Page 1

Application Note 61

August 1994

Practical Circuitry for Measurement and Control Problems

Circuits Designed for a Cruel and Unyielding World

Jim Williams

INTRODUCTION

This collection of circuits was worked out between June

1991 and July of 1994. Most were designed at customer

request or are derivatives of such efforts. All represent

substantial effort and, as such, are disseminated here

1

for wider study and (hopefully) use.

The examples are

roughly arranged in categories including power conversion, transducer signal conditioning, amplifiers and signal

generators. As always, reader comment and questions

concerning variants of the circuits shown may be addressed

directly to the author.

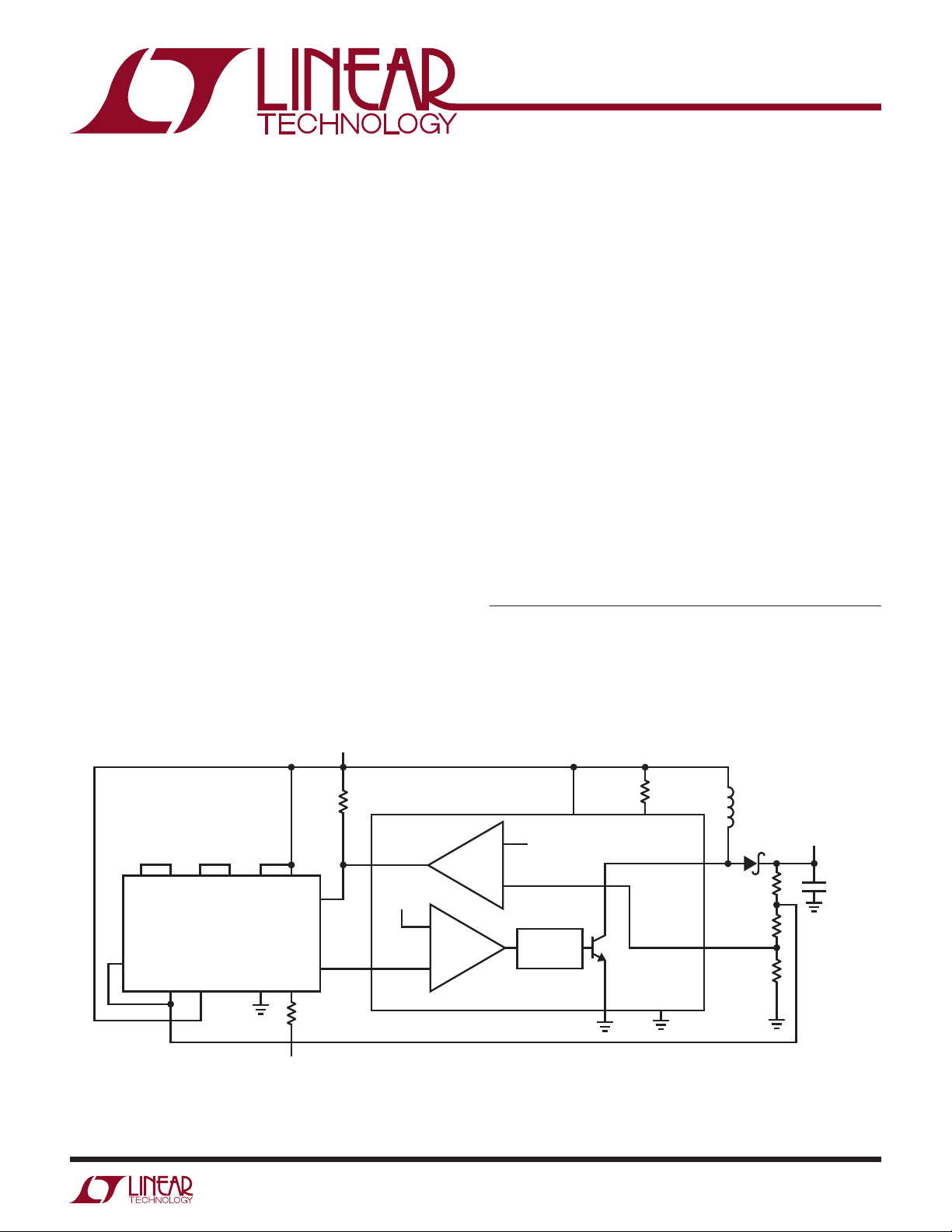

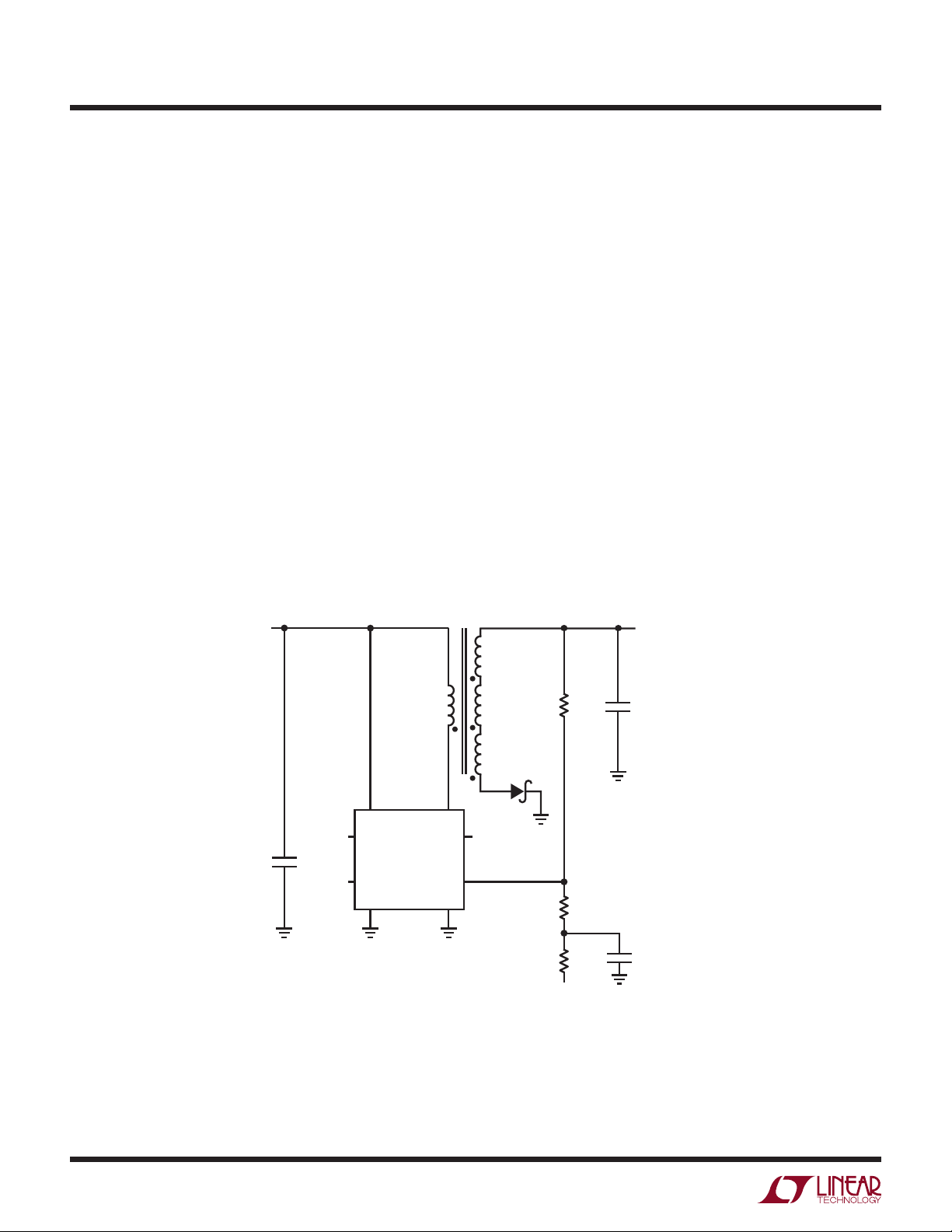

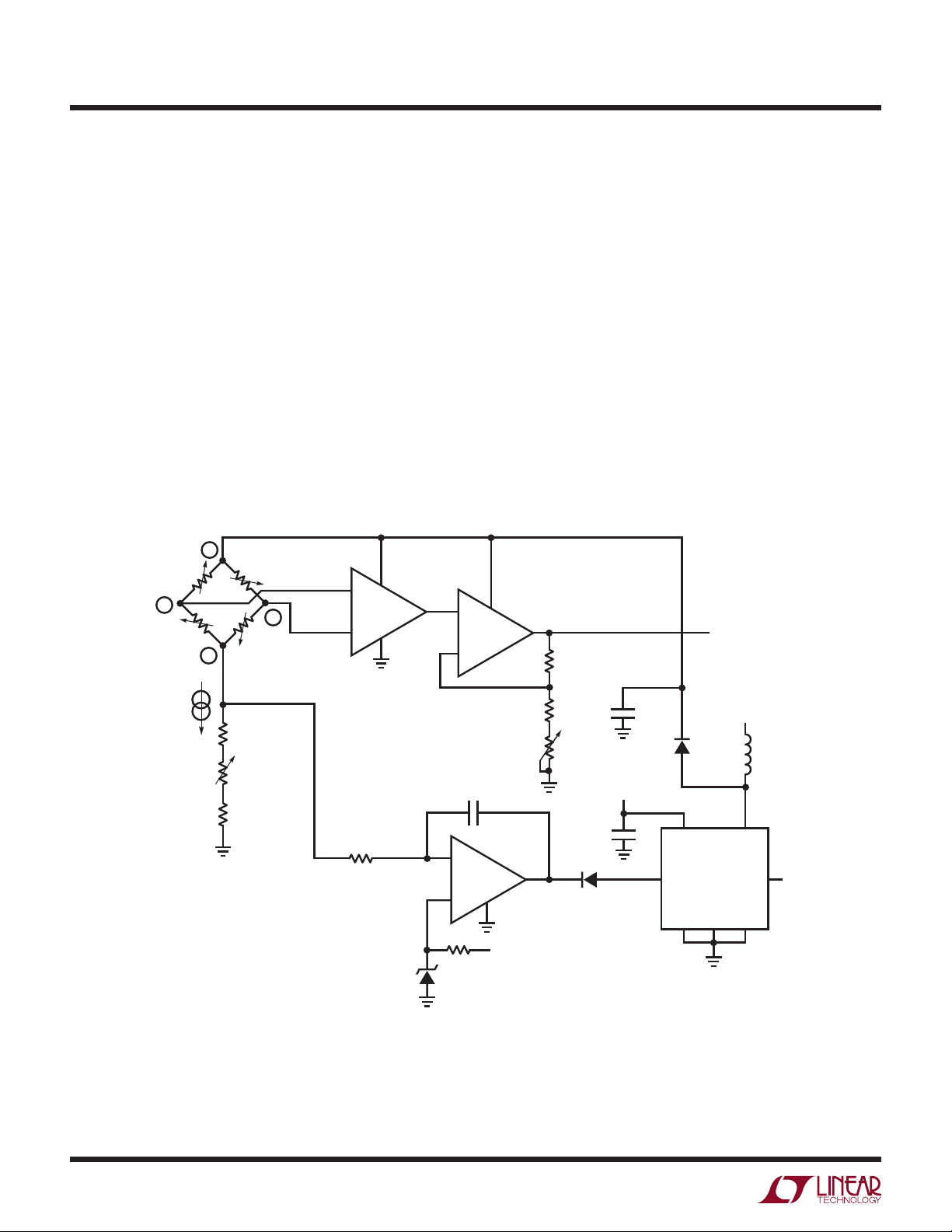

Clock Synchronized Switching Regulator

Gated oscillator type switching regulators permit high

efficiency over extended ranges of output current. These

regulators achieve this desirable characteristic by using

a gated oscillator architecture instead of a clocked pulse

width modulator. This eliminates the “housekeeping”

V

IN

2V TO 3.2V

(2 CELLS)

currents associated with the continuous operation of fixed

frequency designs. Gated oscillator regulators simply

self-clock at whatever frequency is required to maintain

the output voltage. Typically, loop oscillation frequency

ranges from a few hertz into the kilohertz region, depending upon the load.

In most cases this asynchronous, variable frequency operation does not create problems. Some systems, however, are

sensitive to this characteristic. Figure 1 slightly modifies

a gated oscillator type switching regulator by synchronizing its loop oscillation frequency to the systems clock. In

this fashion the oscillation frequency and its attendant

switching noise, albeit variable, become coherent with

system operation.

Note 1: “Study” is certainly a noble pursuit but we never fail to

emphasize use.

L, LT, LTC, LTM, Linear Technology and the Linear logo are registered trademarks of Linear

Technology Corporation. All other trademarks are the property of their respective owners.

SW2

47Ω

I

LIM

SW1

SET

GND

PRE1

CLR1

Q1

CLK1

74HC74

FLIP-FLOP

D1

PRE2CLR2Q1

V

CC

D2

Q2

CLK2

GND

47k

100kHz CLOCK

POWERED FROM

5V OUTPUT

100k

LT1107

A

OUT

V

1.2V

FB

REF

–

AUXILIARY

AMP

+

+

COMP

OSCILLATOR

–

L1 = COILTRONICS CTX-20-2

*= 1% METAL FILM RESISTOR

V

IN

V

REF

Figure 1. A Synchronizing Flip-Flop Forces Switching Regulator Noise to Be Coherent with the Clock

L1

22μH

1N5817

221k*

82.5k*

100k*

5V

OUT

+

100μF

AN61 F01

an61fa

AN61-1

Page 2

Application Note 61

Circuit operation is best understood by temporarily ignor-

®

ing the flip-flop and assuming the LT

and FB pins are connected. When the output voltage

A

OUT

decays the set pin drops below V

1107 regulator’s

, causing A

REF

OUT

to

fall. This causes the internal comparator to switch high,

biasing the oscillator and output transistor into conduction. L1 receives pulsed drive, and its flyback events are

deposited into the 100μF capacitor via the diode, restoring

output voltage. This overdrives the set pin, causing the IC

to switch off until another cycle is required. The frequency

of this oscillatory cycle is load dependent and variable. If,

as shown, a flip-flop is interposed in the A

-FB pin path,

OUT

synchronization to a system clock results. When the output

decays far enough (trace A, Figure 2) the A

pin (trace B)

OUT

goes low. At the next clock pulse (trace C) the flip-flop Q2

output (traceD) sets low, biasing the comparator-oscillator.

This turns on the power switch (V

pin is trace E), which

SW

pulses L1. L1 responds in flyback fashion, depositing its

energy into the output capacitor to maintain output voltage. This operation is similar to the previously described

case, except that the sequence is forced to synchronize

with the system clock by the flip-flops action. Although the

resulting loops oscillation frequency is variable it, and all

attendant switching noise, is synchronous and coherent

with the system clock.

A start-up sequence is required because this circuit’s

clock is powered from its output. The start-up circuitry

was developed by Sean Gold and Steve Pietkiewicz of

LTC. The flip-flop’s remaining section is connected as a

A = 50mV/DIV

AC-COUPLED

B = 5V/DIV

C = 5V/DIV

D = 5V/DIV

E = 5V/DIV

20μs/DIV

Figure 2. Waveforms for the Clock Synchronized

Switching Regulator. Regulator Only Switches (TraceE)

on Clock Transitions (Trace C), Resulting in Clock

Coherent Output Noise (Trace A)

AN61 F02

buffer. The CLR1-CLK1 line monitors output voltage via the

resistor string. When power is applied Q1 sets CLR2 low.

This permits the LT1107 to switch, raising output voltage.

When the output goes high enough Q1 sets CLR2 high

and normal loop operation commences.

The circuit shown is a step-up type, although any switching regulator configuration can utilize this synchronous

technique.

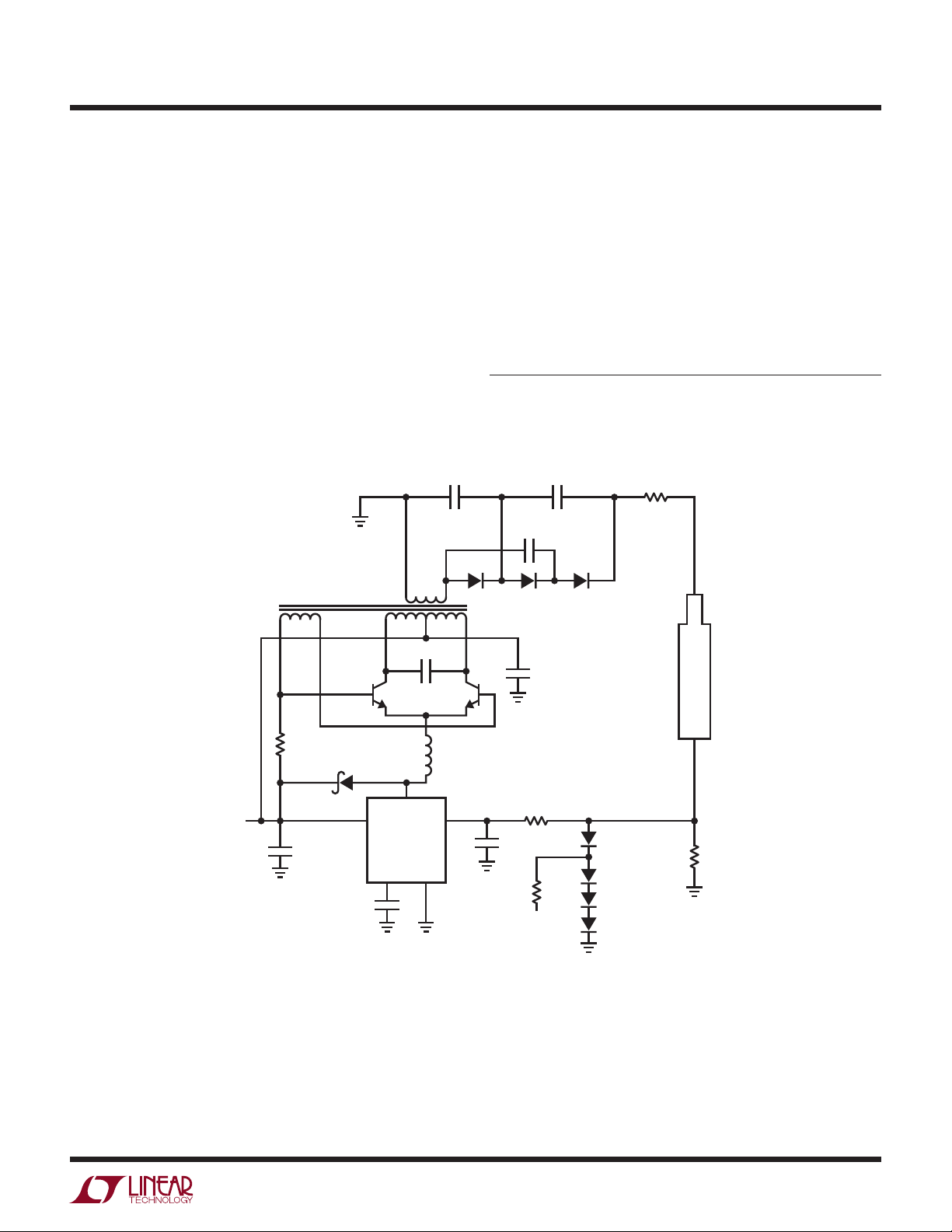

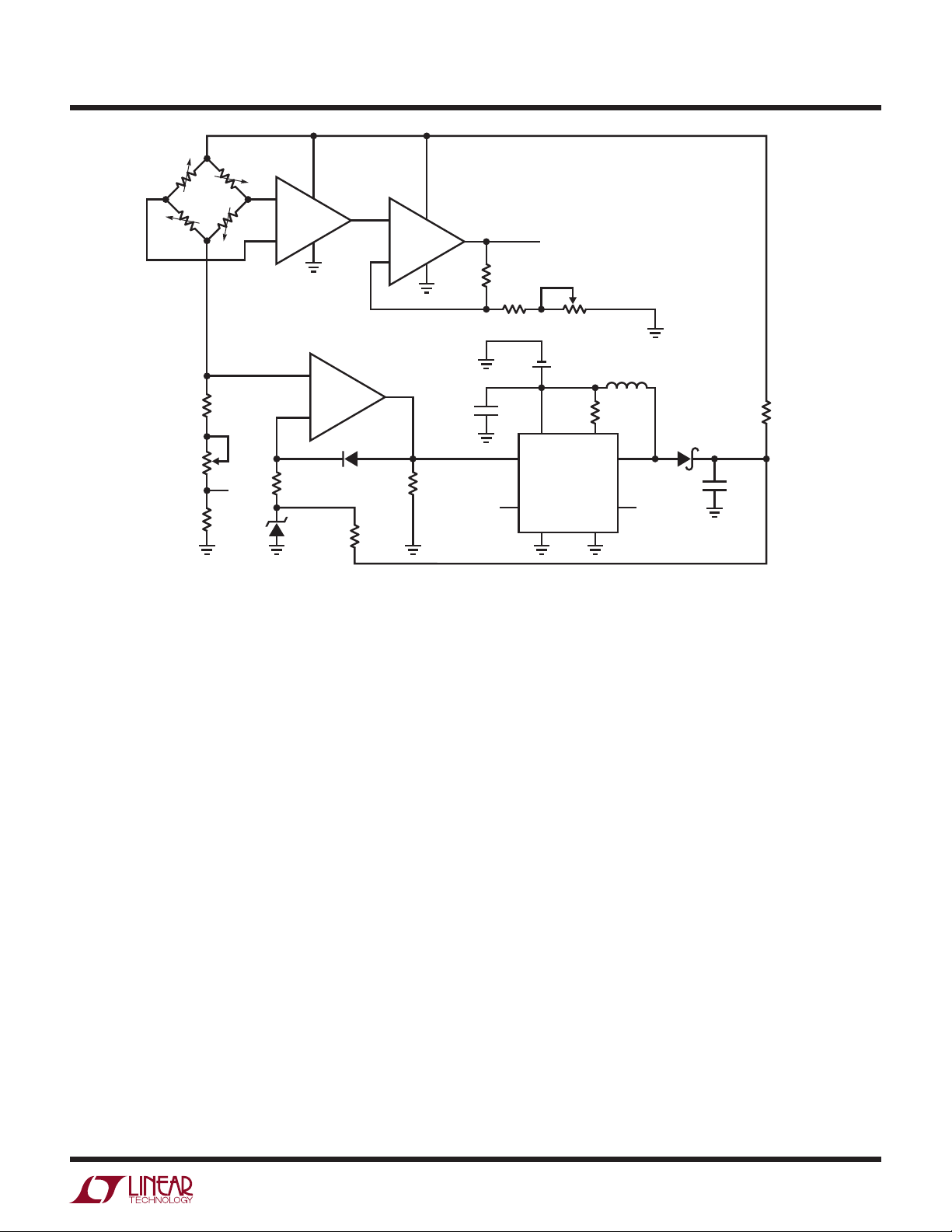

High Power 1.5V to 5V Converter

Some 1.5V powered systems (survival 2-way radios,

remote, transducer-fed data acquisition systems, etc.)

require much more power than stand-alone IC regulators

can provide. Figure 3’s design supplies a 5V output with

200mA capacity.

The circuit is essentially a flyback regulator. The LT1170

switching regulator’s low saturation losses and ease of

use permit high power operation and design simplicity.

Unfortunately this device has a 3V minimum supply requirement. Bootstrapping its supply pin from the 5V output is

possible, but requires some form of start-up mechanism.

1.5V

IN

+

47μF

L1

25μH

LT1170

1k

6.8μF

V

GND

SW

V

FB

IN

I

LIM

V

IN

V

C

+

L1 = PULSE ENGINEERING #PE-92100

* = 1% METAL FILM RESISTOR

Figure 3. 200mA Output 1.5V to 5V Converter. Lower

Voltage LT1073 Provides Bootstrap Start-Up for LT1170

High Power Switching Regulator

SW2

SW1

LT1073

1N5823

SENSE

GND

3.74k*

+

1k*

240Ω*

AN61 F03

5V

OUT

200mA MAX

470μF

AN61-2

an61fa

Page 3

Application Note 61

The 1.5V powered LT1073 switching regulator forms a

start-up loop. When power is applied the LT1073 runs,

causing its V

pin to periodically pull current through L1.

SW

L1 responds with high voltage flyback events. These events

are rectified and stored in the 470μF capacitor, producing

the circuits DC output. The output divider string is set up

so the LT1073 turns off when circuit output crosses about

4.5V. Under these conditions the LT1073 obviously can no

longer drive L1, but the LT1170 can. When the start-up

circuit goes off, the LT1170 V

pin has adequate supply

IN

voltage and can operate. There is some overlap between

start-up loop turn-off and LT1170 turn-on, but it has no

detrimental effect.

The start-up loop must function over a wide range of

loads and battery voltages. Start-up currents approach

1A, necessitating attention to the LT1073’s saturation and

drive characteristics. The worst case is a nearly depleted

battery and heavy output loading.

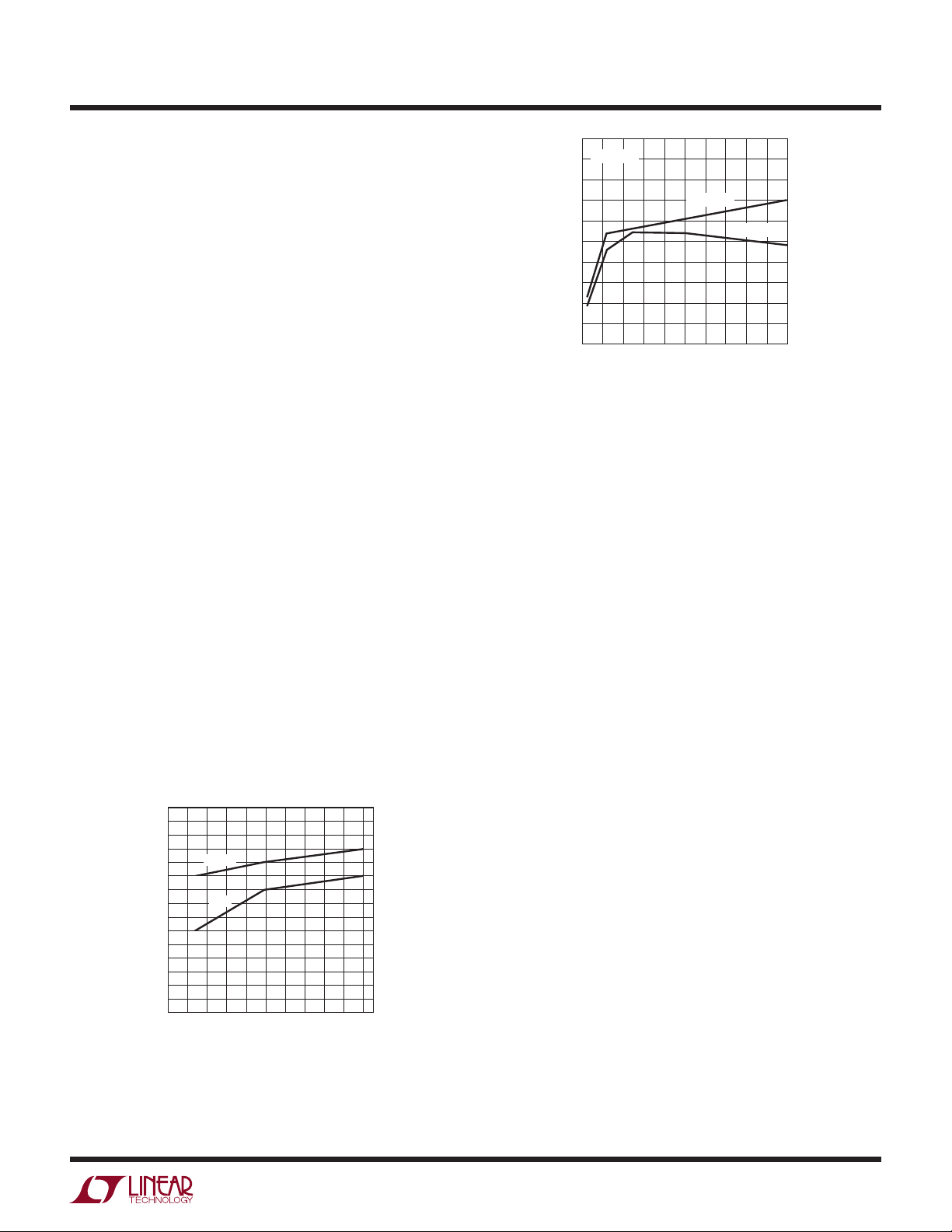

Figure 4 plots input-output characteristics for the circuit.

Note that the circuit will start into all loads with V

BAT

=

1.2V. Start-up is possible down to 1.0V at reduced loads.

Once the circuit has started, the plot shows it will drive full

200mA loads down to V

sible down to V

= 0.6V (a very dead battery)! Figure5

BAT

= 1.0V. Reduced drive is pos-

BAT

graphs efficiency at two supply voltages over a range of

output currents. Performance is attractive, although at

lower currents circuit quiescent power degrades efficiency.

Fixed junction saturation losses are responsible for lower

overall efficiency at the lower supply voltage.

1.5

= 5V

1.4

OUT

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

MINIMUM INPUT VOLTAGE TO MAINTAIN V

START

RUN

120 140

100

0

60 80

20

40

OUTPUT CURRENT (mA)

160 180

200

AN61 F04

100

V

= 5V

OUT

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

0 20 40 60 80 100 120

OUTPUT CURRENT (mA)

VIN = 1.5V

VIN = 1.2V

140 160 180 200

AN61 F05

Figure 5. Efficiency vs Operating Point for the 1.5V to

5V Converter. Efficiency Suffers at Low Power Because

of Relatively High Quiescent Currents

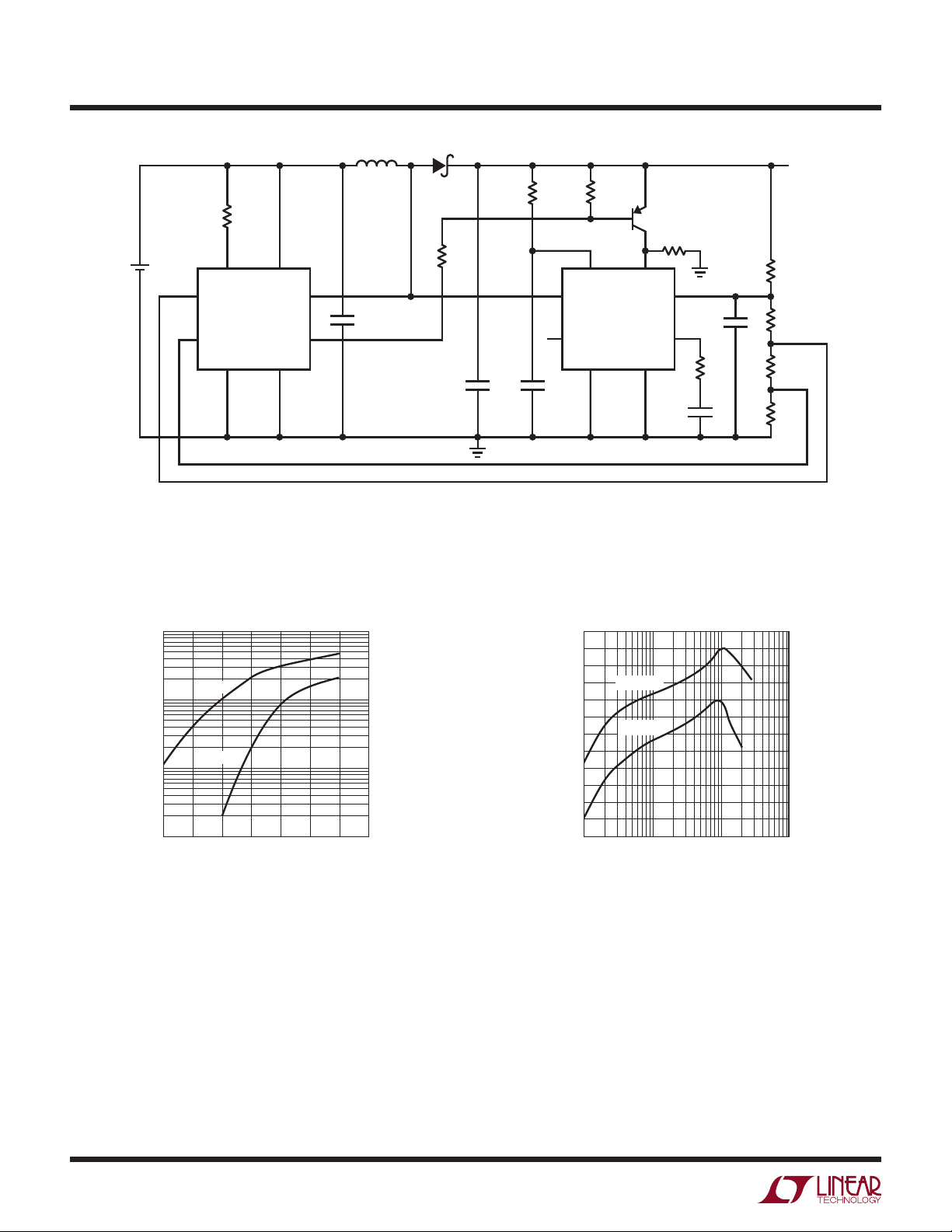

Low Power 1.5V to 5V Converter

Figure 6, essentially the same approach as the preceding circuit, was developed by Steve Pietkiewicz of LTC.

It is limited to about 150mA output with commensurate

restrictions on start-up current. It’s advantage, good efficiency at relatively low output currents, derives from its

low quiescent power consumption.

The LT1073 provides circuit start-up. When output voltage,

sensed by the LT1073’s “set” input via the resistor divider,

rises high enough Q1 turns on, enabling the LT1302. This

device sees adequate operating voltage and responds by

driving the output to 5V, satisfying its feedback node. The

5V output also causes enough overdrive at the LT1073

feedback pin to shut the device down.

Figure 7 shows maximum permissible load currents for

start-up and running conditions. Performance is quite

good, although the circuit clearly cannot compete with the

previous design. The fundamental difference between the

two circuits is the LT1170’s (Figure 3) much larger power

switch, which is responsible for the higher available power.

Figure 8, however, reveals another difference. The curves

show that Figure 6 is significantly more efficient than the

LT1170 based approach at output currents below 100mA.

This highly desirable characteristic is due to the LT1302’s

much lower quiescent operating currents.

Figure 4. Input-Output Data for the 1.5V to 5V

Converter Shows Extremely Wide Start-Up and

Running Range into Full Load

an61fa

AN61-3

Page 4

Application Note 61

220Ω

1.5V

CELL

C1 = AVX TPSD476M016R0150

C2 = AVX TPSE227M010R0100

SET

FB

I

LIM

GND

LT1073

V

SW2

IN

SW1

A

L1

3.3μH

+

C1

47μF

O

L1 = COILCRAFT DO3316-332

D1 = MOTOROLA MBR3130LT3

D1

100k

220μF

10Ω

NC

+

C2

0.1μF

Figure 6. Single-Cell to 5V Converter Delivers 150mA

with Good Efficiency at Lower Currents

SW

I

LIM

V

IN

PGND

100k

LT1302

SHDN

GND

Q1

2N3906

100k

FB

V

C

0.01μF

100pF

20k

R1

301k

1%

56.2k

1%

4.99k

1%

36.5k

1%

5V

OUT

AN61 F06

1000

100

10

MAXIMUM LOAD CURRENT (mA )

1

RUN

START

0.6

1.0 1.2 1.4 1.81.6

0.8 2.0

INPUT VOLTAGE (V)

AN61 F07

Figure 7. Maximum Permissible Loads for Start-Up

and Running Conditions. Allowable Load Current

During Start-Up Is Substantially Less Than Maximum

Running Current.

72

70

68

66

64

62

60

58

EFFICIENCY (%)

56

54

52

50

48

VIN = 1.5V

VIN = 1.2V

1

10 100 1000

LOAD CURRENT (mA)

AN61 F08

Figure 8. Efficiency Plot for Figure 6. Performance

Is Better Than the Previous Circuit at Lower

Currents, Although Poorer at High Power

AN61-4

an61fa

Page 5

Application Note 61

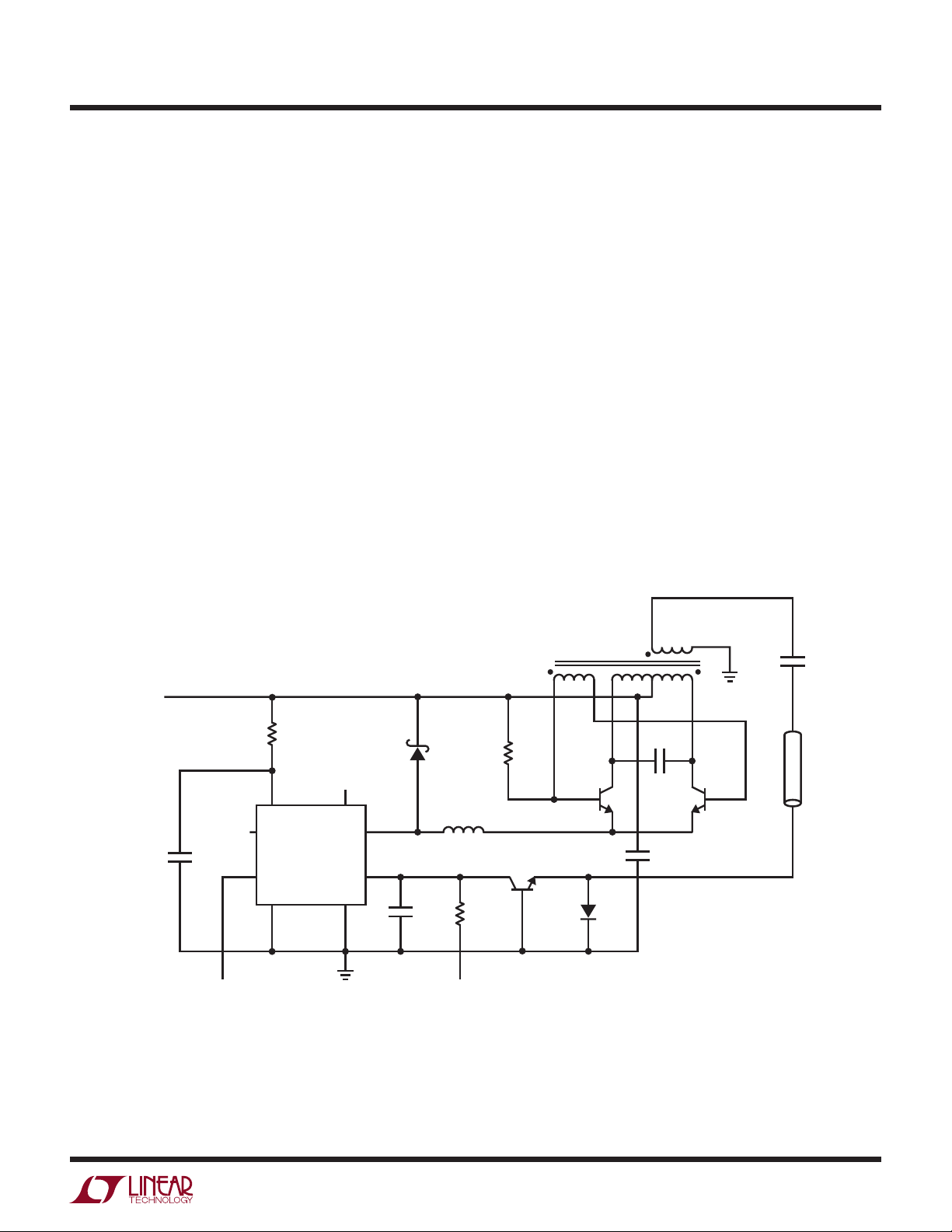

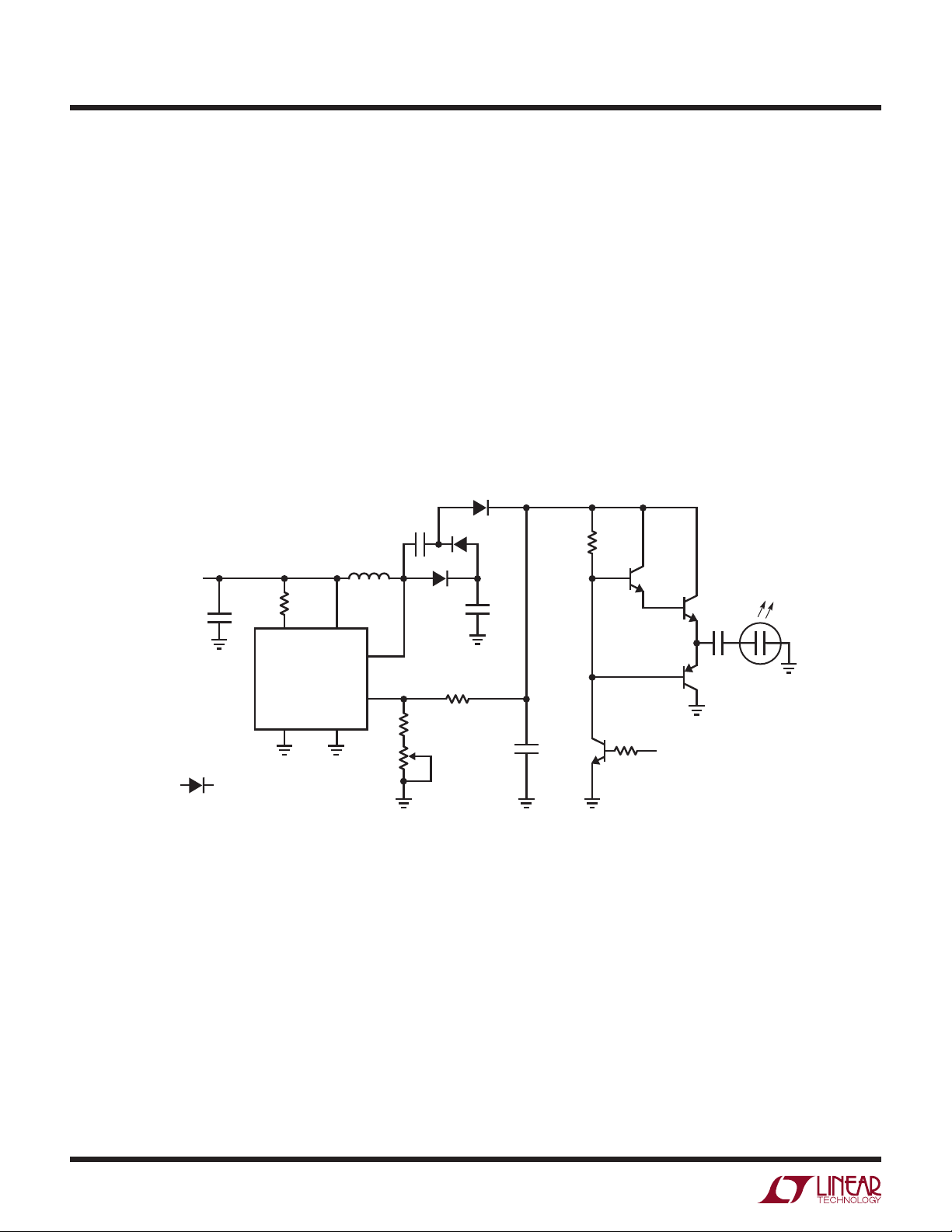

Low Power, Low Voltage Cold Cathode Fluorescent

Lamp Power Supply

Most Cold Cathode Fluorescent Lamp (CCFL) circuits

require an input supply of 5V to 30V and are optimized

for bulb currents of 5mA or more. This precludes lower

power operation from 2- or 3-cell batteries often used in

palmtop computers and portable apparatus. A CCFL power

supply that operates from 2V to 6V is detailed in Figure 9.

This circuit, contributed by Steve Pietkiewicz of LTC, can

drive a small CCFL over a 100μA to 2mA range.

The circuit uses an LT1301 micropower DC/DC converter IC

in conjunction with a current driven Royer class converter

comprised of T1, Q1 and Q2. When power and intensity

adjust voltage are applied the LT1301’s I

pin is driven

LIM

slightly positive, causing maximum switching current

through the IC’s internal switch pin (SW). Current flows

from T1’s center tap, through the transistors, into L1. L1’s

current is deposited in switched fashion to ground by the

regulator’s action.

The Royer converter oscillates at a frequency primarily

set by T1’s characteristics (including its load) and the

0.068μF capacitor. LT1301 driven L1 sets the magnitude of

the Q1-Q2 tail current, hence T1’s drive level. The 1N5817

diode maintains L1’s current flow when the LT1301’s

switch is off. The 0.068μF capacitor combines with T1’s

characteristics to produce sine wave voltage drive at the

Q1 and Q2 collectors. T1 furnishes voltage step-up and

about 1400Vp-p appears at its secondary. Alternating current flows through the 22pF capacitor into the lamp. On

positive half-cycles the lamp’s current is steered to ground

via D1. On negative half-cycles the lamp’s current flows

through Q3’s collector and is filtered by C1. The LT1301’s

pin acts as a 0V summing point with about 25μA

I

LIM

bias current flowing out of the pin into C1. The LT1301

regulates L1’s current to equalize Q3’s average collector

current, representing 1/2 the lamp current, and R1’s current, represented by V

to DC. When V

is set to zero, the I

A

/R1. C1 smooths all current flow

A

pin’s bias current

LIM

forces about 100μA bulb current.

97

V

2V TO 6V

IN

NC

0.1μF

SHUTDOWN

T1 = COILTRONICS CTX110654-1

L1 = COILCRAFT D03316-473

0.68μF = WIMA MKP-20

V

IN

SENSE

SHDN

GND

1Ω

LT1301

SELECT

SW

I

LIM

PGND

1N5817

L1

47μH

+

C1

1μF

INTENSITY ADJUST

100μA TO 2mA BULB CURRENT

R1

7.5K

1%

V

0V TO 5VDC

120Ω

Q3

2N3904

A

IN

15TI4

Q1

ZTX849

D1

1N4148

32

0.68μF

+

10μF

Q2

ZTX849

AN61 F09

Figure 9. Low Power Cold Cathode Fluorescent Lamp Supply Is Optimized for Low Voltage Inputs and Small Lamps

22pF

3kV

CCFL

an61fa

AN61-5

Page 6

Application Note 61

Circuit efficiency ranges from 80% to 88% at full load, depending on line voltage. Current mode operation combined

with the Royer’s consistent waveshape vs input results

in excellent line rejection. The circuit has none of the line

rejection problems attributable to the hysteretic voltage

control loops typically found in low voltage micropower

DC/DC converters. This is an especially desirable characteristic for CCFL control, where lamp intensity must remain

constant with shifts in line voltage. Interaction between

the Royer converter, the lamp and the regulation loop is

far more complex than might be supposed, and subject

to a variety of considerations. For detailed discussion see

Reference 3.

Low Voltage Powered LCD Contrast Supply

Figure 10, a companion to the CCFL power supply previously described, is a contrast supply for LCD panels. It

was designed by Steve Pietkiewicz of LTC. The circuit is

noteworthy because it operates from a 1.8V to 6V input,

significantly lower than most designs. In operation the

LT1300/LT1301 switching regulator drives T1 in flyback

fashion, causing negative biased step-up at T1’s secondary. D1 provides rectification, and C1 smooths the

output to DC. The resistively divided output is compared

to a command input, which may be DC or PWM, by the

IC’s “I

the I

” pin. The IC, forcing the loop to maintain 0V at

LIM

pin, regulates circuit output in proportion to the

LIM

command input.

Efficiency ranges from 77% to 83% as supply voltage

varies from 1.8V to 3V. At the same supply limits, available

output current increases from 12mA to 25mA.

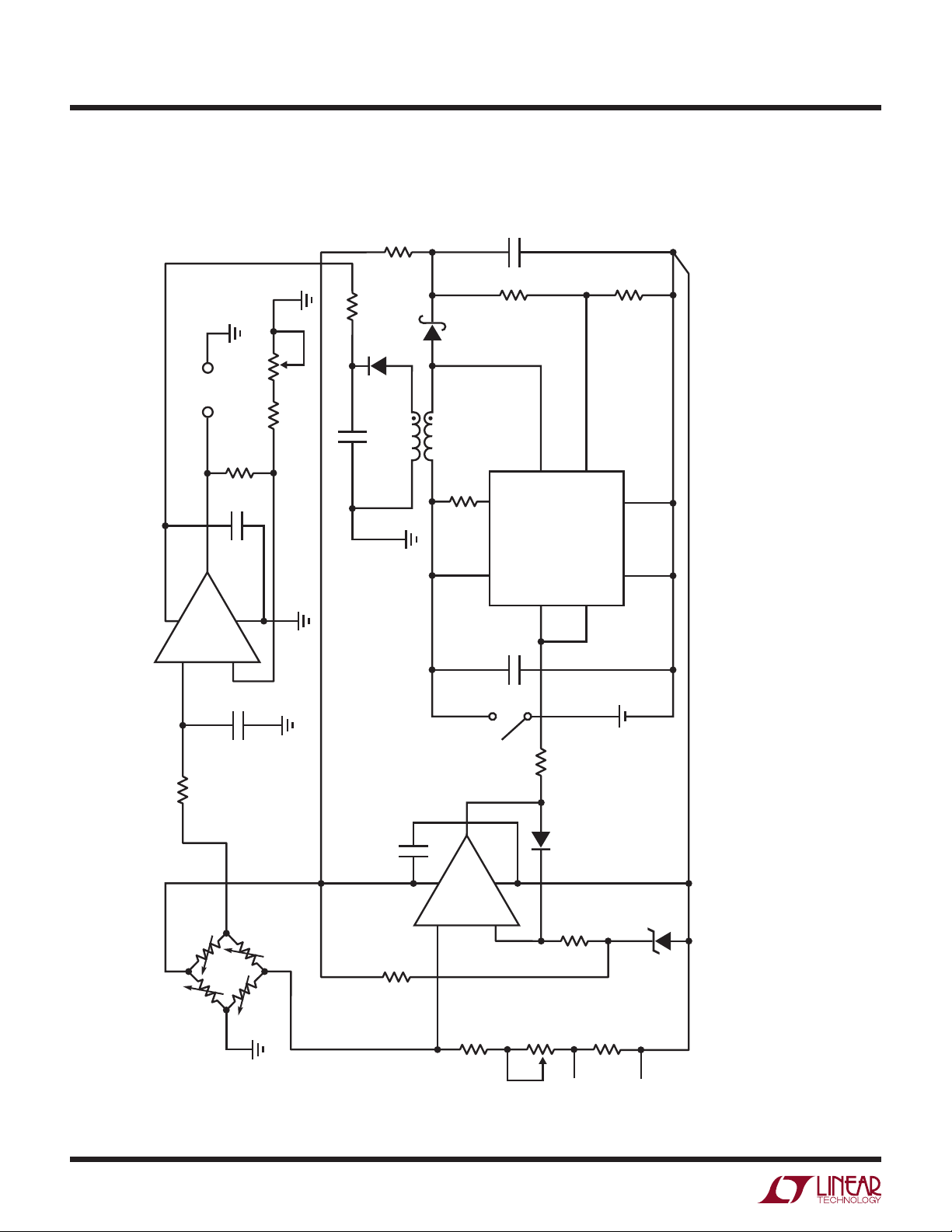

HeNe Laser Power Supply

Helium-Neon lasers, used for a variety of tasks, are difficult loads for a power supply. They typically need almost

10kV to start conduction, although they require only about

1500V to maintain conduction at their specified operating

currents. Powering a laser usually involves some form

of start-up circuitry to generate the initial breakdown

voltage and a separate supply for sustaining conduction.

Figure11’s circuit considerably simplifies driving the laser.

V

1.8V TO 6V

IN

+

100μF

T1 = DALE LPE-5047-AO45

NC

NC

V

IN

SENSE

SELECT

PGND

LT1300

OR

LT1301

1

10

SW

SHDN

I

LIM

GND

T1

SHUTDOWN

4

7

3

8

2

9

1N5819

D1

COMMAND INPUT

PWM OR DC

0% TO 100%

OR 0V TO 5V

150k

12k

12k

CONTRAST OUTPUT

V

OUT

C1

22μF

+

35V

+

2.2μF

–4V TO –29V

AN61 F10

AN61-6

Figure 10. Liquid Crystal Display Contrast Supply Operates from 1.8V to 6V with –4V to –29V Output Range

an61fa

Page 7

Application Note 61

The start-up and sustaining functions have been combined

into a single, closed-loop current source with over 10kV

of compliance. The circuit is recognizable as a reworked

2

CCFL power supply with a voltage tripled DC output.

When power is applied, the laser does not conduct and

the voltage across the 190Ω resistor is zero. The LT1170

switching regulator FB pin sees no feedback voltage, and

its switch pin (V

) provides full duty cycle pulse width

SW

modulation to L2. Current flows from L1’s center tap

through Q1 and Q2 into L2 and the LT1170. This current

flow causes Q1 and Q2 to switch, alternately driving L1.

The 0.47μF capacitor resonates with L1, providing boosted

sine wave drive. L1 provides substantial step-up, causing

0.01μF

5kV

about 3500V to appear at its secondary. The capacitors and

diodes associated with L1’s secondary form a voltage tripler,

producing over 10kV across the laser. The laser breaks

down and current begins to flow through it. The 47k resistor

limits current and isolates the laser’s load characteristic.

The current flow causes a voltage to appear across the

190Ω resistor. A filtered version of this voltage appears

at the LT1170 FB pin, closing a control loop. The LT1170

adjusts pulse width drive to L2 to maintain the FB pin at

1.23V, regardless of changes in operating conditions. In

this fashion, the laser sees constant current drive, in this

Note 2: See References 2 and 3 and this text’s Figure 9.

1800pF

10kV

1800pF

10kV

47k

5W

V

IN

9V TO 35V

HV DIODES =

0.47μF =

Q1, Q2 =

LASER =

L1

5

+

SEMTECH-FM-50

WIMA 3w 0.15μF TYPE MKP-20

ZETEX ZTX849

L1 =

COILTRONICS CTX02-11128-2

L2 =

PULSE ENGINEERING PE-92105

HUGHES 3121H-P

4

150Ω

MUR405

2.2μF

10μF

V

1

+

IN

V

11

Q1

V

LT1170

C

SW

0.47μF

GND

2

L2

145μH

FB

8

Q2

3

HV DIODES

+

2.2μF

10k

0.1μF

V

IN

10k

1N4002

(ALL)

LASER

190Ω

1%

AN61 F11

Figure 11. LASER Power Supply Is Essentially A 10,000V Compliance Current Source

an61fa

AN61-7

Page 8

Application Note 61

case 6.5mA. Other currents are obtainable by varying the

190Ω value. The 1N4002 diode string clamps excessive

voltages when laser conduction first begins, protecting

the LT1170. The 10μF capacitor at the V

pin frequency

C

compensates the loop and the MUR405 maintains L1’s

current flow when the LT1170 V

pin is not conducting.

SW

The circuit will start and run the laser over a 9V to 35V

input range with an electrical efficiency of about 80%.

Compact Electroluminescent Panel Power Supply

Electroluminescent (EL) panel LCD backlighting presents an

attractive alternative to fluorescent tube (CCFL) backlighting

in some portable systems. EL panels are thin, lightweight,

lower power, require no diffuser and work at lower voltage

than CCFLs. Unfortunately, most EL DC/AC inverters use a

0.1μF

100V

L1

V

SW2

100μH

+

IN

SW1

2.26M

FB

30.1k

R1

25k

V

2V TO 12V

33pF

IN

+

= MOTOROLA MURS120T3

L1 = COILCRAFT DO3316-104

47Ω

I

LIM

U1

LT1108CS8

GND

large transformer to generate the 400Hz 95V square wave

required to drive the panel. Figure 12’s circuit, developed

by Steve Pietkiewicz of LTC, eliminates the transformer

by employing an LT1108 micropower DC/DC converter

IC. The device generates a 95VDC potential via L1 and the

diode-capacitor doubler network. The transistors switch

the EL panel between 95V and ground. C1 blocks DC and

R1 allows intensity adjustment. The 400Hz square wave

drive signal can be supplied by the microprocessor or a

simple multivibrator. When compared to conventional EL

panel supplies, this circuit is noteworthy because it can

be built in a square inch with a 0.5 inch height restriction.

Additionally, all components are surface mount types, and

the usual large and heavy 400Hz transformer is eliminated.

95V

1M

MMBTA42

0.1μF

100V

0.47μF

200V

MMBTA42

10k

MMBTA42

400Hz DRIVE

SQUARE WAVE

C1

1μF

100V

MMBTA92

EL

PANEL

AN61 F12

AN61-8

Figure 12. Switch Mode EL Panel Driver Eliminates Large 400Hz Transformer

an61fa

Page 9

Application Note 61

3.3V Powered Barometric Pressure Signal Conditioner

The move to 3.3V digital supply voltage creates problems

for analog signal conditioning. In particular, transducer

based circuits often require higher voltage for proper

transducer excitation. DC/DC converters in standard

configurations can address this issue but increase power

consumption. Figure 13’s circuit shows a way to provide

proper transducer excitation for a barometric pressure

sensor while minimizing power requirements.

The 6kΩ transducer T1 requires precisely 1.5mA of excitation, necessitating a relatively high voltage drive. A1

senses T1’s current by monitoring the voltage drop across

the resistor string in T1’s return path.

A = 10

–

1/2 LT1078

+

LT1034

1.2V

A1

≈10V DURING OPERATIONT1

3.3V

+

A3

1/2 LT1078

–

0.05μF

1μF

1N4148

10k

3.3V

PRESSURE

TRANSDUCER

5

10

6

BRIDGE

CURRENT

TRIM

BRIDGE

CURRENT

MONITOR

(0.1500V)

* = 1% FILM RESISTOR

** = 0.1% FILM RESISTOR

L1 = TOKO 262-LYF-0095K

T1 = NOVASENSOR (FREMONT, CA)

NPH-8-100AH

4

700Ω*

50Ω

100Ω**

100k

1μF

–

A2

LT1101

+

A1’s output biases the LT1172 switching regulator’s operating point, producing a stepped up DC voltage which

appears as T1’s drive and A2’s supply voltage. T1’s return

current out of pin 6 closes a loop back at A1 which is

slaved to the 1.2V reference. This arrangement provides

the required high voltage drive (≈10V) while minimizing

power consumption. This is so because the switching

regulator produces only enough voltage to satisfy T1’s

current requirements. Instrumentation amplifier A2 and A3

®

provide gain and LTC

1287 A/D converter gives a 12-bit

digital output. A2 is bootstrapped off the transducer supply,

enabling it to accept T1’s common-mode voltage. Circuit

current consumption is about 14mA. If the shutdown pin

is driven high the switching regulator turns off, reducing

2N3904

10k*

1M

CALIB

2.2μF

100k

+

3.3V

+

22μF

V

V

C

SHUTDOWN

1N752

5.6V

MUR110

IN

LT1172

TO PROCESSOR

CS

+IN

–IN

3.3V

L1

150μH

V

SW

FB

GNDE2E1

CLK D

LTC1287

GND

NC

OUT

V

REF

V

CC

1N4148

AN61 F13

3.3V

Figure 13. 3.3V Powered, Digital Output, Barometric Pressure Signal Conditioner

an61fa

AN61-9

Page 10

Application Note 61

total power consumption to about 1mA. In shutdown the

3.3V powered A/D’s output data remains valid. In practice,

the circuit provides a 12-bit representation of ambient

barometric pressure after calibration. To calibrate, adjust

the “bridge current trim” for exactly 0.1500V at the indicated

point. This sets T1’s current to the manufacturers specified point. Next, adjust A3’s trim so that the digital output

corresponds to the known ambient barometric pressure.

If a pressure standard is not available the transducer is

supplied with individual calibration data, permitting circuit

calibration.

Some applications may require operation over a wider

supply range and/or a calibrated analog output. Figure14’s

circuit is quite similar, except that the A/D converter is

eliminated and a 2.7V to 7V supply is acceptable. The

calibration procedure is identical, except that A3’s analog

output is monitored.

5

T1

10

6

4

–

LT1101

+

A = 10

A2

+

1/2 LT1078

–

Single Cell Barometers

It is possible to power these circuits from a single cell without sacrificing performance. Figure 15, a direct extension

of the above approaches, simply substitutes a switching

regulator that will run from a single 1.5V battery. In other

respects loop action is nearly identical.

Figure 16, also a 1.5V powered design, is related but

eliminates the instrumentation amplifier. As before, the

6kΩ transducer T1 requires precisely 1.5mA of excitation,

necessitating a relatively high voltage drive. A1’s positive

input senses T1’s current by monitoring the voltage drop

across the resistor string in T1’s return path. A1’s negative

input is fixed by the 1.2V LT1004 reference. A1’s output

biases the 1.5V powered LT1110 switching regulator. The

LT1110’s switching produces two outputs from L1. Pin4’s

rectified and filtered output powers A1 and T1. A1’s output,

A3

20k*

OUTPUT

0V TO 3.100V =

0 TO 31.00" Hg.

2.2μF

1N4148

+

3.3V

+

22μF

3.3V

MUR110

V

IN

V

C

V

LT1172

GNDE2E1

1.500mA

700Ω*

BRIDGE

CURRENT

* = 1% FILM RESISTOR

L1 = TOKO 262-LYF-0095K

T1 = NOVASENSOR NPH-8-100AH

50Ω

TRIM

100Ω

0.1%

100k

–

1/2 LT1078

+

10k

LT1034

1.2V

1μF

10k*

OUTPUT

A1

3.3V

TRIM

1k

Figure 14. Single Supply Barometric Pressure Signal Conditioner Operates Over a 2.7V to 7V Range

SW

L1

150μH

FB

NC

AN61 F13

an61fa

AN61-10

Page 11

Application Note 61

T1

5

10

50Ω

TRIM FOR

150mV AT

POINT “A”

* = 1% FILM RESISTOR

L1 = COILTRONICS CTX50-1

T1 = NOVASENSOR NPH-8-100AH

4

6

700Ω

1%

A

100Ω

0.1%

–

A2

LT1101

+

100k

LT1004-1.2

A =10

+

A1

1/2 LT1078

–

100k

+

–

A3

LT1078

10k

OUTPUT

0 TO 3.100V=

0 TO 31.00"Hg

200k*

100k*

10k

CAL

1.5V

AA CELL

+

1μF

V

IN

FB

LT1110

SET

150

I

L

SW1

AONC NC

SW2GND

L1

50μH

1N5818

100Ω

+

150μF

AN61 F15

Figure 15. 1.5V Powered Barometric Pressure Signal Conditioner Uses

Instrumentation Amplifier and Voltage Boosted Current Loop

in turn, closes a feedback loop at the regulator. This loop

generates whatever voltage step-up is required to force

precisely 1.5mA through T1. This arrangement provides

the required high voltage drive while minimizing power

consumption. This occurs because the switching regulator produces only enough voltage to satisfy T1’s current

requirements.

L1 pins 1 and 2 source a boosted, fully floating voltage,

which is rectified and filtered. This potential powers A2.

Because A2 floats with respect to T1, it can look differentially across T1’s outputs, pins 10 and 4. In practice,

pin10 becomes “ground” and A2 measures pin 4’s output

with respect to this point. A2’s gain-scaled output is the

circuit’s output, conveniently scaled at 3.000V = 30.00"Hg.

A2’s floating drive eliminates the requirement for an

instrumentation amplifier, saving cost, power, space and

error contribution.

To calibrate the circuit, adjust R1 for 150mV across the

100Ω resistor in T1’s return path. This sets T1’s current

to the manufacturer’s specified calibration point. Next,

adjust R2 at a scale factor of 3.000V = 30.00"Hg. If R2

cannot capture the calibration, reselect the 200k resistor

in series with it. If a pressure standard is not available,

the transducer is supplied with individual calibration data,

permitting circuit calibration.

This circuit, compared to a high-order pressure standard,

maintained 0.01"Hg accuracy over months with widely

varying ambient pressure shifts. Changes in pressure,

particularly rapid ones, correlated quite nicely to changing

weather conditions. Additionally, because 0.01"Hg corresponds to about 10 feet of altitude at sea level, driving over

hills and freeway overpasses becomes quite interesting.

an61fa

AN61-11

Page 12

Application Note 61

"Hg.

0V TO 3.100V =

0 TO 31.00

OUTPUT

200k*

0.1μF

A2

LT1077

+

–

R2

10k

1%

1k

1%

100Ω

+

1N4148

100μF

100Ω

1N5818

1

2

390μF

16V

NICHICON

PL

+

430k

4

L1

3

L

I

150Ω

21

IN

V

83

1μF

SW1

FB

LT1110

AN61 F16

39k

7

SET

SW2

54

GND

AO

6

L1 = COILTRONICS CTX50-1

68k

5

†

T1

NOVASENSOR

NPH-8-100AH

4

10

1μF

NON-POLAR

+

= LUCAS NOVASENSOR

FREMONT, CA (510) 490-9100

†

100k

100Ω

0.1%

AA CELL

A2

LT1004-1.2

Figure 16. 1.5V Powered Barometric Pressure Signal Conditioner Floats Bridge Drive to

Eliminate Instrumentation Amplifier. Voltage Boosted Current Loop Drives Transducer

* = NOMINAL VALUE. EACH SENSOR REQUIRES SELECTION

** = TRIM FOR 150mV ACROSS A1-A2

100k

R1**

1N4148

50Ω

A1

0.1μF

A1

LT1077

+

6

100k

698Ω

–

1%

AN61-12

an61fa

Page 13

Application Note 61

Until recently, this type of accuracy and stability has only

been attainable with bonded strain gauge and capacitivelybased transducers, which are quite expensive. As such,

semiconductor pressure transducer manufacturers whose

products perform at the levels reported are to be applauded.

Although high quality semiconductor transducers are still

not comparable to more mature technologies, their cost

is low and they are vastly improved over earlier devices.

The circuit pulls 14mA from the battery, allowing about

250 hours operation from one D cell.

Quartz Crystal-Based Thermometer

Although quartz crystals have been utilized as temperature sensors (see Reference 5), there has been almost no

widespread adaptation of this technology. This is primarily

due to the lack of standard product quartz-based temperature sensors. The advantages of quartz-based sensors

include simple signal conditioning, good stability and a

direct, noise immune digital output almost ideally suited

to remote sensing.

Figure 17 utilizes an economical, commercially available

(see Reference 6) quartz-based temperature sensor in a

thermometer scheme suited to remote data collection.

The LTC485 RS485 transceiver is set up in the transmit

6

7

2

5V

8

LTC485

3

5

1

4

NC

0°C TO 100°C

= 261.900kHz

– 262.800kHz

OUT

"/t'

10M

6

4

LTC485

1

NC

+33.5ppm/°C

10pF

Figure 17. Quartz Crystal Based Circuit Provides

Temperature-to-Frequency Conversion. RS485

Transceivers Allow Remote Sensing

7

3

2

8

5

5V

Y1

1000 FEET

TWISTED-PAIR

100k

15pF

100Ω

Y1 = MICRO CRYSTAL (SWISS)

MT1/33.5ppm/°C

0°C = 261.900kHz

100°C = 262.800kHz

mode. The crystal and discrete components combine

with the IC’s inverting gain to form a Pierce type oscillator. The LTC485’s differential line driving outputs provide

frequency coded temperature data to a 1000-foot cable

run. A second RS485 transceiver differentially receives

the data and presents a single-ended output. Accuracy

depends on the grade of quartz sensor specified, with 1°C

over 0°C to 100°C achievable.

Ultra-Low Noise and Low Drift Chopped-FET Amplifier

Figure 18’s circuit combines the extremely low drift of

a chopper-stabilized amplifier with a pair of low noise

FETs. The result is an amplifier with 0.05μV/°C drift, offset

within 5μV, 100pA bias current and 50nV noise in a 0.1Hz

to 10Hz bandwidth. The noise performance is especially

noteworthy; it is almost 35 times better than monolithic

chopper-stabilized amplifiers and equals the best bipolar

types.

FETs Q1 and Q2 differentially feed A2 to form a simple

low noise op amp. Feedback, provided by R1 and R2,

sets closed-loop gain (in this case 10,000) in the usual

fashion. Although Q1 and Q2 have extraordinarily low noise

characteristics, their offset and drift are uncontrolled. A1,

a chopper-stabilized amplifier, corrects these deficiencies.

It does this by measuring the difference between the

amplifier’s inputs and adjusting Q1’s channel current via

Q3 to minimize the difference. Q1’s skewed drain values

ensure that A1 will be able to capture the offset. A1 and

Q3 supply whatever current is required into Q1’s channel to force offset within 5μV. Additionally, A1’s low bias

current does not appreciably add to the overall 100pA

amplifier bias current. As shown, the amplifier is set up

for a noninverting gain of 10,000 although other gains

and inverting operation are possible. Figure 19 is a plot

of the measured noise performance.

The FETs’ V

they must be selected for 10% V

can vary over a 4:1 range. Because of this,

GS

matching. This match-

GS

ing allows A1 to capture the offset without introducing

any significant noise.

an61fa

AN61-13

Page 14

Application Note 61

15V

0.02μF

+

A1

LTC1150

–

–15V

100k100k

+ INPUT

* = 1% FILM RESISTOR

Q1, Q2 = 2SK147 TOSHIBA

0.02μF

10k

Q3

2N2907

–15V

1k*

450Ω*

Q1

–15V

200Ω*

15V

Q2

750Ω*

900Ω*

COMPENSATION

– INPUT

–

A2

LT1097

+

OPTIONAL

OVER

OUTPUT

5

R1

100k

R2

Ω10

Figure 18. Chopper-Stabilized FET Pair Combines Low Bias, Offset and Drift with 45nV Noise

AN61 F18

100

NANOVOLTS

AN61 F19

10 SECONDS

Figure 19. Figure 18’s 45nV Noise Performance in a 0.1Hz to 10Hz Bandwidth.

A1’s Low Offset and Drift Are Retained, But Noise Is Almost 35 Times Better

an61fa

AN61-14

Page 15

Application Note 61

Figure 20 shows the response (trace B) to a 1mV input

step (trace A). The output is clean, with no overshoots or

uncontrolled components. If A2 is replaced with a faster

device (e.g., LT1055) speed increases by an order of

magnitude with similar damping. A2’s optional overcompensation can be used (capacitor to ground) to optimize

response for low closed-loop gains.

A = 500μV/DIV

B = 5V/DIV

100μs/DIV

Figure 20. Step Response for the Low Noise × 10,000

Amplifier. A 10× Speed Increase Is Obtainable by

Replacing A2 with a Faster Device

AN61 F20

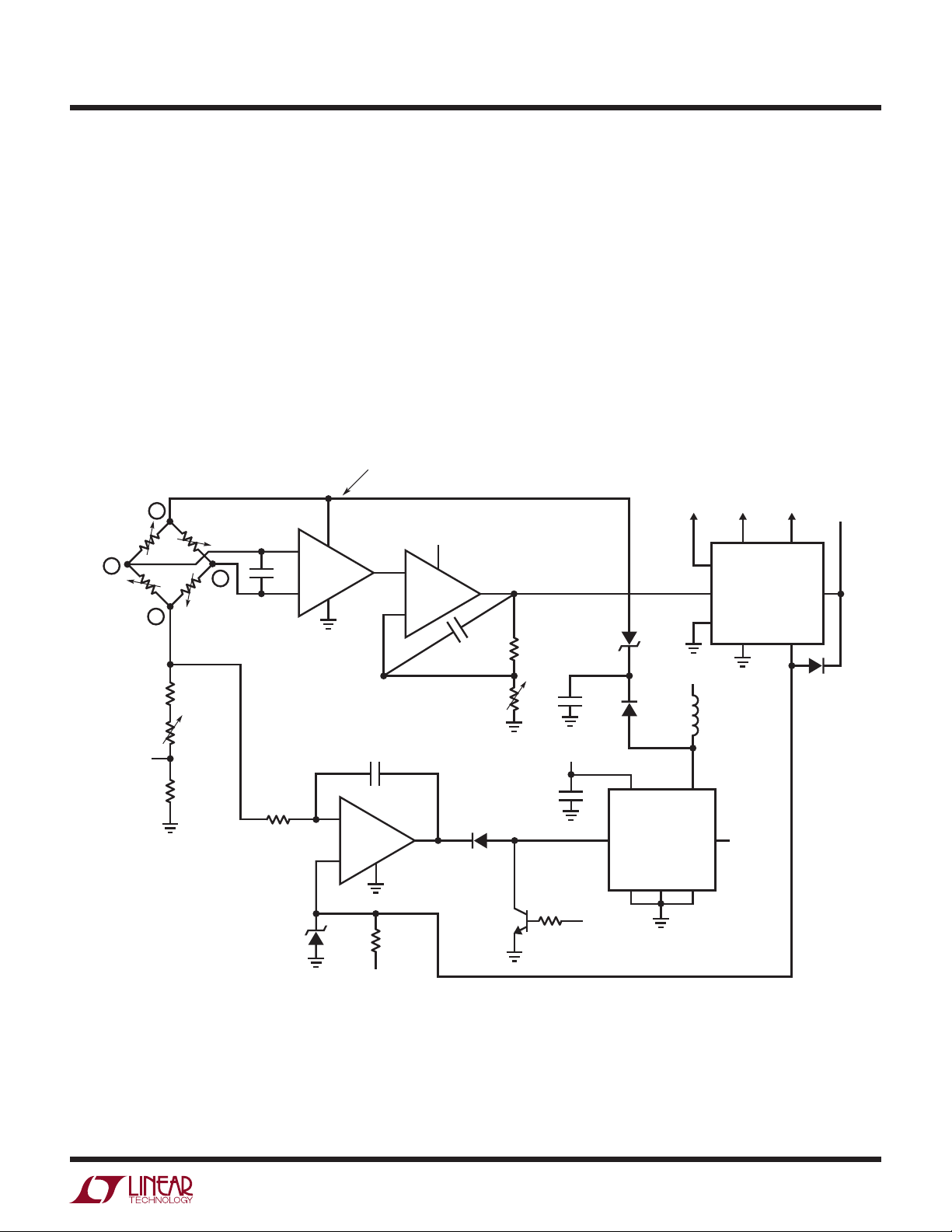

High Speed Adaptive Trigger Circuit

Line receivers often require an adaptive trigger to compensate for variations in signal amplitude and DC offsets. The

circuit in Figure 21 triggers on 2mV to 100mV signals from

100Hz to 10MHz while operating from a single 5V rail. A1,

operating at a gain of 20, provides wideband AC gain. The

output of this stage biases a 2-way peak detector (Q1-Q4).

The maximum peak is stored in Q2’s emitter capacitor,

while the minimum excursion is retained in Q4’s emitter

capacitor. The DC value of A1’s output signal’s midpoint

appears at the junction of the 500pF capacitor and the

10MΩ units. This point always sits midway between the

signal’s excursions, regardless of absolute amplitude. This

signal-adaptive voltage is buffered by A2 to set the trigger

voltage at the LT1116’s positive input. The LT1116’s negative input is biased directly from A1’s output. The LT1116’s

output, the circuit’s output, is unaffected by 50:1 signal

amplitude variations. Bandwidth limiting in A1 does not

affect triggering because the adaptive trigger threshold

varies ratiometrically to maintain circuit output.

Split supply versions of this circuit can achieve bandwidths to 50MHz with wider input operating range (See

Reference 7).

5V

3k

Q1

5V

+

A1

LT1192

–

50Ω

C1

100μF

1k

Q3

C2

0.1μF

NPN = 2N3904

PNP = 2N3906

2k

INPUT

750Ω

0.01μF

+

5V

10μF

+

0.005μF

0.005μF

3k

500Ω

Q2

500pF

10M

5V

+

10M

A2

LT1006

–

Q4

+

LT1116

–

5V

Q

Q

TRIGGER

OUT

AN61 F21

1N4148

1N4148

500Ω

0.1μF

Figure 21. Fast Single Supply Adaptive Trigger. Output Comparator’s Trip Level Varies Ratiometrically

with Input Amplitude, Maintaining Data Integrity Over 50:1 Input Amplitude Range

an61fa

AN61-15

Page 16

Application Note 61

Wideband, Thermally-Based RMS/DC Converter

Applications such as wideband RMS voltmeters, RF leveling

loops, wideband AGC, high crest factor measurements,

SCR power monitoring and high frequency noise measurements require wideband, true RMS/DC conversion.

The thermal conversion method achieves vastly higher

bandwidth than any other approach. Thermal RMS/DC

converters are direct acting, thermoelectronic analog

computers. The thermal technique is explicit, relying on

“first principles,” e.g,. a waveforms RMS value is defined

as its heating value in a load.

Figure 22 is a wideband, thermally-based RMS/DC con-

3

verter.

It provides a true RMS/DC conversion from DC

to 10MHz with less than 1% error, regardless of input

signal waveshape. It also features high input impedance

and overload protection.

The circuit consists of three blocks; a wideband FET input

amplifier, the RMS/DC converter and overload protection.

The amplifier provides high input impedance, gain and

drives the RMS/DC converters input heater. Input resistance

is defined by the 1M resistor with input capacitance about

3pF. Q1 and Q2 constitute a simple, high speed FET input

buffer. Q1 functions as a source follower, with the Q2 current source load setting the drain-source channel current.

The LT1206 provides a flat 10MHz bandwidth gain of ten.

Normally, this open-loop configuration would be quite drifty

because there is no DC feedback. The LT1097 contributes

this function to stabilize the circuit. It does this by comparing the filtered circuit output to a similarly filtered version

of the input signal. The amplified difference between these

signals is used to set Q2’s bias, and hence Q1’s channel

current. This forces Q1’s V

to whatever voltage is re-

GS

quired to match the circuit’s input and output potentials.

The capacitor at A1 provides stable loop compensation.

The RC network in A1’s output prevents it from seeing

high speed edges coupled through Q2’s collector-base

junction. Q4, Q5 and Q6 form a low leakage clamp which

precludes A1 loop latch-up during start-up or overdrive

conditions. This can occur if Q1 ever forward biases. The

5k-50pF network gives A2 a slight peaking characteristic at

the highest frequencies, allowing 1% flatness to 10MHz.

A2’s output drives the RMS/DC converter.

The LT1088 based RMS/DC converter is made up of

matched pairs of heaters and diodes and a control amplifier.

The LT1206 drives R1, producing heat which lowers D1’s

voltage. Differentially connected A3 responds by driving

R2, via Q3, to heat D2, closing a loop around the amplifier. Because the diodes and heater resistors are matched,

A3’s DC output is related to the RMS value of the input,

regardless of input frequency or waveshape. In practice,

residual LT1088 mismatches necessitate a gain trim, which

is implemented at A4. A4’s output is the circuit output. The

LT1004 and associated components frequency compensate

the loop and provide good settling time over wide ranges

of operating conditions (see Footnote 3).

Start-up or input overdrive can cause A2 to deliver excessive current to the LT1088 with resultant damage. C1

and C2 prevent this. Overdrive forces D1’s voltage to an

abnormally low potential. C1 triggers low under these

conditions, pulling C2’s input low. This causes C2’s output

to go high, putting A2 into shutdown and terminating the

overload. After a time determined by the RC at C2’s input,

A2 will be enabled. If the overload condition still exists the

loop will almost immediately shut A2 down again. This

oscillatory action will continue, protecting the LT1088 until

the overload condition is removed.

Note 3: Thermally based RMS/DC conversion is detailed in Reference 9.

AN61-16

an61fa

Page 17

Application Note 61

OUT

V

3k

10k*

10k*

0.022μF

1.5M 1k

3300pF

LT1004-

9.09M*

15V

ZERO TRIM

FULL-SCALE)

(TRIM AT 10% OF

1.2V

15V

500Ω

2.7k*

2.7k*

1k*

1k

A3

–

Q3

+

1/2 LT1013

1k*

0.01μF

2N2219

9.09M*

0.01μF

A4

1N914

C1

+

15V

24k

C2

1/2 LT1018

–

0.1

15V

1/2 LT1018

–

+

2k

15V

4.7k

10k

LT1004

1.2V

10k

AT FULL SCALE

AN61 F22

+

–

1/2 LT1013

10k

TRIM

FULL-SCALE

D2

12 5

3 250Ω 10250Ω

LT1088

R1 R2

D1

7

13 6 81

14

0.1μF

–15V

–15V

15V

1k 510k

15V

15V

15V

RMS

0 – 1V

DC –10MHz

Q1

2N5486

1M

OVERLOAD TRIM. SET AT

WITH CIRCUIT OPERATING

10% BELOW D1's VOLTAGE

–

0.01

330pF

100Ω*

5k

TRIM

10MHz

50pF

10k

10M

0.1

2N3904s

Q4

Q5

Q6

900Ω*

SD

A2

LT1206

+

–

10M

0.1

+

A1

LT1097

3k

Figure 22. Complete 10MHz Thermally-Based RMS/DC Converter Has 1% Accuracy, High Input Impedance and Overload Protection

330Ω

–15V

* = 1% FILM RESISTOR

an61fa

Q2

2N3904

AN61-17

Page 18

Application Note 61

Performance for the circuit is quite impressive. Figure 23

plots error from DC to 11MHz. The graph shows 1% error

bandwidth of 11MHz. The slight peaking out to 5MHz is

due to the gain boost network at A2’s negative input. The

peaking is minimal compared to the total error envelope,

and a small price to pay to get the 1% accuracy to 10MHz.

To trim this circuit put the 5kΩ potentiometer at its

maximum resistance position and apply a 100mV, 5MHz

signal. Trim the 500Ω adjustment for exactly 1V

OUT

. Next,

apply a 5MHz 1V input and trim the 10k potentiometer for

10.00V

trimmer for 10.00V

. Finally, put in 1V at 10MHz and adjust the 5kΩ

OUT

. Repeat this sequence until circuit

OUT

output is within 1% accuracy for DC-10MHz inputs. Two

passes should be sufficient.

It is worth considering that this circuit performs the same

4

function as instruments costing thousands of dollars.

1

convenient current transformers are the “clip-on” type,

commercially sold as “current probes.” A problem with

all simple current transformers is that they cannot sense

DC and low frequency information. This problem was addressed in the mid-1960’s with the advent of the Hall effect

stabilized current probe. This approach uses a Hall effect

device within the transformer core to sense DC and low

frequency signals. This information is combined with the

current transformers output to form a composite DC-tohigh frequency output. Careful roll-off and gain matching

of the two channels preserves amplitude accuracy at all

5

frequencies.

Additionally, the low frequency channel

is operated as a “force-balance,” meaning that the low

frequency amplifier’s output is fed back to magnetically

bias the transformer flux to zero. Thus, the Hall effect

device does not have to respond linearly over wide ranges

of current and the transformer core never sees DC bias,

both advantageous conditions. The amount of DC and

low frequency information is obtained at the amplifier’s

output, which corresponds to the bias needed to offset

the measured current.

0

ERROR (%)

0.7% ERROR AT 10MHz

–1

0

2

1

3456

FREQUENCY (MHz)

Figure 23. Error Plot for the RMS/DC Converter.

Frequency Dependent Gain Boost at A2 Preserves 1%

Accuracy, But Causes Slight Peaking Before Roll-Off

7891011

AN61 F23

Hall Effect Stabilized Current Transformer

Current transformers are common and convenient. They

permit wideband current measurement independent

of common-mode voltage considerations. The most

Note 4: Viewed from a historical perspective it is remarkable that so much

precision wideband performance is available from such a relatively simple

configuration. For perspective, see Appendix A, “Precision Wideband

Circuitry . . . Then and Now.”

Figure 24 shows a practical circuit. The Hall effect transducer lies within the core of the clip-on current transformer

specified. A very simplistic way to model the Hall generator is as a bridge, excited by the two 619Ω resistors. The

Hall generator’s outputs (the midpoints of the “bridge”)

feed differential input transconductance amplifier A1,

which takes gain, with roll-off set by the 50Ω, 0.02μF RC

at its output. Further gain is provided by A2, in the same

package as A1. A current buffer provides power gain to

drive the current transformers secondary. This connection

closes a flux nulling loop in the transducer core. The offset

adjustments should be set for 0V output with no current

flowing in the clip-on transducer. Similarly, the loop gain

and bandwidth trims should be set so that the composite

output (the combined high and low frequency output across

the grounded 50Ω resistor) has clean step response and

correct amplitude from DC to high frequency.

Note 5: Details of this scheme are nicely presented in Reference 15.

Additional relevant commentary on parallel path schemes appears in

Reference 7.

AN61-18

an61fa

Page 19

+16V

Application Note 61

CONCEPTUAL MODEL

OF HALL EFFECT

SENSOR-XFORMER.

TEKTRONIX

120-0464-00 OR

120-0464-02

CURRENT

CARRYING

CONDUCTOR

AND

RESULTANT

FIELD

–16V

619Ω

(TYPICAL)

619Ω

(TYPICAL)

10μH

10μH

DIFFERENTIAL

HALL SENSOR

AMPLIFIER

3

2

+

OTA

LT1228

–

COMPOSITE OUTPUT TO OPTIONAL

+16V

A1

5

7

I

SET

2k

50Ω

50Ω

BANDWIDTH

1k 1k

OFFSET

TRIM

ATTENUATOR AND WIDEBAND AMPLIFIER

0.02

(TYPICAL)

1k

100Ω

1k

OFFSET

ADJ.

1

8

330Ω

1k

OFFSET

TRIM

DC AND LOW FREQUENCY OUTPUT

+

CFA

LT1228

–

A2

–16

6

4

–16V+16V

Figure 24. Hall Effect Stabilized Current Transformer (DC → High Frequency Current Probe)

X1

CURRENT

BUFFER

200Ω

20k

LOOP GAIN

4.7k

A1, A2 = LT1228 DUAL

16Ω

AN62 TA24

Figure 25 shows a practical way to conveniently evaluate

this circuits performance. This partial schematic of the

Tektronix P-6042 current probe shows a similar signal

conditioning scheme for the transducer specified in

Figure24. In this case Q22, Q24 and Q29 combine with

differential stage M-18 to form the Hall amplifier. To evaluate Figure 24’s circuit remove M-18, Q22, Q24 and Q29.

Next, connect LT1228 pins 3 and 2 to the former M-18

pins 2 and 10 points, respectively. The ±16V supplies are

available from the P-6042’s power bus. Also, connect the

right end of Figure 24’s 200Ω resistor to what was Q29’s

collector node. Finally, perform the offset, loop gain and

bandwidth trims as previously described.

an61fa

AN61-19

Page 20

Application Note 61

TO

WIDEBAND

AMPLIFIER

SECTION

AN61 F25

AN61-20

Figure 25. Tektronix P-6042 Hall Effect Based Current Probe Servo Loop.

Figure 24 Replaces M18 Amplifier and Q22, Q24 and Q29

Figure reproduced with permission

of Tektronix, Inc.

an61fa

Page 21

Application Note 61

Triggered 250 Picosecond Rise Time Pulse Generator

Verifying the rise time limit of wideband test equipment

setups is a difficult task. In particular, the “end-to-end”

rise time of oscilloscope-probe combinations is often

required to assure measurement integrity. Conceptually,

a pulse generator with rise times substantially faster than

the oscilloscope-probe combination can provide this

information. Figure 26’s circuit does this, providing an

800ps pulse with rise and fall times inside 250ps. Pulse

amplitude is 10V with a 50Ω source impedance. This

circuit has similarities to a previously published design

(see Reference 7) except that it is triggered instead of free

running. This feature permits synchronization to a clock or

other event. The output phase with respect to the trigger

is variable from 200ps to 5ns.

The pulse generator requires high voltage bias for operation. The LT1082 switching regulator to forms a high

voltage switched mode control loop. The LT1082 pulse

5V

+

1μF

L1

820μH

MUR120

430k

10k

+

2μF

+

1μF

width modulates at its 40kHz clock rate. L1’s inductive

events are rectified and stored in the 2μF output capacitor.

The adjustable resistor divider provides feedback to the

LT1082. The 10k-1μF RC provides noise filtering.

The high voltage is applied to Q1, a 40V breakdown device,

via the R3-C1 combination. The high voltage “bias adjust”

control should be set at the point where free running

pulses across R4 just disappear. This puts Q1 slightly

below its avalanche point. When an input trigger pulse

is applied Q1 avalanches. The result is a quickly rising,

very fast pulse across R4. C1 discharges, Q1’s collector

voltage falls and breakdown ceases. C1 then recharges to

just below the avalanche point. At the next trigger pulse

this action repeats.

6

Figure 27 shows waveforms. A 3.9GHz sampling oscilloscope (Tektronix 661 with 4S2 sampling pug-in) measures

the pulse (trace B) at 10V high with an 800ps base. Rise

time is 250ps, with fall time indicating 200ps. The times

are probably slightly faster, as the oscilloscope’s 90ps rise

7

time influences the measurement.

The input trigger pulse

is trace A. Its amplitude provides a convenient way to vary

the delay time between the trigger and output pulses. A

1V to 5V amplitude setting produces a continuous 5ns to

200ps delay range.

V

E2

E1

GND V

TRIGGER INPUT

= 10NS OR

T

RISE

LESS. 1V TO 5V

(SEE TEXT)

50kHz MAXIMUM

L1 = J.W. MILLER # 100267

L2 = 1 TURN # 28 WIRE, 1/4" TOTAL LENGTH

IN

LT1082

V

SW

FB

C

+

2μF

L2

3pF TO 12pF

C2

500k

BIAS ADJUST

12k

5pF

50Ω

AVALANCHE BIAS

TYPICALLY 70V.

(SEE TEXT)

R3

1M

Q1

2N2369 (SEE TEXT)

R4

10k

50Ω

Figure 26. Triggered 250ps Rise Time Pulse Generator.

Trigger Pulse Amplitude Controls Output Phase

C1

2pF

OUTPUT

AN62 F26

A = 0.5V/DIV

B = 1V/DIV

(UNCALIBRATED)

100 PICOSECONDS/DIV

AN61 F27

Figure 27. Input Pulse Edge (Trace A) Triggers the

Avalanche Pulse Output (Trace B). Display Granularity Is

Characteristic of Sampling Oscilloscope Operation

Note 6: This circuit is based on the operation of the Tektronix Type 111

Pulse Generator. See Reference 16.

Note 7: I’m sorry, but 3.9GHz is the fastest ’scope in my house (as of

September, 1993).

an61fa

AN61-21

Page 22

Application Note 61

Some special considerations are required to optimize

circuit performance. L2’s very small inductance combines

with C2 to slightly retard the trigger pulse’s rise time. This

prevents significant trigger pulse artifacts from appearing

at the circuit’s output. C2 should be adjusted for the best

compromise between output pulse rise time and purity.

Figure 28 shows partial pulse rise with C2 properly adjusted. There are no discernible discontinuities related to

the trigger event.

0.2V/DIV

500 PICOSECONDS/DIV

Figure 28. Expanded Scale View of Leading Edge Is

Clean with No Trigger Pulse Artifacts. Display Granularity

Derives from Sampling Oscilloscope Operation

AN61 F28

Q1 may require selection to get avalanche behavior. Such

behavior, while characteristic of the device specified, is not

guaranteed by the manufacturer. A sample of 50 Motorola

2N2369s, spread over a 12 year date code span, yielded

82%. All “good” devices switched in less than 600ps. C1

is selected for a 10V amplitude output. Value spread is

typically 2pF to 4pF. Ground plane type construction with

high speed layout, connection and termination techniques

are essential for a good results from this circuit.

Flash Memory Programmer

Although “Flash” type memory is increasingly popular,

it does require some special programming features. The

5V powered memories need a carefully controlled 12V

“VPP” programming pulse. The pulse’s amplitude must

be within 5% to assure proper operation. Additionally, the

pulse must not overshoot, as memory destruction may

8

occur for VPP outputs above 14V.

These requirements

usually mandate a separate 12V supply and pulse forming

circuitry. Figure 29’s circuit provides the complete flash

memory programming function with a single IC and some

discrete components. All components are surface mount

types, so little board space is required. The entire function

runs off a single 5V supply.

L1

33μH

5V

1 = FLASH PROGRAM

0 = STANDBY

Figure 29. Switching Regulator Provides Complete

Flash Memory Programmer

V

MBRS130T3

(MOTOROLA)

SWITCH

IN

LT1109-12

SENSESHDN

GND

L1 = SUMIDA CD54-330

+

33μF

VPP FLASH V

12V

60mA

"/t'

OUT

The LT1109-12 switching regulator functions by repetitively pulsing L1. L1 responds with high voltage flyback

events, which are rectified by the diode and stored in the

10μF capacitor. The “sense” pin provides feedback, and

the output voltage stabilizes at 12V within a few percent.

The regulator’s “shutdown” pin provides a way to control

the VPP programming voltage output. With a logical

zero applied to the pin the regulator shuts down, and no

VPP programming voltage appears at the output. When

the pin goes high (trace A, Figure 30) the regulator is

activated, producing a cleanly rising, controlled pulse at

the output (trace B). When the pin is returned to logical

zero, the output smoothly decays off. The switched mode

delivery of power combined with the output capacitor’s

filtering prevents overshoot while providing the required

pulse amplitude accuracy. Trace C, a time and amplitude

expanded version of trace B, shows this. The output

steps up in amplitude each time L1 dumps energy into

the output capacitor. When the regulation point is reached

the amplitude cleanly flattens out, with only about 75mV

of regulator ripple.

Note 8: See Reference 17 for detailed discussion.

AN61-22

an61fa

Page 23

A = 5V/DIV

B = 5V/DIV

C = 0.1V/DIV

A, B = 1ms/DIV

C = 50μs/DIV

AN61 F30

Figure 30. Flash Memory Programmer Waveforms Show

Controlled Edges. Trace C Details Rise Time Settling

3.3V Powered V/F Converter

Figure 31 is a “charge pump” type V/F converter specifi-

9

cally designed to run from a 3.3V rail.

A 0V to 2V input

produces a corresponding 0kHz to 3kHz output with

linearity inside 0.05%. To understand how the circuit

works assume that A1’s negative input is just below 0V.

The amplifier output is positive. Under these conditions,

LTC1043’s pins 12 and 13 are shorted as are pins 11 and7,

allowing the 0.01μF capacitor (C1) to charge to the 1.2V

LT1034 reference. When the input-voltage-derived current ramps A1’s summing point (negative input-traceA,

Figure32) positive, its output (trace B) goes low. This

reverses the LTC1043’s switch states, connecting pins

12 and 14, and 11 and 8. This effectively connects C1’s

positively charged end to ground on pin 8, forcing current

to flow from A1’s summing junction into C1 via LTC1043

pin 14 (pin 14’s current is trace C). This action resets A1’s

summing point to a small negative potential (again, trace

A). The 120pF-50k-10k time constant at A1’s positive input

ensures A1 remains low long enough for C1 to completely

discharge (A1’s positive input is trace D). The Schottky

diode prevents excessive negative excursions due to the

120pF capacitors differentiated response.

When the 120pF positive feedback path decays, A1’s

output returns positive and the entire cycle repeats. The

oscillation frequency of this action is directly related to

the input voltage.

This is an AC coupled feedback loop. Because of this,

start-up or overdrive conditions could force A1 to go low

Application Note 61

3.3V

IN

5

LTC1043

4

22k

7

11

12

16

IN

INPUT

0V TO

FULL SCALE

2V

10k

TRIM

22μF

75k*

+

1μF

LT1034

1.2V

3.3V

–

A1

1/2 LT1017

13

+

1N5712

50k

10k

* = 1% FILM RESISTOR, TYPE TRW-MTR+120ppm/°C

** = POLYSTYRENE

Figure 31. 3.3V Powered Voltage-to-Frequency Converter.

Charge Pump Based Feedback Maintains High Linearity

and Stability

A = 0.02V/DIV

B = 2V/DIV

C = 5mA/DIV

D = 2V/DIV

50μs/DIV

Figure 32. Waveform for the 3.3V Powered V/F. Charge

Pump Action (Trace C) Maintains Summing Point (Trace A),

Enforcing High Linearity and Accuracy

Note 9: See Reference 20 for a survey of V/F techniques. The circuit

shown here is derived from Figure 8 in LTC Application Note 50,

“Interfacing to Microprocessor Based 5V Systems” by Thomas Mosteller.

2

6

17

8

C1**

0.01

μF

14

D1

1N4148

120pF

1.6M

(10Hz TRIM)

f

OUT

0kHz TO

3kHz

AN61 F32

C2

560pF

AN61 F31

an61fa

AN61-23

Page 24

Application Note 61

and stay there. When A1’s output is low the LTC1043’s

internal oscillator sees C2 and will begin oscillation if A1

remains low long enough. This oscillation causes charge

pumping action via the LTC1043-C1-A1 summing junction

path until normal operation commences. During normal

operation A1 is never low long enough for oscillation to

occur, and controls the LTC1043 switch states via D1.

To calibrate this circuit apply 7mV and select the 1.6M

(nominal) value for 10Hz out. Then apply 2.000V and set

the 10k trim for exactly 3kHz output. Pertinent specifications include linearity of 0.05%, power supply rejection

of 0.04%/V, temperature coefficient of 75ppm/°C of scale

and supply current of about 200μA. The power supply

may vary from 2.6V to 4.0V with no degradation of these

specifications. If degraded temperature coefficients are

acceptable, the film resistor specified may be replaced

1μF

D1

NC201

+

A2

LT1226

1k

–

15V

16k

by a standard 1% film resistor. The type called out has a

temperature characteristic that opposes C1’s –120ppm/°C

drift, resulting in the low overall circuit drift noted.

Broadband Random Noise Generator

Filter, audio, and RF-communications testing often require

10

a random noise source.

Figure 33’s circuit provides an

RMS-amplitude regulated noise source with selectable

bandwidth. RMS output is 300mV with a 1kHz to 5MHz

bandwidth, selectable in decade ranges.

Noise source D1 is AC coupled to A2, which provides a

broadband gain of 100. A2’s output feeds a gain control

stage via a simple, selectable lowpass filter. The filter’s

Note 10: See Appendix B, “Symmetrical White Gaussian Noise,” guest

written by Ben Hessen-Schmidt of Noise Com, Inc. for tutorial on noise.

0.1(1kHz)

1.6k

0.01(10kHz)

0.001(100kHz)

+

A3

LT1228

SET

–

NC 201 =

NOISE COM =

3k

NOISE COM CORP.

(201) 261-8797

0.1μF

15V

A5

LT1006

–15V

1k

10Ω

–

+

910Ω

1k

15V

+

A4

LT1228

CFA

–

–15V

10k

1M

1N4148

THERMALLY

COUPLED

10Ω

100pF(1MHz)

NC

(5MHz)

510Ω

22μF

+

–

0.5μF

22μF

–

+

LT1004

1.2V

4.7k

OUTPUT

1μF

NON POLAR

10k

–15V

AN61 F33

Figure 33. Broadband Random Noise Generator Uses Gain Control Loop to Enhance Noise Spectrum Amplitude Uniformity

AN61-24

an61fa

Page 25

output is applied to A3, an LT1228 operational transconductance amplifier. A3’s output feeds LT1228 A4, a current

feedback amplifier. A4’s output, also the circuit’s output, is

sampled by the A5-based gain control configuration. This

closes a gain control loop to A3. A3’s set current controls

gain, allowing overall output level control.

Figure 34 shows noise at 1MHz bandpass, with Figure 35

showing RMS noise versus frequency in the same bandpass. Figure 36 plots similar information at full bandwidth

(5MHz). RMS output is essentially flat to 1.5MHz with

about ±2dB control to 5MHz before sagging badly.

12

9

6

3

Application Note 61

1V/DIV

10μs/DIV

Figure 34. Figure 33’s Output in the 1MHz Filter Position

AN61 F34

0

–3

–6

AMPLITUDE VARIANCE (dB)

–9

–12

0.1 0.2 0.3 0.4 0.5

0

FREQUENCY (MHz)

0.6 0.7 0.8 0.9 1.0

AN61 F35

Figure 35. Amplitude vs Frequency for the Random Noise Generator Is Essentially Flat to 1MHz

9

6

3

0

–3

–6

–9

–12

AMPLITUDE VARIANCE (dB)

–15

–18

–21

12345

0

FREQUENCY (MHz)

678910

AN61 F36

Figure 36. RMS Noise vs Frequency at 5MHz Bandpass Shows Slight Fall-Off Beyond 1MHz

an61fa

AN61-25

Page 26

Application Note 61

Figure 37’s similar circuit substitutes a standard zener for

the noise source but is more complex and requires a trim.

A1, biased from the LT1004 reference, provides optimum

drive for D1, the noise source. AC coupled A2 takes a

broadband gain of 100. A2’s output feeds a gain-control

stage via a simple selectable lowpass filter. The filter’s output

is applied to LT1228 A3, an operational transconductance

amplifier. A3’s output feeds LT1228 A4, a current feedbacks

1M

15V

100k

–

2

1/2 LT1013

3

+

3

+

1/2 LT1228

2

–

A1

–15V

15V

A3

5

8

4

7

SET

3k

0.1μF

7

1

5k

6.2k

15V

A5

1/2 LT1013

900Ω

6

–

5

+

50k

+

1μF

1

+

1/2 LT1228

8

–

A4

–15V

D1

1N753

6

4

10k

1M

1μF

510Ω

10Ω

1N4148s

COUPLE THERMALLY

amplifier. A4’s output, the circuit’s output, is sampled by

the A5-based gain control configuration. This closes a gain

control loop back at A3. A3’s set input current controls its

gain, allowing overall output level control.

To adjust this circuit, place the filter in the 1kHz position

and trim the 5k potentiometer for maximum negative bias

at A3, pin 5.

0.1μF

1kHz

0.01μF

3

+

A2

1k

2

–

1k

10Ω

1μF

NONPOLAR

LT1226

1k

10k

22μF+22μF

1.6k

1V

P-P

OUTPUT

0.001μF

100pF

10pF

+

0.05μF

4.7k

LT1004

1.2V

–15V

10kHz

100kHz

1MHz

5MHz

Figure 37. A Similar Circuit Uses a Standard Zener Diode, But Is More Complex and Requires Trimming

AN61-26

–15V

AN61 F37

an61fa

Page 27

Application Note 61

Switchable Output Crystal Oscillator

Figure 38’s simple crystal oscillator circuit permits crystals

to be electronically switched by logic commands. The

circuit is best understood by initially ignoring all crystals.

Further, assume all diodes are shorts and their associated

1k resistors open. The resistors at the LT1116’s positive

input set a DC bias point. The 2k-25pF path sets up phase

shifted feedback and the circuit looks like a wideband unity

gain follower at DC. When “Xtal A” is inserted (remember,

D1 is temporarily shorted) positive feedback occurs and

XTAL X

XTAL B

XTAL A

5V

Q'

+

LT1116

–

5V

D1

2k

1k

1k

oscillation commences at the crystals resonant frequency.

If D1 and its associated 1k value are realized, oscillation

can only continue if logic input A is biased high. Similarly,

additional crystal-diode-1k branches permit logic selection

of crystal frequency.

For AT cut crystals about a millisecond is required for

the circuit output to stabilize due to the high Q factors

involved. Crystal frequencies can be as high as 16MHz

before comparator delays preclude reliable operation.

LOGIC INPUTS

RX

AS MANY STAGES

1k

1k

AS DESIRED

B

A

OUTPUT

= 1N4148

"/t'

DX

D2

GROUND CRYSTAL CASES

Figure 38. Switchable Output Crystal Oscillator. Biasing A

orB High Places the Associated Crystal in the Feedback Path.

Additional Crystal Branches Are Permissible

REFERENCES

1. Williams, Jim and Huffman, Brian. “Some Thoughts

on DC-DC Converters,” pages 13-17, “1.5V to 5V Converters.” Linear Technology Corporation, Application

Note 29, October 1988.

2. Williams, J., “Illumination Circuitry for Liquid Crystal

Displays,” Linear Technology Corporation, Application

Note 49, August 1992.

3. Williams, J., “Techniques for 92% Efficient LCD Illumination,” Linear Technology Corporation, Application

Note 55, August 1993.

4. Williams, J., “Measurement and Control Circuit Collection,” Linear Technology Corporation, Application

Note 45, June 1991.

5. Benjaminson, Albert, “The Linear Quartz Thermometer ––a New Tool for Measuring Absolute and Difference

Temperatures,” Hewlett-Packard Journal, March 1965.

6. Micro Crystal-ETA Fabriques d’Ebauches., “Miniature

Quartz Resonators - MT Series” Data Sheet. 2540

Grenchen, Switzerland.

an61fa

AN61-27

Page 28

Application Note 61

7. Williams, J., “High Speed Amplifier Techniques,” Linear

Technology Corporation, Application Note 47, August

1991.

8. Williams, Jim, “High Speed Comparator Techniques,”

Linear Technology Corporation, Application Note 13,

April 1985.

9. Williams, Jim, “A Monolithic IC for 100MHz RMS-DC

Conversion,” Linear Technology Corporation, Applica-

tion Note 22, September 1987.

10. Ott, W.E., “A New Technique of Thermal RMS Measurement,” IEEE Journal of Solid State Circuits, December

1974.

11. Williams, J.M. and Longman, T.L., “A 25MHz Thermally

Based RMS-DC Converter,” 1986 IEEE ISSCC Digest

of Technical Papers.

12. O’Neill, P.M., “A Monolithic Thermal Converter,” H.P.

Journal, May 1980.

13. C. Kitchen, L. Counts, “RMS-to-DC Conversion Guide,”

Analog Devices, Inc. 1986.

14. Tektronix, Inc. “P6042 Current Probe Operating and

Service Manual,” 1967.

15. Weber, Joe, “Oscilloscope Probe Circuits,” Tektronix,

Inc., Concept Series. 1969.

16. Tektronix, Inc., Type 111 Pretrigger Pulse Generator

Operating and Service Manual, Tektronix, Inc. 1960.

17. Williams, J., “Linear Circuits for Digital Systems,”

Linear Technology Corporation, Application Note 31,

February 1989.

18. Williams, J., “Applications for a Switched-Capacitor

Instrumentation Building Block,” Linear Technology

Corporation, Application Note 3, July 1985.

19. Williams, J., “Circuit Techniques for Clock Sources,”

Linear Technology Corporation, Application Note 12,

October 1985.

20. Williams, J. “Designs for High Performance Voltageto-Frequency Converters,” Linear Technology Corporation, Application Note 14, March 1986.

APPENDIX A

Precision Wideband Circuitry . . . Then and Now

Text Figure 22’s relatively straightforward design provides

a sensitive, thermally-based RMS/DC conversion to 10MHz

with less than 1% error. Viewed from a historical perspective it is remarkable that so much precision wideband

performance is so easily achieved.

Thirty years ago these specifications presented an extremely

difficult engineering challenge, requiring deep-seated knowledge of fundamentals, extraordinary levels of finesse and

an interdisciplinary outlook to achieve success.

Note 1: We are all constantly harangued about the advances made in

computers since the days of the IBM360. This section gives analog

aficionados a stage for their own bragging rights. Of course, an HP3400A

was much more interesting than an IBM360 in 1965. Similarly, Figure 22’s

The Hewlett-Packard model HP3400A (1965 price

$525 . . . about 1/3 the yearly tuition at M.I.T.) thermallybased RMS voltmeter included all of Figure 22’s elements,

1

but considerably more effort was required in its execution.

Our comparative study begins by considering H-P’s version

of Figure 22’s FET buffer and precision wideband amplifier.

The text is taken directly from the HP3400A Operating and

Service Manual.

capabilities are more impressive than any contemporary computer I’m

aware of.

Note 2: All Hewlett-Packard text and figures used here are copyright 1965

Hewlett-Packard Company. Reproduced with permission.,

2

AN61-28

an61fa

Page 29

Application Note 61

Figure A1. The “Impedance Converter Assembly,” H-P’s Equivalent of Figure 22’s Wideband FET Buffer

Note 3: Although JFETs were available in 1965 their performance was