Page 1

LTC3220/LTC3220-1 User’s Guide

by Marty Merchant

Application Note 115

February 2008

INTRODUCTION

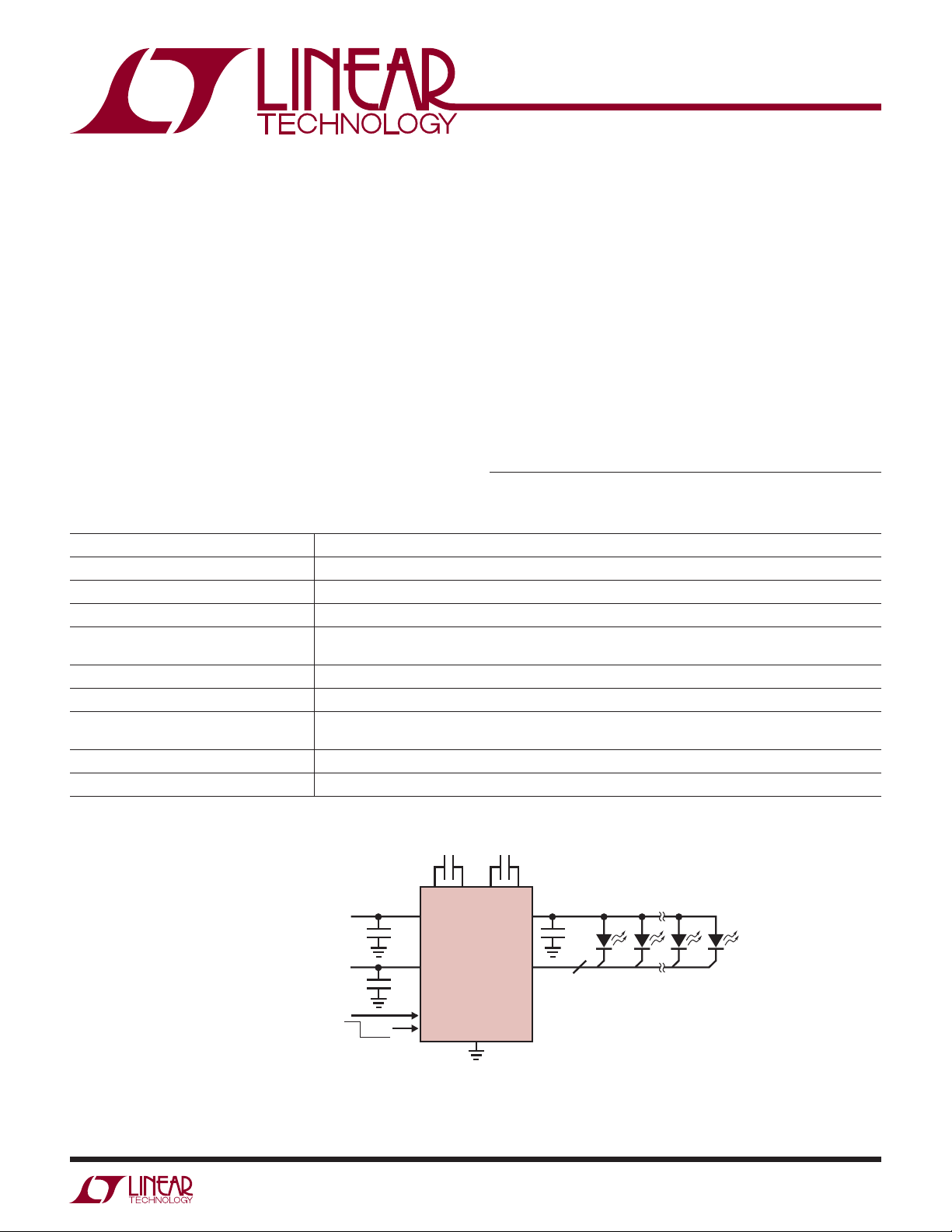

This application note illustrates how to program and use

the unique features of the LTC3220/LTC3220-1 Universal

LED (ULED) Driver. These features include individually

controlling, gradually turning on and off, or blinking up to

18 LEDs. This device may also be used to provide digital

signal(s) to other devices while in shutdown using a strong

pull-down general purpose output (GPO) and an external

power source. Current limited GPO mode may also be used

to control other devices using the charge pump output

(CPO) of the device or an external supply. A programmable

shutdown feature allows the device to go into and out

of shutdown returning to its pre-shutdown state. These

features give the user vast fl exibility and control of LEDs

and other devices while saving memory space, program-

2

ming time, I

L, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

C traffi c, and even battery power.

Table 1. Features of LTC3220

FEATURE BENEFITS

18 Separate Outputs 18 Individually Controlled 20mA Current Sources with 64-Step Linear Dimming Control

Blink Mode Blinks One of Four Blinking Patterns

Gradation Gradually Turns On and Off LEDs

2

GPO Mode (Strong) • I

GPO Mode (Current Limited) I2C Controlled Open Drain Drivers with Adjustable Current Limit

External Reset Resets All Internal Registers and Forces Part into Shutdown

Programmable Shutdown • I

Auto Switching Charge Pump Automatically Switches to 1x, 1.5x, or 2x Modes for Better Effi ciency

Forced Charge Pump Mode May Be Programmed to Remain in 1x, 1.5x, or 2x Mode

C Controlled Open Drain Drivers

• Operates in Shutdown, Low Q Current

2

C Controlled Shutdown

• Data Registers Retain Data and Outputs Return to Previous State when Shutdown Terminates

DV

C2

2.2μF

C1P C1M

V

IN

CC

I2C

RESET

C1

2.2μF

0.1μF

V

IN

DV

CC

SCL/SDA

RST

C3

2.2μF

C2P C2M

LTC3220

LTC3220-1

ULED1-18

GND

AN115 F01

Figure 1. Typical LTC3220 Application

CPO

C4

4.7μF

18

an115fa

AN115-1

Page 2

Application Note 115

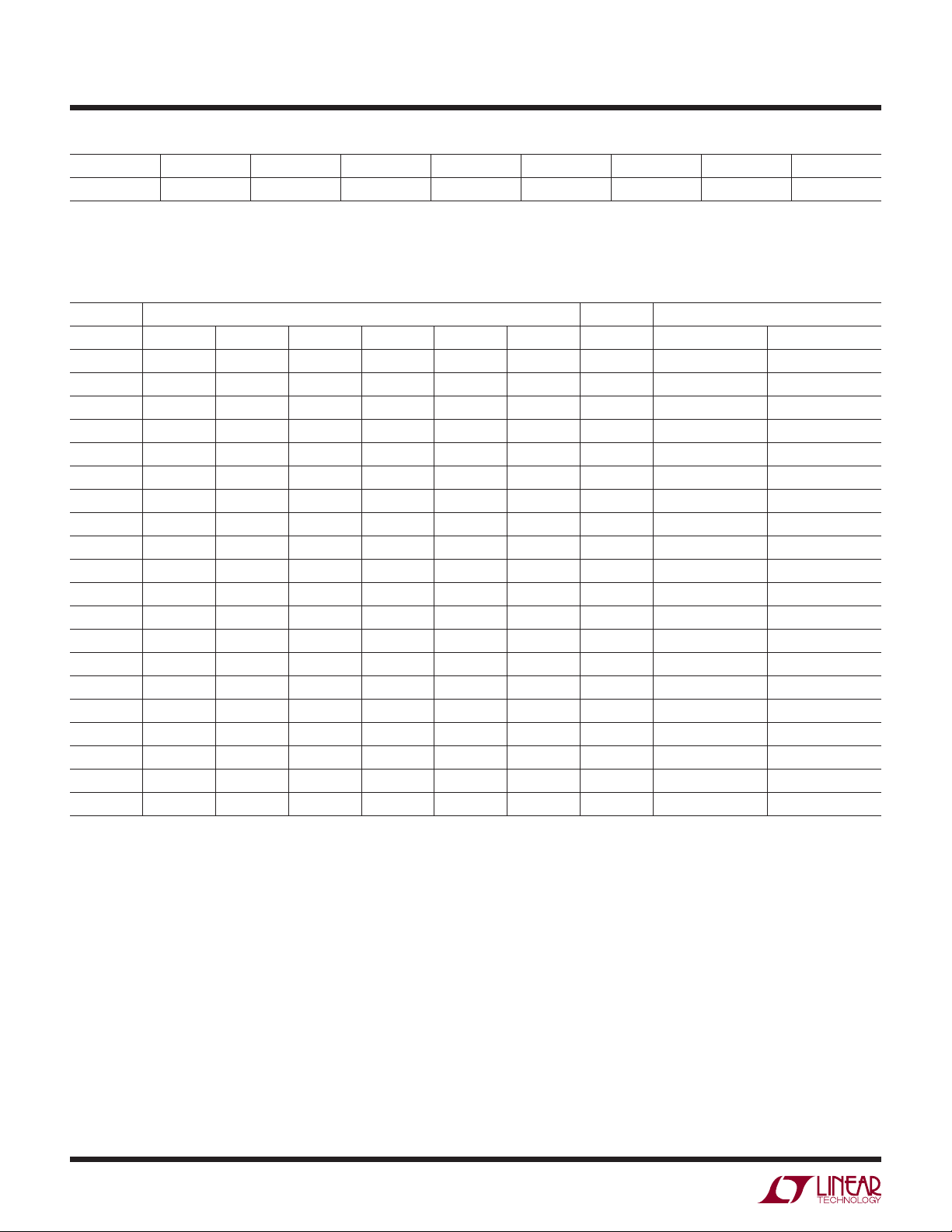

Table 2. Write Word Protocol Used By the LTC3220/LTC3220-1

171181811

S Slave Address Wr A *Sub-Address A Data Byte A P**

S = Start Condition, Wr = Write Bit = 0, A = Acknowledge, P = Stop Condition

*The sub-address uses only the fi rst 5 bits, D0, D1, D2, D3 and D4.

**Stop can be delayed until all of the data registers have been written.

Table 3. Sub-Address Byte Assignment

MSB LSB

76543210Register Function

00000000 REG0 COMMAND

00000001 REG1 ULED1

00000010 REG2 ULED2

00000011 REG3 ULED3

00000100 REG4 ULED4

00000101 REG5 ULED5

00000110 REG6 ULED6

00000111 REG7 ULED7

00001000 REG8 ULED8

00001001 REG9 ULED9

00001010 REG10 ULED10

00001011 REG11 ULED11

00001100 REG12 ULED12

00001101 REG13 ULED13

00001110 REG14 ULED14

00001111 REG15 ULED15

00010000 REG16 ULED16

00010001 REG17 ULED17

00010010 REG18 ULED18

00010011 REG19GRAD/ BLINK

I2C Control

The LTC3220/LTC3220-1 has 20 data registers, each with

its own sub-address as shown in Table 3. The data is

loaded into the registers when the device receives a Stop

2

bit. This device is written using the standard I

C protocol

(a 7-bit slave address and write bit, followed by the 8-bit

sub-address byte and an 8-bit data byte) as illustrated

2

in Table 2. This device is a slave I

C device that can only

receive data.

The only difference between the LTC3220 and the

2

LTC3220-1 is the 7-bit I

address is 0011100 and the LTC3220-1 I

C address. The LTC3220 I2C

2

C address is

0011101.

AN115-2

DATA BYTES

Register 0 (Table 4 and Table 5) is used to enter or exit

shutdown, set the charge pump to Auto, Force 1x, Force

1.5x, or Force 2x modes, and to parallel write to the part

using the Quick Write bit. Register 1 through register 18 set

the intensity and mode for each of the eighteen individual

ULED outputs (Table 6). Register 19 is separated into three

portions as illustrated in Table 7, Table 8 and Table 9. The

blink bits, D4 and D3, are used to select the blinking ontime and period. The gradation timer bits, D2 and D1, are

used to control the gradation time while the Up bit, D0, is

used to control the gradation ramp direction.

an115fa

Page 3

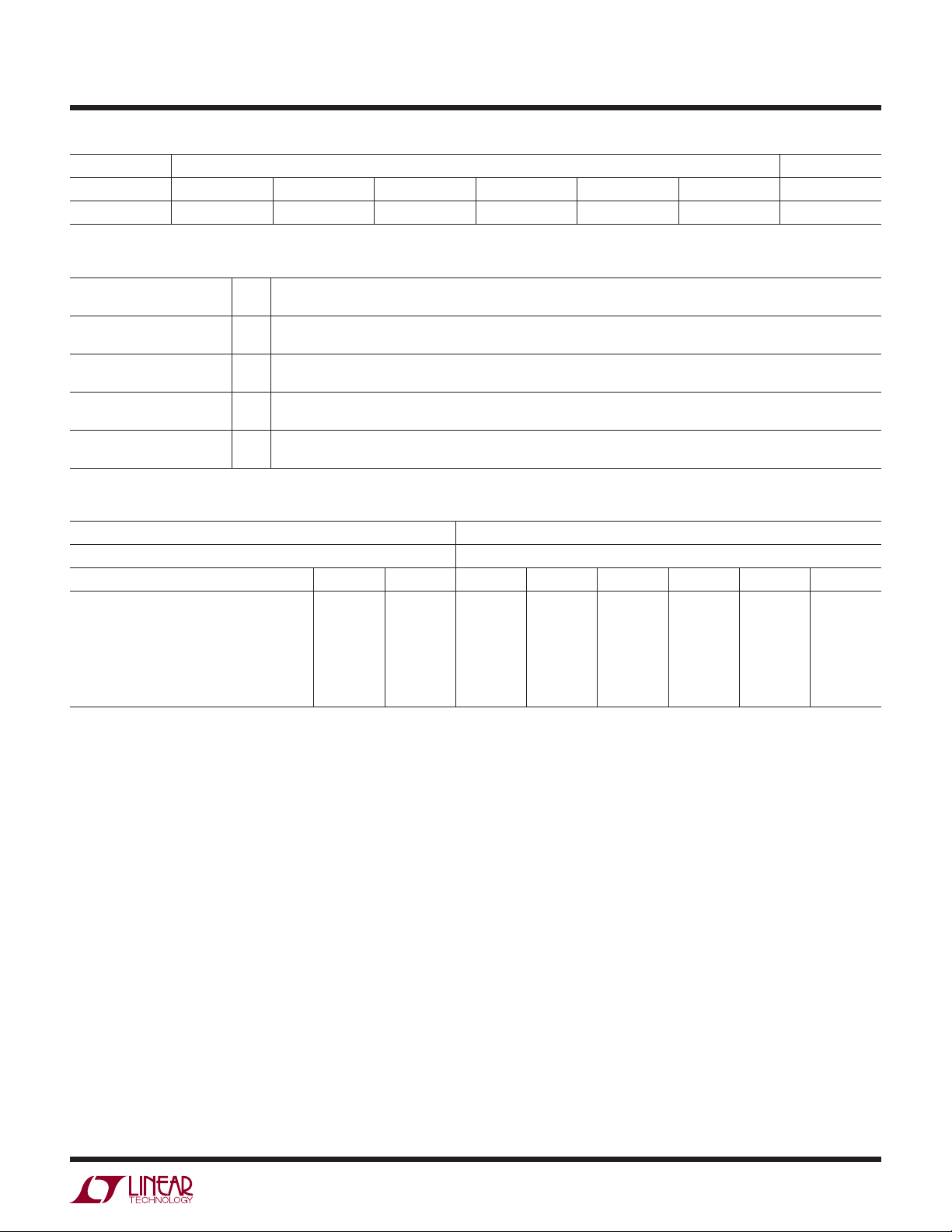

Application Note 115

Table 4. REG0, Command Byte

MSB LSB

D7 D6 D5 D4 D3 D2 D1 D0

Unused Unused Unused Unused Shutdown Force2x Force1p5x Quick Write

Table 5. Command Byte Bit Functions

Quick Write 01Serial Write to Each Register

Force1p5x 10Forces Charge Pump into 1.5x Mode

Force2x 10Forces Charge Pump into 2x Mode

Force1x D1 (Force1p5x) =1

Shutdown 10Shuts Down Part, While Preserving Data in Registers

Table 6. REG1 to REG18, Universal LED 6-Bit Linear DAC Data with Blink/Gradation/GPO Modes

BLINK/GRADATION/GPO MODE BITS LED CURRENT DATA

Normal

Blink Enabled

Gradation Enabled

GPO Mode*

Strong Pull-Down Mode

Current Limited Mode

High Impedance/OFF

*(Gradation/Blink/Dropout Disabled)

Parallel Write, REG1 Data Is Written to All Eighteen Universal Registers

Enables Mode Logic to Control Mode Changes Based on Dropout Signal

Enables Mode Logic to Control Mode Changes Based on Dropout Signal

Forces Charge Pump into 1x Mode

D2 (Force2x) = 1

Normal Operation

MSB LSB

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

}

0

0

1

1

1

0

0

1

0

1

1

0

D5

D5

D5

0

D5

0

D4

D4

D4

0

D4

0

D3

D3

D3

0

D3

0

D2

D2

D2

D2

D1

D1

D1

0

0

0

D1

0

D0

D0

D0

0

D0

0

an115fa

AN115-3

Page 4

Application Note 115

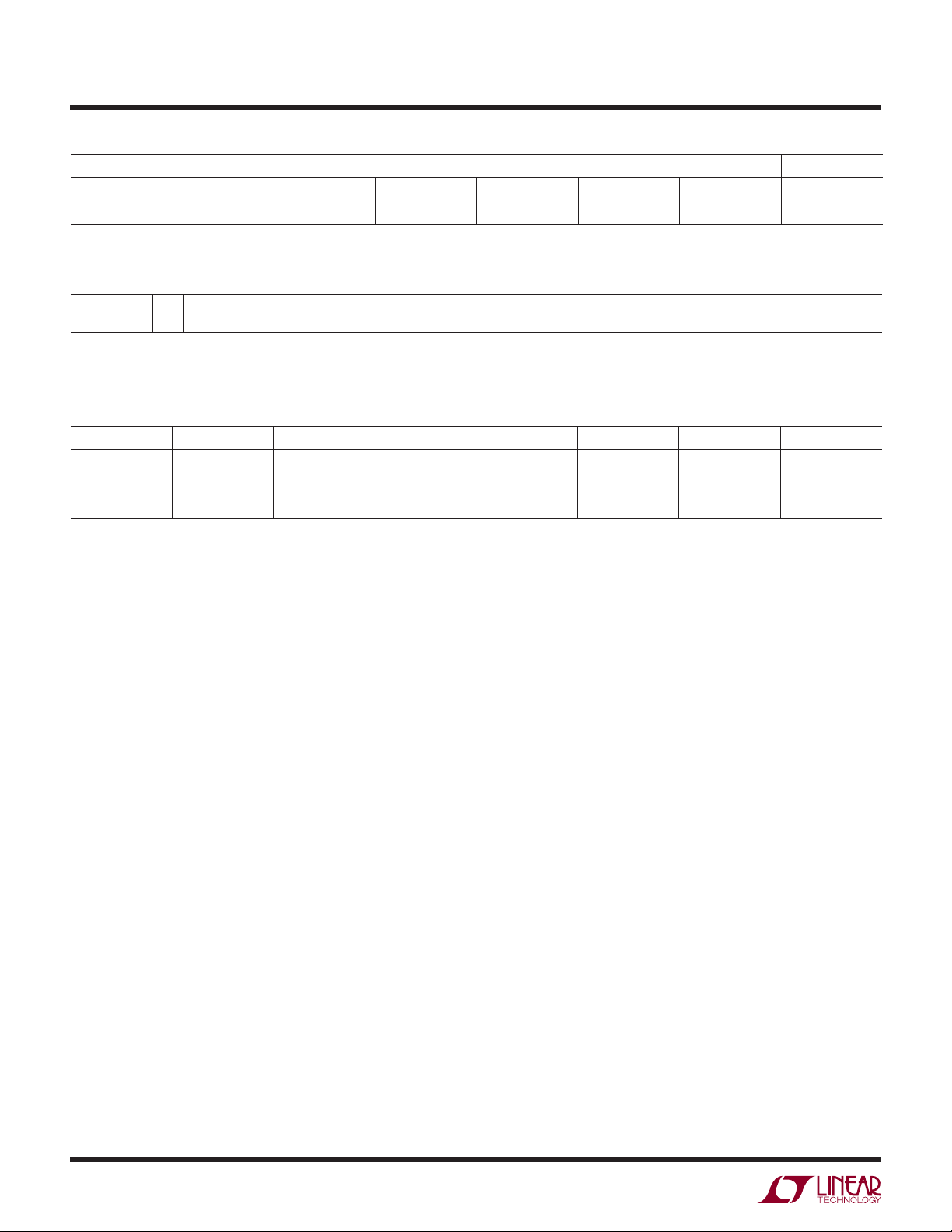

Table 7. REG19, Gradation and Blinking Register

MSB LSB

D7 D6 D5 D4 D3 D2 D1 D0

Unused Unused Unused GB4 GB3 GB2 GB1 UP

Table 8. Gradation Up Bit

UP 01Gradation Counts Down

Table 9. Gradation and Blinking Register Bit Functions

D4 D3 Blink Period D2 D1 Times Period

0

0

1

1

Gradation Counts Up

BLINK TIMES AND PERIOD GRADATION TIMES AND PERIOD

0

1

0

1

0.625s

0.156s

0.625s

0.156s

1.25s

1.25s

2.5s

2.5s

0

0

1

1

0

1

0

1

Disabled

0.24s

0.48s

0.96s

Disabled

0.313

0.625

1.25

AN115-4

an115fa

Page 5

Application Note 115

DEVICE SETUP AND OPERATION

This device requires an input supply of 2.9V to 5.5V and

a DV

supply of 1.5V to 5.5V. Refer to the LTC3220/

CC

LTC3220-1 data sheet for electrical connections and

specifi cations. Although the power on reset clears all the

data registers, it is good practice to reset the part using the

RST pin to make sure all data registers are reset after V

and/or DV

be used to clear all ULED registers with few I

power up. The Quick Write feature may also

CC

2

C writes.

IN

SET ONE OR MORE ULED OUTPUT(S)

2

To set one or more ULED output(s) using the I

C bus,

write the intensity setting to the desired ULED registers

with the mode enable bits (Bit 7 and Bit 6) low, followed

by a Stop bit. The following example illustrates how to set

ULED1 and ULED2 to 5mA. Since the full-scale current is

20mA, use the following formula to determine the number

of steps needed to acquire 5mA.

Steps = ILED • StepsFullScale/IFullScale (1)

5mA • 63Steps/20mA = 15.75 Steps

The number of steps is rounded to 16 and converted to

the hexadecimal value 10H. Setting the ULED register to

10H will set the ULED output to approximately 5mA. In

Example 1, the “S” designates the Start Bit and 38H des-

2

ignates the LTC3220 7-bit I

C address plus the write bit to

form the 8-bit hexadecimal byte of 38. For the LTC3220-1,

2

substitute 3AH in place of 38H for the I

C address. The

second hexadecimal bytes, 01 and 02, are the sub-address

bytes. The third hexadecimal byte is the register data byte.

The “P” designates the Stop bit. The Stop bit was set after

the last write to load ULED1 and ULED2 registers and set

the ULED outputs simultaneously. A Stop bit may be used

2

after each I

C write, however it is not desired in some

cases while gradating. All of the following examples will

use the same format used in Example 1.

Example 1. Setting ULED1 and ULED2 to 5mA.

S 38H 01H 10H* ‘Set ULED1 to 5mA, No Stop bit

needed

S 38H 02H 10H P ‘Set ULED2 to 5mA, Stop bit

loads data

*A Stop bit may be used here if desired.

USING THE GPO FEATURE

This device has two GPO modes: the Current Limited GPO

mode limits the output current from 0.4mA to 20mA in

63 steps and the Strong Pull-Down GPO mode acts like

a switch. The GPO modes may be used as an open drain

output to drive a logic signal to a microprocessor or some

other device. This is accomplished by allowing the ULED

pin to be driven to 0V without causing the charge pump

to change modes.

If the device is forced into shutdown while in Current

Limited GPO mode, the output is disabled and the supply current will be reduced to a few hundred microamps.

This mode is useful for driving other devices which are

not to be controlled during shutdown, or to control the

current to other devices which would otherwise cause the

LTC3220/LTC3220-1 to go into dropout. When a Current

Limited GPO is used as an open drain output, the current

setting should be set greater than the maximum current

needed. However a current setting greater than 10 times

the maximum current may increase the quiescent current

by more than 10%.

To set one or more ULED output(s) to Current Limit GPO

mode, write the intensity setting greater than 0mA to

the desired ULED registers with the GPO mode enable

bits (Bit 7 and Bit 6) high, followed by a Stop bit. It was

determined using formula (1) that 3 steps are required to

provide 1mA, therefore the hexadecimal code needed to

provide 1mA of current in GPO mode is C3H. Example 2

illustrates how to set ULED1 and ULED2 to 1mA Current

Limited GPO mode.

an115fa

AN115-5

Page 6

Application Note 115

Example 2. Set ULED1 and ULED2 to 1mA in Current

Limited GPO mode.

S 38H 01H C3H* ‘Set ULED1 to 1mA in GPO mode

S 38H 02H C3H P ‘Set ULED2 to GPO mode, Stop

bit loads data

*A Stop bit may be used here if desired.

In Strong Pull-Down GPO mode, the current is not limited

by the device and needs to be limited externally to 25mA or

less. The advantage of this mode is that it only uses 3μA

of quiescent current and may be used while the part is in

shutdown. CPO should not be used for supplying current

to a Strong Pull-Down GPO during shutdown since CPO

is limited by a weak pull-up current source. To set one or

more ULED output(s) to Strong Pull-Down GPO mode,

write the intensity setting of 0mA to the desired ULED

registers with the GPO enable bits high as illustrated in

Table 6. A Stop bit loads the data and sets the output.

Example 3 illustrates how to set ULED1 and ULED2 into

Strong GPO mode.

of shutdown, the ULED outputs will start blinking in the

“off” state. To set one or more ULED output(s) blinking,

set the blinking rate in register 19, and then set the ULED

register(s) and blinking bit with the desired intensity. Send

a Stop bit to start the ULED output(s) blinking. The blink

rate may be changed at any time by changing the blink

bits in register 19. Example 4 shows how to start ULED1

and ULED2 blinking.

Example 4. Setting ULED1 and ULED2 to blink at 5mA

with a 2.5s period and a 0.625s on-time.

S 38H 13H 10H* ‘Set blinking time to 0.625s on,

2.5s period

S 38H 01H 50H* ‘Set ULED1 to blink at 5mA

S 38H 02H 50H P ‘Set ULED2 to blink, Stop bit

loads all data

*A Stop bit may be used here if desired.

USING GRADATION

Example 3. Set ULED1 and ULED2 to Strong GPO

mode.

S 38H 01H C0H* ‘Set ULED1 to Strong GPO mode

S 38H 02H C0H P ‘Set ULED2 to Strong GPO mode,

Stop bit loads data

*A Stop bit may be used here if desired.

USING THE BLINKING FEATURE

Blinking LEDs may be used to indicate voicemail messages, missed calls, low battery, or other messages. The

LTC3220/LTC3220-1 has a blinking feature that allows the

user to choose between one of four different blinking rates

as illustrated in Table 9. This feature reduces processor

2

time and I

C traffi c. The blinking times are controlled by

a single free running counter. When one or more ULED

outputs are set to blink, they will synchronously blink with

the blinking timer. The ULED outputs may start blinking in

the “on” or the “off” state except when the part is coming out of shutdown. When the device starts blinking out

It is sometimes desirable to gradually turn on and off LEDs

2

or displays. Normally substantial I

C bus time is required

to gradually turn on and off LEDs. The LTC3220/LTC3220-1

has a gradation feature that allows the user to smoothly

2

turn on and off LEDs with little I

C interaction. This device

uses a single gradation ramp to gradate one or more

LED(s) from off-to-on or from on-to-off simultaneously.

Ideally the ULED gradation enable bit and the gradation

timer are enabled at the same time as described in the

following procedures. If the gradation mode bit is set in

the ULED register prior to starting the gradation timer,

the ULED outputs will provide a 100μA current which will

cause the LEDs to turn on.

Gradation consists of a gradation time and a gradation

period. The gradation period is the time that the gradation

timer is running. The gradation timer starts running as

soon as the gradation timer bits are loaded into register

19 and stops after a set amount of time. The gradation

time is when the LED current starts to change to when it

stops changing. This typically starts 40ms after the gradation timer has started and is approximately 80% of the

AN115-6

an115fa

Page 7

Application Note 115

gradation period. The gradation period can be observed

on the down gradation ramp as shown in Figure 2. The

gradation period shown in Figure 2 is 670ms and the

gradation time is about 570ms.

I

LED

5mA/DIV

SCL

SDA

START OF

GRADATION

PERIOD

END OF

GRADATION

PERIOD

100ms/DIV

Figure 2. 625ms Gradation Period

AN115 F02

GRADATING ONE OR MORE ULED OUTPUT(s) UP

FROM OFF-TO-ON

To gradate one or more ULED output(s) from the off-to-on

2

state via the I

C bus, the gradation timer bits in register

19 (D2 and D1) should be initialized to 0. Set the ULED

register to the desired intensity with the gradation bit (Bit 7)

set without sending a Stop bit. Then set the gradation time

and the gradation Up bit (D0) high in register 19. The Stop

bit loads the registers and starts the gradation process.

Example 5 illustrates how to gradate ULED1 and ULED2

from 0mA to 5mA. Figure 3 illustrates how a ULED output

current is ramped from 0mA to 5mA at 0.48s.

Example 5. Gradating ULED1 and ULED2 from 0mA to

5mA at 0.48s:

S 38H 13H 00H P ‘Clear gradation timer if not

already clear

S 38H 01H 90H** ‘Set ULED1 to gradate to 5mA

S 38H 02H 90H** ‘Set ULED2 to gradate to 5mA

Prior to disabling the gradation timer or gradating up any

other ULED outputs, the gradation bits in the ULED register must be cleared

. This is accomplished by writing an

intensity value with the gradation bit cleared as illustrated

in Example 6

Example 6. Disabling gradation with ULED1 and

ULED2 at 5mA.

S 38H 01H 10H* ‘Set ULED1 to 5mA with

gradation bit low

S 38H 02H 10H* ‘Set ULED2 to 5mA with

gradation bit low

S 38H 13H 00H P ‘Disable gradation, Stop bit loads

all data

*A Stop bit may be used here if desired.

GRADATING ONE OR MORE ULED OUTPUT(S) DOWN

FROM ON-TO-OFF

The gradating down procedure is similar to the gradating

up procedure except the initial state of the ULED output

and the state of the Up bit in register 19. One advantage

of the LTC3220/LTC3220-1 compared to its predecessors

is that the ULED registers are automatically set to 0 when

the gradation down ramp completes. This allows the ULED

outputs to turn off and the part to go into shutdown with-

2

out any additional I

ULED output(s) from the on-to-off state via the I

C interaction. To gradate one or more

2

C bus,

the gradation timer in register 19 (D2 and D1) should be

initialized to 0. Set the ULED register to the initial intensity

with the gradation bit (D7) set without sending a Stop

bit. Then set the gradation time and the gradation Up bit

(D0) low in register 19 followed by a Stop bit as shown

in Example 7. The Stop bit loads the registers and starts

the gradation process. Figure 4 illustrates how the ULED

current gradates down from 5mA to 0mA in 0.48s.

S 38H 13H 05H P ‘Set gradation time to 0.48s and

set the Up Bit, Stop bit starts

gradation

**A Stop bit may be used here but is not desired

an115fa

AN115-7

Page 8

Application Note 115

SDA

2V/DIV

SCL

2V/DIV

I

LED

1mA/DIV

100ms/DIV

Figure 3. Gradation from 0mA to 5mA in 0.48s

SDA

2V/DIV

SCL

2V/DIV

I

LED

1mA/DIV

100ms/DIV

Figure 4. Gradation from 5mA to 0mA in 0.48s

AN115 F03

AN115 F04

USING QUICK WRITE

The Quick Write feature allows the user to control all 18

2

ULED outputs simultaneously with few I

C commands by

parallel writing the 18 ULED registers. This feature may be

used to set, clear, blink, gradate, or set the ULED outputs

into GPO mode. To set (or clear) all ULED outputs using

the Quick Write feature, fi rst set the Quick Write bit in the

Command register. Then set the ULED1 register to the

desired value. When done using the Quick Write feature,

clear the Quick Write bit. Example 8 illustrates how to clear

all of the ULED registers using the Quick Write feature.

Example 8. Clear all ULED registers using the Quick

Write Feature.

S 38H 00H 01H* ‘Set the Quick Write Bit

S 38H 01H 00H P ‘Load the ULED1 Register

with 00H

S 38H 00H 00H P*** ‘Clear Quick Write Bit, Stop bit

Sets all Registers to 0

*A Stop bit may be used here if desired.

Example 7. Gradating ULED1 and ULED2 from 5mA

to 0mA at 0.48s (ULED1 and ULED2 previously set to

10H, 5mA).

S 38H 13H 00H P ‘Clear gradation timer if not

already clear

S 38H 01H 90H** ‘Set ULED1 with gradation bits

S 38H 02H 90H** ‘Set ULED2 with gradation bits

S 38H 13H 04H P ‘Set gradation timer with Up bit

low and start gradation

**A Stop bit may be used here but is not desired

See Appendix A for more information on gradation and

gradation programming techniques.

***This step is only need if the Quick Write feature is no

longer needed.

All ULED outputs may be set to blink or GPO mode using

the Quick Write feature by setting the mode enable bits

when loading the ULED1 register as shown in Example

8. However, the desired blinking time should be selected

prior to enabling all ULED outputs in blink mode.

AN115-8

an115fa

Page 9

Application Note 115

USING PROGRAMABLE SHUTDOWN

The programmable shutdown allows the user to shutdown

the device at anytime while maintaining the data in all of

the data registers. During shutdown, all ULED outputs

not in Strong GPO mode will turn off, CPO will connect

via a weak switch, and the LTC3220/LTC3220-1 will

to V

IN

only consume about 3uA. When the device comes out of

shutdown, all ULED outputs and the charge pump will

return to their pre-shutdown state. If the ULED output

was set to blink, it will start blinking starting with the off

cycle at the previously selected on-time and period. If a

ULED output was set to gradate up, it will gradate up at

the previously selected gradation time. If shutdown was

programmed after a ULED output has completed a gradation down cycle, the output will remain off when shutdown

ends. If shutdown was programmed while a ULED output

was gradating down, the gradation ramp will reset and the

ULED output will go to the previous set intensity and then

SDA

2V/DIV

SCL

2V/DIV

START

SHUTDOWN

gradate down at the set gradation time. Figure 5 shows

how a gradation down cycle is reset if shutdown is set

before the gradation cycle completes.

CONCLUSION

The LTC3220/LTC3220-1 features are designed to give the

user more control of LEDs or other devices while minimizing

2

C bus time and battery power. The blinking and gradation

I

features allow the user to provide visual effects without

2

extensively using the I

C bus. The Strong GPO mode allows the user to control other devices while using only

3μA of quiescent current when the part is in shutdown.

The Quick Write feature allows all of the outputs to be

2

changed at once with little I

C interaction. The shutdown

feature puts the device into shutdown and will return the

device to its pre-shutdown state. All these features make

controlling complex illumination schemes easier.

STOP

SHUTDOWN

RESTART

GRADATION

CYCLE

ULED

I

LED

1mA/DIV

Figure 5. Shutdown Set During a Gradation Down Cycle

OFF

50ms/DIV

AN115 F05

an115fa

AN115-9

Page 10

Application Note 115

APPENDIX A: MORE GRADATION TECHNIQUES

CONTINUOUSLY GRADATING ONE OR MORE ULED

OUTPUT(S) UP AND DOWN

It may be desired to continuously gradate a ULED output

up and down. This may be achieved by fi rst initiating the

gradation as in Example 5 or Example 7. To gradate down

again after gradating up, clear the Up bit in register 19.

Do not clear the gradation timer bits in register 19 or the

gradation enable bit in the ULED register. If it is desired

to change the gradation ramp time, the gradation timer

bits may be changed when clearing the Up bit in register

19. Example 9 illustrates how to gradate back down again

without resetting the gradation enable bit or gradation

timer bits.

Example 9. Gradating down after gradating up as

illustrated in Example 5.

S 38H 13H 04H P ‘Clear Up bit, Stop bit starts

gradation ramp down

To gradate back up after gradating down is similar to gradating one or more ULED outputs up. The only difference

is that the gradation timer does not have to be reset as in

Example 5. Gradating back up is done by setting the ULED

intensity and the gradation bit without a Stop bit. Then set

the gradation Up bit and gradation timer in register 19,

as illustrated in Example 10. If a different gradation rate

is desired, the gradation time may be changed when the

Up bit is set in register 19.

Example 10. Gradating ULED1 and ULED2 back up to

5mA after gradating down.

CONTINUOUSLY GRADATING ONE OR MORE ULED

OUTPUT(S) UP AND DOWN WITH STOP BITS AFTER

2

EVERY I

C WRITE

If a Stop bit must be set after the ULED registers are written when gradating up and prior to setting the gradation

timer and Up bit, one of two results will occur. If the device

went into shutdown after gradating down, then the ULED

output(s) will jump to the destination gradation current

after the ULED register data and Stop bit are received. The

ULED will remain at this setting until the gradation timer

is set. This may cause an LED to fl ash briefl y. Figure 6

illustrates how a ULED output current jumps after loading

the ULED register until the gradation timer is set with a

clock speed of 100KHz. This fl ash may be reduced to tens

2

of microseconds by using a 400KHz I

C clock and reducing

the delay between bytes and start and stop bits.

SDA

2V/DIV

SCL

2V/DIV

1ST STOP BIT

I

LED

1mA/DIV

200μs/DIV

Figure 6. Gradating Up After Gradating Down and Going Into

Shutdown. Stop Bit After 1st Stop Bit Causes ULED Output to

Jump Until Gradation Timer Is Set with 2nd Stop Bit

2ND STOP BIT

START

GRADATION

CYCLE

AN115 F06

S 38H 01H 90H** ‘Set ULED1 to gradate to 5mA

S 38H 02H 90H** ‘Set ULED2 to gradate to 5mA

S 38H 13H 05H P ‘Set Up bit, Stop bit starts

gradation

**A Stop bit may be used here but is not desired

AN115-10

an115fa

Page 11

Application Note 115

When a part is not in shutdown after the gradating down

and the ULED register data and a Stop bit were received,

the ULED output will provide a 100μA current until the

gradation timer is loaded. This 100μA output state may

2

be reduced by using a 400KHz I

C clock and reducing the

delay between bytes, Start, and Stop bits. Figure 7 illustrates how a ULED output provides 100μA after loading

the ULED register until the gradation timer is set with a

clock speed of 100kHz.

SDA

2V/DIV

SCL

2V/DIV

200μs/DIV

2ND START BIT

STARTS GRADATION

AN115 F07

1ST STOP BIT

I

LED

500μA/DIV

Figure 7. Gradating Up After Gradating Down and Device Does

Not Go into Shutdown

ULED STARTS AT 100μA

GRADATING MULTIPLE ULED OUTPUTS IN SAME

DIRECTION CONSECUTIVELY

It may be desired to gradate a number of ULED outputs

in the same direction consecutively. This is easily done,

however since there is only one gradation ramp one gradation cycle must be completed prior to starting the next.

To gradate multiple ULED outputs up consecutively, fi rst

initiate gradation as done in Example 5. After the gradation cycle has completed, disable gradation as done in

Example 6, then start the next ULED output gradating as

done in Example 5.

Gradating down consecutive ULED outputs is even less

complicated since the ULED registers are cleared automatically after the gradation cycle has completed. To do this,

gradate the fi rst ULED output down as illustrated in Example

7. Wait until the gradation down cycle has completed and

then clear the gradation timer. Now gradate the next ULED

down again as shown in Example 7.

GRADATING USING QUICK WRITE

The Quick Write feature may also be used to gradate up or

down. This process is similar to setting the ULED outputs

in normal mode using the Quick Write feature except the

gradation time is set prior to sending a Stop bit. The ULED

outputs may also be gradated up and down consecutively

by leaving the Quick Write bit set, changing the Up bit in

register 19, and reloading the ULED1 register prior to the

up gradation. Example 11 illustrates how to consecutively

gradate all ULED outputs up and down using the Quick

Write feature.

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

an115fa

AN115-11

Page 12

Application Note 115

Example 11. Gradate all ULEDs Up and Down using

the Quick Write Feature.

S 38H 00H 01H* ‘Set the Quick Write Bit

S 38H 01H 90H** ‘Load the ULED1 Register

with 90H

S 38H 13H 05H P ‘Set the Gradation Timer and

Up Bit, Stop Bit starts gradation

Wait for gradation period to fi nish.

S 38H 13H 04H P ‘Clear the gradation Up Bit,

Stop Bit starts gradation

Wait for gradation period to fi nish.

S 38H 01H 90H** ‘Load the ULED1 Register

with 90H

S 38H 13H 05H P ‘Set the Gradation Timer and

Up Bit, Stop Bit starts gradation

S 38H 00H 00H P*** ‘Clear Quick Write Bit

*A Stop bit may be used here if desired.

**A Stop bit may be used here but is not desired

***This step is only need if the Quick Write feature is no

longer needed.

SDA

2V/DIV

SCL

2V/DIV

1ST STOP BIT

ULED STARTS AT 100μA

I

LED

500μA/DIV

Figure 8. Start of Up Gradation when a Stop Bit Is Received

After the ULED Register Data Is Received

2ND START BIT

STARTS GRADATION

500μs/DIV

AN115 F08

If it is not possible to delay the Stop bit until after the data

is loaded when gradating down, set the ULED registers

with a Stop bit and then set the gradation timer and clear

the Up bit in register 19 with as little delay as possible

between writes. Although the ULED outputs will provide

100μA within tens of microseconds of the corresponding

Stop bit, all of the ULED outputs will return to their initial

state and gradate down together after the gradation timer

is loaded. Figure 9 illustrates how the ULED output current

will behave when a Stop bit is sent after the ULED register

is written to using a 100kHz clock speed with a 400μs

delay between writes. This 100μA state may be reduced by

using a 400kHz clock and by reducing the delay between

bytes and start and stop bits.

2

GRADATING WITH STOP BITS AFTER EVERY I

C WRITE

If it is not possible to delay the Stop bit until after the data

is loaded when gradating up, set the ULED registers with

a Stop bit and then set the gradation timer and Up bit in

register 19 with as little delay as possible between writes.

Although the ULED outputs will turn on at 100μA within

several hundreds of microseconds, all of the ULED outputs

will gradate together after the gradation timer is loaded.

Figure 8 shows the ULED output current at 100μA until

the gradation timer is set in register 19 using a 100kHz

2

C clock. The duration of this 100μA current state may

I

be reduced by using a 400kHz I2C clock and reducing the

delay between bytes and start and stop bits.

Linear Technology Corporation

AN115-12

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

SDA

2V/DIV

SCL

2V/DIV

I

LED

1mA/DIV

1ST STOP BIT

100μA

STAT E

200μs/DIV

Figure 9. Start of Gradation from 5mA to 0mA with A Stop Bit

After Writing the ULED Register

© LINEAR TECHNOLOGY CORPORATION 2008

2ND STOP BIT

START

GRADATION

AN115 F09

LT 0308 REV A • PRINTED IN USA

an115fa

Loading...

Loading...