Page 1

Application Note 7

February 1985

Some Techniques for Direct Digitization of Transducer Outputs

Jim Williams

Almost all transducers produce low level signals. Normally,

high accuracy signal conditioning amplifi ers are used to

boost these outputs to levels which can easily drive cables,

additional circuitry, or data converters. This practice raises

the signal processing range well above the error fl oor,

permitting high resolution over a wide dynamic range.

Some emerging trends in transducer-based systems are

causing the use of signal conditioning amplifi ers to be

reevaluated. While these amplifi ers will always be useful,

their utilization may not be as universal as it once was.

In particular, many industrial transducer-fed systems are

employing digital transmission of signals to eliminate

noise-induced inaccuracies in long cable runs. Additionally, the increasing digital content of systems, along with

pressures on board space and cost, make it desirable to

digitize transducer outputs as far forward in the signal chain

as possible. These trends point toward direct digitization

of transducer outputs—a diffi cult task.

Classical A/D conversion techniques emphasize high level

input ranges. This allows LSB step size to be as large

as possible, minimizing offset and noise-caused errors.

For this reason, A/D LSB size is almost always above a

millivolt, with 100μV to 200μV per LSB available in a few

10V full-scale devices. The requirements to directly A/D

convert the output of a typical strain gauge transducer are

illuminating. The transducer ’s full-scale output is 30mV,

meaning a 10-bit A/D converter must have an LSB increment of only 30μV. Performing a 10-bit conversion on a

type K thermocouple monitoring a 0°C to 60°C environment

proves even more stringent. The type K thermocouple

puts out 41.4μV/°C over the 0°C to 60°C range. The LSB

increment is found by:

60 41 4

°°

CμVC

•. /

These examples furnish extraordinarily small step sizes,

far below commercially available A/D units and seemingly

impossible to digitize without DC preamplifi cation. In fact,

both transducers’ outputs may be directly digitized to stable

10-bit resolution using circuitry specifi cally designed for

the function.

This application note details circuit techniques which

directly digitize the low level outputs of a variety of transducers. The approaches described are unique in that they

do not utilize any DC gain stage. The transducer outputs

receive no DC signal conditioning; A/D conversion is directly

performed at low level. The circuits produce a serial data

output which may be transmitted over a single wire with

the characteristic noise immunity of digital systems. By

eliminating the traditional DC gain stage, these circuits

furnish a direct, economical way to digitize low level

transducer outputs without sacrifi cing performance.

1024

242

=

μV LSB

./

an7f

AN7-1

Page 2

Application Note 7

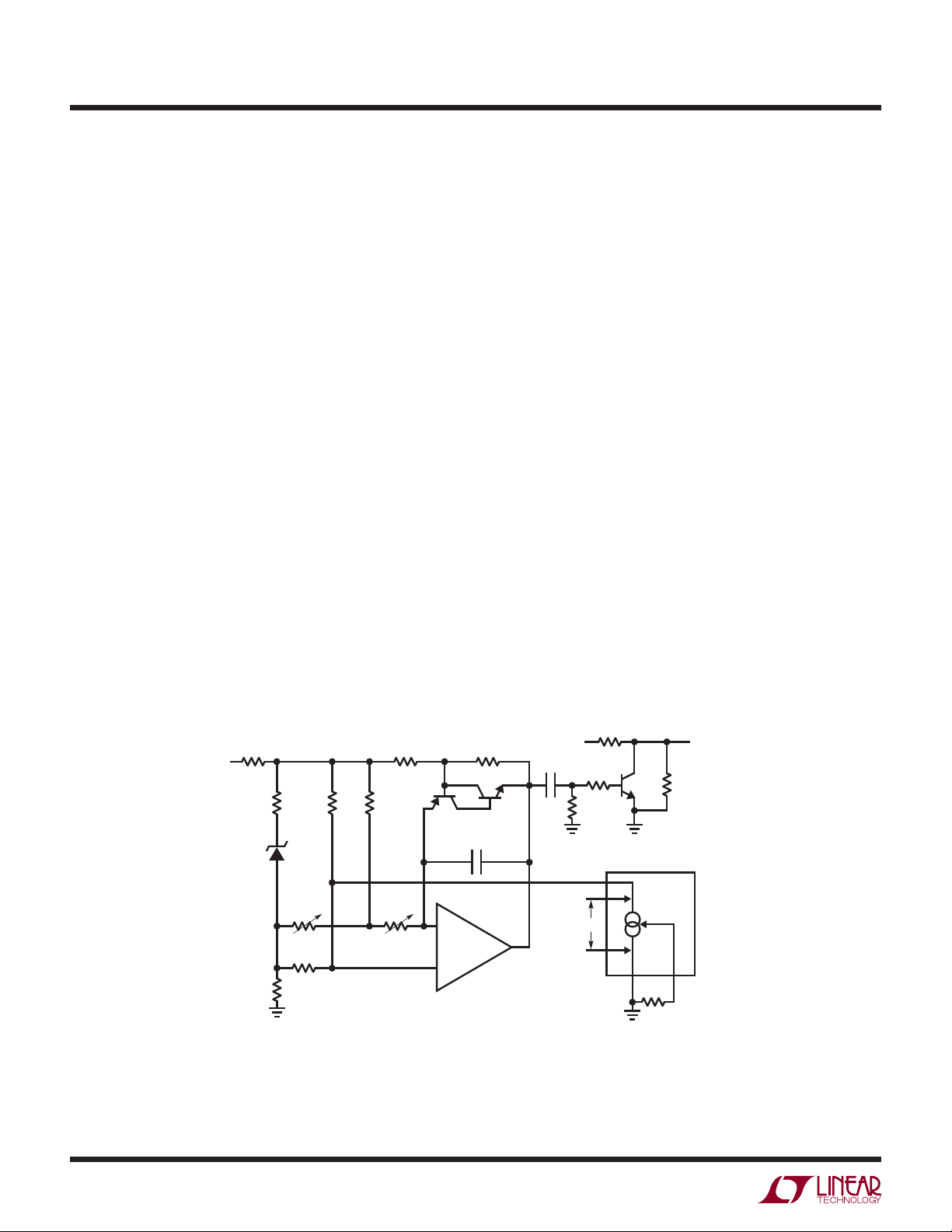

Figure 1 shows a simple way to convert the current output

of an LM334 temperature sensor to a corresponding output

frequency. The sensor pulls a temperature-dependent current (0.33%/°C) from A1’s positive input node. This point,

biased from the LM329-driven resistor string, responds

with a varying, temperature-dependent voltage. The voltage

varies the operating point of A1, confi gured as a self-resetting integrator. A1 integrates the LM329 referenced current

into its summing point, producing a negative-going ramp

at its output. When the ramp amplitude becomes large

enough, the transistors turn on, resetting the feedback

capacitor and forcing A1’s output to zero. When the capacitor’s reset current goes to zero, the transistors go off and

A1 begins to integrate negatively again. The frequency of

this oscillation action is dependent on A1’s DC operating

point, which varies with the LM334’s temperature. The

circuit’s DC biasing values are arranged so that a 0°C to

100°C sensor temperature excursion produces 0kHz to

1kHz at the output. Additionally, only 2V appear across

the LM334, minimizing sensor power dissipation related

errors. The differentiator-transistor network at A1’s output

provides a TTL compatible output. To calibrate this circuit,

place the LM334 in a 0°C environment and trim the “0°C

adjust” for 0Hz. Next, put the LM334 in a 100°C environment and set the “100°C adjust” for 1kHz output.

Repeat this procedure until both points are fi xed. This circuit

has a stable 0.1°C resolution with ±1.0°C accuracy.

Figure 2 shows another temperature-to-frequency converter, but this circuit uses the popular type K thermocouple as

a sensor. The design includes cold junction compensation

for the thermocouple over a 0°C to 60°C range. Accuracy

is ±1°C and resolution is 0.1°C.

The thermocouple’s extremely low output (41.4μV/°C) and

the requirement for cold junction compensation make it

one of the most diffi cult transducers to directly digitize.

The approach used is based on the 50nV/°C input offset

®

drift performance of the LTC

1052 chopper-stabilized

amplifi er.

In this circuit, A1’s positive input is biased by the thermocouple. A1’s output drives a crude V→F converter,

comprised of the 74C04 inverters and associated components. Each V→F output pulse causes a fi xed quantity

of charge to be dispensed into a 1μF capacitor from the

100pF capacitor via the LTC1043 switch. The larger capacitor integrates the packets of charge, producing a DC

voltage at A1’s negative input. A1’s output forces the V→F

converter to run at whatever frequency is required to balance the amplifi er’s inputs. This feedback action eliminates

drift and nonlinearities in the V→F converter as an error

560 1k* 1k*

15V

6.2k* 6.2k* 6.2k*

LM329

500Ω

0°C ADJ

820Ω*

510Ω

Figure 1. Temperature-to-Frequency Converter

2k

100°C ADJ

0.01

POLYSTYRENE

–

A1

LT1056

+

*1% FILM RESISTOR

NPN = 2N2222

PNP = 2N2907

510pF

15V

10k

2V

2.7k

10k

TTL OUT

0kHz TO 1kHz

0°C TO 100°C

4.7k

LM334-3

137Ω*

AN07 F01

an7f

AN7-2

Page 3

–

+

TYPE K

THERMOCOUPLE 41.4μV/°C

OPTIONAL INPUT

FILTER-OVERLOAD

CLAMP

50k

60°C TRIM

A

A1 LTC1052

STABILIZING AMP

1N914100k

1μF

150k**

†

COLD JUNCTION BIAS

0.1μF

33k**

1μF

301k*487Ω*

3

2

+

LTC1052

–

1

5V

–5V

7

4

16

LTC1043

8

2

6

0.1μF

3300pF

100pF

CHARGE

PUMP

65

R

T

COLD JUNCTION TEMPERATURE TRACKING

1.8k*

33k

1μF

74C04

0.68μF

74C04

4.75k*

1k*

1N4148

A

10k

5V

F

–5V

LT1004

1.2V

Application Note 7

470Ω

B

74C04C74C04D74C04E74C04

820pF

VmF

5V

3k

OUTPUT

0Hz TO 600Hz

0°C TO 60°C

187Ω*

0.01% FILM-TRW MAR-6

*

TRW/MTR/5/ + 120

**

= YELLOW SPRINGS INST. #44007

R

T

100pF = POLYSTYRENE

†

FOR GENERAL PURPOSE (1mV FULL-SCALE)

10-BIT A/D, REMOVE THERMOCOUPLE—

COLD JUNCTION NETWORK, GROUND POINT A

AND DRIVE LTC1052 POSITIVE INPUT

Figure 2. Thermocouple-to-Frequency Converter

term and the output frequency is solely a function of the

DC conditions at A1’s inputs. The 3300pF capacitor forms

a dominant response pole at A1, stabilizing the loop.

A1’s low drift eliminates offset errors in the circuit, despite

an LSB value of only 4.14μV (0.1°C)!

, a thermistor, and the 1.8k, 187Ω, 487Ω and 301k

R

T

values form a cold junction compensation network which

®

is biased from the LT

1004 1.2V reference. In addition

to cold junction compensation, the network provides

offsetting, permitting a 0°C sensor temperature to yield

0Hz at the output.

AN07 F02

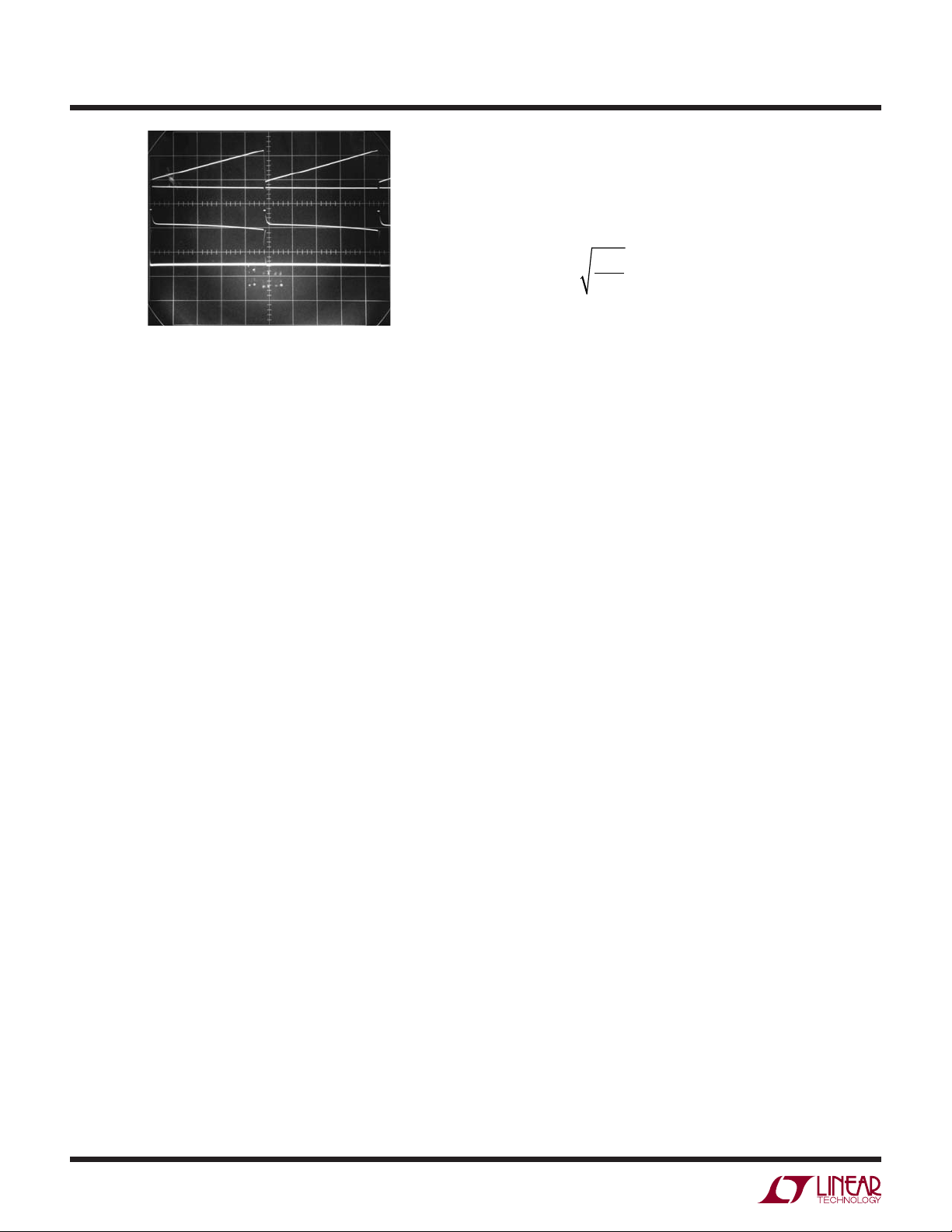

Figure 3 details circuit operation. A1’s output drives the

33k-0.68μF combination, producing a ramp (Trace A,

Figure 3) across the capacitor. When the ramp crosses

inverter A’s threshold, the cascaded inverter chain switches,

producing a low output at E (Trace B). This causes the

0.68μF capacitor to discharge through the diode, resetting

the capacitor to 0V. The 820pF unit provides positive AC

feedback to inverter B’s input (Trace C), assuring a clean

reset. The frequency of this ramp-and-reset sequence varies

with A1’s output. Inverter F ’s output controls the LTC1043

switch. When the inverter output is high, Pins 2 and 6 are

connected, allowing the 100pF capacitor to charge to a

an7f

AN7-3

Page 4

Application Note 7

A = 100mV/DIV

B = 10V/DIV

C = 10V/DIV

Figure 4 is another temperature measuring circuit, but

the transducer used is unusual. The circuit measures

temperature by utilizing the relationship between the

speed of sound and temperature in a medium. In dry air

the relationship is governed by:

D = 10μA/DIV

HORIZONTAL = 200μs/DIV

Figure 3. Thermocouple Digitizer Waveforms

AN07 F03

potential derived from the LT1004 1.2V reference. When

the inverter goes low, Pin 2 is connected to Pin 5. During

this interval, the 100pF capacitor completely discharges

(Trace D) into the 1μF unit. The amount of charge delivered

is constant over each cycle (Q = CV), so the voltage the

1μF capacitor charges to is a function of frequency and

discharge path resistance. This voltage is summed with

the LT1004-derived offsetting potential at A1’s negative

input, closing a loop around A1. The –120ppm/°C drift

of the 100pF charge-dispensing polystyrene capacitor is

compensated by the opposing tempco of the specifi ed

resistors used in the 1μF’s discharge path. Typical circuit

gain is 20ppm/°C, allowing less than 1LSB (0.1°C) output

drift over a 0°C to 70°C ambient operating range.

The thermocouple’s known characteristics, combined with

A1’s low offset and the cold junction/offsetting network

components specifi ed, eliminate zero trimming. Calibration

is accomplished by placing the thermocouple in a 60°C

environment and adjusting the 50kΩ potentiometer for

a 600Hz output. Beyond 60°C the cold junction network

departs from the thermocouple’s response and output

error increases rapidly. Although the digital output will

be a function of the thermocouple’s temperature over

hundreds of degrees, linearization by a monitoring processor is required.

It is worth noting that this circuit can directly convert any

low level, single-ended signal. If the offsetting/cold junction

network is removed and the 50kΩ potentiometer returned

directly to ground, inputs may be applied to A1’s positive

terminal. The circuit produces a 10-bit accurate output

with a full-scale range of only 1mV (1μV per LSB)! The

high impedance of A1’s input allows fi ltering or overload

clamping of the input signal without introducing error.

C = 331 5,

T

meters/second

273

where C = speed of sound.

Acoustic thermometry is used where extremes in operating temperature are encountered, such as cryogenics and

nuclear reactors. Additionally, acoustic temperature standards have been built by operating the acoustic transducer

inside a sealed, known medium.

The inherent time domain operation of acoustic thermometers allows a direct conversion into a digital output.

Figure 4 shows a circuit that does this. A1, the inductor,

and their associated components for a simple fl yback

type regulated 200V supply which biases the transducer.

The transducer is composed of the Polaroid ultrasonic

element noted, mounted at one end of a sealed, 6-inch

long Invar tube. The Invar material minimizes mechanical

tube deformation with temperature. The medium inside

the tube is dry air. The transducer may be thought of as a

capacitor, composed of an insulating disc with a conductive coating on each side.

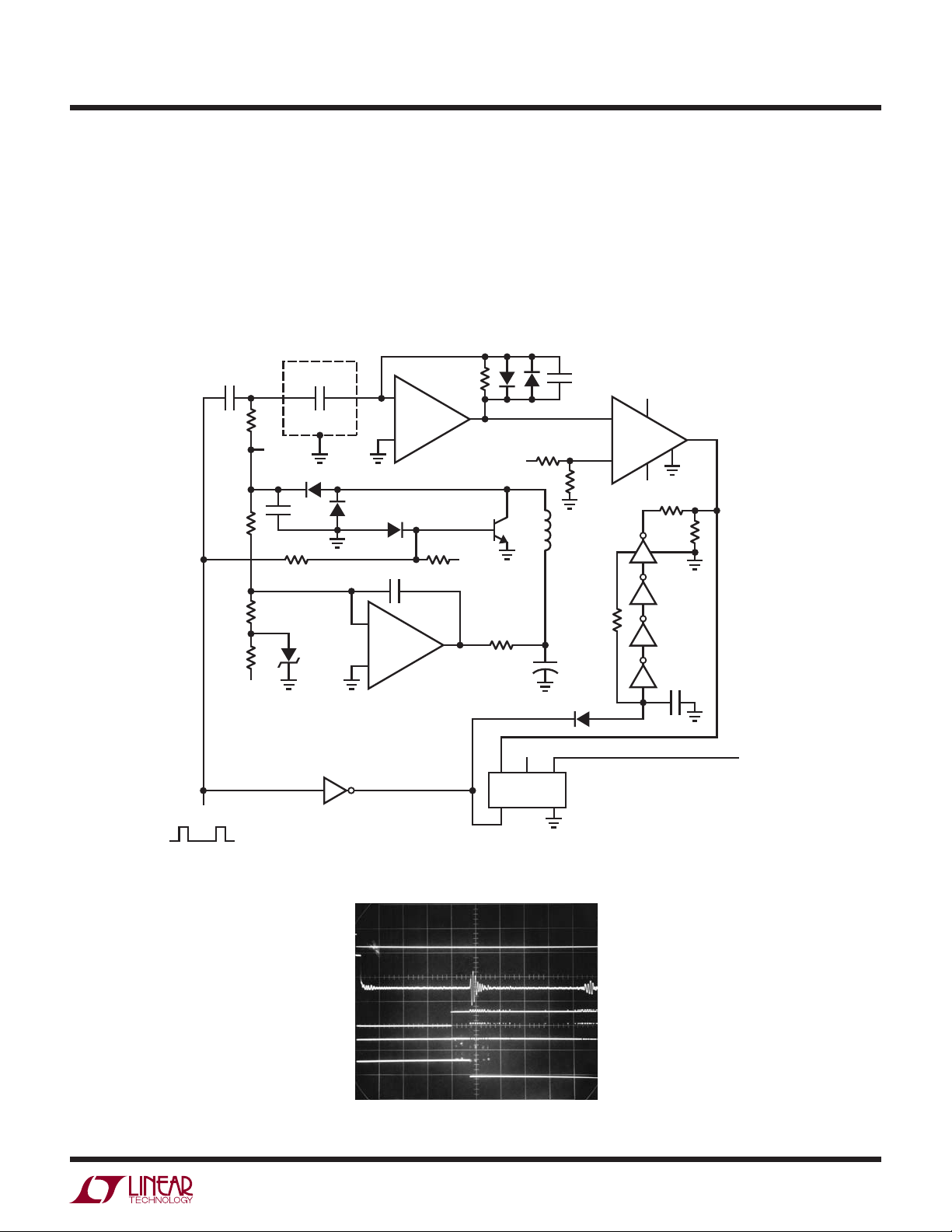

Each time the TTL clock (Trace A, Figure 5) goes high,

the transducer receives AC drive via the 0.22μF capacitor.

This drive causes mechanical movement of the disc and

ultrasonic energy is emitted. The clock input simultaneously sets the 74C74 fl ip-fl op output (Trace E) low and

pulls the 0.01μF capacitor to ground. This cuts off drive

to C1’s 3k output pull-up resistor (Trace C), forcing C1’s

output (Trace D) to zero. During the clock pulse’s period,

A2’s output (Trace B) is saturated due to excessive signal

at its input. When the clock pulse ceases, A2 comes out

of bound and amplifi es in its linear region. The ultrasonic

transducer now acts like a capacitance microphone, with

the 200V supply providing bias. Residual disc ringing is

picked up and appears at A2’s output. This signal cannot

trigger C1, however, because the 0.01μF capacitor has not

charged high enough to allow the inverter to chain output

to bias C1’s output pull-up resistor.

AN7-4

an7f

Page 5

Application Note 7

The ultrasonic energy emitted by the transducer travels

down the tube, bounces off the far end and heads toward

the transducer. Before it returns, the 0.01μF capacitor

crosses the inverter’s threshold and C1’s 3k resistor

(Trace C) receives bias. Upon returning, the sonic energy

causes a mechanical displacement of the transducer, forcing a shift in capacitance. This capacitance shift causes

charge to be displaced into C2’s summing point, and the

INVAR

TUBE

0.22

600V

100M**

ENCLOSURE

TRANSDUCER

10k

200V

1N645

0.01

2k 39k

1N645

1N914

0.02

–

LT1056

+

10M

A2

–15V

output responds with an amplifi ed version of this signal

(Trace B). C1’s output (Trace D) triggers, resetting the fl ipfl op. The fl ip-fl op’s output pulse (Trace E) represents the

transit time down the tube and will vary with temperature

according to the equation given. A monitoring processor

can convert this pulse width into the desired temperature

information.

1N4148

15V

2N3440

10pF

14.7k

250Ω

L

–

+

15V

15V

C1

LT1011

–15V

7

1

3k

22k

INPUT

TTL CLOCK INPUT

100Hz, 10μs

–15V

1.2M*

10k

LT1004

2.5V

1/6 74C04

A = 20V/DIV

B = 20V/DIV

C = 20V/DIV

D = 20V/DIV

–

100Ω

15V

R Q

74C74

S

+

22

1N4148

LM307

+

A1

Figure 4. Acoustic Thermocouple

180k

L = AIE VERNITRON-24-104 1MHy

TRANSDUCER = POLAROID-604029

ENCLOSURE = INVAR 6" TUBE SEALED, DRY AIR

*

1% FILM RESISTOR

**

VICTOREEN #MOX-300

74C04

0.01

WIDTH

OUTPUT

E = 20V/DIV

HORIZONTAL = 200μs/DIV

Figure 5. Acoustic Thermocouple Waveforms

AN07 F05

an7f

AN7-5

Page 6

Application Note 7

In the photograph another received signal, lower in

amplitude, is visible at the extreme right-hand side of

Trace B. Its position in time identifi es it as a second bounce

return from the tube’s far end. Also, note the increased

detected noise level after the return of the fi rst bounce.

This is due to sonic energy dispersion inside the tube.

The transducer picks up energy defl ected from the tube

walls, which is phase shifted from the desired signal. C1

is seen to respond to these unwanted signal sources, but

the circuit’s fi nal pulse output is unaffected. Additionally,

the time window gating supplied to C1’s pull-up resistor

greatly reduces the likelihood of false triggering due to

noise coming from outside the tube.

DIRECTLY ACROSS

1000pF

1

3

+

LM301A

2

–

7

5V

CONNECT

BRIDGE DRIVE

POINTS

8

6

4

–5V

BRIDGE DRIVE

1k

100k

10k

STRAIN GAUGE

TRANSDUCER

= 350Ω

Z

IN

= 350Ω

Z

OUT

20Ω

2N2905

CONNECT TO BRIDGE

END OF 470k RESISTOR

(OPTIONAL)

TRANSDUCER ZERO

NETWORK

5V

20Ω

1N4148

–5V

3.3M

1000pF

470k*

3.3M*

1/2 LTC1043

SW1

11

12

SW2

Temperature sensors are not the only transducers which can

be directly digitized. Strain gauge transducers account for a

large class of pressure and force measurements. Typically,

a strain gauge bridge-based transducer produces 3mV of

full-scale output per volt of bridge drive. Figure 6 shows

a way to directly digitize a strain gauge bridge’s output

to 10-bit accuracy. For a 7.5V bridge drive, an LSB increment is 25μV, considerably larger than the thermocouple

example but still far below conventional A/D converters.

The bridge’s differential output complicates the required

converter input structure, but is accommodated.

5V

28k

–5V

INTEGRATOR

–

2

LTC1052

3

+

1

0.1μF

87

16

DATA OUTPUT =

*0.1% METAL FILM TRW MAR-5

1413

SW1 = MAIN CURRENT SWITCH

SW2 = CURRENT LOADING COMPENSATION SWITCH

5V

–5V

74C00

14k

CLOCK

7

62

8

4

0.1μF

OUT A

OUT B

0.003μF

5V

14 1 473

1/2 74C74

–5V

= 1000 COUNTS FULL SCALE

10k

5

6

OUTPUT GATING

FREQUENCY

OUT B

5V

FREQUENCY

OUT A

–5V

AN7-6

22.3k*

1k* 33

AN07 F06

Figure 6. Strain Gauge Digitizer

+

an7f

Page 7

Application Note 7

A1 and the transistor provide bridge excitation. One signal

output of the bridge is connected to A1’s negative input.

A1’s positive input is at ground. A1 drives the transistor to

bias the bridge at whatever voltage is required to bring its

negative input to ground potential. The diode drops in the

bridge’s –5V return line allow the transistor to force the

bridge’s positive end far enough to servo A1’s inputs. This

arrangement allows the bridge’s other output to be sensed

in a single-ended, ground-referred fashion. In practice, a

slight error exists due to A1’s offset voltage. This error

is eliminated by referring the A/D converter input to A1’s

negative input instead of ground.

The A/D converter is made up of A2, a fl ip-fl op and some

gates. It is based on a current balancing technique. Once

again, the chopper-stabilized LTC7652’s 50nV/°C input drift

is required to implement the low level input A/D. Figure 7

details key A/D waveforms. Assume the fl ip-fl op’s Q output (Trace B) is low, connecting LTC1043 Pins 11 and 12

to Pins 7 and 13, respectively. The main current switch

passes no current, as the 3.3M resistor is placed across

A2’s inputs. The current loading compensation switch puts

a 3.3M value across the 1k divider resistor, lowering the

voltage across it by 0.03%.

Under these conditions the only current into A2’s summing

point is from the bridge via the 470k resistor. This positive

current forces A2’s output (Trace A, Figure 7) to integrate

in a negative direction. The negative ramp continues and

fi nally passes the 74C74 fl ip-fl op’s switching threshold. At

the next clock pulse (clock is Trace C), the fl ip-fl op changes

state (Trace B), causing the LTC1043 switch positions to

reverse. Pin 12 connects to Pin 14 and Pin 11 to Pin 8.

In this case, the 3.3M resistor, controlled by the current

loading compensation switch, is disconnected from the

1k unit, but the 3.3M value, controlled by the main current switch, replaces it. The 0.03% loading of the 3.3M

resistor, combined with this switching scheme, eliminate

any sag or loading effects across the 1k resistor during

switching. The result is a quickly rising, precise current

fl ow out of A2’s summing point.

This current, scaled to be greater than the bridge’s maximum output, forces A2’s output movement to reverse and

integrate in the positive direction. At the fi rst clock pulse

after A2’s output has crossed the fl ip-fl op’s triggering

threshold, switching occurs and the entire cycle repeats.

Because the reference current is fi xed, the fl ip-fl op’s duty

cycle is solely a function of the bridge signal current into

A2’s summing point. Additionally, the reference current

is supplied from the 22.3k-1k divider, which is derived

from the bridge drive. Thus, the A/D’s reference current

varies ratiometrically with the bridge output, eliminating

bridge drive variations as an error source. The fl ip-fl op’s

output gates the clock, producing the “frequency output A”

waveform (Trace D). The 10k resistor combines with the

output gate’s input capacitance to slightly delay the clock

signal, eliminating spurious output pulses due to fl ip-fl op

delay. The circuit’s data output, the ratio of output A to the

clock frequency, may be extracted with counters. Because

the output is expressed as a ratio, clock frequency stability

is unimportant.

A = 100mV/DIV

B = 10V/DIV

C = 10V/DIV

D = 10V/DIV

HORIZONTAL = 2ms/DIV

Figure 7. Strain Gauge Digitizer Waveforms

AN07 F07

an7f

AN7-7

Page 8

Application Note 7

Several subtle factors are critical in setting up and using this

circuit. The 470k input resistor at A2 has been selected to

produce less than 1LSB loading error on the strain gauge

bridge. The bridge receives only about 7.5V of drive due to

the deliberate resistor and diode drops in its supply lines.

At 3mV output per volt of bridge drive, full-scale signal is

22.5mV. This produces a signal current of only:

.

470

nV

V

k

48

48

pA==

nA==

0 0225

I

To maintain 10-bit accuracy, leakage and amplifi er bias

current into A2’s summing point must be less than 0.1%

of this fi gure or:

48

I

1000

Although A2’s bias current is much lower than this, board

leakage can cause trouble. At a minimum, careful layout

and a clean PC board are required. The best practice is to

use a Tefl on stand-off for all summing point connections.

The 470k and 3.3M resistors associated with A2’s negative input should be placed as close as possible to the IC

pin. Note also that the 3.3M current summing resistor is

switched to A2’s positive input when it is not sourcing

current to the summing point. This seemingly unnecessary

connection prevents minute stray 60Hz and noise currents

from being coupled to A2’s summing point when the current reference is off. Failure to utilize this connection will

cause jitter in the LSB. Gain trimming of this circuit may be

accomplished by varying the 22.3k value. If the particular

strain gauge transducer used requires zero trimming, use

the optional network shown. Over a 0°C to 70°C range the

circuit will typically maintain its 10-bit output within 1LSB

accuracy. The tracking errors of the starred resistors are

the primary contributors to this small error.

Because of their extremely wide dynamic range, photo diodes present a diffi cult challenge for signal conditioning circuitry. A high quality device furnishes a linear current output

over a 100dB range, requiring a 17-bit A/D converter as well

as a current-to-voltage input amplifi er. A common approach

employs a logarithmically responding current-to-voltage

input amplifi er to nonlinearly compress the photodiode’s

output, allowing a much lower resolution A/D converter to

be used. Although this scheme saves the cost of the 17-bit

A/D, it has the inconvenience of a nonlinear output. Also,

logarithmic amplifi ers respond relatively slowly, which

may be detrimental in some photometric measurements.

Figure 8’s circuit directly converts a photodiode’s current

output into an output frequency with 100dB of dynamic

range. Optical input power of 20nW to 2mW produces a

linear, calibrated 20Hz-to-2MHz output. Output response

to input light steps is fast and cost is low.

The photodiode’s output current feeds a highly modifi ed,

high frequency version of a Pease type charge pump

I→F converter. Diode output current biases A1’s negative

input, causing its output (Trace A, Figure 9) to ramp in a

negative direction. When A1’s output crosses zero, C1’s

output (Trace B) goes low, causing the LT1009 diode bridge

to bound at –3.7V. The 200pF-1.8k lead network at C1’s

positive input aids comparator high frequency response.

C1’s output going low also provides AC positive feedback

to its positive input (Trace D). Additional AC positive

feedback is supplied by output transistor Q3’s collector

(Trace C). During this interval, charge is pulled from A1’s

summing point via the 47pF-5pF capacitors (Trace E). This

causes A1’s output to move quickly positive, switching

C1 after the positive feedback around it has decayed. The

LT1009 diode bridge now bounds at 3.7V. The 47pF-5pF

pair receives charge, A2’s summing junction recovers and

the entire cycle repeats at a frequency linearly related to

photodiode output current. D1 and D2 compensate the

bridge diodes. Diode connected Q1 compensates steering

diode Q2. The diode connected transistors provide lower

leakage than simple diodes. C2 provides circuit latch-up

protection, necessary because of the circuit’s AC-coupled

feedback loop. If latch-up occurs, A1’s output saturates

low, causing C2’s emitter-follower connected output to go

high. This forces A1’s output positive, initiating normal

circuit action.

AN7-8

an7f

Page 9

15V

15V

–15V

LT1021-10

IN

3.3M

DARK

CURRENT

TRIM

1.8k

OUT

10k

D1

1N4148

D2

1N4148

20nW TO 20mW

LIGHT INPUT

15V

10M

Application Note 7

5pF

FULL-SCALE TRIM

15V

Q2

2N2222

Q1

2N2222

1000pF

–

2

3

+

1k 100k1k

15V

1

7

C2

LT1011

4

–15V

POLYSTYRENE

15V

A1

LT1056

–15V

8

2

+

3

–

7

4

47pF*

100k

15V

1.8k

200pF

6

200k

0.1μF

1.8k

15V

2

+

C1

LT1011

3

–

1k

= HEWLETT PACKARD

PHOTODIODE HP-5082-4204

1

–15V

12pF

5pF

8pF 20k

8

1.8k

1.8k

7

4

1N4148

1N4148 (4)

LT1009

2.5V

–15V

AN07 F08

1N4148

1.8k

15V

SCALE FACTOR =

10k1.8k

900 NANOMETERS

FROM 20nW TO 2mW

Q3

2N2369

4.7k

1nW/Hz AT

TTL OUT

20Hz TO 2MHz

A = 0.5V/DIV

B = 50V/DIV

C = 20V/DIV

D = 0.5V/DIV

E = 10mA/DIV

Figure 8. Photodiode Digitizer

HORIZONTAL = 2μs/DIV

AN07 F09

Figure 9. Photodiode Digitizer Waveforms

an7f

AN7-9

Page 10

Application Note 7

The LT1021-10 reference biases the photodiode, providing optimum optical current response characteristics. To

trim this circuit, place the photodiode in a completely dark

environment. Trim the “dark current” adjustment so the

circuit oscillates at the lowest possible frequency, typically 1Hz to 2Hz. Next, apply or electrically simulate (see

manufacturer ’s data sheet for light input versus output current data) a 2mW optical input. Trim the 5pF adjustment for

an output frequency of 2MHz. If the adjustment is outside

the range of the trimmer, alter the 47pF capacitor’s value

appropriately. Once calibrated, this circuit will maintain 1%

accuracy over the photodiodes’s entire 100dB range. The

accuracy obtained is limited by photodiode characteristics

and not the circuit. Figure 10 shows dynamic response

of the circuit to a fast light pulse (Trace A, Figure 10). The

frequency output settles within 1μs on both edges.

One of the most diffi cult physical parameters to transduce

is relative humidity. A recently introduced humidity transducer, based on a capacitance shift versus relative humidity

(RH), offers good accuracy, fast response, wide range and

linear response. The transducer features a nominal 1.7pF

per percent RH capacitance shift with a 500pF value at RH

= 76%. It does not require temperature compensation. A

signifi cant consideration in signal conditioning this transducer is that the average voltage across the device must be

zero. No net DC may pass through the transducer. Figure

11’s circuit converts the RH transducer’s capacitive shifts

directly into a calibrated frequency output. The LTC1043

switched-capacitor instrumentation building block IC free

runs at 150kHz. Pin 2 (Figure 12, Trace A) is alternately

connected between the LT1004 negative reference and

A1’s summing junction. The 1μF-22MΩ combination

associated with the RH transducer ensures the device’s

required pure AC biasing.

When Pin 2 is connected to Pin 6, the transducer receives a negative charge. When the LTC1043’s internal

clock switches, Pin 2 is tied to Pin 5, depositing all of the

transducer ’s charge into A1’s summing point. A1’s input

(Trace B), just faintly visible, shows transducer current,

while Trace C is A1’s output. A1, an integrator, ramps up in

stepped fashion as successive discrete packets of charge

are deposited into its summing point. Concurrent with

this action, a second set of LTC1043 switches (Pins 7, 8,

11,12, 13 and 14) works to synchronously transfer a fi xed

amount of charge of opposing polarity into A1’s summing

junction. The amount of fi xed charge is set to cancel the

sensor offset (e.g., 0% RH does not extrapolate to 0pF

sensor capacitance). Thus, the slope of the stepped ramp

at A1’s output is a function of the sensor’s value minus its

offset term. A1 continues to ramp positive until it equals

the voltage at C1’s negative input. This triggers C1’s output

high (Trace D). AC positive feedback holds C1’s output high

long enough for the 2N4393 FET to completely discharge

A1’s feedback capacitor. A1’s output drops to zero and the

entire cycle repeats. The frequency of repetition is a function of the RH transducer’s capacitance. C1’s input voltage

is derived from the LT1004 reference. LTC1044 Pins 3, 18

and 15 and the 330pF value form a simple charge pump

which biases A2’s summing point. A2’s output assumes

whatever value is required to maintain its summing point

at zero. The 0.22μF capacitor integrates A2’s response

to DC, while the feedback resistors establish the operating point. Because A2’s output voltage determines ramp

height, its feedback resistor ’s value sets the circuit’s gain

slope. Traces E, F and G, time and amplitude expansions

of Traces A, B and C, permit a detailed look at the effects of

the transducer’s charge dumping on A1’s output ramp.

AN7-10

A = 10V/DIV

B = 2V/DIV

HORIZONTAL = 1μs/DIV

Figure 10. Step Response of Photodiode Digitizer

AN07 F10

an7f

Page 11

Application Note 7

10k

5% RH TRIM

–5V

1k

0.1

RH

TRANSDUCER

0.1

LT1004

1.2V

1μF

22M

LTC1043

11

12

13

2

87

470pF*

14

56

3

1518

330pF*

33k

30.1k

1%

2N4393

0.01*

–

LT1056

+

+

LT1056

–

A1

A2

0.22

20k

90% RH TRIM

1N4148

+

LT1011

–

C1

30pF

5V

7

1

–5V

68k

*POLYSTYRENE

RH TRANSDUCER = PANAMETRICS #RHS

AN07 F11

2k

5V

FREQUENCY OUTPUT

0% TO 100%

RH = 0Hz TO 1000Hz

Figure 11. Humidity-to-Frequency Converter

A = 5V/DIV

B = 20mA/DIV

C = 2V/DIV

D = 5V/DIV

E = 2V/DIV

F = 20mA/DIV

G = 100mV/DIV

HORIZONTAL A, B, C, D = 100μs/DIV

HORIZONTAL E, F, G = 10μs/DIV

AN07 F12

Figure 12. Humidity-to-Frequency Converter Waveforms

an7f

AN7-11

Page 12

Application Note 7

Circuit temperature dependence is low because the 330pF

and 0.01μF polystyrene capacitors’ (both gain terms)

–120ppm drifts ratiometrically cancel. Further ratiometric

error cancellation occurs because the transducer’s charge

source and A2’s output voltage are both derived from the

LT1004 reference. The sole uncompensated term in the

circuit is the 470pF capacitor which supplies the offsetting

charge. Its –120ppm/°C drift is well below the transducer’s

2% accuracy specifi cation, and circuit temperature independence is assured.

To calibrate this circuit, place the transducer in a 5% RH

environment and adjust the 5% trim for 50Hz output. Next

place the transducer in a 90% RH environment and adjust

the 90% trim for a 900Hz output. Repeat this procedure

until both points are fi xed. Relative humidity accuracy will

be 2% over the 5% to 90% RH range. If RH standards are

not available, the circuit may be approximately calibrated

against using fi xed capacitors in place of the sensor. Ideal

values are 5% RH = 379.3pF and 90% = 523.8pF. Note

that these values assume an ideal sensor. An actual device

may depart from them by as much as 10%.

Another frequently required physical parameter is level.

Level transducers which measure angle from ideal level

are employed in road construction, machine tools, inertial

navigation systems and other applications requiring a

gravity reference. One of the most elegantly simple level

transducers is a small tube nearly fi lled with a partially

conductive liquid. Figure 13 shows such a device. If the

tube is level with respect to gravity, the bubble resides in

the tube’s center and the electrode resistances to common are identical. As the tube shifts away from level,

the resistances increase and decrease proportionally. By

controlling the tube’s shape at manufacture, it is possible

to obtain a linear output signal when the transducer is

incorporated into a bridge circuit.

Transducers of this type must be excited with an AC waveform to avoid damage to the partially conductive liquid

inside the tube. Signal conditioning involves generating

this excitation as well as extracting angle information and

polarity determination (e.g., which side of level the tube

is on). Figure 14 shows a circuit which does this, directly

producing a calibrated frequency output corresponding to

level. A sign bit, also supplied at the output, gives polarity

information.

PARTIALLY

CONDUCTIVE

LIQUID IN

SEALED

GLASS TUBE

BUBBLE

AN07 F13

COMMON ELECTRODE

Figure 13. Bubble-Based Level Transducer

ELECTRODEELECTRODE

an7f

AN7-12

Page 13

Application Note 7

10

+

TRANSDUCER

LEVEL

2N3906

10k

2k*

5V

2M

10k

10k

Q1

200k

+

100μF

200k

2k*

100k*

100k*

I

K

LTC1043

1

0.03

5V

C1A

1/2 LT319A

2

–5V

–

A1

LT1056

+

1N4148 (4)

153

5 162

1412

811

–

0.01μF

+

9.09M*

220pF

1N4148

1M

0.1

1M

1N4148

–

A2

LT1056

+

CALIBRATE

5V

330Ω

1N4148 (2)

LT1009

2.5V

*1% RESISTOR

LEVEL TRANSDUCER = FREDERICKS #7630

0.1

9.09M*

3.01k

5k

220k

1.3k

–

A3

LM301A

+

–

C1B

1/2 LT319A

+

SIGN BIT

+ OR – FOR

EITHER SIDE

OF LEVEL

5V

1k

FREQUENCY OUT

6

0 TO 40 ARC

MINUTES =

7

47pF

0Hz TO 400Hz

AN07 F14

10k*

10k*

4.32M*

4.32M*

Figure 14. Level Transducer Digitizer

an7f

AN7-13

Page 14

Application Note 7

The level transducer is confi gured with a pair of 2k resistors to form a bridge. The required AC bridge excitation is

developed at C1A, which is confi gured as a multivibrator.

C1 biases Q1, which switches the LT1009’s 2.5V potential

through the 100μF capacitor to provide the AC bridge drive.

The bridge differential output AC signal is converted to a

current by A1, operating as a Howland current pump. This

current, whose polarity reverses as bridge drive polarity

switches, is rectifi ed by the diode bridge. Thus, the 0.03μF

capacitor receives unipolar charge. A2, running at a differential gain of 2, senses the voltage across the capacitor

and presents its single-ended output to C1B. When the

voltage across the 0.03μF capacitor becomes high enough,

C1B’s output goes high, turning on the paralleled sections

of the LTC1043 switch. This discharges the capacitor. The

47pF capacitor provides enough AC feedback around C1B

to allow a complete zero reset for the capacitor. When

the AC feedback ceases, C1B’s output goes low and the

LTC1043 switch goes off. The 0.03μF unit again receives

constant-current charging and the entire cycle repeats. The

frequency of this oscillation is determined by the magnitude

of the constant current delivered to the bridge-capacitor

confi guration. This current’s magnitude is determined by

the transducer bridge’s offset, which is level related.

Figure 15 shows circuit waveforms. Trace A is the AC

bridge drive, while Trace B is A1’s output. Observe that

when the bridge drive changes polarity, A1’s output fl ips

sign rapidly to maintain a constant current into the bridgecapacitor confi guration. A2’s output (Trace C) is a unipolar,

ground-referred ramp. Trace D is C1B’s output pulse and

the circuit’s output. The diodes at C1B’s positive input

provide temperature compensation for the sensor’s positive tempco, allowing C1B’s trip voltage to ratiometrically

track bridge output over temperature.

A3, operating open loop, determines polarity by comparing the rectifi ed and fi ltered bridge output signals with

respect to ground.

To calibrate this circuit, place the level transducer at a

known 40 arc-minute angle and adjust the 5k trimmer at

C1B for a 400Hz output. Circuit accuracy is limited by the

transducer to about 2.5%.

The fi nal example concerns direct digitization of a piezoelectric accelerometer. These transducers rely on the

property of ceramic materials to produce charge when

mechanically excited. In this device a mass is coupled

to the ceramic element. An acceleration acting on the

mass causes charge to be dispensed from the ceramic

element. Sensitivity and frequency response are related

to the characteristics of the ceramic used and the mechanical design of the transducer. The best way to signal

condition a piezoelectric output is to unload it directly into

the virtual ground of an op amp’s summing point. This

method provides no voltage difference between the center

conductor and the shield of the coaxial cable connecting

the accelerometer and the single conditioning amplifi er.

This eliminates cable capacitance as a parasitic term, an

important consideration in any charge output transducer.

Because the accelerometer produces AC outputs, a direct

digitization of its output must produce a sign bit as well

as amplitude data.

AN7-14

A = 5V/DIV

B = 2V/DIV

C = 2V/DIV

D = 10V/DIV

HORIZONTAL = 20ms/DIV

Figure 15. Level Transducer Digitizer Waveforms

AN07 F15

an7f

Page 15

Application Note 7

ACCELEROMETER

10Ω

+

–

15V

C1

LT1011

–15V

Q1

4.7k

2N4393

–

LT1011

+

6.8k

15V

15V

C2

–15V

–

A1

LT1056

+

100pF

100k

15V

2k

2k

7

1

4.7k

LT1009

2.5V

0.01

100k*

1M

GAIN TRIM

1M*

GAIN TRIM

1.2k

10k

7

1

200pF

1/4 74C86

1k

1/4 74C86

1.5k

AN07 F16

15V

10k

6.2k

–15V

1/4 74C86

*1% FILM

ACCELEROMETER = ENDEVCO #2225

6.2k

= 1N4148

15V

10k

Q2

2N3904

Q3

2N3904

10k

DATA OUT (TTL)

4.7k

10k

SIGN OUT (TTL)

4.7k

Figure 16. Accelerometer Digitizer

Figure 16’s circuit accomplishes a complete, direct A/D

conversion on the piezoelectric accelerometer noted and

is generally applicable to other devices in this class. To

understand the circuit it is convenient to replace the accelerometer with a square wave source coming through a

resistor. When the square wave is positive, the A1 integrator responds with a negative-going ramp output (Trace A,

Figure 17). C1, detecting the square wave polarity, goes

high and the LT1009 diode bridge (Trace B) limits at 3.7V.

A1’s ramp output is summed with the bridge’s output at

C2’s negative input. The series diodes temperature-compensate the bridge diodes. When A1’s output goes far

enough negative, C2’s (Trace C) output goes high. The

output gating is arranged so that with C1’s output low

and C2 high, Q1’s gate (Trace D) receives turn-on bias.

Q1 comes on, discharging A1’s feedback capacitor and

resetting A1’s output to zero. Local AC positive feedback

at C2 ensures adequate time for a complete zero reset of

A1’s feedback capacitor. The 100pF capacitor at C2’s input

aids high frequency response. When the AC feedback

decays away, Q1 goes off, A1 begins to ramp negative

again and the cycle repeats as long as the input square

wave is positive. The frequency of oscillation is directly

proportional to the current into A1’s summing point. When

the input square wave goes negative, A1 abruptly begins

to ramp in the positive direction. Simultaneously, the C1

input polarity detector output goes negative, forcing the

LT1009 bridge output negative. C2’s output now switches

when A2’s output exceeds a positive limit. The output gating, directed by C1’s polarity signal, inverts C2’s output to

supply proper drive to Q1’s gate. Q1 turns on and resetting

occurs. Thus, the loop maintains oscillation, but with all

signs reversed. The Q2 and Q3 level shifters supply TTL

data outputs for data and sign.

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

an7f

AN7-15

Page 16

Application Note 7

This circuit constitutes an I→F converter which responds

to AC inputs. If the square wave source is replaced with

a piezoelectric accelerometer, direct digitization results.

Figure 18 shows circuit response when an acceleration

(Trace A), in this case a damped sinusoid, is applied to

the transducer. The sign bit (Trace B) keeps track of acceleration polarity, while the frequency output supplies

amplitude data. Observe the drop in output frequency

A = 0.2V/DIV

B = 10V/DIV

C = 20V/DIV

(UNCAL)

D = 20V/DIV

(UNCAL)

Figure 17. Accelerometer Digitizer Waveforms with Square Wave Test Drive

HORIZONTAL = 100μs/DIV

as the input waveform damps. A monitoring processor,

sampling the sign and frequency waveforms faster than

twice the highest acceleration frequency of interest, can

extract desired acceleration waveform data. To trim the

circuit, apply a known amplitude acceleration and adjust

the 1MΩ gain trim at C2. Alternately, the accelerometer

may be electrically simulated (see manufacturer’s data

sheet for scale factors).

AN07 F17

A = UNCAL

B = 10V/DIV

(INVERTED)

A = 10V/DIV

HORIZONTAL = 10ms/DIV

Figure 18. Accelerometer Digitizer Response

AN07 F18

AN7-16

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

an7f

GP/IM 0285 10K • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 1985

Loading...

Loading...