Page 1

UniNet 2000

Workstation

Installation, Operation,

and Administration Manual

Document 51540

4/8/02 Rev

51540:B1 ECN 02033

B1

Workstation

Page 2

This page intentionally left blank.

2

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

Page 3

Fire Alarm System Limitations

While a fire alarm system may lower insurance rates, it is not a substitute for fire insurance!

An automatic fire alarm system–typically made up of smoke

detectors, heat detectors, manual pull stations, audible warning

devices, and a fire alarm control with remote notification

capability–can provide early warning of a developing fire. Such a

system, however, does not assure protection against property

damage or loss of life resulting from a fire.

The Manufacturer recommends that smoke and/or heat detectors be located throughout a protected premise following the recommendations of the current edition of the National Fire

Protection Association Standard 72 (NFPA 72), manufacturer's

recommendations, State and local codes, and the recommendations contained in the Guide for Proper Use of System Smoke

Detectors, which is made available at no charge to all installing

dealers. A study by the Federal Emergency Management

Agency (an agency of the United States government) indicated

that smoke detectors may not go off in as many as 35% of all

fires. While fire alarm systems are designed to provide early

warning against fire, they do not guarantee warning or protection

against fire. A fire alarm system may not provide timely or adequate warning, or simply may not function, for a variety of reasons:

Smoke detectors may not sense fire where smoke cannot

reach the detectors such as in chimneys, in or behind walls, on

roofs, or on the other side of closed doors. Smoke detectors

also may not sense a fire on another level or floor of a building.

A second-floor detector, for example, may not sense a first-floor

or basement fire.

Particles of combustion or "smoke" from a developing fire

may not reach the sensing chambers of smoke detectors because:

• Barriers such as closed or partially closed doors, walls, or

chimneys may inhibit particle or smoke flow.

• Smoke particles may become "cold," stratify, and not reach

the ceiling or upper walls where detectors are located.

• Smoke particles may be blown away from detectors by air

outlets.

• Smoke particles may be drawn into air returns before reaching the detector.

The amount of "smoke" present may be insufficient to alarm

smoke detectors. Smoke detectors are designed to alarm at

various levels of smoke density. If such density levels are not

created by a developing fire at the location of detectors, the detectors will not go into alarm.

Smoke detectors, even when working properly, have sensing

limitations. Detectors that have photoelectronic sensing chambers tend to detect smoldering fires better than flaming fires,

which have little visible smoke. Detectors that have ionizingtype sensing chambers tend to detect fast-flaming fires better

than smoldering fires. Because fires develop in different ways

and are often unpredictable in their growth, neither type of detector is necessarily best and a given type of detector may not provide adequate warning of a fire.

Smoke detectors cannot be expected to provide adequate warning of fires caused by arson, children playing with matches (especially in bedrooms), smoking in bed, and violent explosions

(caused by escaping gas, improper storage of flammable mate-

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

rials, etc.).

Heat detectors do not sense particles of combustion and alarm

only when heat on their sensors increases at a predetermined

rate or reaches a predetermined level. Rate-of-rise heat detectors may be subject to reduced sensitivity over time. For this

reason, the rate-of-rise feature of each detector should be tested

at least once per year by a qualified fire protection specialist.

Heat detectors are designed to protect property, not life.

IMPORTANT! Smoke detectors must be installed in the same

room as the control panel and in rooms used by the system for

the connection of alarm transmission wiring, communications,

signaling, and/or power. If detectors are not so located, a devel-

oping fire may damage the alarm system, crippling its ability to

report a fire.

Audible warning devices such as bells may not alert people if

these devices are located on the other side of closed or partly

open doors or are located on another floor of a building. Any

warning device may fail to alert people with a disability or those

who have recently consumed drugs, alcohol or medication.

Please note that:

• Strobes can, under certain circumstances, cause seizures in

people with conditions such as epilepsy.

• Studies have shown that certain people, even when they hear

a fire alarm signal, do not respond or comprehend the meaning of the signal. It is the property owner's responsibility to

conduct fire drills and other training exercise to make people

aware of fire alarm signals and instruct them on the proper

reaction to alarm signals.

• In rare instances, the sounding of a warning device can cause

temporary or permanent hearing loss.

A fire alarm system will not operate without any electrical

power. If AC power fails, the system will operate from standby

batteries only for a specified time and only if the batteries have

been properly maintained and replaced regularly.

Equipment used in the system may not be technically compatible with the control. It is essential to use only equipment listed

for service with your control panel.

Telephone lines needed to transmit alarm signals from a

premise to a central monitoring station may be out of service or

temporarily disabled. For added protection against telephone line

failure, backup radio transmission systems are recommended.

The most common cause of fire alarm malfunction is inadequate maintenance. To keep the entire fire alarm system in

excellent working order, ongoing maintenance is required per the

manufacturer's recommendations, and UL and NFPA standards.

At a minimum, the requirements of Chapter 7 of NFPA 72 shall

be followed. Environments with large amounts of dust, dirt or

high air velocity require more frequent maintenance. A maintenance agreement should be arranged through the local

manufacturer's representative. Maintenance should be scheduled monthly or as required by National and/or local fire codes

and should be performed by authorized professional fire alarm

installers only. Adequate written records of all inspections

should be kept.

Precau-L-3-2002.p65

3

Page 4

Installation Precautions

Adherence to the following will aid in problem-free installation with long-term reliability:

WARNING - Several different sources of power can be con-

nected to the fire alarm control panel. Disconnect all sources of

power before servicing. Control unit and associated equipment

may be damaged by removing and/or inserting cards, modules,

or interconnecting cables while the unit is energized. Do not

attempt to install, service, or operate this unit until this manual is

read and understood.

CAUTION - System Reacceptance Test after Software

Changes. To ensure proper system operation, this product

must be tested in accordance with NFPA 72 Chapter 7 after any

programming operation or change in site-specific software. Reacceptance testing is required after any change, addition or deletion of system components, or after any modification, repair or

adjustment to system hardware or wiring.

All components, circuits, system operations, or software functions known to be affected by a change must be 100% tested. In

addition, to ensure that other operations are not inadvertently

affected, at least 10% of initiating devices that are not directly

affected by the change, up to a maximum of 50 devices, must

also be tested and proper system operation verified.

This system meets NFPA requirements for operation at

0-49° C/32-120° F and at a relative humidity of 85% RH - 93%

per ULC - (non-condensing) at 30° C/86° F. However, the useful

life of the system's standby batteries and the electronic components may be adversely affected by extreme temperature

ranges and humidity. Therefore, it is recommended that this

system and all peripherals be installed in an environment with a

nominal room temperature of 15-27° C/60-80° F.

Verify that wire sizes are adequate for all initiating and

indicating device loops. Most devices cannot tolerate more than

a 10% I.R. drop from the specified device voltage.

Like all solid state electronic devices, this system may

operate erratically or can be damaged when subjected to lightning-induced transients. Although no system is completely immune from lightning transients and interferences, proper grounding will reduce susceptibility. Overhead or outside aerial wiring

is not recommended, due to an increased susceptibility to

nearby lightning strikes. Consult with the Technical Services

Department if any problems are anticipated or encountered.

Disconnect AC power and batteries prior to removing or inserting circuit boards. Failure to do so can damage circuits.

Remove all electronic assemblies prior to any drilling, filing,

reaming, or punching of the enclosure. When possible, make all

cable entries from the sides or rear. Before making modifications, verify that they will not interfere with battery, transformer,

and printed circuit board location.

Do not tighten screw terminals more than 9 in-lbs.

Over-tightening may damage threads, resulting in reduced

terminal contact pressure and difficulty with screw terminal removal.

Though designed to last many years, system components

can fail at any time. This system contains static-sensitive components. Always ground yourself with a proper wrist strap

before handling any circuits so that static charges are removed

from the body. Use static-suppressive packaging

to protect electronic assemblies removed from the unit.

Follow the instructions in the installation, operating, and

programming manuals. These instructions must be followed to

avoid damage to the control panel and associated

equipment. FACP operation and reliability depend upon proper

installation by authorized personnel.

FCC Warning

WARNING: This equipment generates, uses, and can radiate

radio frequency energy and if not installed and used in accordance with the instruction manual, may cause interference to

radio communications. It has been tested and found to

comply with the limits for class A computing device pursuant

to Subpart B of Part 15 of FCC Rules, which is designed to

provide reasonable protection against such interference when

operated in a commercial environment. Operation of this

equipment in a residential area is likely to cause interference,

in which case the user will be required to correct the interference at his own expense.

Canadian Requirements

Acclimate Plus™, HARSH™, NOTI•FIRE•NET™, ONYX™, and VeriFire™ are trademarks, and FlashScan® and VIEW ® are registered trademarks of NOTIFIER.

NION™ and UniNet™ are trademarks of NIS. NIS™ and Notifier Integrated Systems™ are trademarks and NOTIFIER® is a registered trademark of Fire•Lite

Alarms, Inc. Echelon® is a registered trademark and LonWorks™ is a trademark of Echelon Corporation. ARCNET® is a registered trademark of Datapoint

Corporation. Microsoft® and Windows® are registered trademarks of the Microsoft Corporation. LEXAN® is a registered trademark of GE Plastics, a subsidiary

of General Electric Company.

4

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

This digital apparatus does not exceed the Class A

limits for radiation noise emissions from digital

apparatus set out in the Radio Interference Regulations of the

Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruits radioelectriques depassant les limites applicables aux appareils

numeriques de la classe A prescrites dans le Reglement sur

le brouillage radioelectrique edicte par le ministere des Communications du Canada.

Precau-L-4-2002.p65

Page 5

Contents

Workstation ...............................................................................1

Foreword................................................................................................ 12

Introduction............................................................................................ 12

Part 1 Workstation Installation ................................................13

Section 1.1: UWS Computer Installation ................................................. 15

1.1.1 Description of the Computer Components ............................................................................. 15

1.1.2 Installation Description........................................................................................................... 16

Figure 1-1: Attaching the PCLB-5 to the Intel Pentium II Computer ............................................ 16

Figure 1-2: Attaching the PCLB-6 to the Intel Pentium III Rack Mountable Computer ............... 17

Figure 1-3: Connecting the Power Cord and Primary AC Power to the HSP-121B ........................ 17

Figure 1-4: Computer UPS Supervision............................................................................................ 18

Figure 1-5: Intel Pentium III Rack Mountable Computer and Peripheral Connections................ 19

Figure 1-6: Intel Pentium II Computer and Peripheral Connections ............................................. 20

1.1.3 The Workstation Supervisor ..................................................................................................... 21

Figure 1-7: The WSSUP Board ......................................................................................................... 21

Figure 1-8: Workstation Supervisor DIP Switch Settings ............................................................... 22

1.1.4 Network Hubs .......................................................................................................................... 23

Figure 1-9: The Hub Location on the Network ............................................................................... 23

1.1.5 Screen Savers, Power Management and Screen Resolution ................................................ 24

Figure 1-10: Accessing Taskbar Properties .................................................................................... 24

Figure 1-11: Adding UniNet to the Startup Folder ........................................................................ 24

Section 1.2: Printer Installation ............................................................. 25

1.2.1 General Printer Setup ............................................................................................................. 25

Figure 1-12: PRN Series Serial Cable Wiring Diagram................................................................... 26

1.2.2 Event and Report Printer Setup .............................................................................................. 26

Figure 1-13: The Printers Dialog ...................................................................................................... 26

Section 1.3: Basic Workstation Setup....................................................... 27

1.3.1 Configuring Event Managers and Alarm Servers.................................................................. 27

Figure 1-14: Alarm Server Connections .......................................................................................... 27

Figure 1-15: Alarm Server Connection Fields ................................................................................. 28

Figure 1-16: Event Manager Configuration .................................................................................... 28

Figure 1-17: New Alarm Server Connection ................................................................................... 29

1.3.2 The System Setup Folder ......................................................................................................... 29

Figure 1-18: System Options : General Tab ................................................................................... 29

Figure 1-19: System Options: Printers Tab .................................................................................... 31

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

5

Page 6

Figure 1-20: System Options: Speech Annunciation Tab ............................................................. 32

Figure 1-21: System Options: Operator Response Tab ................................................................. 32

Figure 1-22: System Options: Operator Features Setup............................................................... 33

Figure 1-23: System Options: Site Information Setup Tab ........................................................... 34

Figure 1-24: System Options: Arm/Disarm Filter Tab ................................................................... 34

Part 2 Operation......................................................................35

Figure 2-1: The Workstation Main Screen ...................................................................................... 37

Section 2.1: Basic Workstation Operation............................................... 37

2.1.1 The Workstation Main Screen Tour.......................................................................................... 37

Figure 2-2: The Event Display .......................................................................................................... 38

Figure 2-3: Network Communications ............................................................................................ 39

Figure 2-4: Toolbar - Operator Area ............................................................................................... 39

2.1.2 Logging Into the Workstation.................................................................................................. 40

Figure 2-5: Operator Login .............................................................................................................. 40

Figure 2-6: Operator Login Dialog Box........................................................................................... 40

Section 2.2: Event Handling ................................................................... 41

2.2.1 About Events ............................................................................................................................ 41

2.2.2 Types of Events ......................................................................................................................... 41

2.2.3 Event Handling ........................................................................................................................ 42

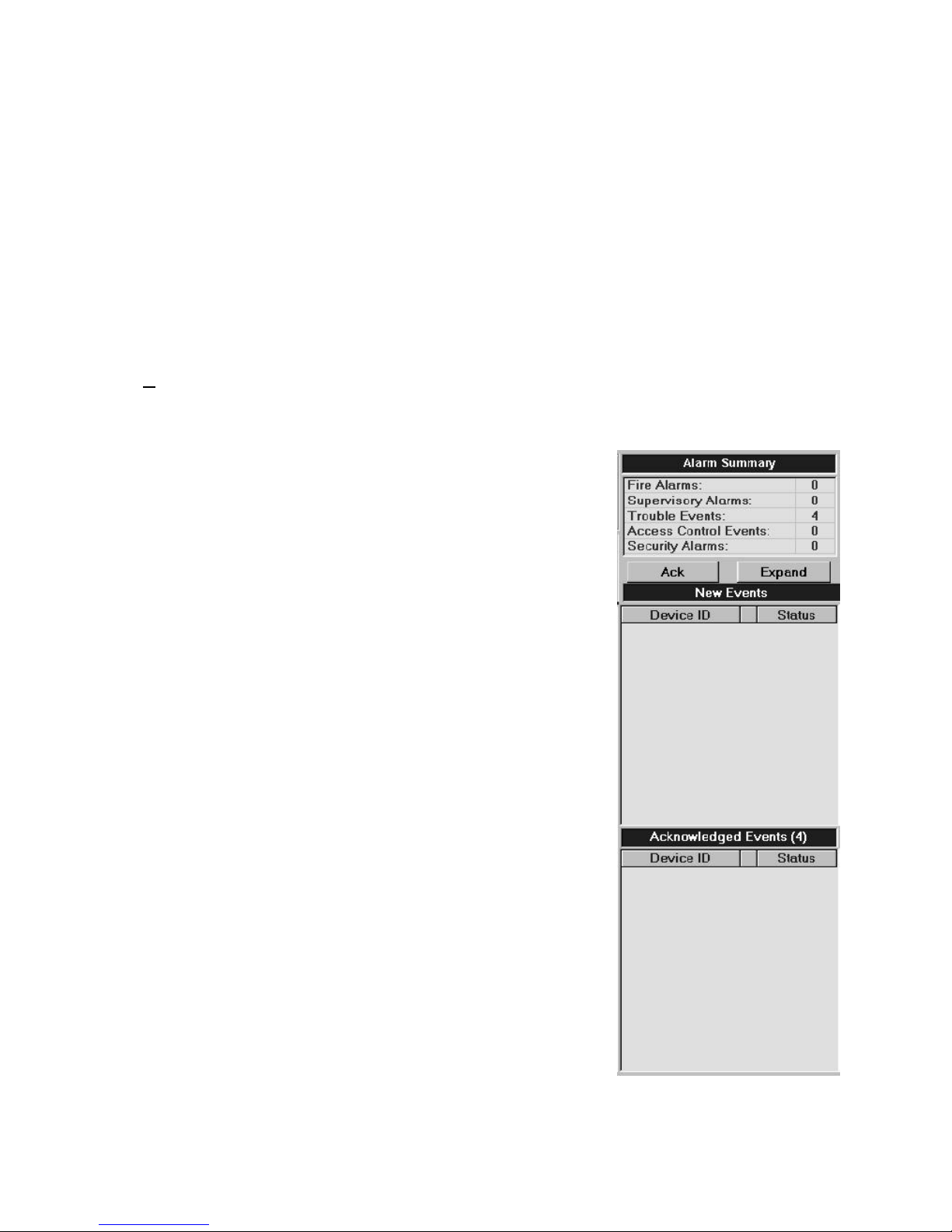

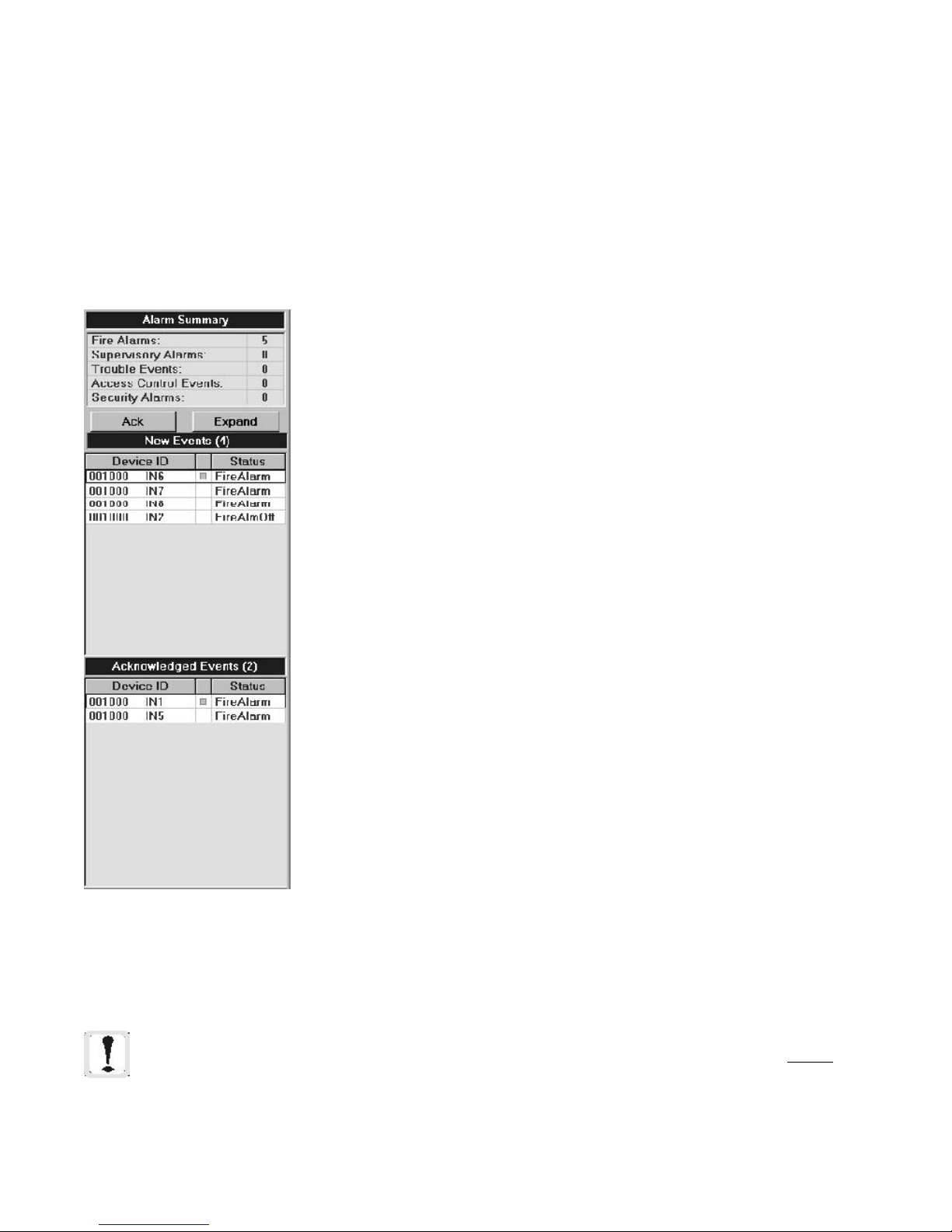

Figure 2-7: Event Display Box .......................................................................................................... 42

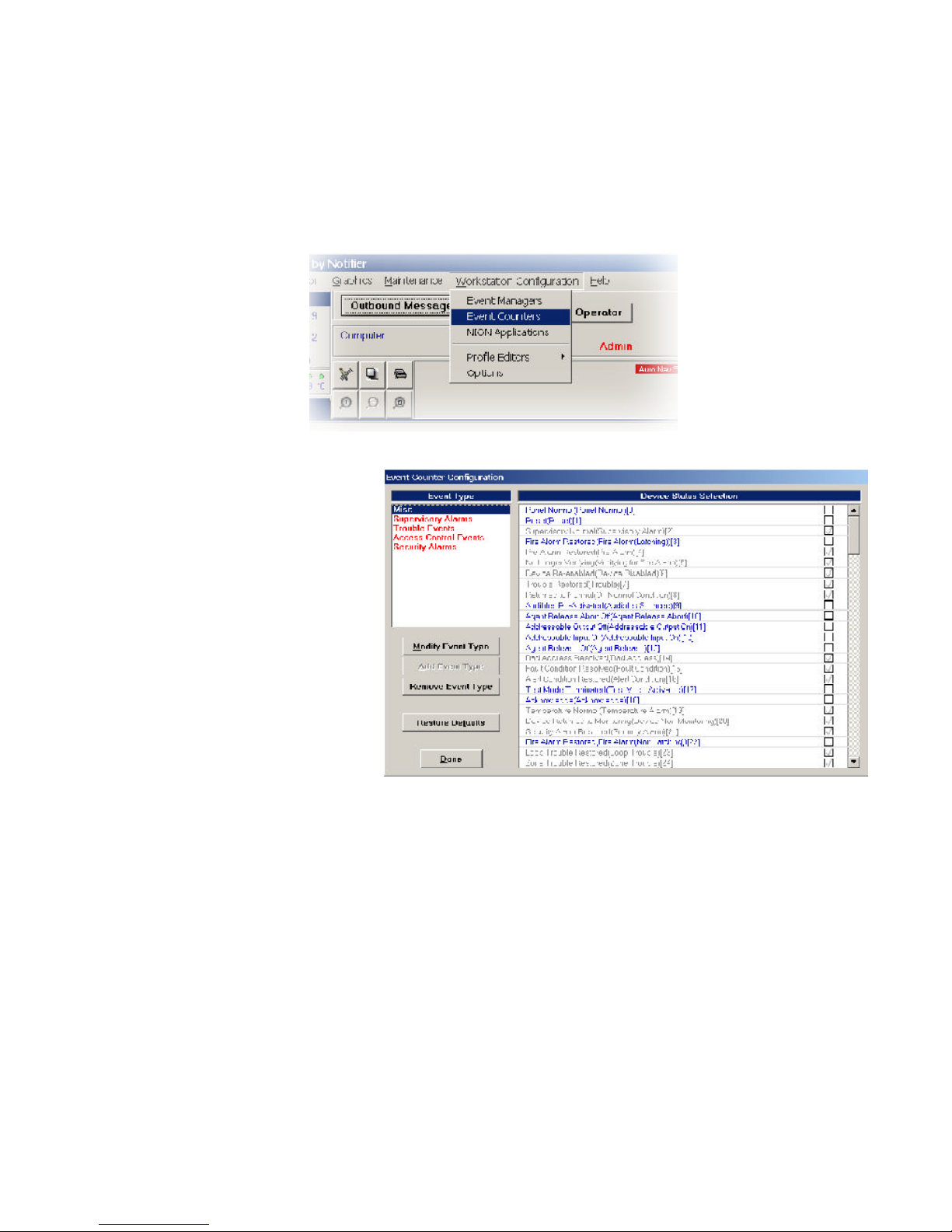

2.2.4 Configurable Event Counters .................................................................................................. 43

Figure 2-8: Starting Configurable Counters ................................................................................... 43

Figure 2-9: Configurable Counters.................................................................................................. 43

Figure 2-10: Modifying/Adding an Event Type............................................................................... 44

2.2.5 Getting More Information about Events ................................................................................ 44

Figure 2-11: Expanded Event Box.................................................................................................... 44

2.2.6: The View Latest Events and Messages Window ................................................................... 45

Figure 2-12: Latest Events and Messages Window ........................................................................ 45

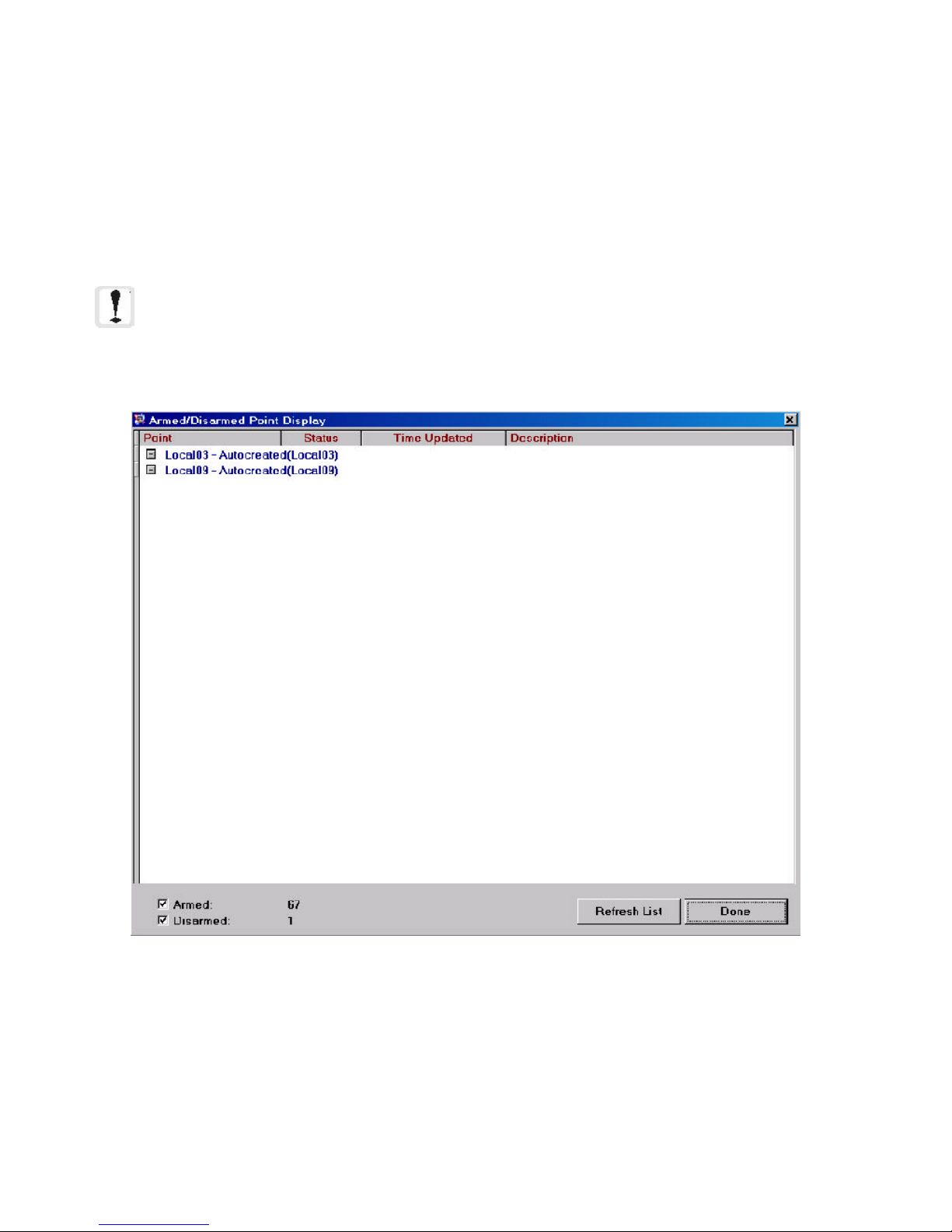

2.2.7 Armed / Disarmed Points Display .......................................................................................... 46

Figure 2-13: Armed / Disarmed Points Display ............................................................................. 46

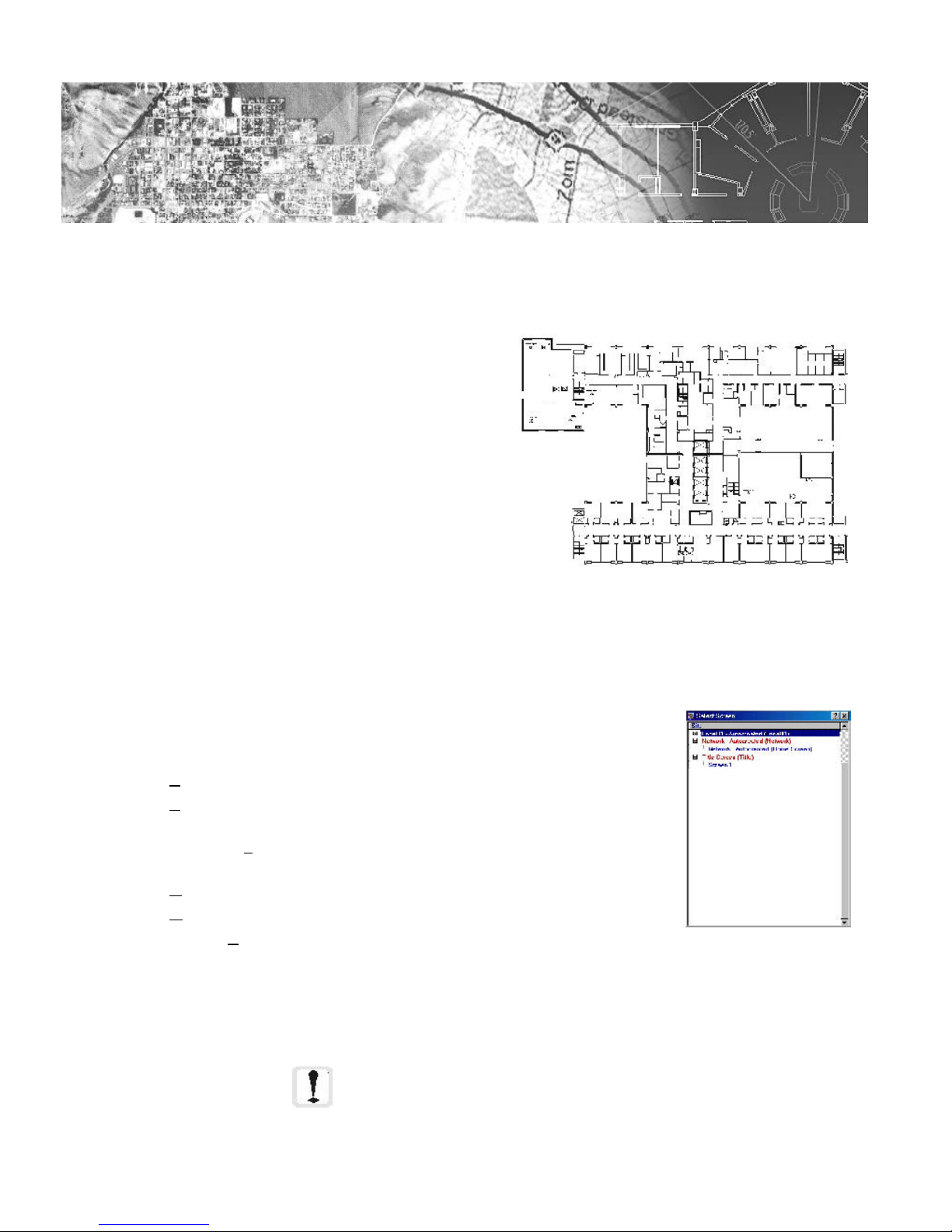

Section 2.3: Floor Plan Display .............................................................. 47

2.3.1 Introduction to the Floor Plan................................................................................................. 47

Figure 2-14: Floor Plan Display ........................................................................................................ 47

Figure 2-15: Select Screen Dialog ................................................................................................... 47

2.3.2 Contents of the Floor Plan Display .......................................................................................... 48

Figure 2-16: Sample Pop-up Menu................................................................................................. 48

Figure 2-17: Sample Information Window ..................................................................................... 49

Figure 2-18: Common Tools .............................................................................................................. 49

2.3.3 Keymap .................................................................................................................................... 50

Figure 2-19: Overview / Keymap .................................................................................................... 50

2.3.4 Addressable Device Pop-Up Menus....................................................................................... 51

Figure 2-20: Addressable Device Pop-Up Menus .......................................................................... 51

2.3.5 Symbol Key .............................................................................................................................. 52

Figure 2-21: Symbol Key .................................................................................................................. 52

2.3.6 Linked Information and Guidance Text ................................................................................. 52

6

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

Page 7

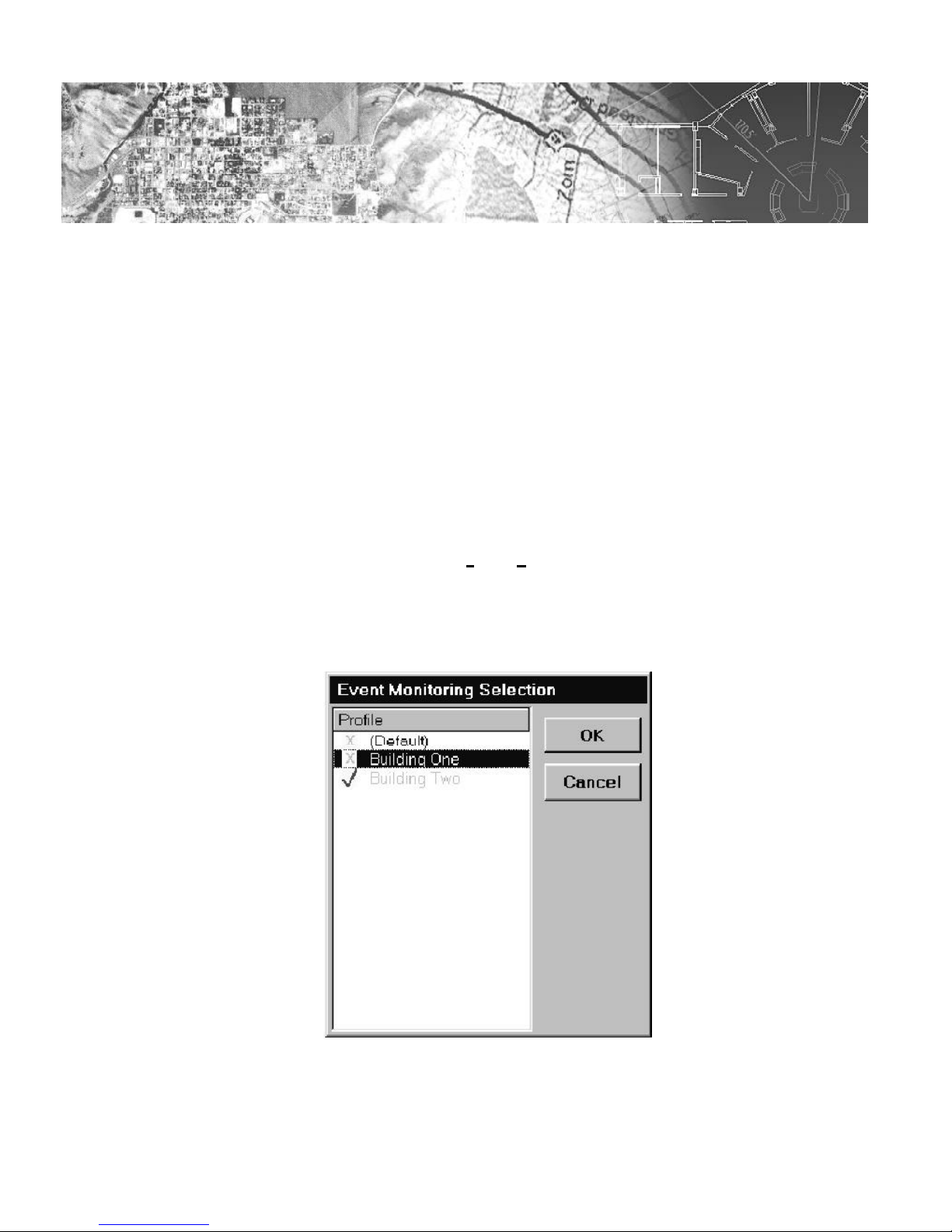

Section 2.4: Advanced Features ............................................................. 53

2.4.1 Monitoring and Control Profiles ............................................................................................. 53

Figure 2-22: Event Monitoring Configuration Dialog..................................................................... 53

Figure 2-23: Control Profile Select Dialog....................................................................................... 54

2.4.2 Function Keys........................................................................................................................... 55

2.4.3 Printing in the Workstation .................................................................................................... 55

2.4.4 History Manager ....................................................................................................................... 56

Figure 2-24: History Manager Main Screen.................................................................................... 56

Figure 2-25: The Event Display........................................................................................................ 57

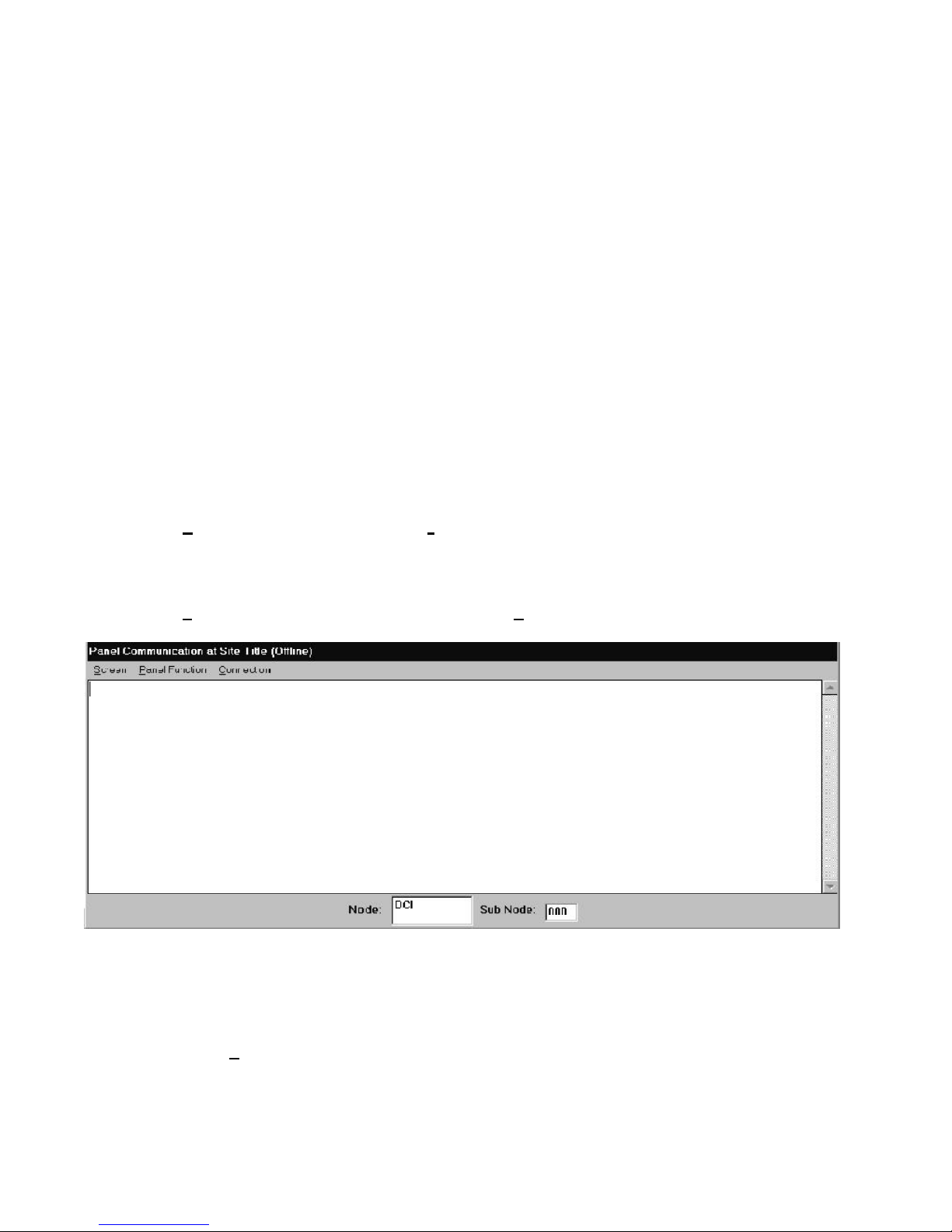

2.4.5 Panel Communications ........................................................................................................... 58

Figure 2-26: Panel Communications Session Box .......................................................................... 58

2.4.6 View Member Information Window........................................................................................ 59

Figure 2-27: View Member Information Window ........................................................................... 59

2.4.7 View Site Information.............................................................................................................. 60

Figure 2-28: View Site Information ................................................................................................. 60

Figure 2-29: View Site Information Menus ..................................................................................... 60

Part 3 System Administration ...................................................61

Section 3.1: User Management .............................................................. 63

3.1.1 The Member Editor and Member Database .......................................................................... 63

Figure 3-1: The Member Editor Dialog............................................................................................ 63

Figure 3-2: Member Name and Name Format .............................................................................. 64

3.1.2 Member Editor Configuration ................................................................................................. 65

Figure 3-2: Profile Access Editor - Edit Profiles Tab ....................................................................... 65

Figure 3-3: New UDF Dialog............................................................................................................ 66

Figure 3-4: Profile Access Editor - Edit Fields Tab .......................................................................... 66

Figure 3-5: Modifying a User Defined Field ................................................................................... 66

3.1.3 Security and Security Profiles ................................................................................................. 67

Figure 3-6: Security Profile Maintenance Dialog ........................................................................... 69

3.1.4 Defining Monitor and Control Profiles ................................................................................... 70

Figure 3-7: The Event Monitor Profiles Manager Dialog ............................................................... 70

Figure 3-8: The Control Profiles Configuration Dialog................................................................... 72

Section 3.2: Screen and Site Management.............................................. 73

3.2.1 Screen Structure ...................................................................................................................... 73

3.2.2 Creating a New Site................................................................................................................. 73

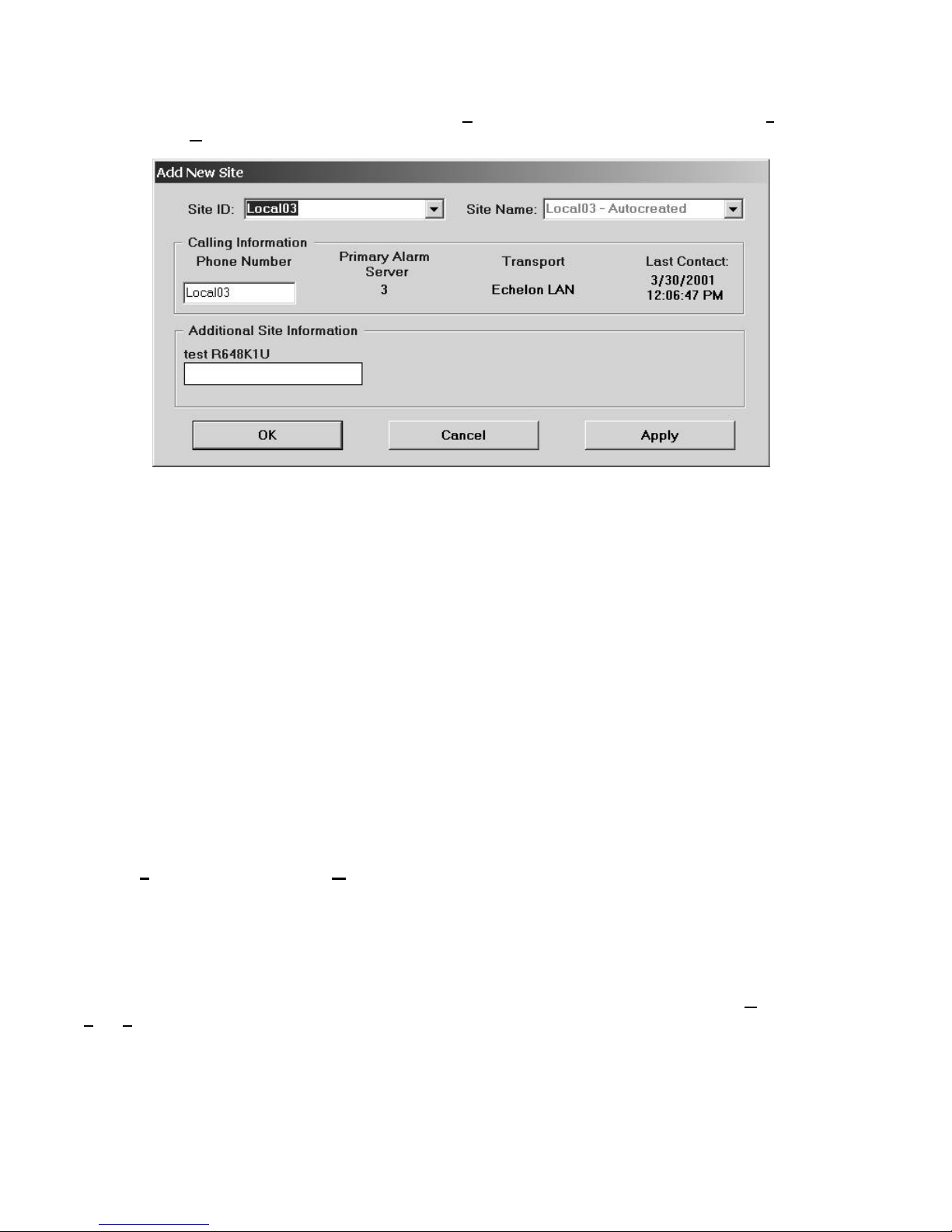

Figure 3-9: Add New Site Form ....................................................................................................... 74

3.2.3 Adding and Editing Screens ................................................................................................... 75

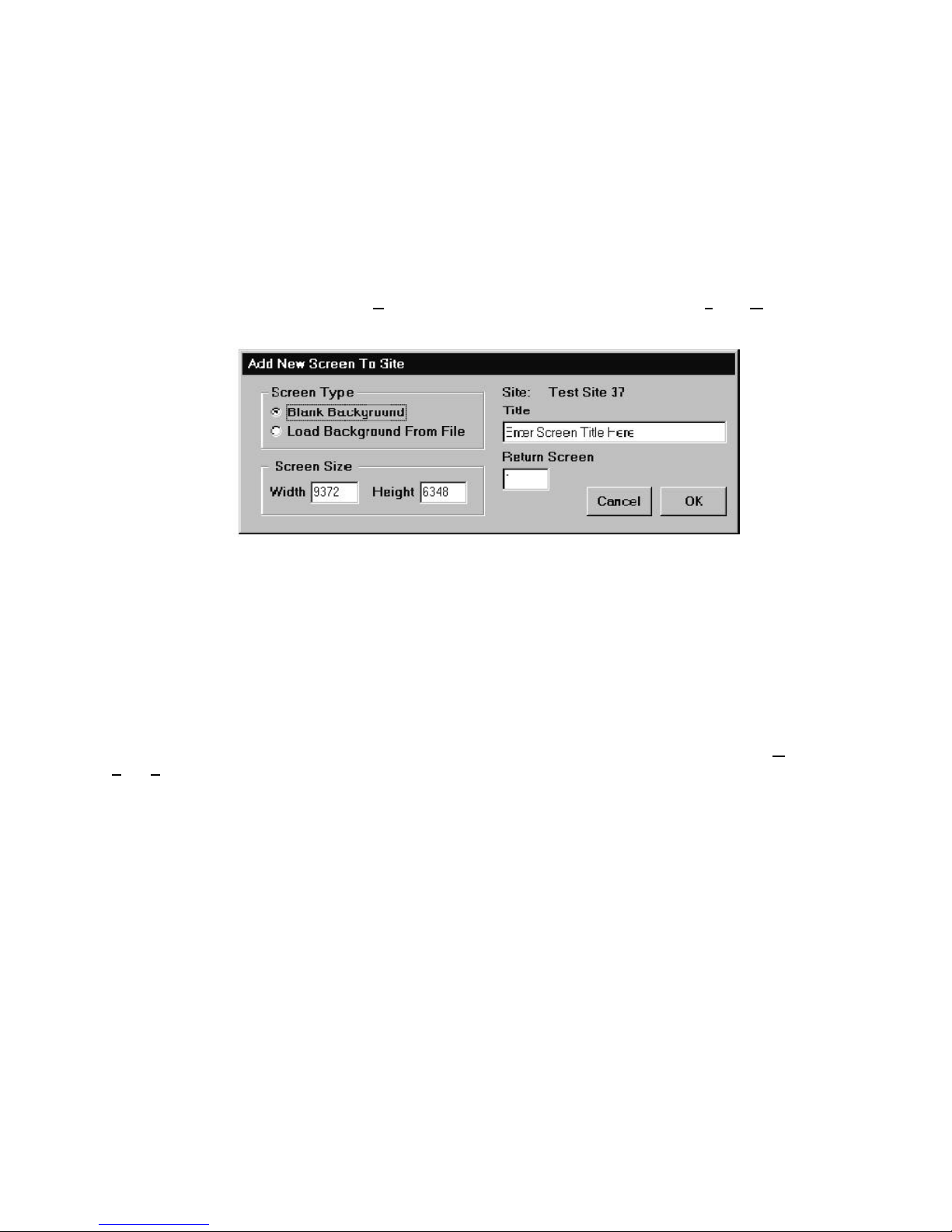

Figure 3-10: Add New Screen to Site Form..................................................................................... 75

3.2.4 Other Screen and Site Related Operations ........................................................................... 76

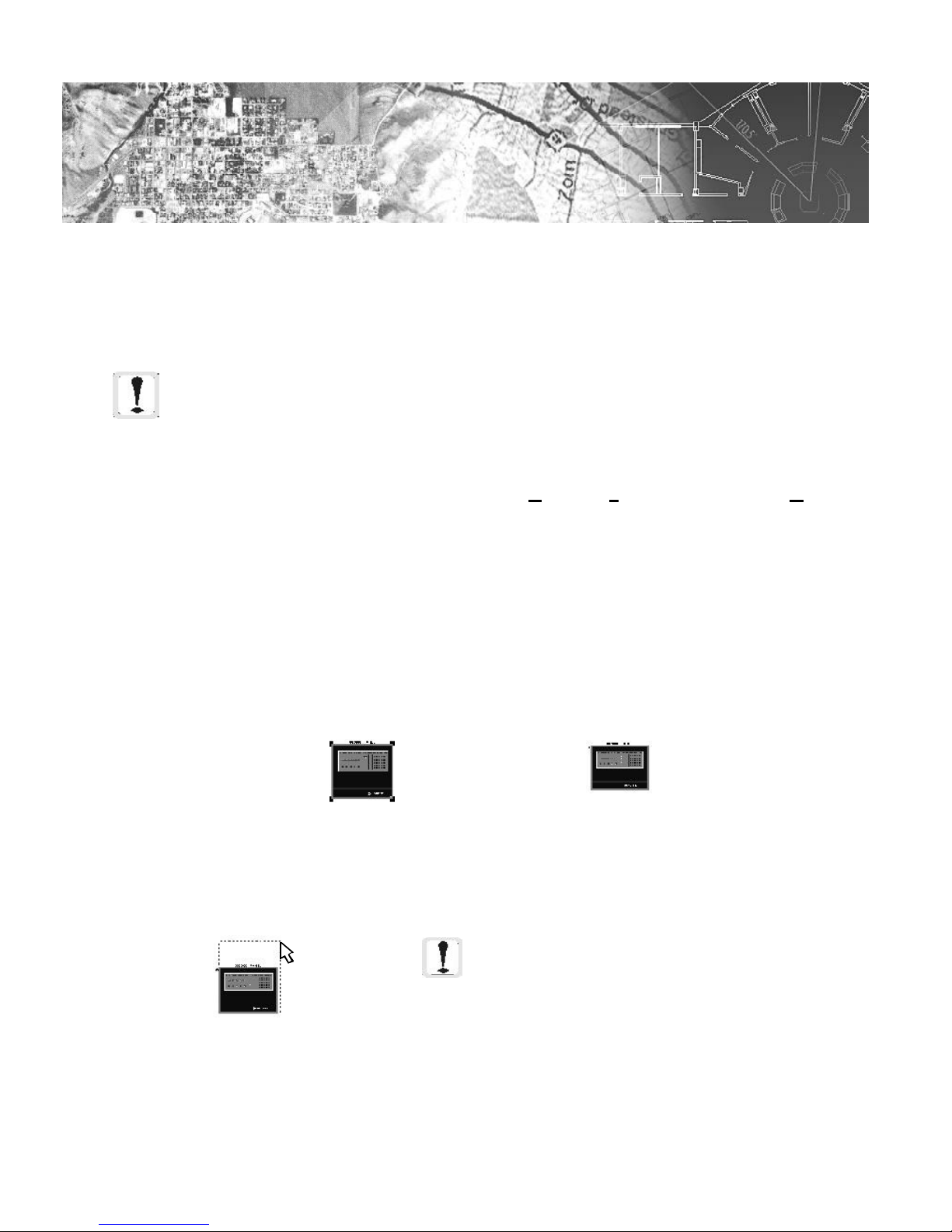

Section 3.3: Graphic and Screen Editing Tools ........................................ 77

3.3.1 Editing Screens ........................................................................................................................ 77

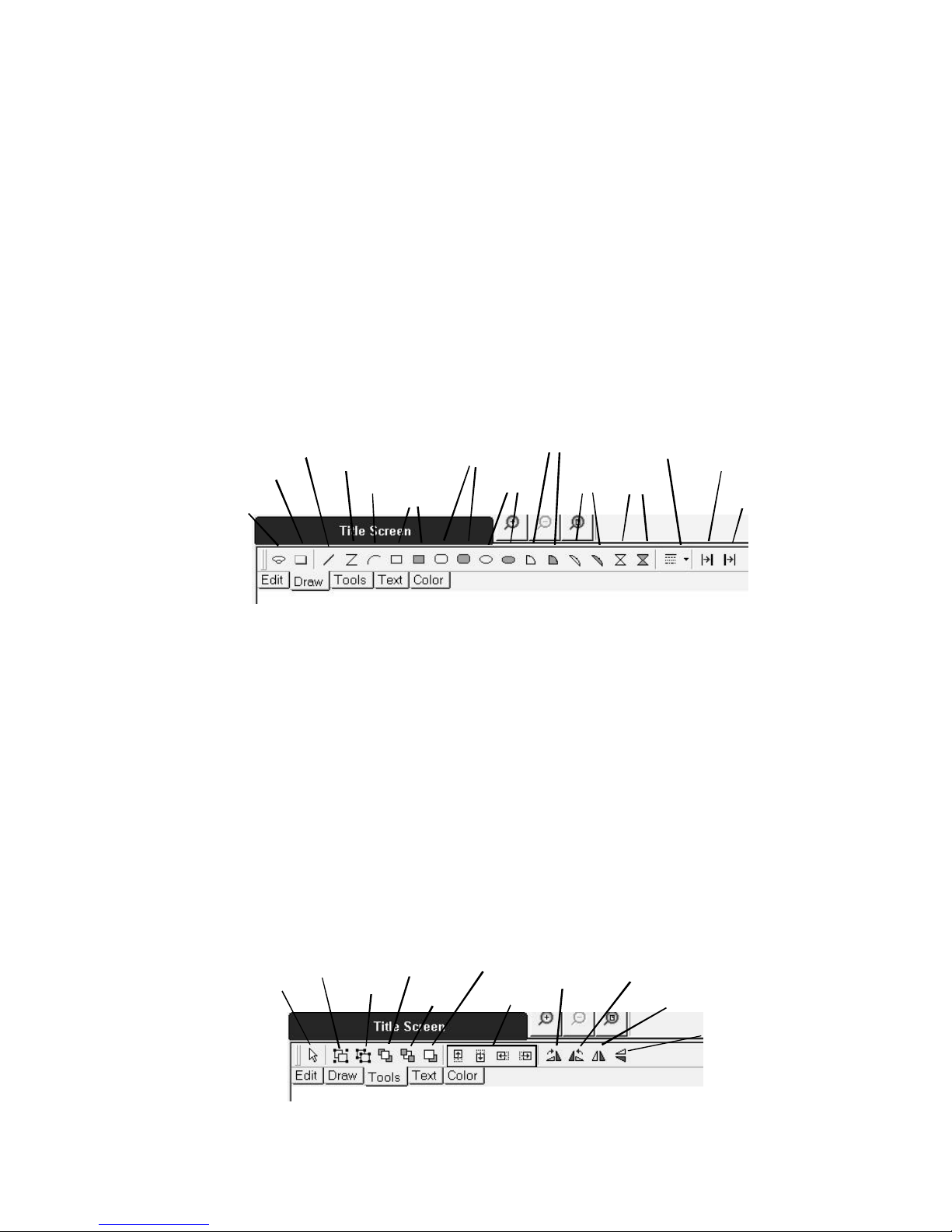

3.3.2 Graphics Toolbox ..................................................................................................................... 78

Figure 3-11: Common Screen Tools ................................................................................................. 78

Figure 3-12: Edit Tab ........................................................................................................................ 78

Figure 3-13: Draw Tab...................................................................................................................... 79

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

7

Page 8

Figure 3-14: Tools Tab ...................................................................................................................... 79

Figure 3-15: Text Tab ........................................................................................................................ 80

Figure 3-16: Color Tab ...................................................................................................................... 80

3.3.3 Vector Drawing Tools ............................................................................................................... 81

Figure 3-17: Mouse Pointer Tools .................................................................................................... 81

3.3.4 Using Text................................................................................................................................. 84

3.3.5 Importing .BMP and .WMF Files ............................................................................................. 84

3.3.6 Cutting, Copying and Pasting ................................................................................................. 85

3.3.7 Repairing Screens ................................................................................................................... 85

Section 3.4: Device Placement and Configuration................................... 87

3.4.1 Graphic Devices - Description ................................................................................................ 87

3.4.2 Adding Addressable Devices .................................................................................................. 88

Figure 3-18: Addressable Device .................................................................................................... 88

3.4.3 The New Devices Dialog.......................................................................................................... 89

Figure 3-19: New Device Dialog...................................................................................................... 89

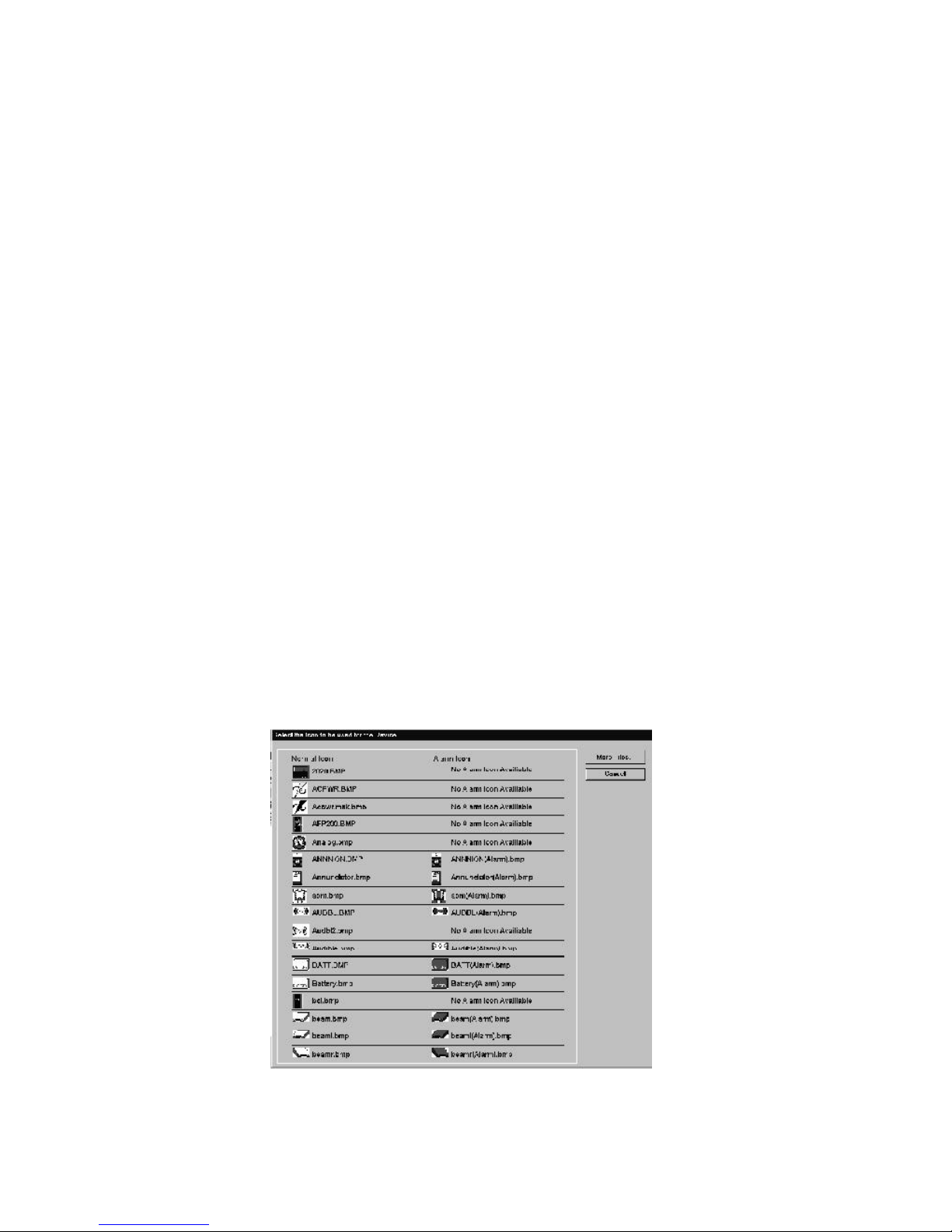

Figure 3-20: The Device Library ...................................................................................................... 90

3.4.4 Defining Analog Devices......................................................................................................... 91

Figure 3-21: Analog Input Device Dialog ....................................................................................... 91

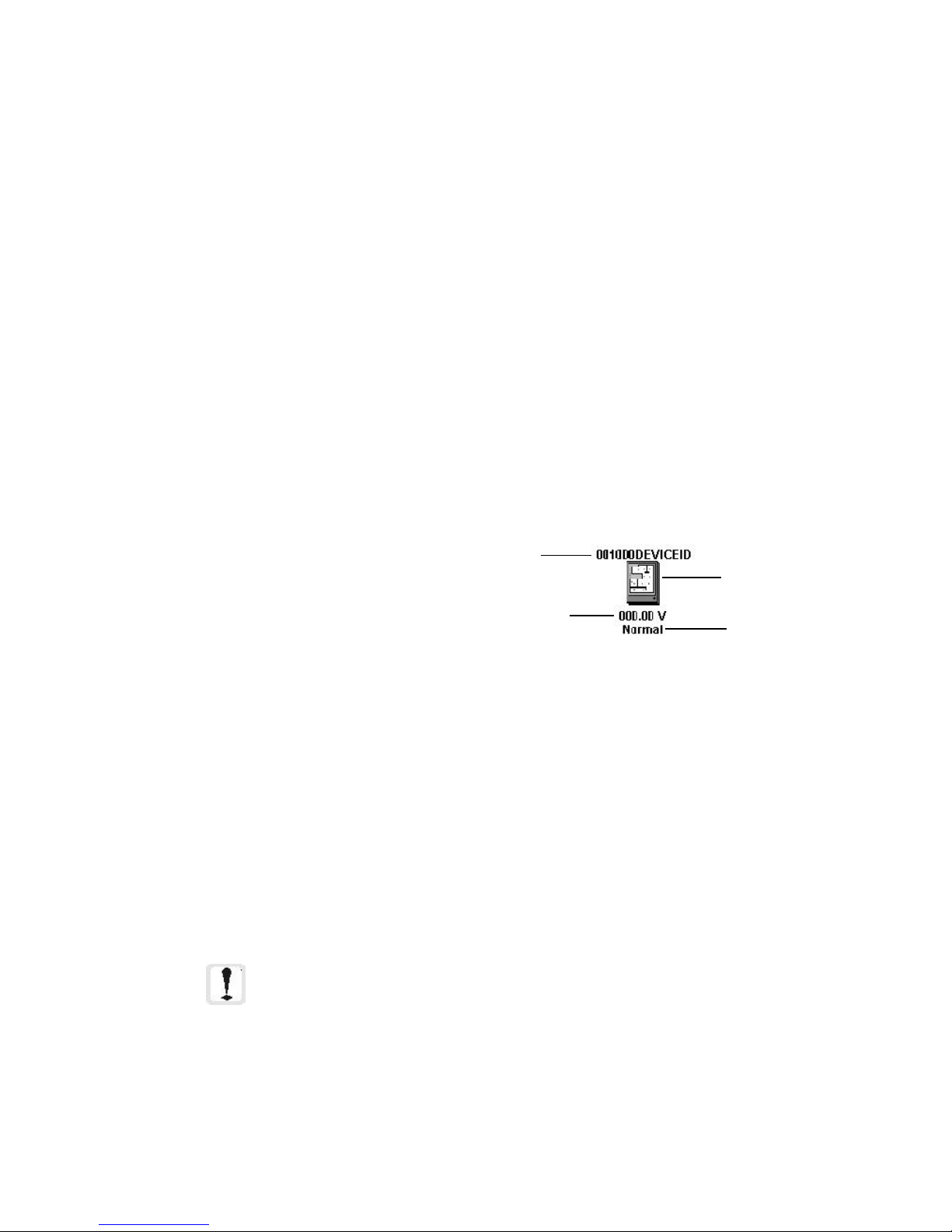

Figure 3-22: The Analog Device ...................................................................................................... 92

3.4.5 Adding Sound, Video and Text ............................................................................................... 93

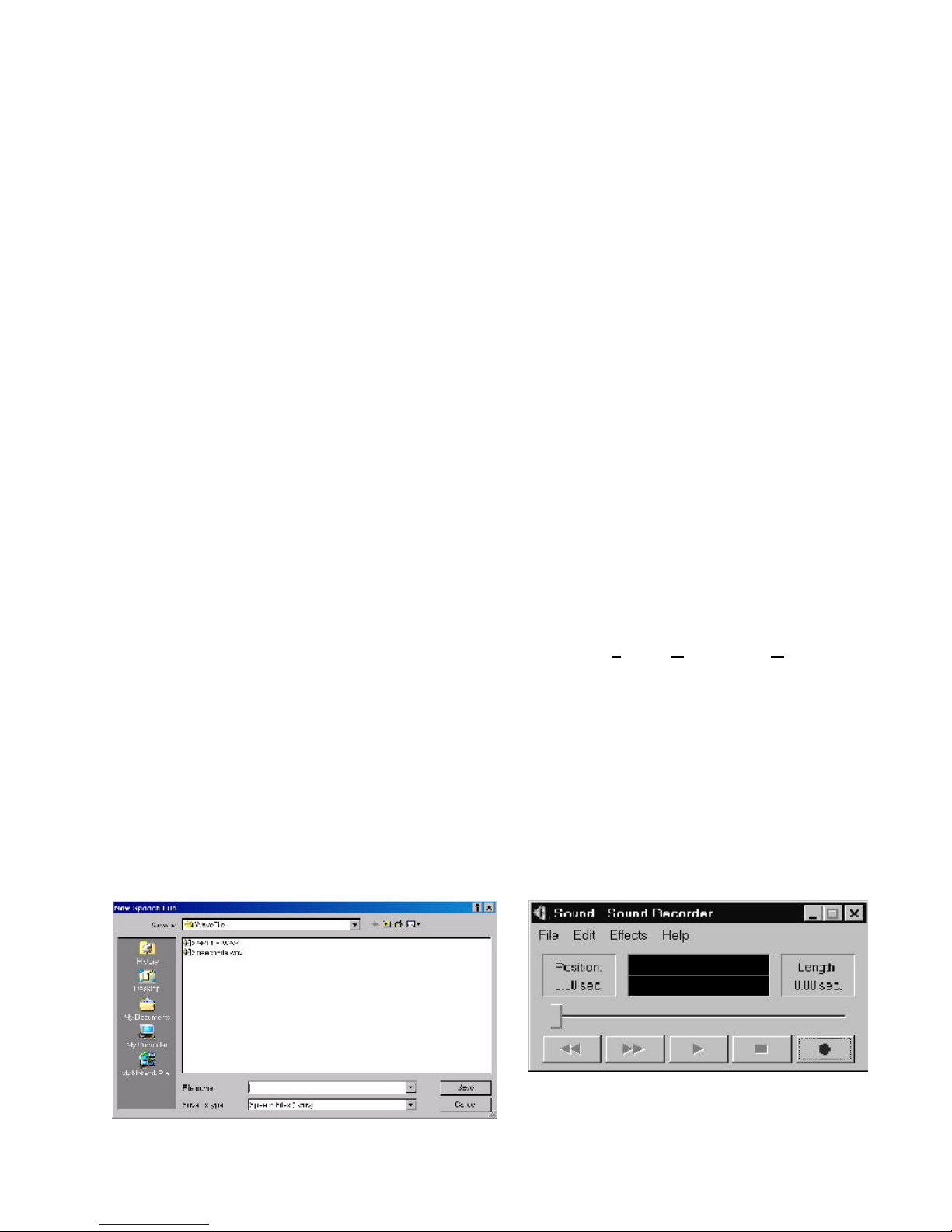

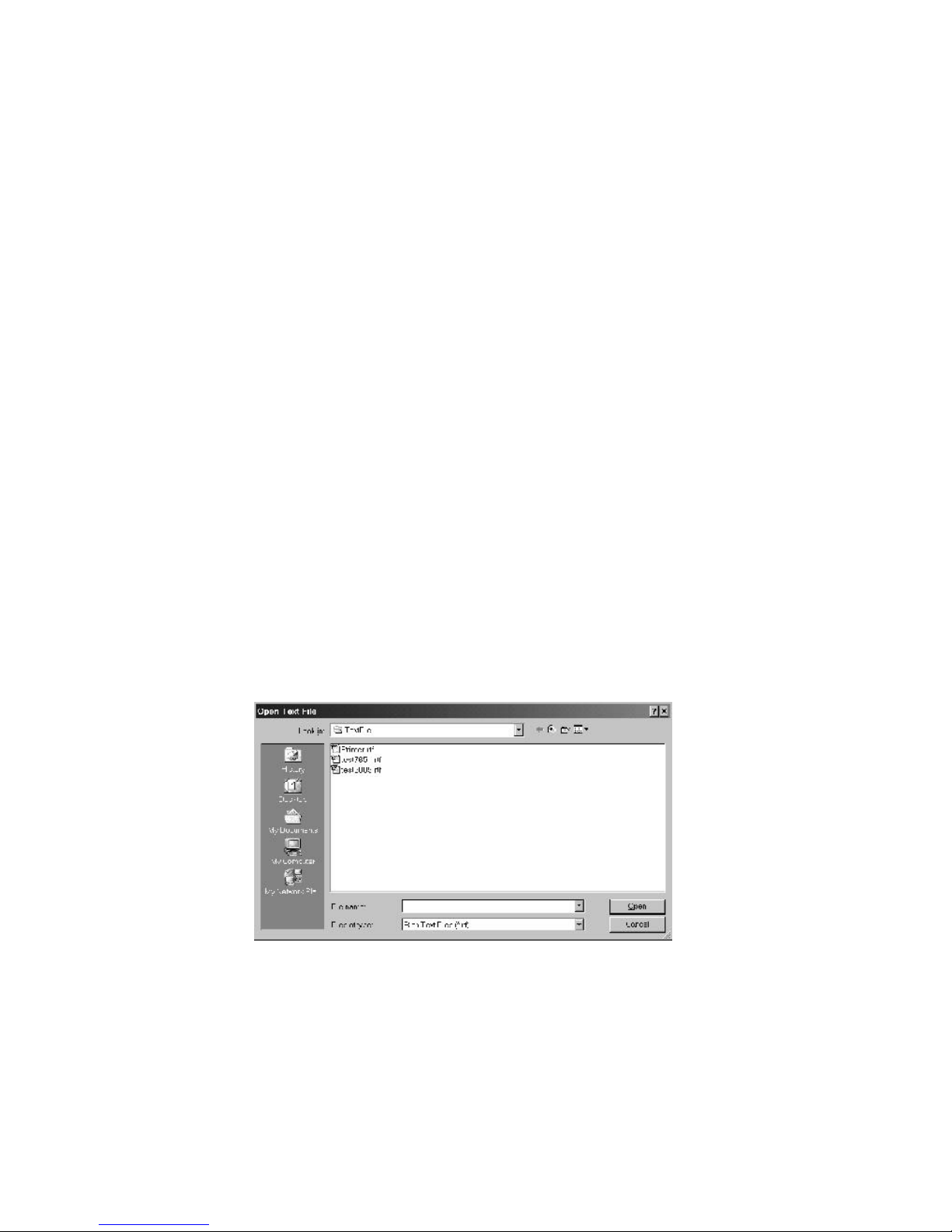

Figure 3-23: The Sound Recorder .................................................................................................... 93

Figure 3-24: The Open Text File Dialog........................................................................................... 94

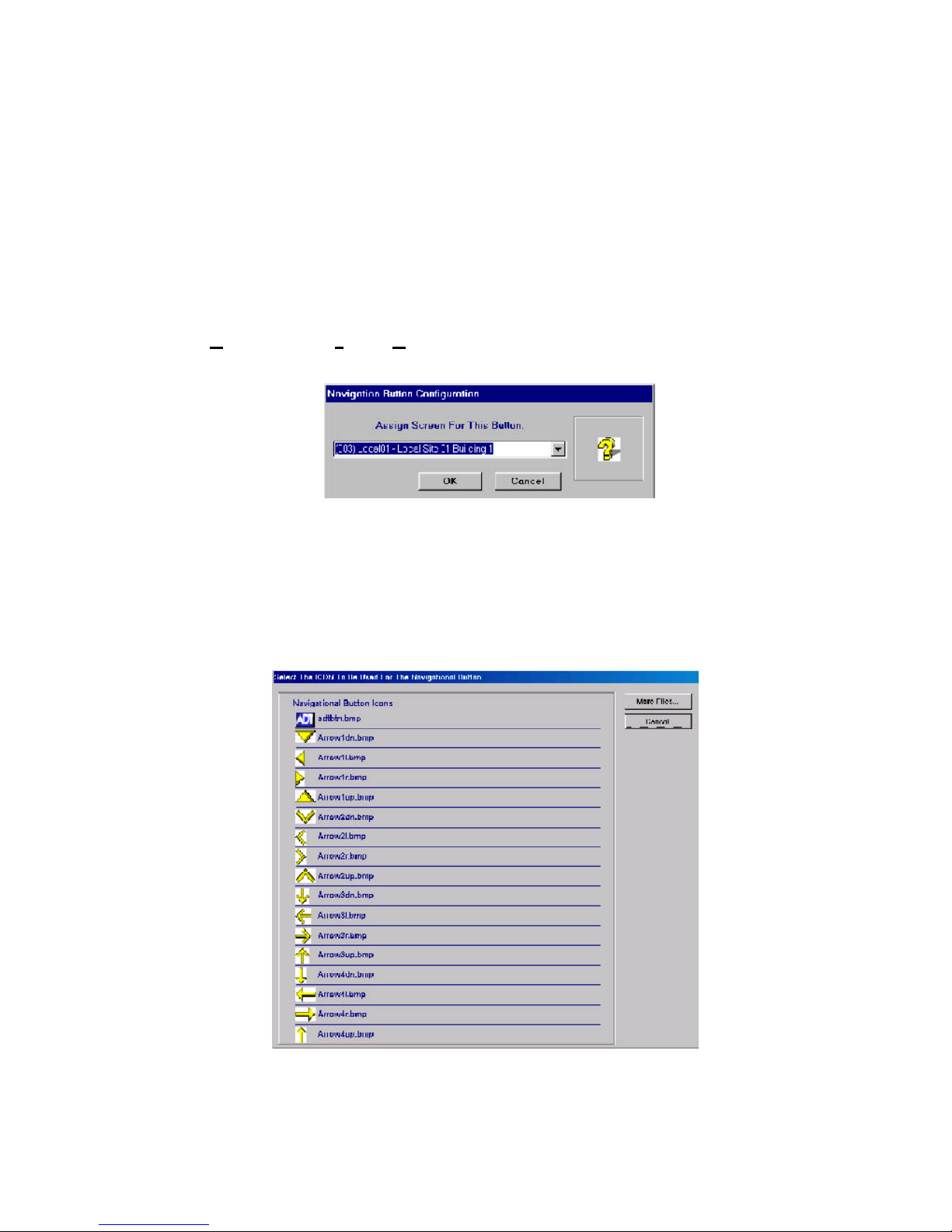

3.4.6 Navigation and Functional Buttons ....................................................................................... 95

Figure 3-25: Button Link Dialog...................................................................................................... 95

Figure 3-26: The Navigation Button Library................................................................................... 95

Figure 3-27: Functional Button Configuration Dialog.................................................................... 96

Figure 3-28: The Functional Button Library.................................................................................... 96

3.4.7 Annunciation Icons.................................................................................................................. 97

Figure 3-29: Site Link Dialog........................................................................................................... 97

Figure 3-30: The Site Symbol Library .............................................................................................. 97

3.4.8 Information Labels .................................................................................................................. 98

Figure 3-31: Information Label Link Dialog................................................................................... 98

Figure 3-32: The Information Label Library ................................................................................... 98

3.4.9 Creating a Device Symbol....................................................................................................... 99

Figure 3-33: Using the Selection Tool to Create a Box ................................................................... 99

3.4.10 Other Device Features......................................................................................................... 100

Figure 3-34: Device List Report...................................................................................................... 100

Figure 3-35: The Symbol Key ......................................................................................................... 100

3.4.11 The Effect of Zooming on Devices....................................................................................... 101

Figure 3-36: Setting Icon Zoom Levels.......................................................................................... 101

Section 3.5: System Maintenance ......................................................... 103

3.5.1 Database Management ........................................................................................................ 103

Figure 3-37: Network Configuration Window............................................................................... 105

3.5.2 Node Configuration............................................................................................................... 105

3.5.3 Defining Function Keys and Command Buttons.................................................................. 106

8

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

Page 9

Figure 3-38: Function Key Configuration form............................................................................. 106

Figure 3-39: Function Key Help Bar .............................................................................................. 108

3.5.4 Using Macro Editor ................................................................................................................ 108

Figure 3-40: Command Buttons in the Operator Area ................................................................ 108

Figure 3-41: Macro Editor .............................................................................................................. 108

3.5.5 Guidance Text ........................................................................................................................ 110

Figure 3-42: Guidance Text Reader / Editor ................................................................................. 110

3.5.6 Creating and Assigning Voice Annunciation Files ............................................................... 110

Figure 3-43: Speech Annunciation Tab......................................................................................... 110

3.5.7 Universal Time Code Editor .................................................................................................... 112

Figure 3-44: Time Code Editor Form.............................................................................................. 112

Figure 3-45: Holiday Codes Form .................................................................................................. 114

3.5.8 Device Test Manager ............................................................................................................. 115

Figure 3-46: Device Test Manager ................................................................................................. 115

Figure 3-47: Device Test Manager ................................................................................................. 115

Part 4 Plug-In Applications and Installations .........................117

4.1: Plug-In Installation ...................................................................... 119

4.1.1 Plug-In Selection and Configuration ................................................................................... 119

Figure 4-1: NION Plug-In Selection and Configuration Form..................................................... 119

4.1.2 Mapping Plug-ins With NIONs............................................................................................. 120

Figure 4-2: Network Configuration Window................................................................................. 120

4.2: GenFire Plug-In Application ........................................................ 121

4.2.1 GenFire.CFG Configuration File ............................................................................................ 121

4.3: AFP-400/AFC-600 Plug-In Application ......................................... 123

4.3.1 Command Options................................................................................................................. 123

4.4: NION-ENV Plug-in Application...................................................... 125

4.4.1 NION-ENV Configuration and Settings Forms .................................................................... 125

4.4.2 Configuration Options ........................................................................................................... 125

Figure 4-3: NION-ENV Configuration Form.................................................................................. 125

4.4.3 View Current Settings ............................................................................................................ 127

Figure 4-4: View Current Settings Form........................................................................................ 127

4.4.4 HVAC Operation .................................................................................................................... 127

4.5: Reserved ...................................................................................... 129

4.6: Burle Plug-In Application ............................................................. 131

4.6.1 The Burle Plug-In Interface .................................................................................................. 131

Figure 4-5: Burle CCTV NION Plug-In Interface........................................................................... 131

Figure 4-6: Sequencing and Preset Location ............................................................................... 131

Figure 4-7: Burle CCTV NION On-Line Session Dialog ................................................................ 132

4.6.2 UniLogic Applications for the Burle CCTV NION Plug-In .................................................... 132

4.7: Javelin Plug-In Application........................................................... 133

4.7.1 Javelin PTZ and Switcher Plug-Ins....................................................................................... 133

4.7.2 Javelin PTZ ............................................................................................................................. 133

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

9

Page 10

Figure 4-8: Javelin PRZ Controller Interface ................................................................................ 133

Figure 4-9: Javelin Plug-In Interface............................................................................................ 134

4.7.3 Javelin Video Switcher (JavVid) Plug-In.............................................................................. 134

4.8: Pelco Plug-In Application.............................................................. 137

4.8.1 Pelco CCTV NION Plug-In ..................................................................................................... 137

Figure 4-10: Pelco CCTV NION Plug-In Interface......................................................................... 137

4.8.2 Command Buttons ................................................................................................................. 138

Figure 4-11: The Sequence Dialog................................................................................................ 138

Figure 4-12: Playing a Macro ........................................................................................................ 138

Figure 4-13: Playing a Macro ........................................................................................................ 138

Figure 4-14: Patterns ..................................................................................................................... 139

Figure 4-15: Presets ....................................................................................................................... 139

4.8.3 UniLogic Applications for the Pelco CCTV NION Plug-In .................................................... 140

4.9: Vicon Plug-In Application ............................................................. 141

4.9.1 Vicon CCTV NION Plug-In ..................................................................................................... 141

Figure 4-16: Vicon CCTV NION Plug-In Interface ........................................................................ 141

4.9.2 CCTV Operation ..................................................................................................................... 141

4.10: NION-2C8M / 16C48M Point Scheduling Plug-In Applications ..... 143

4.10.1 NION-2C8M/16C48M Overview .......................................................................................... 143

Figure 4-17: 2C8M I/O Configuration............................................................................................ 143

Figure 4-18: 16C48M I/O Configuration........................................................................................ 144

Figure 4-19: Time Code Configuration .......................................................................................... 145

4.10.2 Time Codes ........................................................................................................................... 145

4.10.3 Universal Time Codes and Time Code Groups................................................................... 146

Figure 4-20: Holiday Code Configuration ..................................................................................... 146

4.10.4 Functional Properties of the 2C8M / 16C48M..................................................................... 147

4.11: NFN Explorer ............................................................................. 151

4.11.1 NFN Explorer Overview ....................................................................................................... 151

4.11.2 Registering the NFN Explorer with UniNet ........................................................................ 151

4.11.3 Launching the NFN Explorer .............................................................................................. 151

Figure 4-21: Starting the NFN Explorer ......................................................................................... 151

4.11.4 The NFN Explorer ................................................................................................................. 152

4.11.5 Operation............................................................................................................................. 152

4.11.6 Compatible Panels .............................................................................................................. 152

Figure 4-22: The NFN Explorer ....................................................................................................... 152

4.11.7 Editing Panel Properties ..................................................................................................... 153

4.11.8 Detectors .............................................................................................................................. 153

Figure 4-23: Updating Changes ..................................................................................................... 153

Figure 4-24: Detecting Detectors ................................................................................................... 153

4.11.9 Modules ................................................................................................................................ 154

Figure 4-25: Detecting Modules ..................................................................................................... 154

Figure 4-26: Module Controls ......................................................................................................... 154

Figure 4-27: Enable and Disable.................................................................................................... 154

4.11.10 Panels................................................................................................................................. 155

10

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

Page 11

Figure 4-28: Finding Panel Circuits ................................................................................................ 155

4.11.11 Panel Interfaces ................................................................................................................ 156

NFS-640/3030 Panels...................................................................................................................... 156

NFS-640/3030 Panels (Cont’d) ....................................................................................................... 157

NFS-640/3030 Panels (Cont’d) ....................................................................................................... 158

NFS-640/3030 Panels (Cont’d) ....................................................................................................... 159

AFP-300/400 Panels ........................................................................................................................ 160

AFP-300/400 Panels (Cont’d) .......................................................................................................... 161

AFP-300/400 Panels (Cont’d) .......................................................................................................... 162

AFP1010/AM2020 Panels ................................................................................................................ 163

AFP1010/AM2020 Panels (Cont’d) .................................................................................................. 164

AFP1010/AM2020 Panels (Cont’d) .................................................................................................. 165

AFP1010/AM2020 Panels (Cont’d) .................................................................................................. 166

AFP1010/AM2020 Panels (Cont’d) .................................................................................................. 167

Appendices Additional System Information ............................169

Appendix A: UniNet Keyboard Shortcuts .............................................. 171

Figure A-1: EDIT MODE KEYBOARD SHORTCUTS .......................................................................... 171

Figure A-2: EDIT MODE KEYBOARD SHORTCUTS (CONT.) ............................................................ 172

Figure A-3: MISC. KEYBOARD SHORTCUTS ................................................................................... 172

Appendix B: Pull Down Menu Hierarchy............................................... 173

Appendix C: Terminology Index........................................................... 177

Appendix D: Using Sound Recorder ..................................................... 183

The Sound Recorder ........................................................................................................................ 183

Figure D-1: The Sound Recorder ................................................................................................... 183

Sound Recorder Pull Down Menu Hierarchy.................................................................................. 184

Appendix E: Event Data (Status, Priority, and Color Coding) ................ 187

Figure E-1: Events By Priority (Highest Priority First) ................................................................... 187

Event Data........................................................................................................................................ 187

Figure E-2: Event Color Coding ...................................................................................................... 189

Figure E-3: Event Abbreviations .................................................................................................... 190

Printer Output Format..................................................................................................................... 192

Index ................................................................................................... 193

Network Installation Manual 51539 UniLogic 51547

Workstation 51540 UniBadge 51549

System Utilities 51592 UniTour 51550

BCI ver. 3-3 51543 NION-ENV Environmental Monitoring 51541

Local Area Server 51544 IRM/IM 51591

Wide Area Server 51545 2DRN 51542

Event Manager 51546 UniGuard Access Control Application 51548

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

Related Documentation

11

Page 12

Foreword

The contents of this manual are important and must be kept in close proximity of the Workstation. If building

ownership is changed, this manual including all other testing and maintenance information must also be passed to

the current owner of the facility. A copy of this manual was shipped with the equipment and is also available from

the manufacturer.

NFPA Standards

• National Fire Protection Association Standards 72.

• National Electric Code (NFPA 70).

• Life Safety Code (NFPA 101).

Underwriters Laboratories U.S. Documents

• UL-864 Control Units for Fire Protective Signaling Systems.

• UL-1076 Proprietary Burglar Alarm Units and Systems.

• UL-294 Access Control System Units.

Underwriters Laboratories Canada Documents

• CAN/ULC-S524-M91 Standard for Installation of Fire Alarm Systems.

• CAN/ULC-S527-M99 Standard for Control Units for Fire Alarm Systems.

Other

• Requirements of the Local Authority Having Jurisdiction (LAHJ).

WARNING: Improper installation, maintenance, and lack of routine testing could result in system malfunction.

Introduction

The UniNet Workstation Software is the next step in facility monitoring and control. The software provides extensive

control and monitoring functions for fire, security, and building automation of local and remote sites. The software

is fully customizable in order to adapt to a wide variety of monitoring situations. The software supports multiple

operators and multiple workstations, monitoring all or a portion of local and remote sites.

This system is suitable for proprietary systems listed under:

• NFPA 72-1993 Proprietary Service.

UniNet consists of graphical workstations monitoring and controlling, local or remote twisted pair or fiber optic

networks. Remote network monitoring is achieved through the use of a Building Communications Interface (BCI).

A twisted pair network topology (FT-10) may be a maximum length of 6000 feet per network segment with no Ttaps, allowing communications between 32 nodes in each segment. In addition FT-10 allows dedicated runs of

8000 feet point-to-point or multiple T-taps within 1500 feet of any other node on the segment. FO-10 communicates over fiber-optic cable and can be configured in either a bus or ring topology with up to 8 db of attenuation

between nodes. The network has a maximum system capacity of 200 nodes. The network is supervised for shorts,

opens and node failures as dictated in Style 4 wiring.

The network power is 24 VDC nominal and receives operating power from a filtered, power limited source which is

listed for use with fire protective signaling units.

12

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

Page 13

Part 1

Workstation Installation

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

UniNet 2000

13

Page 14

NOTES

14

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

Page 15

1.1

Section 1.1: UWS Computer Installation

The UniNet 2000 network may be comprised of two different UL listed computers. UniNet 2000 is now available

with a rack mount capable UL listed Pentium III computer. These new computers may be used in conjunction with

a UniNet 2000 system using the Intel Pentium II previously offered with UniNet 2000. The following will describe

the installation and configuration of both computers.

1.1.1 Description of the Computer Components

The following is a list of components common to all computers on the UniNet 2000 network.

Intel Pentium II 400 Computer

• Intel Pentium Computer with:

- Intel Pentium II 400 Mhz CPU.

- 128 MB RAM.

- 3 GB Hard Drive

• (1) Monitor:

- 19"

• (1) Pointing Device:

- Microsoft Serial PS/2 compatible mouse.

• 101 key keyboard.

• Workstation Supervisor card.

• Ethernet network interface card.

• Software key.

• PCLB-5

Intel Pentium III 800 Computer

• Intel Pentium III Computer with:

- Intel Pentium III 800 Mhz CPU with 512Kb Cache Memory

- 256 MB RAM Expandable to 512 MB

- 20 GB Hard Drive

• (1) Monitor:

- 19"

• (1) Pointing Device:

- Microsoft Serial PS/2 compatible mouse.

• 101 key keyboard.

• Workstation Supervisor card.

• Ethernet network interface card.

• Software key.

• PCLB-6

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

15

Page 16

1.1.2 Installation Description

This section describes the procedures for installing the computer system.

Site Requirements

The computer system can be installed in the following environmental conditions:

• Temperature range of 0ºC - 49ºC (32ºF - 120ºF).

• 93% humidity non-condensing at 30ºC (86ºF).

Setup

The computer should be placed on a desk or table with the monitor, keyboard, and pointing device. This must be

done in accordance with local code requirements.

Connecting AC Power to the PC Power Supply of UniNet 2000 Computers

AC power must be connected in a permanent manner and enclosed by the included PCLB-5 (Intel Pentium II

computer) or PCLB-6 (Intel Pentium III computer) electrical box. An AC power line protector (HSP-121B) and UPS

are required for each power line on the workstation (CPU and monitor). Attach the AC power line to the CPU per

the following three figures:

NOTES: The workstation requires 115 VAC, 60Hz primary power.

A UPS (Uninterruptable Power Supply) which is UL listed for use with fire protective signaling units is

required for each workstation.

The front power switch for the Intel Pentium II computer has been permanently disabled.

Power management options must be disabled in the CPU BIOS and on the monitor, or loss of network

communication or alarm reporting may result.

16

Intel Pentium

II

PCLB-5

Knockout

Power Supply

Socket

Mounting Screws

Figure 1-1: Attaching the PCLB-5 to the Intel Pentium II Computer

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

Page 17

NOTES: The workstation requires 115 VAC, 60Hz primary power.

A UPS (Uninterruptable Power Supply) which is UL listed for use with fire protective signaling units is

required for each workstation.

The power switch on the back of the Intel Pentium III computer has been disabled and permanently

fixed in the ON psition. A functional power supply switch is located behind the locking front door.

Power management options must be disabled in the CPU BIOS and on the monitor, or loss of network

communication or alarm reporting may result.

Intel Pentium

III

PCLB-6

Cover

Mounting Screws

PCLB-6

Power Supply

Socket

Knockout

Figure 1-2: Attaching the PCLB-6 to the Intel Pentium III

Rack Mountable Computer

Connecting the HSP-121B AC Power Line Protector

The following diagram shows the connections of the HSP-121B. It must be installed on each Multi-Net Manager

computer.

Black

To 115 VAC, 60

Hz Primary Power

White

Green

Figure 1-3: Connecting the Power Cord and Primary AC Power to the HSP-121B

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

Junction Box

HSP-121B

Fuse

Neutral - White

AC - Black

Conduit

Power Cord

Ground Green

17

Page 18

UPS Supervision

Where a workstation or server PC is not ancillary, the use of a supervised 115VAC Uninterruptable Power Supply

(UPS) is required. A networked NION with supervised dry contact inputs must be located within three feet of the

UPS, and wiring must be in conduit. Refer to figures 1-3 for wiring information.

Example: NION2C8M

UPS Supervision of Workstation/Server/Monitor/PRN

Used with the Lamarche Mfg. Company Battery Charger A36F-25-48V-ABD1 and Inverter A31-1.5K-48V-A6

Figure 1-4: Computer UPS Supervision

18

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

Page 19

NOTE: Use only wire for power limited systems.

Power limited wire runs use type FPLR, FPLP, FPL

or equivalent cabling per NEC 760.

RJ-45 Ethernet

Connection

Echelon PCLTA-20

LPT Port

Software Key

Connection

COM Ports 1 and

2

USB Ports 1 and

2

Workstation

Supervisor

AC Power

Connector

COM Ports 3

and 4

Audio

Mouse/Keyboard

Port

Figure 1-5: Intel Pentium III Rack Mountable Computer

and Peripheral Connections

NOTE: The power switch on the back of the UnInet 2000 Intel Pentium III computer has

been disabled and permanently fixed in the ON position. A functional power supply

switch is located behind the locking front door.

Connecting the Computer Peripherals

1) Connect AC power to the AC power connector.

2) Connect the keyboard to the mouse/keyboard port.

3) Connect the mouse to the PS/2 mouse/keyboard port.

4) Connect the monitor cable to the monitor port.

5) Connect the Echelon PCLTA-20 to the network using the terminal screws (This is only available on computers with the Local Area Server installed).

6) Connect the software key to LPT-1.

7) For the Event Printer option, connect the Event Printer to the workstation at COM Port 1.

8) For the Graphic Printer option, connect the Graphic Printer into the workstation key at LPT-1.

Monitor

Port

Not

Used

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

19

Page 20

NOTE: Use only wire for power limited systems.

Power limited wire runs use type FPLR, FPLP, FPL

or equivalent cabling per NEC 760.

RJ-45 Ethernet

Connection

LPT-1

AC Power Connector

Monitor Port

Workstation

Supervisor

Speaker

Connection

COM Port 1

COM Port 2

USB Ports

Keyboard

PS/2 Mouse Port

Figure 1-6: Intel Pentium II Computer and Peripheral Connections

NOTE: The front power switch of the PC has been disabled at the factory by removing the connector

from J8G3 and placing a jumper across pins 1 and 2 of J8G3 on the motherboard.

Connecting the Computer Peripherals

1) Connect AC power to the AC power connector.

2) Connect the keyboard to the keyboard adapter.

3) Connect the mouse to the PS/2 mouse port.

4) Connect the monitor cable to the monitor port.

5) Connect the Echelon PCLTA-20 to the network using the terminal screws (This is only available on computers with the Local Area Server installed).

6) Connect the software key to LPT-1.

7) For the Event Printer option, connect the Event Printer to the workstation at COM Port 1.

8) For the Graphic Printer option, connect the Graphic Printer into the workstation key at LPT-1.

IMPORTANT: Once the Workstation has been assembled and powered on, Windows Settings must be configured. Since these settings

affect multiple Multi-Net Manager applications, they are detailed in

a separate manual entitled System Utilities. For the Workstation to

function properly, these instructions must be followed.

20

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

Page 21

1.1.3 The Workstation Supervisor

The workstation supervisor is designed to monitor the workstation. In the event that the software stops running or

the CPU fails, an onboard sounder is activated to notify operators of the problem. The board also has an onboard

output relay to allow annunciation by any external device which uses dry contact inputs. Alarms may be acknowledged by pressing a button on the back of the board.

This board mounts internally in the UWS 586T computer using an ISA slot and a standard mounting bracket.

Power is provided by an external 24VDC source, power limited and regulated with battery backup which is UL/ULC

listed (as appropriate for your area) for use with fire protective signalling units. The unit comes pre-installed and

configured and requires only external power to activate. Maximum power use is 35mA @ 24VDC.

The onboard relay may be wired for normally open (NO) or normally closed (NC) operation by setting jumper JP1

to the desired position. Refer to the board markings for jumper settings. This relay is rated for 1A @ 30VDC.

NOTE: Do not connect power from

a fire alarm panel, as it may cause a

ground fault in the panel.

Jumper JP1

Address Selection DIP

Onboard

Sounder

Relay Output

(Use power limited

contacts only)

GND

+24VDC

Acknowledge

Button

Operation

Alarm LED

Figure 1-7: The WSSUP Board

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

21

Page 22

The address of the workstation supervisor is set using the DIP switch settings shown in Figure 1-8 (S2). If the board

came pre-installed from the factory, the address will already be set. If the supervisor is being installed in the field, be

sure to use the currently defined default setting unless directed by a Notifier technician to do otherwise.

The default setting is 700H.

S1 S2 S3 S4 Address

ON ON ON ON 700H - 706H

OFF ON ON ON 710H - 716H

ON OFF ON ON 720H - 726H

OFF OFF ON ON 730H - 736H

ON ON OFF ON 740H - 746H

OFF ON OFF ON 750H - 756H

ON OFF OFF ON 760H - 766H

OFF OFF OFF ON 770H - 776H

ON ON ON OFF 780H - 786H

OFF ON ON OFF 790H - 796H

ON OFF ON OFF 7A0H - 7A6H

OFF OFF ON OFF 7B0H - 7B6H

ON ON OFF OFF 7C0H - 7C6H

OFF ON OFF OFF 7D0H - 7D6H

ON OFF OFF OFF 7E0H - 7E6H

OFF OFF OFF OFF 7F0H - 7F6H

22

Figure 1-8: Workstation Supervisor DIP Switch Settings

NOTE: Switches S5 & S6 are

not used.

NOTE: Use only wire for power

limited systems. Power limited

wire runs use type FPLR, FPLP,

FPL or equivalent cabling per

NEC 760.

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

Page 23

1.1.4 Network Hubs

For network hookup and expansion, you will need a hub. Hubs provide the means to for multiple computers to

connect to an Ethernet network. The following model is recommended and listed to U.L. 864:

• ENIC-HUB (TP800) 100 Base TX Stackable Hub

Each hub used must be mounted in a NISCAB-5 enclosure with network and power transient protection. For more

information on the enclosure and its use, refer to the Network Installation Manual, Section 1.8, Enclosures.

Additional Workstations

Ethernet Cable

NISCAB-5 containing:

ENIC-HUB (TP800) Hub

PNET1 for each Ethernet cable

HSP-121B

Figure 1-9: The Hub Location on the Network

Workstation and

Local Area

Server

Echelon Network

Ethernet Cable

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

23

Page 24

1.1.5 Screen Savers, Power Management and Screen Resolution

To ensure that the workstation annunciates every message; all power management functions, including CPU and

monitor sleep modes, must be disabled. No third party screen savers (i.e. After Dark) or Open GL applications

should be used; however, standard Windows screens savers may be used without loss of monitoring on computers

that have only the workstation application running (Do not run any standard Windows screen savers on servers,

event managers, or other clients such as UniLogic).

The display properties must always be set to the following:

1024 x 768, Large Fonts, 16 bit Color.

This is done through the Windows desktop properties or Control

Panel, Display properties.

Setting the Workstation to Autoboot

To activate the software whenever Windows is started, the UniNet

application must be added to the Start-up folder.

1) Open the Taskbar Properties by clicking on the Start

button, then select Settings, and then Taskbar & Start

Menu.

2) Click on the Start Menu Programs tab.

3) Click on the Add button to begin the process of adding the

UniNet Application to the Start-up folder.

4) Type the drive and path of the UniNet Application, for

example, C:\uninet\uninet.EXE. Click the Next>

button to continue.

5) Type UniNet as the name of the shortcut to the UniNet

Application. Click the Finish button and the OK button.

Figure 1-10: Accessing

Taskbar Properties

Figure 1-11: Adding UniNet to the Startup Folder

24

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

Page 25

1.2

Section 1.2: Printer Installation

UniNet workstations support two types of printers:

• An event printer can be attached to the COM port of the workstation for the printing of off-normal events.

• A screen/report printer can be attached to the workstation to print:

- Screens (requires the Enhanced Printing option).

- Text of linked files.

- Guidance text (requires the Enhanced Printing option).

- History logs.

The Network and Standalone Event Printers are addressed in the "Network Installation" portion of the

manual.

1.2.1 General Printer Setup

Any printer attached to the workstation for use by the workstation requires some setup when it is installed. In the

case of event printers, they need only to be set up in the workstation software; screen/report printers must be

installed in Windows as well.

Screen/Report Printer Setup

The screen/report printer is attached to the workstation computer by the LPT port. The setup for this printer must be

done in Windows, including installation of the printer driver. When installing these drivers, be sure to disable

bidirectional support and set the graphics mode to raster. This can be done through the Windows Start menu by

selecting Settings, Printers, Properties. Any Windows-compatible printer that will work connected to the

parallel port can be a screen/report printer. Printer font and printer pitch can be configured for the screen/report

printer by selecting Workstation Configuration, Options, then clicking on the Printers tab.

To print floor plans, the Enhanced Printing option must be installed.

NOTES: When using the HP Laserjet 5, be sure that Advanced Functions are turned off

under the Parallel menu. With any printer always be sure to disable bidirectional

communication. Never use bidirectional devices such as tape or disk drives on the parallel port.

NOTE:This feature does not support the HP Laserjet Series II printers.

Event Printer Setup

The event printer is a dot-matrix printer (i.e. NOTIFIER PRN series) that receives all messages from the COM port; it

is configured in the Printers tab of the System Setup folder. Do not install this printer in Windows.

Windows Printer Setup

Selecting Printer Setup from the File menu displays a dialog box for setting up your specific printer for screen/

report printing.

To choose a printer, select either the default printer or a specific printer displayed in the list box.

There are two page orientations available:

• Portrait is a vertical page layout. This orientation is preferred for report printing.

• Landscape is horizontal page layout. This orientation is preferred for a screen print.

The paper settings (size and source) are specific to the printer. The Options button gives the user choices regarding graphics and print quality. The options are specific to the printer.

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

25

Page 26

Event Printer Connections

PRN series event printers require a serial cable assembled with the following connections.

DB9F Serial Connector

DB25M Serial Connector

Figure 1-12: PRN Series Serial Cable Wiring Diagram

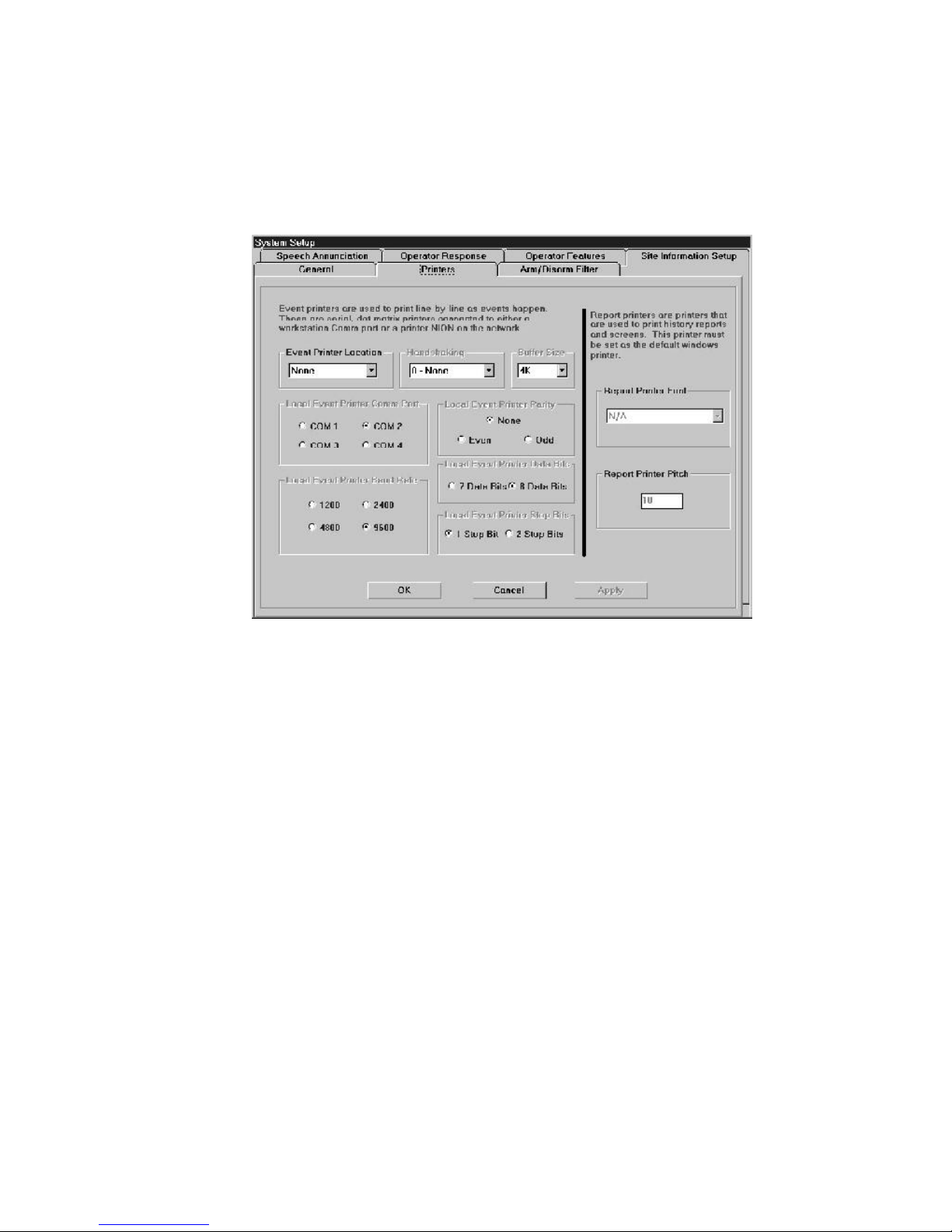

1.2.2 Event and Report Printer Setup

The UniNet software must be configured properly for communication with optional event and report printers.

IMPORTANT: Report printers must be configured and installed in Windows.

The following event printer parameters must be set up to match the parameters configured in the serial event

printer:

• Event printer location - select the following from the combo box:

- none (default) if no event printer is attached to the system.

- local if an event printer is connected directly to a computer COM port.

• Handshaking - default is None. (Special applications)*

• Buffer Size - default is 4k. (Special applications)*

• Local Event Printer COM Port - select the COM port (1-4) that the local printer is attached to.

• Local Event Printer Parity - select none, even or odd.

• Local Event Printer Data Bits - select seven or eight.

• Local Event Printer Baud Rate - select 1200, 2400, 4800 or 9600.

• Local Event Printer Stop Bits - select one or two.

If an optional report printer is connected to the LPT port, then a desired font and pitch size can be selected in the

Report Printer Font combo box and the Report Printer Pitch field.

*Always use the default settings

(special applications only).

Figure 1-13: The Printers Dialog

26

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

Page 27

1.3

Section 1.3: Basic Workstation Setup

1.3.1 Configuring Event Managers and Alarm Servers

Event Managers provide the workstation with a buffer of events from each of its configured Alarm Servers .

The Alarm Servers interface with the actual devices and pass the information to the Event Manager. All

communication between the Workstation and any other device goes through the Event Manager. For more

information on the UniNet system architecture, see the related section in the System Utilities manual. To begin

Event Manager configuration, select Workstation Configuration, Event Managers from the menu bar.

NOTES: All communication between PCs and applications is performed using TCP/IP protocol over

Ethernet. For information on setting up TCP/IP communication, refer to the Local Area Server

manual.

The secondary Event Manager is optional and serves as a backup in case the primary Event

Manager fails. It does not add any additional functionality past this fall-back feature.

Figure 1-14: Alarm Server Connections

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

27

Page 28

Column Description

# The Event Manager or Alarm Server number

Type The application type: EM=Event Manager, LAS=Local Area Server, WAS=Wide Area Server

Name The name of the computer on which the application resides

IP Address The static network IP address of the computer

Port An Ethernet parameter describing the port on which the current Event Manager resides; not configurable

State Current status of the application

Connect Time The date/time when the application began/resumed communication with the system

Connect Count The number of times that the Event manager has connected to that server

Backing Up

Backed Up By Denotes whether another like client is serving as the selected application's backup

Denotes whether the selected application is serving as a backup of another like client. When this field is

blank, that Event Manager/Alarm Server does not back up any other.

Figure 1-15: Alarm Server Connection Fields

Event Manager Configuration

Event Managers must be configured in the Workstation for it to

communicate with other network clients and process events.

Follow these steps to configure the Primary and optional

Secondary Event Managers:

1. From the main menu bar, select Workstation Con-

figuration, Event Managers.

2. On the Socket Connections screen, select Event

Managers, Configure, and the Event Manager

Configuration form will be displayed (see Figure 3-

3).

3. Enter the PC network name and/or IP address for the

Primary/Secondary, then click OK.

4. After these settings have been made, you must also

update these connections by selecting Event

Managers, Update All.

When viewing Event Manager connections in general, you

can update single Event Manager entries by highlighting the

desired EM in the list, then selecting Event Managers,

Update Selected. To view the most updated list of connections, select Refresh Display. This will reset the Socket

Connections screen and show any recent configuration

changes.

Figure 1-16: Event Manager

Configuration

Alarm Server Configuration

Alarm Servers must be configured so they can communicate over the network. To

configure a new Alarm Server, follow these steps:

1. Select Alarm Servers, New Connection.

28

The Workstation Installation/Operation Manual Version 2 Document 51540 Rev. B1 4/8/02

Page 29

2. Give the server a unique Server Number. Specify the Network Name of the computer on which the server

resides, or enter the computer's static IP address. If applicable, select the number of the server it either

backs up or is backed up by.

3. When all information has been entered, click OK, then select Alarm Servers, Update All to update the

settings.

NOTE: Update Selected will only update the highlighted Alarm Server entry. Update All will update all

Alarm Server entries. Refresh Display will reset the Socket Connections form to reflect any configuration

changes made. Drop Selected will disconnect the highlighted server from the network, and a status message

will be displayed on the screen. Drop All will disconnect all servers from the network.

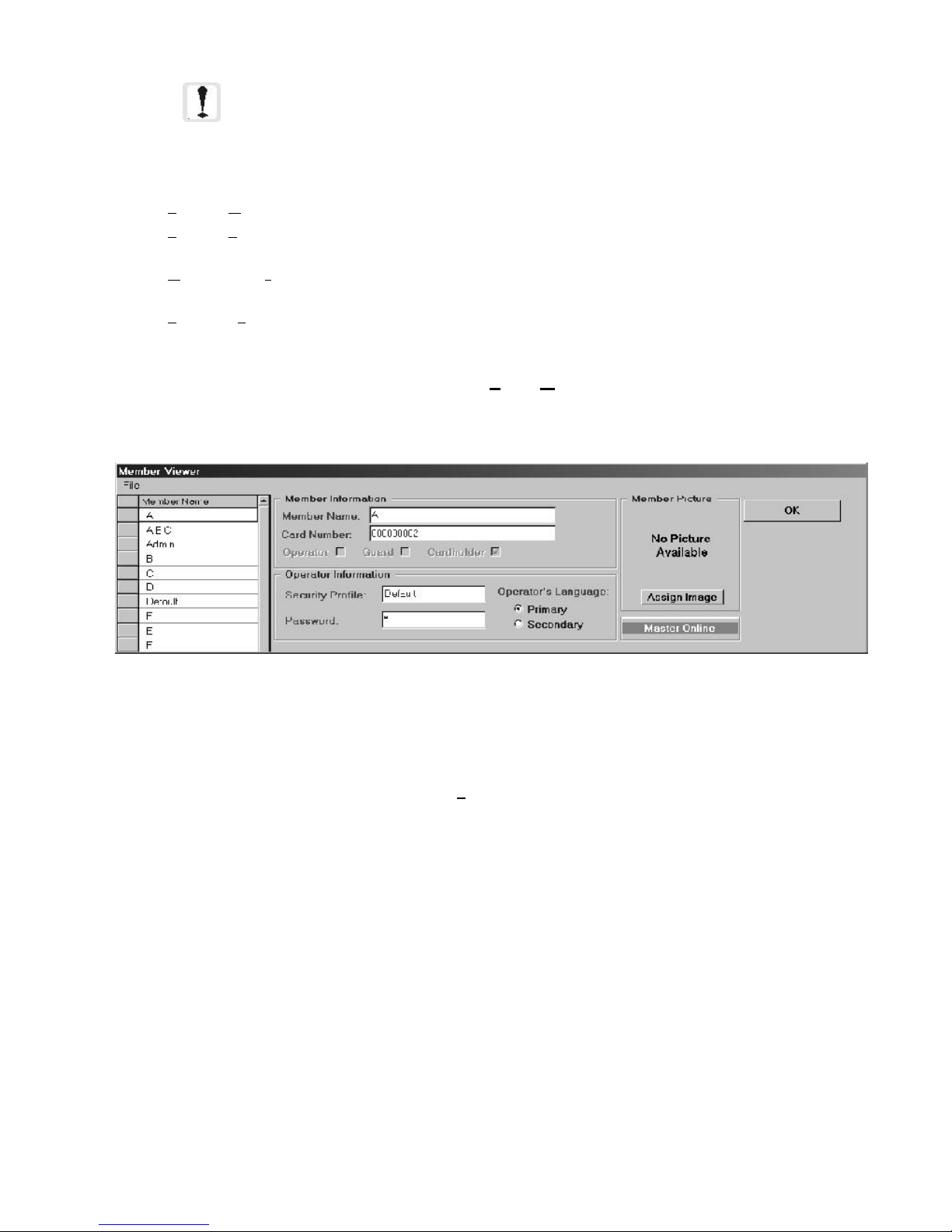

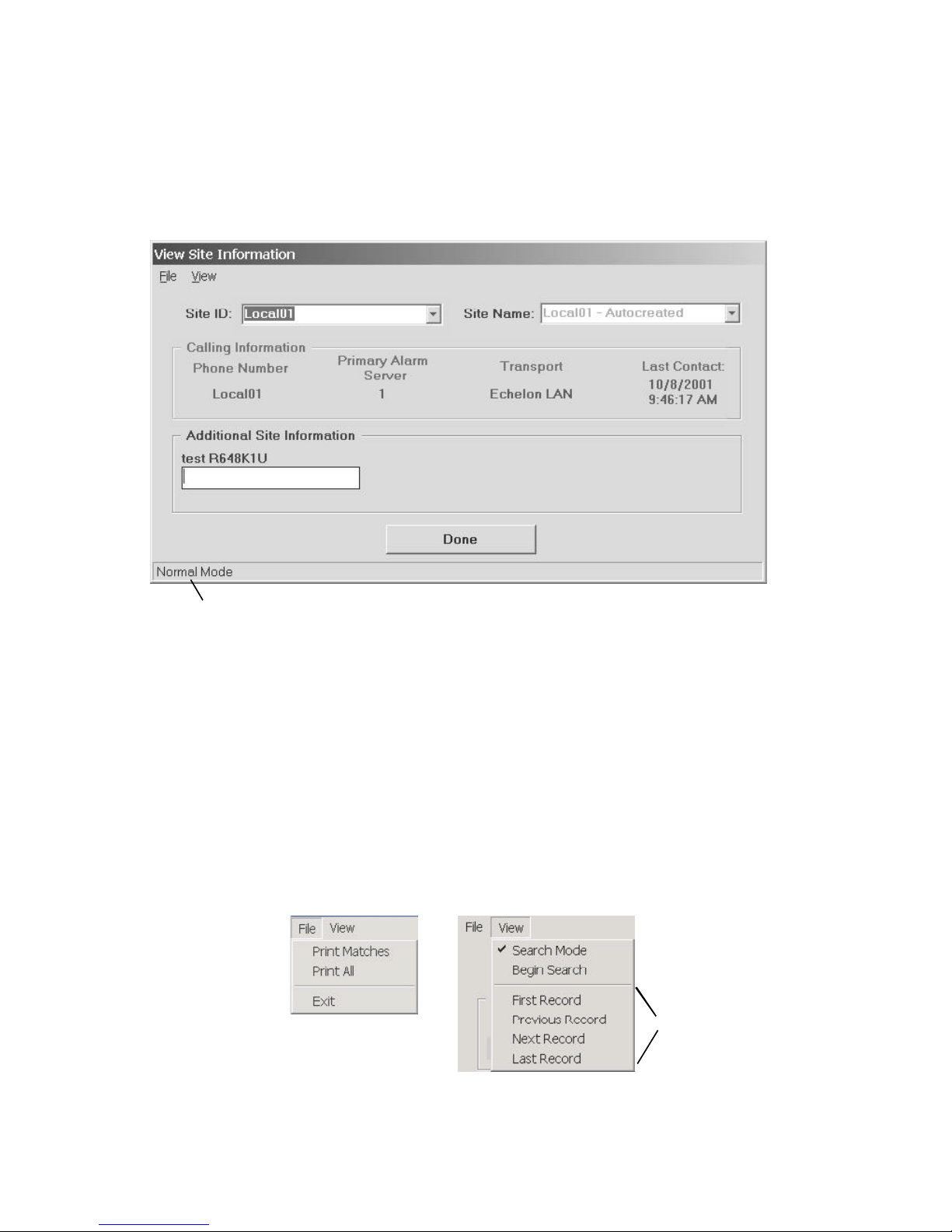

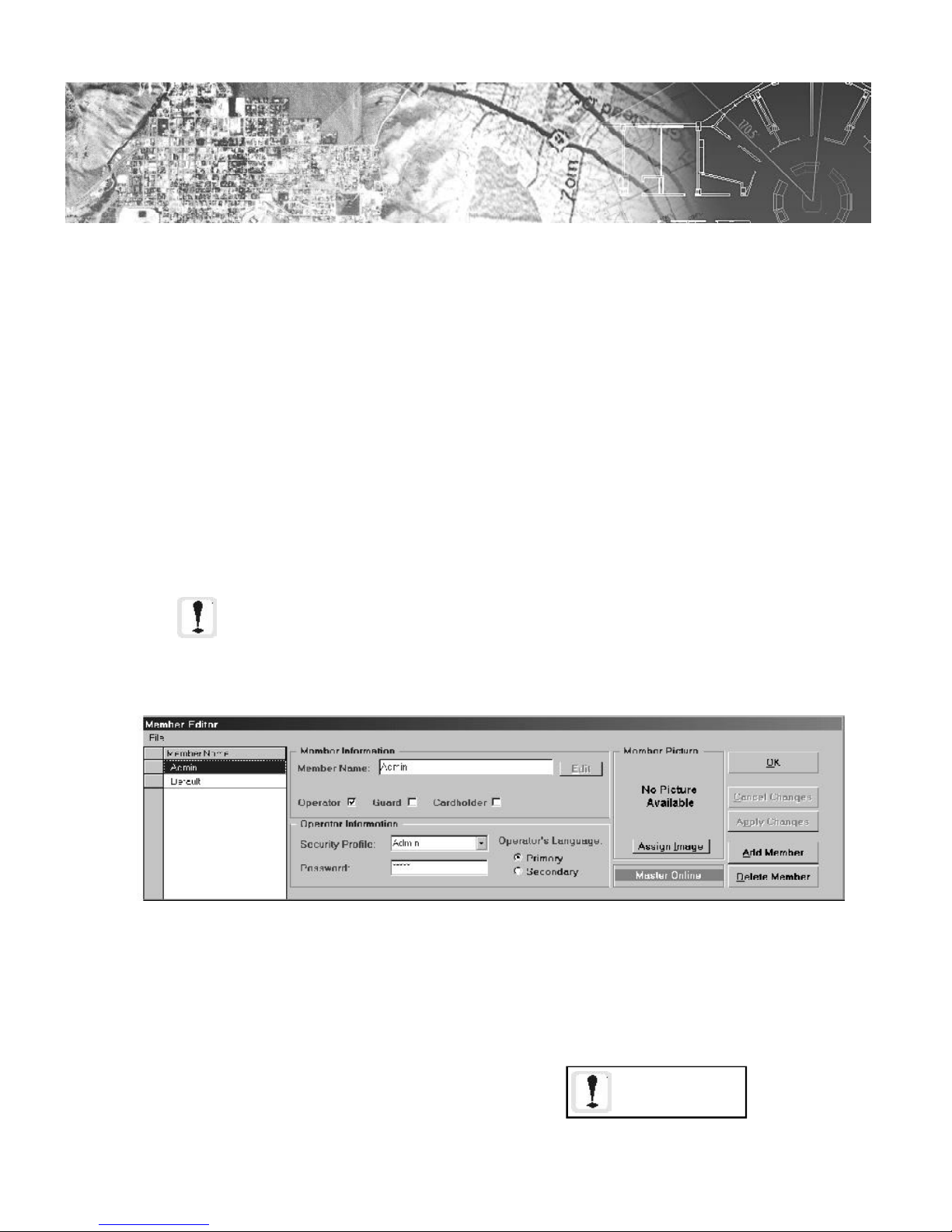

Figure 1-17: New Alarm Server Connection