Page 1

Application Note 126

October 2010

2-Wire Virtual Remote Sensing for Voltage Regulators

Clairvoyance Marries Remote Sensing

Jim Williams, Jesus Rosales, Kurk Mathews, Tom Hack

Introduction

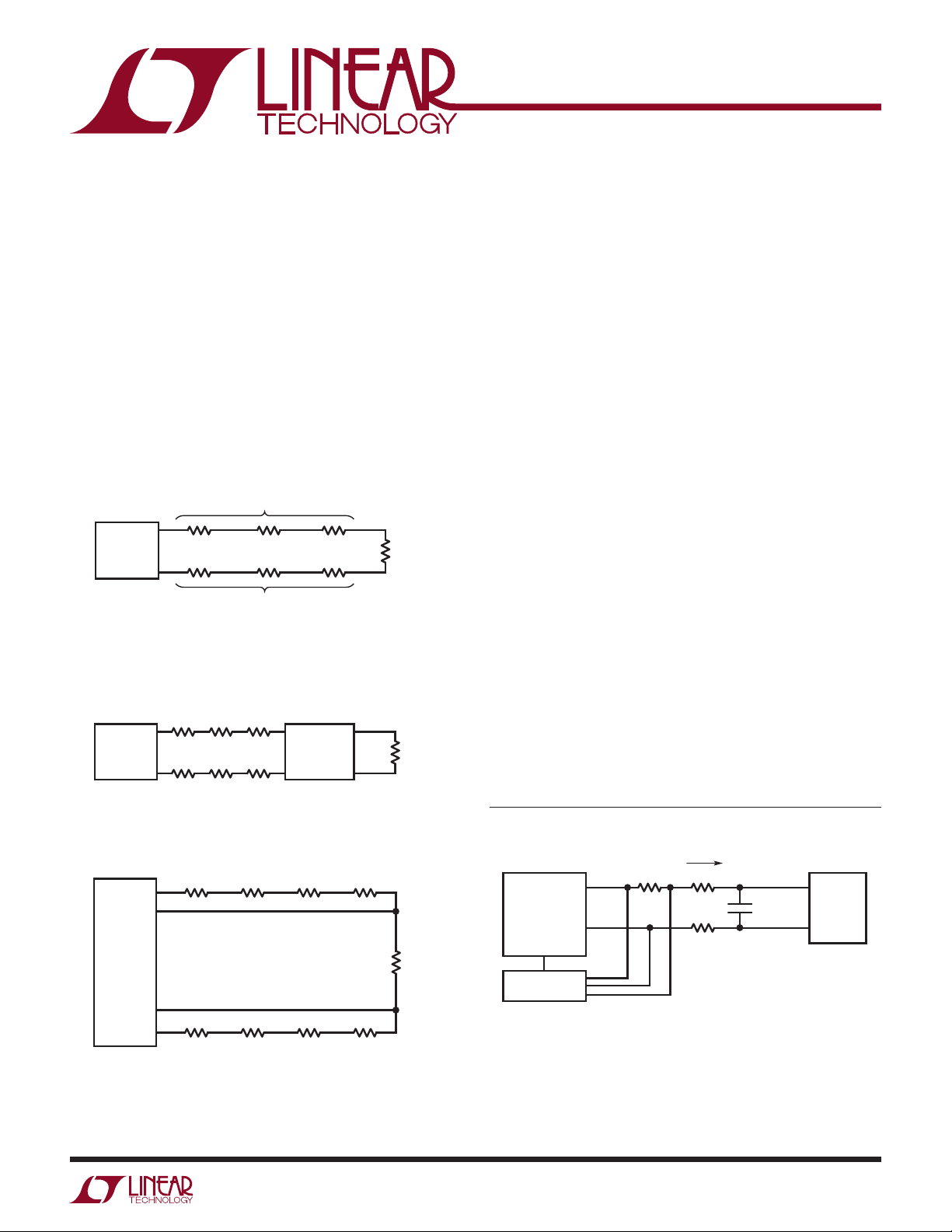

Wires and connectors have resistance. This simple, unavoidable truth dictates that a power source’s remote load

voltage will be less than the source’s output voltage. Figure 1

shows this, and implies that intended load voltage can

be maintained by raising regulator output. Unfortunately,

line resistance and load variations introduce uncertainties,

limiting achievable performance.

WIRING DROPS

POWER

SUPPLY

WIRING DROPS

Figure 1. Unavoidable Wiring Drops Cause Low Load

Voltage. Line and Load Resistance Variations Introduce

Additional Load Voltage Uncertainty, Mitigating Against

Compensation by Raising Supply Voltage

POWER

SUPPLY

LOAD

VOLTAGE

REGULATOR

Figure 2. Local Regulation Stabilizes

Load Voltage But is Ineffi cient

V

SENSE

POWER

SUPPLY

SENSE

V

OUT

OUT

VOLTAGE DROP R

+

+

–

VOLTAGE DROP R

–

WIRE

WIRE

Figure 3. Classical “4-Wire” Remote Sensing. V

Voltage Drops Are Compensated by Regulator Sensing at Load.

High Impedance Sense Inputs Negate Sense Wire Resistance.

Approach Requires Four Wires

AN125 F01

AN125 F02

OUT

LOAD

LOAD

LOAD

AN125 F03

Line

Figure 2 illustrates one compensatory approach. Locally

positioned regulation stabilizes load voltage against line

drops but is ineffi cient due to regulator losses. Figure 3,

the classical approach, utilizes “4-wire” remote sensing to

eliminate line drop effects. The power supply sense inputs

are fed from load referred sense wires. The sense inputs

are high impedance, negating sense line resistance effects.

This scheme works well, but requires dedicated sense

wires, a signifi cant disadvantage in many applications.

“Virtual” Remote Sensing

Figure 4 retains the advantages of classical 4-wire remote sensing while eliminating the sense leads. Here,

the LT4180 Virtual Remote Sense™ (VRS) IC alternates

output current between 95% and 105% of the nominal

required output current. The LT4180 forces the power

supply to provide a DC current plus a small square wave

current with peak-to-peak amplitude equal to 10% of the

DC current. Decoupling capacitor C

, normally required

LOAD

for low impedance under transient conditions in non-VRS

systems, takes an additional role by fi ltering out the VRS

square wave excursions.

L, LT, LTC, LTM, Linear Technology and the Linear logo are registered trademarks and Virtual

Remote Sense is a trademark of Linear Technology Corporation. All other trademarks are the

property of their respective owners.

SENSE

+

V

POWER SUPPLY

OUT

–

CONTROL PIN

LT4180

V

= DC + SQUAREWAVE FROM WIRING VOLTAGE DROP

OUT

REMOVES SQUAREWAVE, SO VL CONTAINS ONLY DC.

C

LOAD

= DC + SQUAREWAVE

I

L

Figure 4. LT4180 2-Wire Virtual Remote Sense Estimates

Wiring Voltage Drops, Compensates by Adjusting Supply

Output Voltage. Wiring Loss Is Determined by Measuring

Small Signal Square Wave Carrier Induced Voltage Drop.

Load Capacitor Absorbs Square Wave; Load Is at DC

R

R

WIRE

WIRE

I

L

/2I

+

V

C

L

/2

LOAD

LOAD

–

AN125 F04

an126fa

AN126-1

Page 2

Application Note 126

Because C is sized to produce an “AC short” at the square

wave frequency, a square wave voltage is produced at the

power supply equal to V

= 0.1 • IDC • R

OUTAC

WIREVP-P

. The

square wave voltage at the power supply has a peak-topeak amplitude equal to one tenth the DC wiring drop. This

is a direct measurement of wiring drop, not an estimate,

accurate over all load currents. Signal processing produces

a DC voltage from this AC signal which is introduced into

the supply feedback loop to provide accurate load regula-

1

. Note that the “power supply” may be an IC linear or

tion

switching regulator, a module or any other power source

capable of variable output. Power supplies can be synchronized to the LT4180 and VRS operating frequency is

adjustable over more than three decades. Optional spread

spectrum operation provides partial immunity from singletone interference and a 3V to 50V input range simplifi es

design. Because this technique is based on an estimate

of load voltage, not a direct measurement, the resultant

correction is an approximation, but a very good one.

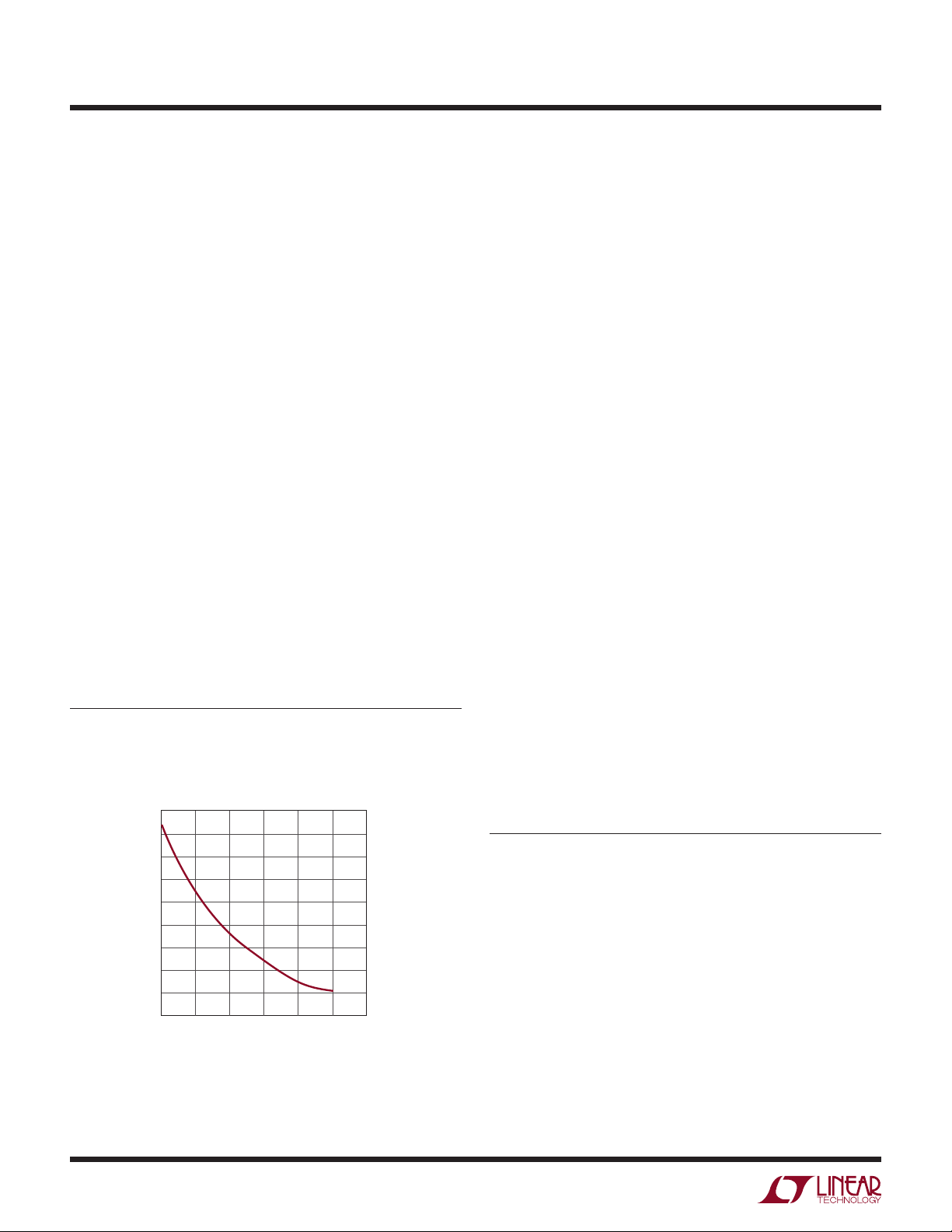

Typical LT4180 load regulation is plotted in Figure 5. In

this example, load current increases from zero until it

produces a 2.5V wiring drop. Load voltage drops only

73mV at maximum current. A voltage drop equivalent to

50% of load voltage results in only a 1.5% shift in load

voltage value. Smaller wiring drops produce even better

results.

Note 1. Readers fi nding their intellectual prowess unsatiated by this

admittedly cursory description will fi nd more studious coverage in

Appendix A, “A Primer on LT4180 VRS Operation.”

5.00

4.99

4.98

4.97

4.96

(V)

LOAD

4.95

V

4.94

4.93

4.92

4.91

0

0.5 1.51 2 2.5 3

V

(V)

WIRING

AN126 F05

Applications

The following applications are all VRS augmented voltage

regulators of various descriptions. The power regulation

stages employed are, with one exception, generic LTC

designs and are spared exhaustive commentary, permitting emphasis on the LT4180 VRS role. Additionally, the

similarity of the VRS associated circuitry across the broad

array of applications shown should be noted, and is indicative of the relative ease of implementation. Surprisingly

little change is needed to use the VRS in the different

situations presented.

VRS Linear Regulators

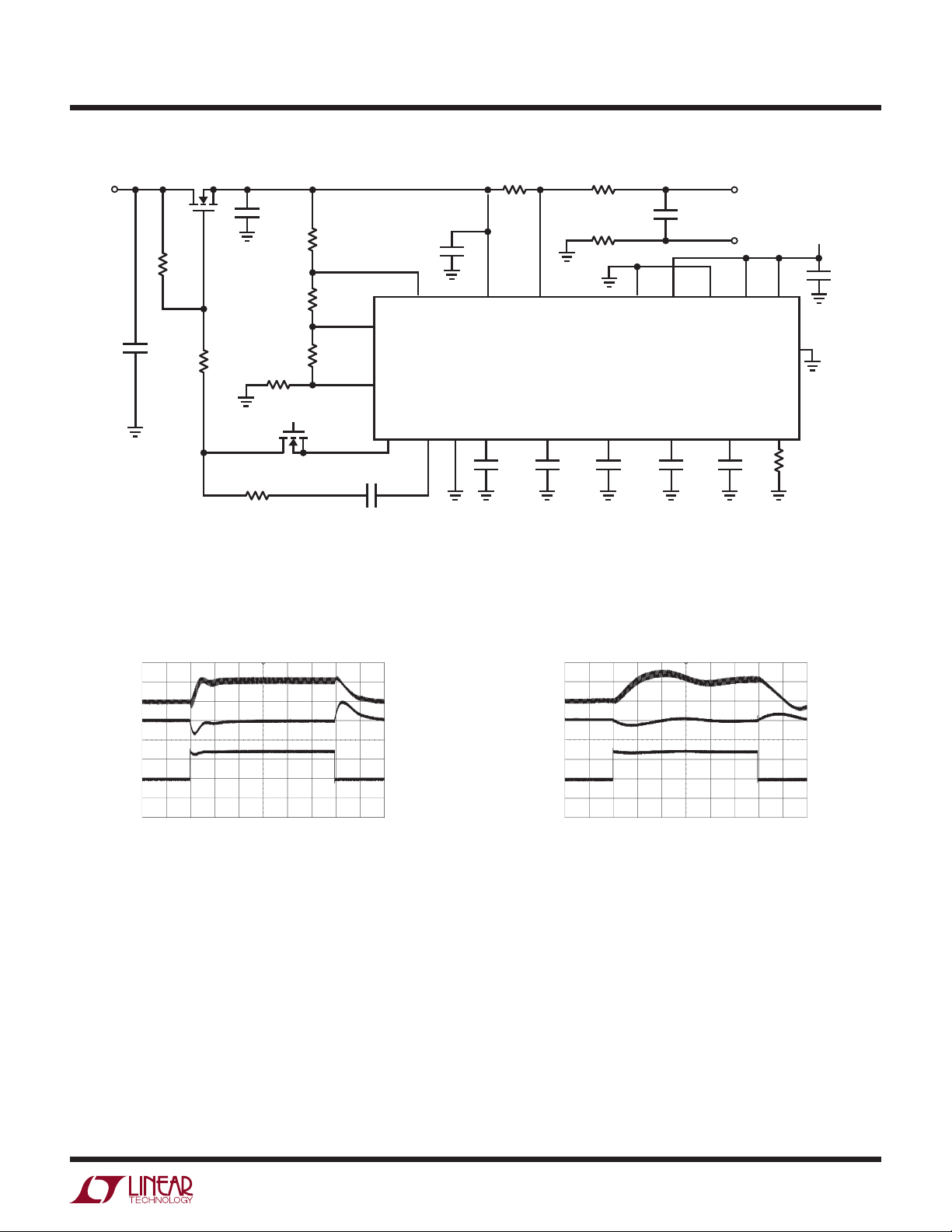

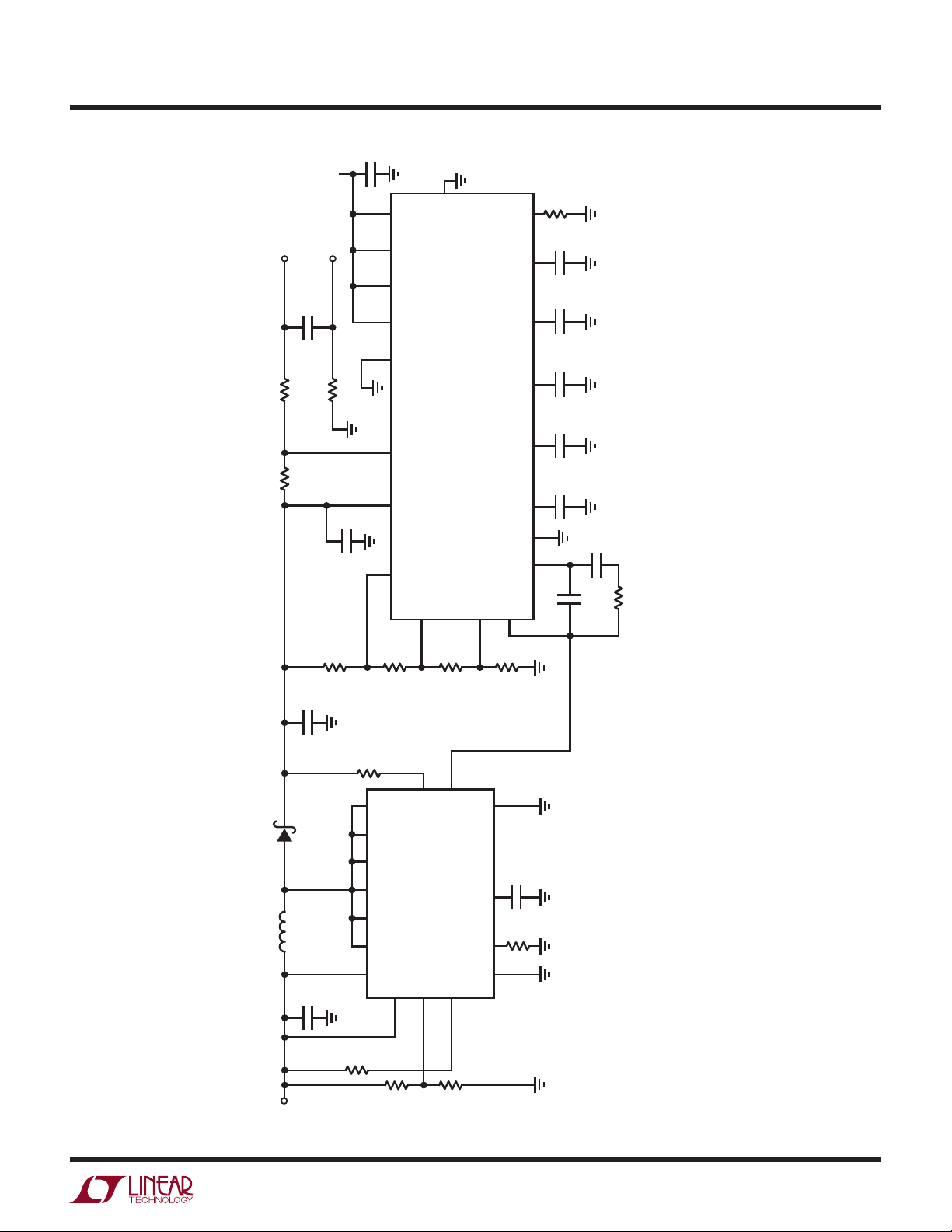

Figure 6 adds a simple stage to the LT4180 to implement

a complete VRS aided linear regulator. The LT4180 senses

current via the 0.2 shunt and feedback controls Q1 with

Q2, completing a control loop. Cascoded Q2 permits the

ICs 5V capable open drain output to control a high voltage

at Q1’s gate. Components at the compensation pin furnish

2

loop stability, promoting good transient response

shows Figure 6’s load step waveforms. They include V

(trace A), V

LOAD

(B) and I

(C). Transient response is

LOAD

. Figure 7

SENSE

determined by loop compensation, load capacitance and

remote sense sample rate. Figure 8 shows response with

increased to 1100µF. Load voltage transient excur-

C

LOAD

sion reduces and duration increases.

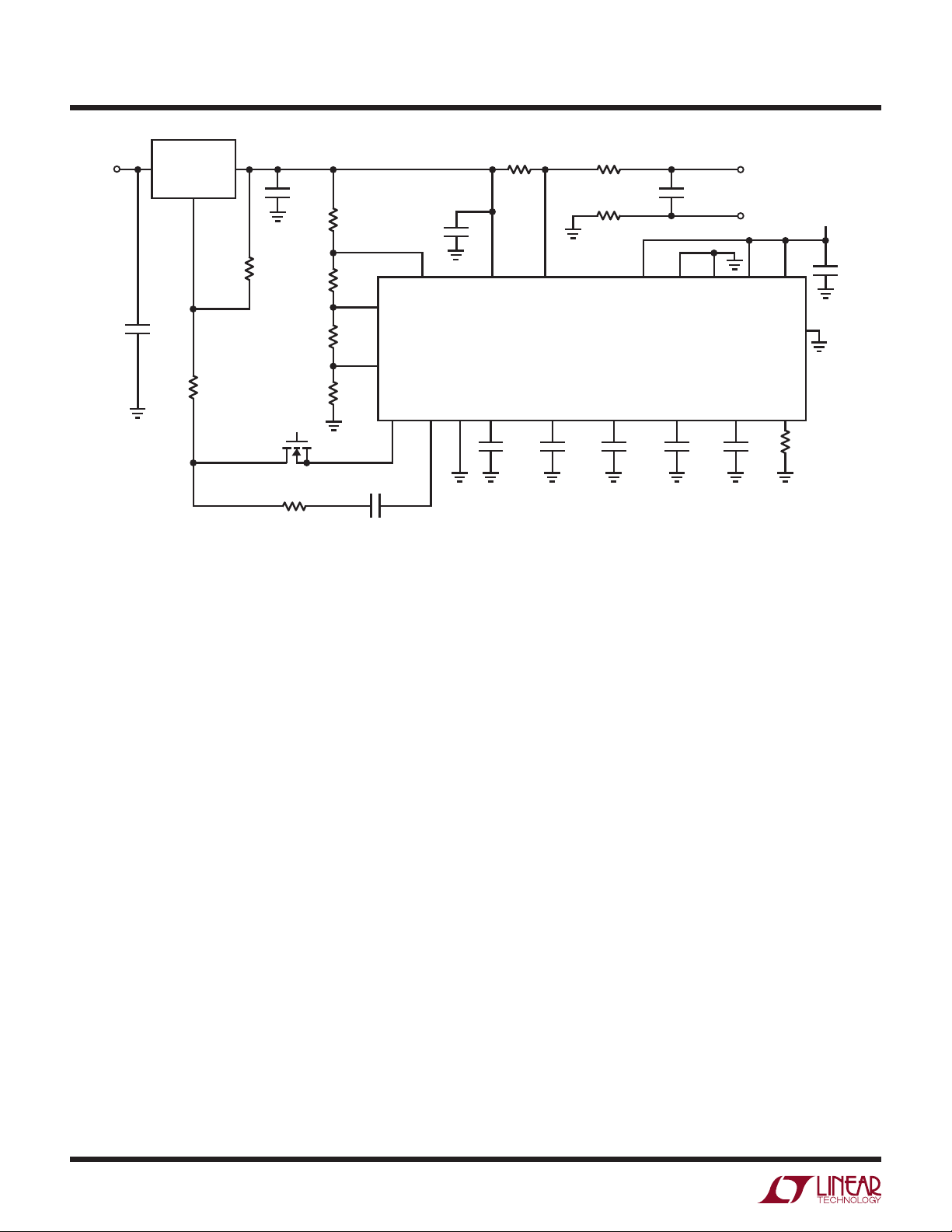

Figure 9, employing a monolithic regulator, adds current

limiting and simplifi es loop compensation. Transient response approximates Figure 6’s. As before, the LT4180’s

low voltage drain pin requires a cascode transistor to

control the high voltage at the LT3080 set pin.

Note 2. Value selection procedure for LT1480 VRS circuits is detailed in

Appendix B, “Design Guidelines for LT4180 VRS Circuits.”

Figure 5. Typical LT4180 Virtual Remote Sense Performance

Shows 1.6% Regulation vs 0V → 2.5V Wiring Drop

AN126-2

an126fa

Page 3

Application Note 126

V

20V

Q1

10µF

25V

IRLZ44

27k

10k

GUARD PINS NOT SHOWN

200k

4.7µF

5.36k

1%

Q2

INTV

VN2222

63.4k

1%

3.74k

1%

2.2k

1%

CC

330pF

RUN

FB

OV

COMP GNDDRAIN

IN

0.2

1%

1µF

SENSE

V

IN

CHOLD1 CHOLD2 CHOLD3 CHOLD4

WIRING DROP

LOAD RETURN

WIRING DROP

LT4180

470pF47nF

DIV2

100µF

33nF

LOAD VOLTAGE

12V, 500mA

8Ω TOTAL WIRING DROP

LOAD

RETURN

V

DIV0DIV1

PP

C

OSC

470pF470pF

INTV

SPREAD

R

OSC

CC

41.2k

1%

AN126 F06

INTV

CC

1µF

Figure 6. Virtual Remote Sense Controls Discrete Linear Regulator. Q2 Cascodes Drain Output,

Buffering High Voltage Q1 Gate Drive. COMP Pin Associated Components Stabilize Loop

A = 2V/DIV

B = 2V/DIV

AC COUPLED

C = 0.2A/DIV

ON 0.2A

DC LEVEL

5ms/DIV

AN126 F07

Figure 7. Figure 6’s Load Step Waveforms with 100μF Load

Capacitor Include V

(Trace A), V

SENSE

LOAD

(B) and I

LOAD

(C).

Transient Response is Determined by Loop Compensation,

Load Capacitance and Remote Sense Sample Rate

A = 2V/DIV

B = 2V/DIV

AC COUPLED

C = 0.2A/DIV

ON 0.2A

DC LEVEL

5ms/DIV

Figure 8. Same Conditions as Figure 7 with C

1100μF. V

Transient Excursion Reduces, Duration Extends

LOAD

LOAD

AN126 F08

Increased to

an126fa

AN126-3

Page 4

Application Note 126

V

18V

IN

LT3080

IN OUT

SET

10µF

25V

100k

GUARD PINS NOT SHOWN

10k

4.7µF

INTV

VN2222

51k

60.4k

1%

3.57k

1%

1.78k

1%

5.36k

1%

CC

1500pF

RUN

FB

OV

COMP GNDDRAIN

0.2

1%

1µF

SENSE

V

IN

CHOLD1 CHOLD2 CHOLD3 CHOLD4

WIRING DROP

LOAD RETURN

WIRING DROP

DIV2

LT4180

470pF47nF

470µF

47nF

DIV0DIV1

LOAD VOLTAGE

12V, 500mA

4Ω TOTAL

WIRING DROP

LOAD

RETURN

V

PP

C

OSC

330pF470pF

INTV

SPREAD

R

OSC

CC

22.1k

1%

AN126 F06

INTV

CC

1µF

Figure 9. Figure 6’s Approach Utilizing IC Regulator Adds Current Limiting,

Simplifi es Loop Compensation. Transient Response Approximates Figure 6’s

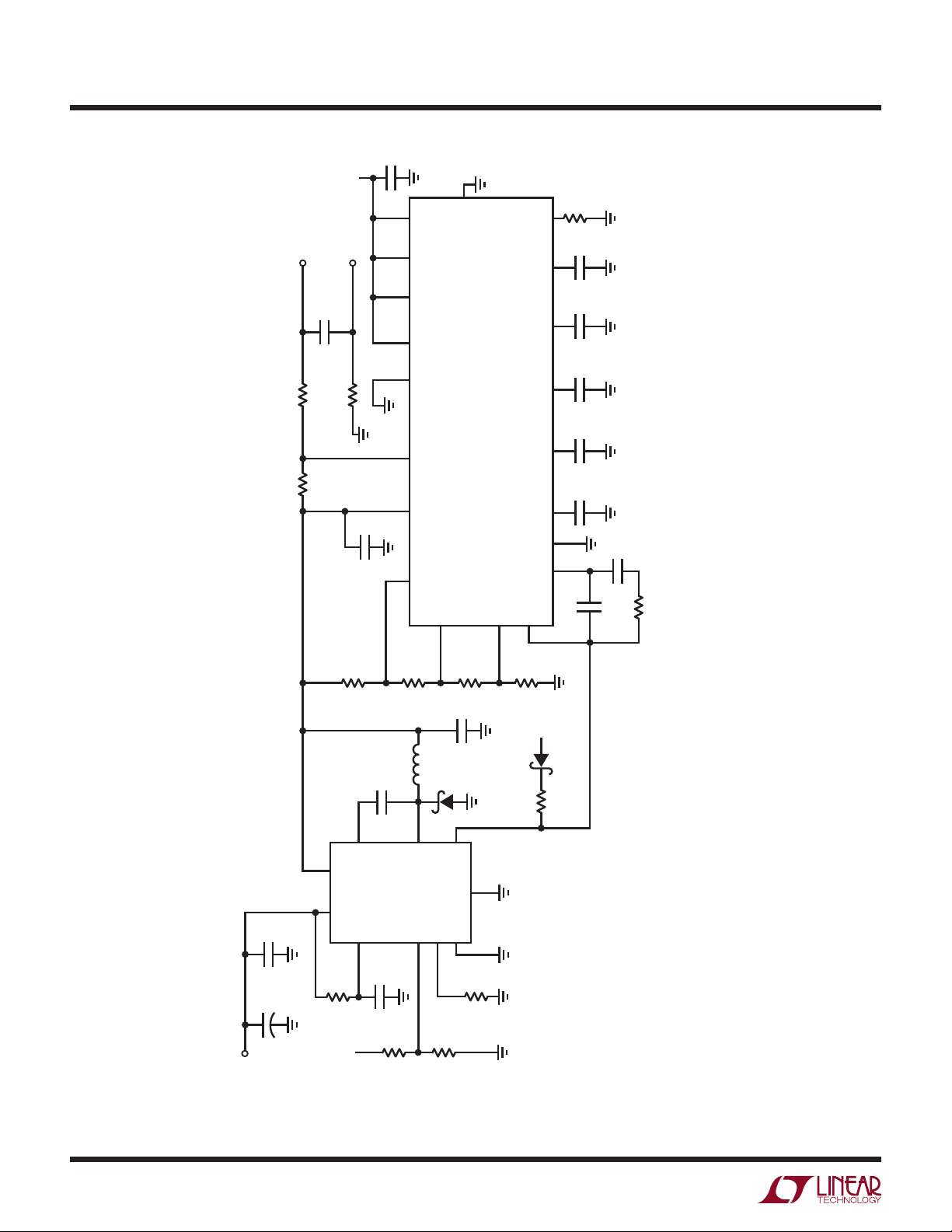

VRS Equipped Switching Regulators

VRS based switching regulators are readily constructed.

Figure 10’s fl yback voltage boost confi guration has similar

architecture to the linear examples although output voltage

is above the input. In this case, the LT4180 open drain output

is directly compatible with the LT3581 boost regulator low

voltage V

pin––no cascode stage is necessary.

C

Step down (“Buck”) VRS equipped switching regulators are

similarly easily achieved. Figure 11’s scheme, reminiscent

of the previously described linear regulators, substitutes

an LT3685 step down regulator which is directly controlled

from the LT4180 open drain output. A single pole roll-off

stabilizes the loop and a 12V, 1.5A output is maintained

from a 22V to 36V input despite a 0Ω to 2.5Ω wiring drop

loss. Figure 11A is similar, except that it provides a 5V, 3A

output from a 12V to 36V input.

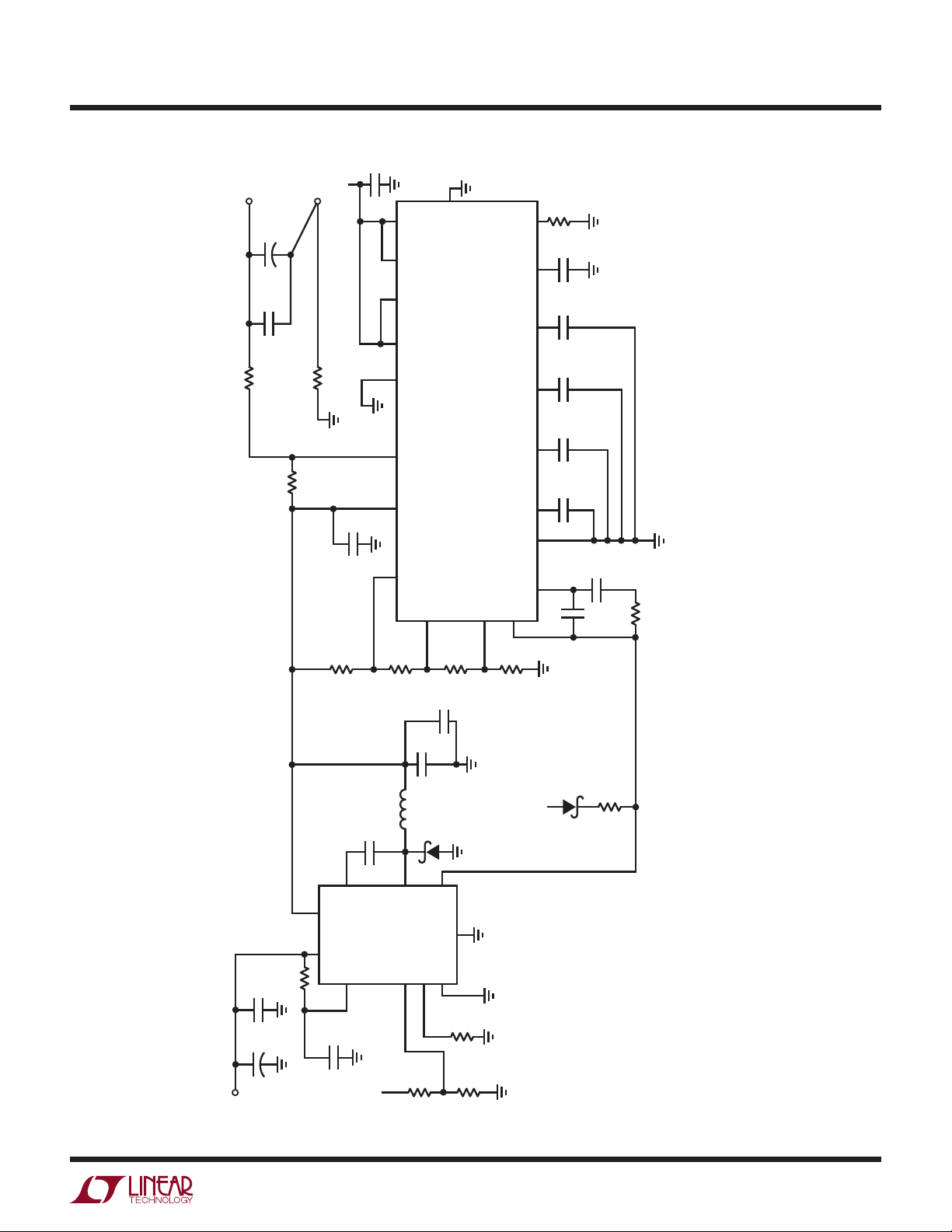

VRS Based Isolated Switching Supplies

The VRS approach is adaptable to isolated output supplies.

Figure 12’s 24V output converter utilizes an approach

similar to the previous examples except that it supplies

a fully isolated output. The virtual remote sense feature

accommodates a 10Ω wire resistance. The LT3825 and T1

form a transformer coupled power stage. Opto-coupled

feedback maintains output isolation.

Figure 13’s 48V → 3.3V, 3A design also has a fully isolated

output, facilitated by power delivery through a transformer

and optically coupled feedback loop closure. The LT3758

drives T1 via Q1. T1’s rectifi ed and fi ltered secondary

supplies output power which is corrected for line drops

by the LT4180. Isolation is maintained by transmitting the

feedback signal with an opto-isolator. The opto-isolators

output collector ties back to the LT3578 V

pin, closing

C

the control loop.

AN126-4

an126fa

Page 5

OV

FB

DIV0DIV1

V

IN

INTV

CC

INTV

CC

V

PP

COMP GND

DRAIN

DIV2

CHOLD1 CHOLD2 CHOLD3 CHOLD4

47nF

AN126 F10

RUN

R

OSC

C

OSC

40.2Ω

1%

SENSE

SPREAD

LT4180

470pF470pF

470pF47nF

10nF

1µF

41.7k

1%

73.2Ω

1%

1.24k

1%

24.3k

1µF

0.2

1%

WIRING DROP

VIN5V

LOAD VOLTAGE

12V, 500mA

(100mA MIN.)

6Ω TOTAL WIRING DROP

LOAD

RETURN

10µF

25V

4.7µF

16V

L1

4.7µH

DFLS220

LOAD RETURN

WIRING DROP

100µF

191k

100k

10k

107Ω

1%

47pF

15k

LT3581

SW2SW2SW2SW1SW1SW1GATE

RT SSSYNC GND

V

CC

SHDN

FAULT

FB

VC

84.5k

0.1µF

L1 = VISHAY IHLPI525CZ-11

GUARD PINS NOT SHOWN

+

–

Application Note 126

Pin

C

Figure 10. Virtual Remote Sensed Voltage Boost Confi guration.

LT4180 Drain Output Controls Flyback Regulator via LT3581 V

an126fa

AN126-5

Page 6

Application Note 126

12V, 1.5A

2.5Ω TOTAL

WIRING DROP

CC

INTV

LOAD

RETURN

1µF

AN126 F11

22.1k

R

C

1%

OSC

330pF470pF

OSC

CC

INTV

SPREAD

PP

V

470µF

WIRING DROP

LOAD RETURN

0.067 WIRING DROP

61.9k

1%

DIV0DIV1

DIV2

LT4180

SENSE

IN

V

1µF

RUN

22µF

2k

25V

1%

OV

DRAIN

5.36k

1%

3.65k

FB

1%

CHOLD1 CHOLD2 CHOLD3 CHOLD4

COMP GND

CC

INTV

47pF

47nF

470pF47nF

3.3nF

28k

Step-Down

IN

to 36V

IN

AN126-6

1µF

22µF

+

IN

V

22V TO 36V

50V

50V

BD

IN

V

100k

INTV

CC

0.47µF

BOOST

RUN/SD

0.1µF

LT3685

50V

30.1k

10µH

SW

FBRTSYNC

DFLS240

VC

GND

10k

68.1k

1%

CMDSH-3

1k

Regulator Maintains 12V Output Despite Wiring Losses

Figure 11. Remote Sense Corrected 22V

L1 - VISHAY IHLP2020CZ-11

GUARD PINS NOT SHOWN

an126fa

Page 7

OUT

5V, 3A

0.4Ω TOTAL

WIRING DROP

V

C2

470µF

10V

+

C1

470µF

10V

+

–

WIRING DROP

1%

0.033Ω

CC

LOAD

RETURN

INTV

WIRING DROP

LOAD RETURN

Application Note 126

1µF

AN126 F11A

22.1k

CC

INTV

SPREAD

PP

V

DIV0

DIV1

DIV2

LT4180

SENSE

IN

V

1µF

OSC

R

OSC

C

CHOLD1 CHOLD2 CHOLD3 CHOLD4

1%

330pF

47nF

470pF

470pF47nF

4.7µF

50V

100k

BD

V

IN

21.5k

1%

BOOST

RUN/SD

1.87k

6.8µH

0.47µF

LT3693EDD

RUN

FB

2.15k

1%

47µF

10V

47µF

10V

MBRA340T3G

VC

SW

GND

FBRTSYNC

1%

OV

DRAIN

5.36k

1%

COMP GND

4.7nF

Step-Down Remote

OUT

47pF

CMDSH-3

CC

INTV

23.2k

1k

GUARD PINS NOT SHOWN

C1 = C2 = AVXTPSE477M010R0050

to 5V

IN

→ 36V

IN

Figure 11A. 12V

Sensed Regulator Has Similar Architecture to Figure 11

+

IN

V

8V TO 36V

22µF

50V

68.1k

1%

10k

1%

1%

an126fa

0.1µF

30.1k

CC

INTV

AN126-7

Page 8

Application Note 126

V

36V to 72V

T1

t

IN

4.7µH

+

V

IN

383k

1%

14k

1%

3.01k

1%

BAS21LT1

40.2k

1%

OPTIONAL

MMBT3906

+

10µF

100V

2.2µF

100V

–

V

IN

56pF

3.9k

1/4W

20

1/8W

33nF

+

68µF

20V

FB

OVLO

OSCAP ROCMPPGOLYENOL CMPC TON

38.3k

*

3.9k

1/4W

10k

56pF

56pF

0.1µF

SYNCSFST

30k

0.022µF

LT3825

2.05k

130k

1%

47k

1/4W

12.3V TO 16.5V

CC

0.1µF

–V

OUT

1µF

50V

+V

CC

100k

PGV

SGND/

PGND

SENP

SENN

VC

220pF

0.2

1%

30k

1nF

68pF

250V

47k

1/4W

Si7302DN

0.05

1206

R

WIRE

–V

OUT

ES1G

tt

tt

t

4.7nF

250V

V

OUT

24V, 500mA

10Ω TOTAL WIRING DROP

+

220µF

35V

LOAD RETURN

200

1/4W

10µF

35V

30pF

500V

100µF

35V

10µF

35V

LOAD RETURN

WIRING DROP

INTV

CC

1.37k

* 12mA MINIMUM

LOAD REQUIREMENT

+V

CC

12k

1k

MMBT3908

10µF TANYO YUDEN GMK325BJ106KN 1210

100µF 36V NICHICON PL (M)

10µF 100V SANYO 100CE10FS

68µF 20V KEMET T491D686K020AS

4.7nF 250V MURATA GA343DR7GD472KW01L

4.7µH COOPER BUSSMANN SO3814-4R7-R

1/4W RESISTORS ARE 1206

1/8W RESISTORS ARE 0805

T1 PULSE PA2925NL

GUARD PINS NOT SHOWN

6.8k

MOC207

2k

INTV

VN2222

1%

1.58k

1%

5.36k

1%

–V

OUT

CC

= INPUT COMMON

Figure 12. Virtual Remote Sensed, Isolated 36VIN → 72VIN to 24V

FB

OV

DRAIN

47pF

330pF

10k

1%

RUN

V

COMP GND

SENSE

IN

CHOLD1

Converter Accommodates

OUT

DIV2

LT4180

CHOLD2 CHOLD3 CHOLD4

0.047µF

3.3nF

3.3nF

V

DIV0DIV1

PP

C

OSC

0.1µF

10Ω Lead Wire Resistance. LT3825/T1 Form Transformer Coupled Power Stage. LT4180 Provides

Virtual Remote Sense, Opto-Coupled Feedback Maintains Output Isolation

INTV

SPREAD

R

470pF

CC

OSC

41.7k

1%

1µF

AN126 F12

–V

OUT

AN126-8

an126fa

Page 9

3.3V, 3A

+

0.4 TOTAL WIRING DROP

LOAD

RETURN

*

LOAD

C

Application Note 126

1µF

CC2

INTV

CC

INTV

PP

V

DIV0DIV2

SPREAD

R

C

OSC

470pF

OSC

41.2k

0.1µF

1%

AN126 F13

0.4

WIRING DROP

1%

0.033

T1

WIRING DROP

LOAD RETURN

1µF

13k

100µF

10V

w2

UPS840

ttt

1%

DIV1

SENSE

IN

V

RUN

523Ω

INTV

1%

CC2

470pF

LT4180

OV

FB

2.74k

1.3k

0.01µF

1%

DRAIN

5.36k

1%

CHOLD2 CHOLD3 CHOLD4

47nF

CHOLD1

COMP GND

47pF

PS2801-1

470pF

0.015µF

1%

10.7k

1M

2200pF

Figure 13. 48V → 3.3V Isolated Step-Down, Remote Sensed

Regulator. T1 Delivers Isolated Power, LT4180 Remotely

Senses Output, Supplies Feedback via Opto-Isolator

an126fa

1µF

1µF

IN

V

18V TO 72V

BAV21W

10k

4700pF

100V

100V

4.7µF

BAS516

51

50V

9.1k

Si4848DV

1Ω

1µF

IN

V

RCS1

0.033

100Ω

= INPUT COMMON

CC

GATE

SYNC

SENSE

INTV

IN

V

LTC3758

SS

VC

105k

1%

SHDN/UVLOFBRT

8.66k

1%

GND

36.5k

1%

= OUTPUT COMMON

= 4×, 470µF

LOAD

T1 = PULSE ENERGY PA1277NL

GUARD PINS NOT SHOWN

* C

AVXTPSE477M010R0050

AN126-9

Page 10

Application Note 126

Figure 14, also a VRS isolated step-down supply, uses a

commercially produced 48V isolated input module augmented with virtual remote sensing. The module sense

terminals are unused. The LT4180 wiring drop correction

is introduced at the module trim pin. Component values

are shown for 3.3 and 5V outputs. The “black box” Vicor

module trim pin transient response defi nes available control

bandwidth. Figure 15, trace A, is the trim pin input step

(see test circuit A), trace B, the module output. The trim

pin directed dynamics set practical expectations for VRS

equipped loop response around the module. Figures 16

and 17 do not disappoint. Figure 14’s load step response

appears in Figure 16. Trace A is load step current, trace B,

the resultant output voltage transient. The response envelope, bounded by module trim pin dynamics, is clean and

well controlled. Figure 17 shows Figure 14’s turn-on into

a 2.5Amp load. LT4180 activation arrests the initial abrupt

rise at the 3rd vertical division. The ascent’s conclusion

is controlled to the regulation point in damped fashion.

1µF

13.3k/

17.4k

LT4180 sampling square wave residue is just discernible

in the waveforms settled portion.

BEFORE PROCEEDING ANY FURTHER, THE READER

IS WARNED THAT CAUTION MUST BE USED IN THE

CONSTRUCTION, TESTING AND USE OF THIS CIRCUIT.

HIGH VOLTAGE, AC LINE CONNECTED POTENTIALS

ARE PRESENT IN THIS CIRCUIT. EXTREME CAUTION

MUST BE USED IN WORKING WITH AND MAKING CONNECTIONS TO THIS CIRCUIT. REPEAT: THIS CIRCUIT

CONTAINS DANGEROUS, AC LINE CONNECTED HIGH

VOLTAGE POTENTIALS. USE CAUTION.

Figure 18’s VRS aided “Off-Line” isolated output supply

has a 5V output with 2A capacity. The schematic appears

complex, but inspection reveals it to be essentially an AC

line powered variant of Figure 13’s isolated approach. The

LT4180 provides remote sensing and closes an isolated

feedback loop with optical transmission.

0.04

WIRING DROP

LOAD RETURN

WIRING DROP

+

3.3V/2.5A

5V/2A

0.4Ω TOTAL WIRING DROP

2200µF

LOAD

RETURN

523Ω/

4.64k

2.4k

48V

V

V

IN+

VI-230-EX

IN–

V

IN+

V

IN–

VICOR

MODULE

V

OUT+

V

SEN+

TRIM

V

SEN–

V

OUT–

2.74k/

1.69k

5.36k/

5.36k

10k

GUARD PINS NOT SHOWN

FB

OV

DRAIN

47pF

240k

RUN

V

COMP GND

IN

4.7nF

CHOLD1

SENSE

CHOLD2 CHOLD3 CHOLD4

0.047µF

DIV2

LT4180

3.3nF

DIV0DIV1

3.3nF

0.1µF

INTV

V

C

OSC

PP

1nF

SPREAD

R

OSC

CC

42.2k

1%

AN126 F14

1µF

Figure 14. Commercially Produced, Isolated 48V Input Module Augmented with

Virtual Remote Sense. Module Sense Terminals Are Unused. Wiring Drop Correction

Introduced at Module Trim Pin. Component Values Shown for 3.3V/5V Outputs

AN126-10

an126fa

Page 11

A = 5V/DIV

B = 0.5V/DIV

ON 5VDC

A = 2A/DIV

ON 1A DC

Application Note 126

48V

IN4148

24k

48V

RETURN

Trim Pin Pulse Test Circuit

5ms/DIV

PULSE

GENERATOR

AN126 F15

Figure 15.Vicor Module Trim Pin Transient Response Defi nes Available Control Bandwidth.

Trace A is Trim Pin Input Step (See Test Circuit), Trace B, Module Output

1V/DIV

TRIM

VICOR

VI-230-EX

SEN

SEN

+

V

LOAD

–

V

B = 0.2V/DIV

20ms/DIV

AN126 F16

Figure 16. Figure 14’s Load Step Response. Trace A is

Load Step Current, Trace B Resultant Output Voltage

Transient. Response Envelope, Bounded by Module

Trim Pin Dynamics, is Well Controlled

VRS Halogen Lamp Drive Circuit

A fi nal circuit, Figure 19, uses the VRS to stabilize drive to

a halogen lamp, in this case a 12V, 30W automotive type.

Lamp output power remains constant despite 9V to 15V

input variation and line resistance/connection uncertainties. Additional benefi ts include constant color output and

extended lamp life. The circuit, a step up/down (“SEPIC”)

converter, maintains 12V at the lamp despite the 9V to 15V

3

input range

. The VRS functions in the manner previously

described. Line resistance losses due to switches, wiring

and connectors are obviated by VRS action. Figure 20

plots unaided vs remote sensed and regulated halogen

lamp light output. VRS equipped luminosity is fl at over

the 9 to 15V input range while unregulated performance

Note 3. SEPIC operation is described in Reference 2.

20ms/DIV

AN126 F17

Figure 17. Figure 14’s Turn-On into a 2.5A Load. LT4180

Activation Arrests Initial Abrupt Rise at Third Vertical Division.

Ascent Conclusion is Controlled to Regulation Point. LT4180

Sampling Square Wave Residue is Discernible

suffers dramatically. The regulation also benefi ts lamp

life by greatly reducing lamp turn-on current. Figure 21

shows unregulated lamp turn-on exceeding 20A without

regulation. In Figure 22, regulation cuts current peaking

to 7A, a 3x reduction. This soft turn-on and constant 12V

drive under high/low line conditions optimizes illumination

and improves lamp life.

References

1. LT4180 Data Sheet, Linear Technology Corporation,

2010.

2. Ridley, R. “Analyzing the Sepic Converter”, Power

Systems Design Europe, November, 2006.

an126fa

AN126-11

Page 12

Application Note 126

200pF

IN

V

200V

62

6mH

RT1

30pF

DF06M

t

500V

200V

47µF

+

470k

T1

P6KE200A

400V

1/4W

220

150µF

+

10µF

1µH

270µF

+

MBR20200CT

7T70T

t

510

2W

MUR160E

470k

1/4W

t

1/4W

16V

16V

16V

t

BAS21

2.2nF

IN

V

12Ω

250VAC “Y”

OUT

* V

5V, 2A

0.05Ω

17T

270k

+

WIRE

R

1%

t

1/4W

270k

1/4W

1.2Ω

SPB03N60C3

IN

V

CC

INTV

2200µF

1Ω TOTAL

WIRING DROP

10µF

16V

20.5k

2N7002

1/4W

200k

1/2W

1%

1k

13V

200k

4.53k

CC

INTV

3.9

2N3904

1k

CMPZ5243B

1/2W

1µF

CC

INTV

PP

V

DIV0DIV1

DIV2

SENSE

IN

V

RUN

1%

CC

V

FB

0.47µF

150µF

+

OUT

REF

V

CC

V

18k

SPREAD

2.67k

750Ω

16V

SEN

I

VCCFB

LT4180

1%

LT1241

OV

CNY17-3

COMP

5.36k

150pF

RT/CT

DRAIN

1%

12nF

GND

0.1µF

OSC

R

OSC

C

CHOLD1 CHOLD2 CHOLD3 CHOLD4

COMP GND

1µF220pF

41.2k

0.047µF

3.3nF

100pF

1%

AN126 F11

470pF

3.3nF

10nF

0.1µF

6.8k

1M

* 100mA MINIMUM LOAD REQUIRED.

NOTE:

47µF 400V CHEMICON EKXG401ELL470ML25S

2200µF 10V SANYO 10MV2200AX

150µF 16V SANYO 16MV150AX

270µF 16V SANYO 16SEPC270M

10µF 16V TDK C3225X7RK106M

1µH VISHAY IHLP2525CZER1ROM

6mH PANASONIC ELF11M030E

2

Figure 18. A 5V Output “Off-Line” Converter Equipped with Virtual Remote Sense.

LT4180 Provides Remote Sensing, Closes Isolated Feedback Loop via Opto-Isolator

WARNING! SCREENED AREA CONTAINS LETHAL AC LINE CONNECTED HIGH

VOLTAGES. USE CAUTION IN CONSTRUCTION AND TESTING.

RT1 CANTHERM MF72-33D7

T1 PULSE PA3072NL EF20 AL = 100nH/T

DANGER!! HIGH VOLTAGE!!

AN126-12

IN

0.1µF

250VAC “X”

= AC LINE COMMON

SCREENED AREA CONTAINS LETHAL

HIGH VOLTAGES! USE CAUTION IN

90V to 264VAC

CONSTRUCTION AND TESTING!

= OUTPUT COMMON

GUARD PINS NOT SHOWN

an126fa

Page 13

Application Note 126

1µF

12V, 30W

HALOGEN LAMP

1000µF

25V

+

LOAD RETURN

WIRING DROP

1%

0.04

1 CONNECTOR/SWITCH

WIRING DROP

1µF

SPREAD

CC

INTV

PP

V

DIV0DIV1

DIV2

SENSE

IN

V

RUN

42.2k

OSC

LT4180

FB

OV

DRAIN

OSC

R

OSC

C

CHOLD1 CHOLD2 CHOLD3 CHOLD4

COMP GND

47pF

1%

150pF470pF

0.1µF

470pF47nF

47nF

13.7k

1%

AN126 F19

0.1µH

PDS1045

50V

10µF

6.8µH

IN

V

9V TO 15V

84.5k

C2X

10µF

20V

++

22µF

25Vw3CERAMIC

50V

10µF

10µF

63V

+

6.8µF

50V

1%

200k

6.8µH

4.99k

43.2k

1%

42.2k

1%

IN

V

SHDN/UVLO

CC

INTV

3.4k

1%

4.7µF

10V

4.12k

LT3757

SS

1%

Q1

Si7850DP

GATE

0.1µF

6.65k

1%

SENSE

SYNC

6.8k

0.005

RT FBX VCGND

1W

42.2k10k

100pF

Figure 19. LT4180 Step Up/Down Converter Stabilizes 12V Drive to 30W Halogen

Automotive Lamp Despite 9V → 15V Input Variation and Line Resistance Uncertainties

GUARD PINS NOT SHOWN

IHLP4040DZR6R8M11 = 6.8µH

UMK325Bd106MM-T = 10µF, 50V

TMKBd226MM-T = 22µF

C2X = ZOSVPIO

IHLP1616ABERR10M01 = 0.1µH

an126fa

AN126-13

Page 14

Application Note 126

2

KILOCANDLES/M

Figure 20. Unaided vs Remote Sensed/Regulated Halogen Lamp Light

Output. Regulation Benefi ts Include Stable Illumination, Constant Color

Output and Extended Lamp Life

14.5

14.0

12.0

10.0

8.0

6.0

2.0

4.0

WITHOUT VIRTUAL REMOTE

SENSE/REGULATOR

WITH VIRTUAL REMOTE

SENSE/REGULATOR

0

9

10 1211 13 14 15

BATTERY VOLTAGE (V)

AN126 F20

A = 5A/DIV

50ms/DIV

Figure 21. Lamp Turn-On Current Exceeds 20A

Without Regulation, Degrading Lifetime

AN126 F21

A = 5A/DIV

50ms/DIV

AN126 F22

Figure 22. Regulation Promotes Soft Turn-On, 12V Drive

Under High/Low Line Conditions, Optimizing Illumination

and Improving Lamp Life

AN126-14

an126fa

Page 15

APPENDIX A

A Primer on LT4180 VRS Operation

Application Note 126

Voltage drops in wiring can produce considerable load

regulation errors in electrical systems (Figure A1). As load

current I

increases and the voltage delivered to the system (V

increases, voltage drop in the wiring (IL • RW)

L

)

L

drops. The traditional approach to solving this problem,

remote sensing, regulates the voltage at the load, increasing the power supply voltage (V

) to compensate for

OUT

voltage drops in the wiring. While remote sensing works

well, it does require an additional pair of wires to measure

at the load, which may not always be practical.

The LT4180 eliminates the need for a pair of remote sense

wires by creating a virtual remote sense. Virtual remote

sensing is achieved by measuring the incremental change

in voltage that occurs with an incremental change in current

in the wiring (Figure A2). This measurement can be used

to infer the total DC voltage drop in the wiring, which can

then be compensated for. The Virtual Remote Sense takes

AN125 A1

FB

),

over control of the power supply via its feedback pin (V

maintaining tight regulation of load voltage V

I

L

POWER SUPPLY

+

V

OUT

–

REMOTE SENSE WIRING

RW

POWER WIRING

.

L

SYSTEM

+

V

L

–

Figure A3 shows the timing diagram for Virtual Remote

Sensing (VRS). A new cycle begins when the power

supply and VRS close the loop around V

= H). Both V

V

OUT

OUT

and I

slew and settle to a new

OUT

(Regulate

OUT

value, and these values are stored in the Virtual Remote

Sense (Track V

OUTHIGH

= L and Track I

= L). The V

OUT

OUT

feedback loop is opened and a new feedback loop is set

up commanding the power supply to deliver 90% of the

previously measured current (0.9 I

OUT

). V

drops to a

OUT

new value as the power supply reaches a new steady state,

and this information is also stored in the Virtual Remote

Sense. At this point, the change in the output voltage

(∆V

) for a –10% change in output current has been

OUT

measured and is stored in the Virtual Remote Sense. This

voltage is used during the next VRS cycle to compensate

for voltage drops due to wiring resistance.

I

L

POWER SUPPLY

V

V

FB

VIRTUAL

REMOTE SENSE

OUT

I

SENSE

+

–

RW

POWER WIRING

+

–

V

L

SYSTEM

AN125 A2

Figure A1. Traditional Remote Sensing Works Well

But Requires Two Sense Wires

V

OUT

REGULATE V

TRACK V

REGULATE I

TRACK V

OUTHIGH

TRACK I

OUT

OUT

TRACK DV

OUT

OUT

LOW

LOW

OUT

Figure A3. Simplifi ed Virtual Remote Sense Timing

Diagram. State Machine Driven Sequence Samples

and Stores Information Necessary to Set Appropriate

Power Supply Voltage to Correct for Wiring Losses

Figure A2. Virtual Remote Sensing Eliminates Sense Wires

AN126 A3

an126fa

AN126-15

Page 16

Application Note 126

APPENDIX B

Design Guidelines for LT4180 VRS Circuits

INTRODUCTION

The LT4180 is designed to interface with a variety of power

supplies and regulators having either an external feedback

or control pin. In Figure B1, the regulator error amplifi er

(which is a g

amplifi er) is disabled by tying its inverting

m

input to ground. This converts the error amplifi er into a

constant-current source which is then controlled by the

drain pin of the LT4180. This is the preferred method of

interfacing because it eliminates the regulator error amplifi er from the control loop which simplifi es compensation

and provides best control loop response.

REGULATOR

OR

I

TH

+

V

C

–

Figure B1. Nonisolated Regulator Interface

For proper operation, increasing control voltage should

correspond to increasing regulator output. For example,

in the case of a current mode switching power supply, the

control pin ITH should produce higher peak currents as

the ITH pin voltage is made more positive.

Isolated power supplies and regulators may also be used

by adding an opto-coupler (Figure B2). LT4180 output

voltage INTV

In situations where the control pin V

supplies power to the opto-coupler LED.

CC

of the regulator may

C

exceed 5V, a cascode may be added to keep the DRAIN

pin of the LT4180 below 5V (Figure B3). Use a Low VT

MOSFET for the cascode transistor.

LT4180

DRAIN

AN126 B1

AN126-16

REGULATOR

+

OPTO-COUPLER

V

C

INTV

CC

LT4180

–

DRAIN

AN126 B2

Figure B2. Isolated Power Supply Interface

TO V

C

COMP

LT4180

INTV

CC

DRAIN

AN126 B3

Figure B3. Cascoded DRAIN Pin for Isolated Supplies

an126fa

Page 17

DESIGN PROCEDURE

The fi rst step in the design procedure (Figure B4) is to

determine whether the LT4180 will control a linear or

switching supply/regulator. If using a switching power

supply or regulator, it is recommended that the supply be

synchronized to the LT4180 by connecting the OSC pin to

the SYNC pin (or equivalent) of the supply.

If the power supply is synchronized to the LT4180, the

power supply switching frequency is determined by:

f

=

OSC

Recommended values for R

4

R

OSC•COSC

are between 20k and 100k

OSC

(with 30.1k the optimum for best accuracy) and greater

. C

than 100pF for C

OSC

may be reduced to as low as

OSC

50pF, but oscillator frequency accuracy will be somewhat

degraded.

The following example synchronizes a 250kHz switching

power supply to the LT4180. In this example, start with

= 30.1k:

R

OSC

C

=

OSC

250kHz • 30.1k

4

= 531pF

This example uses 470pF. For 250kHz:

R

=

OSC

250kHz • 470pF

4

= 34.04k

Application Note 126

LT4180 DESIGN FLOW

LINEAR

WHAT TYPE OF POWER

SUPPLY/REGULATOR?

f

= 2MHz, UNLESS SYSTEM

OSC

REQUIRES ANOTHER FREQUENCY

CALCULATE f

RESPONSE TIME OR CABLE PROPAGATION TIME

D

= f

RATIO

HIGHER FREQUENCY DIVISION RATIO

(TABLE 1, DATA SHEET)

CALCULATE ACTUAL f

SELECTED DIVISION RATIO

USE ACTUAL f

AND C

HOLD1–3

CALCULATE FEEDBACK, UNDER AND

OVERVOLTAGE RESISTOR NETWORK

BUILD PROTOTYPE, ADJUST POWER SUPPLY

COMPENSATION USING LOAD STEP TESTING

WITH SPREAD SPECTRUM OFF

START

FROM POWER SUPPLY

DITHER

TO COMPUTE C

DITHER

, SET C

. USE NEAREST

OSC/fDITHER

DITHER

HOLD4

SWITCHING

IS SUPPLY

NO

SYNCHRONIZED

TO LT4180?

f

= SWITCHING

OSC

SUPPLY FREQUENCY

USING

,

LOAD

= 1µF

YES

The closest standard 1% value is 34k.

The next step is to determine the highest practical dither

frequency. This may be limited either by the response

time of the power supply or regulator, or by the propagation time of the wiring connecting the load to the power

supply or regulator.

ADJUST C

TRY SPREAD SPECTRUM IF NARROW BAND

FOR PROPER VRS RESPONSE

HOLD4

INTERFERENCE IS ANTICIPATED

DONE

Figure B4. Design Flow Chart

AN126-17

AN126 B4

an126fa

Page 18

Application Note 126

First determine the settling time (to 1% of fi nal value)

of the power supply. The settling time should be the

worst-case value (over the whole operating envelope: V

, etc.).

I

LOAD

F1 =

2•t

1

SETTLING

Hz

IN

,

For example, if the power supply takes 1ms to settle

(worst-case) to within 1% of fi nal value:

F1 =

1

2•1e–3

= 500Hz

Next, determine the propagation time of the wiring. In

order to ignore transmission line effects, the dither period

should be approximately twenty times longer than this.

This will limit dither frequency to:

V

F

Hz

F2 =

20 • 1.017ns/ft • L

where VF is the velocity factor (or velocity of propagation),

and L is the length of the wiring (in feet).

For example, assume the load is connected to a power

supply with 1000ft of CAT5 cable. Nominal velocity of

propagation is approximately 70%.

0.7

= 34.4kHz

F2 =

20 • 1.017e– 9 • 1000

After the dither frequency is determined, the minimum

load decoupling capacitor can be determined. This load

capacitor must be suffi ciently large to fi lter out the dither

signal at the load.

C

where C

R

WIRE

=

LOAD

R

WIRE

is the minimum load decoupling capacitance,

LOAD

is the minimum wiring resistance of one conductor of

the wiring pair, and f

2.2

•2• f

DITHER

DITHER

is the minimum dither frequency.

Continuing the example, our CAT5 cable has a maximum

9.38Ω/100m conductor resistance.

Maximum wiring resistance is:

R

R

= 2 • 1000ft • 0.305m/ft • 0.0938Ω/m

WIRE

= 57.2Ω

WIRE

With an oscillator tolerance of ±15%, the minimum

dither frequency is 414.8Hz, so the minimum decoupling

capacitance is:

C

LOAD

=

57.2Ω • 2 • 414.8Hz

2.2

= 46.36µF

This is the minimum value. Select a nominal value to account for all factors which could reduce the nominal, such

as initial tolerance, voltage and temperature coeffi cients

and aging.

The maximum dither frequency should not exceed F1 or

F2 (whichever is less):

f

< min (F1, F2).

DITHER

Continuing this example, the dither frequency should be

less than 500Hz (limited by the power supply).

With the dither frequency known, the division ratio can

be determined:

f

D

RATIO

=

OSC

f

DITHER

250,000

=

500

= 500

The nearest division ratio is 512 (set DIV0 = L, DIV1 =

DIV2 = H). Based on this division ratio, nominal dither

frequency will be:

f

DITHER

f

OSC

=

D

RATIO

250,000

=

512

= 488Hz

AN126-18

CHOLD Capacitor Selection and Compensation

CHOLD1

A 47nF capacitor will suffi ce for most applications. A

smaller value might allow faster recovery from a sudden

load change, but care must be taken to ensure full load

p-p ripple at this node is kept within 5mV:

CHOLD2 = CHOLD3 =

2.5nF

f

DITHER

(kHz)

For a dither frequency of 488Hz:

CHOLD2 = CHOLD3 =

2.5nF

0.488(kHz)

= 5.12nF

NPO ceramic or other capacitors with low leakage and dielectric absorption should be used for all HOLD capacitors.

Set CHOLD4 to 1µF. This value will be adjusted later.

an126fa

Page 19

Compensation

Start with a 47pF capacitor between the COMP and DRAIN

pins of the LT4180. Add an RC network in parallel with the

47pF capacitor, 10k and 10nF are good starting values.

Once the output voltage has been confi rmed to regulate at

the desired level at no load, increase the load current to the

100% level and monitor the wire current (dither current)

with a current probe. Verify the dither current resembles

a square-wave with the desired dither frequency.

If the output voltage is too low, increase the value of the

10k resistor until some overshoot is observed at the leading

edge of the dither current waveform. If the output voltage

is still too low, decrease the value of the 10nF capacitor

and repeat the previous step. Repeat this process until the

full load output voltage increases to within 1% below the

no load level. Refer to Figures B5a, B5b and B5c, which

show compensation of the 12V 1.5A Buck Regulator Application on the data sheet. Check for proper voltage drop

correction over the load range. The “dither current” should

have good half-wave symmetry. Namely, waveform should

have similar rise and fall times, enough settling time at top

and bottom and minimum to no over/undershoot.

Application Note 126

V

LOAD

11.9V

I

DITHER

50mA/DIV

OUT

AN126 B5c

with

20µs/DIV

Figure B5c. Dither Current and V

3.3nF, 28k Compensation 1.5A Load

Set Final Value of CHOLD4

Set the minimum value for CHOLD4, by performing a

transient load test of 30% to 60% of the load and set the

value of CHOLD4 to where a nicely damped waveform is

observed. Refer to Figures B6a and B6b for an illustration.

After all the CHOLD values have been fi nalized, check for

proper voltage drop correction and converter behavior

(start-up, regulation etc.), over the load and input voltage ranges.

V

LOAD

11.2V

I

DITHER

50mA/DIV

20µs/DIV

Figure B5a. Dither Current and V

10nF, 10k Compensation 1.5A Load

V

LOAD

11.9V

I

DITHER

500mA/DIV

20µs/DIV

Figure B5b. Dither Current and V

10nF, 37k Compensation 1.5A Load

OUT

OUT

AN126 B5a

with

4180 F07b

with

V

LOAD

1V/DIV

I

DITHER

500mA/DIV

10ms/DIV

AN126 B6a

Figure B6a. 500mA to 1A Transient Response

Test with CHOLD4 = 25nF CHOLD4 Too Small

V

LOAD

1V/DIV

I

DITHER

500mA/DIV

10ms/DIV

AN126 B6b

Figure B6b. 500mA to 1A Transient Response Test

with CHOLD4 = 47nF Nicely Damped Behaviour

an126fa

AN126-19

Page 20

Application Note 126

Setting Output Voltage, Undervoltage and Overvoltage

Thresholds

The RUN pin has accurate rising and falling thresholds

which may be used to determine when Virtual Remote Sense

operation begins. Undervoltage threshold should never

be set lower than the minimum operating voltage of the

LT4180 (3.1V).

The overvoltage threshold should be set slightly greater

than the highest voltage which will be produced by the

power supply or regulator:

V

OUT(MAX)

V

OUT(MAX)

= V

LOAD(MAX)

should never exceed 1.5 • V

+ V

WIRE(MAX)

LOAD

Since the RUN and OV pins connect to MOSFET input

comparators, input bias currents are negligible and a common voltage divider can be used to set both thresholds

(Figure B7).

V

R1

R2

R3

R4

IN

LT4180

RUN

FB

OV

AN126 B5

R

SERIES

R1= R

R3 =

R2 = R

Where V

⎛

1.22 • R

=

⎜

V

⎝

UVL

−R

T

SERIES

⎛

1.22V − V

SERIES

UVL

⎜

OUT(NOM)

⎝

V

OUT(NOM)

−R3

is the RUN voltage and V

−R4

R

⎞

T

−R4

⎟

⎠

R4

•

R

T

nominal output voltage desired.

For example, with V

RT=

7.5V

= 4V, VOV = 7.5V and V

UVL

= 37.5k

200µA

R4 =

1.22V

= 6.1k

200µA

R

SERIES

⎛

1.22V • 37.5k

=

⎜

⎝

4V

⎞

− 6.1k = 5.34k

⎟

⎠

R1 = 37.5k −5.34k −6.1k = 26.06k

⎞

⎟

⎠

T

OUT(NOM)

is the

OUT(NOM)

= 5V,

Figure B7. Voltage Divider for UVL and OVL

The voltage divider resistors can be calculated from the

following equations:

RT=

V

OV

200µA

,R4=

1.22V

200µA

where RT is the total divider resistance and VOV is the

overvoltage set point.

Find the equivalent series resistance for R2 and R3 (R

SERIES

).

This resistance will determine the RUN voltage level.

AN126-20

R3 =

1.22V −

⎛

5V • 6.1k

⎜

37.5k

⎝

5V

⎞

⎟

⎠

= 3.05k

37.5k

R2 = R

SERIES

−R3 = 2.29k

R

Select the value of R

SENSE

SELECTION

so that it produces a 100mV volt-

SENSE

age drop at maximum load current. For best accuracy, V

and SENSE should be Kelvin connected to this resistor.

an126fa

IN

Page 21

Application Note 126

Soft-Correct Operation

The LT4180 has a soft-correct function which insures

orderly start-up (Figure B8). When the RUN pin rising

threshold is fi rst exceeded (indicating V

has crossed

IN

its undervoltage lockout threshold), power supply output

voltage is set to a value corresponding to zero wiring voltage drop (no correction for wiring). Over a period of time

(determined by C

), the power supply output voltage

HOLD4

ramps up to account for wiring voltage drops, providing

best load-end voltage regulation. A new soft-correct cycle

is also initiated whenever an overvoltage condition occurs.

10V

5V

200ms/DIV

HOLD4

AN126 B8

= 1μF

POWER SUPPLY

OUTPUT VOLTAGE

POWER SUPPLY

INPUT VOLTAGE

Figure B8. Soft-Correct Operation, C

substantial leakage current through the leakage resistance

). By adding a guard ring driver with approximately

(R

LKG

the same voltage as the voltage on the hold capacitor node,

the difference voltage across R

is reduced substantially

LKG1

thereby reducing leakage current on the hold capacitor.

Synchronization

Linear and switching power supplies and regulators may

be used with the LT4180. In most applications regulator

interference should be negligible. For those applications

where accurate control of interference spectrum is desirable, an oscillator output has been provided so that

switching supplies may be synchronized to the LT4180

(Figure B10). The OSC pin was designed so that it may

directly connect to most regulators, or drive opto-isolators

(for isolated power supplies).

REGULATOR

LT4180

OSCSYNC

AN126 B10

Using Guard Rings

The LT4180 includes a total of four track/holds in the

Virtual Remote Sense path. For best accuracy, all leakage

sources on the CHOLD pins should be minimized.

At very low dither frequencies, the circuit board layout

may include guard rings which should be tied to their

respective guard ring drivers.

To better understand the purpose of guard rings, a simplifi ed

model of hold capacitor leakage (with and without guard

rings) is shown in Figure B9. Without guard rings, a large

difference voltage may exist between the hold capacitor

(Pin 1) node and adjacent conductors (Pin 2) producing

R

LKG

12

WITHOUT

GUARD RING

Figure B9. Simplifi ed Leakage Models

(with and without Guard Rings)

R

LKG1

12

WITH

GUARD RING

R

LKG2

AN126 B9

Figure B10. Clock Interface for Synchronization

Spread Spectrum Operation

Virtual remote sensing relies on sampling techniques.

Because switching power supplies are commonly used, the

LT4180 uses a variety of techniques to minimize potential

interference (in the form of beat notes which may occur

between the dither frequency and power supply switching frequency). Besides several types of internal fi ltering,

and the option for VRS/power supply synchronization, the

LT4180 also provides spread spectrum operation.

By enabling spread spectrum operation, low modulation index pseudo-random phasing is applied to

Virtual Remote Sense timing. This has the effect of

converting any remaining narrow-band interference into

broadband noise, reducing its effect.

Increasing Voltage Correction Range

Correction range may be slightly improved by regulating

INTV

V

to 5V. This may be done by placing an LDO between

CC

and INTVCC. Contact Linear Technology Applications

IN

for more information.

an126fa

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

AN126-21

Page 22

Application Note 126

AN126-22

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

an126fa

LT 1212 REV A • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2011

Loading...

Loading...