Page 1

INSTALLATION AND PROGRAMMING MANUAL

1010

2020

INTELLIGENT FIRE

DETECTION AND

NSW (Head Office)

7 Columbia Court

Norwest Business Park

Baulkham Hills NSW 2153

Ph: (02) 9899-4155

Fax: (02) 9899-4156

Notifier Inertia Pty Ltd (A.C.N 002 692 962)

A PITTWAY COMPANYA PITTWAY COMPANY

www.inertia.com.au

QLD

16 Lucy St

Moorooka

Qld 4104

Ph: (07) 3892-6444

Fax: (07) 3892-6455

ALARM SYSTEM

SOFTWARE VERSION 3.0

REVISION AUS 1

VIC

Unit 2 297 Ingles St

Port Melbourne

Vic 3207

Ph: (03) 9681-9929

Fax: (03) 9681-9930

Page 2

PAGE 2 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

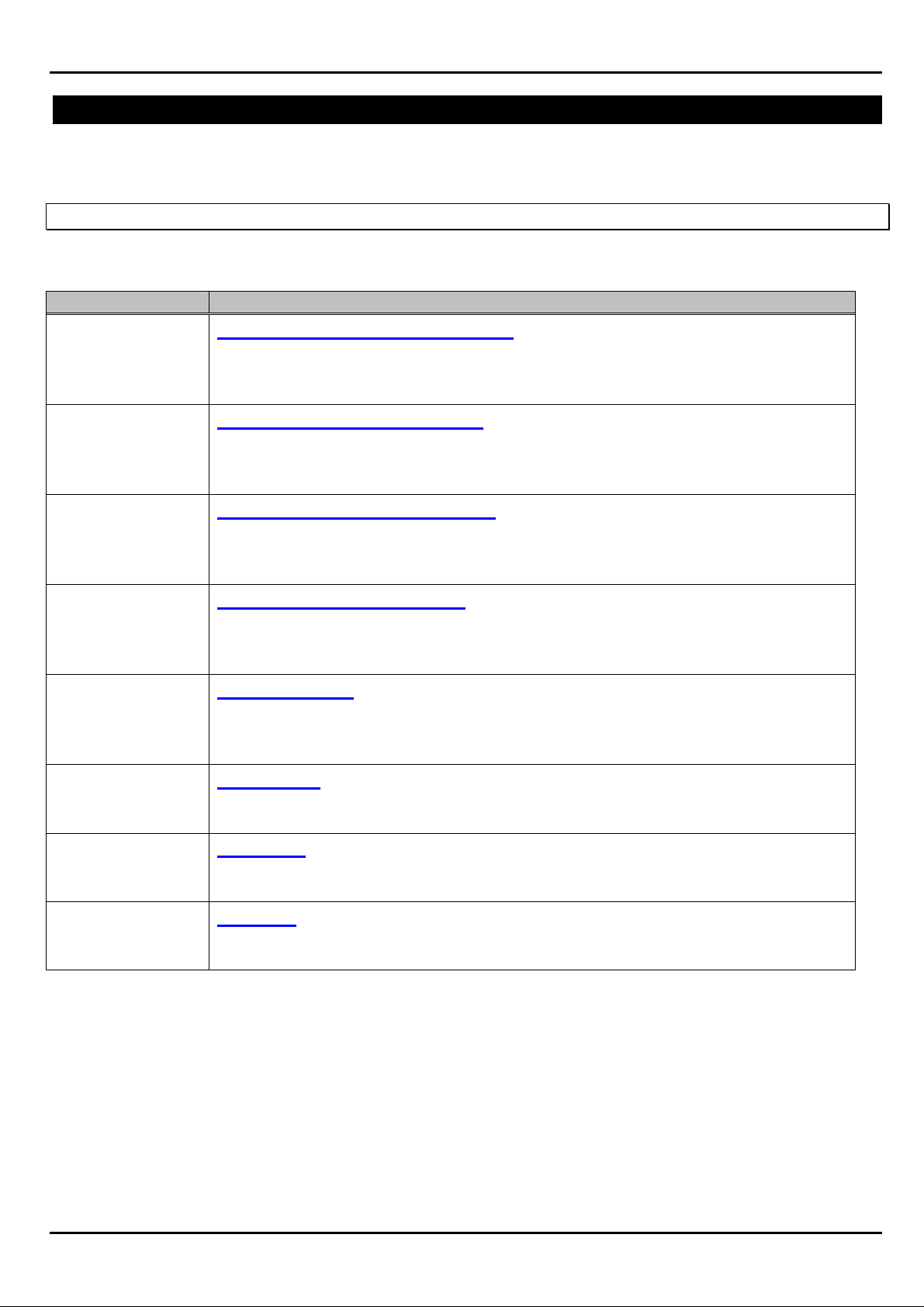

Table Of Contents

SECTION 1: INSTALLATION .............................................................................................5

PANEL OVERVIEW. ............................................................................................................................................................. 5

USING THE 1010/2020 DISPLAY INTERFACE ASSEMBLY (DIA)...................................................................................................................................5

The Keypad....................................................................................................................................................................................................5

Description....................................................................................................................................................................................................5

The “ACK NEXT” Button.............................................................................................................................................................................. 5

The “EXT Bell ISOLATE” Button .................................................................................................................................................................5

The “RESET’ Button......................................................................................................................................................................................6

The “TEST MENU” Button...........................................................................................................................................................................6

The “ISOLATE” Button.................................................................................................................................................................................6

CABINET SIZES ..................................................................................................................................................................6

LOOP TERMINATIONS FOR THE 1010 FIRE INDICATOR PANEL ..............................................................................................7

1010 PANEL – 1 LOOP...........................................................................................................................................................................................7

1010 PANEL – 2 LOOPS.........................................................................................................................................................................................7

1010 PANEL – 3 LOOPS.........................................................................................................................................................................................8

1010 PANEL – 4 LOOPS.........................................................................................................................................................................................8

LOOP TERMINATIONS FOR THE 2020 FIRE INDICATOR PANEL ..............................................................................................9

2020 PANEL – 1 LOOP...........................................................................................................................................................................................9

2020 PANEL – 2 LOOPS.........................................................................................................................................................................................9

2020 PANEL – 3 LOOPS.......................................................................................................................................................................................10

2020 PANEL – 4 LOOPS.......................................................................................................................................................................................10

2020 PANEL – 5 LOOPS.......................................................................................................................................................................................11

2020 PANEL – 6 LOOPS.......................................................................................................................................................................................11

2020 PANEL – 7 LOOPS.......................................................................................................................................................................................12

2020 PANEL – 8 LOOPS.......................................................................................................................................................................................12

2020 PANEL – 9 LOOPS.......................................................................................................................................................................................13

2020 PANEL – 10 LOOPS..................................................................................................................................................................................... 13

LOOP WIRING SPECIFICATION........................................................................................................................................... 14

EXPLANATION OF LOOP BOARDS...........................................................................................................................................................................14

LOOP WIRING SPECIFICATION................................................................................................................................................................................14

COMMON FAULT FINDING TECHNIQUES ............................................................................................................................. 15

NETWORK WIRING SYSTEMS............................................................................................................................................. 16

RS-485 AND RS-232 CIRCUITS....................................................................................................................................... 16

PRINTER CONNECTIONS.................................................................................................................................................... 16

CONNECTING A PRINTER DIRECTLY TO THE DISPLAY (DIA) ....................................................................................................................................17

CONNECTING A PRINTER TO THE SIB BOARD .......................................................................................................................................................17

CONNECTING A LAPTOP IN TERMINAL MODE TO EMULATE A PRINTER.....................................................................................................................18

TERMINAL MODE PROGRAMMING FROM A LAPTOP COMPUTER...............................................................................................................................18

ANNUNCIATOR TERMINATIONS ..........................................................................................................................................19

RS-485 FROM SIB CARD TO ANNUNCIATORS........................................................................................................................................................ 19

RS-485 TO AN LCD-80TM...................................................................................................................................................................................19

CONNECTING AND PROGRAMMING AN LCD-80 (ACS MODE) FROM A LAPTOP................................................................. 20

LAPTOP TO LCD-80 TERMINATIONS......................................................................................................................................................................20

PROGRAMMING CUSTOM MESSAGES.....................................................................................................................................................................21

ENTERING CUSTOM POINT LABELS........................................................................................................................................................................22

CPU TERMINATIONS ........................................................................................................................................................23

POWER SUPPLY TERMINATIONS........................................................................................................................................ 23

TERMINATING THE LOOP AND DEVICES ON THE LOOP.........................................................................................................24

TERMINATING THE ANALOGUE LOOP TO THE LIB CARDS.........................................................................................................................................24

WIRING ANALOGUE ADDRESSABLE DETECTORS.....................................................................................................................................................24

WIRING CONVENTIONAL CIRCUITS (MMX-2)..........................................................................................................................................................25

WIRING MONITOR MODULES (MMX-101) ..............................................................................................................................................................25

WIRING CONTROL MODULES (CMX-2).................................................................................................................................................................. 26

WIRING SHORT CIRCUIT ISOLATOR MODULES (ISO-X)...........................................................................................................................................26

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 3

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 3

XP-5M & XP-5C MODULES ................................................................................................................................................................................. 27

1668 FAN CONTROLS....................................................................................................................................................... 28

TERMINATION OF MODULES .................................................................................................................................................................................28

APPLICATION OF FAN CONTROL MODULES.............................................................................................................................................................28

DIP-SWITCH SETTINGS .....................................................................................................................................................29

SETTING ANNUNCIATOR BOARD ADDRESSES:........................................................................................................................................................29

SCS-8 FAN CONTROL MODULE ANNUNCIATOR......................................................................................................................................................29

ACM-16AT PUSHBUTTON & LED INDICATOR ANNUNCIATOR....................................................................................................................................30

ACM-32A LED INDICATOR ANNUNCIATOR ............................................................................................................................................................. 30

ACM-8R RELAY BOARD ANNUNCIATOR ................................................................................................................................................................30

LDM-32 LED DRIVER ANNUNCIATOR....................................................................................................................................................................31

LCD-80 LCD MIMIC ANNUNCIATOR (DUAL MODE) IN ACS MODE............................................................................................................................31

LCD-80 LCD MIMIC ANNUNCIATOR (DUAL MODE) IN TERMINAL MODE....................................................................................................................32

LCD-80TM LCD MIMIC ANNUNCIATOR (TERMINAL MODE).....................................................................................................................................32

APPLYING/REMOVING POWER TO THE FIRE ALARM SYSTEM .............................................................................................. 33

SECTION TWO: PROGRAMMING.....................................................................................34

PROGRAMMING OVERVIEW ............................................................................................................................................... 34

RECOMMENDED PROCEDURE ...............................................................................................................................................................................34

OVERVIEW ..........................................................................................................................................................................................................34

MAIN PROGRAMMING MENU.............................................................................................................................................. 35

PARTIAL SYSTEM PROGRAMMING ..................................................................................................................................... 36

LIB INSTALLATION 1=INST) .................................................................................................................................................................................37

LIB LOOP STYLE 4 OR STYLE 6 (2=STY)..............................................................................................................................................................37

TIME DELAYS (3=TDLY) ......................................................................................................................................................................................38

AUDIO VISUAL POWER SUPPLIES (4=AVPS)..........................................................................................................................................................38

ZONE BOUNDARY (5=ZBND)................................................................................................................................................................................39

EXTERNAL EQUIPMENT (6=EXTEQ.......................................................................................................................................................................39

LOCAL PARAMETERS (7=LOCP)...........................................................................................................................................................................40

ISIB (8=ISIB)......................................................................................................................................................................................................41

ADDITIONAL SYSTEM PARAMETERS (9=PARM)..................................................................................................................................................... 41

Day/Night Sensitivity...................................................................................................................................................................................42

Drift Compensation .....................................................................................................................................................................................43

INTERNATIONAL DISPLAY OPTION (0=CONT, 1=IDO)............................................................................................................................................43

FULL SYSTEM PROGRAMMING .......................................................................................................................................... 43

PARTIAL POINT PROGRAMMING ........................................................................................................................................44

TYPE ID (1=TYPID) ............................................................................................................................................................................................45

CONTROL-BY-EVENT 2=CBE)..............................................................................................................................................................................45

LABEL (3=LBL)....................................................................................................................................................................................................46

OPTIONAL FEATURES (4=OPTNS)........................................................................................................................................................................47

ANNUNCIATOR MAPPING (5=AMAP).....................................................................................................................................................................47

COOPERATIVE CONTROL-BY-EVENT (6=CCBE) .................................................................................................................................................... 48

REMOVING A DEVICE (5=REMV) ......................................................................................................................................52

CHANGING THE PASSWORD 6=PSWD............................................................................................................................... 52

A Forgotten Password?...............................................................................................................................................................................52

CHANGING THE “ALL SYSTEMS NORMAL” MESSAGE (7=MSG).......................................................................................... 52

ACCESSING THE HISTORY LOG (8=HIS)............................................................................................................................ 53

START...............................................................................................................................................................................................................53

STOP.................................................................................................................................................................................................................53

CLEAR ..............................................................................................................................................................................................................53

PROGRAMMING GUIDELINES:............................................................................................................................................ 54

WHAT IS A SOFTWARE ZONE ................................................................................................................................................................................54

FORWARD-ACTIVATING ZONES .............................................................................................................................................................................54

REVERSE ACTIVATING ZONES............................................................................................................................................................................... 54

CONTROL BY EVENT -LISTS AND EQUATIONS .........................................................................................................................................................54

C.B.E Equations: Operators........................................................................................................................................................................56

C.B.E SIZE LIMITATIONS ...................................................................................................................................................................................... 59

COOPERATIVE CONTROL-BY-EVENT ..................................................................................................................................................................... 60

C.B.E PROGRAMMING EXAMPLES.........................................................................................................................................................................60

SOFTWARE TYPE-ID’S - AN OVERVIEW........................................................................................................................63

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 4

PAGE 4 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

RECOMMENDED TYPE ID’S FOR COMMON APPLICATIONS ......................................................................................................................................... 63

Input Devices...............................................................................................................................................................................................63

Output Devices ............................................................................................................................................................................................63

Addressable Detectors.................................................................................................................................................................................64

Alarm Initiation Modules.............................................................................................................................................................................64

System Common Output Modules................................................................................................................................................................65

Output Modules ...........................................................................................................................................................................................66

Software Zones ............................................................................................................................................................................................66

Annunciator Zone........................................................................................................................................................................................67

Annunciator Input........................................................................................................................................................................................ 67

Annunciator Output.....................................................................................................................................................................................67

1668 (SCS-8) PROGRAMMING .........................................................................................................................................68

A fan that starts in firemode with associated duct detector:........................................................................................................................68

A fan that stops in firemode, with associated duct detector.........................................................................................................................69

Fire Trip Relay ............................................................................................................................................................................................ 69

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 5

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 5

SECTION 1: INSTALLATION

PANEL OVERVIEW.

The following section describes the Keypad functions, the cabinet sizes, the 1010 (4 loop) and the

2020 (10 loop) Analogue Fire Detection System.

USING THE 1010/2020 DISPLAY INTERFACE ASSEMBLY (DIA)

THE KEYPAD

DESCRIPTION

The Keypad on the right has both Alpha and Numeric facilities for each button, in most cases to

enter an Alpha character you may need to press the button more than once. In the case of entering

Loop 3 Detector 33, you will need to use the Next Char button to advance the cursor on the LCD

display between each keystroke, as D and the number 3, share the same button.

THE “ACK NEXT” BUTTON

When pressed allows you to scroll through the list of Alarms, Faults and Isolates on the LCD

display, the “ACK NEXT” button is also used to acknowledge any alarms or faults that may appear

on the LCD display

THE “EXT BELL ISOL” BUTTON

“EXT BELL ISOL” will isolate all CON and FORC type outputs flagged with “Bell Isolate”. This is to

prevent the main bells from ringing during routine testing. Also once an alarm has been

acknowledged, you can press the “EXT BELL ISOL” button, and the bells will silence and remain

silenced. If automatic bell cut-off is set, then once the cut-off is initiated the EXT BELL ISOL will

remain isolated until a system reset. If bell cut-off is not set, the EXT BELL ISOL can be toggled

on/off by pressing the button.

Please also refer to TDLY setting in programming section for further information on Bell Isolate

Inhibit and Automatic Bell Cut-off Times.

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 6

PAGE 6 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

THE “SYSTEM RESET’ BUTTON

Once all alarms have been acknowledged, the “RESET” button can be pressed, and the panel will

return to all systems normal, unless the alarms are still present, in which case the panel will go back

into alarm.

THE “TEST MENU” BUTTON

Allows you to enter a detector to place into alarm

THE “ISOL” BUTTON

This facility allows you to isolate the currently displayed device in alarm.

CABINET SIZES

There are three sizes of cabinets:

1/ 1865mm,x 610mm, x 380mm.

2/ 1330mm, x 610mm, x 380mm.

3/ 885mm, x 610mm, x 220mm.

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 7

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 7

LOOP TERMINATIONS FOR THE 1010 FIRE INDICATOR PANEL

1010 PANEL – 1 LOOP

Notifier 1010

Loop Hardware Arrangement

1 Loop Panel

Top Top

SIB CPU 1010

Loop 1

Bottom Bottom

LIB-200A Not Used

1010 PANEL – 2 LOOPS

Loop 1

Top Top

Not Used Not Used

Bottom Bottom

Not Used Not Used

Notifier 1010

Loop Hardware Arrangement

2 Loop Panel

Top Top

SIB CPU 1010

Bottom Bottom

LIB-200A LIB-200A

Loop 2

Top Top

Not Used Not Used

Bottom Bottom

Not Used Not Used

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 8

PAGE 8 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

1010 PANEL – 3 LOOPS

Notifier 1010

Loop Hardware Arrangement

3 Loop Panel

Top Top

SIB CPU 1010

Loop 1

Bottom Bottom

Loop 3

LIB-400 LIB-200A

Top Top

Not Used Not Used

Loop 2

1010 PANEL – 4 LOOPS

Loop 1 Loop 4

Loop 3

Bottom Bottom

Not Used Not Used

Notifier 1010

Loop Hardware Arrangement

4 Loop Panel

Top Top

SIB CPU 1010

Bottom Bottom

LIB-400 LIB-400

Loop 2

Top Top

Not Used Not Used

Bottom Bottom

Not Used Not Used

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 9

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 9

LOOP TERMINATIONS FOR THE 2020 FIRE INDICATOR PANEL

2020 PANEL – 1 LOOP

Notifier 2020

Loop Hardware Arrangement

1 Loop Panel

Top Top

SIB CPU 2020

Loop 1

Bottom Bottom

LIB-200A Not Used

2020 PANEL – 2 LOOPS

Loop 1

Top Top

Not Used Not Used

Bottom Bottom

Not Used Not Used

Notifier 2020

Loop Hardware Arrangement

2 Loop Panel

Top Top

SIB CPU 2020

Bottom Bottom

LIB-200A LIB-200A

Loop 2

Top Top

Not Used Not Used

Bottom Bottom

Not Used Not Used

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 10

PAGE 10 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

2020 PANEL – 3 LOOPS

Notifier 2020

Loop Hardware Arrangement

3 Loop Panel

Top Top

SIB CPU 2020

Loop 1

Bottom Bottom

LIB-200A LIB-200A

Loop 2

Loop 3

2020 PANEL – 4 LOOPS

Loop 1

Top Top

LIB-200A Not Used

Bottom Bottom

Not Used Not Used

Notifier 2020

Loop Hardware Arrangement

4 Loop Panel

Top Top

SIB CPU 2020

Bottom Bottom

LIB-200A LIB-200A

Loop 2

Loop 3

Top Top

LIB-200A LIB-200A

Bottom Bottom

Not Used Not Used

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Loop 4

Page 11

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 11

2020 PANEL – 5 LOOPS

Notifier 2020

Loop Hardware Arrangement

5 Loop Panel

Top Top

SIB CPU 2020

Loop 1

Bottom Bottom

LIB-200A LIB-200A

Loop 2

Loop 3

Loop 5

2020 PANEL – 6 LOOPS

Loop 1

Loop 6 Bottom Bottom Loop 2

Top Top

LIB-200A LIB-200A

Bottom Bottom

LIB-200A Not Used

Notifier 2020

Loop Hardware Arrangement

6 Loop Panel

Top Top

SIB CPU 2020

LIB-400 LIB-200A

Loop 4

Loop 3

Loop 5

Bottom Bottom

LIB-200A Not Used

Top Top Loop 4

LIB-200A LIB-200A

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 12

PAGE 12 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

2020 PANEL – 7 LOOPS

Notifier 2020

Loop Hardware Arrangement

7 Loop Panel

Top Top

SIB CPU 2020

Loop 1 Loop 7

Bottom Bottom

Loop 6

LIB-400 LIB-400

Loop 2

Loop 3

Loop 5

2020 PANEL – 8 LOOPS

Loop 1 Loop 7

Loop 6

Top Top

LIB-200A LIB-200A

Bottom Bottom

LIB-200A Not Used

Notifier 2020

Loop Hardware Arrangement

8 Loop Panel

Top Top

SIB CPU 2020

Bottom Bottom

LIB-400 LIB-400

Loop 4

Loop 2

Loop 3

Loop 8

Loop 5

Bottom Bottom

LIB-200A Not Used

Top Top

LIB-400 LIB-200A

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Loop 4

Page 13

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 13

2020 PANEL – 9 LOOPS

Notifier 2020

Loop Hardware Arrangement

9 Loop Panel

Top Top

SIB CPU 2020

Loop 1 Loop 7

Bottom Bottom

Loop 6

LIB-400 LIB-400

Loop 2

Loop 3 Loop 9

Loop 8

Loop 5

Bottom Bottom

LIB-200A Not Used

2020 PANEL – 10 LOOPS

Loop 1 Loop 7

Loop 6

Top Top

LIB-400 LIB-400

Notifier 2020

Loop Hardware Arrangement

10 Loop Panel

Top Top

SIB CPU 2020

Bottom Bottom

LIB-400 LIB-400

Loop 4

Loop 2

Loop 3 Loop 9

Loop 8

Loop 5

Bottom Bottom

Loop 10

LIB-400 Not Used

Top Top

LIB-400 LIB-400

Loop 4

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 14

PAGE 14 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

LOOP WIRING SPECIFICATION

EXPLANATION OF LOOP BOARDS.

The LIB-200A is a 1-loop board for the 1010 & 2020 panel and can support 99 detectors and 99

modules. The field wiring is electrically isolated from the rest of the system so that any two-ground

faults on separate loops will not cause invalid replies from devices. A short to any other system

circuit will not cause communication loss. The LIB-200A has an earth fault detection circuit with

selectable high/low sensitivity and isolate. The LIB-200A has two LED’s; yellow displays earth fault

and red indicates alarm condition.

The LIB-400 is a two Loop version, and has the same features as the LIB-200A,

LOOP WIRING SPECIFICATION

The recommended wiring to be used is two core twisted pair, .75mm2 minimum.

Style 4. (Loop does not return to the panel)

Port A, (Channel A) 3800M maximum, 50 Ohms resistance maximum.

Port B, (Channel B) 3800M maximum, 50 Ohms resistance maximum

Style 6. (Closed loop, returning to panel)

Total Loop, 3800M maximum, 50 Ohms resistance maximum.

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 15

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 15

COMMON FAULT FINDING TECHNIQUES

If using optional shielded twisted pair cable to minimise radiated emissions of radio

frequency energy, do not allow the shield drain wire to enter the cabinet. Connect the drain wire

to the outside of the cabinet via an earth type connector. Maintain the continuity of the shield wire

throughout the loop but do not connect to any devices, and only earth one end.

Before connecting the loop to the LIB-200A or LIB-400 card, carry out the following tests;

1. Check continuity of loop wiring, by placing a short on one end and reading the short with a

multimeter at the other end.

2. Check the loop resistance, same as above (be sure to set the multimeter to ohms), the loop

resistance cannot exceed 50 ohms, which is 25 ohms per leg. (See examples above).

3. Check for devices incorrectly wired, set the multimeter to diode Test, and place the leads on the

cable, the reading should be approx. .645,- reverse the leads- now the reading should be approx.

1.2 or higher, if both readings read low- this indicates a device incorrectly wired, or a short on the

wiring. Note: (Each device has a diode installed)

4. Voltage reading, set the multimeter to D.C. volts and read the voltage at the loop card before

connecting the loop, the reading should be approx. 24 volts, now connect the loop, the reading

should now be 15-16 volts. If the voltage goes down low this could indicate a short on the line, or

there is a device incorrectly wired (possible Reverse polarity), find the device and correct the loop

connections at that device.

5. Earth Fault test, Select ohms on the multimeter and check between each leg of the loop and

earth, if the reading falls below 50,000 ohms, an earth fault will appear on the loop when

connected, find the cause of the earth fault and rectify. (Possible causes of an earth fault are

moisture, inadequate insulation from surrounding building, equipment or materials).

NOTE:

A note on ‘Loop Resistance Measurement’, when ISO-X devices are present. When power is

removed from the Loop, the positive side of the circuit is opened at each ISO-X isolation module.

To measure the Loop resistance, temporarily place a jumper between Terminals 2 and 4 on each

ISO-X while taking measurements. Remember to remove all the jumpers and test all isolator

modules when you have finished taking the readings.

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 16

PAGE 16 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

NETWORK WIRING SYSTEMS

The Noti-fire-net network wiring system is to be wired in 1.5mm2- 2core twisted pair (no shield)

The network cable can run up to 1 klm between nodes (Each Fire Panel is a Node). For optimal

performance, Noti-fire Net should be run in a closed loop (style 6), however, Noti-fire-Net does have

the ability to run in an open-ended format (style 4). The cable is terminated on to a network card

(see the Noti-fire-Net manual for termination data).

RS-485 AND RS-232 CIRCUITS

The 1010/2020 has multiple RS-232 and RS-485 circuits, the illustrations below show the positions

and where to find them.

RS-485 circuits used for Annunciators wired outside of the Panel, are to be wired in 2 core Twisted

Shielded. Total RS485 run should not exceed 1.5 k’s in length. A second 2-core twin for 24Vdc is

also required for powering the Annunciators. (The last Annunciator must have a 120-ohm resistor

fitted across the RS-485 circuit). The shield must be earthed at the panel end, to the nearest earth

point immediately inside the Panel.

RS-485 circuits used for Terminal mode operation (LCD-80tm direct from the DIA) wired outside the

Panel, are to be wired in 4 core Twisted Shielded, or 2 x 2 core Twisted Shielded, and 2 core twin

for power supply requirements if needed. (The last Annunciator must have two 120-ohm resistors

fitted across the RS-485 circuits) The shields must be earthed at the Panel end, to the nearest earth

point immediately inside the Panel.

RS-232 circuits used for printer’s etc, wired outside of the Panel, are to be wired in Twisted Shielded

wiring and not to exceed 15 mtrs in length. The shield must be earthed at the Panel end, to the

nearest earth point immediately inside the Panel.

The following illustrations indicate the connection points for RS-485 and RS-232 circuits.

PRINTER CONNECTIONS

The following section indicates the terminations required, connecting a printer to various points on

the 1010/2020 Fire Panel.

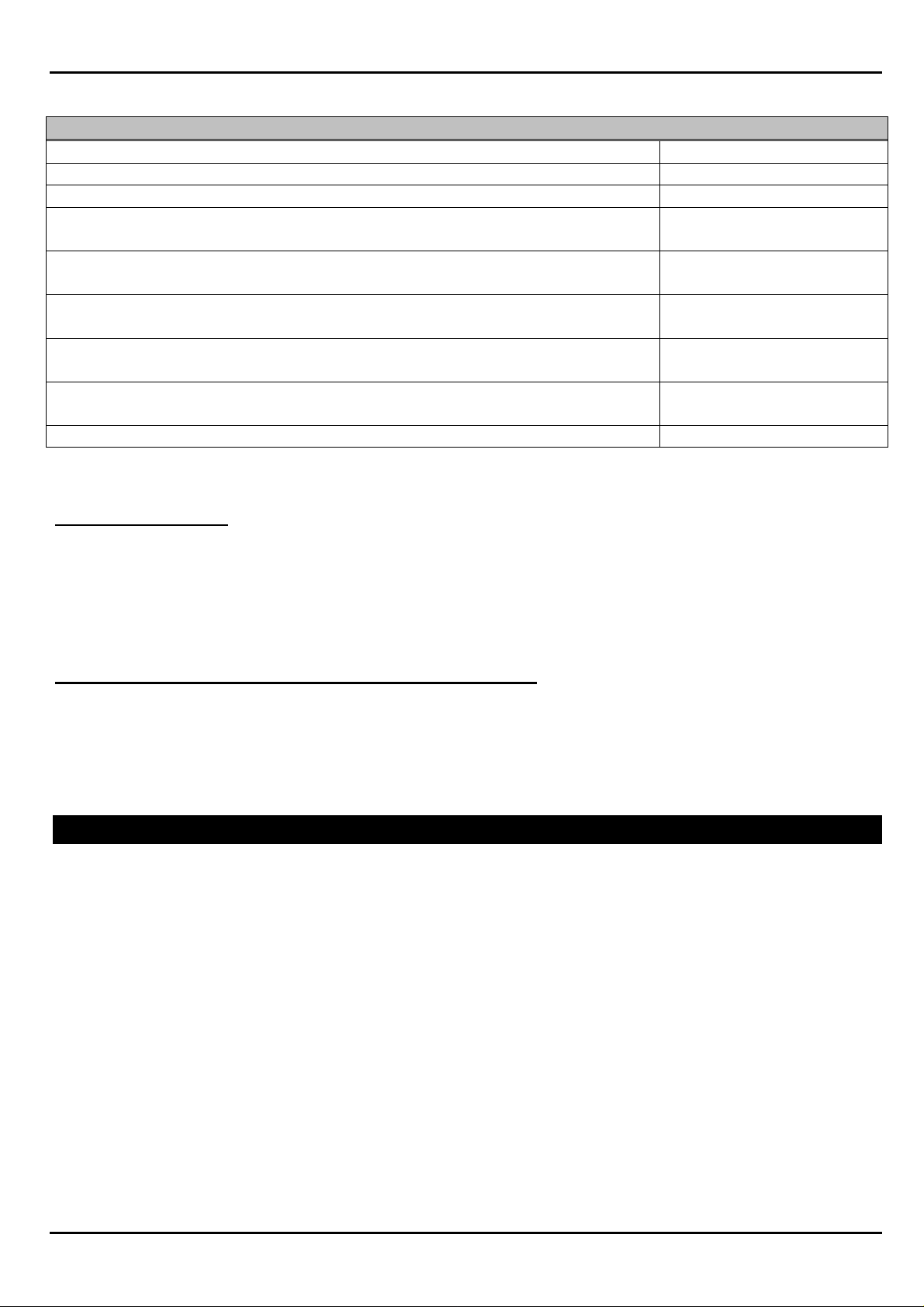

When converting to a DB9 or a DB25 pin connector, follow the tables below for connection details.

Conversion

from a

DB9 to a DB25

DB9 DB25

Rx pin 2 Rx pin 3

ref pin 5 ref pin 7

Tx pin 3 Tx pin 2

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 17

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 17

CONNECTING A PRINTER DIRECTLY TO THE DISPLAY (DIA)

RS-232 from DIA card to Printer

DIA DB9 DB25

5 Tx Rx pin 2 Rx pin 3

6 ref Ref pin 5 ref pin 7

This printer connection is a Non Monitored Non Supervised port, and one directional. The printer will

print whatever appears on the LCD.

CONNECTING A PRINTER TO THE SIB BOARD

SIB-NET/SIB-2048A RS-232 “Printer” Terminal Designations

SIB DB9 DB25

2 Tx Rx 2 Rx 3

3 ref Ref 5 ref 7

4Rx Tx 3 Tx 2

This printer connection will print events and reports from the system as requested, and this

connection is monitored.

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 18

PAGE 18 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

CONNECTING A LAPTOP IN TERMINAL MODE TO EMULATE A PRINTER

A Laptop computer can be used in lieu of a printer for uploading the history file or capturing reports

from the fire panel.

Set the Laptop up in terminal mode, and connect as per the instructions above for connecting a

printer to the SIB card. (Terminals 2, 3, & 4).

Place the Laptop in “terminal mode” (Hyperterm or equivalent) and set with the following

options for the COM port.

2400 Baud.

7 Data bits.

1 Stop Bit.

Even Parity.

Xon/Xoff handshaking.

Select “Capture text to file” in the Terminal Mode program on the Laptop.

Then Press the Special Function button on the 1010/2020 Panel,

and press “2=HIS”, and follow the prompts.

The 1010/2020 panel will now upload the entire history log to the Laptop computer which can then

be saved to disk for permanent records.

TERMINAL MODE PROGRAMMING FROM A LAPTOP COMPUTER

A Laptop computer can also be used in Terminal Mode to operate and program the panel in lieu of

using the system keypad. This makes for much faster input of device descriptions etc when not

using Verifier TM.

Terminal Mode Settings:

2400 Baud.

7 Data bits.

1 Stop Bit.

Even Parity.

Xon/Xoff.

SIB DB9 DB25 Contact Notifier Inertia Fire Systems for

10 Tx Rx 2 Rx 3 Function key setting in Terminal Mode.

11 ref Ref 5 ref 7

12 Rx Tx 3 Tx 2

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 19

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 19

ANNUNCIATOR TERMINATIONS

RS-485 FROM SIB CARD TO ANNUNCIATORS

The RS-485 circuit must be wired in 2 core twisted pair, and can be run to a distance of 1.5 klms,

The 24Vdc must be from the Non-resettable terminals on the power supply, or a remote 24Vdc-

power supply can be used.

A record of any external power supplies used must be placed within the 1010/2020 enclosure,

preferably in a place easily recognisable to service personal.

LCD-80TM Connection

The LCD80TM is a terminal mode remote LCD mimic. Ie: It displays whatever is on the main LCD.

RS-485 TO AN LCD-80TM

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 20

PAGE 20 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

CONNECTING AND PROGRAMMING AN LCD-80 (ACS MODE) FROM A LAPTOP

The following section details the programming procedure for programming LCD-80 (Dual Mode)

Mimics. Note the terminations for a DB-9 or DB-25 pin connector.

LAPTOP TO LCD-80 TERMINATIONS

LCD-80 DB-9 Db-25

1 Rx 3 Tx 2 Tx

6 ref 5ref 7 ref

7 Tx 2 Rx 3 Rx

Programming outline:

Remove 24vdc power.

Connect the RS-232 interface to the Laptop as shown above.

Reconnect 24vdc to the LCD-80

Insert the PK-1 Programming Key onto the connector P6.

Program the LCD-80.

Exit Program mode by removing the Programming Key.

The Laptop must be in “terminal mode” and set with the following options:

2400 Baud.

7 Data bits.

1 Stop Bit.

Even Parity.

Xon/Xoff.

The LCD-80 now is ready for programming

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 21

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 21

PROGRAMMING CUSTOM MESSAGES

Once in Program mode, the LCD-80 ceases all communication on the RS-485 and waits for

commands from the RS-232 circuit. The LCD-80 screen will display:

READY FOR PROGRAMMING

Configure the Laptop in Terminal Mode, and it will display:

ENTER 1 to 9 FOR 9 CUSTOM MESSAGES

OR 0 FOR CUSTOM POINT LABEL:

Any one of the nine custom messages may be programmed by pressing the respective number

followed by ENTER on the keyboard. The LCD-80 screen and the display monitor will display either

a default message or whatever message was last stored in the unit. Text cannot be immediately

entered since the cursor starts at the end of the message. The LCD-80 programmer must edit the

message using the backspace key, then enter a new message.

Once the message has been edited, press the ENTER key to store the message.

The screen will return to the display,

READY FOR PROGRAMMING.

These custom messages have various character widths and are displayed under different conditions

present within the fire alarm system.

Number

Message

Conditions under which each message will be displayed

Number

1 Standard display banner for the LCD-80.

2 Displayed under Normal conditions

3 Displayed when communications between LCD-80 and the control panel have

been interrupted.

4 Displayed under all Alarm conditions.

5 Displayed under all Fault conditions.

6

7

8

Messages 6 through 9 are not displayed on the LCD-80.

These messages are sent to a printer connected to the LCD-80.

9

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 22

PAGE 22 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

under which each

ENTERING CUSTOM POINT LABELS

Custom point labels may be programmed by entering "0" from the initial program prompt.

ENTER 1 to 9 FOR 9 CUSTOM MESSAGES

OR 0 FOR CUSTOM POINT LABEL:

Select “0”

A second prompt will be displayed on the computer monitor.

LCD-80 set for 20-character labels:

ENTER 1 to 128 FOR CUSTOM POINT LABEL (20 CHARACTERS):

where 1-128 represent zones in the control panel.

Once a point number has been entered, the LCD-80 screen will display either the

custom zone message or the last stored point message. The label may be changed by backspacing

over the existing label and typing a new one.

Once the message has been changed or entered satisfactorily, press ENTER to store

the message. The LCD-80 screen will retain the previous point label information while

the monitor display will return to the 40-character custom label prompt:

ENTER 1 to 128 FOR CUSTOM POINT LABEL (40 CHARACTERS):

Continue to enter point label information or press ESC to return to the initial programming

prompt:

ENTER 1 to 9 FOR 9 CUSTOM MESSAGES OR 0 FOR CUSTOM POINT LABEL:

Once all programming of the LCD-80 has been completed, remove the Programming

Key.

See the next section for setting the switches for the LCD-80 in Programming Mode.

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 23

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 23

Active

Secondary Power

+ -

Power-limited, filtered, non-resettable, 3 amps (in alarm)

maximum. JP5 may be cut to convert this power (TB3

Terminals 3 and 4) to a resettable, 2-amp maximum circuit.

CPU TERMINATIONS

CPU 1010/2020 General Isolate and General Fault Relays

POWER SUPPLY TERMINATIONS

27.6 V DC, supervised and power-limited.

Fast charge = 2 amps,

Trickle charge = 20 mA.

Battery + -

Neutral

Earth

Circuit Breaker

and Fuse are

by- passed for

use in Australia

+ - Resettable Power

24V DC (20.4-26.4, 200 mV ripple), 1 amp

maximum. Filtered and resettable. Power-limited.

Non Resettable Power

This output can also be used to power ACS series

Annunciators (do not cut JP5).

Cut R27 to disable Earth Fault

Detection.

LED Indicators

Earth Fault

Battery Fail

AC Power Fail

NiCad High Charge Rate

JP1: When employing an NR45-24/E or CHG-120,

Remote Battery Charger, JP1 must be cut.

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

JP5: Cut to make notification

appliance power on TB3

Terminals 3 and 4 a resettable 2amp maximum circuit.

JP2: must be cut otherwise a

short on the 24vdc power

(Terminals 3 and 4) would register

incorrectly as a loss of primary

(AC) power.

MPM-2 Voltmeter/Ammeter Connector

Page 24

PAGE 24 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

TERMINATING THE LOOP AND DEVICES ON THE LOOP

PLEASE NOTE:

The following examples are the actual wiring terminations for the devices, the example for wiring

Conventional Circuits (MMX-2’s) only applies to Version 3.0 release, and shouldn’t be used for

previous release software. Please contact support staff for additional information.

TERMINATING THE ANALOGUE LOOP TO THE LIB CARDS

Note:

Terminal 8 should be connected straight to the nearest earth point on the Chassis.

If optional shielding is used, do not terminate to terminal 8, connect the shield straight to the nearest

Earth point

WIRING ANALOGUE ADDRESSABLE DETECTORS

Note:

If optional shield used, do not connect to the spare terminal on the detector base, join the shield and

insulate it from the other cables.

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 25

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 25

WIRING CONVENTIONAL CIRCUITS (MMX-2)

The MMX-2 when used with Version 3 Release Software, utilises the 24Vdc Non-Resettable power

supply, thereby negating the need for Resettable power in the field.

Note:

If optional shield used do not terminate to this device, the shield must be continuous.

WIRING MONITOR MODULES (MMX-101)

This Module is a single input device, and can be used for Flow switch, Tamper Switch, sprinkler

pressure switch, and pump run/stop, and Tank Hi/Low monitoring.

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 26

PAGE 26 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

WIRING CONTROL MODULES (CMX-2)

CMX-2’s are used for Bells, Solenoids or any general relay application and can be monitored

outputs or relay outputs.

WIRING SHORT CIRCUIT ISOLATOR MODULES (ISO-X)

Note: When using

the ISO-X module,

limit the devices

between each ISO-X

to 25 devices.

In the case of “T”

taping the limit of 25

also applies.

The ISO-X doesn’t

affect the device

count unless the

amount of ISO-x’s

exceeds 100

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 27

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 27

XP-5M & XP-5C MODULES

The XP-5 Control and XP-5 Monitor modules are 5 separate modules and addresses mounted on

one circuit card, the address is chosen by one rotary switch and one slide switch.

The rotary switch selects the address in increments of ten, and the slide switch selects either 0 or 5.

Eg; address 52- the rotary switch will be 5, and the slide switch will be 0.

Address 52 will be the third point on the XP-5 card.

The wiring of both the XP-5C and XP-5M are wired exactly as the CMX-2 and MMX-101 devices,

the only difference being that they share the same loop connection.

Address Sw1-5 set ON,

If not used, set OFF.

For Future Use, Set

SW1-5 Off

Note: Each output on the XP-5C is selectable via a switch.

Monitored output = Switch Depressed (Above Line)

Relay Output = Switch Not Depressed (Below Line).

Monitored output circuits are to be wired as per a CMX-2 and connected to the XP5-C as shown.

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 28

PAGE 28 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

1668 FAN CONTROLS

TERMINATION OF MODULES

87654321

+24

D

ANALOGUE

C

-VE

LOOP

+VE

REPEAT FOR EACH FIRE TRIP

+ ANALOGUE LOOP

- ANALOGUE LOOP

FTR FAN START FAN STOP

9

8

7

6

COM

5

N/C N/C

COM

N/C

9

8

7

6

5

CMX-2

DATA

(-)

DATA

(+)12

3

4

N/O

CMX-2

DATA

(-)

DATA

(+)12

3

4

N/O

TABS TO BE BROKEN TABS TO BE BROKENTABS TO BE BROKEN

+24FTR FAN START FAN STOP

REPEAT FOR EACH FAN

3

4

N/O

(-)

(+)12

CMX-2

DATA

DATA

9

8

7

6

COM

5

INDICATION

RUN [ CLOSED CCT ]

STOP [ 47K RES ]

FAULT [ OPEN CCT ]

INDICATION

MMX-101

(-)

BLACK

RED

(+)

(+)

VIOLET

YELLOW

(-)

D

C

FIELD CABLING

B

A

+24

SUPPLY

0V

FTR

FTR

POWER

MECHANICAL SERVICES BOARD

1 2 3 4 5 6 7 8

No. Revision - revise on CAD. Do not amend by hand Eng. App. Date

RUN

STOP

FR

FS

COMM RUN FAULT

47K

SEE NOTE A SEE NOTE B

AFR AFR

PFR PFR

TYPICAL FAN INDICATION CONTACT ARRANGEMENT

Copyright

This document is & shall

remain the property of

Notifier Inertia Fire Systems

Unauthorised use of this

document in any way is

prohibited.

E:\JOBS\..\Nifs_fan.sch

C

O

Drawing File No.

7 Columbia Court,

Norwest Business Park

Baulkham Hills NSW 2153

AUSTRALIA

Tel

61 2 9894 1444

Fax

61 2 9899 4156

Email: support@inertia.com.au

Sheet:

Drawn/

Traced

Approved

This Drawing must not be used for Construction

unless signed as approved

47K

1 1

NOTE :

Of:

Engineer

G.W.25/2/00

Design

USE ONLY RESISTOR A OR B

(A) = FAULT CONTACT NOT USED

(B) = FAULT CONTACT USED

LEGEND

SR =START RELAY

AFR =AIR FLOW RELAY

SR

FR = FAN RUN RELAY

FS = FAN STOP RELAY

PFR = PHASE FAILURE RELAY

FTR = FIRE TRIP RELAY

title

FAN CONTROLS

FIELD I/O-VER3

Size

Drg.

NIFS_FAN

A3

No.

Rev

APPLICATION OF FAN CONTROL MODULES

It's required that all fan controls utilise Two CMX-2's (with tabs broken) and One MMX-101 per fan.

When installing the modules on the SLC loop, always make the address on the Start CMX-2 lower

numerically than the Stop CMX-2.

eg: CMX-2 Start = L1M1

CMX-2 Stop = L1M2

MMX-101 Airflow = L1M3

B

A

A

NOTE:

For programming Fan Controls please consult the Programming section of the Manual

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 29

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 29

DIP-SWITCH SETTINGS

The following section indicates the typical Dip-switch settings for Annunciators (SCS-8, ACM-16AT,

ACM-8R, ACM-32A, LDM-32, LDM-32R, LCD-80 and LCD-80TM)

SETTING ANNUNCIATOR BOARD ADDRESSES:

Typical Annunciator address selection method

The first decimal dial on the left-hand side selects the address in unit of ten, the second dial selects

the address in units of one.

SCS-8 FAN CONTROL MODULE A NNUNCIATOR

SW ON OFF

1 –10sec to duct detector latching time

(Standard time = 60 Seconds)

2 –20sec to duct detector latching time

(Standard time = 60 Seconds, )

3 Instant Fan Faults Fan Faults Delayed 30 Sec

4 Addresses 33-64 Are ALL additional

latching fire trips.

5 Global mode Reset Activated ie: Broadcast

latching plant trip reset to all SCS-8’s

6 Latching A/C Trip Non-Latching A/C Trip

7* Fire Mode LED From Z240. Fire Mode Led, from Common Alarm

8 EOL Resistor for RS485 EOL resistor out of circuit.

No Change

No Change

Addresses 33-63 are for SCE-8

Address 64 is the only FTR.

Global Mode Reset Disabled: Ie:

plant trip reset restricted to current

SCS-8.

LED.

* With the SCS-8 there is a choice as to how a Fire Mode trip is activated.

Dip Switch 7 when ON- selects Z240 as the input to the SCS-8 to activate Fire Mode.

Dip Switch 7 when OFF- selects the common alarm LED as the input for the SCS-8 Fire Mode Trip.

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 30

PAGE 30 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

ACM-16AT PUSHBUTTON & LED INDICATOR ANNUNCIATOR

SW ON OFF

1 Keys Disabled Keys Enabled

2 1 Or 3 Expanders None or 2 Expanders

3 2 Or 3 Expanders None or 1 Expander

4 N/A Always Use This Setting

5 Receive Only Mode Normal Mode

6 Piezo Disabled Piezo Enabled

7 Lamp Test Enabled Lamp Test Disabled

8 LED’s to Come on Steady LED’s to Flash (until Acknowledged)

ACM-32A LED INDICATOR ANNUNCIATOR

SW ON OFF

1 N/A Always Use This Setting

2 Expander Installed Expander Not Installed

3 N/A Always Use This Setting

4 N/A Always Use This Setting

5 Receive Only Mode Normal Mode

6 Piezo Disabled Piezo Enabled

7 Lamp Test Enabled Lamp Test Disabled

8 LED’s to Come on Steady LED’s to Flash (until Acknowledged)

ACM-8R RELAY BOARD ANNUNCIATOR

Relay Addresses On Off

1-8 1,5 All Others OFF

9-16 2,5 All Others OFF

17-24 3,5 All Others OFF

25-32 4,5 All Others OFF

33-42 1,6 All Others OFF

43-48 2,6 All Others OFF

49-56 3,6 All Others OFF

57-64 4,6 All Others OFF

SW4 ON OFF

1 Always Use This Setting N/A

2 Receive Only Mode Normal Mode

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 31

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 31

LDM-32 LED DRIVER ANNUNCIATOR

SW3 ON OFF

1 N/A Always Use This Setting

2 Expander Installed Expander Not Installed

3 N/A Always Use This Setting

4 N/A Always Use This Setting

5 Receive Only Mode Normal Mode

6 Piezo Disabled Piezo Enabled

7 Lamp Test Enabled Lamp Test Disabled

8 LED’s to Come on

LED’s to Flash (until Acknowledged)

Steady

SW3-8 must be on, when used in conjunction with an LDM32R(Relay Board)

SW4 (Slide Switch On PCB, must always be set to the left)

LCD-80 LCD MIMIC ANNUNCIATOR (DUAL MODE) IN ACS MODE

SW1 ON OFF

1 Receive Only Normal Mode

2 Australian Time & Date USA Time & Date

3 Piezo Disabled Piezo Enabled

4 Disable Keys Enable Keys

5 N/A Always Off

6 Always On N/A

7 N/A ACS Mode Enabled

8 N/A Always Off

Annunciator Tens Addressing - SW3

Tens Digit SW3-1 SW3-2

0 OFF OFF

1 ON OFF

2 OFF ON

3 ON ON

Annunciator Units Addressing – SW2

SW2 Use Rotary Dial For

Annunciator Units Digit.

EG: Annunciator Address 25 would be SW3-1 = OFF

SW3-2 = ON

SW2 = 5

Note: In the above configuration the LCD-80 in ACS mode will use its Annunciator address and the

NEXT Annunciator address. In this mode, you can have 128 Messages of 40 Characters in length.

For other combinations please contact Notifier/Inertia.

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 32

PAGE 32 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

LCD-80 LCD MIMIC ANNUNCIATOR (DUAL MODE) IN TERMINAL MODE

SW1 ON OFF

1 N/A Always Off

2 N/A Always Off

3 Piezo Disabled Piezo Enabled

4 Disable Keys Enable Keys

5 N/A Always Off

6 N/A Always Off

7 Terminal Mode Enabled N/A

8 N/A Always Off

SW3 ON OFF

1 Set if Last LCD-80 Set if not Last LCD-80

2 Terminal Supervision No Terminal Supervision

SW-2 Not Use in Terminal Mode.

‘Operation Mode’ the 2 slide switches must be set to Terminal Mode (Down Position)

LCD-80TM LCD MIMIC ANNUNCIATOR (TERMINAL MODE)

SW1 ON OFF

1 Disable Piezo Enable Piezo

2 Disable Keys Enable Keys

SW3 ON OFF

1 Set if Last LCD-80 Set if not Last LCD-80

2 Terminal Supervision No Terminal Supervision

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 33

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 33

APPLYING/REMOVING POWER TO THE FIRE ALARM SYSTEM

After completing the proper installation of all boards, cables and components, apply power in the

following manner:

1. Apply AC power

2. Connect the battery/secondary power terminals.

3. Do not connect any releasing devices until the releasing circuits have been tested using

simulated loads.

4. Test system as per your requirements.

When servicing the panel, perform the following steps before removing or connecting any power or

supervisory cables:

1. Isolate system from the brigade

2. Disconnect any releasing devices

3. Remove all RS-485 connections

4. Remove battery/secondary power

5. Remove AC power

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 34

PAGE 34 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

SECTION TWO: PROGRAMMING

PROGRAMMING OVERVIEW

RECOMMENDED PROCEDURE

The 1010/2020 programmablility is extremely versatile. It can be programmed 4 ways.

1. Via the panel keypad on the DIA

2. Via a Laptop in terminal mode

3. Via a Laptop using the Notifier Verifire Program with full Upload & Download facility.

4. Via the NCS graphics system direct connected on the network.

For initial programming of the 2020 or 1010 the following procedure must be followed.

• Locate the Program Configuration work Sheets (Supplied by Notifier/Inertia Fire systems). Use

these Work Sheets to record the exact information for every detector, module, Annunciator point

and groups in the system.

1. Install all system boards.

2. Apply power to the control panel as described in the section one of Installation manual.

3. Perform a full system program from the DIA telling the system of all boards installed.

4. Re-power the system.

5. Then you may use a Laptop or NCS or the DIA to perform point installation.

Once system programming is complete it is strongly recommended you perform 3 steps.

1. Change the system password from that of the default supplied from the factory. This will prevent

unauthorised access to configuration information.

2. Make a hard-copy record of the program on the printer (If fitted).

3. Upload the program to a PC and save to disk.

OVERVIEW

The 1010/2020 programming is menu driven, simply choose which function you want and implement

it. This manual describes the basic functionality of the programming, assuming that the operator

has received programming training from Notifier Inertia fire Systems.

Programming is separated into two basic functions;

1. Full Programming,- allows you to install new devices, Annunciators and loop cards etc.

2. Partial programming,- allows you to change parameters of devices Annunciators and Loops etc.

Both functions can only be accessed via the Prog button and entering the password.

Important Note: This programming manual refers to the Software Release Version 3 AUS 1. Do not

attempt to use any Software Type ID’s described in this manual, on any Notifier

Inertia Product prior to this Version 3 software release. The software release

number can be found on the Eprom label on the CPU card.

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 35

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 35

MAIN PROGRAMMING MENU

On entering the Programming Mode, (and after entering the password) the display will show the

Main Programming menu:

PRESS 1=PSYS, 2=FSYS, 3=PPRG, 4=FPRG, 5=REMV, 6=PSWD, 7=MSG, 8=HIS

The Main Programming menu has eight options, which are:

Option Description

1=PSYS

PARTIAL SYSTEM PROGRAMMING - Selective programming of system-

wide functions (number of LIBs, ISIB, Alarm Verification, number of

Annunciator modules, etc.).

2=FSYS

3=PPRG

4=FPRG

5=REMV

6=PSWD

7=MSG

FULL SYSTEM PROGRAMMING - Complete programming of system-wide

functions (number of LIBs, ISIB, Alarm Verification, number of Annunciator

modules, etc.).

PARTIAL POINT PROGRAMMING - Selectively altering the operating

parameters of Loop devices, software-defined zones and Annunciator

points.

FULL POINT PROGRAMMING - Complete programming of Addressable

Loop devices, software-defined zones, Annunciator points and their

operating parameters.

REMOVE POINT - Permits the selective removal (from control panel

memory) of any of the system's Addressable Loop devices, softwaredefined zones or Annunciator points.

PASSWORD - Allows the programmer to assign a custom five-digit

password.

MESSAGE - Allows the programmer to define the custom 40-Character User

Label displayed on the Monitor and the panel's Liquid Crystal Display (LCD).

8=HIS

HISTORY – Allows the programmer to Stop or Start storage of events and

the clearing of stored events.

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 36

PAGE 36 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

PARTIAL SYSTEM PROGRAMMING

Option 1 from the Main Programming menu allows the programmer to change the programming of

system-wide functions such as Alarm Verification of detectors, enabling Rapid Polling, and enabling

supervision of peripheral equipment in the system, Additional system parameters, such as the

number of Loops, Annunciators and ISIB in the system. Loops can also be changed in Partial

System Programming.

After selecting option 1 from the Main Programming menu, the display will show the Partial System

Programming submenu:

PRESS.1=INST, 2=STY, 3=TDLY, 4=AVPS, 5=ZBND, 6=EXTEQ, 7=LOCP, 8=ISIB, 9=PARM...

The Partial System Programming submenu has nine options, where:

Option Description

1=INST Installation – Installation or removal of the Loop Interface Boards from memory.

2=STY Style - Changing (in memory) loops wiring style 6 or 4.

3=TDLY Time Delays - Setting the time delays for Alarm Verification, Bell cutout etc.

4=AVPS Not Used in Australia.

5=ZBND Zone Boundary - Setting the zone boundary for the software memory map.

6=EXTEQ External Equipment - Changing the external equipment options, such as electrical

supervision of the Graphics Monitor.

7=LOCP Local Parameters - Setting local parameters, of Loop devices, and Loop local

mode.

8=ISIB Intelligent Serial Interface Board - Installation or removal of the Intelligent Serial

Interface Board (SIB-2048A or SIB-NET) or Annunciator modules, Also used for

setting ACS port for Upload/Download with Verifire.

9=PARM Additional System Parameters – Selection of additional system parameters such

as the detector day/night sensitivity settings, rapid polling, etc.

0=CONT Continued …….

Subsequent option is 1=IDO, “International Display Option”

Notes

When removing loop interface boards, all installed points on the affected LIBs are automatically

removed upon cycling power to the system. Programming information for installed points can be

stored in a Verifire™ database prior to removal of the LIB. Use of the Verifire™ application for the

reprogramming of previously removed points is highly recommended.

When removing Annunciator modules, all installed points on the affected Annunciators must be

removed first for proper system operation.

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 37

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 37

LIB INSTALLATION (1=INST)

Option 1 from the Partial System Programming submenu allows the installation or removal of LIB

boards from memory. The LIB boards must still be physically installed or removed from the system

to prevent a system fault condition.

The 2020 is capable of a maximum of ten LIBs (1,980 devices total in the system)

The 1010 is capable of a maximum of four LIBs (792 devices total in the system)

A LIB200A(1 Loop) or a LIB400 (2 Loop) Card can be used. The following procedure is setting the

loops up in memory and has no concern for the hardware used other than ensuring it is correctly

installed in the correct location. Please refer to page 7 for LIB board locations/configurations.

The following programming example illustrates the installation of LIB number 3.

From the Partial System programming menu, select 1=INST:

ENTER THE LIB BOARD NUMBER TO CHANGE (1 - 10) 3

IS LIB BOARD 03 TO BE INSTALLED IN SYSTEM? (Y=YES, N=NO). Y

ENTER THE STYLE OF SLC LOOP 03 (6 OR 4) 6

DO YOU WANT TO CHANGE ANOTHER LIB BOARD? (Y=YES,N=NO) N

PROGRAMMING COMPLETE POWER DOWN TO MAKE APPROPRIATE CHANGES

LIB LOOP STYLE 4 OR STYLE 6 (2=STY)

Option 2 allows the programmer to change in 1010/2020 memory, the style 6 or 4 for the Loop

connected to each LIB. The Loop must be field wired in accordance with the style set in memory.

The following programming example illustrates setting Loop number 5 as a Style 6 circuit. The

screen prompts are displayed as follows:

From the Partial System programming menu, select 2=STY:

ENTER THE SLC LOOP NUMBER TO CHANGE (1 - 10) 5

ENTER THE STYLE OF SLC LOOP 05 (6 OR 4) 6

DO YOU WANT TO CHANGE ANOTHER SLC LOOP? (Y=YES, N=N0) N

Note: When shipped from the factory, each loop will be setup as Style 6.

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 38

PAGE 38 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

TIME DELAYS (3=TDLY)

Option 3 allows the programmer to activate or de-activate Alarm Verification of Analog Addressable

detectors, as well as setting the appropriate time delays for this function.

Note: MMX-2 modules AVF is hard coded at 20 seconds.

The following programming example illustrates enabling the AVF function:

From the Partial System programming menu, select 3=TDLY:

DO YOU WANT TO CHANGE THE DETECTOR VERIFICATION TIME?.

Y

DO YOU WANT THE DETECTOR VERIFICATION TIME ACTIVATED? Y

ENTER THE DETECTOR VERIFICATION TIME. 20

This sets the global parameters for the System, eg; 20 second time on AVF. When installing each

detector you are required to select if you want AVF or not.

DO YOU WANT TO SET THE BELL-ISOLATE INHIBIT TIME?.

N

SELECT TIME

DO YOU WANT TO SET THE BELL CUTOFF TIME?.

Y

SELECT TIME 600

Bell Isolate Inhibit time is the period of time after the first alarm that the Bell Isolate key is disabled.

We recommend this function not be used, unless there are special circumstances.

Answer NO to disable function. Range = 0-240 seconds.

Bell Cut-Off time is for the automatic isolation of bells X seconds after an alarm.

We recommend this function not be used, unless there are special circumstances.

Answer NO to disable function. Range = 0-2040 seconds.

Please note that if bell cut-off is set, the EXT BELL ISOL state will remain latched on until a system

reset is performed, normal toggle on/off will then resume.

Please note, both Bell Cut-Off & Inhibit functions are global and will apply to all devices marked with

the “bell-isolate” flag.

Please refer to BCA and Standard requirements for your application.

AUDIO VISUAL POWER SUPPLIES (4=AVPS)

4=AVPS -Not Used in Australia.

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 39

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 39

ZONE BOUNDARY (5=ZBND)

The 1010/2020 can make use of up to 240 software-defined “zones.” These zones can be either

forward–activated (FZON) or reverse–activated (RZON), depending upon the particular installation

requirements. These forward and reverse zones are grouped separately, with the forward group

always preceding the reverse group. The highest forward-activated zone in the system is the Zone

Boundary, which can be in the range of Z001 - Z239. (For an explanation of software zones, refer to

What is a Software Zone on page 54).

Unless the use of complex Control-By-Event or Cooperative Control-By-Event Equations is required

in the system, set the Zone Boundary to Z99.

The following programming example illustrates setting the Zone Boundary for zone 99.

PRESS.1=INST, 2=STY, 3=TDLY, 4=AVPS, 5=ZBND, 6=EXTEQ, 7=LOCP, 8=ISIB, 9=PARM 5

ENTER.ZXXX.OF.HIGHEST.FORWARD.ACTIVATED.ZONE.IN.SYSTEM Z99

EXTERNAL EQUIPMENT (6=EXTEQ

Option 6 allows the changing of any optional features, such as the following:

Terminal Supervision Monitors the RS 485 port on the DIA

Terminal Status Line (Not Used)

Auxiliary Printer

Monitoring

The 1010/2020 will monitor the auxiliary printer's Ready/Busy line

for error conditions. Note: This option should not be de-activated

for external 80-column printers.

Control Module Reporting Control module state changes will be logged in History and sent

immediately across the network.

NONA/NOA Module

Reporting

Module state changes for modules with the software type ID

NONA will be logged in history and sent immediately across the

network. (NOA Not Used)

Devices Purchased after

11/91

For Retro fit applications, into older systems. All Devices to

Australia were after this Date. Always answer YES.

LED LATCH De-activates or activates 99-device LED latching. Always answer

Yes for Australian Standards and answer Yes to more LED’s

when asked.*

Printer Error Continue

Data will be transmitted to the printer under Printer Error

conditions (Paper Out or Printer Off Line generates an error

condition under which data may be lost).

Bidirectional Copy

(Not Used)

Printer Fault Inhibit The 1010/2020 monitors the primary printer's Rx line for error

conditions. This option inhibits the generation of a fault message

for Paper Out or Printer Off Line.

Printer Reports

(Not Used)

Redirected to

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 40

PAGE 40 1010/2020 INSTALLATION AND PROGRAMMING MANUAL

* Default Latching (Not recommended)

• Maximum of six devices can be latched at once (five modules maximum).

• Detectors have priority over modules. After six devices have been latched, detectors that

come into alarm will assume LED-latch priority over previously latched module LEDs.

• Under secondary (DC) power, only intelligent detectors (including DHX-501 Duct

Detectors) will be latched.

• Software Type I.D SCON will never latch under Default Latching.

* Optional Latching for More Devices (recommended)

• The control panel will latch up to 99 devices, subject to the limitations outlined below.

• Under primary (AC) power, 99 devices can be latched.

• Detectors have priority over modules. After 99 devices have been latched, detectors that

come into alarm will assume LED-latch priority over previously latched module LEDs.

• Under secondary (DC) power, only intelligent detectors (including DHX-501 Duct

Detectors) will be latched.

LOCAL PARAMETERS (7=LOCP)

Option 7 allows the changing of optional features, as Follows:

Piezo for Programming Allows you to isolate the piezo whilst programming.

LIB local mode parameters Allows the Loop to maintain operational status if CPU fails.

Modify NFPA Listing This Option not used in Australia.

Battery Programming Change the type of battery used (Lead Acid or Nicad).

Battery Capacity When Increasing or decreasing the battery capacity.

Battery Standby Time Change the Duration of Standby time.

24 hr High rate charge Activate or de-activate charge rate.

Event Reminder If activated the piezo will sound every 12-14 seconds when an

acknowledged fault is present on the display.

Device Blink If activated, the detectors will blink when polled.

Pre-alarm Function If active, the detectors will activate a pre-alarm status when the

obscuration level exceeds 80% of alarm level.

Note: With pre-alarm activated, the 80% condition must be present for at least a 60 second period

and will indicate a "PRE-ALARM ALERT" message on the Panel after that period. With prealarm de-activated the 80% condition must be present for at least a 26-hour period and will

indicate a "MAINTENANCE REQ" message on the FACP after that period.

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Page 41

1010/2020 INSTALLATION AND PROGRAMMING MANUAL PAGE 41

ISIB (8=ISIB)

Option 8 allows the changing of any of the following:

Intelligent SIB Allows you to add or delete the ISIB and set the network address.

ANN Add or Delete Annunciators Boards.

XINT When activated allows Upload/Download through Verifire. This will

disconnect the Annunciators RS485 stream to be dedicated to

UP/DL. Repeat to return too normal once UP/DL complete.

UDACT Not Used in Australia.

ADDITIONAL SYSTEM PARAMETERS (9=PARM)

This option allows the programmer to de-activate/activate the following:

High Day/Night Zone Allows you to set detector sensitivity for High see Note below *.

Low Day/night Zone Allows you to set detector sensitivity for Low see Note below *.

Detector Verification

Counter

This option resets the counter that records the number times a

detector went into AVF without alarming.

SACM/SAQM Reporting Not Used In Australia.

Drift Compensation When selected the Panel automatically adjusts the detectors to

the environmental condition of the surroundings, within certain

parameters, see Note below **.

Pager Programming Activate if Pager Interface installed.

Modem Programming Activate if Modem installed.