Page 1

Application Note 136

June 2012

PCB Layout Considerations for Non-Isolated Switching

Power Supplies

Henry J. Zhang

Introduction

The best news when you power up a prototype supply board

for the very first time is when it not only works, but also

runs quiet and cool. Unfortunately, this does not always

happen. A common problem of switching power supplies

is “unstable” switching waveforms. Sometimes, waveform

jittering is so pronounced that audible noise can be heard

from the magnetic components. If the problem is related

to the printed circuit board (PCB) layout, identifying the

cause can be difficult. This is why proper PCB layout at

the early stage of a switching supply design is very critical.

Its importance cannot be overstated.

The power supply designer is the person who best understands the technical details and functional requirements of

the supply within the final product. He or she should work

closely with the PCB layout designer on the critical supply

layout from the beginning. A good layout design optimizes

supply efficiency, alleviates thermal stress, and most importantly, minimizes the noise and interactions among traces

and components. To achieve these, it is important for the

designer to understand the current conduction paths and

signal flows in the switching power supply. The following

discussion presents design considerations for a proper

layout design for non-isolated switching power supplies.

PLAN OF THE LAYOUT

Location of the Power Supply in System Board

For the embedded DC/DC supply on a large system board,

the supply output should be located close to the load devices in order to minimize the interconnection impedance

and the conduction voltage drop across the PCB traces to

achieve best voltage regulation, load transient response

and system efficiency. If forced-air cooling is available,

the supply should also be located close to the cooling

fan or have good air flow to limit the thermal stress. In

addition, the large passive components such as inductors

and electrolytic capacitors should not block the air flow

to the low profile, surface mount semiconductor components such as power MOSFETs, PWM controller, etc. To

prevent the switching noise from upsetting other analog

signals in the system, avoid routing sensitive signal traces

underneath the supply if possible. Otherwise, an internal

ground plane between the power supply layer and small

signal layer is needed for shielding.

It is necessary to point out that this power supply location and board real estate planning should be done at the

early design/planning stage of the system. Unfortunately,

sometimes people focus on other more “important” or

“exciting” circuits on the big system board first. If power

management/supply is the last thought and is relegated

to whatever space is left on the board, this certainly does

not help ensure efficient and reliable power supply design.

Placement of Layers

On a multilayer PCB board, it is highly desirable to place

the DC ground or DC input or output voltage layers between the high current power component layer and the

sensitive small signal trace layer. The ground and/or DC

voltage layers provide AC grounds to shield the small signal

traces from noisy power traces and power components.

As a general rule, the ground or DC voltage planes of a

multilayer PCB should not be segmented. If the segmentation is unavoidable, the number and length of traces in

these planes must be minimized. The traces should also

be routed in the same direction as the high current flow

direction to minimize the impact.

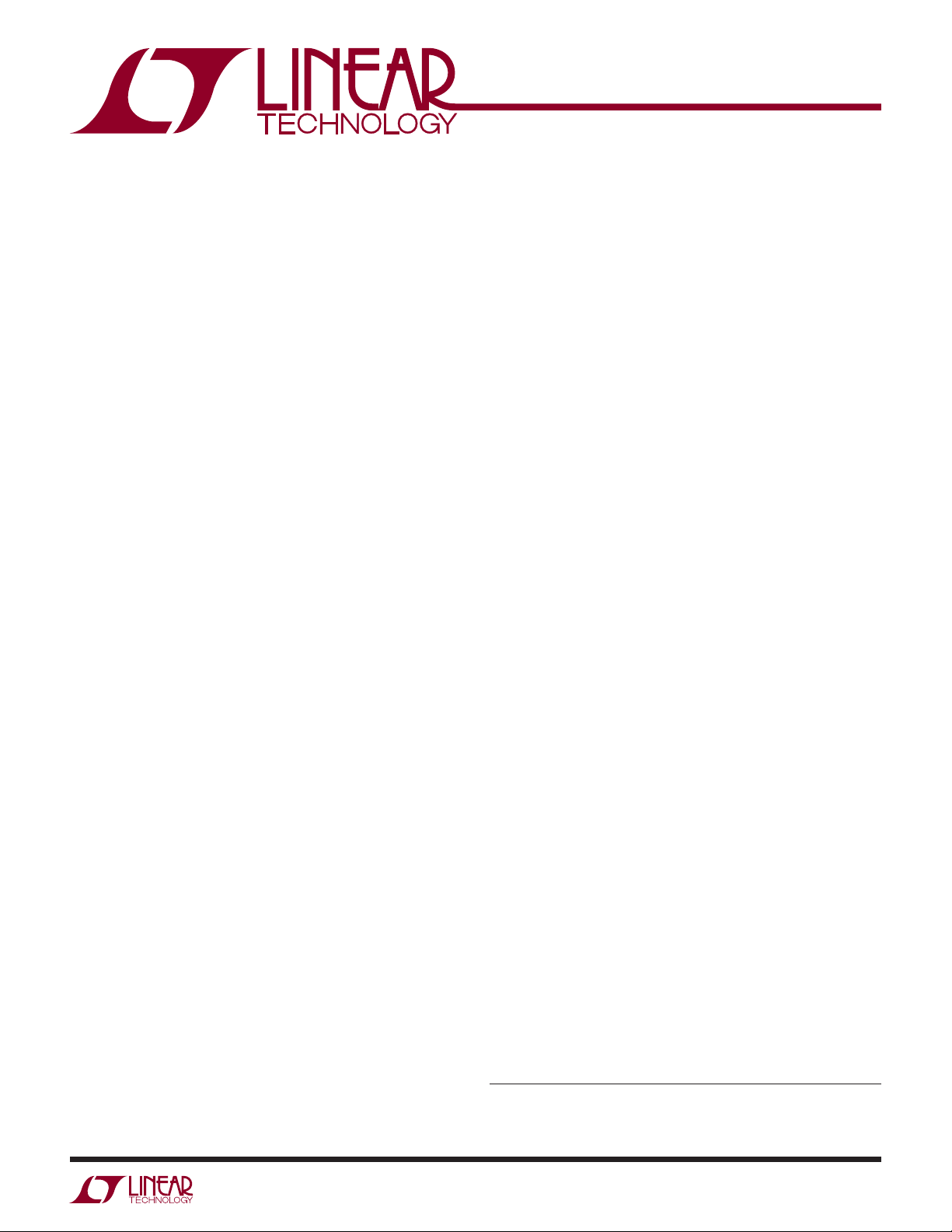

Figures 1a and 1c provide examples of the undesired layer

arrangement of the 6-layer and 4-layer PCB boards for

switching power supply. In these examples, the small signal

layer is sandwiched between the high current power layer

and the ground layer. These configurations increase the

L, LT, LTC, LTM, Linear Technology, the Linear logo and PolyPhase are registered trademarks

of Linear Technology Corporation. All other trademarks are the property of their respective

owners.

an136f

AN136-1

Page 2

Application Note 136

Undesired

Layer 1 - Power Component

Layer 2 - Small Signal

Layer 3 - GND Plane

Layer 4 - DC Voltage or GND Plane

Layer 5 - Small Signal

Layer 6 - Power Component/Controller

(a)

Undesired

Layer 1 - Power Component

Layer 2 - Small Signal

Layer 3 - GND Plane

Layer 4 - Small Signal/Controller

(c)

Figure 1. Desired and Undesired Layer Arrangement of 6-Layer and 4-Layer PCBs

capacitive noise coupling between the high current/voltage

power layer and small analog signal layer. To minimize

the noise coupling, Figures 1b and 1d show examples

of desired layer arrangement for 4-layer and 6-layer PCB

designs. In these two examples, the small signal layer is

shielded by the ground layer(s). It is important to always

have a ground layer next to the outside power stage layer.

Finally, it is also desirable to have thick copper for the

external high current power layers to minimize the PCB

conduction loss and thermal impedance.

POWER STAGE COMPONENT LAYOUT

A switching power supply circuit can be divided into the

power stage circuit and the small signal control circuit.

The power stage circuit includes the components that

conduct high current. In general, these components

should be placed first. The small signal control circuitry

is subsequently placed in specific spot in the layout. In

this section, we will discuss the layout of power stage

components.

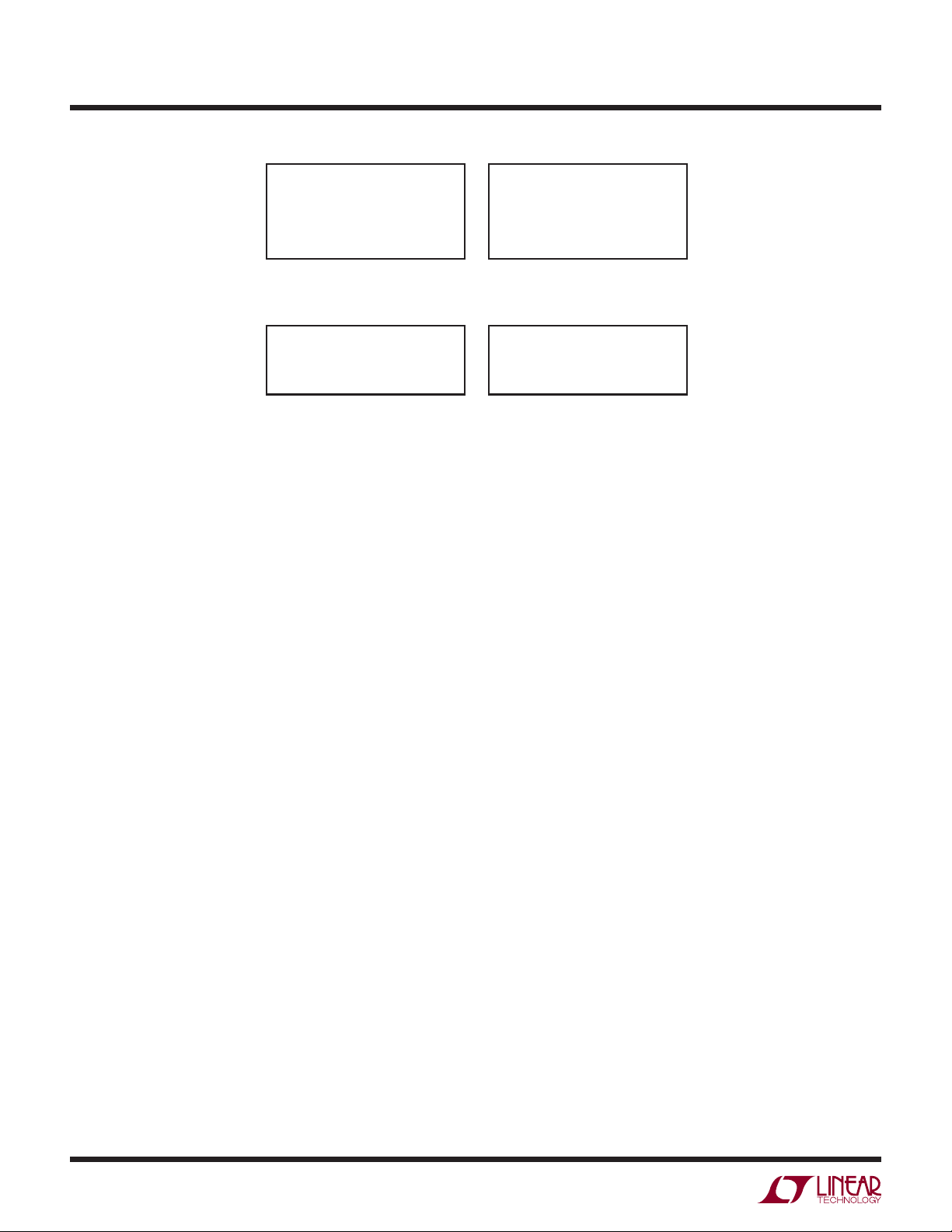

Continuous and Pulsating Current Paths – Minimize

Inductance in High di/dt Loop (Hot Loop)

The large current traces should be short and wide to minimize PCB inductance, resistance and voltage drop. This is

especially critical for the traces with high di/dt pulsating

current flow. Figure 2 identifies the continuous current and

pulsating current paths in a synchronous buck converter.

Desired

Layer 1 - Power Component

Layer 2 - GND Plane

Layer 3 - Small Signal

Layer 4 - Small Signal

Layer 5 - DC Voltage or GND Plane

Layer 6 - Power Component/Controller

(b)

Desired

Layer 1 - Power Component

Layer 2 - GND Plane

Layer 3 - Small Signal

Layer 4 - Small Signal/Controller

(d)

AN136 F01

The solid line represents the continuous current paths,

and the dashed line represents the pulsating (switching)

current paths. The pulsating current paths include the

traces connected to the input decoupling ceramic capacitor,

, the top control FET, QT, the bottom synchronous FET,

C

HF

, and its optional paralleled Schottky diode. Figure 3a

Q

B

shows the parasitic PCB inductors in these high di/dt current paths. Due to the parasitic inductance, the pulsating

current paths not only radiate magnetic fields, but also

generate high voltage ringing and spikes across the PCB

traces and MOSFETs. To minimize the PCB inductance,

this pulsating current loop (hot loop) should be laid out

so that it has a minimum circumference and is composed

of traces that are short and wide. The high frequency decoupling capacitor, C

, should be a 0.1F to 10F, X5R

HF

or X7R dielectric ceramic capacitor with very low ESL and

ESR. Higher-capacitance dielectrics (such as Y5V) can

allow a large reduction in capacitance over voltage and

temperature. Therefore, these kinds of capacitors are not

preferred for C

HF

.

Figure 3b provides a layout example of the critical pulsating

current loop (hot loop) in the buck converter. To limited

resistive voltage drops and the number of vias, power

components should be placed on the same side of board,

with power traces routed on the same layer. When it becomes necessary to route a power trace to another layer,

choose a trace in the continuous current paths. When vias

are used to connect PCB layers in the high current loop,

multiple vias should be used to minimize via impedance.

AN136-2

an136f

Page 3

Application Note 136

VIN+

HIGH dV/dt NODE

Q

T

ESR

IN

+

V

IN

–

C

IN

C

HF

SW

PGND

Q

B

L

F

ESR

OUT

C

D

OUT

RV

OUT

+

–

CONTINUE CURRENT

PULSATING CURRENT

AN136 F02

Figure 2. Continuous and Pulsating Current Paths of a Synchronous Buck Converter

+

V

IN

Q

T

Q

T

C

HF

PGND

SW

VIN+

C

D

Q

B

0.1µF TO 10µF

CERAMIC CAPACITOR

HF

Q

MINIMIZE THIS

LOOP AREA

SW

B

PGND

(a) (b)

+

D

AN136 F03

L

F

Figure 3. Minimize the High di/dt Loop Area in the Synchronous Buck Converter.

(a) High di/dt loop (Hot Loop) and its Parasitic PCB Inductors, (b) Layout Example

an136f

AN136-3

Page 4

Application Note 136

+

V

IN

–

C

IN

HIGH dV/dt NODE

L

F

SW

D

Q

B

V

+

OUT

C

HF

C

OUT

V

OUT

LOAD

PGND

CONTINUE CURRENT

PULSATING CURRENT

Figure 4. Continuous and Pulsating Current Paths of a Boost Converter

L

F

SW

PGND

D

C

Q

B

HF

(a) (b)

Figure 5. Minimize the High di/dt Loop Area in the Boost Converter.

(a) High di/dt Loop (Hot Loop) and its Parasitic PCB Inductors, (b) Layout Example

Similarly, Figure 4 shows the continuous and pulsating

current loops (hot loop) in the boost converter. In this

case, the high frequency ceramic capacitor, C

be placed on the output side close to the MOSFET, Q

boost diode, D. The loop formed by switch, Q

diode, D, and high frequency output capacitor, C

, should

HF

, and

B

, rectifier

B

, must

HF

be minimized. Figure 5 shows the layout example of the

pulsating current loop in the boost converter.

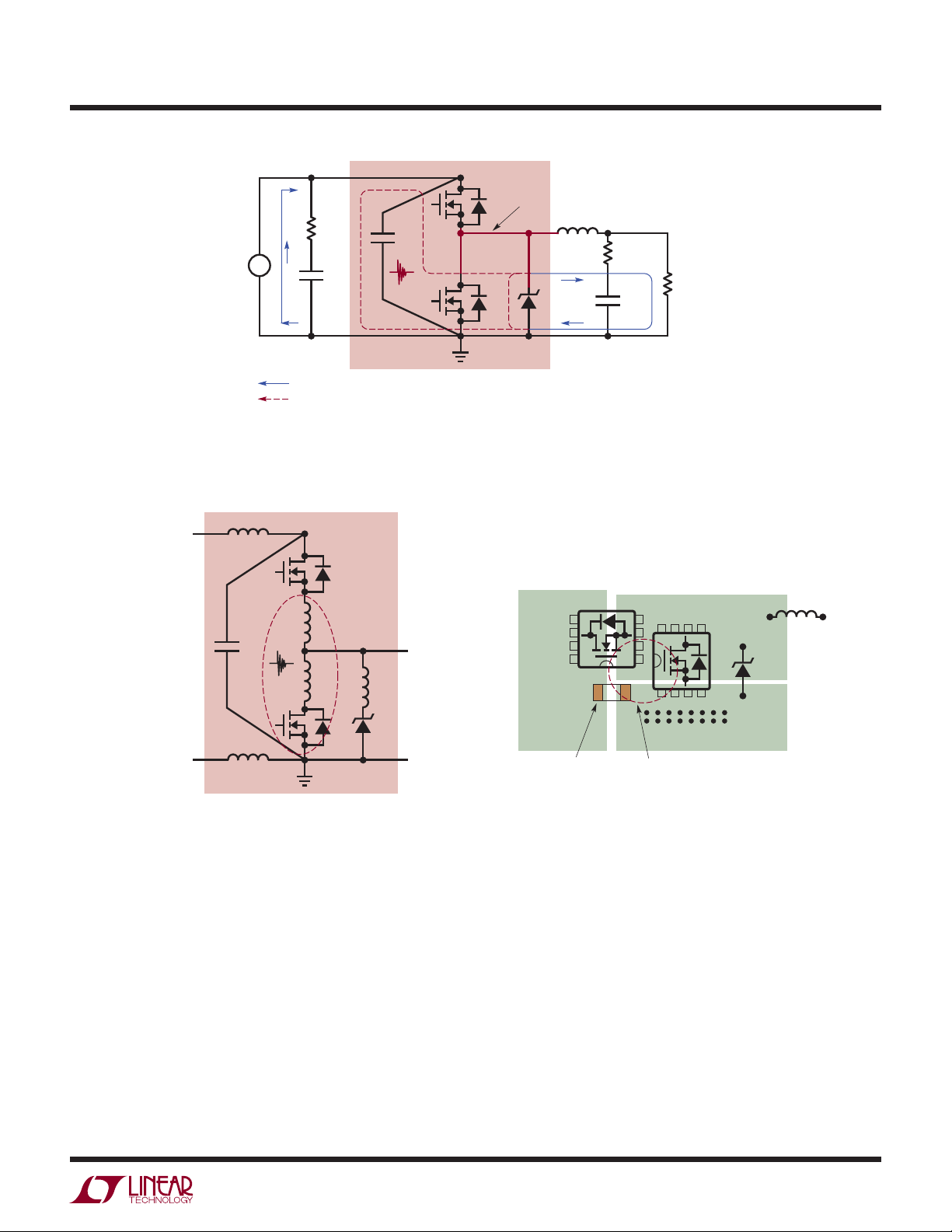

To emphasize the importance of the decoupling capacitor C

, Figures 6 and 7 provide an actual example of a

HF

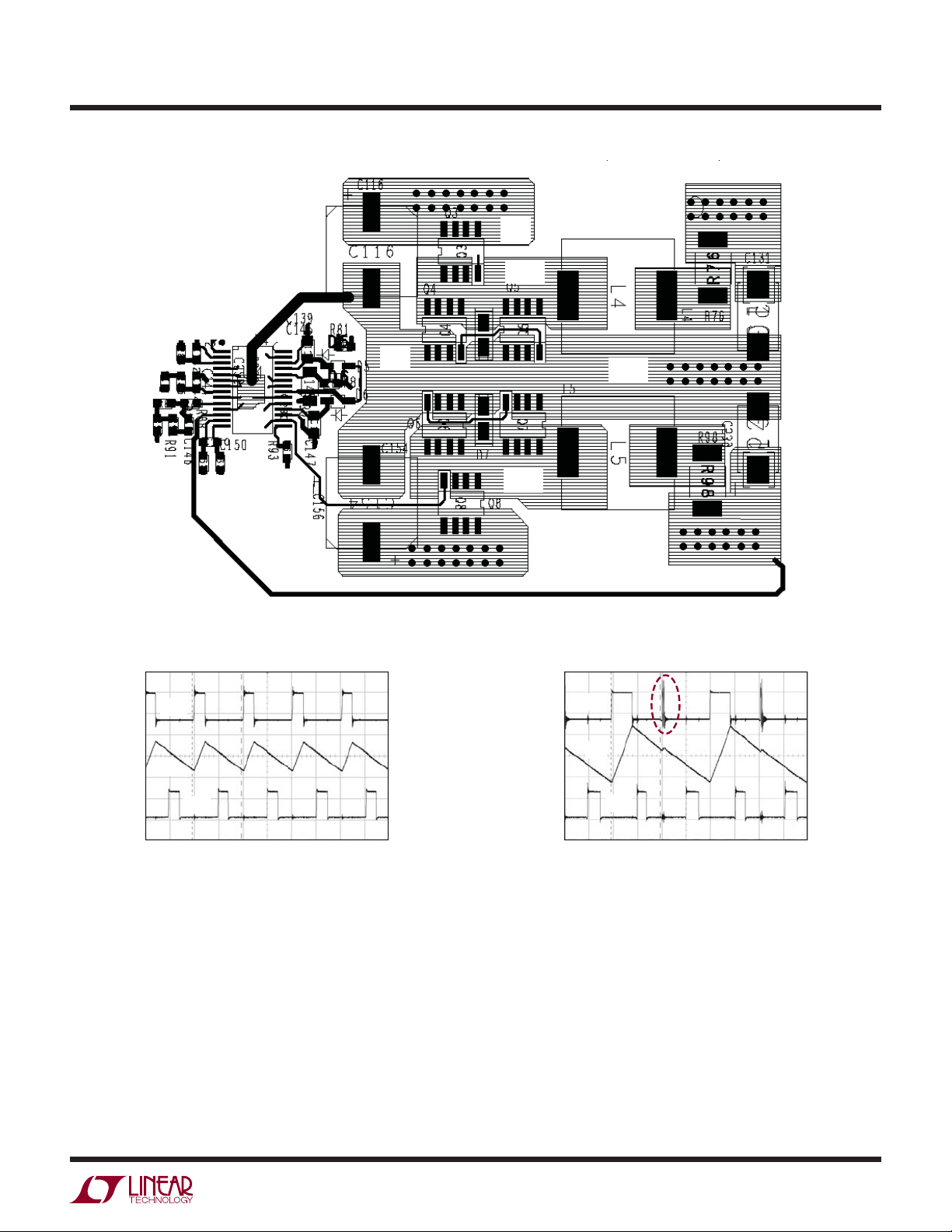

synchronous buck circuit. Figure 6a shows the layout of

a dual phase, 12V

to 2.5V

IN

buck supply using the LTC3729 2-phase, single V

/30A max, synchronous

OUT

OUT

controller IC. As shown in Figure 6a, the switching nodes

SW1 and SW2 and output inductor current i

waveforms

LF1

are stable at no load. But if the load current increases

to above 13A, the SW1 node waveform starts missing

cycles. The problem becomes even worse with higher load

AN136 F04

L

F

Q

SW

B

+

D

PGND

MINIMIZE THIS

LOOP AREA

C

HF

0.1µF TO 10µF

CERAMIC CAPACITOR

AN136 F05

current. Figure 7 shows that adding one 1F high frequency

ceramic capacitors on each channel’s input side solves

the problem. It separates and minimzes the hot loop area

of each channel. The switching waveform is stable even

with maximum load current up to 30A.

Isolate and Minimize High dv/dt Switching Area

In Figures 2 and 4, the SW node voltage swings between

(or V

V

IN

) and ground with a high dv/dt rate. This

OUT

node is rich in high frequency noise components and is

a strong source of EMI noise. To minimize the coupling

capacitance between SW node and other noise-sensitive

traces, the SW copper area should be minimized. However,

on the other hand, to conduct high inductor current and

provide a heat sink to the power MOSFET, the SW node

PCB area cannot be too small. It is usually preferred to

have a ground copper area placed underneath this SW

node to provide additional shielding.

AN136-4

an136f

Page 5

Application Note 136

+

(12V)

V

IN

L

Q

C

IN

T

F1

SW1

V

OUT

+

(2.5V)

I

V

LF1

SW1

LTC3729

C

OUT

Q

B

GND

GND

C

OUT

SW2

+

V

IN

+

V

(2.5V)

OUT

(a)

V

SW1

I

LF1

I

OUT

= 0A

V

SW2

AN136 F06b

I

OUT

V

= 13.3A

SW2

(b) (c)

Figure 6. An Example of a 2-Phase, 2.5V/30A Output Buck Converter with Noise Problem.

(a) Layout, (b) Switching Waveform at I

= 0A, (c) Switching Waveform at I

OUT

OUT

AN136 F06c

= 13.3A

an136f

AN136-5

Page 6

Application Note 136

C

ADD

1µF/16V/X7R

LTC3729

IN

+

(12V)

V

IN

L

Q

T

F1

+

V

(2.5V)

OUT

SW1

C

OUT

Q

B

GND

GND

C

OUT

SW2

I

OUT

+

V

IN

+

(2.5V)

V

OUT

(a)

V

SW1

I

LF1

V

SW2

= 0A

AN136 F07b

I

OUT

I

LF1

V

SW1

= 30A

V

SW2

AN136 F07c

(b) (c)

Figure 7. Adding Two 1μF High Frequency Input Capacitors Solves the Problem.

(a) Layout with Added Capacitors, (b) Switching Waveform at I

(c) Switching Waveform at I

OUT

= 30A

OUT

= 0A,

AN136-6

an136f

Page 7

Application Note 136

Sufficient Copper Area to Limit Power Component

Thermal Stress

In a design without external heat sinks for surface mounted

power MOSFETs and inductors, it is necessary to have

sufficient copper area as a heat sink. For a DC voltage

node, such as input/output voltage and power ground, it

is desirable to make the copper area as large as possible.

Multiple vias are helpful in further reducing thermal stress.

For the high dv/dt SW nodes, the proper size of the SW

node copper area is a design trade-off between minimizing

the dv/dt related noises and providing good heat sinking

capability for the MOSFETs.

Proper Land Pattern of Power Components to

Minimize Impedance

It is important to pay attention to the land (or pad) pattern of power components, such as low ESR capacitors,

MOSFETs, diodes and inductors. Figures 8a and 8b show

examples of undesired and desired power component

land patterns, respectively. As shown in Figure 8b, for a

decoupling capacitor, the positive and negative via pair

should be as close to each other as possible to minimize the

PCB equivalent series inductance (ESL). This is especially

effective for capacitors with low ESL. Large valued low

ESR capacitors are usually more expensive. Improper land

pattern and poor routing can degrade their performance

and thus increase overall cost. In general, the desired land

patterns reduce the PCB noise, reduce thermal impedance,

and minimize trace impedance and voltage drops for the

high current components.

One common mistake in high current power component

layout is the improper use of thermal relief land patterns,

as shown in Figure 8a. Unnecessary use of thermal relief

land patterns increases the interconnection impedance of

power components. This results in higher power losses and

decreases the decoupling effect of low ESR capacitors. If

vias are used to conduct high current, sufficient numbers

of via must be used to minimize via impedance. Similarly,

the thermal relief should not be used for those vias.

CONNECTED VIA

Undesired

+–

C R/C/D/L

+

C

FET

CONNECTED VIA

(a)

Figure 8. Desired and Undesired Land Patterns for Power Components.

(a) Improper Use of Thermal Relief for the Pads of Power Components,

(b) Recommended Land Patterns for Power Components

Desired

–

R/C/D/L

(b)

AN136 F08

an136f

AN136-7

Page 8

Application Note 136

Undesired Desired

R

PCB

R

PCB1

R

DC/DC

#1

PCB2

+

–

PGND

C

IN

DC/DC

#1

DC/DC

#2

Figure 9. Separate the Input Current Paths Among Supplies

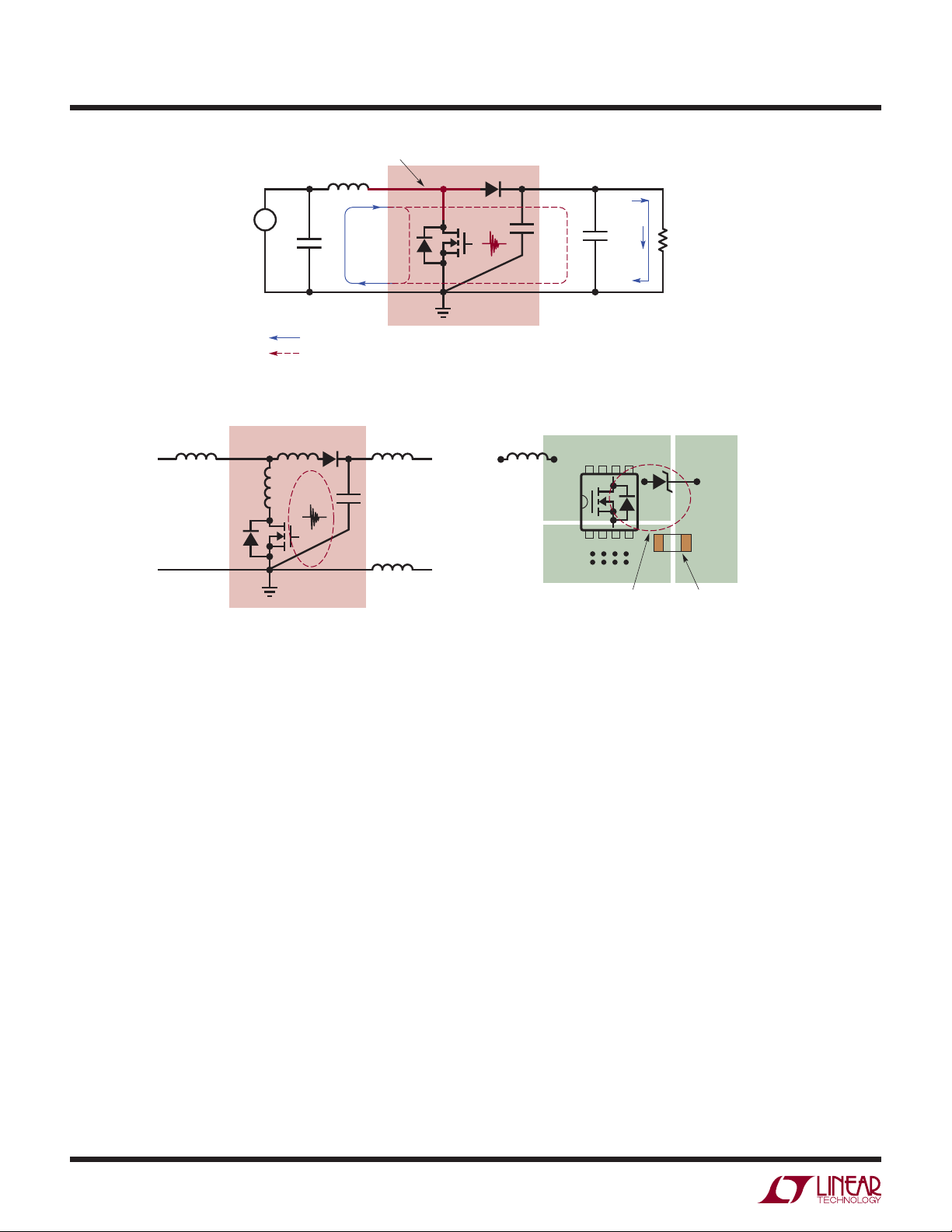

Separation of Input Current Paths Among Supplies

Figure 9 shows an application with several onboard

switching supplies sharing the same input voltage rail.

When these supplies are not synchronized to each other,

it is necessary to separate the input current traces to

avoid common impedance noise coupling between different power supplies. It is less critical to have local input

decoupling capacitor for each power supply.

®

PolyPhase

, Single Output Converter

For a PolyPhase, single output converter, try to have

symmetric layout for each phase. This helps to balance

thermal stresses.

+

–

PGND

C

IN

PGND

DC/DC

#2

PGND

AN136 F09

Layout Design Example – 1.2V/40A Dual Phase Buck

Converter

Figure 10 provides a design example of a 4.5V to 14V

IN

to 1.2V/40A max dual phase synchronous buck converter

using PolyPhase current mode step-down controller,

the LTC3855. Before the start of PCB layout, one good

practice is to highlight the schematic traces for the high

current traces, the noisy high dv/dt traces and the sensitive small signal traces with different colors, so the PCB

designer understands the differences between these traces.

Figure 11 shows the power stage layout example of the

power component layer of this 1.2V/40A supply. In this

figure, the Q

the bottom side synchronous FET. An optional Q

is the top side control MOSFET and QB is

T

footprint

B

is added for even more output current. A solid power

ground plane layer is placed just underneath the power

component layer.

AN136-8

an136f

Page 9

Application Note 136

,

VIN4.5V TO

14V

270µF

16V

+

10µF

=4

Â

Â

0.001

M1

1%

L1

0.1µF

0.44µH

Â

OUT

V

1.2V

40A

OUT2

C

330µF

2.5V

=4

+

OUT1

C

100µF

6.3V

=4

1%

0.001

L2

0.44µH

M2

2.2

Â

0.1µF

4.7µF

M3

Â

Â

0.1µF

M4

Â

Â

AN136 F10

100

1nF

100

100k

RUN

SW1

TG1

CLKOUT

BOOST1

PHSASMD

MODE/PLLIN

FREQ

ITEMP2

ITEMP1

RUN1

SENSE1

+

SENSE1

–

TH1

TK/SS1

I

0.1µF

PGND1

FB1

V

BG1

SGND

IN

V

LTC3855

FB2

V

20k

CC

INTV

TH2

I

CC

BG2

EXTV

TK/SS2

SENSE2+SENSE2–DIFFP

2200pF

100pF

PGND2

1nF

5.9k

20k

BOOST2

TG2

SW2

NC

PGOOD2

PGOOD1

LIM2

I

LIM1

I

RUN2

DIFFOUT

DIFFN

RUN

100

100

PGNDSGND

Figure 10. Dual Phase 1.2V/40A Max LTC3855 Buck Converter

HIGH dv/dt NODES/TRACES

HIGH CURRENT TRACES

MOST NOISE SENSITIVE, SMALL SIGNAL TRACES

NOISY

Â

an136f

AN136-9

Page 10

Application Note 136

GND

C

HF1

V

IN

C

HF2

Q

Q

B1

B1

Q

T1

Q

T2

SW1

L1

L2

SW2

Q

Q

B2

B2

Figure 11. Example of Power Stage Layout of

Dual-Phase, Single-V

Buck Converter

OUT

CONTROL CIRCUITRY LAYOUT

Location of the Control Circuitry

The control circuitry should be located away from the noisy

switching copper areas. It is preferable to have the control

circuitry located close to the V

verter and close to the V

IN

+

+

OUT

side for the boost converter,

where the power traces carry continuous current. If space

allows, locate the control IC a small distance (0.5–1") from

the power MOSFETs and inductors, which are noisy and

hot. However, if the space constraint forces the controller to be located close to power MOSFETs and inductors,

special care must be taken to isolate the control circuitry

from power components with ground planes or traces.

Separation of the Signal Ground and Power Ground

The control circuitry should have a separate signal (analog)

ground island from the power stage ground. If there are

separate signal ground (SGND) and power ground (PGND)

pins on the controller IC, they should be routed separately.

For controller ICs that have integrated MOSFET drivers,

the small signal section of the IC pins should use the

V

OUT

C

OUT

R

SEN1

C

OUT

R

SEN2

C

OUT

AN136 F11

side for the buck con-

SGND, as shown in Figure 12. Only one connection point

between the SGND and PGND is required. It is desirable

to return the SGND to a clean point of the PGND plane.

The two grounds can be done by connecting both ground

traces just under the controller IC. Figure 12 shows the

preferred ground separation of the LTC3855 supply. In this

example, the IC has an exposed GND pad. It should be

soldered down to PCB to minimize electrical and thermal

impedance. Multiple vias should be placed on this GND

pad area.

Decoupling Capacitors for the Controller IC

The decoupling capacitors for the controller IC should

be physically close to their pins. To minimize connection

impedance, it is preferable to connect the decoupling

capacitors directly to the pins without using vias. As

shown in Figure 12, the following LTC3855 pins should

have their decoupling capacitors closely located: current

+

sensing pins, SENSE

/SENSE–, compensation pin, ITH,

signal ground pin, SGND, feedback voltage divider pin, FB,

voltage pin, INTVCC, and power ground pin, PGND.

IC V

CC

R

SEN

SHORTEST DISTANCE

41

16 17 18 19

INTV

CC

AN136 F12

30

TG1

BST1

29

28

27

26

25

24

23

22

21

PGND

BG1

PGND

C

I

TH1

SGND

SGND ISLAND

RR

C

3940 38 37 36 35 34 33 32 31

1

SEN1–

SEN1+

2

C

3

4

5

6

7

8

9

10

12 13 14 15

11 20

LTC3855

EXPOSED GND PAD

Figure 12. Decoupling Capacitors of

Controller IC and Ground Separation

AN136-10

an136f

Page 11

Application Note 136

Minimize Loop Area and Crosstalk

Separate Noisy Traces and Sensitive Traces

Two or more adjacent conductors can be coupled capacitively. High dv/dt voltage change on one conductor will

couple currents to another through the parasitic capacitor. To reduce the noise coupling from the power stage

to the control circuitry, it is necessary to keep the noisy

switching traces far from the sensitive small signal traces.

If possible, route the noisy traces and sensitive traces on

different layers, with an internal ground layer for noise

shielding. As to the LTC3855 controller, the following pins

have high dv/dt switching voltages: FET driver TG, BG,

SW and BOOST. The following pins are connected to the

+

most sensitive small signal nodes: SENSE

and SGND. If these sensitive signal traces are routed

I

TH

/SENSE–, FB,

close to high dv/dt nodes, the ground traces or a ground

layer must be inserted between these signal traces and

high dv/dt traces to shield the noise.

TOP VIEW

BOOST1

1

2

3

4

5

6

7

8

9

10

11

12

13

LTC3729

14

INTV

PGND

28

TG1

27

26

SW1

25

CC

24

BG1

23

22

INTV

CC

21

20

19

18

17

16

15

Gate Driver Traces

It is desirable to use short and wide traces to route

gate drive signals in order to minimize the impedance

in gate drive paths. As shown in Figure 13, the top FET

driver traces TG and SW should be routed together with

minimum loop area to minimize the inductance and high

dv/dt noise. Similarly, the bottom FET driver trace BG

should be routed close to a PGND trace. If a PGND layer

is placed under the BG trace, the AC ground return current

of the bottom FET will be automatically coupled in a path

close to the BG trace. AC current flows where it finds the

minimum loop/impedance. In this case, a separate PGND

return trace for the bottom gate driver is not required. It

is best to minimize the number of layers that the gate

driver traces are routed on. This prevents gate noise from

propagating to other layers.

Q

T

Q

B

AUTOMATICALLY

COUPLED AC GROUND

RETURN CURRENT

PGND

PLANE

AN136 F13

Figure 13. Gate Driver Trace Routing of the MOSFETs

an136f

AN136-11

Page 12

Application Note 136

Current Sensing Trace and Voltage Sensing Trace

Of all the small signal traces, current sensing traces are

most sensitive to noise. The current sensing signal amplitude is usually less than 100mV, which is comparable to

+

the noise amplitude. In the LTC3855 example, its SENSE

–

SENSE

traces should be routed in parallel with minimum

/

spacing (Kelvin sense) to minimize the chance of picking

up di/dt-related noise, as shown in Figure 14. In addition,

the filter resistors and capacitor for current sensing traces

should be placed as close to the IC pins as possible. This

provides the most effective filtering in case noise is injected

into the long sense lines. If inductor DCR current sensing

is used with an R/C network, the DCR sensing resistor, R,

should be close to the inductor, while the DCR sensing

capacitor, C, should be close to the IC. If via is used in

–

the return path of the trace to SENSE

contact another internal V

may conduct large V

OUT

+

OUT

+

current and the resulting voltage

DIRECT TRACE CONNECTION.

DO NOT USE VIA.

, this via should not

layer. Otherwise, this via

L

F

drop may distort the current sensing signal. Avoid routing the current sensing traces near the noisy switching

nodes (TG, BG, SW, BOOST traces). If possible, place the

ground layer between the current sensing traces and the

layer with power stage traces.

If the controller IC has differential voltage remote sensing

pins, use separated traces for the positive and negative

remote sensing traces with Kelvin sense connection as well.

Trace Width Selection

Current level and noise sensitivity are unique to specific

controller pins. Therefore, specific trace widths need to

be selected for different signals. In general, the small

signal nets can be narrow and routed with 10 to 15 mil

wide traces. The high current nets (gate driving, V

CC

and

PGND) should be routed with short and wide traces. At

least 20 mil width is recommended for these nets.

R

SENSE

+

V

OUT

R

C

R

DIRECT TRACE CONNECTION.

DO NOT USE VIA.

13

C

14

Figure 14. Kelvin Sensing for Current Sensing

(a) R

SENSE

PWMIC

SENSE

SENSE

–

16

+

15

AN136 F14a

13

14

(a)

SW

PWMIC

SENSE

SENSE

–

16

+

15

R

AN136 F14b

(b)

, and (b) Inductor DCR Sensing

THIS VIA SHOULD NOT TOUCH

ANY OTHER INTERNAL V

COPPER PLANE.

L

F

+

V

OUT

THIS VIA SHOULD NOT TOUCH

ANY OTHER INTERNAL V

COPPER PLANE.

+

O

+

O

AN136-12

an136f

Page 13

SUMMARY

Power Design Layout Checklist

Application Note 136

To summarize the layout design discussion in this article,

Table 1 provides a sample checklist of the dual phase

will aid the designer to ensure that the result is a well layed

out power supply design.

LTC3855 supply shown in Figure 10. Using such a checklist

Table 1. Sample Layout Checklist for the LTC3855 Current Mode Buck Supply

ITEM/COMMENTS YES/NO

1. Plan of the Layout

1.0 Understand the system mechanical and thermal constraints. Save sufficient board real estate/area for power supply in the

beginning/planning stage of the big system. Don’t wait to do it as the last step.

1.1 Power supply output capacitors are located physically close to the supply load.

– To minimize impedance between the output capacitors and the fast transient load.

1.2 Locate power supply near cooling fan; ensure good air flow path.

– For optimal cooling of the power supply.

1.3 Ground layer is placed between the power layer and the small signal layer (Figure 1).

– To return the current from the power component layer and to shield sensitive small signal traces from power stage

switching noise.

1.4 Highlight the schematic traces to identify high current traces, noisy traces and sensitive small signal traces.

1.5 Decide the components on top and bottom sides of the PCB board. Try to keep all power components on the same side.

2. Power Stage Layout

2.1 Place the power components first. Please them in the way that minimizes the length of the high current flow paths through input

capacitors, power FETs, inductors, R

– To minimize the PCB impedance and conduction losses on high current paths.

2.2 Have solid, low impedance land patterns for the power components, including capacitors, FETs, diodes, inductors and current

sensing resistors. Use large copper plane for V

– To minimize the trace impedance and power component thermal stress.

2.3 Use thick copper or multiple layers for high current power layers.

– To minimize the PCB conduction loss and reduce thermal stress.

2.4 If it is necessary to route a power trace to another layer, choose a trace in low di/dt paths and use multiple vias for

interconnection.

– To minimize noise propagation and connection impedance between layers.

2.5 Minimize the pulsating current loop area that includes the top FET QT, bottom FET QB and ceramic input filter capacitor CHF

(Figure 3).

– To minimize the pulsating loop (hot loop) inductance and absorb switching noise.

2.6 Minimize and isolate/shield the high dv/dt SW node areas.

– To minimize the EMI noise source from the high dv/dt SW nodes.

2.7 Separate input current paths among supplies if there is more than one supply on the same input rail (Figure 9) and the supplies

are not synchronized. Have local input decoupling capacitor for each supply.

– To avoid common impedance noise coupling among supplies.

2.8 PolyPhase converter. Try to have symmetric layout for each phase. Have local ceramic decoupling capacitor for each phase.

and output capacitors.

SENSE

, V

IN

OUT

and GND (Figure 8).

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

an136f

AN136-13

Page 14

Application Note 136

Table 1. Sample Layout Checklist for the LTC3855 Current Mode Buck Supply

ITEM/COMMENTS YES/NO

3. Control Circuit Layout

3.1 Locate the control circuitry in a quiet location that is close to output capacitors or input capacitors.

– To minimize the noise to the control circuitry.

3.2 Use a separate SGND ground island for the components to the following small signal pins: I

V

, FREQ, MODE/PLLIN, RUN, TK/SS, I

DIFFOUT

, PHASMD and PGOOD (Figure 12). Ground connections are short and go

LIM

directly to the SGND island.

– To minimize the noise to the control circuitry.

3.3 Use PGND the INTV

capacitors (Figure 12).

CC

3.4 Has a single connection point between SGND and PGND. One suggested location is underneath the IC (Figure 12). If the IC has

an exposed ground thermal pad, connect this pad to PCB and have multiple vias to other SGND/PGND layers.

– To minimize SGND noise and provide low impedance gate driver current return path.

3.5 The following pins should have their ceramic decoupling capacitor located close by on the same controller layer and directly

connected: SENSE

+

/SENSE–, ITH, SGND, FB, INTVCC and PGND (Figure 12).

– To minimize the connection impedance and provide best noise decoupling with HF capacitors.

3.6 Current sensing traces – Kelvin sensing is required with closely routed SENSE+/SENSE– traces (Figure 14). SENSE– via should

not touch internal V

Have direct trace connections between SENSE

+

SENSE

/SENSE– pins.

– To minimize the noise pickup by SENSE

+

plane. SENSE+/SENSE– traces should be separated from the following nets: TG, SW, BOOST and BG.

OUT

+

/SENSE– pins and their filtering capacitors. Filtering C must to be close to

+

/SENSE– current sensing loop. SENSE+/SENSE– traces are the most sensitive small

signal (< 75mV) traces.

+

3.7 Remote voltage sensing traces – V

OS

–

/V

traces should be routed together with a pair of traces.

OS

– To minimize the noise and sensing error.

3.8 Gate driver traces – TG and SW traces should be routed together with minimum loop area (Figure 13).

Try to route TG, SW and BG traces on one layer only.

– To minimize the noise source from the high dv/dt gate driver traces.

3.9 Maintain distance between sensitive small signal traces and noisy traces/planes. Most sensitive traces include SENSE

FB, I

and SGND. Noisy traces/planes include SW, TG, BOOST and BG. If possible, place the ground trace/layer between the

TH

noisy trace/layer and the small signal trace/layer.

– To minimize the capacitive noise coupling between noisy traces and small signal traces.

3.10 Trace width – The following controller traces should be at least 20 mil wide: INTVCC, PGND, TG, BG, SW and BOOST.

– To minimize the trace impedance.

, SGND, SENSE+/SENSE–, FB,

TH

+

/SENSE–,

AN136-14

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

an136f

LT 0912 • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2012

Loading...

Loading...