P

M

L

AHGI

N

K

O

A-Side D ring

B-Bridge adjustment strap

C-Bridge strap buckle

EB

D-Rope bridge

E-Bridge ring

F-Bridge anchor plate

G-Elastic waist strap

H-Waist belt strap

Q

J

K

I-Waist belt connect buckle

J-Leg strap with connect buckle

K-Leg pad keeper straps

L-Accessory loops (8)

M-Accessory rings (2)

N-Accessory pouch straps (not pictured)

O-Leg Pads

P-Suspender Loop

Q-Chainsaw Snap (not pictured)

D

F

C

B

J

Notch™ Sentinel Arborist Harness

FIELD OF APPLICATION:

This product can be part of personal protective equipment for

protection (PPE) for position at the work station, or to prevent

the operator from entering a zone where a fall is possible. The

product should be allocated to one individual.

Attention! Sit harnesses are not suitable for fall ar rest

purposes!

Personal protection equipment products may only be used to

belay persons. Do not use the personal protective equipment

for work load.

Work at height is inherently dangerous activity. Understand and

accept the risks involved before participating.

These instructions for use contain important notes, a control

card, and proof of inspection. Before using this product, all

documents must have been read and their content understood.

This document must be provided to the user by the retailer in

the respective country’s language and must be kept with the

equipment while it is in use.

WEARING INSTRUCTIONS:

Thoroughly inspect har ness and all components before each

use. Your safety is related to the integrity of your equipment.

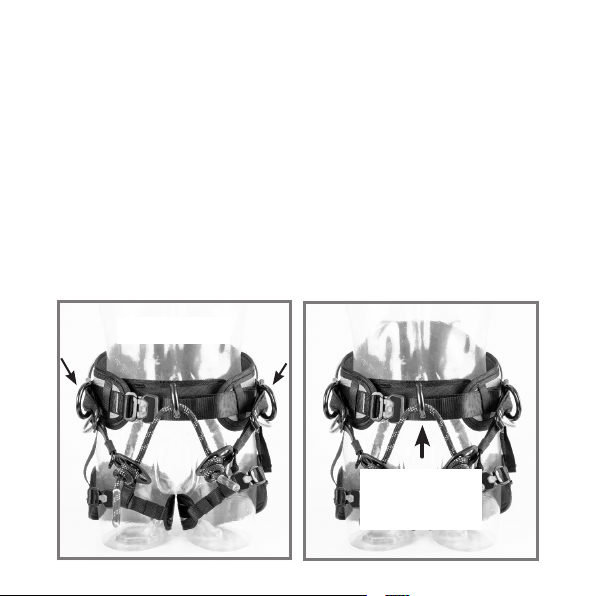

•Release and open the elastic waist strap

•Open the waist belt connect buckle

•Open the leg strap connect buckles (if necessary)

•Hold the harness facing forward and step into the harness

•Raise harness into position just above your hip bones

•Secure the elastic waist strap

Note: Elastic waist strap is for support and comfort only.

Caution, do not over tension.

• Ensure the work positioning side D rings are slightly forward

of the hip then close the waist belt connect buckle (using

thumb press in the center of buckle to open/close)

• Pull on the waist belt strap until strap feels snug (Fig 1), fold

excess strap into the waist strap keeper

• Wrap the leg straps around the leg so that the padded

portions of the leg straps are behind the leg and the buckles

are on the side of the leg

•Connect the leg strap buckles (if not connected)

• Adjust the leg strap as necessary so they are snug, but

comfortable

•Fold the excess strap into the elastic leg strap keeper E

Fig. 1

ADJUSTMENT INSTRUCTIONS:

Adjust the fit of your harness so that your body is supported

with weight evenly distributed between the belt and leg straps,

balanced to hang upright and relaxed, without uncomfortable

pinching or pressure. Fit the harness before your first climb

where you can hang.

Choose the correct size:

hipbelt min.

(elastic, not stretched)

72 cm 28,35 in 75 cm 29,53 in

1

92 cm 36,22 in 95 cm 37,40 in

2

hipbelt max. legloops min.

100 cm 39,37 in 50 cm 19,69 in

1

130 cm 51,18 in 65 cm 25,59 in

2

hipbelt min.

(webbing)

BRIDGE STRAP ADJUSTMENT:

• Locate the Bridge strap buckle positioned between the Bridge

anchor plate and the Side D ring

• Using thumb pull back on the tension buckle releasing the

webbing to extend distance (Fig 2), to shorten simply loosen

webbing and work it back through the tension buckle

• Fold the excess strap into the elastic leg strap keeper

Fig 2

• Tightening the adjustment straps will bring the bridge closer

to your body while loosening them will move the bridge away

from your body.

REPLACEMENT OF ROPE BRIDGE:

Replacement rope bridges are supplied separately and include

detailed replacement instructions to be used when replacing

worn bridge. Use only replacement Notch™ bridge

(manufactured from approved arborist climbing rope) supplied

by Notch Equipment. Replace suspension bridge if protective

cover of stitching (shrink tube) is damaged, missing or torn.

Ring

TYING THE ROPE BRIDGE STOPPER KNOT:

This stopper knot is recommended by the rope manufacturer

to secure the replacement Notch™ rope bridge. It stops the

rope from passing thought the hole in the bridge anchor plate.

The knots should be hand-tightened to prevent any possibility

of movement/slippage. Tie one at the end of the bridge leaving

at minimum 3 inches of tail. Pass the rope from the outside to

the inside of one anchor plate, using the center hole, pass it

though the ring, then through the center hole of the opposite

anchor plate, form inside to outside. Finish by tying another

knot on the outside with the desired length of the bridge

between the two plates after tightening. Only use double

fisherman’s knots on both sides. Construct the knot as shown

below:

Rigging

Plate

transparent Shrinking

Tube

Stopp Bartack

Double Fishermen‘s

knot

black Shrinked Label

Label

80 mm ≈ 3 in

TRIPLE-LOCK BUCKLE OPERATION:

The Triple-Lock Buckles offer a very high safety standard by providing a three-way closure. To open the buckle, press the top

button releasing the frame and pull back as shown below.

To close the buckle, push frame into the main buckle body and pull back, audible click will be heard confirming secure closure.

Strap length can be adjusting by pulling on the tail end of the webbing. Strap end can be retrieved by pulling up on the end as

shown below.

LEG PAD BUCKLE ADJUSTMENT:

• Open the Leg strap connect buckle by pressing in the center

of the buckle and release the single slot frame from main

buckle

• Adjust the length of the webbing by pulling on webbing in

either direction to move the main buckle frame

• Close buckle and test fit, continue adjustment until leg pads

are snug

•Repeat for opposite side of leg strap

•Fold the excess strap into the elastic leg strap loop keeper

• Proper adjustment of the leg pad straps will ensure the leg

pads will be in the most comfortable position on your legs

REAR LEG STRAP ADJUSTMENT:

• Adjust the length of the elastic webbing by pulling in either

direction through the plastic friction buckle, retain excess

webbing in the strap loop keeper

• Proper adjustment of the rear leg strap will ensure the pads

are in the correct distance below the waist

USING BRIDGE ANCHOR PLATES:

Bridge anchor plates are designed for maximum strength along

their major axis. Anchor plates should be loaded ONLY between

the single slot shaped connector holes and any combination of

the other three round holes. Only use the bridge anchor plates

for tie-in the rope bridge and only use both plates together.

Inspection:

Prior to each use, carefully inspect this equipment for

indications of wear or deterioration. The inspection should

include but not be limited to inspection for:

•tearing, cuts, severe abrasion of the webbing or rope

•burnt, singed, or melted webbing or rope

• faded, discolored from exposure to ultraviolet light, chemical

exposure of webbing or rope

•torn or pulled threads (broken fibers)

• nicks, cracks, distortion or corrosion of hardware (buckle,

rigging plate, D-ring, etc.)

•nonfunctional buckles

•evidence of involvement in dynamic fall

•readability of the marking

•if there are any indications for impact loading

Note: All load bearing bartacks are constructed of contrast

color stitching for easy identification. Replace suspension

bridge if protective cover of stitching (shrink tube) is damaged,

missing or torn.

If any evidence of wear or deterioration as outlined is observed,

immediately cease use, destroy the product and replace with

new equipment. Should any unusual condition conditions not

outlined above be observed, or you have reasonable doubt

about a particular condition, remove the equipment from

service. Failure to carefully and completely inspect your

equipment could result in serious injur y or death. Notch

Equipment recommends a detailed inspection by competent

person at least once every 12 months (depending on current

regulations in your country, and your conditions of use). Record

the results on your PPE inspection form: type, model,

manufacturer contact info, serial number or individual number,

dates: manufacture, purchase, first use, next periodic

inspection, problems, comments, Inspector’s name and

signature.

WORK POSITIONING HARNESS EN 358:1999

These attachment points are designed to either hold the user

in position at the work station, or to prevent the operator from

entering a zone where a fall is possible.

Attachment points according EN 358 must only be used to

attach a restraint or work positioning system, maximum fall

height 0.5 m. The connection device for work positioning

harnesses must be kept tight, the tie-in point must

be above or at hip height.

These attachment points are not designed for fall arrest usage.

It may be necessary to supplement work positioning or travel

restraint system with collective or personal fall arrest systems.

A – Side D rings

The two side D rings must always be used together.

EN 358: 1999

SEAT HARNESS EN 813:2008

Nominal maximum load = 140 kg (308 lbs). Designed for progression on rope and work positioning. Use the attachment

bridge to attach a descender, positioning lanyards, or progression lanyards.This attachment point is not suitable for fall

arrest.

EN 813: 2008

and

EN 358:1999

LIFESPAN AND REPLACEMENT:

The lifespan of the product will depend on frequency of use and

external conditions. This product is made from synthetic fibre

(polyamide, polyester, aluminium alloy, steel). Part of these

components degrade over time. Seven years is considered the

safe life of nylon climbing equipment when it is stored properly

and never used.

WHEN TO RETIRE THE EQUIPMENT:

A product must be retired when:

•It’s over 10 years old and made of plastic or textiles

•It has been subjected to a major fall (or load)

• It fails to pass inspection. You have any doubt as to its

reliability

•You do not know its full usage history

• When it becomes obsolete due to changes in legislation,

standards, technique, or incompatibility with other equipment

STORAGE:

Store in a clean, cool, dark, place free of acids, alkalis, exhaust

emissions, rust and strong chemicals. Store without

mechanical stress caused by jamming, pressure or tension.

TRANSPORT:

The product must be transported to avoid direct sunlight,

moisture, chemicals, dirt, extreme temperatures and

mechanical damage.

CLEANING:

Clean soiled products in luke warm water (if necessary, use pH

neutral soap). Rinse well. Hang dry at room temperature in well

ventilated area out of direct sunlight, never use a tumble dryer.

If required, halogen-free commercial disinfectants may be

used.

Metal hardware parts (anchor plates, buckles, etc.) should be

cleaned and dried. If necessary, minor sharp edges may be

polished using a fine abrasive cloth before cleaning.

Periodic lubrication of metal hardware using a lightweight

lubricant will maintain smooth operation, wipe off any excess

lubricant with a clean dry cloth.

WARNINGS FOR ROPE BRIDGE:

Rope bridge attached to this harness is designed to be replaced

by the user at regular intervals. Interval will be dictated by the

frequency of use and external working conditions rather than

set time.

Manufacturer does not place a time limit on the replacement

of the rope bridge. Due to the rigorous strain the rope bridge

endures, it should be replaced at the earliest signs of wear.

Bridge should be carefully inspected prior to each use. This

inspection should include but not be limited to: rope cuts, nicks,

tears, kinks, abrasions, burns, excessive swelling, excessive

jacket wear, discoloration, broken, fraying, or unraveling fibers,

loose stitching, chemical or physical exposure. Failure to

regularly inspect and replace the rope bridge could result in

injury or death.

WARNINGS:

• Manufacturer’s instructions shall be provided by the user of

this product. If additional copy is needed, contact Notch

Equipment.

• Completely read, understand, and follow all instructions,

warnings, and cautions pertaining to this particular harness

and all associated equipment before use. Failure to do so

could result in serious injury or death.

•Make sure the markings on the product are legible

• Service (repairs) may only be carried out by the manufacturer

or a center authorized by the manufacturer.

• Notch™ harnesses are manufactured in accordance with EN

358:1999, EN 813:2008, ASTM F887 and are intended for use

as personal protective equipment only comply with the

requirements of ANSI Z133-12.

• This product is designed to be used by a person with a

maximum weight of 308 lbs when fully equipped.

• This harness is not designed to be used with a retro fit Fall

Arrest Harness.

• Notch™ harness is to be used for work positioning and

suspension only, NOT FOR FALL ARREST.

• In any case of fall arrest use a fall arrest system according EN

363. If you use a fall arrest system, it must be ensured that

the necessary free space in the work area beneath the user

(clear height) of 7 m is guaranteed.

• Retire and destroy the harness and all other personal

protective equipment if involved in a fall.

• Retire harness if it’s been seven or more years past the

manufacturing date.

• Only trained and experienced people under guidance and

supervision are allowed to make use of it.

• Users must be aware that poor physical and/or mental health

can jeopardise safety under normal conditions and in

emergencies.

• Prior to first use, the user should carry out a suspension test

in a safe place that the equipment is of the correct size, has

sufficient adjustment and is of an acceptable comfort level

• Before using the equipment, the user must ensure that, in the

event of falling into the personal protection equipment

system, the person caught can be rescued immediately,

safely and effectively. A rescue plan for all work operations is

recommended.

• In case of an emergency, an accident or loss of consciousness

prevent the victim from suspension trauma. Suspension

trauma can cause serious harm to health and death.

• Keep equipment from contacting with sharp edges, abrasive

surfaces, extreme temperatures, excessive ultra violet rays,

chemical agents, moving machinery, and electrical hazards.

Exposure to these elements may compromise the integrity of

the equipment.

• Always visually check that all buckles are properly closed.

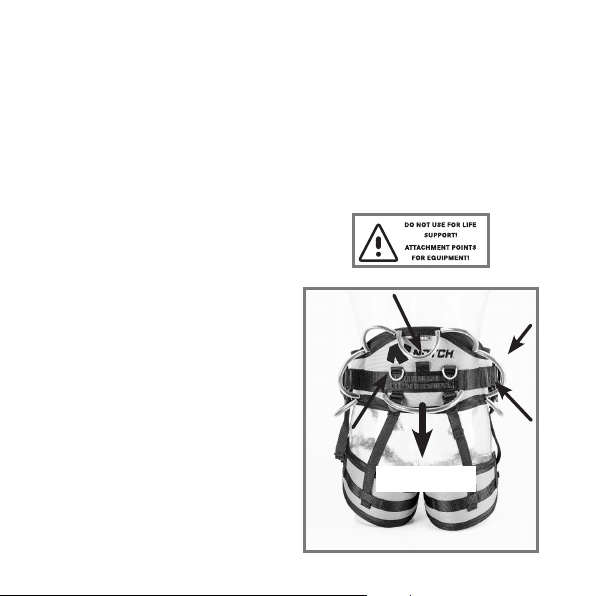

• The large loop centered at the rear of the back pad is intended

for connection of harness suspenders only (Fig 4). Harness

suspenders are not safety products. Suspenders are

designed to support only the weight of the saddle and the

equipment it contains, NOT the individual.

• Accessory loops (8), carabiner slots, accessory rings (2) are

attachment points (Fig 4) for equipment ONLY. Do not use for

any life safety attachment, gear loops are not suitable for

anchoring or belaying.

Fig 4

10 kg max

• During use all fastening and adjusting elements must be

regularly checked to ensure proper adjustment and closure.

• Attach only connecting devices meeting standard/

regulations for intended use for positioning and suspension

to belt D rings and bridge anchor plate.

• Only positioning equipment, such as lanyards, should be

attached to D rings, as D rings are not intended for fall arrest

• The equipment should not be modified in any way or altered

to allow attachment of additional parts without the

manufacturer’s written recommendation.

• Make sure the anchor point is correctly positioned in order to

limit the risk and the height of the fall.

• The anchor points for fall arrest forces must be rated for at

least 12 kN, see also EN 795.

• For Connecting to the anchor points only use ppe partial

systems (e. g. connecting elements (karabiners) to EN 362).

• When combining this product with other components, the

safety aspects of the products may interfere with each other.

• If this product is used in combination with other components

of a rescue/fall arrest system, users must acquaint

themselves with the enclosed recommendations, notes and

instructions for these components prior to use and comply

with them.

WARRANTY:

Every Notch™ harness carries a limited lifetime warranty

against defects in materials and workmanship. Notch

Equipment will replace the defective product at no charge and

return it back to the customer.

Coverage terminates if the product is sold or transferred.

RETURNS:

You may return your Notch™ product for any reason. Please call

Notch Equipment at 866-345-2468 to request a Return

Merchandise Authorization (RMA). Mark the package with the

RMA number and follow the instructions on the enclosed return

slip.

Returned products will be inspected within three working days

of receipt and you will be contacted with the results of the

inspection. Depending on our findings, Notch Equipment will

replace your product or refund your purchase price, at our sole

discretion.

No returns will be accepted on items returned after 30 days.

Only authorized replacement parts from Notch Equipment

should be used on this product. The use of unauthorized

replacement parts will void manufacturer’s warranty.

PRODUCT INFORMATION:

Manufacturer: EDELRID

Model: Name of the product

Size: 1 – small, 2 – large;

Product description: Work positioning harness according to

EN 358:1999, sit harness according to EN 813:2008.

Standards indicated in some cases with year of issue;

Users weight: max. 140 kg/ 308 lbs;

Lot number: GV XXX MM YYYY NNN

Nomenclature of the lot number:

XXX – Lot Number

MM – Month of Production

YYYY - Year of production

NNN – Serial Number

MM YYYY: Month and year of manufacturing

Identification: To be entered by the user if appropriate

i-Symbol: Warning notices and instructions must be read and

observed

CE 0123: the authority supervising production of PPE

(TÜV SÜD Product Service GmbH, 80339 Munich, Germany)

NOTCH EQUIPMENT Distribution Europe:

496 GALLIMORE DAIRY ROAD, SUITE D Notch by EDELRID

GREENSBORO, NC 27409 Achener Weg 66

1-800-525-8873 88316 Isny im Allgäu

info@notchequipment.com Germany

PSA-Richtlinie / PPE-Guideline / EPI-directive 89/686 / (EWG/EEC/CEE)

Certified by CE 0123: TÜV SÜD Product Service GmbH

01.17

80339 München, Ridlerstraße 65, Germany

Loading...

Loading...