Page 1

Circuit Techniques for Clock Sources

Jim Williams

Application Note 12

October 1985

Almost all digital or communication systems require some

form of clock source. Generating accurate and stable clock

signals is often a difficult design problem.

Quartz crystals are the basis for most clock sources. The

combination of high Q, stability vs time and temperature,

and wide available frequency range make crystals a

price-performance bargain. Unfortunately, relatively little

information has appeared on circuitry for crystals and

engineers often view crystal circuitry as a black art, best

left to a few skilled practitioners (see box, “About Quartz

Crystals”).

In fact, the highest performance crystal clock circuitry does

demand a variety of complex considerations and subtle

implementation techniques. Most applications, however,

don’t require this level of attention and are relatively easy

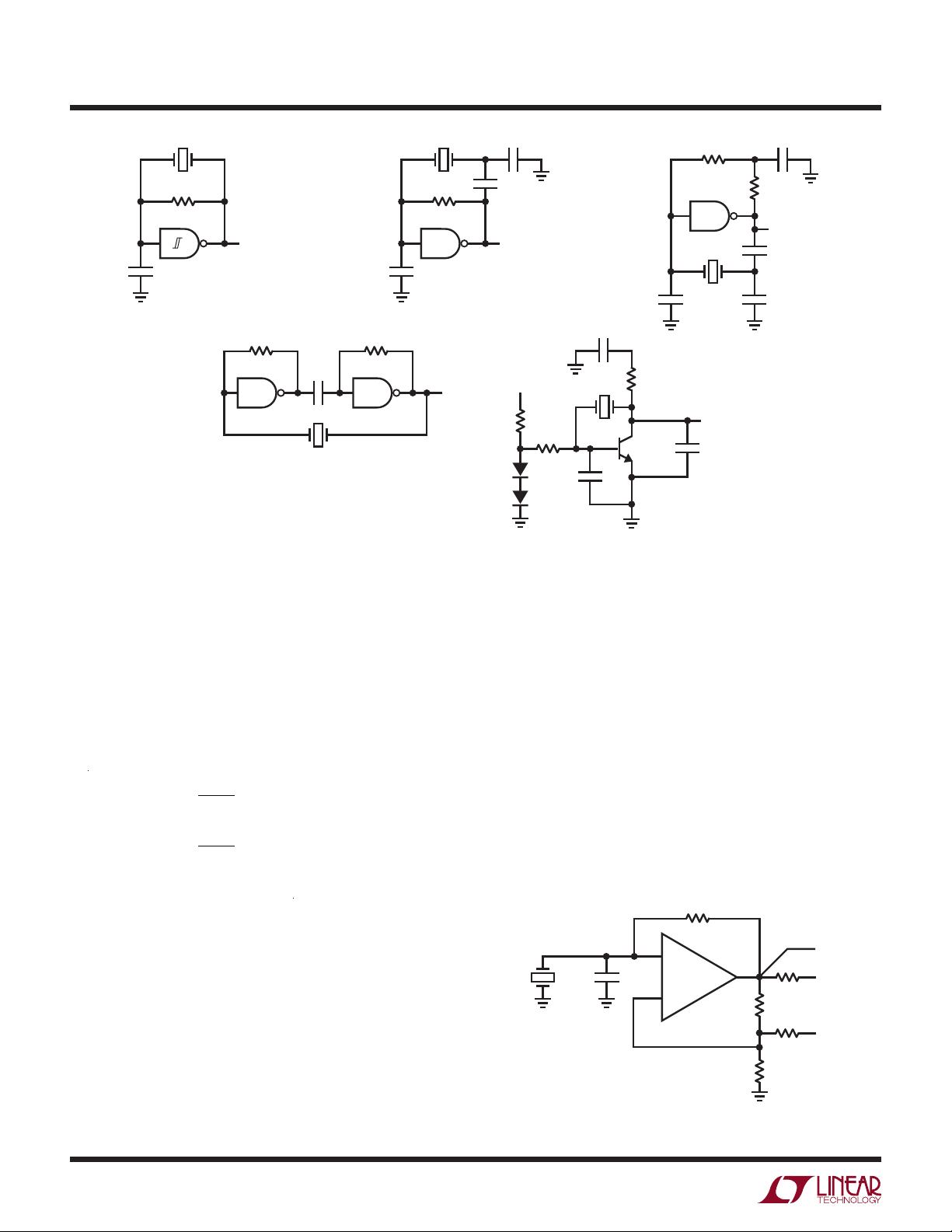

to serve. Figure 1 shows five (5) forms of simple crystal

clocks. Types 1a through 1d are commonly referred to

as gate oscillators. Although these types are popular,

they are often associated with temperamental operation,

spurious modes or outright failure to oscillate. The primary reason for this is the inability to reliably identify the

analog characteristics of the gates used as gain elements.

It is not uncommon in circuits of this type for gates from

different manufacturers to produce markedly different

circuit operation. In other cases, the circuit works, but is

influenced by the status of other gates in the same package. Other circuits seem to prefer certain gate locations

within the package. In consideration of these difficulties,

gate oscillators are generally not the best possible choice in

a production design; nevertheless, they offer low discrete

component count, are used in a variety of situations, and

bear mention. Figure 1a shows a CMOS Schmitt trigger

biased into its linear region. The capacitor adds phase shift

and the circuit oscillates at the crystal resonant frequency.

Figure 1b shows a similar version for higher frequencies.

The gate gives inverting gain, with the capacitors providing

additional phase shift to produce oscillation. In Figure 1c, a

TTL gate is used to allow the 10MHz operating frequency.

The low input resistance of TTL elements does not allow

the high value, single resistor biasing method. The R-C-R

network shown is a replacement for this function. Figure 1d

is a version using two gates. Such circuits are particularly

vulnerable to spurious operation but are attractive from a

component count standpoint. The two linearly biased gates

provide 360 degrees of phase shift with the feedback path

coming through the crystal. The capacitor simply blocks

DC in the gain path. Figure 1e shows a circuit based on

discrete components. Contrasted against the other circuits, it provides a good example of the design flexibility

and certainty available with components specified in the

linear domain. This circuit will oscillate over a wide range

of crystal frequencies, typically 2MHz to 20MHz.

The 2.2k and 33k resistors and the diodes compose a

pseudo current source which supplies base drive.

At 25°C the base current is:

1.2V –1V

To saturate the transistor, which would stop the oscillator, requires V

necessary to do this is:

IC(sat) =

with 18μA of base drive a beta of:

5mA

18µA

At 1mA the DC beta spread of 2N3904’s is 70 to ≅210.

The transistor should not saturate...even at supply voltages below 3V.

In similar fashion, the effects of temperature may also

be determined.

vs temperature over 25°C – 70°C is:

V

BE

–2.2mV/°C • 45° = –99mV.

L, LT, LTC, LTM, Linear Technology and the Linear logo are registered trademarks of Linear

Technology Corporation. All other trademarks are the property of their respective owners.

BE

33k

= 18µA

to go to near zero. The collector current

CE

5V

= 5mA

1k

= 278 is required

an12fa

AN12-1

Page 2

Application Note 12

100kHz

2M

74C14

OUT

43pF

(1a) (1b) (1c)

1k 3k

74LS04 74LS04

ALL CRYSTALS PARALLEL

RESONANT AT-CUT TYPES

1200pF

5MHz

4049

68pF

1MHz

6.8M

OUT

68pF

68pF

OUT

0.1μF

5V

5V

2.2k

33k

20MHz

100pF

1k

2N3904

(1e)(1d)

Figure 1. Typical Gate Oscillators and the Preferred Discrete Unit

74LS04

10MHz

68pF

1k

OUT

22pF

0.25μF

1k

OUT

68pF

68pF

AN-12 F01

The compliance voltage of the current source will move:

2 • –2.2mV/°C • 45°C = –198mV.

Hence, a first order compensation occurs:

–198mV – 99mV = –99mV total shift.

This remaining –99mV over temperature causes a shift

in base current:

25°C current =

70°C current =

18µA – 15µA = 3µA

0.6V

33k

0.5V

33k

= 18µA

= 15µA

This 3μA shift (about 16%) provides a compensation for

transistor hFE shift with temperature, which moves about

20% from 25°C to 70°C. Thus the circuit’s behavior over

temperature is quite predictable. The resistor, diode and

tolerances mean that only first order compensations

V

BE

for V

and hFE over temperature are appropriate.

BE

to the crystal’s resonance, the crystal “steals” energy from

the RC, forcing it to run at the crystal’s frequency. The

crystal activity is readily apparent in Trace A of Figure 3,

®

which is the LT

1011’s “–” input. Trace B is the LT1011’s

output. In circuits of this type, it is important to ensure

that enough current is available to quickly start the crystal

resonating while simultaneously maintaining an RC time

constant of appropriate frequency. Typically, the free running frequency should be set 5% to 10% above crystal

resonance with a resistor feedback value calculated to

allow about 100μA into the capacitor-crystal network. This

type of circuit is not recommended for use above a few

hundred kHz because of comparator delays.

50k

85kHz

100pF

–

+

LT1011

10k

1k

10k

0UT

5V

5V

Figure 2 shows another approach. This circuit uses a

standard RC-comparator multivibrator circuit with the

crystal connected directly across the timing capacitor.

Because the free running frequency of the circuit is close

AN12-2

10k

AN-12 F02

Figure 2. Crystal Stabilized Relaxation Oscillator

an12fa

Page 3

Application Note 12

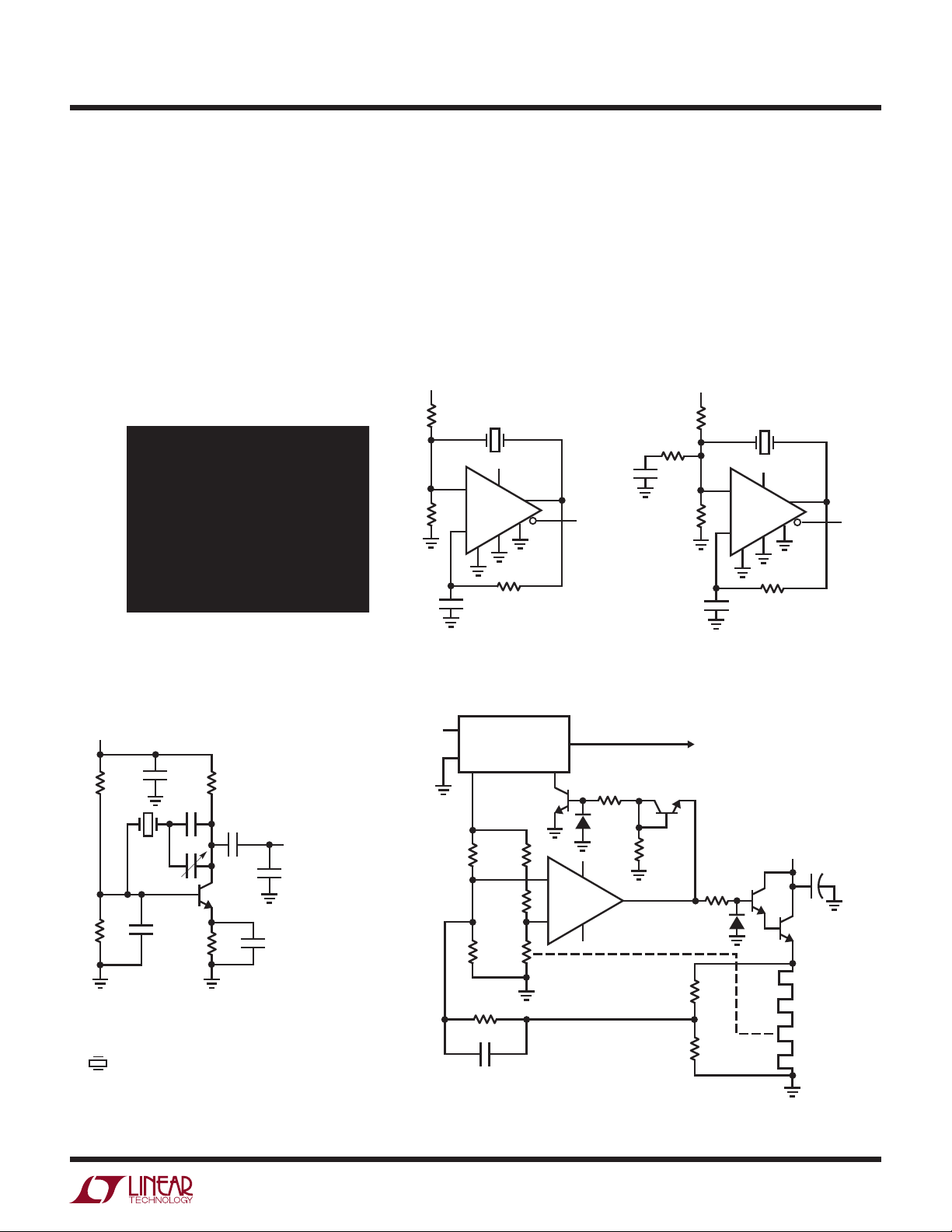

Figures 4a and 4b use another comparator based approach.

In Figure 4a, the LT1016 comparator is set up with DC

negative feedback. The 2k resistors set the common mode

level at the device’s positive input. Without the crystal,

the circuit may be considered as a very wideband (50GHz

GBW) unity gain follower biased at 2.5V. With the crystal

inserted, positive feedback occurs and oscillation commences. Figure 4a is useful with AT-cut fundamental mode

crystals up to 10MHz. Figure 4b is similar, but supports

oscillation frequencies to 25MHz. Above 10MHz, AT-cut

5V

1MHz TO 10MHz

2k

A = 1V/DIV

B = 5V/DIV

10μs/DIV

2k

0.068μF

AN-12 F03

+

–

crystals operate in overtone mode. Because of this, oscillation can occur at multiples of the desired frequency. The

damper network rolls off gain at high frequency, insuring

proper operation.

All of the preceding circuits will typically provide temperature coefficients of 1ppm/°C with long term (1 year)

stability of 5ppm to 10ppm. Higher stability is achievable

with more attention to circuit design and control of temperature. Figure 5 shows a Pierce class circuit with fine

frequency trimming provided by the paralleled fixed and

5V

10MHz TO 25MHz

22Ω

820pF

200pF

2k

(AT CUT)

5V

+

V

+

LT1016

2k

–

V

–

LATCH

2k

GND

Q

OUTPUT

Q

AN-12 F04b

CRYSTAL

5V

LT1016

–

V

+

V

LATCH

2k

GND

Q

OUTPUT

Q

AN-12 F04a

Figure 3. Figure 2’s Waveforms

15V

10k

5.6k

* TRW MAR-6 RESISTOR

R

= YELLOW SPRINGS INST. #44014 75°C = 35.39k

T

= BLILEY #BG61AH-55, 75°C TURNING POINT. 5MHz FREQUENCY

0.1μF

330pF

Oscillator

33pF

10pF

5.6k

1000pF

Q1

2N3904

3.3k

OUTPUT

(50Ω)

100pF

0.1μF

Figure 4a. 1MHz to 10MHz

Crystal Oscillator

15V

AUX

OUT

5V

R SELECT

TYPICAL

34.8k

22M

0.01μF

LT1005

34.8k34.8k

600Ω

2N3904

R

V

CONTROL

Q3

–

LT1001

+

T

Oven Control

5V MAIN

OUT TO SUPPLY

10k

1N914

15V

–15V

THERMAL FEEDBACK

Figure 4b. 10MHz to 25MHz

Crystal Oscillator

“OSCILLATOR READY”

AND MAIN 5V POWER

Q2

2N3904

100k

3k

1N914

8.2k

2k

15V

8.2μF

+

2N6387

DARLINGTON

AN-12 F05

Figure 5. Ovenized Oscillator

an12fa

AN12-3

Page 4

Application Note 12

variable capacitors. The transistor provides 180° of phase

shift with the loop components adding another 180°,

resulting in oscillation. The LT1005 voltage regulator and

the LT1001 op amp are used in a precision temperature

servo to control crystal temperature. The LT1001 extracts

the differential bridge signal and drives the Darlington

stage to power the heater, which is monitored by the

thermistor. In practice, the sensor is tightly coupled to

the heater. The RC feedback values should be optimized

for the thermal characteristics of the oven. In this case,

the oven was constructed of aluminum tube stock 3" long

× 1" wide × 1/8" thick. The heater windings were distributed around the cylinder and the assembly placed

within a small insulating Dewar flask. This allows 75°C

setpoint (the zero TC or “turnover” temperature of the

crystal specified) control of 0.05°C over 0°C to 70°C. The

LT1005 regulator sources bridge drive from its auxiliary

output and also keeps system power off until the crystal’s

temperature (hence, its frequency) is stabilized. When

power is applied the negative TC thermistor is high in

value, causing the LT1001 to saturate positive. This turns

on zener-connected Q2, biasing Q3. Q3’s collector current

pulls the regulator’s control pin low, disabling its output.

When the oven arrives at its control point, the LT1001’s

output comes out of saturation and servo controls the

oven at a point well below Q2’s zener value. This turns off

Q3, enabling the regulator to source power to whatever

system the clock is associated with. For the crystal and

circuit values specified, this clock will drift less than

–9

1 × 10

10

over 0°C to 70°C with a time drift of 1 part

–9

week.

The oven approach to removing temperature effects of

crystal clock frequency is the most effective and in wide

use. Ovens do, however, require substantial power and

warm-up time. In some situations, this is unacceptable.

Another approach to offsetting temperature effects is

to measure ambient temperature and insert a scaled

compensation factor into the crystal clock’s frequency

trimming network. This open loop correction technique

relies on matching the clock frequency vs temperature

characteristic, which is quite repeatable. Figure 6 shows

a temperature compensated crystal oscillator (TXCO)

which uses a first order linear fit to correct for temperature. The oscillator is a Colpitts type, with a capacitive

tapped tank network. The LT319A picks off the output

and the RC network at the LT319’s “–” input provides

a signal adaptive trip threshold. The LT1005 regulator’s

auxiliary output buffers supply variations and the main

regulator output control pin allows the system to be shut

down without removing power from the oscillator, aiding

overall stability. The ambient temperature is sensed by

the linear thermistor network in A1’s feedback loop with

A2 used for scaling and offsetting. A2’s voltage output

–15V

6.8k

LT1034

1.2V

R

T

3k*

–

A1

LT1055

+

10.7k*

*1% FILM RESISTOR

= YELLOW SPRINGS INST, CO

R

T

THERMISTOR NETWORK #44201

Figure 6. Temperature Compensated Crystal Oscillator (TXCO)

10k*

–

+

84.5k*

1μF

15V

A2

LT1055

0 – 3.955

100k 100k 100k

MV-209

MAIN OUTPUT

CONTROL

3.5MHz

500k

510pF

510pF

IN

GND

LT1005

EN

OUT

AUX

5V AUX

OUTPUT

2N2222A

680Ω

20k

20k

56.5mV/°C

5V MAIN OUTPUT

TO SYSTEM

+

1/2 LT319A

–

5

0.05μF

5V

1k

OUTPUT

2

AN-12 F06

an12fa

AN12-4

Page 5

Application Note 12

expresses the ambient temperature information required

to compensate the clock. The correction is implemented

by biasing the varactor diode (a varactor diode’s capacitance varies with reverse bias) which is in series with the

crystal. The varactor’s shift in capacitance is used to pull

the crystal’s frequency in a complementary fashion to the

circuit’s temperature error. If the thermistor is maintained

isothermally with the circuit, compensation is very effective. Figure 7 shows the results. The –40ppm frequency

shift over 0°C to 70°C is corrected to within 2ppm. Better compensation is achievable by including 2nd and 3rd

order terms in the temperature to voltage conversion to

more accurately complement the nonlinear frequency drift

characteristic.

Figure 8 is another voltage-varactor tuned circuit but is

configured to allow frequency shift instead of opposing

it. This voltage controlled crystal oscillator (VXCO) has a

40

30

20

10

0

–10

–20

FREQUENCY DEVIATION (ppm)

–30

–40

0

UNCOMPENSATED

20 40

10 30 50 70

TEMPERATURE (°C)

COMPENSATED

60

AN-12 G07

clean 20MHz sine wave output (Figure 9) suitable for communications applications. The curve of Figure 10 shows

a 7kHz shift from 20MHz over the 10V tuning range. The

25pF trimmer sets the 20MHz zero bias frequency. In many

applications, such as phase-locking and narrow bandwidth

FM secure communications, the nonlinear response is

irrelevant. Improved linearity will require conditioning

the tuning voltage or the varactor network’s response. In

circuits of this type it is important to remember that the

limit on pulling frequency is set by the crystals Q, which is

high. Achieving wide dynamic “pull” range without stopping

the oscillator or forcing it into abnormal modes is difficult.

Typical circuits, such as this one, offer pull ranges of several

hundred ppm. Larger shifts (e.g., 2000ppm to 3000ppm)

are possible without losing crystal lock, although clock

output frequency stability suffers somewhat.

0.01μF

0.01μF

10k

2.7k

24V

12k

2N2369

4.7k 220pF

330pF

OUTPUT

20.0000MHz TO 20.0070MHz

100Ω

20MHz25pF100pF

100k

MV-1405

TUNING

VOLTAGE

0V TO 10V

AN-12 F08

A = 100mV/DIV

Figure 7. TXCO Drift Performance

10ns/DIV

AN-12 F09

Figure 9. Figure 8’s Output

Figure 8. Voltage Controlled Crystal Oscillator (VCXO)

7000

6000

5000

4000

3000

2000

FREQUENCY SHIFT (Hz)

1000

0

0

2

1

TUNING VOLTAGE (V)

6384

10579

AN-12 F10

Figure 10. Figure 8’s Tuning Characteristics

AN12-5

an12fa

Page 6

Application Note 12

Noncrystal Clock Circuits

Although crystal based circuits are universally applied,

they cannot serve all clock requirements. As an example,

many systems require a reliable 60Hz line synchronous

clock. Zero crossing detectors or simple voltage level

detectors are often employed, but have poor noise rejection characteristics. The key to achieving a good line

clock under adverse conditions is to design a circuit which

takes advantage of the narrow bandwidth of the 60Hz

fundamental. Approaches utilizing wide gain bandwidth,

even if hysteresis is applied, invite trouble with noise.

Figure 11 shows a line synchronous clock which will not

lose lock under noisy line conditions. The basic RC multivibrator is tuned to free run near 60Hz, but the AC-line

derived synchronizing input forces the oscillator to lock

to the line. The circuit derives its noise rejection from the

integrator characteristics of the RC network. As Figure 12

shows, noise and fast spiking on the 60Hz input (Trace A,

Figure 12) has little effect on the capacitor’s charging

characteristics (Trace B, Figure 12) and the circuit’s output

(Trace C, Figure 12) is stable.

Figure 13 is another synchronous clock circuit. In this

instance, the circuit output locks at a higher frequency than

the synchronizing input. Circuit operation is the time domain

equivalent of a reset stabilized DC amplifier. The LT1055

and its associated components form a stable oscillator.

The LM329 diode bridge and compensating diodes provide

a stable bipolar charging source for the RC located at the

amplifier’s negative input. The synchronizing pulse (Trace

A, Figure 14) is level shifted by the LT1011 comparator

to drive the FET. When the synchronizing pulse appears,

the FET turns on, grounding the capacitor (Trace B, Figure

14). This interrupts normal oscillator action, but only for

a small fraction of a cycle. When the sync pulse falls, the

capacitor’s charge cycle, which has been reset to 0V, starts

again. This resetting action forces the frequency of the RC

charging to be synchronous and stabilized by the sync

pulse. The only evidence of this operation at the output

is an occasional, slightly enlarged pulse width (Trace C,

Figure 14), which is caused by the synchronizing interval.

The sync adjust potentiometer should be trimmed so the

sync pulse appears when the capacitor is near 0V. This

60Hz

INPUT

SYNC

20k

0.15μF

68k

–

+

LT1055

60Hz

OUTPUT

10k

10k

AN-12 F11

A = 10V/DIV

B = 5V/DIV

C = 5V/DIV

5ms/DIV

Figure 11. Synchronized Oscillator Figure 12. Figure 11’s Waveforms

5k

SYNC

15V

SYNC ADJ

0.05μF

–

15V

IN

12k

+

–

3k

330k

LT1011

4

1

2N4392

3.3k

LT1055

+

Figure 13. Reset Stabilized Oscillator

10k

10k

7.5k*

3k

620Ω

OUTPUT

LM329

1N4148

AN-12 F13

AN-12 F12

an12fa

AN12-6

Page 7

Application Note 12

minimizes output waveform width deviation and allows

maximum protection against losing lock due to RC drift

over time and temperature. The maximum practical output

frequency to sync frequency ratio is about 50×.

Pure RC oscillators are a final form of clock circuit. Although this class of circuit cannot achieve the stability

of a synchronized or crystal based approach, it offers

simplicity, economy and direct low frequency output. As

such they are used in baud rate generators and other low

frequency applications. The key to designing a stable RC

oscillator is to make output frequency insensitive to drift

in as many circuit elements as possible. Figure 15 shows

an RC clock circuit which depends primarily on the RC

elements for stability. All other components contribute

very low order error terms, even for substantial shifts. In

addition, the RC components have been chosen for opposing temperature coefficients, further aiding stability.

The circuit is a standard comparator-multivibrator with

parallel CMOS inverters interposed between the comparator output and the feedback resistors. This replaces the

relatively large and unstable bipolar V

saturation losses

CE

of the LT1011 output with the superior ON characteristics

of MOS. Not only are the MOS switching losses to the rails

low and resistive, but they tend to cancel. The paralleling

of inverters further reduces errors to insignificant levels.

With this arrangement, the charge and discharge time

constant of the capacitor is almost totally immune from

supply and temperature shifts. The 10k units need not

be precision types, because shifts in them will cancel. In

addition, the effect of the comparator’s DC input errors

is also negated because of the symmetrical nature of the

oscillator. This leaves only the RC network as a significant

error term. The nominal—120ppm/°C temperature coefficient of the polystyrene capacitor is partially offset by

the opposing positive temperature coefficient designed

into the specified resistor. In practice, only a first order

compensation is achievable because of the uncertainty of

the capacitor’s exact TC. For the test circuit, 0°C to 70°C

temperature excursion showed a 15ppm/°C TC with a

power supply rejection factor of less than 20ppm/V. In

contrast, a clock constructed from the popular 555 timer,

using the compensating RC network, showed 95ppm/°C

and 1050ppm/V of supply shift. Because of comparator

propagation delays, circuits of this type are less stable

above a 5kHz to 10kHz operating frequency.

A = 5V/DIV

B = 2V/DIV

C = 50V/DIV

200μs/DIV

Figure 14. Figure 13’s Waveforms

AN-12 F12

*

C

0.015μF

+

LT1011

–

1

*TRW TYPE MTR-5/+120ppm/°C

C = 0.015μF = POLYSTYRENE—

120ppm/°C ±30ppm WESCO TYPE 32-P

Figure 15. Stable RC Oscillator

15V

4.7k

4

74C04s

10k

10k

10k

OUTPUT

15V

AN-12 F15

an12fa

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

AN12-7

Page 8

Application Note 12

ABOUT QUARTZ CRYSTALS

The frequency stability and repeatability of quartz

crystals represent one of nature’s best bargains for the

circuit designer. The equivalent circuit of a crystal looks

like a series-parallel combination of elements.

C

O

C

L

R

Typical Values:

R = 100Ω

L = 500μH

C = 0.01pF

= 5pF

C

O

Q = 50,000

is the static capacitance produced by the contact

C

O

wires, crystal electrodes and the crystal holder. The RLC

term is called the motional arm. C is the mechanical

mass. R includes all electrical losses in the crystal and

L is the reactive component of the quartz. Different

angles of cut from the mother crystal produce different electrical characteristics in individual crystals. Cuts

can be optimized for temperature coefficient, frequency

range and other parameters. The basic “AT” cut used in

most crystals in the 1MHz to 150MHz range is a good

compromise between temperature coefficient, frequency

range, ease of manufacture and other considerations.

Other factors affecting resonator performance include

the method of lead attachment, package sealing method

and internal environment (e.g., vacuum, partial pressure, etc.). Some circuit considerations when using

crystals include:

Load Capacitance—The reactance the crystal must

present to the circuit. Some circuits use the crystal in the

parallel resonant mode (e.g., the crystal looks inductive).

Other circuits are specified as series resonant and the

crystal appears resistive. In this mode, the circuit’s load

capacitance, including all parasitics, must be specified.

A typical number is around 30pF.

Resistance—The impedance the crystal presents when

it is resonating.

Drive Level—How much power may be dissipated in

the crystal and still maintain all specifications. 10mW is

typical. Excessive levels can fracture the crystal.

Temperature Coefficient/Turning Point—The tempco of

the crystal is usually specified near the “turning point.”

This is the temperature at which the crystal tempco

is zero. Typically the tempco will be below 1ppm/°C

over the operating range and the turning point around

75°C, although different cuts can considerably alter

these numbers.

Frequency Tolerance—The deviation from ideal frequency when used under specified circuit conditions

at a defined temperature. Tolerances vary from 50ppm

to less than 1ppm.

AN12-8

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

an12fa

LT/TP 1101 1.5K REV A • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 1985

Loading...

Loading...