Page 1

Sensepoint XCD

Flammable, toxic and

oxygen gas detector for

industrial applications

Page 2

Sensepoint XCD

One-Stop Shop

• Flammable (catalytic or infrared), toxic

and oxygen versions available

• New and retrofit applications

• Suitable for indoor or outdoor use

• Stainless steel or aluminium

explosion-proof housing options

• IP66 as standard

Proven and Reliable

Sensor Technology

• SurecellTM electrochemical sensors

• Poison immune infrared sensors

• Poison resistant catalytic bead sensors

• Long life sensors

Global Approvals

• US and Latin America, European,

Canadian and Asian

• Compliant with UL, INMETRO, ATEX,

IECEx, CSA, KTL, PA, GB and CCCF

standards

Easy to Use

• User friendly and intuitive tri-colour

backlit display with digits, bar graph

and icons

• Fully configurable via magnetic switches

• Optional remote sensor mounting*

• Selectable sink or source 4-20mA output

• Auto-inhibit during maintenance

• MODBUS communications for remote

diagnostics/configuration*

Cost Effective

• Common transmitter platform

• Minimal training required

• Reduced spares

• Non-intrusive, one-man operation

• Plug-in sensor replacement

• MODBUS multi drop option offers

cabling savings*

Simple Installation

• Plug-in display module removes to give access

to terminal area

• Integral mounting bracket

• 2 x M20 or ¾” NPT cable/conduit entries

(certification dependent)

• Removable plug/socket type terminal blocks for

ease of wiring

• Sink/source switch to suit preferred wiring

topology

Range of Optional Accessories

• Remote sensor mounting kit*

• Remote sensor gassing kit

• Duct mounting kit

• Calibration gas flow housing

• Collecting cone

* Contact Honeywell Analytics for availability of these options.

Typical Applications

• Industrial manufacturing facilities

• Power plants

• Waste water facilities

• Utilities

• Food and beverage production

• Refineries and chemical plants

• Onshore oil and gas terminals

• Production platforms

• Exploration and drilling

The Sensepoint XCD range provides

comprehensive monitoring of flammable,

toxic and Oxygen gas hazards in potentially

explosive atmospheres, both indoors and

outdoors. Users can modify detector

operation using the LCD and magnet

switches without ever needing to open the

unit. This enables one-man, non-intrusive

operation and reduces routine maintenance

time and costs.

A tri-colour backlit LCD clearly indicates the

unit’s status at a glance, even from a distance.

A steady green backlight indicates normal

operation, flashing yellow indicates fault and

flashing red indicates an alarm.

All detectors are supplied pre-configured

and include 2 programmable alarm relays,

1 programmable fault relay as well as an

industry standard 4-20mA output (sink or

source selectable) and MODBUS*.

The scale, range, relay operation, alarm set

point and electronic tag number of the detector

can be adjusted using the transmitter's LCD

and non-intrusive magnetic switches. Outputs

are automatically inhibited during adjustment,

thereby reducing the risk of false alarm at the

control panel during maintenance.

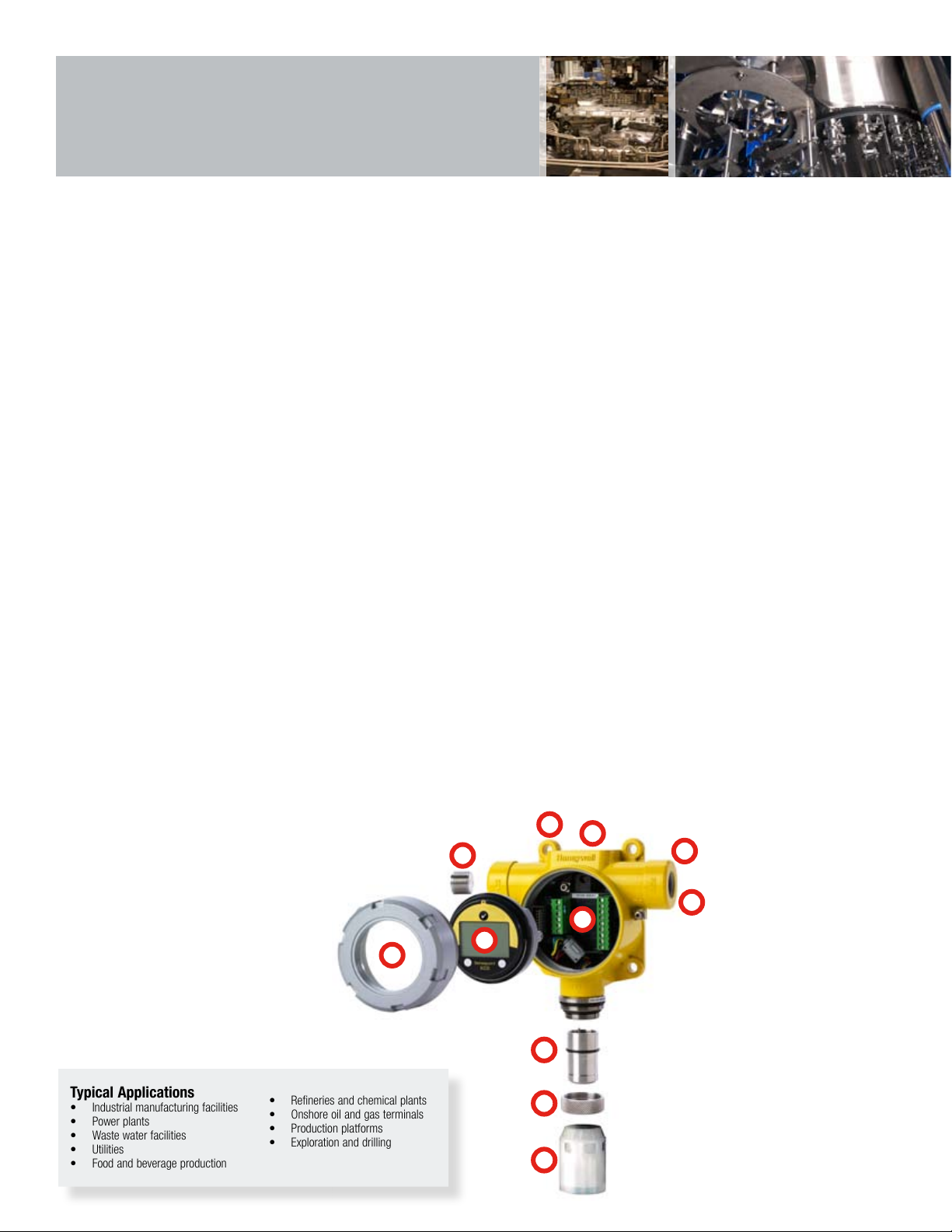

8

4

2

1

6

7

9

Sensepoint XCD has an integral mounting plate

for surface mounting or can be mounted to a

horizontal or vertical pipe using the optional

pipe mounting bracket. Electrical installation

can be made using either conduit or cable

with suitable mechanical protection. Two M20

or ¾”NPT entries are provided (depending

on certification). A weatherproof cap is also

included for use in the harshest outdoor

conditions. Other optional accessories include

a sunshade/deluge protection, duct mounting

kit, collecting cone and remote mounting

sensor socket*.

Sensepoint XCD ensures easy installation

and the fastest routine operation by removing

the need for hot work permits in hazardous

areas. Using easy to replace plug-in sensors,

downtime is also reduced and on-going costs

are minimised through the use of poison

resistant flammable sensors, poison immune

infrared Hydrocarbon sensors and patented

Surecell™ toxic sensors.

11

5

10

3

1 Cover

2 Display module

3 Terminal area

4 Blanking plug

5 Transmitter

6 Plug-in XCD sensor

7 Sensor retaining ring

8 Integral mounting plate

9 Weather protection assembly

10 Cable/conduit entry (x2)

11Certicationlabel

Page 3

Sensepoint XCD Overview

There are three different types of the XCD

transmitter for use with three different families

of sensors.

The mV type transmitter is for use with the

mV family of XCD sensors including catalytic

sensors to detect flammable gases in the

range 0-100%LEL and infrared (IR) sensors

for detection of Hydrocarbon gases in the

range 0-100%LEL and 0-100%Vol*, as well as

Carbon Dioxide (CO

) in the range 0-2%Vol.

2

The EC type transmitter is for use with

the EC family of XCD sensors including

Carbon Monoxide (CO), Hydrogen Sulfide,

S) and Hydrogen (H2).

(H

2

The Oxygen transmitter is for use with the

Oxygen (O

) XCD sensors.

2

A transmitter can auto-recognise any sensor

from within its sensor family. The sensor

simply plugs into the bottom of the transmitter

and the transmitter automatically configures

itself accordingly.

Sensepoint XCD Sensor Families, Gases and Ranges

Gas

Flammable 1 to 8* 20.0 to 100.0%LEL 100%LEL 10%LEL

mV

Methane 20.0 to 100.0%LEL 100%LEL 10%LEL

Methane 20 to 100%Vol.* 100%Vol. 10%Vol.

Carbon Dioxide 0.1 to 2%Vol. 2%Vol. 0.1%Vol.

Sensor Family

Hydrogen Sulfide 10.0 to 100.0ppm 50.0ppm 0.1ppm

EC

Carbon Monoxide 100 to 1,000ppm 300ppm 100ppm

Hydrogen 1,000ppm only 1,000ppm n/a

2

O

Oxygen 25.0%Vol. only 25.0%Vol. n/a

User Selectable

Full Scale Range

Catalytic Bead Sensors

Infrared Sensors

Electrochemical Sensors

mV Transmitter

Default

Range

EC Transmitter

Steps

Selectable Cal

Gas Range

30 to 70% of selected

full scale range

20.9%Vol. (Fixed) 20.9%Vol.

Default Cal Point

50%LEL

50%LEL

50%Vol.

1%Vol.

10ppm

100ppm

500ppm

O2 Transmitter

Ready, Steady, Go!

Sensepoint XCD uses three instantly

recognisable ‘traffic light’ colours to indicate

its status. The large tri-colour backlit LCD

is steady green to indicate normal operation,

flashes yellow to indicate a fault/warning

and flashes red to indicate an alarm. This

allows anyone in the area to clearly see at a

glance the status of any detector. This can be

particularly useful to identify detector status if

the detector is located in a difficult to access

area or if a number of detectors are located in

the same area.

IR Methane %LEL

IR Methane %Vol*

EC CO

2

EC H

0-100%LEL)

4

IR Carbon Dioxide %Vol

(default CH

Catalytic Flammable 1* to 8* %LEL

S

2

EC H

Normal Fault/Warning Alarm

2

EC O

Page 4

XCD is the right choice for a variety of demanding industrial applications

Building

Environment (Detected by XCD)

SpecicArea

• Raw material storage

• Process Areas

Chemical Plants

• Laboratories

• Pump rows

• Compressor stations

• Loading/unloading areas

• Exploration drilling rigs

• Production platforms

Oil & Gas

• Onshore oil and

gas terminals

• Reneries

• Around the boiler pipework

and burners

Power Stations

• Turbines

• Coal silos and conveyor

belt areas in older coal/oil

red stations

Waste Water

Treatment Plants

• Digesters

• Plants sumps

• H2S scrubbers

• Pumps

Boiler Rooms

• Incoming gas main

• Boiler and gas piping

• Laboratories

Hospitals

• Refrigeration plants

• Boiler rooms

Gases Present

• General

Hydrocarbons

• H2S

• NH

3

• O

2

• General

Hydrocarbons

• H2S

• CO

• O

2

• Flammable

• CH

4

• H

2

• O

2

• General

Hydrocarbons

• H2S

• CO

• O

2

• General

Hydrocarbons

• H2S

• CO

• O

2

• General

Hydrocarbons

• H2S

• CO

• O

2

Honeywell Analytics

Serves Every Business

We offer the industry's most complete

range of gas detection products and

services to meet all customer needs.

Commercial

Vulcain-brand gas detection from standalone

units to fully engineered, multi-point systems,

all offering cost-effective regulatory compliance

» Applications: parking structures, chillers,

mechanical rooms, office towers,

commercial buildings, shopping centers,

swimming pools, golf courses, schools

and universities, laboratories

Industrial

Renowned Sieger and Manning gas detection

systems with advanced electrochemical,

infrared and open path sensing technologies

» Applications: oil and gas, cold storage,

water/wastewater treatment, chemicals,

engine rooms, plastics and fibers, agriculture,

printing and light industrial

Portables

Single or multi-gas Lumidor and other premium

detectors with compact, lightweight designs

ranging from simple alarm only units to

advanced, fully configurable and serviceable

instruments

» Applications: underground utility and

electricity ducts, boiler rooms, post-fire sites,

sewers, industrial plants, industrial hygiene,

first esponder teams, remote fleets

High Tech/Government

A complete portfolio of gas and chemical

detection instrumentation including infrared

spectroscopy (MST) with no cross interference,

to Chemcassette paper-based solutions (MDA

Scientific) offering detection down to parts

per billion

» Applications: semiconductor manufacturing

and nanotechnology, aerospace propulsion

and safety, specialty chemicals industry,

research laboratories, emergency response

H_XCD_DS01082_V1_US 5/09

© 2009 Honeywell Analytics

Technical Services

24/7 global network includes post-sales service

and Systems Integration teams

» Emergency call out, service contracts, on/

off-site repair, training and commissioning

» Complete range of spares, consumables

and accessories

HWA6181

Loading...

Loading...