Page 1

Application Note 137

May 2012

Accurate Temperature Sensing with an External P-N

Junction

Michael Jones

Introduction

Many Linear Technology devices use an external PNP

transistor to sense temperature. Common examples are

LTC3880, LTC3883 and LTC2974. Accurate temperature

sensing depends on proper PNP selection, layout, and

device configuration. This application note reviews the

theory of temperature sensing and gives practical advice

on implementation.

Why should you worry about implementing temperature

sensing? Can’t you just put the sensor near your inductor

and lay out your circuit any way you want? Unfortunately,

poor routing can sacrifice temperature measurement

performance and compensation. The purpose of this application note is to allow you the opportunity to get it right

the first time, so you don’t have to change the layout after

your board is fabricated.

Why Use Temperature Sensing?

Some Linear Technology devices measure internal and

external temperature. Internal temperature is used to

protect the device by shutting down operation or locking

out features. For example, the LTC3880 family will prevent

writing to the NVRAM when the internal temperature is

above 130°C.

External temperature compensation is used to compensate for temperature dependent characteristics of external components, typically the DCR of an inductor. The

LTC3880 uses inductor temperature to improve accuracy

of current measurements. The LTC3883 and LTC2974 also

compensate for thermal resistance between the sensor

and inductor, plus the thermal time constant.

This application note will focus on external temperature

sensing. Proper up front design and layout will prevent

performance problems.

Temperature Sensing Theory

Linear Technology devices use an external bipolar transistor p-n junction to measure temperature. The relationship

between forward voltage, current, and temperature is:

IC=ISe

V

⎛

⎜

(nVT)

⎜

⎝

kT

=

T

q

BE

–1

⎞

⎟

⎟

⎠

V

IC is the forward current

is the reverse bias saturation current

I

S

is the forward voltage

V

BE

is the thermal voltage

V

T

n is the ideality factor

k is Boltzmann’s constant

For V

>> VT the –1 can be ignored, and the approximate

BE

model of the forward voltage is:

⎛

VBE≈ n•

kT

q

In

⎞

I

C

⎜

⎟

I

⎝

⎠

S

The approximation eliminates the need for an iterative

solution to the forward voltage. This equation can be

rearranged to give the temperature

V

nk •In

BE

⎛

⎞

I

C

⎜

⎟

⎜

⎟

I

S

⎝

⎠

T =q•

L, LT, LTC, LTM, LTspice, Linear Technology and the Linear logo are registered trademarks of

Linear Technology Corporation. All other trademarks are the property of their respective owners.

an137f

AN137-1

Page 2

Application Note 137

Because n, k, and IS are constants, the simplest way to

measure temperature is to force current, measure voltage, and calculate temperature. However, the accuracy

will depend on n and I

, the ideality factor and reverse

S

saturation current. These constants are process dependent

and vary from lot to lot.

The diode voltage can be rewritten in delta form:

ΔVBE= V

BE1–VBE2

=

nkT

q

In

⎛

⎞

I

C1

⎜

⎟

⎜

⎟

I

C2

⎝

⎠

Rewriting for temperature:

V

()

BE1–VBE2

T =

nk

q

In

⎛

⎞

I

C1

⎜

⎟

I

⎝

⎠

C2

If we set the currents such that:

= N • I

I

C2

C1

we now have:

V

()

BE1–VBE2

T =

nk

q

In

⎞

⎛

1

⎟

⎜

⎠

⎝

N

V1

C1

2N3906

10μF

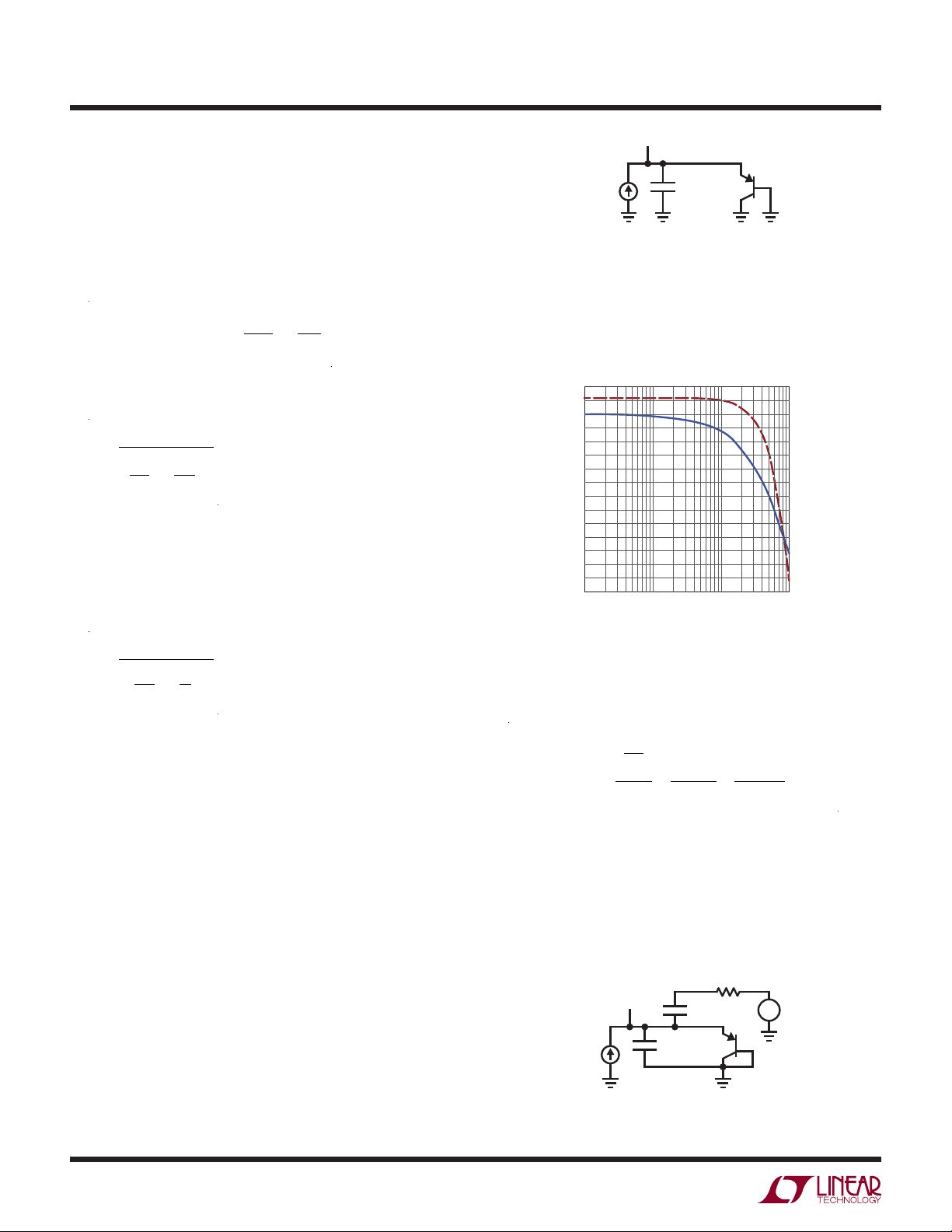

Figure 1.

Q1

AN137 F01

500μA

I

1

The operating point at 500μA gives a DC impedance of

1.27kΩ. The small signal impedance can be plotted in

spice and is 52Ω out to 10MHz.(Solid line is magnitude

of impedance, and dashed line is phase of impedance).

4

AN137 F02

2

0

–2

–4

–6

–8

–10

–12

–14

–16

–18

–20

–22

–24

–26

(DEGREE)

(dB)

34.3

34.2

34.1

34.0

33.9

33.8

33.7

33.6

33.5

33.4

33.3

33.2

33.1

33.0

32.9

100k

10M 100M1M

(Hz)

Figure 2.

The small signal impedance can be calculated as follows:

Now the temperature measurement only depends on the

ideality factor n.

The ideality factor is relatively stable compared to the saturation current. Conceptually, the delta measurement is far

more accurate than the single measurement, because the

delta measurement cancels the saturation current and all

other non-ideal mechanisms not modeled by the equations.

For both cases, the accuracy of temperature measurement depends on the forcing current accuracy, the voltage

measurement accuracy, and relatively noise free signals.

Noise Sources

A typical diode temperature sensor is comprised of a

2N3906, 10μF capacitor, current source, and voltage

measurement.

⎛

⎞

kT

⎜

R

small–signal

⎟

q

⎝

=

26mV

⎠

=

I

C

I

C

26mV

=

500μA

= 52Ω

This implies that fast clock and PWM signals may inject

noise into the measurement if the driving impedance is

close to 52Ω.

A simulation of a capacitive coupled source shows that

the filter capacitor is quite effective.

R1

1Ω

V1

I

1

500μA

Figure 3. Pulse (0 3.30 10ps 10ps 100ns 2.5μs 10000)

C1

10μF

C2

10nF

2N3906

Q1

+

–

AN137 F03

V1

an137f

AN137-2

Page 3

Application Note 137

672

665

658

651

644

637

(mV)

630

623

616

609

602

0

(ms)

2024681012141618

AN137 F04

Figure 4.

The simulation uses a 10ps 3.3V signal (V1) injected into

the p-n junction (V1) via a 10nF capacitor (C1). Even a

10nF coupled noise source with very fast 10ps edges can

only generate 30mV spikes shown in the simulation plot.

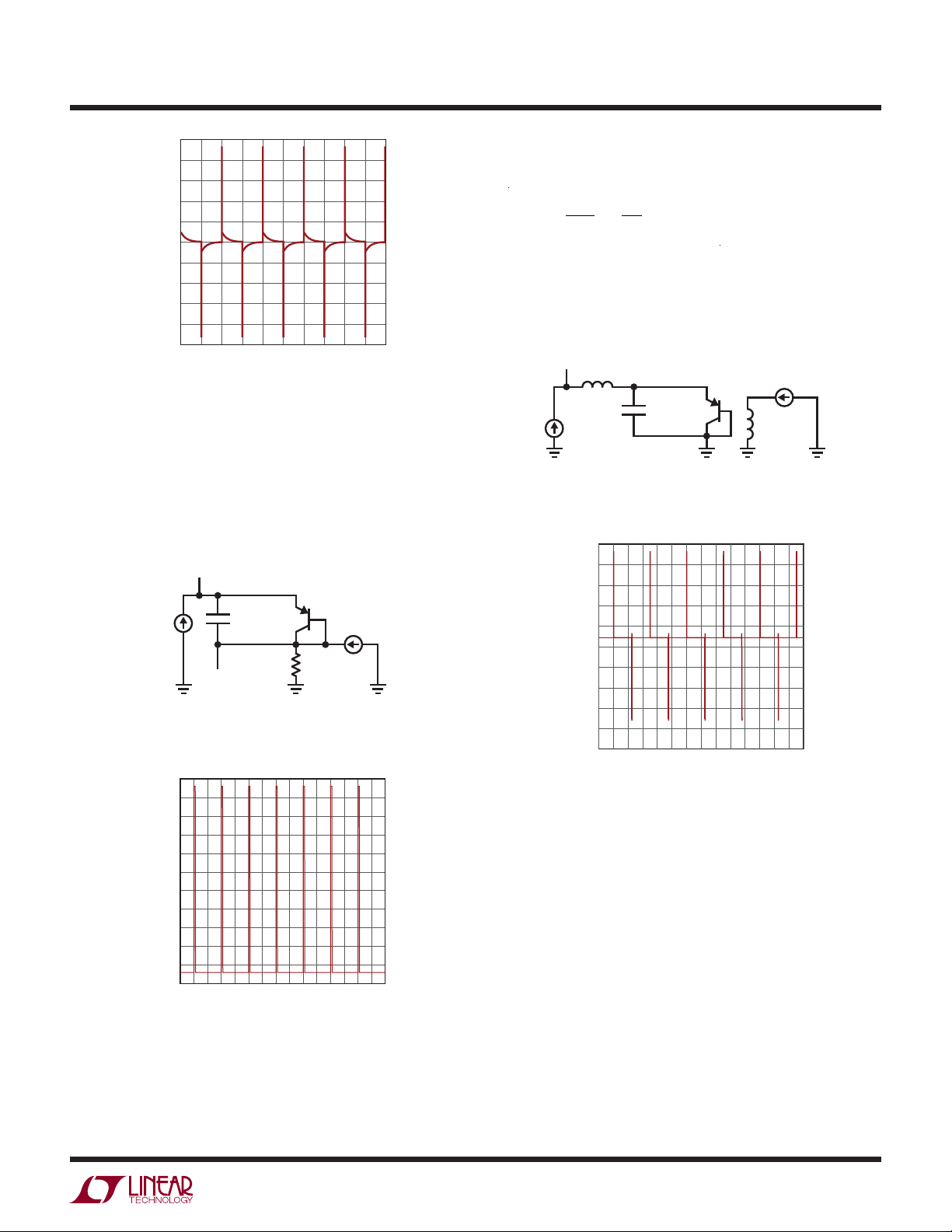

Another source of error comes from ground impedances.

V1

C1

I

1

500μA

REMOTE

GND

Figure 5. Pulse (0 2A 0 10n 10n 100ns 2.5μs 10000)

658

656

654

652

650

648

(mV)

646

644

642

640

638

636

33

2N3906

10μF

Figure 6.

(μs)

Q1

R2

0.01Ω

I

2

AN137 F05

4834 35 36 37 38 39 40 41 42 43 44 45 46 47

AN137 F06

A 2A current and 10mΩ trace results in a 20mV error. A

typical delta V

ΔVBE=

nkT

q

is

D

⎞

⎛

1

⎜

⎝

10

≈ 60mV

⎟

⎠

In

For a 10% duty cycle, this might result in a 2mV DC shift.

A third source of error is a magnetic field and loop. Magnetic

coupling can be modeled as a coupling between inductors.

V1

K L2 L1 0.01

t

L1

10nH

I

1

500μA

C1

10μF

2N3906

Q1

I

2

t

L2

10nH

AN137 F07

Figure 7. Pulse (0.2A 0 10n 10n 1.25μs 2.5μs 10000)

660

655

650

645

640

635

(mV)

630

625

620

615

610

464

(μs)

478466 468 470 472 474 476

AN137 F08

Figure 8.

A 3cm PCB trace over a ground plane can have about

10nH of inductance. If 2A is injected into a parallel trace

and the coupling is 1.0%, 30mV of noise can be generated, possibly causing a DC shift of 3mV.

HOW NOISE AFFECTS MEASUREMENTS

Linear Technology devices typically implement a lowpass

filter, which filters spikes and noise. However, in some

cases filtering results in a significant DC shift.

an137f

AN137-3

Page 4

Application Note 137

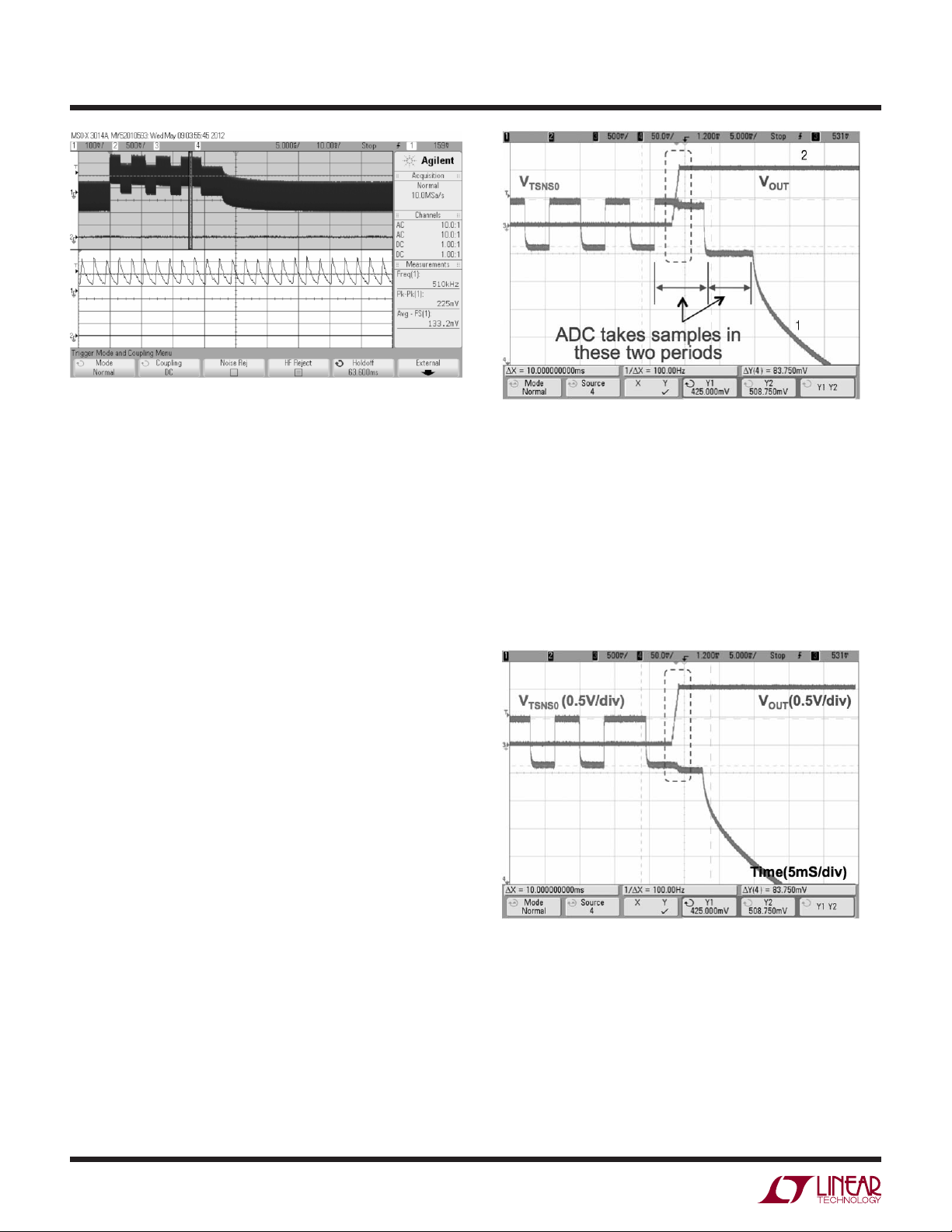

Figure 9.

The example shown in Figure 9, from an LTC3880, shows

an asymmetrical waveform on the TSENSE pin (channel

1) caused by injecting some of the switch node signal into

the TSENSE pin. When this is filtered, it results in a DC

shift. If temperature is calculated using a ΔV

and the DC shift is the same for both V

the effect will be cancelled out. This means that if the

error mechanism is consistent between current measurements, ΔV

is robust. If the single VBE measurement is

BE

used, the DC shift from the filtering will be a source of

measurement error. (LTC3880 does not support single

measurements)

ΔV

BE

calculation,

BE

measurements,

BE

Figure 10.

An Example Coupling Problem

The example shown in Figure 10 comes from an LTC3880.

Signal 1 is the TSENSE signal. When the LTC3880 is applying 32μA, you get the higher signal level, and when it

is applying 2μA, you get the lower signal level. The last

high and low portions of the waveform are where the

two measurements are taken. Signal 2 is the V

OUT

of the

LTC3880, which is coupling into the 32μA measurement.

If the magnitude of noise is very large with respect to ΔV

BE

,

and the noise is asymmetrical (as in the scope shot) and

different between current measurements, ΔV

cannot

BE

cancel out the noise. In this case a single measurement

can produce a more accurate temperature measurement.

For example, suppose noise causes an error of 50mV. A

typical ΔV

single V

Therefore, in systems with systematic noise, the ΔV

is 70mV. The error can be as high as 70%. If a

BE

is used, the error is about 50mV/600mV, or 8%.

D

BE

measurement produces the highest accuracy by eliminating

as a source of error. (See ΔVBE equation). In systems

I

S

with large non-systematic noise, the V

measurement

BE

produces the highest accuracy.

Overall, the best accuracy comes from a good layout that

ensures near zero noise that is systematic, and uses a

calculation.

ΔV

BE

Non-systematic noise sources require good layout because

the ΔV

approach cannot reject them.

BE

Figure 11.

The same coupling can occur in the 2μA measurement as

shown in Figure 11. The asymmetry comes from the fact

that the coupling affects only one of two measurements, so

it is not cancelled by the ΔV

calculation. Furthermore, the

BE

error will appear random because the output turn-on event

and the current forcing mechanism are not synchronized.

The only defense against this error is prevention of the

coupling by proper layout, or widening the fault limits.

an137f

AN137-4

Page 5

Figure 12.

MITIGATING ERROR SOURCES

There are two primary methods of preventing errors, both

require proper PCB layout. The first involves elimination of

shared ground paths. The second involves proper signal

trace routing.

Linear Technology data sheets specify how to return current

from the collector and base of the temperature measurement

transistor to the device. Typically the current returns to a

sense ground (SGND), or an amplifier negative (–) input.

Application Note 137

The current should return to the device via its own sense

trace to ensure there is no shared impedance with high

current paths, and to the data sheet specified pin.

Figure 12 shows a LTC3883 and 2N3906 PNP current

sense. Q10 in circle 1 is the p-n junction temperature

sensor and is filtered by C99. The purpose of C99 is to

provide a low AC impedance to prevent any DC offsets

from rectification or non-linear waveforms, and to keep

coupled noise out of the LTC3883 ADC. The routing uses

two parallel pairs on the same layer so that any coupling

from noise sources becomes a common mode signal

to the ADC in the LTC3883 and are rejected. The anode

trace routes to the sense pin to the LTC3883 Pin 32

shown in circle 2, and the cathode is routed to SGND: the

exposed PAD on the back of the LTC3883. The cathode

routing to the exposed PAD ensures no high current from

the power ground flows through the sense line.

Figure 13 shows an LTC2991 and two 2N3906 PNP

temperature sensors. As in the previous example, capacitor filtering is added near the PNP. However, capacitor filtering was also added at the input of the LTC2991.

Figure 13.

an137f

AN137-5

Page 6

Application Note 137

The longer trace run offers more opportunity to pick up

noise farther from the PNP due to trace inductance. Typically this capacitor is added as an option and installed

only if there is a problem. Additionally, notice that the

routes avoid switching areas by following the edges of

the plane between functional circuits. The routes from

the PNP farthest to the right go right between a LTC3883

buck converter below, and a LT1683 isolated boost above.

NOTE: Linear Technology strongly recommends

Placement of a filter capacitor near the PNP tem-

perature sensor, Routing differentially, and Avoiding

noisy signals. Long routes may pick up more noise,

so optionally add a filter capacitor near the device.

Some designs may use a power block with built in temperature diode. Some of these power blocks do not have

a pin for the low sense of the diode. These blocks may not

have a filter capacitor. In these situations, you can place a

filter on your board as close to the high side diode sense

pin of the power block as possible, and try to minimize all

noise sources. A low sense line can still be routed from the

power ground, but you can’t eliminate the shared current

from the switching path, so some noise will be injected.

You can mitigate some of the problems that may result by:

1. Using a slower V

ramp rate when turning on

OUT

2. Adding an offset to the measurement using the proper

register (digital power device) to lower the measured

temperature

3. Raising the overtemperature fault limit

over temperature. In general, a large ideality factor will not

produce an accurate temperature measurement using the

method. The large ideality factor will lead to larger

ΔV

BE

. Furthermore, VBE may be lower because of differ-

ΔV

BE

ences in I

. This may use less of the dynamic range of

S

the ADC and increase signal to noise ratio. In the case of

a single V

measurement, this will degrade results more.

BE

NOTE: Use a diode connected bipolar transistor rather

than a true diode. If you want to use a diode anyway,

contact Linear Technology for advice on suitability for

the given device.

600

570

V

(V1)

540

510

(mV)

480

450

420

390

360

330

300

270

0

30 40 50 7060 80 90 10010 20

(μA)

V

(V2)

AN137 F14

Figure 14. 2N3906 and IN4148

An LTspice® simulation demonstrates the difference between a diode connected 2N3906 and a 1N4148. The diode

has almost 150mV lower voltage at 30μA.

4. Adding a capacitor on the power block

CHOICE OF P-N JUNCTION DEVICE

Even though a diode can be used to measure temperature,

a diode connected PNP or NPN is preferred. The ideality

factor of a diode is up to twice as large as a diode connected bipolar transistor. Some diodes do not exhibit

increasing ΔV

with temperature, resulting in large errors

BE

AN137-6

(mV)

570

V

(V1)

540

510

480

450

420

390

360

330

300

270

0

70mV

Figure 15. 2N3906 DV

(μA)

2N3906

V

(V2)V(V2)

1N4148

10010 20 30 40 6050 70 80 90

AN137 F15

BE

an137f

Page 7

Application Note 137

The diode-connected transistor shows a typical room

temperature ΔV

(mV)

of 70mV.

BE

570

V

(V1)

540

510

480

450

420

390

360

330

300

270

0

Figure 16. IN4148 ΔV

127mV

(μA)

2N3906

V

(V2)V(V2)

2N4148

10010 20 30 40 6050 70 80 90

AN137 F16

BE

The diode shows a typical room temperature ΔVBE of

127mV. If the part is using a ΔV

measurement, and if

BE

the ADC has a null and diff amp with gain, you must make

certain the device can handle the larger ΔV

BE

.

4. Avoid routing near noise generators such as switch

nodes, large current traces, large transformers, etc.

5. If using a power block, add a filter cap to the block if

possible, or as close as possible to the diode pin if it

can’t be on the power block.

6. Use a power block with two-pin sensing of the diode if

possible.

7. If you have a sub-optimal layout, add offset to the offset

register if one is available, or raise the fault limit. In some

designs you can make these adjustments during turn

on or soft start and restore them during steady state.

APPENDIX A: GENERAL NOISE SOURCES AND

MITIGATION

A more general and analytical approach to noise is offered

based on material from Noise Reduction Techniques in

Electronic Systems, Henry W. Ott. These principles can

guide you in solving problems not directly covered in the

application note.

In all cases, if a diode is used, the controller IC must have

a register for setting the ideality. Some Linear Technology

controller ICs have a register for this and others don’t. The

ones that don’t are typically set for a 2N3904 or 2N3906.

REVIEW OF DESIGN RULES

A simple set of design rules can prevent a lot of problems:

1. Use a diode-connected transistor. Either 2N3904 or

2N3906. Follow recommendations on the data sheet.

2. Place a filter capacitor near the diode (less than a few

millimeters. Add a capacitor near the controller IC if

the transistor is more than a couple of inches away if

there is space.

3. Route a differential connection from the transistor to

the controller IC with minimum spacing whether the

part has a separate -TSENSE pin or not. If not, tie the

low side to the SGND pin. If there is no SGND pin, use

the PGND. Connect at the pin in all cases if possible.

Noise Sources

Conduction: noise on any PCB trace will move noise from

one part of the PCB to another. Generators of voltage

noise are the gate drivers, the switch node, and switching

currents that flow through resistors and inductive traces.

Coupling through Impedance: Any time two currents share

an impedance, the resulting voltage from one current path

is superimposed on the resulting voltage due to the other

current path. Shared current paths include the gate-driveloop/drain-source-loop/temperature-sense-loop.

Coupling through parasitic impedance: PCB traces that

are close together can couple through parasitic capacitance and mutual inductance. Low impedance switching

nodes can couple to higher impedance sense nodes. For

example, a gate drive can couple into a temperature sense

line via stray capacitance, or a switch current can couple

into a temperature sense line via an inductively coupled

parallel trace.

an137f

AN137-7

Page 8

Application Note 137

NOISE MITIGATION

Capacitive Coupling

If a noisy trace is routed next to a sensing trace, the noise

will couple to the sensing trace via capacitance.

C

COUPLING

10p

+

V

NOISE

–

REC

C

REC

6p

R

REC

50Ω

AN137 A1

Figure A1.

The analytical expression of the coupling from Ott is:

V

REC

=

⎡

C

jω

COUPLING

⎢

⎢

C

⎣

COUPLING+CREC

jω+

R

()

RECCCOUPLING+CREC

1

⎤

⎥

⎥

⎦

V

NOISE

(dB)

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

–110

–120

100

(Hz)

AN137 A2

90.3

90.0

89.7

89.4

89.1

(DEGREE)

88.8

88.5

88.2

87.9

87.6

87.3

87.0

10M1k 10k 100k 1M

Figure A2.

At 500kHz, the noise coupled to the receiver (temp sensor) is 10mV.

If a shield is added, the equivalent circuit looks like this:

+

–

C

COUPLING

10p

V

NOISE

C

SHIELD

100p

REC

C

REC

6p

R

50Ω

REC

In the case where R

is smaller than the impedance

REC

of the two capacitors, the equation can be simplified to:

REC

= jω R

REC CCOUPLING VNOISE

V

To get a sense of magnitude, a simulation of the above

circuit with an input of 5V to represent a gate drive signal,

and 50Ω to represent a temperature sensor, the following

is the frequency response:

AC 5

AN137 A3

Figure A3.

In this case there is no coupling to the receiver at all. An

example of shielding is given in the LTC2991 data sheet

as shown in Figure A4:

GND SHIELD

TRACE

470pF

NPN SENSOR

Figure A4.

LTC2991

V1

V2

V3

V4

V5

V6

V7

V8

V

ADR2

ADR1

ADR0

PWM

SCL

SDA

GND

CC

0.1μF

AN137 A4

In this case, the signals are routed differentially, so the

shield is protecting against capacitive coupling into both

traces. Notice that a portion of the traces is not shielded.

This area must be kept small and away from noise sources.

AN137-8

an137f

Page 9

Application Note 137

The example uses 10pF coupling to give some general

idea of magnitudes of coupling. It is best to make real

estimates of coupling capacitance and calculate the effect.

Also note, that parallel routing does not protect against

capacitive coupling if the low sense is not a high impedance input.

C

COUPLING

10p

+

V

NOISE

–

C1

10p

C

REC

6p

C2

6p

+

REC

R

REC

50Ω

–

R1

REC

10

AN137 A5

Figure A5.

The model in Figure A5 shows capacitive coupling into

both traces.

The frequency response is almost identical to the single

route because the impedance of the negative sense is

almost zero, therefore the noise can’t couple into it to

cancel the high side.

If the impedance on the negative sense is very high, such

as 1M shown in Figure A6:

AN137 A8

99

90

81

72

63

(DEGREE)

54

45

36

27

18

9

0

–9

10M1k 10k 100k 1M

(dB)

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

–110

–120

100

(Hz)

Figure A8.

(dB)

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

–110

–120

C

COUPLING

10p

+

V

NOISE

–

C1

10p

C

REC

6p

REC

+

R

50Ω

REC

the attenuation is 80dB at 10kHz.

Therefore, parallel routing would work on an LTC2991

current/temperature monitor, which has ± high impedance inputs, but would not work on an LTC3880 family

AC 5

C2

6p

Figure A6.

R1

1M

REC

–

AN137 A6

digital power buck converter which has a low impedance

minus input.

1

One last note: looking at the coupling equation:

V

If R

= jωR

REC

REC

REC CCOUPLING VNOISE

is reduced, so is the coupled noise. Adding a

capacitor to the input of the receiver will lower the AC

impedance. The simulation of this is left to the reader.

Inductive Coupling

Inductive coupling occurs when high currents flow through

a trace, creating a magnetic field, and the field enters the

current loop of another circuit. The current loop will have

a series voltage noise source from the external field.

REC

= jωMI

V

100

(Hz)

AN137 A7

89.6

89.2

88.8

88.4

(DEGREE)

88.0

87.6

87.2

86.8

86.4

86.0

85.6

10M1k 10k 100k 1M

Figure A7.

Note 1: Parallel routing will still eliminate shared current coupling from

power ground

an137f

AN137-9

Page 10

Application Note 137

inductance and current. For example:

L

COUPLING1

20n

K1 L

+

V1

–

COUPLING1 LCOUPLING2 0.5

L

COUPLING2

20n

REC

t

t

AC 5

R

SENSOR

50Ω

R

1M

Figure A9.

Suppose the noise source is 5V, like a gate driver, driving

15Ω, which is about 300mA, similar to a typical gate driver.

This couples into a 50Ω sensor that drives an amplifier

input with 1M input impedance.

–10

–20

–30

–40

–50

–60

(dB)

–70

–80

–90

–100

–110

–120

100

(Hz)

Figure A10.

This will produce about 10mV at the receiver at 500kHz,

(shown in Figure A10) a value similar to the capacitive

coupling example.

The trace length causes the inductance, but the mutual inductance (represented as coupling factor in the simulation)

causes the coupling. The mutual inductance is proportional

to the area of the loop with the sensor and receiver.

REC

AN137 A10

10M1k 10k 100k 1M

R1

15Ω

AN137 A9

89.5

90.0

90.5

91.0

91.5

92.0

92.5

93.0

93.5

94.0

94.5

95.0

(DEGREE)

Suppose the coupling was reduced to 0.05:The received noise voltage is proportional to the mutual

AN137 A11

89.5

90.0

90.5

91.0

91.5

(DEGREE)

92.0

92.5

93.0

93.5

94.0

94.5

95.0

10M1k 10k 100k 1M

(dB)

–30

–40

–50

–60

–70

–80

–90

–100

–110

–120

–130

–140

100

(Hz)

Figure A11.

The result is a 20dB improvement, or 1mV of coupled

noise at 500kHz (shown in Figure A11).

There are several ways to make the loop smaller. The high

side sense can be routed over a ground plane. This will

only help at high frequencies because at low frequencies

the current will take the shortest path through the ground

plane, which will not be under the trace. Furthermore, the

shared ground may cause coupling, which is discussed

in the next section.

The high side and low side of the sensor can be routed

as parallel traces as close together as possible. As long

as the current only flows through the low side sense and

not an alternate ground path, this will make the loop area

very small. If there is an alternate ground path, the current

will only flow through the low sense line if the frequency

is high. Most situations allow this routing except some

power blocks discussed in the main portion of the application note.

Also, a shield may be added around the parallel traces.

Shields may be grounded at either end, so this must be

considered. Ott gave experimental data that will aid intuition in deciding how to ground the low sense and shield.

AN137-10

an137f

Page 11

Application Note 137

AN137 A12

Figure A12.

The data in Figure A12 applies shielding and routing where

the low sense is grounded at the sensor and receiver. This

applies to the case where a power block is used and the

low sense cannot be removed from the power ground

return signal. Assume the sensor is the 100Ω resistor,

and the receiver is the 1M resistor.

Case C represents routing the high and low sense in parallel

with minimal spacing (low sense on both sides, and with

low sense a ground), with a ground plane in parallel as the

alternate path. Case F represents Case C with an additional

shield. The minor difference in attenuation suggests that

Case C is the better choice because routing is simpler.

Case D represents a simple parallel routing, again with

the low sense a ground.

This shows that the traditional parallel sense traces can

be improved by routing the low sense (ground) on both

sides of the high sense and grounding at both ends. This

would apply to a power block when the low sense is tied

to power ground in the module.

AN137 A13

Figure A13.

Things are better when it is possible to ground at only

one end.

As in the previous cases, the sensor is the 100Ω resistor,

and the receiver is the 1M resistor. Case H represents the

traditional parallel close routing. This is more than 15dB

better than the previous case where you are forced to

ground both ends.

Case G represents routing the low sense (ground) on

both sides of the high sense. This is more than 50dB

better than Case C and 25dB better than Case H. This

is even 10dB better than Case I, which was the example

from LTC2991 used in the capacitive coupling section.

However, the LTC2991 low sense is high impedance and

not ground as in this example. Therefore, don’t disregard

the LTC2991 data sheet.

55dB would be 8mV for a 5V noise source. 80dB would

be 0.5mV for a 5V noise source. This is not an apples to

apples comparison, as the experimental data was taken at

50kHz. However, the principles are clear. If you have the

space, consider routing the low sense/ground on both

sides of the high sense.

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

an137f

AN137-11

Page 12

Application Note 137

Ground Coupling

Grounding loops are not typically the first source of noise

coupling. However, if a sensor low sense is grounded at

both ends, as when using a power block, a ground loop

is formed. This loop can receive a magnetic field, hence

inductive coupling, as discussed in the previous section.

Not much can be done about this other than to make the

shortest low sense route possible back to the receiver,

and keep the layers between the trace and ground plane

as thin as possible.

A more serious problem are share ground paths where one

path contains high current. While it is possible to design

a DC/DC converter using a parallel ground system (all

loops have separate routes to the PGND pin), it is not typically done because at high switching frequencies ground

signals will have inductive and capacitive coupling. The

typical grounding system is a multipoint ground, almost

always a ground plane, or a couple of very large plane

sections that attempt to separate the gate loop from the

power path loop.

For sensing, the main concern is allowing sensor low

sense current to share any of these paths. If the singled

grounded shielding is used, then the high current grounds

are avoided. If a power block is used, current will be shared

on the module and its ground pin. The best you can do

is route the low sense from the module ground pin to

minimize the shared path.

Most devices will have two grounds that are connected at

a single point. One will be called signal ground, and one

power ground. The shield used to prevent capacitive and

inductive grounding is always tied to the signal ground.

This prevents a shared ground path at the device end of

the sensor connection.

Therefore, the worst scenario is a power block without a

low sense pin, with a device that only has a power ground.

The best case is a sensor with access to both high and

low sense, where the low sense is not grounded, and the

device has a signal ground and a power ground. Controlling

these cases has to be done early in the design process

during component selection, long before layout.

AN137-12

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

an137f

LT 0912 • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2012

Loading...

Loading...