Page 1

1451

2-Wire and 4-Wire

Ionization Smoke Detector

General

The System Sensor 400 Series plug-in ionization smoke

detectors respond quickly to both fast flaming and slow smoldering fires as required by UL 268. Unipolar dual chamber

sensor has the sensitivity needed to quickly detect smoke, and

the stability needed to avoid false alarms.

Features

• Unique dual unipolar sensor:

– Provides exceptional stability.

– Factory preset at 1.9% nominal sensitivity.

– Stable operation up to 1,200 feet per minute (6 meters per

second) air velocities.

• Removable cover for field cleaning.

• Two visible LEDs “blink” in standby.

• Sealed against dirt, insects, and back pressure.

• Three-year limited warranty.

• Field metering of detector sensitivity.

• Built-in test switch.

• Low standby current.

• Built-in tamper-resistant feature.

• Designed for direct surface or electrical box mounting.

• 360° field viewing angle of the visual alarm LEDs.

• Insect-resistant screening (0.020"/0.508 mm openings).

• Easy plug-in of the head to base.

• SEMS screws for easy wiring.

• Optional recess mounting.

• Field-adjustable sensitivity.

Applications

Use to contribute to life safety, fire protection, and property

conservation. Superior to photoelectric detectors in detecting

fast-flaming fires. Superior to bipolar detectors in avoiding

false alarms.

Construction & Operation

All 400 Series plug-in ionization smoke detectors contain a

unique dual-source, dual unipolar chamber detection design

which will sense the presence of smoke particles produced by

fast combustion as well as slow smoldering fires. Additional

key features include a blinking LED standby status indicator,

an easily visible alarm indication, and provision for convenient

field test and metering.

The back of the detector is sealed to block back-pressure air

flow. The chamber is protected by a fine mesh (0.020"/0.508

mm) screen to minimize problems with dust, dirt, and insects.

If cleaning is required, it is easy to remove the cover (with a

special tool) and obtain access to the screen and chamber to

perform a thorough cleaning.

Installation

Model 1451 detectors are intended for use with Notifier ULlisted control panels. Maximum number of detectors per zone

is listed in the installation manual for each control panel. Easy

DN-1154:A • I-110

Conventional Initiating Devices

1154pho.jpg

1451

Ionization Detector shown with B401B Base

to install and maintain, this detector is designed for direct surface mounting (using one of the B400 Series bases listed

below). Easy-to-wire screw terminals allow fast and simple

field wiring of IN, OUT, and remote annunciator connections.

Consult Notifier control panel specifications for the maximum

allowable loop resistance for the particular control panel to be

used.

To prevent wiring mistakes, observe polarities and make certain that each conductor is identifiable. A copy of Installation

and Maintenance Instructions is packaged with each detector. For further information, refer to NFPA 72 “Standard on

Automatic Fire Detectors.”

A Mounting Base Selection Guide is included on page 2 of

this document.

Junction Box Selection Guide: Box depth is contingent on

base and wire size. Refer to National Electrical Code or local

applicable codes for appropriate recommendations. Bases

B401 and B401B can utilize a single-gang, 3-1/2" (88.9 mm)

octagonal, 4" (101.6 mm) octagonal, or 4" square junction box.

Bases B402B and B406B can utilize a single-gang, 3-1/2"

octagonal, 4" octagonal, 4" square, 50 mm, 60 mm, or 75 mm

junction box. Base B404B can utilize a 4" octagonal or 4"

square junction box.

General Specifications

Operating voltage: mounting base dependent (see chart

below).

Standby current: 120 micro amps.

Sensitivity: 1.9% nominal.

Weight: 0.6 pounds (272 grams).

Size: 3.2" (81.28 mm) high; 4.0" (101.6 mm) diameter with

unflanged bases, or 6.2" (157.48 mm) diameter with flanged

bases.

Construction: Flame-retardant white Noryl® plastic.

Temperature: 32°F to 120°F (0°C to 49°C).

DN-1154:A • 6/4/08 — Page 1 of 4

Page 2

Humidity range: 10 to 93% R.H. (non-condensing).

Maximum air velocity: 1,200 feet per minute (6 meters per

second).

Agency Listings and Approvals

These listings and approvals apply to the modules specified in

this document. In some cases, certain modules or applications

may not be listed by certain approval agencies, or listing may

be in process. Consult factory for latest listing status.

• UL Listed: S911

• ULC Listed: S911 (1451A)

• MEA Listed: 427-91-E Vol. III

• FM Approved

• CSFM: 7271-1653:108

• BSA: 1202-88-SA

• Maryland State Fire Marshal Certificate: #2185

Product Line Information

1451: Ionization Detector. Must be mounted to one of the

B400 Series Bases listed below.

RA400Z: Remote Annunciator for 2- or 4-wire applications.

Use with any System Sensor 400 Series plug-in detector. Fits

standard U.S. single-gang electrical box.

MOD400R: Field Test module for all of the System Sensor

400 Series Smoke Detectors.

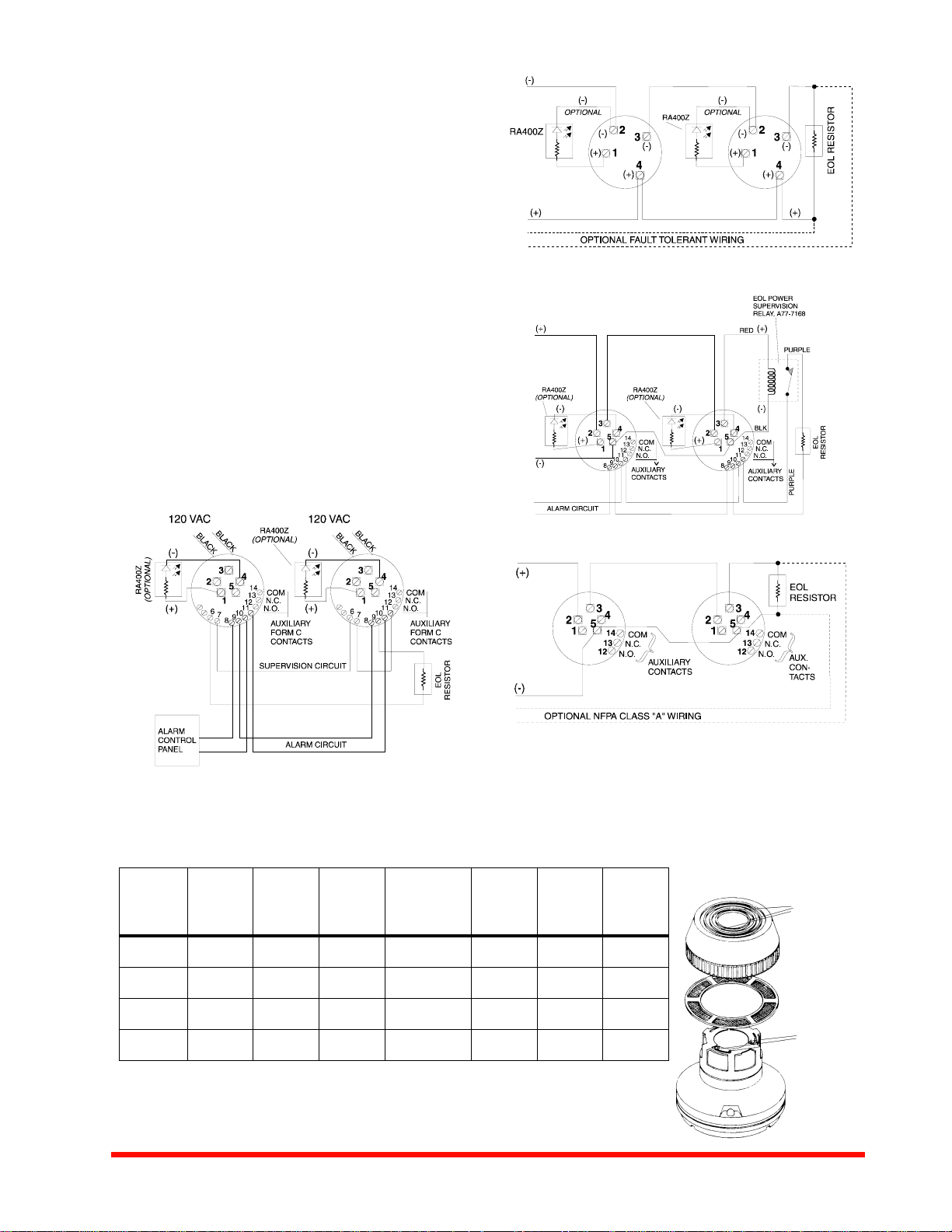

B401(B) Wiring Diagram

B402B Wiring Diagram

5578d1.wmf

5578d4.wmf

5578d3.wmf

B406B Wiring Diagram

B404B Wiring Diagram

Mounting Base Selection Guide

Base

Model

Number

Version

Loop

Type

(A)

B401 &

B401B (A)

B402B (A) UL & ULC 4-wire Yes Form-A & -C 24 VDC

B404B (A) UL & ULC 4-wire Yes

B406B (A)

* Functionality contingent on panel compatibility.

** Must be limited by control panel.

Relay Contact Ratings: Resistive or Inductive (60% power factor load). Form-a: 2.0A at 30VAC/DC.

Form-C: 0.6A at 110VDC, 2.0A at 30VDC, 1.0A at 125 VAC.

(A) = ULC model designation.

UL/ULC/

EN-54

UL/ULC/

EN-54

2-wire* No - 12/24 VDC

2-wire* No Form-C 24 VDC

Current

Limit

Resistor

Alarm

Contact

Type

Form-A & -C/A

Supervisory

Nominal

Voltage

120 VAC 120 VAC

Standby

Voltage

8.5 to 35

VDC

17 to 32

VDC

15 to 32

VDC

Current

Draw on

Alarm

10 to 100

mA**

14 to 39

mA

75 mA AC

maximum

12 to 100

mA**

5578d2.wmf

Location of

holes to

access and

release

locking

prongs.

Cover and

screen are

removable

for cleaning.

Locking

prongs.

1154d1.tif

Page 2 of 4 — DN-1154:A • 6/4/08

Page 3

Notes

DN-1154:A • 6/4/08 — Page 3 of 4

Page 4

Page 4 of 4 — DN-1154:A • 6/4/08

NOTIFIER® is a registered trademark of Honeywell International Inc. Noryl®

is a registered trademark of GE Plastics, a subsidiary of General Electric

Company.

©2008 by Honeywell International Inc. All rights reserved. Unauthorized use

of this document is strictly prohibited.

This document is not intended to be used for installation purposes.

We try to keep our product information up-to-date and accurate.

We cannot cover all specific applications or anticipate all requirements.

All specifications are subject to change without notice.

For more information, contact Notifier. Phone: (203) 484-7161, FAX: (203) 484-7118.

www.notifier.com

Made in the U.S. A.

Loading...

Loading...