Page 1

ID50/60

operating

manual

997-264-000-8, Issue 8 January 2007

Page 2

ID50 Series Panel - Operating Manual

Contents

i 997-264-000-8, Issue 8

January 2007

Contents

1 Introduction 1

1.1 Associated Documents 1

1.2 The ID50 / ID60 Series Panel 1

1.2.1 Device T ype Abbreviations 2

1.3 Cleaning 2

2 Panel Controls and Indicators 3

2.1 Controls 3

2.2 Indicators 4

3 Automatic Alarms - What to do 5

3.1 Fire 5

3.1.1 Fire in Delayed Mode 7

3.2 Pre-alarm 8

3.3 Fault 9

3.2.1 Power Fail 10

3.3 Plant Alarm 11

4 Operator Actions at Panel 12

4.1 Introduction 12

4.1.1 Liquid Crystal Display 12

4.1.2 Internal Buzzer 13

4.1.3 Access Codes 13

4.1.4 Keyswitch 14

4.2 MUTE BUZZER Pushbutton 14

4.3 EXTEND DELAY Pushbutton 14

4.4 END DELA YS/EVA CU ATE Pushbutton 15

4.5 SILENCE/RESOUND Pushbutton 16

4.6 RESET Pushbutton 17

4.7 Numeric Keys 18

4.7.1 Cancellation/T ermination Button 18

4.7.2 Level 2 Options Menu Button 18

4.8 Level 2 Option Menus 19

4.9 TEST - User Option 20

4.9.1 LEDs - User Option 21

4.9.2 LCD - User Option 21

4.9.3 Zones - User Option 22

4.9.4 Auto High Test - User Option 24

4.9.5 Outputs - User Option 25

Page 3

ID50 Series Panel - Operating Manual

Contents

ii997-264-000-8, Issue 8

January 2007

4.9.6 Buzzer - User Option 27

4.9.7 Keyboard - User Option 27

4.10 DISABLE / ENABLE - User Option 28

4.10.1 Zones - User Option 28

4.10.2 Outputs - User Option 31

4.10.3 Day Mode - User Option 32

4.10.4 Delays - User Option 33

4.11 CLOCK - User Option 34

4.11.1 Time - User Option 35

4.11.2 Date - User Option 36

4.12 VIEW MODE - User Option 37

4.12.1 Log - User Option 3 8

4.12.2 Devices - User Option 39

4.12.3 Faults - User Option 40

4.12.4 Input Events - User Option 41

4.12.5 Disabled - User Option 42

4.12.6 Alarm Count - User Option 42

4.12.7 Voltages - User Option 43

4.12.8 Version - User Option 44

4.13 Commissioning 44

4.14 Print 44

Appendix 1 - Log Book A1-1

Appendix 2 - Maintenance A2-1

Appendix 3 - ID60 Single Loop Panel

Differences A3-1

Page 4

ID50 Series Panel - Operating Manual

Contents

iii 997-264-000-8, Issue 8

January 2007

ID50 Series Panel

ID50 Series Panel

Page 5

ID50 Series Panel - Operating Manual

Introduction

1 997-264-000-8, Issue 8

January 2007

1 Introduction

This manual contains operating instructions for the ID50

and ID60 Series Fire Detection Panels. Differences

between the ID50 and ID60 panels are given in

Appendix 3.

Users of this manual are assumed to be working with a

panel that has already been installed and configured

appropriately for the area under its supervision.

1.1 Associated Documents

This manual does not describe the installation or

configuration procedures of the panel. For information

on these topics, refer to the ID50 Series

Panel - Installation, Commissioning and

Configuration Manual (Ref. 997-263-000-X).

1.2 The ID50/ ID60 Series Panel

The panel, as supplied by NOTIFIER, is a 1-loop, 16-zone

Analogue Addressable Panel. The single loop has the

capacity for up to 99 analogue sensors plus up to 99

modules and, in some installations, panels may also be

connected to repeaters using the RS485 Communications

Link.

All the control and operation functions described in this

manual can be carried out using the pushbuttons on the

front of the panel.

A keyswitch is provided which, when set to the right, has

the same effect as entering an access 2 passcode. Set it

to the centre to cancel out of all menus and return to the

Status: NORMAL display. This indicates access level 2

is de-selected.

Page 6

ID50 Series Panel - Operating Manual

Introduction

2997-234-000-8, Issue 8

January 2007

1.2.1 Device Type Abbreviations

Throughout this manual the panel may refer to devices

by an abbreviated name. The following table lists the

device type abbreviation and its description.

Abbreviation Type Description

AUX Plant Warning Input

AVR* Advanced VIEW™ Reference*

AVS* Advanced VIEW™ Sensor*

CTE Monitored (Relay Type) Output (VdS)

CTL Monitored (Relay Type) Output

ESE Extinguishant System Output (VdS)

ESM Extinguishant System

ESO Monitored Extinguishing System Output

EST Extinguishant Monitor System Trigger

ION Ionisation Smoke Detector

IRL Immediate Release Input

MCP† Manual Call Point†

MLT Advanced Multi Sensor

MNS Monitor module (no short-circuit)

MON Fire Alarm Monitor Input

MRL Manual Release Input

OPT Optical/Photo-electric Smoke Detector

OPX Optiplex Multi-sensor

RLE Unmonitored (Relay Type) or O/C Outputs (VdS)

RLY Unmonitored (Relay Type) or O/C Outputs

SDR Monitored (Sounder Type) Output

SM4* SMART Multi-criteria Sensor*

TMP Temperature Detector

TxD Monitored Transmission Routing Output

ZMX Conventional Detector Input

Note: Devices marked ‘*’ are supported by the ID60

Panel only. The Device marked ‘†’ is also

available as ‘DKM’ - not used in this application

(provided to be compatible with VdS

requirements).

1.3 Cleaning

The panel case may be cleaned periodically by wiping

with a soft, damp lint-free cloth.

Do not use solvents.

Page 7

ID50 Series Panel - Operating Manual

Panel Controls & Indicators

3 997-264-000-8, Issue 8

January 2007

2 Panel Controls and Indicators

The panel’s controls and indicators are used to operate

the overall system and display the panel status. The panel

has five function pushbuttons, twelve numeric/cursor keys

and thirty-two zonal LED indicators, two ‘FIRE’ indicators

and fourteen system status LED indicators.

An access level 2 keyswitch is provided to enable the

operation of panel controls and access to user menus

without entering a passcode via the numeric keypad.

2.1 Controls

The pushbuttons are listed below, together with

references to the relevant sections of the manual:

Function Pushbuttons

• MUTE BUZZER - (Section 4.2).

• EXTEND DELA Y - (Section 4.3).

• END DELA Y/EVACUATE

1

- (Section 4.4)

• SILENCE/RESOUND - (Section 4.5).

• RESET - (Section 4.6).

1

Also configurable as Transmission Device (TD)

Enable/Disable.

Numeric/Cursor Keys

• Numeric/Cursor keys - (Section 4.7).

Keyswitch

Turn the keyswitch to enable level 2 access. The

keyswitch provides an alternative to entering the level 2

access code via the numeric keys. See Section 4.1.3

and Section 4.1.4.

Page 8

ID50 Series Panel - Operating Manual

Panel Controls & Indicators

4997-264-000-8, Issue 8

January 2007

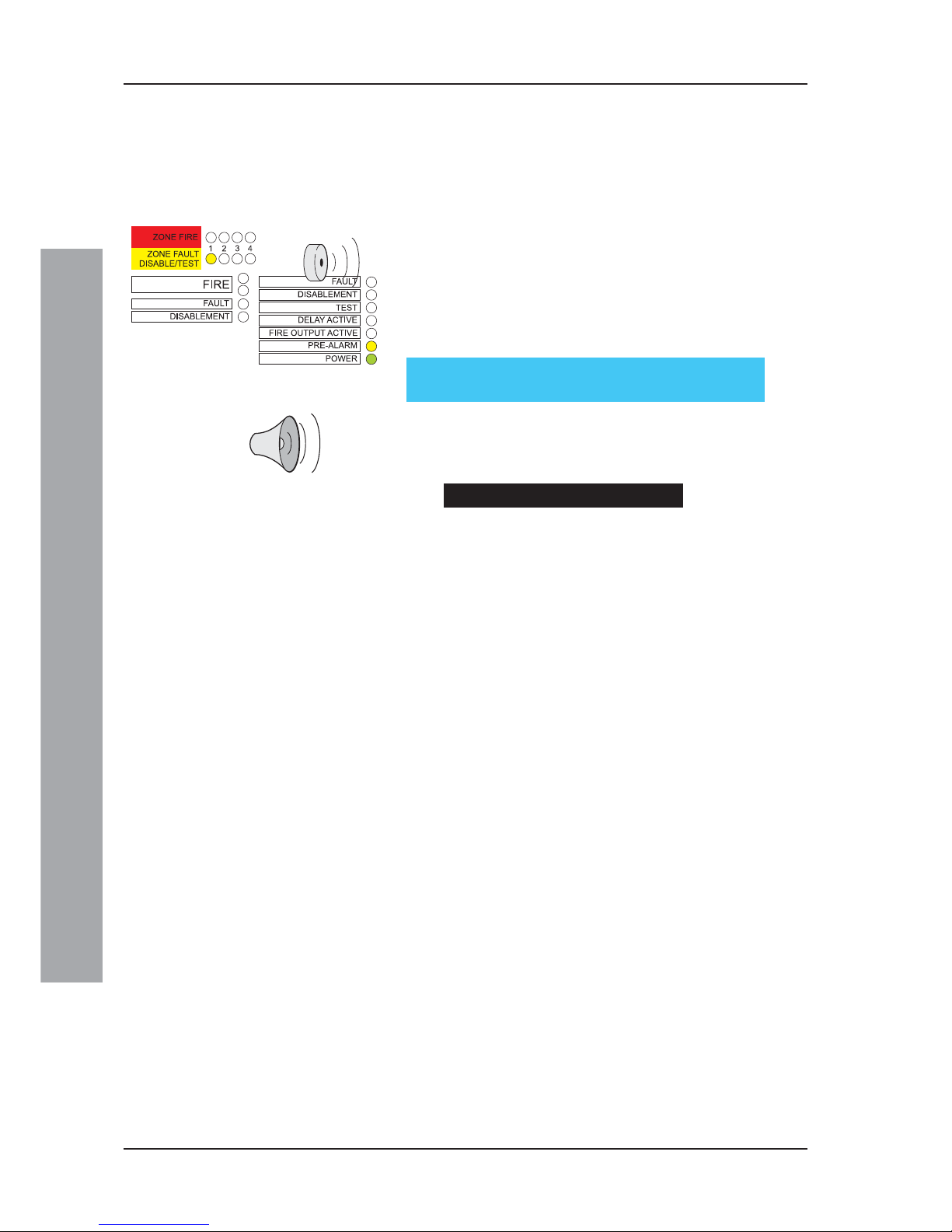

2.2 Indicators

The panel status indicators comprise three groups:

a. Zone S t atus LED indicators.

b. Panel/System LED indicators.

c. Visible/Audible indicators.

Zone Status LED Indicators

• ZONE FIRE - these LEDs indicate affected zone(s).

• ZONE FAULT/DISABLE/TEST - these LEDs indicate

affected zone(s).

Panel/System LED Indicators

• FIRE - these LEDs indicate a fire condition.

• Other System Status LEDs:

FAULT indicates a fault has been

detected by the panel.

DISABLEMENT indicates the presence of a

manually-configured

disablement.

TEST indicates a test is in progress.

DELAY ACTIVE indicates delays are active.

FIRE OUTPUT ACTIVEindicates fire outputs have

been operated.

PRE-ALARM

1

indicates a pre-alarm

condition exists.

POWER indicates status of power

supply.

SYSTEM FAULT indicates the CPU has reset

or a system fault has occurred.

EARTH FAULT indicates an earth fault has

occurred.

PLANT ALARM

2

indicates a fault or warning

from a plant-monitoring device.

FIRE CONTROL O/P: F AUL T/DISABLED

indicates a fire control output

fault or disablement.

FIRE OUTPUT: FAULT/DISABLED

indicates a fire output fault or

disablement

SOUNDER: FAUL T/DISABLED

indicates a sounder circuit

fault or disablement

POWER SUPPLY FAULT

indicates an unsatisfactory

power supply to the panel.

1

This LED is also configurable as SO UND ER S SIL EN CED .

2

This LED can be configured as: FAULT O/P: FAUL T/

DISABLED.

Visible/Audible Indicators

• Liquid Crystal Display (LCD) - (Section 4.1.1).

• Internal Buzzer - (Section 4.1.2).

Page 9

ID50 Series Panel - Operating Manual

Automatic Alarms - What to do

5 997-264-000-8, Issue 8

January 2007

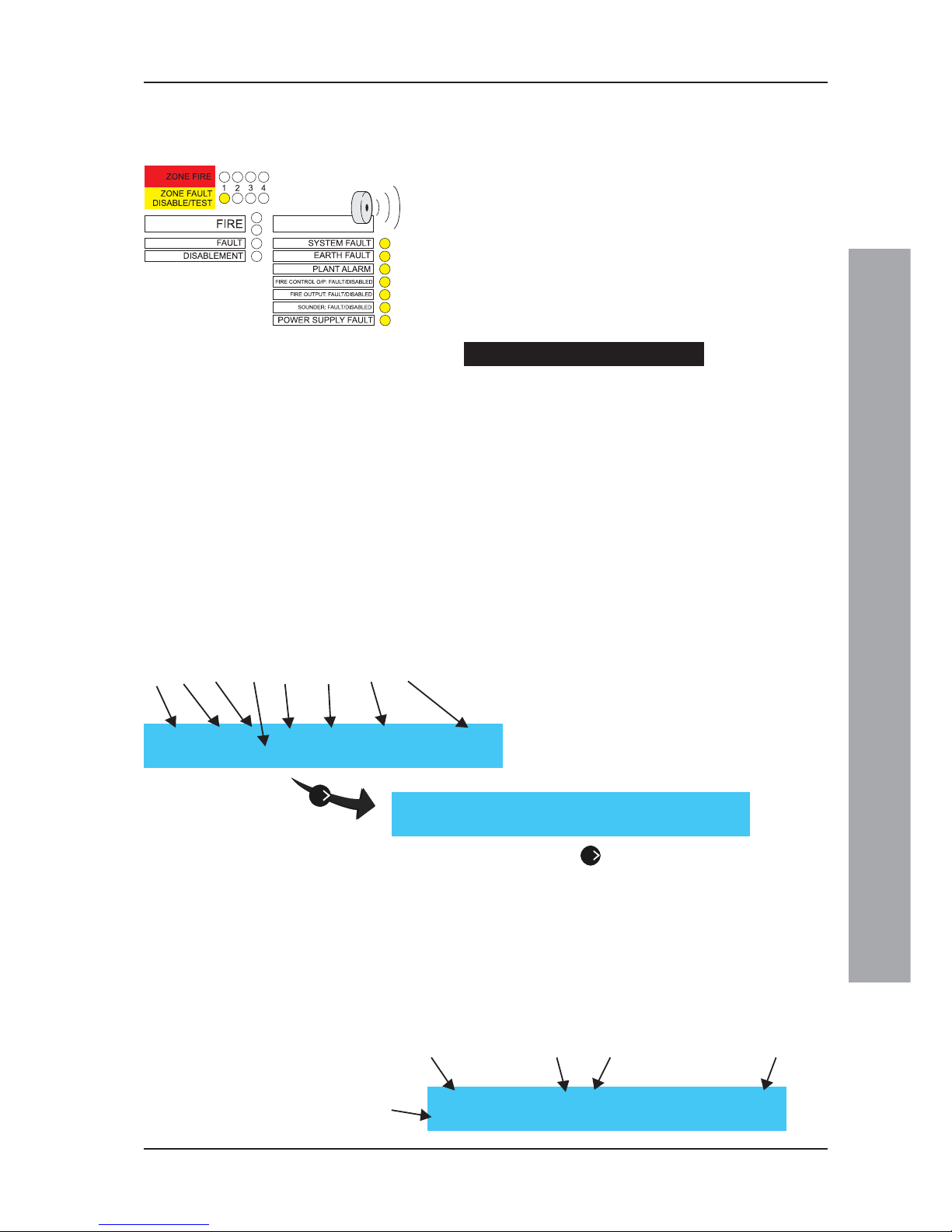

3 Automatic Alarms - What to do

Before any automatic alarms have been sounded the

panel only operates in display mode (quiescent state).

The user must then turn the keyswitch to the right or enter

a Level 2 access code to enable the panel’s pushbuttons.

Only one alarm condition can be displayed at a time

on the LCD. If fire alarms, faults and/or warning conditions

(Plant Alarm) are present on the panel at the same time,

they are displayed in the following priority order:

a. Fire Alarms.

b. Pre-alarms

c. Faults.

d. Warnings.

The alarm condition is registered in a log.

The user must then enter a Level 2 access code, or turn

the keyswitch to the right, to enable the panel’s

pushbuttons. When the Level 2 access code is active,

the ‘2/8’ buttons can be used to scroll through the

alarms and the ‘4’ button will display the first alarm.

3.1 Fire

Automatic panel actions:

If the system detects a fire alarm, the panel always does

the following automatically:

a. Operates the internal (high-pitched) buzzer .

b. Illuminates the red FIRE LEDs, and the numbered

red ZONE FIRE LED.

c. Displays information on the LCD regarding the fire

condition. The information includes device address

and device location (see example below).

FIRE 02 / 05 Z01 M12 MCP 11:59

MAIN BUILDING BASEMENT ROOM 23

Note: If a delay is configured DELAYED is displayed on

the top line of the LCD. When a delay is active the

DELAY ACTIVE LED illuminates and the remaining

time before the first day mode delay expires is

displayed every 5 secs. The LED only extinguishes

when the delay period has expired.

d. Operates the sounders and output modules according

to the panel’s Control-by-Event (CBE) Rules

(configured during the Commissioning stage).

ALARM

CONDITION

ZONE

NUMBER

DEVICE

ADDRESS

ZONE TEXT

TIME OF LOGGED

ALARM CONDITION

DISPLAYED

ALARM

CONDITION

LOGGED

ALARM

CONDITIONS

DEVICE

TYPE

DEVICE

TEXT

Page 10

ID50 Series Panel - Operating Manual

Automatic Alarms - What to do

6997-264-000-8, Issue 8

January 2007

Recommended operator actions:

Note: In the recommended operator actions described below

only MUTE BUZZER and END DELAY are select able

at Access Level 1. The operation of EXTEND DELAY ,

EV ACUATE, SILENCE, RESOUND and RESET must

only be possible at access Level 2, in accordance with

the requirements of EN54:Part 2.

1 Operate the MUTE BUZZER pushbutton to silence

the panel’s internal buzzer .

2 Follow prescribed instructions for evacuation of

premises, notification of Fire Brigade and investigation

of source of fire.

3 If additional sounder operations are required to

achieve a complete and immediate evacuation of the

premises, press the END DELAY /EVACUATE

pushbutton (needs access level 2). This will cause

the internal buzzer to resound, so press the MUTE

BUZZER pushbutton to silence.

4 When more than one fire Alarm condition is present,

it is possible to manually scroll through all logged Fire

Alarm conditions using the ‘2/8’ arrows.

Note: With multiple alarms, the LCD displays the first

alarm event.

5 When evacuation of the premises is achieved, or at

the direction of an authorised person, the Alarm

Sounders may be silenced by pressing the

SILENCE / RESOUND pushbutton.

Note: The SOUNDERS SILENCED LED illuminates if

this option was configured during panel

commissioning. The default function for this LED

is PRE-ALARM.

6 To re-start the sounders, press the

SILENCE / RESOUND pushbutton. Y ou must wait at

least 10 seconds after having originally silenced the

sounders before resounding them. If the SOUNDERS

SILENCED LED option was configured during

commissioning to illuminate, this will now extinguish.

7 When the cause of the alarm has been removed and

call points and input devices have been locally reset,

the system may be returned to ‘Status: NORMAL ’* by

pressing the RESET pushbutton.

* Unless the Site name menu was edited during

commissioning - refer to Section 4.1.1 Liquid crystal

Display.

3

4

7

Status: NORMAL

Sat 01/12/2001 00:00:00

5

6

1

EN54-2: 7.6.1, 7.8, 8.7.1,

9.1.2

Ensure EN54 compliance

for access to controls.

Page 11

ID50 Series Panel - Operating Manual

Automatic Alarms - What to do

7 997-264-000-8, Issue 8

January 2007

1a

2

3

3.1.1 Fire in Delayed Mode

The DeIayed Mode introduces a delay between an alarm

being detected and the sounders and output modules

activating. Depending upon the panel configuration, this

may be a single delay or a 2-stage delay (an initial brief

delay which may be extended by pressing EXTEND

DELA Y to allow an investigation). The delay is initiated i f

the panel enters an alarm condition during Delayed Mode.

Note: For any configured delays, pressing EXTEND

DELA Y cancels the initial response time and initiates

the fire investigation period. Activation of an MCP

will also cancel any configured delay period. The

maximum time for the primary initial response time

is 300 secs; the TOTAL time for both periods is

600 secs. The delay period can only be configured

at Level 3 by the Commissioning Engineer.

The delayed mode status is indicated on the LCD as below:

1a When the panel enters a fire condition the delay

countdown is started and the internal buzzer sounds.

The buzzer can be silenced by pressing the MUTE

BUZZER pushbutton. The LCD displays the alarm

information on the top line; this alternates for 1 sec

every 5 secs with the time remaining before the

shortest day mode delay expires.

1b If the 2-stage delay is configured, pressing the

EXTEND DELAY pushbutton during the primary delay

initiates the fire investigation period.

Note: If configured to do so, the DISABLEMENT LED is

illuminated (not default) from the initiation of the

primary delay and extinguishes at the end of the

primary delay period or fire investigation period.

2 If the delay time elapses, a full alarm condition is

entered (the configured fire outputs are activated). To

cancel the delay , operate the END DELA Y/EVACUA TE

pushbutton; the full alarm condition is entered and the

internal buzzer sounds (it can be silenced by pressing

the MUTE BUZZER pushbutton).

Note: A Fire alarm in a different zone to the first alarm

will also cancel the delay .

3 When the cause of the alarm has been cleared, press

the RESET pushbutton to return to the ‘Status:

NORMAL’ message.

EN54-2: 7.11 (c)

Total time for configured

delays MUST NOT

exceed 600 seconds.

Status: NORMAL

Sat 01/12/2001 00:00:00

1b

Status: DELAYED

Sat 01/12/2001 00:00:00

FIRE 02 / 05 DELAYED: 050

MAIN BUILDING FIRST FLOOR ROOM 36

FIRE 02 / 05 Z01 S16 ION 11:59

MAIN BUILDING FIRST FLOOR ROOM 36

Page 12

ID50 Series Panel - Operating Manual

Automatic Alarms - What to do

8997-264-000-8, Issue 8

January 2007

3.2 Pre-alarm

When one or more input devices signal to the panel a

reading higher than normal but not yet at the FIRE level,

this is a PRE-ALARM condition.

Automatic panel actions

a. Intermittent operation of the internal buzzer (one

second ON, one second OFF).

b. Operation of the appropriate ZONE FAUL T/DISABLE/

TEST LED and yellow PRE-ALARM LED.

c. Displays information on the LCD regarding the pre-

alarm condition.

d. Operation of any assigned outputs in response to a

general pre-alarm condition at the panel (refer to

Section 5.7 Control-by-Event Rules).

Recommended operator actions:

1 Operate the MUTE buzzer pushbutton to silence the

panel’s internal buzzer .

2 Check condition of sensor indicated and check area

for possible fire. If the cause cannot be determined

notify authorised servicing company .

Status: FAULT 01/02 14:55

PRE-ALARM

Page 13

ID50 Series Panel - Operating Manual

Automatic Alarms - What to do

9 997-264-000-8, Issue 8

January 2007

3.3 Fault

Automatic panel actions:

If a fault occurs, the panel automatically does the

following:

a. Operates the internal buzzer (2 sec. on, 1 sec. off).

b. Flashes the appropriate FAULT LEDs, including

numbered ZONE FAULT/ DISABLE / TEST LED(s) if

appropriate.

c. Operates any control outputs which are associated in

the Control-by-Event Rules with fault events.

Recommended operator actions:

1 A fault message typically displays information as

follows (not all items apply to all types of fault):

a. Fault condition.

b. Fault number currently displayed.

c. Total number of faults logged.

d. A text message describing the fault.

e. Zone Number.

f. Device Address.

g. Device Type.

h. Time fault was logged.

Depending upon the fault message, either:

i If the fault message relates to a specific loop device,

investigate whether the cause of the fault is

immediately apparent and can be corrected.

Note: Press the ‘6’ button to view additional zone text

information. To return to the fault message press

any numeric/cursor key (if no key is pressed within

ten [10] seconds the display automatically returns

to the fault message).

ii. If the fault message relates to a system fault condition,

as displayed below, note the full description of the

fault and notify the authorised servicing company .

Note: Items e, f, and g are not applicable.

F AULT 01 / 03 Z01 M12 MCP 14:55

NO REPLY FROM DEVICE >

ABC D E F G H

FAULT 01 / 03 Z01 : M12 MCP 14:55

< - - - Zone Te xt - - - > < - - - Device Text - - - >

FAULT 01 / 03 14:55

EARTH FAULT

ABC

D

H

6

Page 14

ID50 Series Panel - Operating Manual

Automatic Alarms - What to do

10997-264-000-8, Issue 8

January 2007

2 If a service contact number has been entered during

panel commissioning, the LCD alternates between the

fault message(s) and the following:

Note: Press the MUTE BUZZER pushbutton to silence

the panel’s internal buzzer .

3 When the cause of the fault has been cleared, press

the RESET pushbutton.

3.3.1 Power Fail

1 The loss of a power supply causes the panel to enter

a Power Fail condition. The POWER SUPPL Y F AUL T

and general FAULT LEDs illuminate and the internal

buzzer operates. The LCD displays:

a. Fault condition.

b. Fault number currently displayed.

c. Total number of faults logged.

d. Time fault was logged.

e. A text message describing the fault.

A battery fault is shown on the LCD as follows:

2 If a service contact number has been configured, the

LCD alternates between the power fault message and

the service contact number.

Note: Press the MUTE BUZZER pushbutton to silence

the panel’s internal buzzer .

3 When the cause of the fault has been cleared, press

the RESET pushbutton.

If both the AC and

Battery power fail, the

indicators and LCD are

non-operational.

FAULT 01 / 02 14:55

NO MAINS SUPPLY

FAULT 01 / 03 14:55

For Service Contact ***** ******

ABCD

E

FAULT 01 / 02 14:55

BATTERIES MISSING

ABCD

E

Status: NORMAL

Sat 01/12/2001 00:00:00

Status: NORMAL

Sat 01/12/2001 00:00:00

Page 15

ID50 Series Panel - Operating Manual

Automatic Alarms - What to do

11 997-264-000-8, Issue 8

January 2007

Status: NORMAL

Sat 01/12/2001 00:00:00

3.4 Plant Alarm

A Plant Alarm indication is the default configuration setting

for ID50 Series fire control panels. In this configuration,

the panel operates as follows:

A Plant Alarm message is displayed if the panel detects

a non-fire input (AUX) configured in zones 17 to 32. When

a non-fire event occurs the Plant Alarm LED is illuminated

(except for Hold Switch and Abort Switch AUX inputs)

and the LCD displays the following information:

a. Plant Alarm condition.

b. Alarm number currently displayed.

c. Number of alarms.

d. Zone number.

e. Device address.

f. Device type.

g. Time of logged message.

h. Zonal and device text (if any).

When the cause of the alarm has been cleared, the

message will automatically be removed from the LCD

and the LED extinguished. The panel returns to quiescent

mode.

3.5 Fault Output: Fault /Disabled (Optional)

If the panel has been configured to indicate the status of

the Fault Output relay circuit, a message is displayed if a

Fault Output relay circuit fault condition is detected or if it

has been disabled.

Note: An output device configured to a Fault CBE rule

remains active if disabled from a source other than

the panel Fault Output relay disable function.

PLANT 01 / 01 Z21 M12 MCP 14:55

< - - - Zone Te xt - - - > < - - - Device Text - - - >

ABCDEF

GH

Page 16

ID50 Series Panel - Operating Manual

Operator Actions at Panel

12997-264-000-8, Issue 8

January 2007

4 Operator Actions at Panel

4.1 Introduction

Operator actions at the panel require the correct

pushbutton and access code entry. The LCD and the user

pushbuttons located on the panel allow the following

actions to be carried out:

a. Mute the panel buzzer.

b. Extend Delays.

c. Panel reset.

d. End Delays / Evacuate (terminate delays to outputs,

if delay is active and activate sounders).

e. Silence and resound the alarms.

f. Menu navigation and alphanumeric key entry.

g. Operator-controlled tests.

h. Disable and enable of zones, outputs or delays.

i. Set the clock and date.

j. View: log, devices, faults, input events, disablements,

voltages and versions.

Note: Maintenance alarm count is also available but this

is an ID60 feature available at access level 3 only.

All actions are access-controlled either through turning

the panel keyswitch to the right, or by entering a Level 2

access code (see Section 4.1.3 Access Codes).

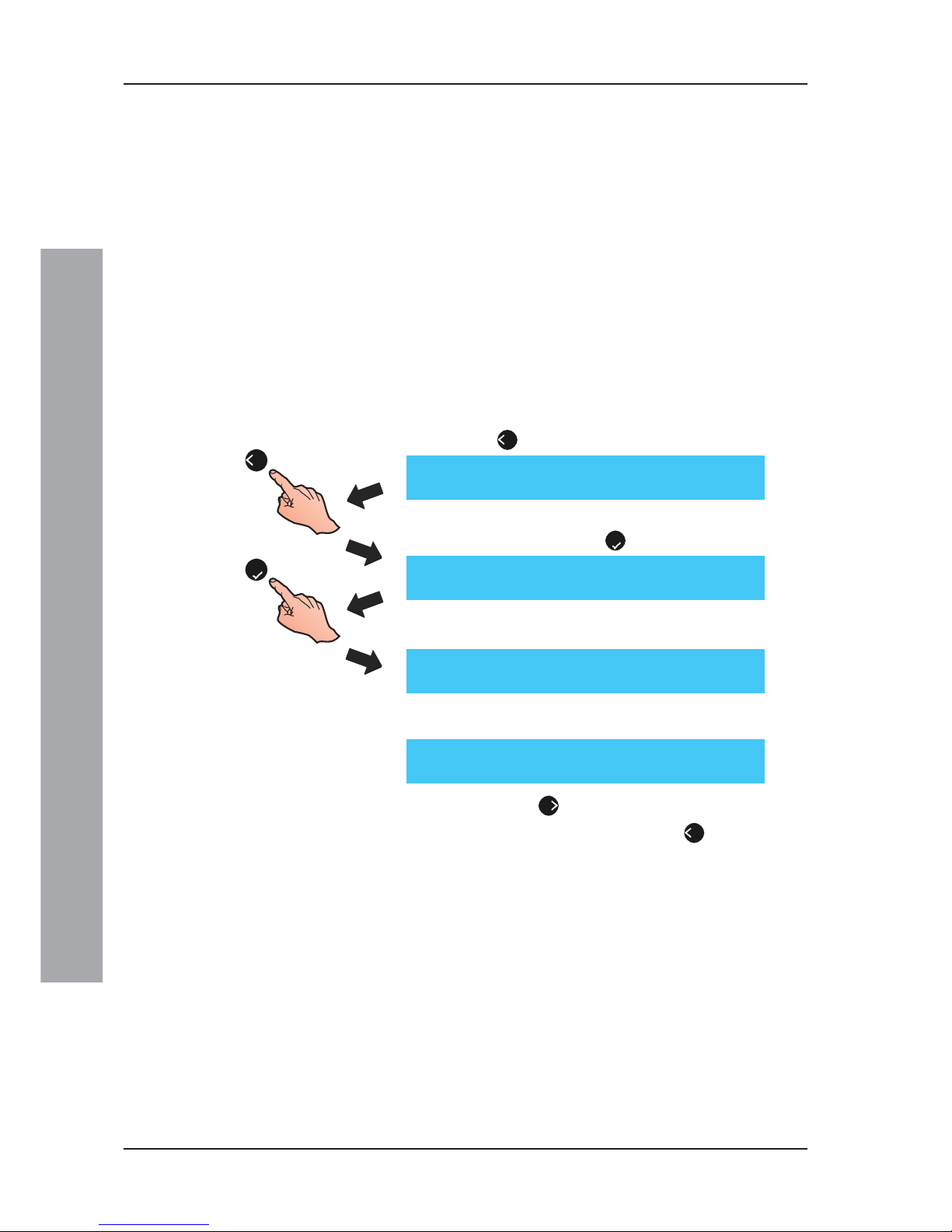

4.1.1 Liquid Crystal Display

The Liquid Crystal Display (LCD) provides 80 characters of

alphanumeric information on a 2 line display. The LCD is

backlit to assist viewing under dim ambient light conditions.

System Normal Display

When in a quiescent state the LCD shows the

‘Status: NORMAL’ message on line 1 and the day, date

and time on line 2. The message will be different if the

Site Name menu was edited during commissioning.

The user options are accessed via a menu structure,

which in turn is accessed from the ‘Status: NORMAL’

message (see opposite).

If the ‘Status: NORMAL’ message is not present, press the

‘4’ button repeatedly until it is displayed (this terminates

access Level 2). Alternatively , turn the keyswitch to the right

and and then back to normal to exit all user menus. Menus

will revert to the panel status display automatically five minutes

after the last key press. Press the ‘ ’ button to toggle

between the menus and top level display .

Note: To exit the Level 3 Commissioning menu press the

numeric ‘7’ button.

* The Commissioning Menu is ONLY

available with a Level 3 passcode

1 : TEST

2 : DISABLE/ENABLE

3 : CLOCK

4 : VIEW MODE

6 : PRINT

5 : COMMISSIONING

SYSTEM NORMAL

Status: NORMAL

Sat 01/12/2001 00:00:00

Page 17

ID50 Series Panel - Operating Manual

Operator Actions at Panel

13 997-264-000-8, Issue 8

January 2007

4.1.2 Internal Buzzer

The panel has an internal buzzer which gives a local

warning when any of the following is detected:

a. Fire condition.

b. Pre-alarm condition.

c. Fault condition.

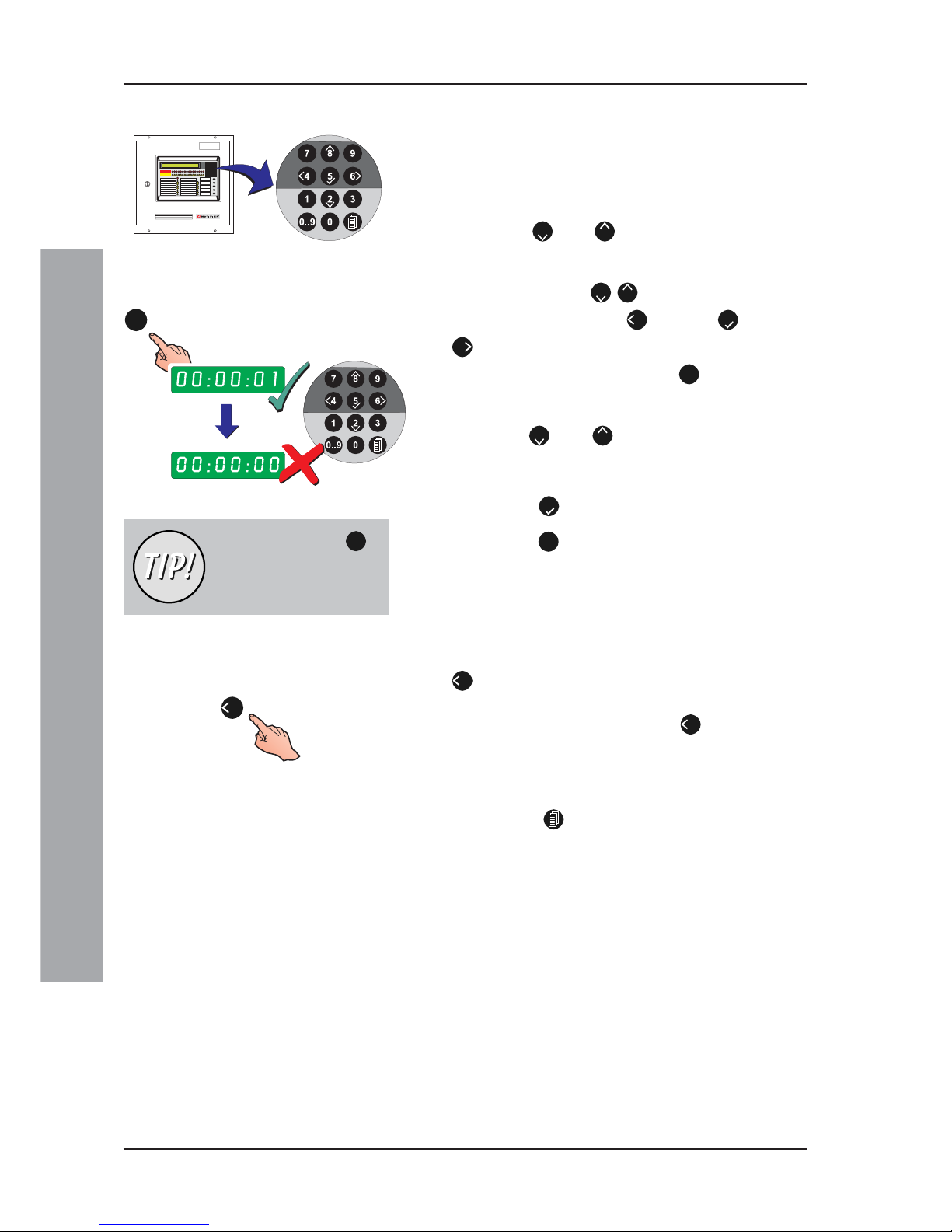

4.1.3 Access Codes

With the exception of the Loop Booster Output T est option,

the actions described in this manual require access Level 2,

which is invoked either by turning the keyswitch or by entry

of an access code. The access code is a sequence of

numbers configured in the panel during commissioning. The

panel has two levels of access codes:7 Level 2 and Level

3. Level 3 is required for testing the loop booster output and

for panel configuration and commissioning procedures.

The panel has a maximum of ten (10) Level 2 access

codes, each defined by the user identification number

[U0 - U9] in the top left-hand corner. Entering a Level 2

access code allows access to all functional controls and

some system operation parameters. (Operating the

keyswitch to enter Level 2 always displays ‘[U9]’).

Note: When the panel is at Level 3, [S1] is displayed in

place of the user identification number.

1 Press the ‘ ’ button at the ‘Status: NORMAL’

message to prompt for a Level 2/3 access code, as

shown below:

2 Press and hold the ‘

0..9

’ button while pressing the

appropriate 4 digit Level 2 access code. ‘*’ will appear

on the LCD as the numbers are entered.

3 Press the ‘5’ button to confirm the entered code.

The Level 2 Options are then displayed.

4 The procedure to cancel Level 2 (and thus prevent

any other person accessing Level 2 options) is given

in Section 4.1.1).

Note: If an incorrect access code is entered, the following

is displayed:

Press the ‘4’ button or wait for approximately one

minute to return to the ‘Status: NORMAL ’ message.

ACCESS TO MENUS RESTRICTED

Enter Level 2/3 Passcode: . . . . < : BackSp

[U0] 1:Test 2:Disable/Enable 3:Clock

4:View Mode 5:Commission

ERROR - INCORRECT PASSCODE ! ! !

ACCESS TO MENUS RESTRICTED

Enter Level 2/3 Passcode:

* * * *

< : BackSp

Throughout this manual a

U accompanied by a

number represents a Level

2 access code.

5

1

2,3

Operations within this

manual require Level 2

access (code or keyswitch),

although a Level 3 access

code may be entered.

Page 18

ID50 Series Panel - Operating Manual

Operator Actions at Panel

14997-264-000-8, Issue 8

January 2007

4.1.4 Keyswitch

The panel is fitted with a keyswitch which provides an

alternative to the Level 2 access code. If the keyswitch is

in the enabled position, it overrides the requirement for a

Level 2 access code. Therefore, if an alarm condition

occurs the keyswitch enables the immediate operation

of the control keys.

With the keyswitch in the enabled position the Level 2

menus are accessible by pressing the ‘ ’ button.

4.2 MUTE BUZZER Pushbutton

Operating the MUTE BUZZER pushbutton when an alarm

or fault has occurred, silences the internal buzzer. If the

Primary Delay is active during an alarm condition this

pushbutton will also terminate this delay and start the

Extend Delay time.

The internal buzzer remains silent until the system is

RESET or the panel detects another alarm condition.

4.3 EXTEND DELAY Pushbutton

With the occurrence of an alarm and with the Primary

Delay active, pressing the EXTEND DELAY pushbutton

cancels the initial response time and initiates the fire

investigation period (refer to Section 3.1.1 Fire in

Delayed Mode). The DELAY ACTIVE LED remains

illuminated until the delay timer expires.

[U0] 1:Test 2:Disable/Enable 3:Clock

4:View Mode 5:Commission

Page 19

ID50 Series Panel - Operating Manual

Operator Actions at Panel

15 997-264-000-8, Issue 8

January 2007

OPERATOR 01 / 05 14:55

EVACUATE

4.4 END DELAY / EVACUATE Pushbutton

The END DELAY/EVACUATE pushbutton is used to

initiate the Evacuate procedure. If this pushbutton is

operated while a delay is active, all delays are cancelled

and all sounders designated in the pre-configured

Evacuate rule are activated.

Fire Alarm Condition

Providing the pushbuttons have been enabled for Level

1 operation and delays are active the following occurs:

1 Press the END DELAY/EVACUATE pushbutton. The

following is typically displayed:

2 No further action is needed until it is required to silence

the sounders, in which case the SILENCE/RESOUND

pushbutton should be pressed, see Section 4.5,

Silence / Resound pushbutton.

Note: If the pushbuttons are enabled to operate at

Level 2, enter the Level 2 passcode in the manner

described in the RESET pushbutton procedure

(Section 4.6).

No Alarm Condition

In quiescent mode, pressing the END DELA Y/EVACUA TE

pushbutton immediately sounds the internal buzzer,

operates all outputs configured in accordance with the

CBE rules (configured at time system was commissioned)

and the LCD displays the ‘EV ACUATE’ message.

OPERATOR 01 / 01 14:55

EVACUATE

Page 20

ID50 Series Panel - Operating Manual

Operator Actions at Panel

16997-264-000-8, Issue 8

January 2007

4.5 SILENCE / RESOUND Pushbutton

The term ‘silence’ as used throughout this manual,

describes a temporary state the panel enters whenever

the SILENCE / RESOUND pushbutton is pressed to stop

the sounders operating. While the panel is in this state, a

new fire alarm, operating the SILENCE / RESOUND

pushbutton again or operation of the

END DELAY/ EVACUATE pushbutton, will re-sound all

previously silenced sounders.

You can suspend all sounder output delays and silence

all sounder outputs which are operating as a result of a

FIRE alarm or an EVACUATE operation. Provided that

the pushbuttons have been enabled for Level 1 operation

and delays are active, proceed as follows:

1 Press the SILENCE / RESOUND pushbutton. The

following are not switched off by this operation:

a. The internal FIRE buzzer.

b. Any output modules configured in the CBE Rules

during commissioning NOT to be silenced by the

SILENCE / RESOUND pushbutton.

2 To start the sounders again in the same pattern as

they were previously operating and reactivate any

programmed delays, press the SILENCE / RESOUND

pushbutton.

3 The panel may have been configured, during

commissioning, to illuminate the SOUNDERS

SILENCED LED when the SILENCE/RESOUND

pushbutton is pressed (non-default selection).

Pressing the SILENCE / RESOUND pushbutton again

to operate the sounders, the SOUNDERS SILENCED

LED extinguishes.

Note: If the pushbuttons are enabled to operate at

Level 2, enter the Level 2 passcode in the manner

described in the RESET pushbutton procedure

(Section 4.6).

1

2

3

Page 21

ID50 Series Panel - Operating Manual

Operator Actions at Panel

17 997-264-000-8, Issue 8

January 2007

CONTROL KEY LOCKED - ACCESS REQUIRED

Enter Level 2/3 Passcode: . . . . < : BackSp

CONTROL KEY LOCKED - ACCESS REQUIRED

Enter Level 2/3 Passcode:

* * * *

< : BackSp

5

4.6 RESET Pushbutton

The RESET pushbutton is used to clear all non-quiescent

conditions and return the panel to a normal quiescent

condition. Provided that the control keys have been

enabled for Level 1 operation, the following occurs:

a. All FIRE and FAULT lamps are switched off.

b. All sounders cease to operate.

c. The system status returns to NORMAL provided that

no operator actions are being carried out.

If the pushbuttons are enabled to operate at Level 2, follow

the procedure below:

1 Press the RESET pushbutton. The LCD displays the

following:

2 Either turn the keyswitch, or enter an appropriate Level

2 access code and confirm using the ‘5’ button.

If Alarm(s), and/or Fault(s) conditions are still present

when RESET is operated, the condition will be reported

as if it were a completely new event with appropriate

annunciation.

Page 22

ID50 Series Panel - Operating Manual

Operator Actions at Panel

18997-264-000-8, Issue 8

January 2007

4.7 Numeric Keys

When using any numeric key, each operation is confirmed

by a sharp audible bleep.

At Access Level 1, the numeric buttons have NO function

until an alarm condition occurs. The alarm condition

enables the ‘2’ and ‘8’ buttons, allowing the user to

view each alarm in turn.

At Access Level 2 the ‘2/8’ function remains identical

to the Level 1 function. The ‘4’ (cancel), ‘5’ (confirm),

‘6’ (go to next option) buttons are enabled. Numeric

entry (used in conjunction with the ‘

0..9

’ [shift] button) is

also enabled.

a. Use the ‘2’ and ‘8’ buttons to scroll through fire

alarms, fault conditions, and warning conditions or to

view the ‘More’ menu list when available.

b. Press the ‘5’ button to confirm an option.

c. Press the ‘

0..9

’ (Shift) button to enable number entry.

Following the input of a number (approx. 1 sec later)

a second audible bleep indicates that number entry is

no longer enabled.

4.7.1 Cancellation/Termination Button

T o cancel or terminate configuration data entry , press the

‘4’ button. The LCD returns to the previous menu.

To cancel access rights, press the ‘4’ button until the

‘Status: NORMAL ’ message is displayed.

4.7.2 Level 2 Options Menu Button

Operating the ‘ ’ button enables the Level 2 menu and

prompts for the entry of an appropriate access code, as

described in Section 4.1.3 Access Codes.

Pressing the menu button toggles between the panel

status and user menus.

Press and hold the ‘

0..9

’

(Shift) pushbutton while

entering numbers.

0..9

4

Page 23

ID50 Series Panel - Operating Manual

Operator Actions at Panel

19 997-264-000-8, Issue 8

January 2007

Notes:

1. Level 3 Configuration Menus are

described in 997-263-000-X, ID50 Series

Panel Installation, Commissioning &

Configuration Manual, Section 5

Configuration.

2. With a fire alarm active the panel status

display will override the user menu 5

secs after the last key press.

4.8 Level 2 Option Menus

The following Level 2 Option Menus are available after a

correct Level 2 access code has been input or the

keyswitch has been operated.

The menu map at left shows an overview of the Level 2

menus. The Commissioning menu is shown inverted to

indicate that a Level 3 access is required.

Page 24

ID50 Series Panel - Operating Manual

Operator Actions at Panel

20997-264-000-8, Issue 8

January 2007

4.9 TEST - User Option

The following tests are available at Access Level 2 from

the Test - User Option menu:

a. LEDs.

b. LCD.

c. Zones.

d. Auto High Test.

e. Outputs.

f. Buzzer.

g. Keyboard.

To start the TEST - User Option:

1 At the ‘Status:NORMAL’ message, press the ‘ ’

button. The LCD prompts for a Level 2/3 access code.

(To cancel, press ‘4’).

Note: Entering an incorrect access code causes the LCD

to display the ‘ERROR - INCORRECT P ASSCODE

! ! !’ message, then an automatic return to the

access code prompt.

2 Either turn the keyswitch or, using the numeric keypad,

enter the correct Level 2 access code and confirm

using the ‘5’ button. The User Option menu is

displayed with the user number ([U0] to [U9]) in the

top left-hand corner.

Extinguishing System - T esting SLC de vice

outputs.

T o prevent inadvertant operation of the direction and

release valves during testing, zones containing the

associated SLC devices MUST FIRST be put into

TEST mode. Also, where a zone test is manually

activated using an input module, extinguishant

bottles MUST FIRST be disconnected to prevent

unauthorized extinguishant discharge.

Note: A manual release reset will not stop the

extinguishant discharge because of a physical link

between the direction valve inputs and outputs.

ACCESS TO MENUS RESTRICTED

Enter Level 2/3 Passcode: . . . . < : BackSp

[U0] 1 : T est 2 : Disable/Enable 3 : Clock

4 : View Mode 5 : Commission

Page 25

ID50 Series Panel - Operating Manual

Operator Actions at Panel

21 997-264-000-8, Issue 8

January 2007

4.9.1 LEDs - User Option

This option, selected from the T est menu, illuminates each

LED in turn. T o test the p anel LEDs, enter access Level 2

and follow the procedure below:

1 Using the numeric keypad, press ‘1’ to display the

TEST menu.

2 To test LEDs, press the ‘1’ button on the numeric

keypad.

3 Each of the panel LEDs illuminates in turn while the

LCD flashes the message shown below. When all

LEDs have been tested, press the ‘4’ button to

cancel and return to the Test menu.

4.9.2 LCD - User Option

The LCD Option, selected from the Test menu, tests the

LCD by displaying each upper case character in turn. To

test the LCD, enter access Level 2 and follow the

procedure below.

1 Using the numeric keypad, press ‘1’ to display the

TEST menu.

2 T o test the LCD, press the ‘2’ button on the numeric

keypad.

3 Each character is then displayed in turn on the LCD.

When all characters have been displayed, press the

‘4’ button to cancel and return to the Test Menu.

[U0] 1 : T est 2 : Disable/Enable 3 : Clock

4 : View Mode 5 : Commission

TESTING LEDs ! ! !

[U0] 1 : T est 2 : Disable/Enable 3 : Clock

4 : View Mode 5 : Commission

AAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAA

AAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAA

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

ZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZ

ZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZ

1

1

1

2

[U0 Test] 1:LEDs 2:LCD 3:Zones

4:Auto High T est 5:Outputs ↕ : More

[U0 Test] 1:LEDs 2:LCD 3:Zones

4:Auto High T est 5:Outputs ↕ : More

Page 26

ID50 Series Panel - Operating Manual

Operator Actions at Panel

22997-264-000-8, Issue 8

January 2007

4.9.3 Zones - User Option

The Test Zones option, selected from the Test Menu,

allows the user to perform a walk test on one zone at a

time.

During the walk test the TEST and relevant ZONE

FAUL T/DISABLE/TEST LEDs are illuminated, indicating

that the system and zone is in TEST mode. To perform a

walk test, at the TEST menu:

1 Press the ‘3’ button on the numeric keypad to select

the walk test procedure.

2 The LCD displays the T est Zones menu. Select either

the Ring Sounders or No Sounders walk test:

a. Using the numeric keypad press ‘1’ to display the

Ring Sounders menu as below. In this mode the

sounders will ring for a few seconds when a device is

tested, then reset automatically.

i Use the ‘2/8’ buttons to select the zone to be

tested. Press the ‘5’ button to confirm the zone

number.

ii The LCD prompts for confirmation. Press the ‘5’

button to start the walk test for this zone. Repeat

steps i and ii for any further zones to be tested. Test

the devices (see Checking the Devices overleaf).

iii Press the ‘4’ button to exit the Ring Sounders menu

and return to the Zones menu.

b. To walk test devices on a specific zone without

activating the sounders, press ‘2’ on the numeric

keypad to select the ‘No Sounders’ option. The walk

test procedure is otherwise the same as given above

for ‘Ring Sounders’.

[U0 Zones] 1: Ring Sounders

2:No Sounders 3:View/Stop Test ↕ : More

[WALK TEST (Sounders)] Select Zone:01

✓: Start ↕ : Change <:Exit

[WALK TEST (Sounders)] Select Zone: 01

Press ✓to Confirm <:Cancel

[WALK TEST (Sounders)] Select Zone: 01

✓: Start ↕ : Change <:Exit

3

52 8

1

2

or

[U0 Test] 1:LEDs 2:LCD 3:Zones

4:Auto High Test 5:Outputs ↕ : More

Page 27

ID50 Series Panel - Operating Manual

Operator Actions at Panel

23 997-264-000-8, Issue 8

January 2007

3 To end the walk test:

a.

For a specified zone: at the Test Zones menu, press

the ‘

3

’ button on the numeric keypad to select the

View/S top Test menu:

i Use the ‘2/8’ buttons to select the zone, then press

the ‘5’ button to confirm the zone number.

ii Press the ‘5’ button to stop the walk test for the

selected zone. If no other walk tests are active, the

following is displayed:

iii Press the ‘4’ button to exit the W alk Test menu and

return to the Test Zones menu.

b. For all zones: from the ‘↕ : More’ option (‘2/8’)

press the ‘4’ button on the numeric keypad to select

the Stop All menu:

4 To exit the Test Zones menu, press the ‘4’ button.

Continue pressing this button until the required menu

or the ‘Status: NORMAL ’ message is displayed.

Checking the Devices

Use the following methods to check devices during a walk test:

i. Test sensors by applying smoke or heat as

appropriate, or by operating the device’s internal test

switch by means of a magnet.

ii. Test Manual Call Point s by using a test key.

For each device, the panel will record the event in the

log, sound its internal buzzer , illuminate the appropriate

ZONE FIRE LED and turn on the LED at the device that

initiated the alarm.

Note: A maximum of ten devices’ LEDs can be illuminated

during the test. Further device testing functions

normally in all other respects. LEDs will not light

again until after the removal of the walk test

condition and manually resetting the panel.

[STOP WALK TEST] Select Zone: 01

✓: Stop ↕ : Change <:Exit

[STOP WALK TEST] Select Zone: 01

Press ✓to Confirm <:Cancel

The system has no walk test zones active

<:Exit

[U0 Zones] 1: Ring Sounders

2:No Sounders 3:View/Stop Test ↕ : More

[U0 Zones] 4: Stop All

↕ : More

Stop all Zones in Walk Test ?

Press ✓to Confirm <:Cancel

52

8

or

2

8

5

4

Page 28

ID50 Series Panel - Operating Manual

Operator Actions at Panel

24997-264-000-8, Issue 8

January 2007

After a few seconds, the panel will automatically return

to Test Mode and the device LED will be turned off. The

panel is then ready to test the next device.

Note: Up to one minute must be allowed for smoke

sensors to clear.

If a fire alarm signal is received from a zone other than

those being tested, all sounder output and relay output

circuits will activate as configured for a zone in alarm. The

sounders will continue to ring until silenced from the panel.

4.9.4 Auto High Test - User Option

The Auto High Test, if configured during commissioning,

automatically polls and tests all devices on the loop at a

specified time of day. This test takes about 70-80 seconds

to complete. To run the test manually:

1 From the T est Menu, using the numeric keypad press

the ‘4’ button to select the Auto High Test.

2 When the LCD displays the start Auto High Test

message, press the ‘5’ button to start the test.

3 The LCD displays the message shown below, then

re-displays the Test Menu.

4 If a fault occurs while the Auto High Test is active the

LCD displays a fault message (example given below):

Press the ‘6’ button to display additional zonal and

device text information. Press the ‘4’ button to return

to the Test menu. Clear the fault and repeat the test.

Manually start automatic high test ?

Press ✓to confirm <:Cancel

F AULT 01 / 03 Z01 M12 MCP 14:55

DEVICE F AILED AUTO HIGH TEST >

Automatic high test started ! ! !

4

5

[U0 Test] 1:LEDs 2:LCD 3:Zones

4:Auto High Test 5:Outputs ↕ : More

Page 29

ID50 Series Panel - Operating Manual

Operator Actions at Panel

25 997-264-000-8, Issue 8

January 2007

4.9.5 Outputs - User Option

The Test Outputs option, accessed from the T est Menu, tests

the panel’s internal sounder and relay circuits and the Signalling

Line Circuit (SLC) loop outputs. To perform this test:

Test Internal Outputs

1 From the Test Menu, press the ‘5’ button on the

numeric keypad to select the Outputs option.

2 Press the ‘1’ button on the numeric keypad to display

the Internal Test menu.

3 Use the ‘2/8’ buttons to select the internal output

required for testing and press the ‘5’ button to start

the test. The LCD then displays the following:

4 Check that the output operates. T o stop the test, press

the ‘4’ button. Press the ‘4’ button again to return

to the Test Outputs menu.

Test SLC Outputs

1 From the Outputs menu, press the ‘2’ button on the

numeric keypad to display the SLC Output Test menu:

2 Use the ‘2/8’ buttons to select the output required

for testing and press the ‘5’ button to start the test.

The LCD then displays the following:

3 Check that the output operates. T o stop the test, press

the ‘4’ button. Press the ‘4’ button again to return

to the Test Outputs menu.

[Internal Test] B:01 SDR

✓: Start ↕ : Change Output <:Exit

[U0 Outputs] 1:Internal 2:SLC

3: Loop P ower

[Internal Test] B:01 SDR

Output test in progress <:Stop

[SLC Test] M:nn SDR

✓: Start ↕ : Change Output <:Exit

[SLC Test] M:nn SDR

Output test in progress <:Stop

[U0 Test] 1:LEDs 2:LCD 3:Zones

4:Auto High T est 5:Outputs ↕ : More

[U0 Outputs] 1:Internal 2:SLC

3: Loop P ower

Page 30

ID50 Series Panel - Operating Manual

Operator Actions at Panel

26997-264-000-8, Issue 8

January 2007

[U0 Outputs] 1:Internal 2:SLC

3:Loop Power

COMMISSION MODE ACCESS

Enter Level 3 passcode - < BackSp

To perform a Loop Booster

output test an access level 3

passcode ( is required.

[LBM Test] Loop : Both Sides 0%

✓: Start ↕ : Change<:Exit

Test Loop Booster Outputs

A number of tests are available to satisfactorily test the

operation of the Loop Booster Modules (LBMs) during

alarm conditions. The tests are designed so that the power

delivered to the loop by the panel can be switched off from

either end, or each LBM in turn can be prevented from

being turned on. The tests are designed, when combined

with a walk-test, to check that:

a. The panel operates all loop-powered devices correctly

with the LBM(s) with one source of loop power isolated.

b. All loop-powered outputs operate correctly with any individual

LBM disabled or with the loop only powered from one end.

1 Press the ‘3’ button on the numeric keypad to select

the Loop Booster test procedure. With the panel currently

at access level 2, the following warning is displayed

prompting for entry of access level 3 passcode:

2 Having entered the access level 3 passcode, press

the ‘5’ button to start the test.

3 Before the test starts a 0% percentage indication of the

equipment under test is displayed on the top line. As the test

progresses, the percentage value increases to 100% as to

indicate that all loop-powered devices under test are operating

correctly. This percentage value may go down if a device

starts reporting incorrectly or becomes de-activated.

4 Press the ‘2/8’ pushbuttons to select the other Loop

Booster options: ‘In Only’ or ‘Out Only’

5 To perform a loop test without loop booster support

you can turn off individual LBMs while testing that looppowered sounders are still able to operate correctly .

6 Press the 4’ button to cancel the test and return to

the Test Menu.

Note: If the test is not cancelled manually, it is cancelled

automatically 4 hours after the last panel keystroke.

[LBM Test] Loop : Both Sides 0%

✓: Start ↕ : Change<:Exit

[LBM Test] Loop : Out Only 0%

✓: Start ↕ : Change<:Exit

[LBM T est] Loop : In Only 0%

✓: Start ↕ : Change<:Exit

[LBM Test] M nn : Inactive 0%

✓: Start ↕ : Change<:Exit

Select ‘Both Sides’ to test looppowered sounders only (LBMs

are not turned on).

Select ‘In Only’ to perform test

with loop powered only from the

‘Loop Out’ end.

Select ‘Out Only’ to perform

test with loop powered only from

the ‘Loop In’ end.

Page 31

ID50 Series Panel - Operating Manual

Operator Actions at Panel

27 997-264-000-8, Issue 8

January 2007

Press ALL keys to exit . . .

0 . . 9 0 MENU 1 2 3 4 5 6 7 8 9 A B C D E

4.9.7 Keyboard - User Option

This option allows the panel keyboard to be functionally

tested.

1 Using the numeric keypad, press ’1’ to display the

TEST menu.

2 Press the ‘2/8’ pushbuttons to display the next

screen options. To test the keyboard, press the ‘7’

button on the numeric keypad.

3 The following screen is displayed. Press each panel

pushbutton in turn. When a pushbutton is pressed, the

corresponding display entry is replaced by an equivalent

number of asterisk (*) characters. The five pushbuttons

are represented by A to E, where A is the top button.

Once all pushbuttons have been pressed the display

will return to the test menu. The keyboard test will

automatically abort after one minute if no key is pressed.

[U0] 1 : Test 2 : Disable/Enable 3 : Clock

4 : View Mode 5 : Commission 6:Print

The standard function of the

control keys is suppressed

while this test is active.

Normal function resumes

upon test completion.

7

[U0 Test] 6:Buzzer 7:Keyboard

↕ : More

1

4.9.6 Buzzer - User Option

The Buzzer User Option, selected from the Test Menu,

tests the internal buzzer . Proceed as follows:

1 Using the numeric keypad, press ’1’ to display the

TEST menu.

2 Press the ‘2/8’ pushbuttons to display the next

screen options. To test the buzzer, press the ‘6’

button on the numeric keypad.

3 The buzzer sounds with a 2:1 mark:space ratio and

the LCD flashes the message below. Press the ‘4’

button to cancel the test and return to the Test Menu.

[U0] 1 : T est 2 : Disable/Enable 3 : Clock

4 : View Mode 5 : Commission

[U0 Test] 6:Buzzer 7:Keyboard

↕ : More

1

TESTING BUZZER ! ! !

6

Page 32

ID50 Series Panel - Operating Manual

Operator Actions at Panel

28997-264-000-8, Issue 8

January 2007

[U0 Disable/Enable] 1:Zone 2:Outputs

3:Day Mode 4:Delays

[Disable/Enable] Zone _ _

Enter Zone Number < : Cancel

1

4.10 DISABLE / ENABLE - User Option

This option allows the user to disable or enable (depending

on their current state) the following parts of the system:

a. Zone (Device or Full Zone).

b. Outputs.

c. Day Mode.

d. Delays.

T o display the DISABLE/ENABLE menu:

1 At the ‘Status: NORMAL’ message, press the ‘ ’

button. The LCD prompts for a Level 2/3 access code.

2 Either turn the keyswitch or, using the numeric keypad,

enter the correct Level 2 access code and confirm

using the ‘5’ button to display the menu. The LCD

displays the user number ([U0] to [U9]) in the top lefthand corner.

Note: An incorrect access code causes the LCD to

display the ‘ERROR - INCORRECT PASSCODE’

message. After one minute the LCD returns to the

‘Status: NORMAL’ message.

3 Using the numeric keypad, press the ‘2’ button to

display the DISABLE / ENABLE menu.

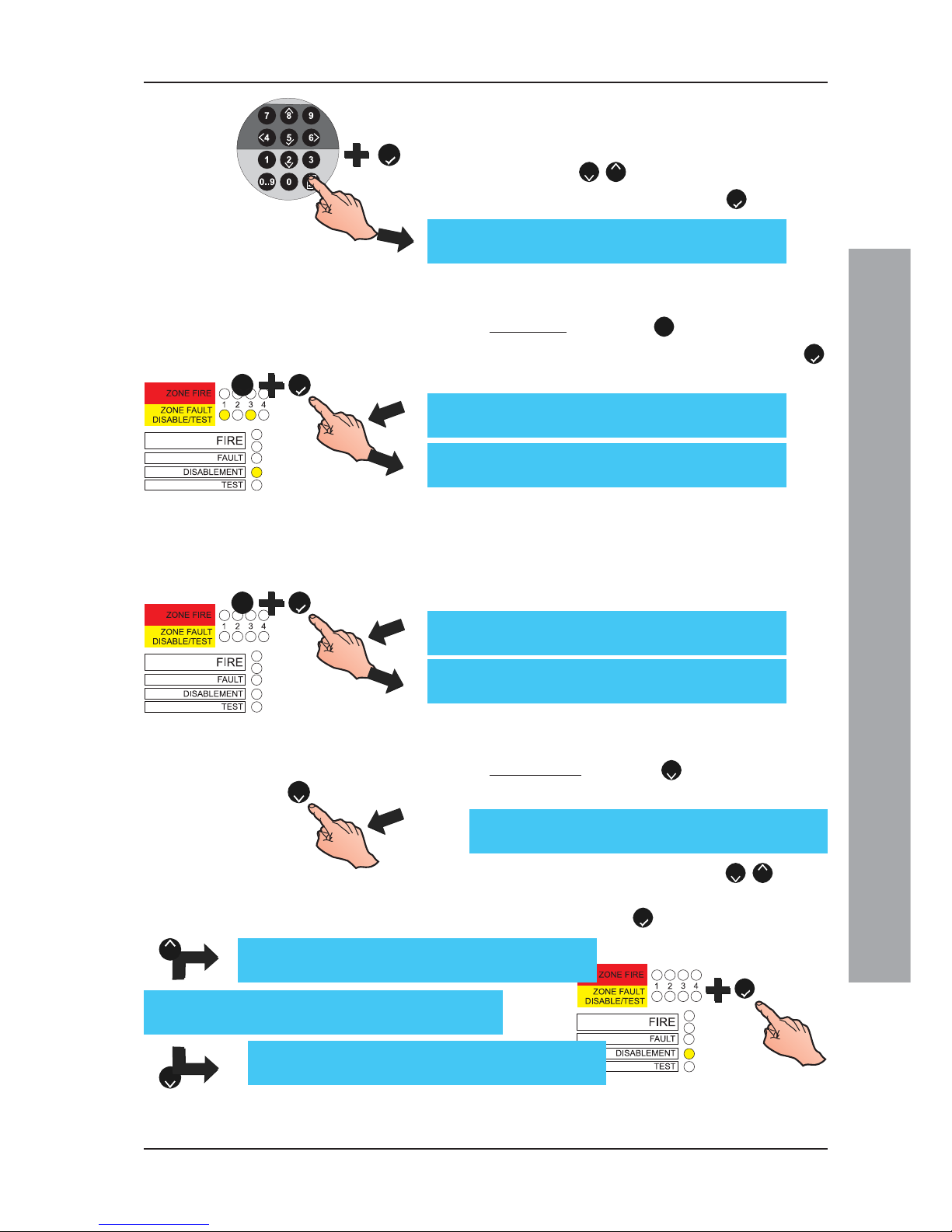

4.10.1 Zone - User Option

This option allows the user to disable/enable a full zone or

part of a zone (selected devices). T o perform this operation:

1 Using the numeric keypad, press the ‘1’ button to

select the Disable/Enable Zone option.

2 The LCD displays the Zone option and prompts for a

zone number. Enter the zone number (one or two digits

entered via the numeric keypad). Press the ‘5’ to

confirm the zone number.

[U0] 1 : Test 2 : Disable/Enable 3 : Clock

4 : View Mode 5 : Commission

[U0 Disable/Enable] 1:Zone 2:Outputs

3:Day Mode 4:Delays

2

ACCESS TO MENUS RESTRICTED

Enter Level 2/3 Passcode: . . . . < : BackSp

Page 33

ID50 Series Panel - Operating Manual

Operator Actions at Panel

29 997-264-000-8, Issue 8

January 2007

3 The LCD then displays the current state of the zone

(Fully enabled, Fully disabled or Part disabled) and

prompts for selection of Full Zone or Devices in zone:

Note: Press the ‘2/8’ buttons to step to the previous/

next zone and confirm using the ‘5’ button.

4 To disable:

a. A Full Zone - Press the ‘1’ button on the numeric

keypad to select the Full Zone option, and the ‘5’

button to confirm.

The DISABLEMENT and relevant ZONE FAULT/

DISABLE/TEST LEDs illuminate, indicating that the

selected zone(s) are now disabled. The LCD returns

to the Disable/Enable menu.

To enable a Full Zone:

The DISABLEMENT and relevant ZONE FAULT/

DISABLE/TEST LEDs extinguish.

b. A Partial Zone - Press the ‘2’ button on the numeric

keypad to select the Device in Zone option:

5 To select individual devices use the ‘2/8’ buttons

to display the required device(s). Confirm selection of

each by pressing the ‘5’ button.

[Disable/Enable] Zone 0 1 (Fully enabled)

1:Full Zone 2:Device in Zone ↕ : More

[Disable/Enable] Zone 0 1 Disable fully ?

Press ✓to Confirm <:Cancel

[Disable/Enable] Zone 0 1 Fully disabled

1:Full Zone 2:Device in Zone ↕ : More

[Disable/Enable] Zone 0 1 Enable fully ?

Press ✓to Confirm <:Cancel

[Disable/Enable] Zone 0 1 Fully enabled

1:Full Zone 2:Device in Zone ↕ : More

5

5

1

5

1

[Disable/Enable] Zone 0 1 Part disabled

1:Full Zone 2:Device in Zone ↕ : More

[Enable] Zone 0 1 - Enable S02 ?

Press ✓to confirm <:Cancel

[Disable] Zone 0 1 - Disable S01 ?

Press ✓to confirm <:Cancel

[Disable] Zone 0 1 - Disable M99 ?

Press ✓to confirm <:Cancel

5

2

8

2

Page 34

ID50 Series Panel - Operating Manual

Operator Actions at Panel

30997-264-000-8, Issue 8

January 2007

Repeat until all devices are in the required state (either

disabled or enabled). The DISABLEMENT LED

remains illuminated if one or more devices are

disabled. It is extinguished when all devices have been

enabled.

The relevant ZONE FAULT/DISABLE/TEST LED is

illuminated when all devices in that zone have been

disabled. Disablement of ALL devices is confirmed

by the ‘Fully Disabled’ LCD message.

6 Press the ‘4’ button to return to the Disable/Enable

menu.

Page 35

ID50 Series Panel - Operating Manual

Operator Actions at Panel

31 997-264-000-8, Issue 8

January 2007

4.10.2 Outputs - User Option

The Outputs option allows the user to disable or enable

all sounders, the extinguishant system (if fitted), and relay

and control outputs.

To Disable/Enable these outputs, proceed as follows:

1 Using the numeric keypad, press the ‘2’ pushbutton

to display the Disable/Enable Outputs menu:

2 Press the appropriate numbered button on the

numeric keypad to display one of the following:

a. Press the ‘1’ button to disable/enable all

sounders.

b. Press the ‘2’ button to disable/enable all

transmission device outputs.

c. Press the ‘2’ button to disable/enable all

Extinguishant System outputs.

d. Press the ‘3’ button to disable/enable all Fault

relay outputs.

e. Press the ‘5’ button to disable/enable ‘other’

(relays and control) outputs.

3 Press the ‘5’ button to confirm the selected

operation. The LCD automatically returns to the

Disable/Enable menu.

When outputs are disabled, the general DISABLEMENT

LED and, if applicable, the FIRE CONTROL O/P: F AULT/

DISABLED, FIRE OUTPUT : F AUL T/DISABLED and/or

SOUNDERS: FAUL T/DISABLED LEDs illuminate. If the

Extinguishant System is disabled, only the

DISABLEMENT LED will illuminate.

[U0 Disable/Enable] 1:Zone 2:Outputs

3:Day Mode 4:Delays

Disable ALL Sounder Outputs

Press ✓to confirm <:Cancel

Disable ALL Extinguishant System Outputs

Press ✓to confirm <:Cancel

1

5

3

2

2

[U0 Disable/Enable] 3:Ext. Systems

4:Fault Relays 5:Other s ↕ :More

[U0 Disable/Enable] 1:Sounder s

2:T ransmission Device Outputs ↕ :More

Disable ALL T ransmission Device Outputs

Press ✓to confirm <:Cancel

4

5

Disable ALL Relay and CTL Outputs

Press ✓to confirm <:Cancel

Disable ALL Fault Relay Outputs

Press ✓to confirm <:Cancel

Page 36

ID50 Series Panel - Operating Manual

Operator Actions at Panel

32997-264-000-8, Issue 8

January 2007

4.10.3 Day Mode - User Option

If Day Mode is enabled during panel commissioning, this

option allows the user to activate/deactivate Day Mode

delays during the set Day Mode time period. This has no

effect on any sensor sensitivity changes that may have

been configured during commissioning. Any sensor

sensitivity changes will automatically occur at the set Day

Mode period start and end times.

To Disable / Enable Day Mode, proceed as follows:

1 From the Disable / Enable menu, press the ‘3’ button

to display the following:

2 Press the ‘5’ button to confirm the requested

operation. The LCD automatically returns to the

Disable / Enable menu.

If Delays have been configured the DELAY ACTIVE

LED illuminates when Day Mode is started.

3 To end Day Mode, repeat step s 1 and 2 (the display is

as shown below):

The DELAY ACTIVE LED will extinguish when the Day

Mode operation has been ended, either when day

mode is turned off or when the timer has timed out.

No delays are active.

Note: If Day Mode is NOT cancelled manually, Day Mode

delays are automatically deactivated at the end of

the set time period.

[U0 Disable/Enable] 1:Zone 2:Outputs

3:Day Mode 4:Delays

Start Day Mode

Press ✓to confirm <:Cancel

[U0 Disable/Enable] 1:Zone 2:Outputs

3:Day Mode 4:Delays

End Day Mode

Press ✓to confirm <:Cancel

3

5

The FIRE CONTROL O/P: F A ULT/DISABLED, FIRE

OUTPUT: FAULT/DISABLED and the SOUNDERS

DISABLED LEDs extinguish when the corresponding

outputs have been enabled. The DISABLEMENT LED

will only extinguish when ALL disablements have been

enabled.

[U0 Disable/Enable] 1:Zone 2:Outputs

3:Day Mode 4:Delays

5

Page 37

ID50 Series Panel - Operating Manual

Operator Actions at Panel

33 997-264-000-8, Issue 8

January 2007

4.10.4 Delays - User Option

The Disable / Enable Delays option allows the user to

cancel or initiate the Delays function of the panel, which

is configured during commissioning (refer to 997-263

ID50 Series Panel Installation, Commissioning and

Configuration Manual, Sections 5.5.5.4 Primary/

Extend Delay Timers and 5.7.8 CBE Zones).

To Disable / Enable Delays:

1 Using the numeric keypad, press the ‘4’ button to

select the Disable/Enable Delays option:

2 At the prompt, press the ‘5’ button to confirm the

Delays operation. If delays are disabled, the LCD

prompts to enable delays, and vice versa.

When the delays are disabled, the DELAY ACTIVE

LED is extinguished. When the delays are enabled,

the LED is illuminated.

If a Day Mode time period is configured, the CBE Rule

delays will activate when Day Mode is started either:

a. Using the Disable / Enable menu, or

b. When Digital / ÜE Input 1 is operated (if this input

is configured during commissioning for Day Mode

Start).

These delays will be deactivated when Day Mode is

ended, either automatically at the end of the configured

Day Mode period, or by one of the following:

a. Using the Disable / Enable menu,

b. When the Digital / ÜE Input 1 is operated,

c. Delays are disabled using the Disable / Enable

menu.

[U0 Disable/Enable] 1:Zone 2:Outputs

3:Day Mode 4:Delays

Disable Delays

Press ✓to confirm <:Cancel

[U0 Disable/Enable] 1:Zone 2:Outputs

3:Day Mode 4:Delays

5

4

Page 38

ID50 Series Panel - Operating Manual

Operator Actions at Panel

34997-264-000-8, Issue 8

January 2007

4.11 Clock - User Option

The CLOCK User Option allows the user to enter or edit

the following:

a. Time.

b. Date.

To edit the CLOCK - User Option:

1 At the ‘Status: NORMAL’ message, press the ‘ ’

button. The LCD prompts for a Level 2/3 access code.

Note: If an incorrect access code is entered, the LCD

displays an ‘ERROR - INCORRECT

P ASSCODE ! ! !’. After one minute the LCD returns

to the ‘St atus: NORMAL’ message.

2 Either turn the keyswitch or, using the numeric keypad,

enter the correct Level 2 access code and confirm

using the ‘5’ button. The Level 2 menu is displayed

with the user number ([U0] to [U9]) in the top left-hand

corner.

3 Press the ‘3’ button on the numeric keypad to select

the Clock menu.

ACCESS TO MENUS RESTRICTED

Enter Level 2/3 Passcode: . . . . < : BackSp

[U0] 1 : T est 2 : Disable/Enable 3 : Clock

4 : View Mode 5 : Commission

[U0 Clock] 1 : Time 2 : Date

5

3

Page 39

ID50 Series Panel - Operating Manual

Operator Actions at Panel

35 997-264-000-8, Issue 8

January 2007

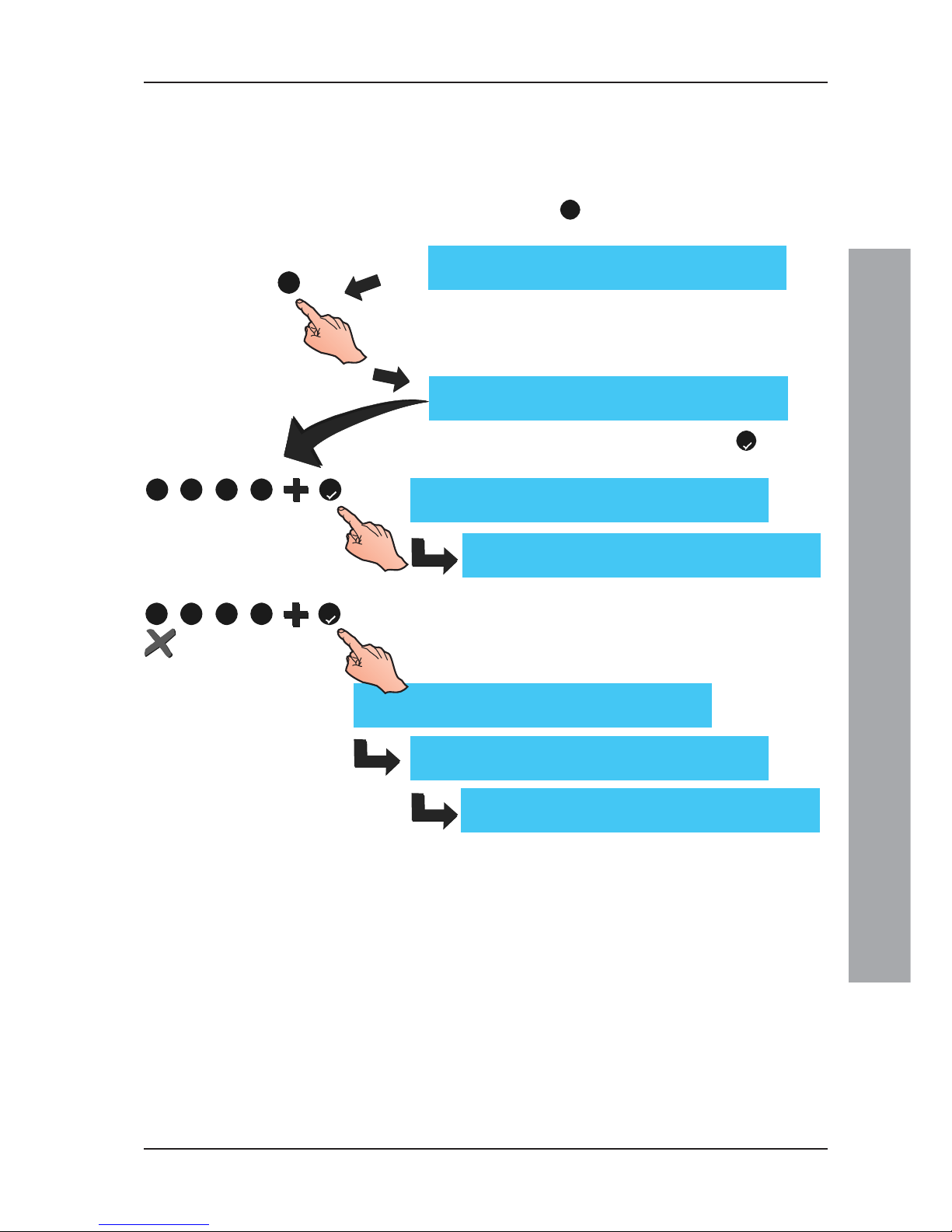

4.11.1 Time - User Option

The Time User Option allows the user to enter or edit the

current time displayed on the LCD. To edit the time,

proceed as follows:

1 Press the ‘1’ pushbutton on the numeric keypad to

select the Time option.

2 The LCD displays the Enter New Time prompt. Using

the numeric keypad, enter the numbers directly. All

digits are automatically entered into position from left

to right on the display .

After entering the last digit, press the ‘5’ to confirm

and return to the CLOCK menu.

Note: The entered time must be in the 24-hour clock

format (e.g. for 07:1 1 pm, enter 1911).

If an invalid time is entered, the LCD displays an error

message and then re-displays the Clock menu.

[U0 Clock] 1 : Time 2 : Date

ENTER NEW TIME (format hh : mm)

- - : - - <:Cancel

ENTER NEW TIME (format hh : mm)

19 : 11 <:Cancel

[U0 Clock] 1 : Time 2 : Date

ENTER NEW TIME (format hh : mm)

91 : 11 <:Cancel

Invalid Value Entered !

[U0 Clock] 1 : Time 2 : Date

1

1

1

1

1

1

5

51

9

9

Page 40

ID50 Series Panel - Operating Manual

Operator Actions at Panel

36997-264-000-8, Issue 8

January 2007

4.11.2 Date - User Option

The Date User Option allows the user to enter or edit the

current date displayed on the LCD. To enter or edit the

date, proceed as follows:

1 Using the numeric keypad, press the ‘2’ button to

select the Date option.

2 The LCD prompts for entry of a new date. Using the

numeric keypad, enter the numbers directly . All digits

are automatically entered into position from left to right

on the display .

After entering the last digit press the ‘5’ to confirm

and return to the Clock menu.

Note: The date MUST be entered in the same format as

indicated on the LCD. Only date entries between

2000 and 2063 are valid.

If an invalid date is entered, for example

222222 - 22/22/22, the LCD displays an error

message and then re-displays the Clock menu.

[U0 Clock] 1 : Time 2 : Date

ENTER NEW DATE (format dd/mm/yy)

- -/- -/- - <:Cancel

Invalid Value Entered !

ENTER NEW DATE (format dd/mm/yy)

12/12/00 <:Cancel

[U0 Clock] 1 : Time 2 : Date

ENTER NEW DATE (format dd/mm/yy)

22/22/22 <:Cancel

[U0 Clock] 1 : Time 2 : Date

1 1

5

2

2 2 0 0

5

2 22

2

2

2

Page 41

ID50 Series Panel - Operating Manual

Operator Actions at Panel

37 997-264-000-8, Issue 8

January 2007

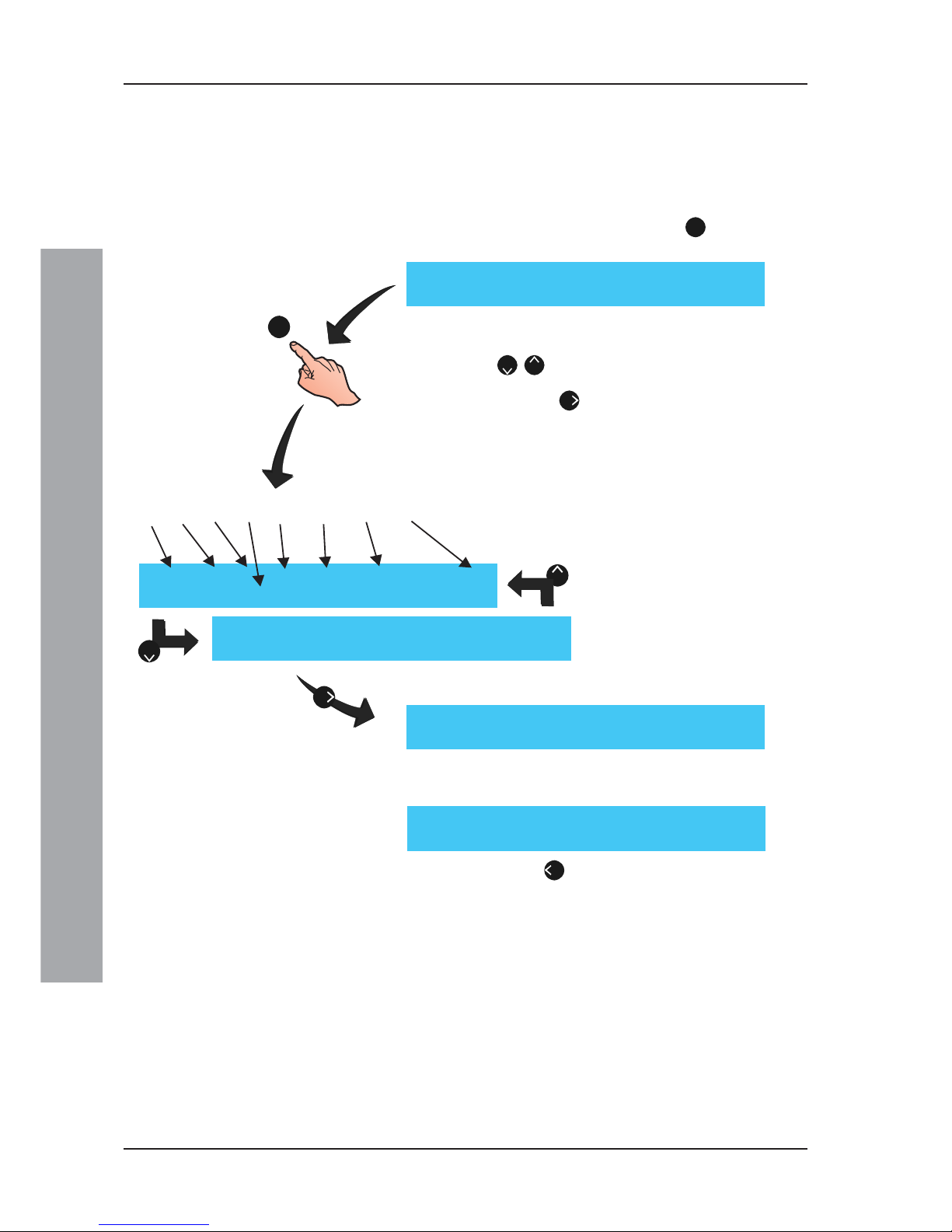

4.12 View Mode - User Option

The VIEW MODE User Option allows the user to view

the following system parameters:

a. Log

b. Devices on the loop

c. Faults

d. Input Events

e. Disablements on the loop

f. Maintenance Log (ID60 only - requires access level 3)

g. Alarm Count

h. Voltages

i. Version (system and loop software).

To display the View Mode menu:

1 From the ‘Status: NORMAL’ message, press the ‘ ’

button. The LCD prompts for a Level 2/3 access code.

Note: If an incorrect access code is entered, the LCD

displays ‘ERROR - INCORRECT P ASSCODE ! ! !’.

After one minute the LCD returns to the ‘Status:

NORMAL’ message.

2 Either turn the keyswitch or, using the numeric keypad,

enter the correct Level 2 access code and confirm using

the ‘5’ button. The Level 2 menu is displayed with the

user number ([U0] to [U9]) in the top left-hand corner .

3 Using the numeric keypad, press the ‘4’ button to

select the View Mode menu:

4 Press the ‘2/8’ buttons to display further menu

options:

* ID60 panels only

ACCESS TO MENUS RESTRICTED

Enter Level 2/3 Passcode: . . . . < : BackSp

5

4

[U0] 1 : T est 2 : Disable/Enable 3 : Clock

4 : View Mode 5 : Commission

[U0 View] 1: Log 2: Devices 3: Faults

4: Input Events 5: Disabled ↕ : More

[U0 View] 6: Maint.* 7: Alarm Count

8: V oltages 9: V ersion ↕ : More

82

or

Page 42

ID50 Series Panel - Operating Manual

Operator Actions at Panel

38997-264-000-8, Issue 8

January 2007

4.12.1 Log - User Option

The Log User Option allows the user to view all logged

events, one at a time. To display the Log, from the VIEW

Mode menu:

1 On the numeric keypad, press the ‘1’ pushbutton to

select the Log option.

2 The LCD automatically displays the last recorded

event. Viewing commences from this point; press the

‘2/8’ buttons to scroll through the Log entries.

Example Log entries are given below:

Note: Press the ‘6’ button to view additional zone text

information. T o return to the previous display press

any numeric/cursor key. Alternatively, if no key is

pressed within ten (10) seconds the LCD returns

to the View Log display automatically .

3 Press the ‘4’ pushbutton to return to the View Mode

menu.

[U0 View] 1:Log 2:Devices 3:Faults

4:Input Events 5:Disabled ↕ : More

[LOG 002/512] M12 MCP 12/12/00 14:55

DEVICE ADDED >

[LOG 001/512] 12/12/00 11:48

CPU FAULT >

[LOG 002/512] M12 MCP 12/12/00 14:55

ZONE10 >

1

6

2

8

Page 43

ID50 Series Panel - Operating Manual

Operator Actions at Panel

39 997-264-000-8, Issue 8

January 2007

4.12.2 Devices - User Option

The Devices User Option allows the user to observe all

loop devices in turn. T o view Devices, from the View Mode

menu:

1 On the numeric keypad, press the ‘2’ button to select

the Devices display .The LCD displays the last-viewed

sensor address:

2 Press the ‘2/8’ buttons to scroll through device

address entries until the desired sensor is displayed.

3 Press the 6’ button to view additional device

information.

Note: Three percentage values are displayed [this is the

device’s alarm level status, e.g. 100% (default) is

equivalent to alarm]. The value on the left is the

current alarm status level. The other percentage

values are historical; the previous two alarm status

percentages are displayed, the one on the left being

the more recent.

4 Press the ‘4’ button to return to the View Mode

menu.

AWACSTM Devices (ID60 only)

The ID60 panel allows the configuration of all sensor

types, except HEAT sensors, to use the AW ACSTM multisensing algorithm. For these devices an additional screen

is available which displays the current percentage values

for alarm and pre-alarm.

[U0 View] 1:Log 2:Devices 3:Faults

4:Input Events 5:Disabled ↕ : More

[U0 Sensor 02 - OPT] >: Next ↕ : More

PW1:286 2:283 3:285 4:1003 5:0292 <:Exit

[U0 Sensor 03 - OPT] >: Next ↕ : More

PW1:286 2:283 3:285 4:1003 5:0292 <:Exit

Device

Type

Device

Address

Pulse Width

Time Periods

2

2

8

[U0 Sensor nn - OPT] >: Next ↕ : More

Level 050% -

〉〉

〉〉

〉 050% -

〉〉

〉〉

〉 050%

[U0 Sensor nn - AAA] >: Next ↕ : More

PW1:286 2:283 3:285 4:1003 5:0292 <:Exit

[U0 Sensor nn - A VS] >: Next ↕ : More

AW A CS - Alarm: 000%, Prealarm: 000%

Page 44

ID50 Series Panel - Operating Manual

Operator Actions at Panel

40997-264-000-8, Issue 8

January 2007

4.12.3 Faults - User Option

This menu option allows the user to view active faults

while the normal active fault display has been overridden

by a higher priority display (alarms). T o view Fault s, from

the View Mode menu:

1 On the numeric keypad, press the ‘3’ button to select

the Faults display .

2 The LCD automatically displays the last recorded

event first. Viewing commences from this point. Press

the ‘2/8’ buttons to scroll through the faults.

Note: Press the ‘6’ button to view additional zone text

information. To return to the fault message press

any numeric/cursor key. Alternatively, if no key is

pressed within ten (10) seconds the display reverts

to the fault message. Example fault displays are

given below:

a. Fault condition

b. Fault currently displayed.

c. Total number of faults

logged.

d. Text description of fault.

e. Zone Number.

f. Device Address.

g. Device Type.

h. Time fault was logged.

Note: If no faults are recorded on the system, the

following message is displayed:

3 Press the ‘4’ button to return to the View Mode

menu.

[U0 View] 1:Log 2:Devices 3:Faults

4:Input Events 5:Disabled ↕ : More

F AULT 01 / 03 Z01 M12 MCP 14:55

< - - - Zone Te xt - - - > < - - - Device Text - - - >

FAULT 01 / 03 Z01 S23 TMP 14:55

NO REPLY FROM DEVICE >

The system has NO faults present

<:Exit

FAULT 01 / 03 Z01 M12 MCP 14:55

NO REPLY FROM DEVICE >

ABC DE F G H

2

8

6

3

Page 45

ID50 Series Panel - Operating Manual

Operator Actions at Panel

41 997-264-000-8, Issue 8

January 2007

4.12.4 Input Events - User Option

The Input Events menu option allows the user to view

active input events/plant alarms while the normal active

input events/plant alarms display has been overridden

by a higher priority display (alarms). T o view Plant Alarms,

from the VIEW Mode menu:

1 Using the numeric keypad, press the ‘4’ button to

select the Input Events display .

2 The LCD automatically displays either:

a. The first input event, or

b. The ‘No Warnings message’, if there are no current

input events recorded on the system.

3 If a number of input events are present, press the

‘2/8’ buttons to scroll through the entries:

a. Plant Alarm condition

b. Alarm currently displayed.

c. Number of alarms.

d. Zone Number.

e. Device Address.

f. Device Type.

g. Time alarm was logged.

h. Zonal and Device text

(if any).

Note: Plant alarms for Hold Switch and Abort Switch

inputs are entered as AUX events in the Fault list.

These input events are not processed by any CBE

rules.

4 Press the ‘4’ button to return to the View Mode

menu.

[U0 View] 1:Log 2:Devices 3:Faults

4:Input Events 5:Disabled ↕ : More

PLANT 01 / 10 Z21 M12 AUX 14:55

< - - - Zone Te xt - - - > < - - - Device Text - - - >

The system has NO warnings present

<:Exit

PLANT 01 / 10 Z21 M12 AUX 14:55

< - - - Zone Te xt - - - > < - - - Device Text - - - >

ABCDEFG

H

PLANT 02 / 10 Z17 M05 MON 15:05

< - - - Zone Te xt - - - > < - - - Device Text - - - >

2

8

4

Page 46

ID50 Series Panel - Operating Manual

Operator Actions at Panel

42997-264-000-8, Issue 8

January 2007

4.12.5 Disabled - User Option

The Disablement User Option allows the user to view all

current loop-based input disablements recorded on the

system. T o view each disablement in turn, from the VIEW

Mode menu:

1 Using the numeric keypad, press the ‘5’ button to

select the Disablements display .

2 The LCD automatically displays either:

a. The zone disablements, or

b. The NO disablements message, if no current

Disablements are present on the system.

3 If more than one disablement is present, press the

‘2/8’ buttons to scroll through the Disablement

entries (see examples below):

a. Condition,

b. Disablement currently

displayed,

c. Active disablements,

d. Zone number,

e. Device address,

f. Device type,

g. Zonal and device text

(if any).

4 Press the ‘4’ button to return to the View Mode

menu.

4.12.6 Alarm Count - User Option

The Alarm Count User Option allows the user to view the

number of times the panel has entered alarm condition

since manufacture. To view the Alarm Count, from the

VIEW Mode menu:

1 Using the numeric keypad, press the ‘6’ button to

select the Alarm Count display.

* ID60 panels only