Page 1

VA301C

Offering unique zoning capabilities

which permit the averaging and

comparison of multiple sensor

readings

Page 2

The VA301C continuously

monitors and controls

toxic gases, combustible

gases, and oxygen

hazards. Designed

for installation and

operational simplicity,

the VA301C reduces the

cost of installation and

ownership.

Using an addressable RS-485 Modbus

communication protocol, the 301C uses

daisy chain wiring requiring only 2 pairs of

wires to connect up to 96 transmitters on the

3 input channels. This simplies installation,

in turn lowering costs. The 301C’s zoning

and averaging abilities signicantly reduce

operational and maintenance costs.

User Friendly

Zero maintenance•

Automatic quick self-test and warm-up•

Continuous alphanumeric display •

Inexpensive and Reliable

Low installation costs•

Allows for up to 126 zoning groups which can save •

energy and extend fan and relay life

Manages up to 768 events with programmable •

latching alarms

Flexible Operation

Modbus compatible; with BACnet/IP available•

Interchangeable transmitters able to detect different •

gases

Expands to handle up to 96 transmitters or relay •

modules and up to 50 301W wireless sensors

Programmable time delays•

Integrated time clock enables scheduling of system •

operations

Safety Measures

Full array of visual indicators and integrated 65dBA •

alarm levels

Fully programmable relays (can be set as fail-safe •

or not)

Benecial Options

Available in a heavy duty industrial housing•

Datalogging option•

Zoning/Averaging Capabilities

Reduce Operational Costs

The 301C controller offers unique zoning

capabilities which permit the averaging and

comparison of multiple sensor readings.

Zoning can reduce operational costs by

ensuring that localized brief uctuations

registered at a single transmitter do not

activate relays. For example, a car idling in

a parking structure may locally increase a

reading at a nearby transmitter. Rather than

activating a fan as a result of the temporary

localized uctuation, zoning can be used

to limit relay activation until the average

reading for a zone exceeds a set-point.

This can reduce run time of fans, yielding

savings in both energy usage and wear and

tear. The 301C has the capacity to manage

input from three Modbus channels for up

to 96 transmitters and up to 50 wireless

transmitters which can be associated with

up to 126 zones. Transmitters can belong

to an unlimited number of zones, providing

maximum operational and control exibility.

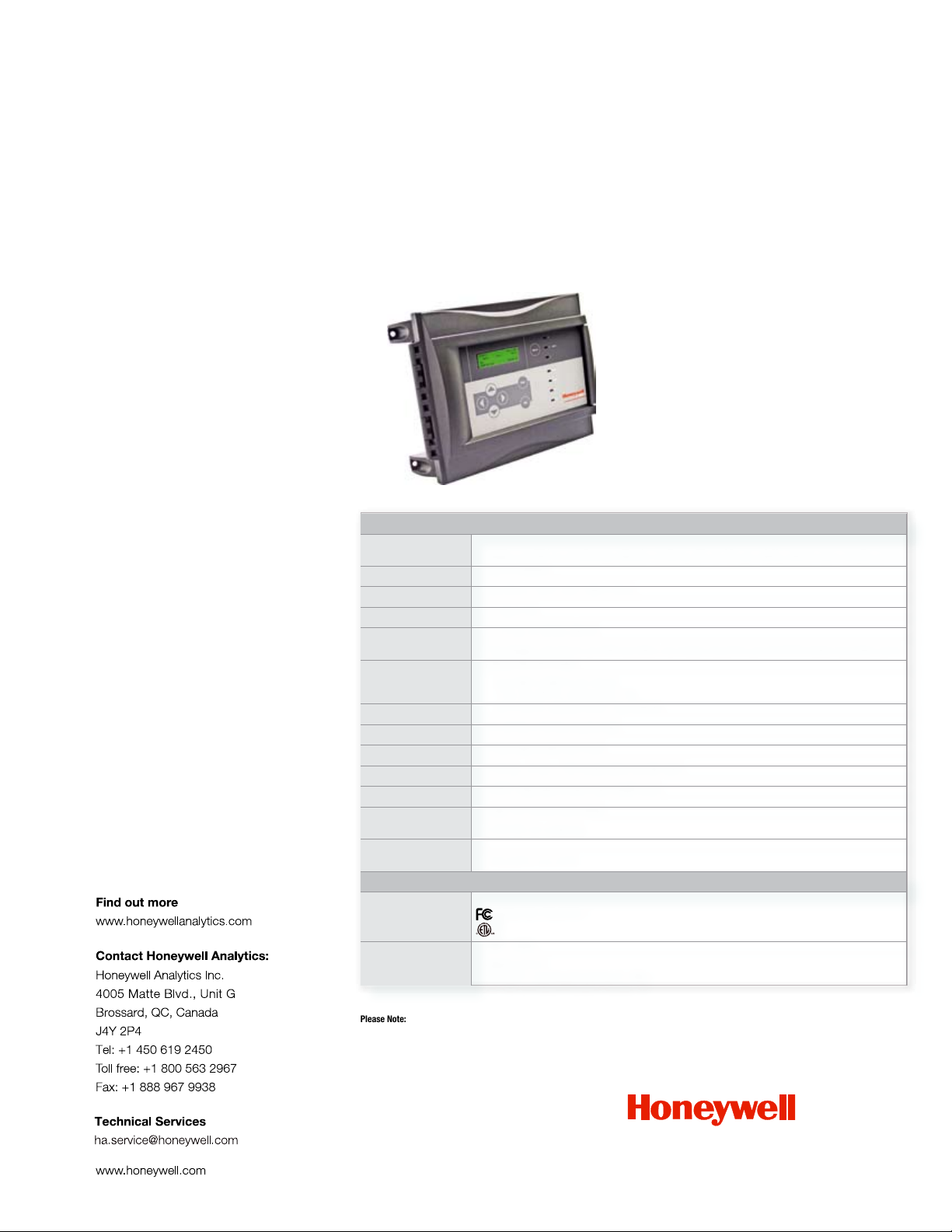

General Specications

Use

Size

Weight

Power Requirement

Network Capacity

Communication Line

Lengths

Relay Output Rating

Alarm Levels

Time Delays

Outputs

Display

Operating Humidity

Range

Operating Temperature

Range

Ratings and Certications

Certied to

Conforms to

Modbus controller for centralized gas detection monitoring with real-time gas reading, selective alarm activation and low

cost of installation.

28 x 20.3 x 7 cm (11.02 x 7.99 x 2.76 in.)

1.1 kg (2.4 lb.)

17-27 Vac, 24-38 Vdc, 500 mA

Three Modbus channels for up to 96 transmitters, one wireless channel for up to 50 301W wireless transmitters and an

optional BACnet/IP output

Up to 609 m (2000 ft.) per channel

T-Tap: 20 m (65 ft.), maximum per T-Tap

40 m (130 ft.), maximum for all T-Tap combined

5 A, 30 Vdc or 250 Vac (resistive load)

3 fully programmable alarm levels

0, 30 sec., 45 sec., 1-99 minutes before and after alarm

4 DPDT relays (alarms and/or fault); 65dBA buzzer

Large 122 x 32 dot matrix display

0-95% RH, non-condensing

-20 to 50°C (-4 to 122°F)

CAN/CSA C22.2 No 61010-1

116662

ANSI/UL 61010-1

IEC 61010-1 Including Amendments A1:1992 +

A2:1995 and National Deviations (Canada, US)

Please Note:

While every effort has been made to ensure

accuracy in this publication, no responsibility

can be accepted for errors or omissions.

Data may change, as well as legislation, and you

are strongly advised to obtain copies of the most

recently issued regulations, standards, and guidelines.

This publication is not intended to form the

basis of a contract.

© 2007 Honeywell Analytics

H_301C_DS01015_V3

10/09

© 2009 Honeywell Analytics

HWA6075

Loading...

Loading...