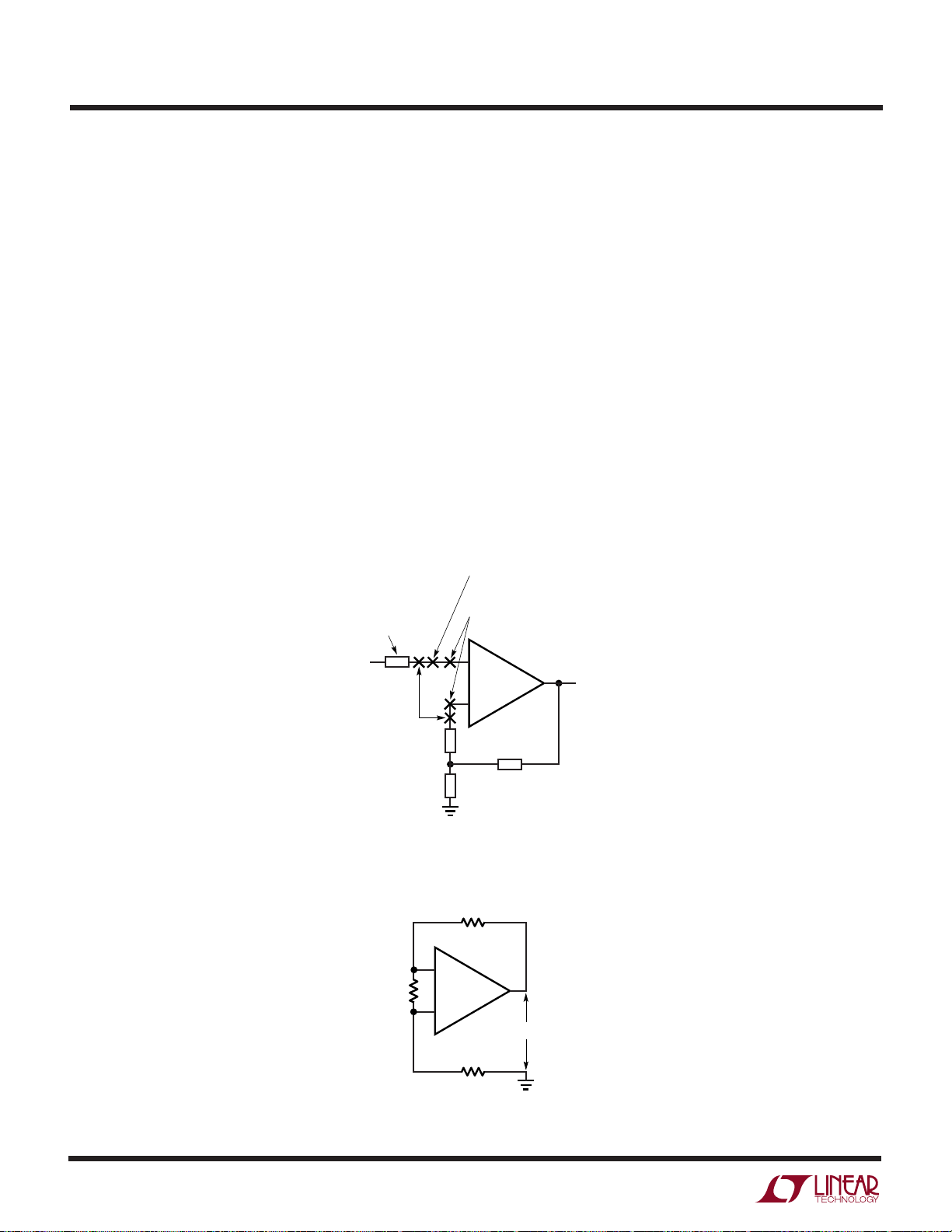

Approach and Error Considerations

This schematic is deceptively simple. In practice, construction details are crucial. Parasitic thermocouples

(Seebeck effect), layout, grounding, shielding, guarding,

cable choice and other issues affect achievable performance.1 In fact, as good as the chopper-stabilized LTC1152

is with respect to drift, offset, bias current and CMRR,

selection is required if we seek sub-ppm nonlinearity

performance. Figure C4, an error budget analysis, details

some of the selection criteria.

10k

0.1µF

–

LTC1152

+

WORST-CASE

SPEC

5µV

0.05µV/°C

50pA

110dB

140dB

–

LTC1152

+

0.1µF

LT1010

REALISTIC SELECTION

TARGET

0.5µV

0.05µV/°C

10pA

140dB

140dB

10k

LT1010

FLOATING, BATTERY-POWERED

µV NULL DETECTOR

HP-419A

OUTPUT

ERROR IN

PPM

0.1

0.01/°C

0.1

0.1

0.1

AN86 FC04

OUTPUT

AN86 FC05

≈ 30k

OUTPUT

ERROR

SOURCE

E

OS

E

OS∆T

I

B

CMRR

5V

KVD RIN = 100k

WORST-CASE

RESISTANCE

FINITE GAIN

Figure C4. Error Budget Analysis for the KVD Buffer.

Selection Permits ≈0.4ppm Predicted Linearity Error

5V

KVD

The buffer is tested with Figure C5’s circuit. As the KVD is

run through its entire range, the floating null detector must

remain well within 1ppm (5µV), preferably below 0.5ppm.

This test ensures that all error sources, particularly IB and

CMRR, whose effects vary with operating point, are accounted for. Measured performance indicates the sum of

all errors called out in Figure C4 is well within desired

limits.

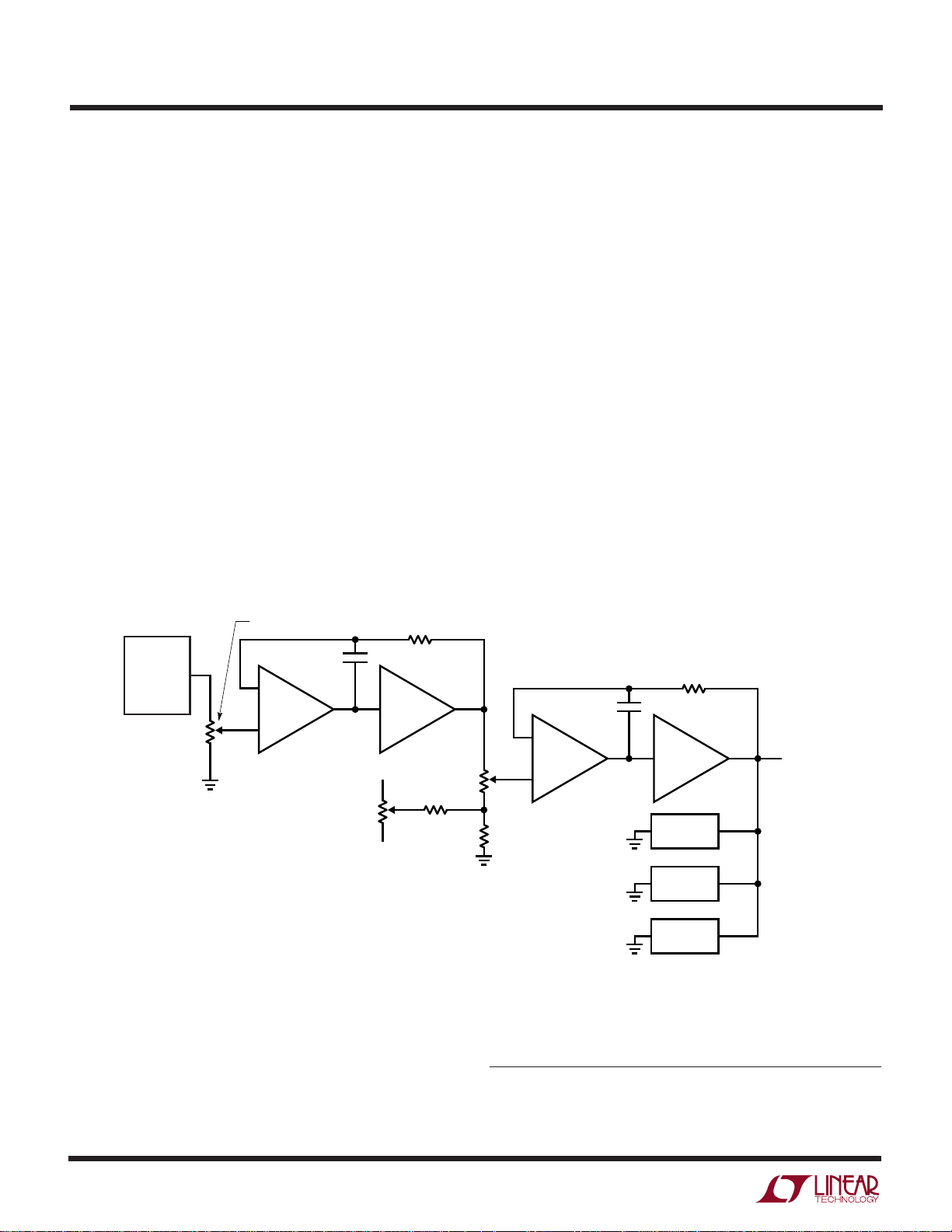

In Figure C6, we add offset trim, a stable voltage source

and a second KVD to drive the main KVD. Additionally, an

ensemble of three HP3458A voltmeters monitor the output.

The offset trim bleeds a small current into the main KVD

ground return, producing a few microvolts of offset-trim

range. This functionally trims out all sources of zero error

(amplifier offsets, parasitic thermocouple mismatches

and the like), permitting a true zero volt output when the

main KVD is set to all zeros.

The voltmeters, specified for < 0.1ppm nonlinearity on the

10V range, “vote” on the source’s output.

Circuitry Details

Figure C7 is a more detailed schematic. It is similar to

Figure C6 but highlights issues and concerns. The grounding scheme is single point, preventing mixing of return

currents and the attendant errors. The shielded cables

used for interconnections between the KVDs and voltmeters should be specified for low thermal activity. Keithley

type SC-93 and Guildline #SCW are suitable. Crush type

copper lugs (as opposed to soldered types) provide lower

parasitic thermocouple activity at KVD and DVM connection points. However, they must be kept clean to prevent

oxidation, thus avoiding excessive thermal voltages.2 A

copper deoxidant (Caig Labs “Deoxit” D100L) is quite

effective for maintaining such cleanliness. Low thermal

lugs and jacks, preterminated to cables, are also available

(Hewlett-Packard 11053, 11174A) and convenient.

Figure C5. Determining Buffer Error By Measuring Input-Output

Deviation with Floating Microvolt Null Detector. Technique

Permits Evaluation of Fixed and Operating Point Induced Errors

Thermal baffles enclosing KVD and DVM connections tend

Note 1: See Appendix J, “Cables, Connections, Solder, Layout,

Component Choice, Terror and Arcana,” for relevant tutorial.

Note 2: See above Footnote.

AN86-9

Page 10

Application Note 86

to thermally equilibrate their associated banana jack terminals, minimizing residual parasitic thermocouple activity. Additionally, restrict the number of connections in the

signal path. Necessary connections should be matched in

number and material so that differential cancellation occurs. Complying with this guideline may necessitate deliberate introduction of solder-copper junctions (marked “X”

on Figure␣ C7) to obtain optimum differential cancellation.

3

This is normally facilitated by simply breaking the appropriate wire or PC trace and soldering it. Ensure that the

introduced thermocouples temperature track the junctions they are supposed to cancel. This is usually accomplished by locating all junctions within close physical

proximity.

The noise filtering capacitor at the main KVD is a low

leakage type, with its metal case driven by the output

buffer to guard out surface leakage.

When studying the approach used, it is essential to differentiate between linearity and absolute accuracy. This

eliminates concerns with absolute standards, permitting

certain freedoms in the measurement scheme. In particular, although single-point grounding was used, remote

sensing was not. This is a deliberate choice, made to

minimize the number of potential error-causing parasitic

thermocouples in the signal path. Similarly, a ratiometric

reference connection between the KVD LTZ1000A voltage

source and the voltmeters was not utilized for the same

reason. In theory, a ratiometric connection affords lower

drift. In practice, the resultant introduced parasitic thermocouples obviate the desired advantage. Additionally,

the aggregate stability of the LTZ1000A reference and the

voltmeter references (also, incidentally, LTZ1000A based)

is comfortably inside 0.1ppm for periods of 10 minutes.

4

This is more than enough time for a 10-point linearity

measurement.

STABLE

VOLTAGE

SOURCE

(LTZ1000A

BASED)

KVD

ADJUST FOR

5.000000V AT A

–

LTC1150

+

Figure C6. Simplified Sub-ppm Linearity Voltage Source

0.1µF

OFFSET

TRIM

+V

–V

10k

LT1010

20k

MAIN

KVD

A

R

WIRE

10k

0.1µF

–

LT1010LTC1152

+

HP3458A

HP3458A

HP3458A

OUTPUT

0.000000V

TO

5.000000V

AN86 FC06

AN86-10

Note 3: See Appendix J, “Cables, Connections, Solder, Layout,

Component Choice, Terror and Arcana,” for further discussion.

Note 4: The LTZ1000A reference is detailed in Appendix I, “ Voltage

References.”

Page 11

Application Note 86

Construction

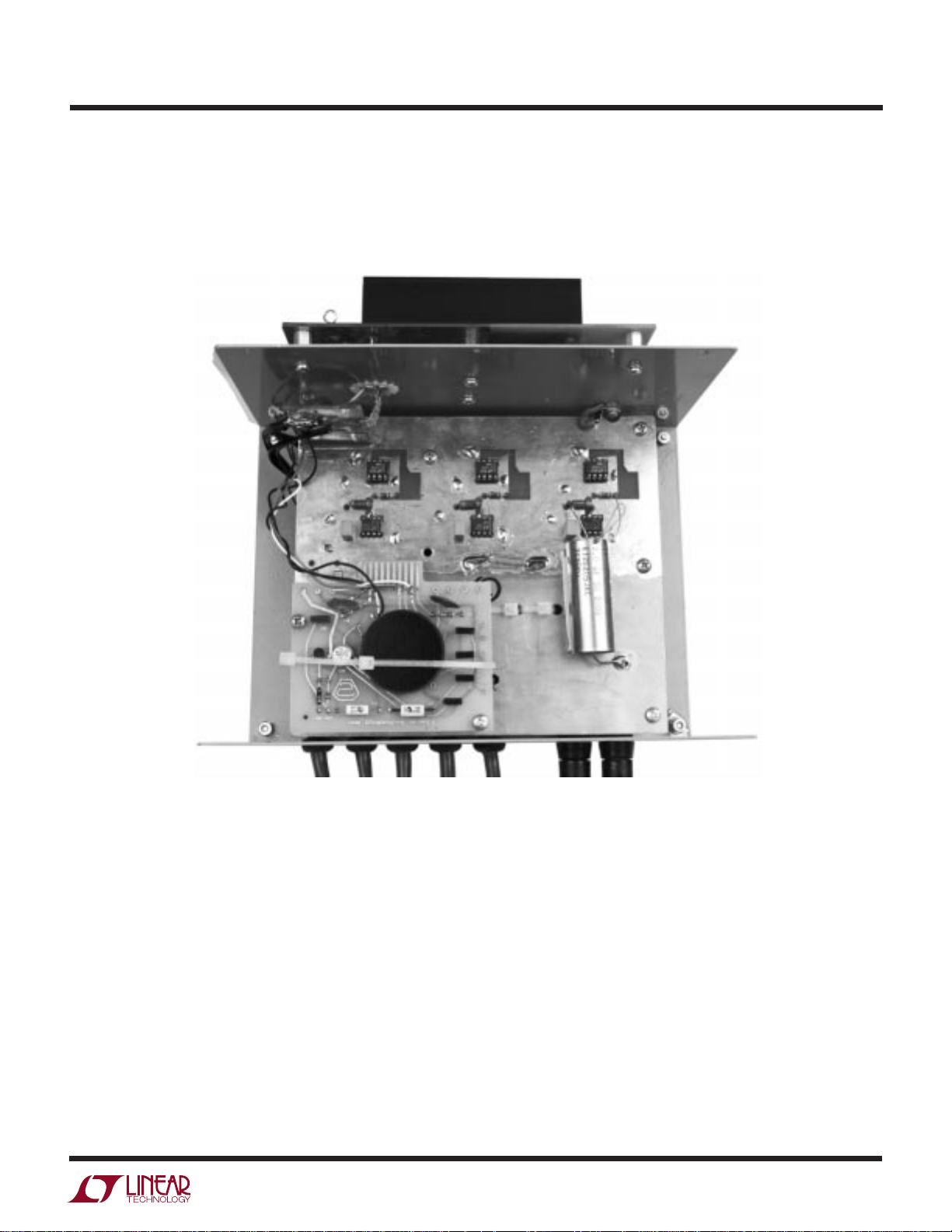

Figures C8 and C9 are photographs of the voltage source

and the reference-buffer box internal construction. The

figure captions annotate some significant features.

Results

This KVD-based, high linearity voltage source has been in

use in our lab for nearly two years. During this period, the

total linearity uncertainty defined by the source and its

monitoring voltmeters has been just 0.3ppm (see Figure

SEE APPENDIX F

FOR CIRCUIT DETAILS

OF LTZ1000A

ADJUST FOR

STABLE

VOLTAGE

SOURCE

(LTZ1000A

BASED)

KVD

5.000000V AT A

10k

0.1µF

–

LTC1150

+

OFFSET

TRIM

2k

+V

–V

10k

LT1010

20k

R

MAIN

KVD

WIRE

C10’s measurement regime). This is more than 3 times

better than the desired 1ppm performance, promoting

confidence in our measurements.

5

Acknowledgments

The author is indebted to Lord Kelvin and to Warren Little

of the C. S. Draper Laboratory (née M. I. T. Instrumentation

Laboratory) standards lab. Warren taught me, with great

patience, the wonders of KVDs some thirty years ago and

I am still trading on his efforts.

10k

A

–

10k

+

2µF

CASE

0.1µF

LT1010LTC1152

HP3458A

OUTPUT

0.000000V

TO

5.000000V

= SOLDER-COPPER JUNCTION.

PLACEMENT AND NUMBER AS REQUIRED

2µF = POLYSTYRENE. COMPONENT RSCH. CORP.

USE LOW THERMAL, LOW TRIBOELECTRIC

SHIELDED CABLE FOR KVD AND DVM CONNECTIONS.

SEE TEXT

Figure C7. Complete Sub-ppm Linearity Voltage Source

HP3458A

HP3458A

AN86 FC07

HIGH QUALITY

GROUND

Note 5: The author, wholly unenthralled by web surfing, has spent

many delightful hours “surfing the Kelvin.” This activity consists of

dialing various Kelvin-Varley divider settings and noting monitoring

A-to-D agreement within 1ppm. This is astonishingly nerdy behavior,

but thrills certain types.

AN86-11

Page 12

Application Note 86

AN86 FC08.tif

Figure C8. The Sub-ppm Linearity Voltage Source. Box Upper Right Is LTZ1000A Based Reference and Buffers. Upper Left Is Offset

Trim. Reference and Main Kelvin-Varley Dividers Are Photo Center—Upper and Center-Middle, Respectively. Three HP3458 DVMs

(Photo Lower) Monitor Output. Computer (Left Foreground) Aids Linearity Calculations

AN86-12

Page 13

Application Note 86

AN86 FC09.tif

Figure C9. Reference-Buffer Box Construction. LTZ1000A Reference Circuitry Is Photo Lower Left, Buffer Amplifiers Photo Center. Note

Capacitor Case Bootstrap Connection (Photo Center—Right). Single Point Ground Mecca Appears Photo Upper Left. Power Supply

(Photo Top) Mounts Outside Box, Minimizing Magnetic Field Disturbance

1. VERIFY KVD LINEARITY BY INTERCOMPARISON AND INDEPENDENT CAL. LAB.

2. TAKE WORST-CASE VOLTMETER ENSEMBLE DEVIATIONS OVER 0V TO 5V, EVERY 0.5V

3. 100 RUNS (10 PER DAY, ONCE PER HOUR)

4. INDICATED RESULT IS 0.3ppm NONLINEARITY

Figure C10. Testing Regime for the High Linearity Voltage Source

AN86 FC10

AN86-13

Page 14

Application Note 86

10k

10k

MCLR

2

3

4

5

6

7

8

9

11

1

10

D0

D1

D2

D3

D4

D5

D6

D7

CLK

OE

GND

19

18

17

16

15

14

13

12

20

Q0

Q1

Q2

Q3

Q4

Q5

Q6

Q7

V

CC

0.1µF

U2

74HCT574

2

3

4

5

6

7

8

9

11

1

10

D0

D1

D2

D3

D4

D5

D6

D7

CLK

OE

GND

19

18

17

16

15

14

13

12

20

Q0

Q1

Q2

Q3

Q4

Q5

Q6

Q7

V

CC

0.1µF

0.1µF

5V

4MHz

CRYSTAL

U3 74HCT574

2

3

4

5

6

7

8

9

11

1

10

D0

D1

D2

D3

D4

D5

D6

D7

CLK

OE

GND

19

18

17

16

15

14

13

12

20

Q0

Q1

Q2

Q3

Q4

Q5

Q6

Q7

V

CC

0.1µF

AN86 FD01

U4 74HCT574

1

2

3

4

5

6

7

8

9

10

11

12

13

14

USER INPUT

V

DD

NC

V

SS

NC

ADC SCK

ADC SDO

NC

NC

LSB OE

MID OE

MSB OE

LSB WR

MSB WR

28

27

26

25

24

23

22

21

20

19

18

17

16

15

10k

10k

10k

10k

10k

10k

10k

10k

MCLR

CLKIN

CLKIN2

MSB D7

D6

D5

D4

D3

D2

D1

LSB D0

DAC RDY

DAC LD

MLBYTE

D7 MSB

D6

D5

D4

D3

D2

D1

D0

5V

DAC

COMMANDS

TO ANALOG

SECTION

TO LTC2400

IN ANALOG

SECTION

U1 PIC16C5X

10k

10k

10k

10k

10k

10k

DAC LD

MLBYTE

MSB WR

LSB WR

ADC SDO

ADC SCK

20pF

20pF

USER

DATA

INPUT

MSB

DAC RDY

DAC WR

LSB

1ppm

5V

2ppm

5V

4ppm

5V

FILTER

5V

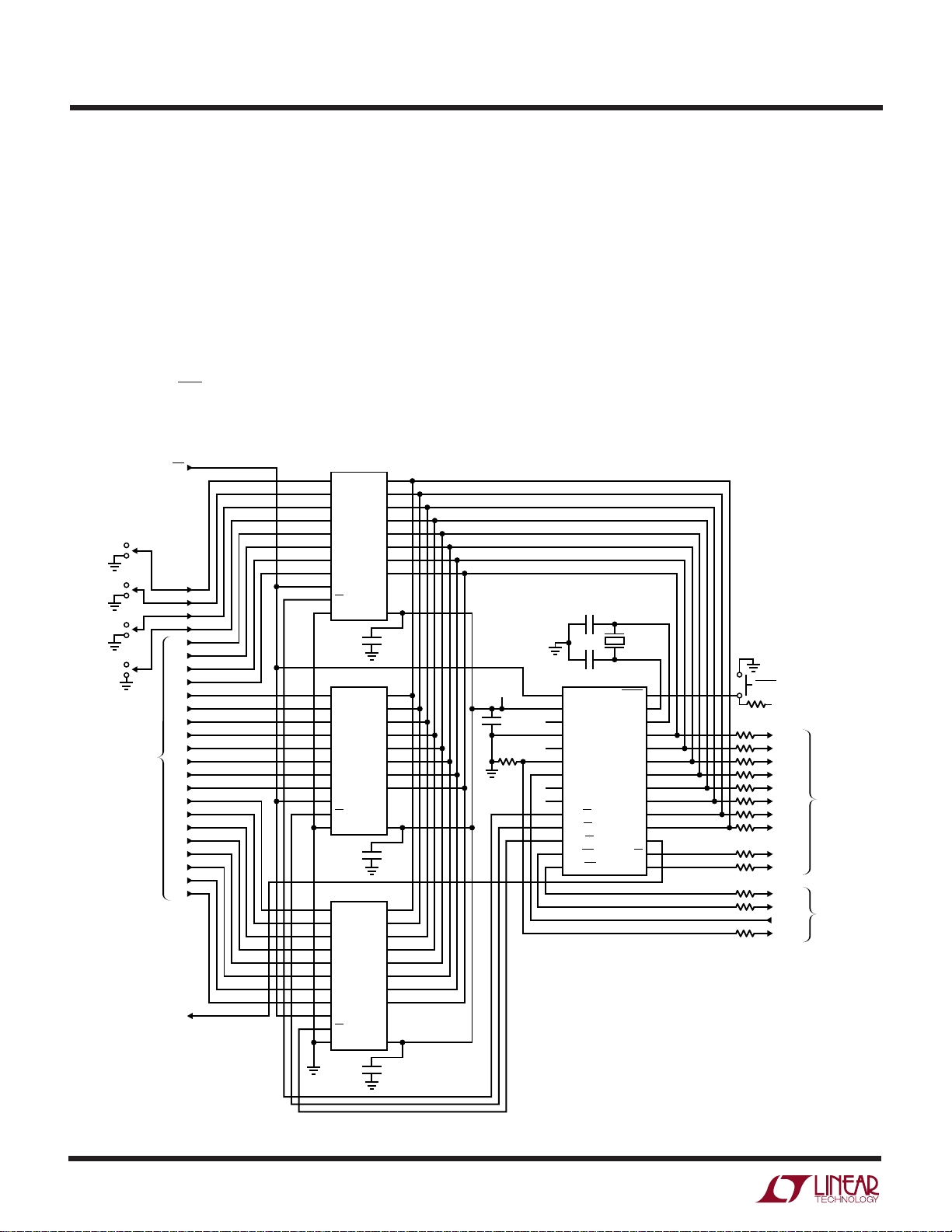

APPENDIX D

A PROCESSOR-BASED CODE COMPARATOR

The code comparator enforces the loop by setting the

slave DAC inputs to the code that equalizes the user input

and the LTC2400 A-to-D output. This action is more fully

described on page one of the text.

Figure D1 is the code comparator’s digital hardware. It is

composed of three input data latches and a PIC-16C5X

processor. Inputs include user data (e.g., DAC inputs),

linearity curvature correction (via DIP switches), convert

command (“DA WR”) and a selectable filter time constant.

An output (“DAC RDY”) indicates when the DAC output is

settled to the user input value. Additional outputs and an

AN86-14

Figure D1. Code Comparator Hardware. User Control Lines Are at Left, Analog Section Connections Appear at Right Side

input control and monitor the analog section (text Figure␣ 2) to effect loop closure. Note that although a total of

32 bits are presented to the two 16-bit slave DACs, there

are 8 bits of overlap, allowing a total dynamic range of 24

bits. This provides 4 bits of indexing range below the 20th

bit, ensuring a stable LSB of 1ppm of scale. The 8-bit

overlap assures the loop will always be able to capture the

correct output value.

The processor is driven by software code, authored by

Florin Oprescu, which is described below.

Page 15

Application Note 86

;20bit DAC code comparator

;

;***************************************************

; *

; Filename: dac20.asm *

; Date 12/4/2000 *

; File Version: 1.1 *

; *

; Author: Florin Oprescu *

; Company: Linear Technology Corp. *

; *

; *

;***************************************************

;

; Variables

;============

; uses 17 bytes of RAM as follows:

;

; {UB2, UB1, UB0} user input word buffer

;———————————————————————————————————————

; 24 bits unsigned integer (3 bytes):

;

; The information is transferred from the external input register

; into {UB2, UB1, UB0} whenever a “user input update” event

; is detected by testing the timer0 content. Following the data

; transfer, the UIU (“user input update”) flag is set and the DAC

; ready flags RDY and RDY2 are cleared. UB0 uses the same physical

; location as U0. The user input double buffering is necessary

; because the loop error corresponding to the current ADC reading

; must be calculated using the previous user input value.

; The old user input value can be replaced by the new user input

; value only after the loop error calculation.

; The worst case minimum response time to an UIU event must be

; calculated. The user shall not update the external input register

; at intervals shorter than this response time. For the moment the

; program can not block the user access to the external input

; register during a read operation. In such a situation the result

; of the read operation can be very wrong.

;

; UB0 - least significant byte. Same physical location as U0

;

; UB1 - second byte.

;

; UB2 - most significant byte.

;

;

; {U2, U1, U0} user input word

;——————————————————————————————

; 24 bits unsigned integer (3 bytes):

;

; The information is transferred from {UB2, UB1, UB0[7:4], [0000]}

; into {U2, U1, U0} whenever the UIU flag is found set within the

; CComp (“code comparator”) procedure. The UIU flag is reset

; following the data transfer.

AN86-15

Page 16

Application Note 86

;

; U0 - least significant byte of current DAC input

; The 4 least significant bits U0[3:0] are set

; to zero.

;

; U1 - second byte of current DAC input

;

; U2 - most significant byte of current DAC input

;

;

; {CON} control byte

;————————————————————

; (1 byte):

;

; The 3 least significant bits CON[2:0] represent the ADC linearity

; correction factor transferred from UB[2:0] when the UIU flag

; is found set within the CComp procedure - at the same time as the

; {U2, U1, U0} variable is updated.

;

; The effect of CON[2:0] is additive and its weight is as follows:

;

; CON[0] = 1 linearity correction effect is about 1ppm

; CON[1] = 1 linearity correction effect is about 2ppm

; CON[2] = 1 linearity correction effect is about 4ppm

;

; The LTC2400 has a typical 4ppm INL error therefore the default

; curvature correction value can be set at CON[2:0] = 100

;

; CON[3] is the control loop integration factor transferred from

; UB[3] when the UIU flag is found set within the CComp procedure.

; If CON[3]=0, after the control loop error becomes less than 4ppm

; the error correction gain is reduced from 1 to 1/4

; If CON[3]=1, after the control loop error becomes less than 4ppm

; the error correction gain is reduced from 1 to 1/16

;

; CON[7] is used as the UIU (“user input update”) flag. It is set

; when {UB2, UB1, UB0} is updated and it is reset when {U2, U1, U0}

; and CON[3:0] are updated.

;

; CON[6] is used as the RDY (“DAC ready”) flag. It is set when

; the DAC loop error becomes less than 4ppm and it is reset when

; the UIU flag is set.

;

; CON[5] is used as the RDY2 (“DAC ready twice”) flag. It is set

; whenever the DAC loop error becomes less than 4ppm and the RDY

; flag has been previously set. It is reset when the UIU flag is set.

;

;

; The bit CON[4] is not used and is always set to 0.

;

;

AN86-16

Page 17

Application Note 86

; {ADC3, ADC2, ADC1, ADC0} formatted ADC conversion result

;—————————————————————————————————————————————————————————

; 32 bits signed integer (4 bytes).

;

; The ADC reading is necessary only for the calculation of the control

; loop error and in order to save RAM space, it can share the same

; physical space as the loop error variable.

;

; The LTC2400 output format is offset binary. It must be converted

; to 2’s complement before any arithmetic operation. A number of

; possible codes are not valid LTC2400 output codes. If such codes

; are detected it can be inferred that a serial transfer error has

; occurred, the data must be discarded and a new conversion must

; be started. For all LTC2400 devices B31=0 and B30=0 always. In

; addition, with the exception of some early samples of the device

; the sequence B[29:28]=00 should not occur in a valid transaction.

;

; ADC0 - least significant byte

; contains ADC output bits B11(MSBIT) to B4 (LSBIT)

;

; ADC1 - second byte

; contains ADC output bits B19(MSBIT) to B12 (LSBIT)

;

; ADC2 - third byte

; contains ADC output bits B27(MSBIT) to B20 (LSBIT)

;

; ADC3 - most significant byte

; contains ADC output bits ~B29(as 7 MSBITS for

; 2’s complement sign extension) and B28 (LSBIT)

;

;

; {ADCC} ADC curvature correction

;————————————————————————————————

; 8 bits unsigned integer (1 byte)

;

; The LTC2400 transfer characteristic has a typical INL of about

; 4ppm and a parabolic shape symmetric with respect to mid-scale.

; This error can be corrected to a first and second order and

; ADDC contains the magnitude of this correction.

;

;

; {ER3, ER2, ER1, ER0} control loop error value

;——————————————————————————————————————————————

; signed integer (4 bytes)

;

; Contains the value of the current control loop error calculated

; as the difference between the previous user input and the last

; ADC reading. It is used to adjust the Low_DAC setting. Uses the

; same physical location as {ADC3, ADC2, ADC1, ADC0}:

;

; ER0 - least significant byte, same location as ADC0

;

; ER1 - second byte, same location as ADC1

AN86-17

Page 18

Application Note 86

;

; ER2 - third byte, same location as ADC2

;

; ER3 - most significant byte, same location as ADC3

;

;

; {DL3, DL2, DL1, DL0} Low DAC control value

;———————————————————————————————————————————

; signed integer (4 bytes):

;

; Contains the Low_DAC setting in a 2’s complement, 32 bit

; format. Must be initialized to 0!

;

; DL0 - least significant byte - used for Low_DAC

; control

;

; DL1 - second byte - used for Low_DAC control after

; conversion to offset binary format {DL1, DL0}

;

; DL2 - third byte - may be only 00 or FF

;

; DL3 - most significant byte - may be only 00 or FF

;

;

; {INDX} Index variable for various program functions

;————————————————————————————————————————————————————

; 1 byte.

;

;

; {TMPV} Temporary variable for various program functions

;————————————————————————————————————————————————————————

; 1 byte.

;

;

;

; Algorithm

;===========

;

; After each ADC conversion cycle the processor calculates the control

; loop error value as the difference between the desired output and

; the latest conversion result. Than it updates the DACs command

; such as to reduce the error magnitude. A new ADC conversion cycle

; is started following the DACs update operation.

;

; In order to maintain adequate control loop stability it is necessary

; for the DACs and the associated amplifiers to settle to better than

; 20 bits accuracy before the ADC starts sampling the system output. For

; an LTC2400 based system this settling time is 66ms.

;

; Initialization:

; Initializes the PIC controller and the hardware interface

; and starts the Scan procedure.

;

AN86-18

Page 19

Application Note 86

; 1. Load ADC control port with default values

; SCKAD = 0

; SDOAD = 1

; 2. Set ADC control port I and O pins

; SCKAD = output

; SDOAD = input

; 3. Load register control port with default values

; NCSR[2:0] = 111

; NCSD[1:0] = 11

; ADDAC = 1

; NLDAC = 1

; DACRDY = 0

; 4. Set register control port in output mode

; 5. Set data bus to default value DBUS[7:0]=0x00

; 6. Set data bus in output mode

; 7. Initialize internal registers and variables:

; OPTION = 0x2F

; Timer0 used as counter is incremented by low-to-high edge

; Prescaler works with watch dog timer in div128 mode

; CON = 0x80

; Simulate a UIU “user interface update” event to force

; the update of both Low_DAC and High_DAC

; {DL3, DL2, DL1, DL0} = 0

; { U2, U1, U0} = 0

; 8. Update hardware using the initialized variables

; 9. Start new ADC conversion by reading and discarding

; 32 serial bits.

; 10.Start the Scan procedure

;

; Scan:

; Continuously looks for “user input update” events. When

; a “user input update” event is detected updates the

; input buffer {UB2, UB1, UB0}, resets timer, sets UIU flag

; and resets RDY and RDY2 flags.

;

; The active low write signal for the external input register

; (which is the same as the user interface NWR input signal)

; is driven by the user and it is connected to the counter

; input of Timer0. The Timer0 is used in counter mode without a

; prescaler and it increments whenever a low-to-high transition

; is detected at its input. This is the same transition which

; latches in the input register a new user command.

; Because of the PIC controller timing constraints, this write

; signal must be maintained low for at least 2*Tosc + 20ns

; where Tosc is the maximum PIC clock period. When a 4 MHz

; clock is used for the PIC processor, the low time must be

; longer than about 520ns.

;

; 1. Test for “user input update” events by testing the Timer0

; value.

; If Timer0>0 an UIU event has occurred. Reset the timer

; and answer Yes.

; If Timer0=0 answer No.

AN86-19

Page 20

Application Note 86

; 1.1 If Yes, read input latch into {UB2, UB1, UB0},

; reset DACRDY output line, set UIU flag and

; and reset RDY and RDY2 flags (CON[7:5]=100)

; Than continue

; 1.2 If No continue

;

; Continuously looks for the ADC end of conversion event. When

; the “end of conversion” is detected it reads the 28 most

; significant bits from the ADC and it constructs the ADC

; result {ADC3, ADC2, ADC1, ADC0} in 2’s complement format

; If ADC3[1] == 0 => ADC3[7:1]=1111 111

; If ADC3[1] == 1 => ADC3[7:1]=0000 000

; For very early LTC2400 samples only, it is possible

; to obtain as a valid 0 conversion result ADC3[1:0]=00

; In this case:

; If ADC3[1:0] == 0 => ADC3=0

; It also calculates the first (x1) and second (x2) order ADC

; curvature correction ADCC as follows:

; x1 = {0x00, 0x80} ; -abs({ADC3, ADC2, ADC1, ADC0}/(2^16)-{0x00, 0x80})

; x2 = {0x00, 0x40} ; -abs({0x00,{0,ADC2[6:0]},ADC1,ADC0}/(2^16)-{0x00,0x40})

; ADCC = floor((x1 + x2/2) * {00000 CON[2:0]} / 4 )

; The actual implementation uses only the least significant

; byte of x without any substantial additional error.

; Thus the above relation can be modified as follows:

; ADCC = floor((abs(ADC2) + abs({ADC2[6],ADC2[6:0]})/2) *

; * {00000 CON[2:0]} / 4 )

; The maximum correction range is about 7ppm INL at mid

; scale for CON[2:0] = 111.

;

; 2. Test for ADC “end of conversion” event by testing the

; value of the ADC_SDO signal.

; If ADC_SDO = LOW answer Yes.

; If ADC_SDO = HIGH answer No.

; 2.1 If Yes read 28 most significant bits from the ADC,

; update {ADC3, ADC2, ADC1, ADC0} and calculate the

; curvature correction byte ADCC. Than start the CComp

; procedure.

; It should be noticed that while reading the first 28

; most significant bits from the ADC the controller

; generates 27 serial clock pulses. An additional 5 serial

; clock pulses (for a total of 32) are necessary to restart

; the conversion.

; 2.2 If No restart the Scan procedure.

;

;

; CComp:

; Calculates the current control loop error as:

;

; error = current_user_input - ADC_reading +

; + new_user_input_LSB - current_user_input_LSB

;

AN86-20

Page 21

Application Note 86

; The curvature correction is included in the ADC

; conversion result and is always positive therefore:

;

; ADC_reading = {ADC3, ADC2, ADC1, ADC0} +

; + { 0, 0, 0, ADCC}

;

; The term “new_user_input_LSB - current_user_input_LSB”

; represents the residue of the new user command which

; is added to the Low_DAC.

;

; {ER3, ER2, ER1, ER0} =

; = {0, U2, U1, U0} - {ADC3, ADC2, ADC1, ADC0} ; - { 0, 0, 0, ADCC} +

; + {0, 0, 0, UB0} - { 0, 0, 0, U0} =

;

; = {0, U2, U1, UB0} - {ADC3, ADC2, ADC1, ADC0} ; - { 0, 0, 0, ADCC}.

;

; The loop error {ER3, ER2, ER1, ER0} is a 32 bit signed number

; and the weight of the least significant bit is 1/16ppm of

; the ADC reference voltage. A 4ppm error value is represented

; as {0, 0, 0, 0x40}.

;

; The ADC output noise is dominated by thermal noise and has a

; white distribution. The control loop noise can be reduced by

; the square root of N by averaging N successive ADC readings.

; The obvious penalty is a slow settling time. Due to the

; limited amount of RAM available a direct implementation

; of this noise reduction strategy is difficult. In an equivalent

; implementation, when the absolute value of the loop error

; {ER3, ER2, ER1, ER0} decreases below a certain threshold, the

; gain of the error correction loop can be decreased. The default

; threshold is set at a very conservative 4ppm. This value must

; always be larger than the peak noise level of the ADC. A very

; quiet implementation can probably operate with a threshold of

; 2ppm. If CON[3]=0 the gain of the error correction loop is

; decreased from 1 to 1/4. If CON[3]=1 the gain of the error

; correction loop is decreased from 1 to 1/16.

;

; The High_DAC is always controlled by the 16 most significant

; bits of the most recent user command {UB2, UB1}

;

; The Low_DAC is controlled by the {DL3, DL2, DL1, DL0}

; variable which integrates the control loop error. Under

; correct operating condition abs({DL3, DL2, DL1, DL0})<2^15.

; In order to avoid roll-overs during large transients the

; {DL3, DL2, DL1, DL0} must be clamped within the +/- 2^15 range.

; The 16 bit Low_DAC can than be controlled by {DL1, DL0}

; after conversion to offset binary format.

;

AN86-21

Page 22

Application Note 86

; The DACRDY output line reflects the state of the

; internal RDY2 flag.

;

; After the updates are completed we must start a new ADC

; conversion by completing the serial transfer.

;

; 1. Test if UIU flag is set

; 1.1 If Yes, move UB[3:0] into CON[3:0]

; and {UB0[7:4], 0000} into U0. The last ADC result

; is curvature corrected using the previous CON[3:0] value!.

; 2. Calculate {ER3, ER2, ER1, ER0}.

; 3. Test if UIU flag is set

; 3.1 If Yes, move {UB2, UB1} into {U2, U1} and

; clear UIU, RDY and RDY2 flags (CON[7:5]=000 )

; 3.2 If No, test if abs({ER3, ER2, ER1, ER0}) < 4ppm

; 3.2.1 If Yes, test if CON[6]=1 (RDY flag)

; 3.2.1.1 If Yes, set RDY2 flag (CON[5]=1 )

; 3.2.1.2 If No, set RDY flag (CON[6]=1 )

; and test if CON[3]=0 (filter flag)

; 3.2.1.3 If Yes, {ER3, ER2, ER1, ER0} =

; = {ER3, ER2, ER1, ER0}/4

; 3.2.1.4 If No, {ER3, ER2, ER1, ER0} =

; = {ER3, ER2, ER1, ER0}/16

; 3.2.2 If No, clear UIU, RDY and RDY2

; flags (CON[7:5]=000 )

; 4 {DL3, DL2, DL1, DL0} = {DL3, DL2, DL1, DL0} +

; +{ER3, ER2, ER1, ER0}.

; 5. Update High_DAC, Low_DAC and DACRDY output line

; 6. Read the 4 least significant bits from ADC and start

; a new conversion

; 7. Restart the Scan procedure

;

;

; Hardware resources

;====================

;

; Uses 8 input/output pins, 9 output pins, 1 input pin and 1

; counter input pin

;

; DBUS[7:0] data bus

;———————————————————

; 8 bit bi-directional data bus is used to read the 20 bit input

; command IC[19:0], the one bit filter selection FS[0] and the 3 bit

; curvature correction selection CC[2:0]. It is also used to write

; the 16 bit Low_DAC command LDAC[15:0] and the 16 bit High_DAC

; command HDAC[15:0].

;

; assigned to PIC port C[7:0]

;

AN86-22

Page 23

Application Note 86

; The data format for the read and write operations is as follows:

;

; DBUS[ 7:0] = IC[19:12] when NCSR[2] = 0

; DBUS[ 7:0] = IC[11: 4] when NCSR[1] = 0

; DBUS[ 7:0] = {IC[3:0], FS[0], CC[2:0]} when NCSR[0] = 0

; LDAC[ 7:0] = DBUS[7:0] when NCSD[0] = 0 and ADDAC = 0

; LDAC[15:8] = DBUS[7:0] when NCSD[0] = 0 and ADDAC = 1

; HDAC[ 7:0] = DBUS[7:0] when NCSD[1] = 0 and ADDAC = 0

; HDAC[15:7] = DBUS[7:0] when NCSD[1] = 0 and ADDAC = 1

;

;

; NCSR[2:0] active low output enable controls for input registers

;————————————————————————————————————————————————————————————————

; 3 output lines used to selectively enable the three 8-bit input

; registers in order to read the user updated DAC command, the 3

; curvature correction bits and the one filter control bit.

;

; NCSR[0] enables the low input byte (LSB) and is assigned to port B[0]

;

; NCSR[1] enables the second input byte and is assigned to port B[1]

;

; NCSR[2] enables the high input byte (MSB) and is assigned to port B[2]

;

;

; NCSD[1:0] active low input enable controls for the DACs

;————————————————————————————————————————————————————————

; 2 output lines used to selectively enable the two DACs

;

; NCSD[0] enables the Low_DAC and is assigned to port B[3]

;

; NCSD[1] enables the High_DAC and is assigned to port B[4]

;

;

; ADDAC DAC address control

;——————————————————————————

; output line. A low enables a write operation to the low byte of

; Low_DAC or High_DAC. A high enables a write operation to the high

; byte of Low_DAC or High_DAC.

;

; ADDAC is assigned to port B[5]

;

;

AN86-23

Page 24

Application Note 86

; NLDAC active low DAC load control

;——————————————————————————————————

; output line. A high to low transition on this line updates the

; Low_DAC and High_DAC output values

;

; NLDAC is assigned to port B[6]

;

;

; DACRDY active high ready output signal

;———————————————————————————————————————

; output line. Indicates that the control loop error has been

; within a +/- 4ppm range for at least 250 ms

;

; DACRDY is assigned to port B[7]

;

;

; SCKAD external serial clock line for the ADC

;—————————————————————————————————————————————

; output line. ADC external serial clock. An external 10Kohm

; pull-down resistor is necessary on this line for correct

; power-up configuration.

;

; SCKAD is assigned to port A[0]

;

;

; SDOAD serial data line from ADC

;————————————————————————————————

; input line. Used to read ADC serial data.

;

; SDOAD is assigned to port A[1]

;

;

;

; NWRUI active low user interface write control

;——————————————————————————————————————————————

; input line. The user must bring this line low in order to update

; the DAC input value. A minimum low and high time is required !

;

; NWRUI is assigned to TOCKI counter input pin

;

;

;

AN86-24

Page 25

Application Note 86

; The spare I/O pins A[3:2] are configured as outputs and maintained LOW.

;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

list p=16c55A ; list directive to define processor

#include <p16c5x.inc> ; processor specific variable definitions

__CONFIG _CP_OFF & _WDT_ON & _XT_OSC

;VARIABLE DEFINITIONS

;====================

UB0 EQU H’0008' ; user input word buffer LSB

UB1 EQU H’0009' ; user input word buffer second byte

UB2 EQU H’000A’ ; user input word buffer MSB

U0 EQU H’0008' ; user input word LSB

U1 EQU H’000B’ ; user input word second byte

U2 EQU H’000C’ ; user input word MSB

CON EQU H’000D’ ; control byte

ADC0 EQU H’000E’ ; ADC conversion result LSB

ADC1 EQU H’000F’ ; ADC conversion result second byte

ADC2 EQU H’0010' ; ADC conversion result third byte

ADC3 EQU H’0011' ; ADC conversion result MSB

ADCC EQU H’0012' ; ADC curvature correction byte

ER0 EQU H’000E’ ; control loop error LSB

ER1 EQU H’000F’ ; control loop error second byte

ER2 EQU H’0010' ; control loop error third byte

ER3 EQU H’0011' ; control loop error MSB

DL0 EQU H’0013' ; Low_DAC LSB

DL1 EQU H’0014' ; Low_DAC second byte

DL2 EQU H’0015' ; Low_DAC third byte

DL3 EQU H’0016' ; Low_DAC MSB

INDX EQU H’0017' ; index variable

TMPV EQU H’0018' ; temporary variable

#define OPRDF 0x2F ; OPTION register default value

#define CONDF 0x80 ; CON register default value

AN86-25

Page 26

Application Note 86

;HARDWARE ASSIGNMENT DEFINITIONS

;===============================

#define DBUS PORTC ; 8bit I/O data bus

#define REGCN PORTB ; register control port

#define REGDF 0x7F ; register control port default value

#define NCSR0 PORTB,0 ; LSB input register active low output enable

#define NCSR1 PORTB,1 ; second byte input register active low output enable

#define NCSR2 PORTB,2 ; MSB input register active low output enable

#define NCSD0 PORTB,3 ; Low_DAC active low write enable

#define NCSD1 PORTB,4 ; High_DAC active low write enable

#define ADDAC PORTB,5 ; address bit for Low_DAC and High_DAC

#define NLDAC PORTB,6 ; active low load control for Low_DAC and High_DAC

#define DACRDY PORTB,7 ; 20bit_DAC ready indicator

#define ADCCN PORTA ; ADC control port

#define ADCTR 0x02 ; ADC control port configuration

; SDOAD input, the rest outputs

#define ADCDF 0x02 ; ADC control port default value

#define SCKAD PORTA,0 ; ADC external serial clock

#define SDOAD PORTA,1 ; ADC serial data output

;THE CODE

;===============================

RESET ORG 0x1FF ; processor reset vector

goto start

ORG 0x000

;Initialization procedure

;————————————————————————

start movlw ADCDF ;write ADC control port default value

movwf ADCCN ;

movlw ADCTR ;set the I and O pin states for the

tris ADCCN ;ADC control port

;

movlw REGDF ;write register control port default value

movwf REGCN ;

clrw ;set register control port pins as

tris REGCN ;output only

;

movwf DBUS ;set DBUS default value of 0

tris DBUS ;set DBUS as output

;

movlw OPRDF ;set OPTION register default value

option ;

;

AN86-26

Page 27

Application Note 86

clrf TMR0 ;

btfss STATUS,NOT_TO ;if this is not a power-on reset

movwf TMR0 ;load Timer0 with a nonzero value

;to force an initial read of the

;external input register

;

clrf DL3 ;initialize {DL3, DL2, DL1, DL0}=0

clrf DL2 ;

clrf DL1 ;

clrf DL0 ;

clrf U2 ;initialize {U2, U1, U0}=0

clrf U1 ;

clrf U0 ;

;

movlw CONDF ;set CON variable default value

movwf CON ;

;prepare to trigger a new ADC conversion

;after completing a hardware update

movlw 0x20 ;read and discard 32 serial bits from

movwf INDX ;the ADC

;

goto iupdt ;go to the hardware update function

;ADC output buffer flush function

;————————————————————————————————

fladc movlw 0x20 ;reads and discards 32 serial bits from

movwf INDX ;the ADC

;ADC dummy serial read function

;——————————————————————————————

;reads and discards the number of serial

;bits indicated by the INDX variable

rddmy bsf SCKAD ;low-to-high ADC serial clock edge

bcf SCKAD ;high-to-low ADC serial clock edge

decfsz INDX,1 ;test if we read enough bits

goto rddmy ;if No, read one more bit

btfss SDOAD ;if Yes test that a new conversion has started

goto fladc ;if No, there is an interface problem. Flush the

;ADC output buffer and start a new conversion

goto scan ;if Yes restart the scan procedure

;external input register read function

;—————————————————————————————————————

rduiu movlw 0xFF ;input register read routine

tris DBUS ;set data bus in read mode (input)

bcf NCSR0 ;output enable for input reg. LSB

nop ;wait for data bus to settle

movf DBUS,0 ;read input reg. LSB

bsf NCSR0 ;output disable for input reg. LSB

bcf NCSR1 ;output enable for input reg. second byte

movwf UB0 ;store input reg. LSB into input buffer

movf DBUS,0 ;read input reg. second byte

bsf NCSR1 ;output disable for input reg. second byte

AN86-27

Page 28

Application Note 86

bcf NCSR2 ;output enable for input reg. MSB

movwf UB1 ;store input reg. second byte into input buffer

movf DBUS,0 ;read input reg. MSB

movwf UB2 ;store input reg. MSB into input buffer

clrw ;terminate input reg. read operation

bsf NCSR2 ;output disable for input reg. MSB

tris DBUS ;return data bus to write mode

clrf TMR0 ;clear Timer0 to continue wait for a UIU event

bcf DACRDY ;signal user that input data has been read

bsf CON,7 ;set UIU flag

bcf CON,6 ;clear RDY flag

bcf CON,5 ;clear RDY2 flag

;scan procedure

;——————————————

;monitors UIU and end-of-conversion events

scan movf TMR0,1 ;test if Timer0 = 0

btfss STATUS,Z ;if Timer0=0 no UIU has occurred, skip next

goto rduiu ;a user interface update has occurred

;go and read the new DAC input data

btfsc SDOAD ;test ADC end of conversion signal

goto scan ;conversion not ready, rescan

;ADC serial read function

;————————————————————————

rdadc movlw 0x1B ;ADC conversion is done, read first 28 bits

movwf INDX ;the first bit must be “0” to get here

;so do not bother with it

rdbit bsf SCKAD ;low-to-high ADC serial clock edge

bcf SCKAD ;high-to-low ADC serial clock edge

bcf STATUS,C ;move ADC output bit to carry. First clear carry

btfsc SDOAD ;read ADC output bit

bsf STATUS,C ;if ADC output is “1” set carry

rlf ADC0,1 ;load carry as msb of ADC result

rlf ADC1,1 ;and shift left all 4 bytes of the ADC result

rlf ADC2,1 ;

rlf ADC3,1 ;

decfsz INDX,1 ;test if all 28 bits have been read

goto rdbit ;if not, continue

;

;we have skipped the first ADC bit (ADC bit31=0)

;which has been tested as =0 when we detected the

;end of conversion.

;we have read 27 additional bits and have generated

;27 clock pulses. To restart the conversion we must

;produce the 5 remaining clock pulses

AN86-28

Page 29

Application Note 86

;verify validity of ADC serial data and format it

;————————————————————————————————————————————————

btfsc ADC3,2 ;test if the ADC bit30 is “0”

goto fladc ;if not there is an interface problem. Flush the

;ADC output buffer and start a new conversion

;if yes, put the ADC result in 2’s complement form

movlw 0x03 ;first clear the 6 most significant bits in ADC3

andwf ADC3,1 ;

btfsc STATUS,Z ;tests for the [ADC_B29,ADC_B28]=00 ADC output

goto rdend ;if Yes the formatting is completed.

;in very early LTC2400 samples the ADC output code

;[ADC_B29,ADC_B28]=00 is valid

; goto fladc ;for current LTC2400 devices improved error

;detection capability is obtained if the

;previous line is replaced with this line.

;The replacement is not mandatory.

;For current LTC2400 parts the output code

;[ADC_B29,ADC_B28]=00 is not valid thus it may

;be assumed that an ADC interface error has

;occurred. Flush the ADC output buffer and start

;a new conversion

movlw 0x02 ;if No, convert ADC3 in 2’s complement form

btfss ADC3,1 ;

movlw 0xFE ;

xorwf ADC3,1 ;

;curvature correction calculator

;———————————————————————————————

;first order curvature correction multiplier

;use ADC2[7:0] as a 2’s complement number

rdend movf ADC2,0 ;calculate abs(ADC2)

btfsc ADC2,7 ;if ADC2[7]=0 w = ADC2

comf ADC2,0 ;else w = !ADC2

movwf ADCC ;ADCC=w=abs(ADC2)

;second order curvature correction multiplier

;use ADC2[6:0] as a 2’s complement number

movf ADC2,0 ;calculate abs(ADC2[6:0])

btfsc ADC2,6 ;if ADC2[6]=0 w = ADC2

comf ADC2,0 ;else w = !ADC2

movwf TMPV ;TMPV=w=abs(ADC2[6:0])

rrf TMPV,0 ;w=TMPV/2 in order to scale the second order

;curvature correction

andlw 0x1f ;clear 3 MSB of w to complete calculation

addwf ADCC,0 ;w=abs(ADC2)+abs(ADC2[6:0])/2

movwf TMPV ;TMPV contains the curvature correction multiplier

;

clrf ADCC ;

bcf STATUS,C ;clear carry for div-by-2 operation

btfsc CON,2 ;if CON[2]=1

AN86-29

Page 30

Application Note 86

movwf ADCC ;ADCC=ADCC+abs(ADC2)

rrf TMPV,1 ;TMPV=TMPV/2

movf TMPV,0 ;

bcf STATUS,C ;clear carry for div-by-2 operation

btfsc CON,1 ;if CON[1]=1

addwf ADCC,1 ;ADCC=ADCC+abs(ADC2)/2

rrf TMPV,1 ;TMPV=TMPV/2

movf TMPV,0 ;

btfsc CON,0 ;if CON[0]=1

addwf ADCC,1 ;ADCC=ADCC+abs(ADC2)/4

;code comparator procedure

;—————————————————————————

ccomp btfss CON,7 ;if the UIU flag is clear

goto ercalc ;skip CON[3:0] and U0 update

movlw 0xF0 ;else update CON[3:0]

andwf CON,1 ;clear CON[3:0]

movlw 0x0F ;extract new CON[3:0]

andwf UB0,0 ;from input buffer

iorwf CON,1 ;and load it

movlw 0xF0 ;move UB[7:4] to U0[7:4]

andwf UB0,1 ;UB0 and U0 use the same

;physical location

;calculate control loop error

;————————————————————————————

ercalc comf ADCC,1 ;ADCC 1’s complement

comf ADC0,1 ;ADC0 1’s complement

movlw 0x02 ;add carry-in for ADCC and for ADC0

;2’s complement conversion

clrf TMPV ;prepare carry-out accumulator

addwf UB0,0 ;w=carry-in + UB0

btfsc STATUS,C ;if there is a carry-out

incf TMPV,1 ;accumulate it

addwf ADCC,0 ;w=carry-in + UB0 - ADCC

btfsc STATUS,C ;if there is a carry-out

incf TMPV,1 ;accumulate it

addwf ADC0,1 ;ER0=UB0 - ADC0 - ADCC

;has same location as ADC0

btfsc STATUS,C ;if there is a carry-out

incf TMPV,1 ;accumulate it

AN86-30

Page 31

Application Note 86

comf ADC1,1 ;ADC1 1’s complement

movlw 0xff ;w=0xff (1’s complement of ADCC second byte)

addwf TMPV,0 ;w=0xff + carry-in

clrf TMPV ;prepare carry-out accumulator

btfsc STATUS,C ;if there is a carry-out

incf TMPV,1 ;accumulate it

addwf U1,0 ;w=0xff + carry-in + UB1

btfsc STATUS,C ;if there is a carry-out

incf TMPV,1 ;accumulate it

addwf ADC1,1 ;ER1=U1 - ADC1 - 0 + carry-in

;has same location as ADC1

btfsc STATUS,C ;if there is a carry-out

incf TMPV,1 ;accumulate it

comf ADC2,1 ;ADC2 1’s complement

movlw 0xff ;w=0xff (1’s complement of ADCC third byte)

addwf TMPV,0 ;w=0xff + carry-in

clrf TMPV ;prepare carry-out accumulator

btfsc STATUS,C ;if there is a carry-out

incf TMPV,1 ;accumulate it

addwf U2,0 ;w=0xff + carry-in + UB2

btfsc STATUS,C ;if there is a carry-out

incf TMPV,1 ;accumulate it

addwf ADC2,1 ;ER2=U2 - ADC2 - 0 + carry-in

;has same location as ADC2

btfsc STATUS,C ;if there is a carry-out

incf TMPV,1 ;accumulate it

comf ADC3,1 ;ADC3 1’s complement

decf TMPV,1 ;ADCC 2’s complement term. The next

;carry-in is not useful - discard

movf TMPV,0 ;w=carry-in

addwf ADC3,1 ;ER3= 0 - ADC3 - 0 + carry-in

;has same location as ADC3

btfsc CON,7 ;test if the UIU flag is set

goto lduiu ;go to U1, U2 update

AN86-31

Page 32

Application Note 86

movf ER3,0 ;W = ER3

btfsc ER3,7 ;test if {ER3, ER2, ER1, ER0} < 0

comf ER3,0 ;if yes W = -ER3

btfss STATUS,Z ;test if W=0

goto nrdy ;if not absolute error >= 4ppm

movf ER2,0 ;W = ER2

btfsc ER3,7 ;test if {ER3, ER2, ER1, ER0} < 0

comf ER2,0 ;if yes W = -ER2

btfss STATUS,Z ;test if W=0

goto nrdy ;if not absolute error >= 4ppm

movf ER1,0 ;W = ER1

btfsc ER3,7 ;test if {ER3, ER2, ER1, ER0} < 0

comf ER1,0 ;if yes W = -ER1

btfss STATUS,Z ;test if W=0

goto nrdy ;if not absolute error >= 4ppm

;error comparator

;————————————————

;calculate absolute value of loop error and

;compare loop error magnitude with the 4ppm

;threshold

movf ER0,0 ;W = ER0

btfsc ER3,7 ;test if {ER3, ER2, ER1, ER0} < 0

comf ER0,0 ;if yes W = -ER0

andlw 0xC0 ;keep only W[7:6] which are bits >= 4ppm

btfss STATUS,Z ;test if W[7:6]=0

goto nrdy ;if not absolute error >= 4ppm

;if we are here the absolute loop error is

;less than 4 ppm. Set the flags and

;scale the loop error.

btfsc CON,6 ;test if RDY flag is already set

bsf CON,5 ;if Yes, set RDY2 flag

bsf CON,6 ;set RDY flag in any case

AN86-32

Page 33

;error scaling

;—————————————

;reduce error correction value for loop

;damping and ADC noise reduction

btfsc CON,3 ;test if CON[3]=0

goto div4 ;if Yes ER0=ER0/4

;if No ER0=ER0/16

rrf ER0,1 ;*1/2

rrf ER0,0 ;*1/2

andlw 0x3F ;clear 2 most significant bits

btfsc ER3,7 ;if {ER3, ER2, ER1, ER0} < 0

iorlw 0xC0 ;set 2 most significant bits

movwf ER0 ;ER0=ER0/4

div4 rrf ER0,1 ;*1/2

rrf ER0,0 ;*1/2

andlw 0x3F ;clear 2 most significant bits

btfsc ER3,7 ;if {ER3, ER2, ER1, ER0} < 0

iorlw 0xC0 ;set 2 most significant bits

movwf ER0 ;ER0=ER0/4

goto eracc ;go to error accumulator

;load latest user input

;——————————————————————

lduiu movf UB1,0 ;

movwf U1 ;U1=UB1

movf UB2,0 ;

movwf U2 ;U2=UB2

nrdy movlw 0x1F ;

andwf CON,1 ;clear UIU, RDY and RDY2 flags

Application Note 86

;error accumulator

;—————————————————

;adds the current loop error to the

;previous Low_DAC control value

;{DL3, DL2, DL1, DL0}={DL3, DL2, DL1, DL0}+

; +{ER3, ER2, ER1, ER0}

eracc movf ER0,0 ;the carry-in is 0

clrf TMPV ;clear carry-in accumulator

addwf DL0,1 ;DL0=DL0+ER0

btfsc STATUS,C ;if there is a carryout

incf TMPV,1 ;accumulate in carry-in

movf TMPV,0 ;load carry-in

clrf TMPV ;clear carry-in accumulator

addwf ER1,0 ;W=ER1+carry-in

btfsc STATUS,C ;if there is a carryout

incf TMPV,1 ;accumulate in carry-in

addwf DL1,1 ;DL1=DL1+ER1

btfsc STATUS,C ;if there is a carryout

incf TMPV,1 ;accumulate in carry-in

movf TMPV,0 ;load carry-in

clrf TMPV ;clear carry-in accumulator

addwf ER2,0 ;W=ER2+carry-in

AN86-33

Page 34

Application Note 86

btfsc STATUS,C ;if there is a carryout

incf TMPV,1 ;accumulate in carry-in

addwf DL2,1 ;DL2=DL2+ER2

btfsc STATUS,C ;if there is a carryout

incf TMPV,1 ;accumulate in carry-in

movf TMPV,0 ;load carry-in

addwf ER3,0 ;W=ER3+carry-in

addwf DL3,1 ;DL3=DL3+ER3

btfss STATUS,Z ;test if DL3=0

goto negpot ;if No, DL may be negative

movf DL2,1 ;

btfss STATUS,Z ;test if DL2=0

goto ovflow ;if No, DL >= 2^15, must truncate

btfsc DL1,7 ;test if DL1[7]=1

goto ovflow ;if No, DL >= 2^15, must truncate

goto updt ;if Yes we are done with DL range control

;Low_DAC control truncation

;——————————————————————————

;limits the {DL3, DL2, DL1, DL0} range to

; abs({DL3, DL2, DL1, DL0}) < 2^15 by

;truncation

;if Yes, DL is positive

;test for overflow (>= 2^15)

;if Yes continue testing for overflow

ovflow clrf DL3 ;if we arrive here DL >= 2^15. Must

clrf DL2 ;truncate to DL=2^15-1 => DL3=DL2=0

movlw 0xFF ;and DL1=0xEF, DL0=0xFF

movwf DL0 ;

movwf DL1 ;

bcf DL1,7 ;

goto updt ;done with overflow correction

AN86-34

Page 35

Application Note 86

udflow clrf DL1 ;if we arrive here DL < -2^15. Must

bsf DL1,7 ;truncate to DL=-2^15-1 => DL3=DL2=0xFF

clrf DL0 ;and DL1=0x80, DL0=0

movlw 0xFF ;

movwf DL3 ;

movwf DL2 ;

goto updt ;done with underflow correction

negpot btfss DL3,7 ;DL may be negative. Test if DL3[7]=1

goto ovflow ;if No, DL > 2^15, must truncate

incf DL3,0 ;if Yes, DL <0.

btfss STATUS,Z ;test if DL3=FF

goto udflow ;if No, DL < -2^15, must truncate

incf DL2,0 ;if Yes continue testing for underflow

btfss STATUS,Z ;test if DL2=FF

goto udflow ;if No, DL < -2^15, must truncate

;if Yes continue testing for underflow

btfss DL1,7 ;test if DL1[7]=0

goto udflow ;if No, DL < -2^15, must truncate

;if Yes we are done with DL range control

;Hardware update function

;————————————————————————

;Low_DAC and High_DAC update

;

;This is the hardware update function

;entry point for normal operation.

;

updt movlw 0x05 ;prepare to generate the last 5 ADC external

movwf INDX ;serial clock pulses

;when going to restart the scan procedure

;at the end of the hardware update function

;This will trigger a new ADC conversion.

;

;This is the hardware update function

;entry point for initial operation.

;The INDX variable has been initialized

;before to 0x2F which will generate

;32 serial clock pulses to the ADC thus

;starting a new conversion

;

AN86-35

Page 36

Application Note 86

iupdt clrw ;set the data bus in write mode

tris DBUS ;

bcf ADDAC ;set DAC address for LSB

movf U1,0 ;load High_DAC LSB

movwf DBUS ;

bcf NCSD1 ;write to High_DAC

bsf NCSD1 ;

movf DL0,0 ;load Low_DAC LSB

movwf DBUS ;

bcf NCSD0 ;write to Low_DAC

bsf NCSD0 ;

bsf ADDAC ;set DAC address for MSB

movf U2,0 ;load High_DAC MSB

movwf DBUS ;

bcf NCSD1 ;write to High_DAC

bsf NCSD1 ;

movlw 0x80 ;change DL1 to offset binary

xorwf DL1,0 ;load Low_DAC MSB

movwf DBUS ;

bcf NCSD0 ;write to Low_DAC

bsf NCSD0 ;

bcf NLDAC ;load Low_DAC and High_DAC

bsf NLDAC ;

;DACRDY output update

btfsc CON,5 ;test if RDY2 flag is set

bsf DACRDY ;if Yes, set DACRDY output

btfss CON,5 ;if No

bcf DACRDY ;and only if No, clear DACRDY output

;

clrwdt ;clear watch dog timer

;

goto rddmy ;generate the necessary number

;of ADC serial clock pulses in order

;to start a new conversion

AN86-36

END ; directive ‘end of program’

Page 37

APPENDIX E

LINEARITY AND OUTPUT RANGE OPTIONS

Application Note 86

The LTC2400 used as the feedback A-to-D element in the

DAC has a typical ±2ppm residual nonlinearity. Figure E1’s

lower curve shows this, along with the first order correction necessary (upper curve) to get nonlinearity inside

1ppm (center curve). If true 1ppm performance is necessary, the software based correction described in Appendix␣ D

can be utilized. The software generates the desired “inverted bowl” correction characteristic. The correction may

be set to complement the residual nonlinearity characteristics of any individual LTC2400 via DIP switches at the

code comparator.

10

8

6

4

2

0

–2

–4

LINEARITY ERROR (ppm)

–6

–8

–10

0 8,338,608 16,777,215

CORRECTION

CHARACTERISITIC