NotaTech 9400 User Manual

Contac t:

®

Nov aTech Pro cess So luti ons, LLC

11500 C ronr idge Dr., Su ite 110

Owings Mills, MD 211 17

T: 410.753.8300

Toll Free: 800.25 3.38 42

ww w.novate chweb.c om

8000 Series I/O

®

Product Catalog

8000 Series I/O

1

®

Contac t:

Nov aTech Pro cess Solu tion s, LLC

11500 C ronr idge Dr., Suit e 110

Owings Mills, MD 21117

T: 410.753.8300

Toll Free: 800.25 3.38 42

ww w.novate chweb.c om

8000 Series I/O

®

Product Catalog

8000 Series I/O

This page intentionally left blank.

2

Contac t:

®

Nov aTech Pro cess So luti ons, LLC

11500 C ronr idge Dr., Su ite 110

Owings Mills, MD 211 17

T: 410.753.8300

Toll Free: 800.25 3.38 42

ww w.novate chweb.c om

8000 Series I/O

®

Product Catalog

Contents

Family Overview

Page

4

Module Data Sheets

Analog Input Modules

• NT-8101-HI-TX 8-channel AI, 4-20mA with HART for 2- or 4-wire

• NT-8103-AI-TX 8-channel AI, 4-20mA for 2- or 4-wire

• NT-8119-VI-05 8-channel Voltage Input, 1-5Vdc

• NT-8132-AI-UN 8-channel isolated AI, 4-20mA with HART, Thermocouple, RTD, Voltage

8000 Series I/O

• NT-8105-TI-TC 4-channel THC/mV input

• NT-8106-TI-RT 4-channel RTD input

Analog Output Modules

• NT-8102-HO-IP 8-channel AO, with HART for 4-20mA

• NT-8104-AO-IP 8-channel AO, 4-20mA

Digital Inputs

• NT-8109-DI-DC 8-Channel DI, 24VdC isolated, sinking

• NT-8110-DI-DC 8-channel DI, 24Vdc non-isolated, module powered

• NT-8121-DI-DC 16-channel DI, 24Vdc non-isolated, module powered

• NT-8122-DI-DC 16-channel DI, 24Vdc isolated, sinking

• NT-8111-DI-AC 8-channel DI, 115Vac isolated, sinking

• NT-8112-DI-AC 8-channel DI, 115Vac non-isolated, module powered

• NT-8113-DI-AC 8-channel DI, 230Vac isolated, sinking

• NT-8114-DI-AC 8-channel DI, 230Vac non-isolated, module powered

8

9

10

11

13

14

15

16

17

18

19

20

21

22

23

24

Digital Outputs

• NT-8115-DO-DC 8-channel DO, 2-60Vdc non-isolated, module powered

• NT-8117-DO-DC 8-channel DO, 2-60Vdc isolated, unpowered

• NT-8116-DO-AC 8-channel DO, 20-250Vac non-isolated, module powered

• NT-8118-DO-AC 8-channel DO, 20-250Vac isolated, unpowered

25

26

27

28

3

®

Contac t:

Nov aTech Pro cess Solu tion s, LLC

11500 C ronr idge Dr., Suit e 110

Owings Mills, MD 21117

T: 410.753.8300

Toll Free: 800.25 3.38 42

ww w.novate chweb.c om

8000 Series I/O

®

Product Catalog

Overview

The NovaTech 8000 Series I/O is the newest remote I/O

family native to the D/3® Process Automation System

(PAS). It is the preferred I/O for new installations and

it can replace the older NovaTech 16000 series I/O

in existing PCM cabinets, using existing field wiring

connected to new termination panels with existing

connectors.

With its -40 to +70° temperature range and G3 corrosive coating, the NovaTech 8000 Series I/O is an I/O

system designed for field mounting. It connects to

conven-tional and smart field devices through multichannel I/O modules. The modules communicate, via

a fast internal bus, with redundant Ethernet Bus Interface Modules (EBIMs) which provide dual-redundant

high speed Ethernet data connections to the D/3®.

Up to 64 I/O modules can be supported within a single

8000 Series node, and each module has between 4

and 16 channels. An EthernetMPC card can support

up to 50 nodes. With the availability of intrinsically

safe modules, 8000 Series I/O provides a solution for

both general purpose and hazardous area applications

- even within the same node.

Designed for use with PCM 4100 or PCM 4200 PCIbased PCMs, it requires an Ethernet Multi Protocol

Controller (EthernetMPC) card and D/3® version 12.2-2

or higher.

Key Features

• Wide range of input and output types, in any mix

• Up to 64 I/O modules per node

• Up to 50 nodes per EthernetMPC card

• Wide operating temperature range, -40 to +70°C

• General-purpose and intrinsically-safe I/O within a

single node

• Redundant Local Area Networks (LAN) and power

supplies supported

• High channel density

• Zone 2 and Division 2 hazardous area mounting as

standard

• I/O module hot-swapping even in Zone 2 and Division 2

• HART® pass-through supported

• Rugged construction, optimized for true field mounting

• Integrated (per-channel) fusing and loop-disconnect

facility

• Bussed field power on carriers eliminates daisy-chain

wiring at field terminals

• Sophisticated mechanical keying system eliminates

risk to plant and personnel

8000 Series connects to both conventional (such as

4-20mA) and smart field devices. It allows the cost

benefits of fieldbus to be enjoyed with existing field

instruments—ideal for plant upgrades and expansions. Pass-through of HART® information between

HART® instruments and the D/3® network is possible.

8000 Series nodes can be located within, and connected into, a hazardous area where there is a risk

of explosion from flammable gases. The standard,

general purpose system is approved for operation in a

Zone 2 or Class I, Division 2 hazardous area, with field

devices in a similarly classified area. I/O modules with

intrinsically safe field circuits can be connected to

certified devices in Zone 0 and Class I, II, III, Division 1

hazardous areas.

8000 Series I/O

4

Enclosures are also available for application where the

Series 8000 node must be located in a Zone 1 or Division 1 area—consult NovaTech for availability.

Contac t:

®

Nov aTech Pro cess So luti ons, LLC

11500 C ronr idge Dr., Su ite 110

Owings Mills, MD 211 17

T: 410.753.8300

Toll Free: 800.25 3.38 42

ww w.novate chweb.c om

8000 Series I/O

®

Product Catalog

8000 Series I/O

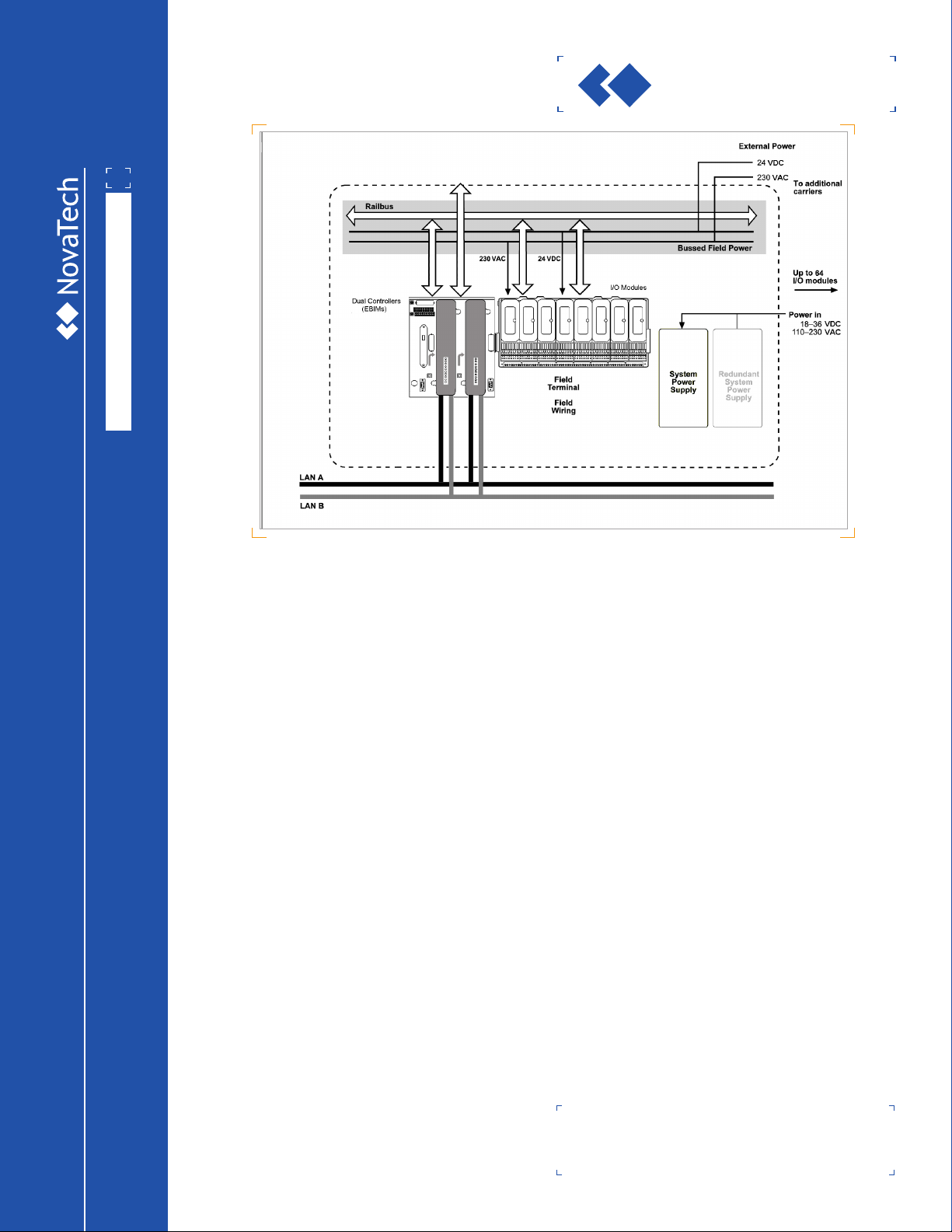

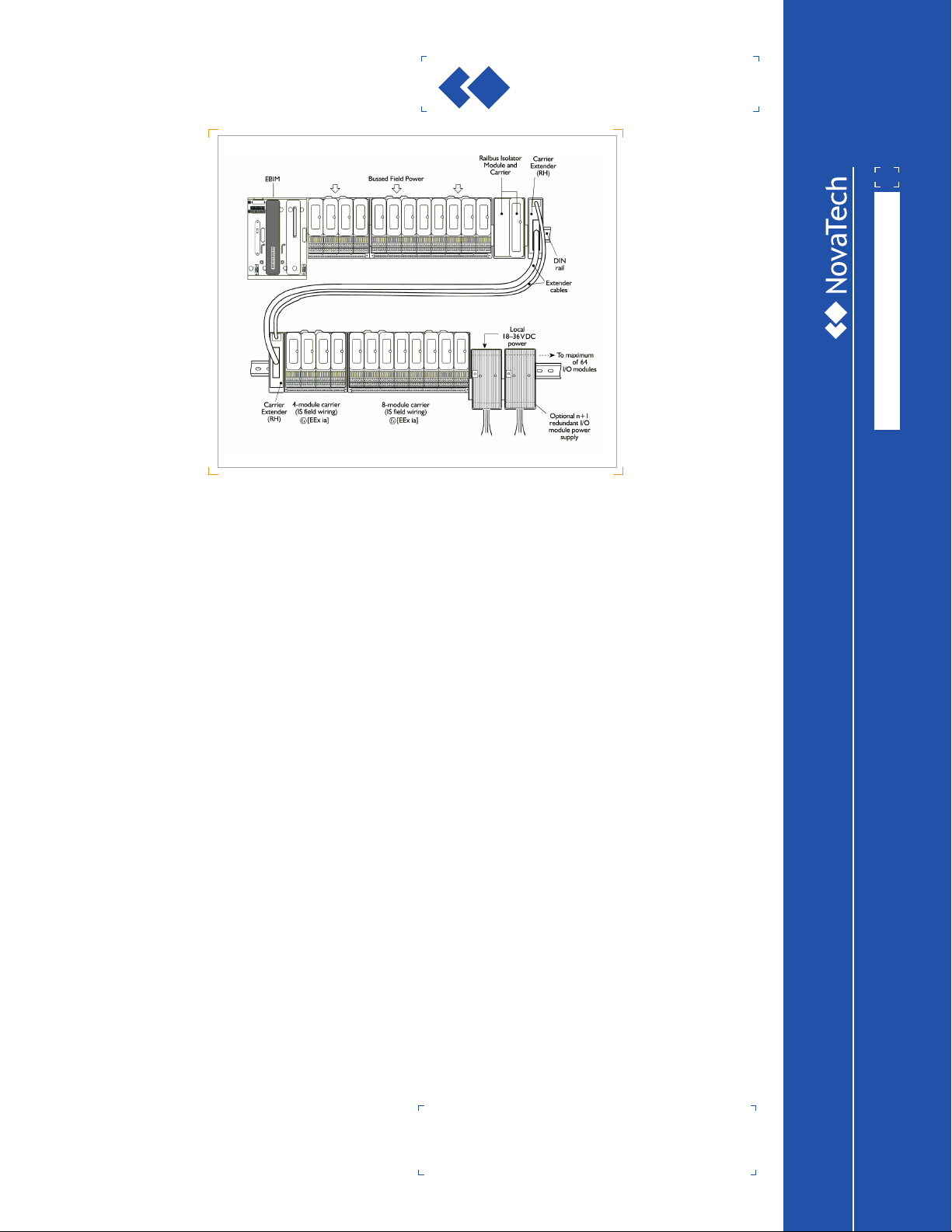

Node Architecture

An 8000 Series node comprises single or redundant

Ethernet Bus Inter-face Modules, up to 64 I/O modules,

field terminals, and associated power supplies.

A schematic node architecture is shown below. Information from the I/O modules is transferred to and

from the communication module (EBIM) via the Railbus. The Railbus is a fast, serial data bus with parallel

module addressing and extends over the full length of

the node. The parallel address architecture means that

each I/O module position has a unique address which

eliminates the need to ‘train’ modules during installation.

Power for the node is provided by integrated power

supply modules; these convert the locally available

power source into a regulated internal supply rail. This

rail energizes the EBIM and all Railbus communication

between the EBIM and I/O modules.

For some I/O module types—such as those with

low-power and intrinsically safe field circuits—it also

provides power for the field wiring. Where additional

power is required for field devices (such as high current AC circuits), power can be provided by means

of cabled connections from each module to external

relays. This Bussed Field Power facility reduces instal-

lation time by removing the need to make daisy chain

wiring connections at the field terminals of each I/O

module.

Node Operation

A typical request for data from the field might happen

as follows:

The D/3® PAS requires the temperature from a particular thermocouple input at a particular node and

transmits a signal on the I/O LAN. There are several

Series 8000 nodes on the I/O LAN, but the EBIM at the

chosen node recognizes its own node address, and

acknowledges the request.

At each node, the input modules constantly monitor,

linearize and digitize their respective field signals,

and make them available to scanning on the node’s

internal bus (Railbus).

The EBIM continually scans the I/O modules via the

Railbus, and builds up a map of the values of the input

variables, ready for the PCM to read. These are converted into the LAN protocol and placed on the LAN

by the EBIM, together with acknowledgement signals.

The D/3 then interprets the signal and reconstructs

the temperature reading.

5

®

Contac t:

Nov aTech Pro cess Solu tion s, LLC

11500 C ronr idge Dr., Suit e 110

Owings Mills, MD 21117

T: 410.753.8300

Toll Free: 800.25 3.38 42

ww w.novate chweb.c om

NovaTech 8000 Series I/O Components

®

8000 Series I/O

Product Catalog

8000 Series I/O

Modules

I/O modules transfer signals to and from field instruments. Input modules receive signals from transmitters and sensors and convert them into a digital form

for presentation to the EBIM. Output modules receive

commands from the EBIM and transfer them to actuators. A wide range of modules is available, including

types for low-level instrumentation, AC circuits, and

intrinsically safe signals. I/O modules typically have 4,

8, or 16 field channels.

Carriers

Carriers allow the 8000 Series I/O to mount onto a flat

panel or T- or G-section DIN rail. They support and interconnect the EBIM, power supplies, I/O modules and

field terminals, and carry the address, data and power

lines of the internal Railbus. They provide termination

points for the LAN and field wiring cable screens and

can also distribute bussed field power to the I/O modules. I/O module carriers support eight I/O modules.

Field Terminals

Field terminals provide the interface between the

I/O modules and the field wiring. They include fusing

and loop disconnect as options. A mechanical keying

system prevents an I/O module from being connected

to the wrong type of field terminal. Field terminals

mount onto the module carrier, one to each I/O

module. They are clamped firmly by the I/O module

to form an electrical and mechanical assembly of high

integrity. They may be replaced in service without

removing carriers or disturbing the operation of other

modules.

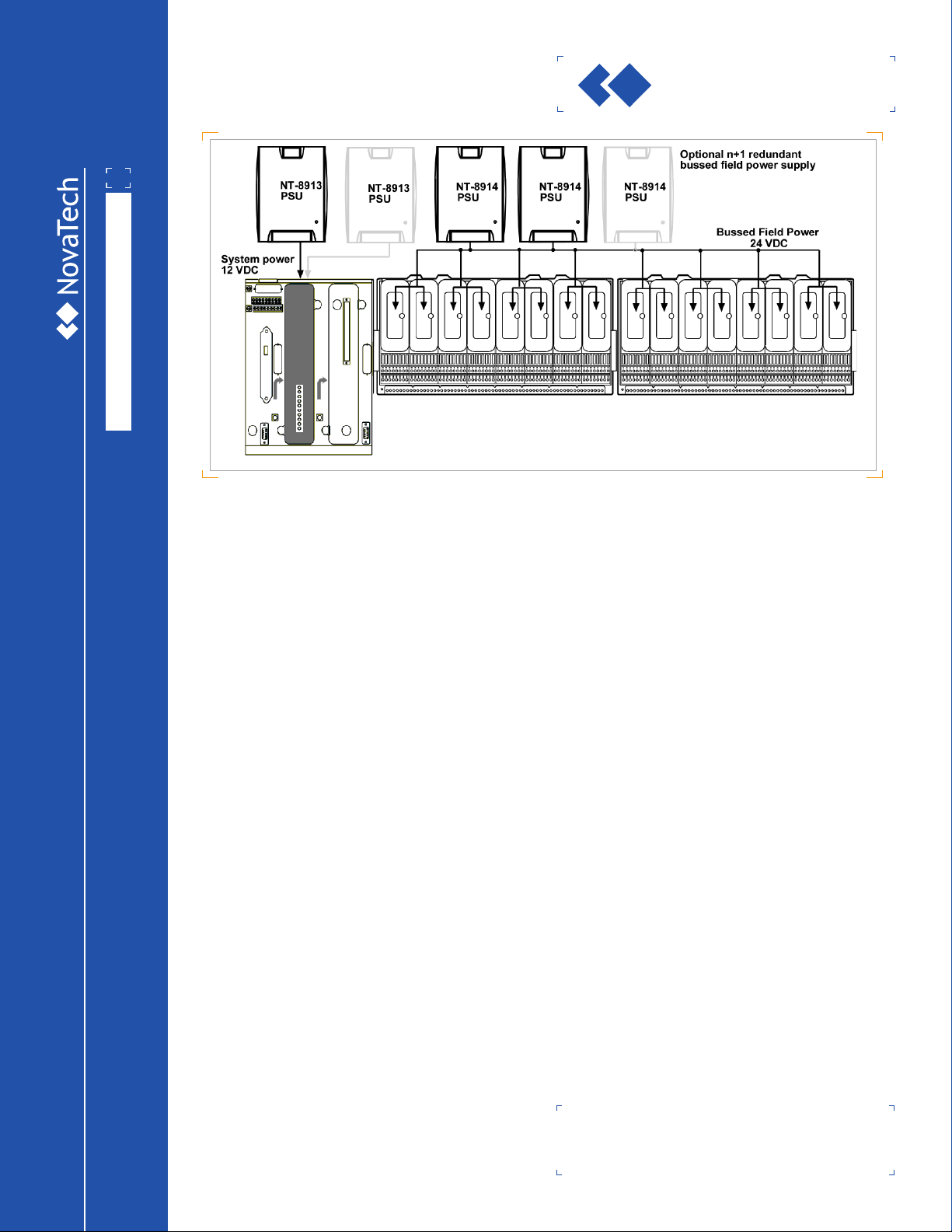

Power Supplies

8000 Series I/O power supplies accept locally available

unregulated power and provide a regulated supply

for the EBIM and I/O modules. Supply redundancy is

supported. The system power supply at an 8000 Series

node converts the local DC supply to power the node,

and can also provide field power for I/O modules with

low-level field circuits. Where heavy-current or AC

mains circuits are handled by the I/O modules, the

8000 Series method for distributing field power avoids

complex wiring at the field terminal and minimizes the

backplane/carrier wiring.

6

Contac t:

®

Nov aTech Pro cess So luti ons, LLC

11500 C ronr idge Dr., Su ite 110

Owings Mills, MD 211 17

T: 410.753.8300

Toll Free: 800.25 3.38 42

ww w.novate chweb.c om

8000 Series I/O

®

Product Catalog

8000 Series I/O

Ethernet Bus Interface Module (EBIM)

NovaTech 8000 Series I/O uses the Ethernet Bus Interface Module (EBIM) to provide a high speed Ethernet

data connection to the D/3®. The EBIMs communicate

using a propri-etary protocol over Ethernet at speeds

of 10/100MB to the D/3® PCMs.

NovaTech 8000 Series I/O Support

8000 Series I/O offers a variety of I/O boards and signal

conditioning termination panels suitable for virtually

every standard process sensor and actuator. Details

on signal conditioning termination panels, as well as

their associated I/O function boards, can be obtained

in individual specification sheets. The standard D/3®

configuration supports such I/O signals as:

• Analog Inputs: 4-20 mA, 10-50 mA, 0-10V (programmable ranges of 0-50mV, 0-100mV, 0-1V and 0-10V ),

100 ohm platinum RTDs, thermocouples

• Analog Outputs: 4-20 mA, 10-50 mA, 0-10V

• Digital and Pulse Inputs:

• Contact Closures +5, +12, +24 and +10 to +32 VDC

• Contact Closures 95 to 130 VAC

• Pulse Train Inputs up to 100 KHz @ +5, +12, +24 VDC

• Pulse Train Inputs up to 50 Hz @ +10 to +32 VDC and

95 to 130 VAC

• Digital and Pulse Outputs:

• DC Output +5, +12, +24, and +5 to +60 VDC

• AC Output 12 to 140 VAC

• Pulse Output 2 msec. to 3.3 sec. @ +5, +12, +24, and

+5 to +60 VDC

• Pulse Output 10 msec. to 11 min. @ +5, +12, +24,

and +5 to +60 VDC

• Pulse Output 2 msec. to 3.3 sec. @ 12 to 140 VAC

• Pulse Output 10 msec. to 11 min. @ 12 to 140 VAC

Cop yrig ht © 20 07 NovaTec h, LLC. Al l rights re serv ed. Al l trademarks

are pro pert ies of their re spec tive owners. NovaTech is a register ed

tra dema rk of NovaTech , LLC. The in formati on in this li terat ure is

subject to chan ge with out not ice and is not to be cons true d a s a

warra nty. DS_ 8KIO _0607

7

Contac t:

®

Nov aTech Pro cess So luti ons, LLC

11500 C ronr idge Dr., Su ite 110

Owings Mills, MD 211 17

T: 410.753.8300

Toll Free: 800.25 3.38 42

ww w.novate chweb.c om

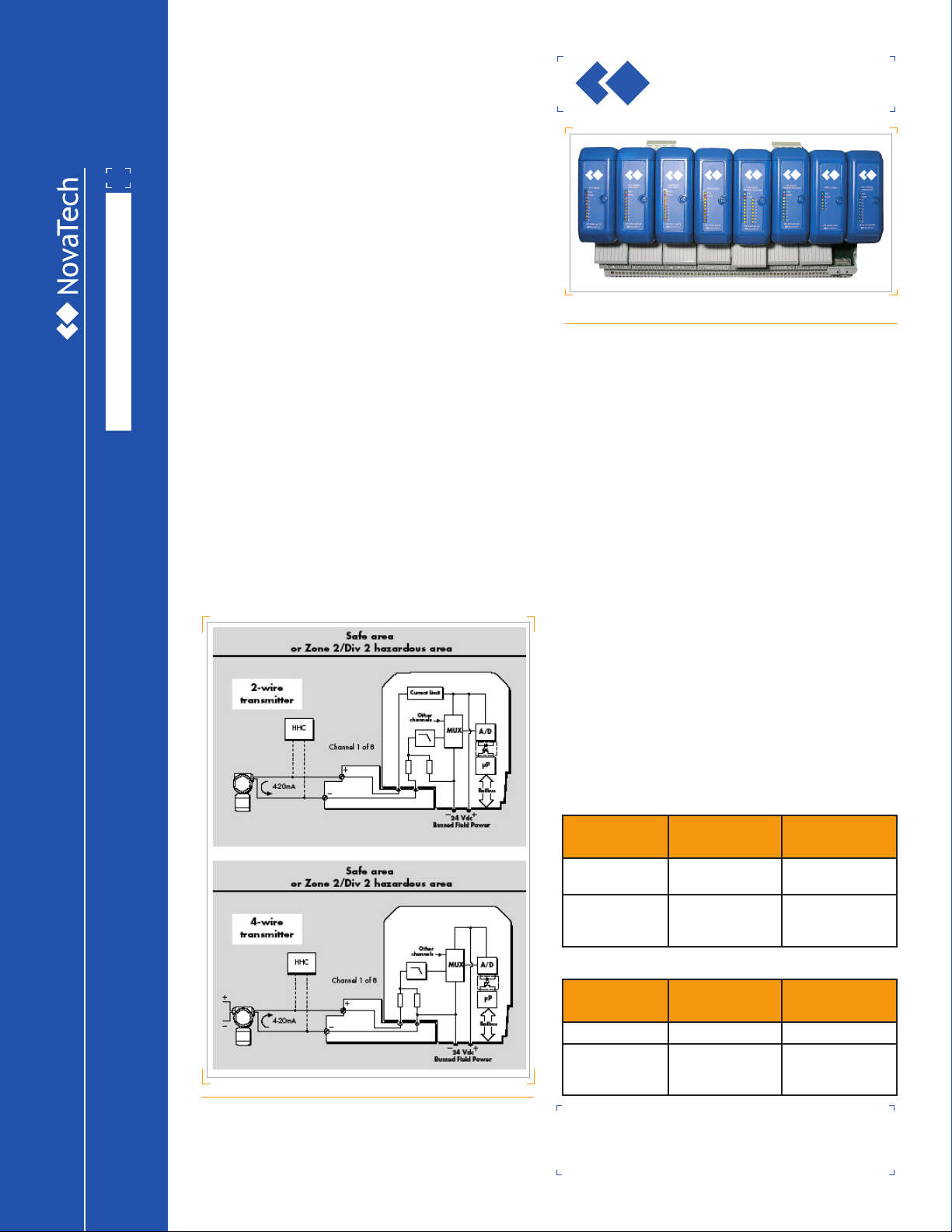

8 Channel Analog Input

4–20 mA with HART®

. 8 single -ended 4-20 mA input channels

. Non-incendive field circuits

. HART pass-through

. HART variable and status reporting

. 2- or 4-wire transmitters

. open and short circuit detection

. 24 V dc bussed field power required

Module Specications

NT-8101-HI-TX

Inputs

Number of channels ...............................................8, single- ended

Nominal signal range (span) ..........................................4 to 20 mA

Full signal range.................................................................1 to 23 mA

Line fault detection

Short circuit current .....................................................> 23.5 mA

Open circuit current ......................................................< 0.5 mA

Output voltage (@ 20mA).............................................13.5 V (min.)

Output current ..............................................................32 mA (max.)

Accuracy (over temp range) ...................................± 0.1% of span

Resolution ..................................................................................16 bits

Repeatability ................................................................0.05% of span

Isolation

(any channel to Railbus) .................................................100 V ac

(between channels)................................................................none

NovaTech 8000 Series I/O Family

Congurable Parameters

Input filter time constant .................................user defined value

Input dead zone .................................................user defined value

Drive on failsafe............................. disabled /upscale /downscale

Channel status.......................................................... active /inactive

Image Descripti on

HART variable and status repor ting ................... enable /disable

Response Time

Signal change to availability on R ailbus

4–20 mA mode .........................................................27 ms (max.)

HART mode......................................................0.75 s per channel

Safety

FM non-incendive field wiring parameters (each channel)

Voc = 28.7 V; Isc = 33 mA; Ca = 0.17 µF; La = 11.0 mH

Power Supplies

Railbus (12V) current .....................100 mA (typ.), 150 mA (max.)

Bussed Field Power 2-wire Tx...................................300 mA (max.)

(@ 24 V dc ±10%) 4-wire Tx.........................................60 mA (max.)

Mechanical

Module Key Code .............................................................................A1

Module width ............................................................................42 mm

Weight............................................................................................200 g

Cop yrig ht © 20 07 NovaTec h, LLC. Al l rights re serv ed. Al l trademarks

are pro pert ies of their re spec tive owners. NovaTech is a register ed

tra dema rk of NovaTech , LLC. The in formati on in this li terat ure is

subject to chan ge with out not ice and is not to be cons true d a s a

warra nty. DS_ 8101 _0607

Field Terminals (2-WIRE TX)

Field Wiring Recommended

Field Terminal

General Purpose NT-8602-FT-ST

Class 1, Div 2

or Zone 2 hazardous area

Field Terminals (4-WIRE TX)

Standard

NT-8601-FT-NI

Non-incendive

Field Wiring Recommended

Field Terminal

General Purpose NT-8615-FT-4W -

Class 1, Div 2

or Zone 2 hazardous area

NT-8615-FT-4W -

Compatible

Field Terminal

NT-8604-FT-FU

NT-8603-FT-FU

Non-incendive

Compatible

Field Terminal

Fused

8

Contac t:

®

Nov aTech Pro cess So luti ons, LLC

11500 C ronr idge Dr., Su ite 110

Owings Mills, MD 211 17

T: 410.753.8300

Toll Free: 800.25 3.38 42

ww w.novate chweb.c om

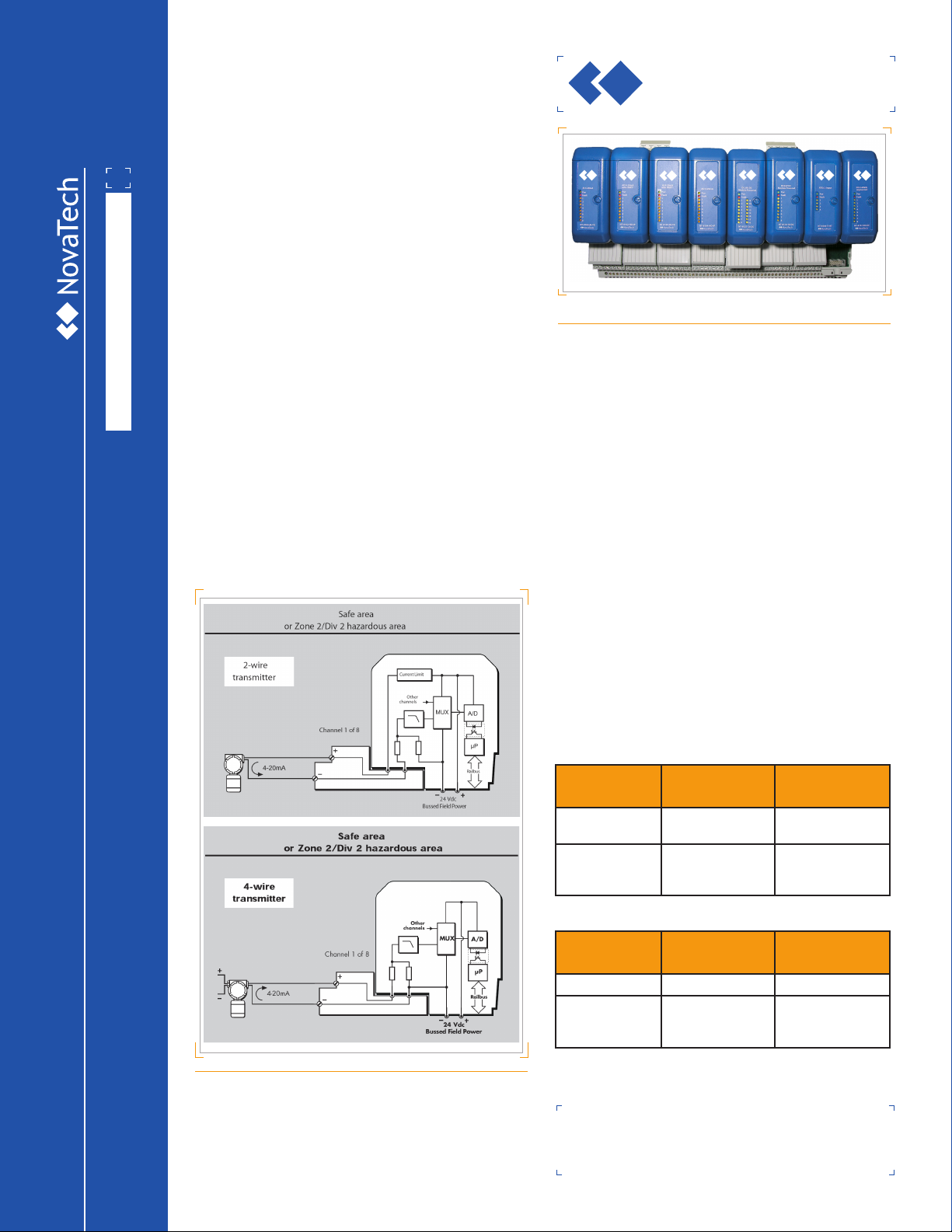

8-channel Analog Input

4–20 mA

. 8 single -ended 4-20mA input channels

. Non-incentive field circuits

. 4-20mA

NT-8103-AI-TX

. 2- or 4-wire transmitters

. Open and short circuit detection

. 24Vdc bussed field power required

Module Specications

Inputs

Number of channels ...............................................8, single- ended

Nominal signal range (span) ..........................................4 to 20 mA

Full signal range.................................................................1 to 23 mA

Out of range alarm

Lower threshold.............................................................> 23.5 mA

Upper threshold .............................................................< 0.5 mA

Output voltage (@ 20 mA)............................................13.5 V (min.)

Output current ..............................................................32 mA (max.)

Accuracy (over temp range) ...................................± 0.1% of span

Resolution ..................................................................................16 bits

Repeatability ................................................................0.05% of span

Isolation

(any channel to Railbus) .................................................100 V ac

(between channels)................................................................none

NovaTech 8000 Series I/O Family

Congurable Parameters

Input filter time constant .................................user defined value

Input dead zone .................................................user defined value

Drive on failsafe............................. disabled /upscale /downscale

Channel status.......................................................... active /inactive

Image Descripti on

Response Time

Signal change to availability on R ailbus .................27 ms (max.)

Safety

FM non-incendive field wiring parameters (each channel)

..................Voc = 28.7 V; Isc = 33 mA; Ca = 0.17 µF; La = 11.0 mH

Power Supplies

Railbus (12V) current .....................100 mA (typ.)/150 mA (max.)

Bussed Field Power ..................................2-wire Tx 300 mA (max.)

(@ 24 Vdc ± 10%) 4-wire Tx 60 mA (max.)

Mechanical

Module Key Code .............................................................................A1

Module width ............................................................................42 mm

Weight............................................................................................200 g

Field Terminals (2-wire TX)

Field Wiring Recommended

Field Terminal

General Purpose NT-8602-FT-ST

Class 1, Div 2

or Zone 2 hazardous area

Field Terminals (4-wire TX)

Standard

NT-8601-FT-NI

Non-incendive

Field Wiring Recommended

Field Terminal

General Purpose NT-8615-FT-4W -

Class 1, Div 2

or Zone 2 hazardous area

NT-8615-FT-4W -

Compatible

Field Terminal

NT-8604-FT-FU

Fused

NT-8603-FT-FU

Non-incendive

Fused

Compatible

Field Terminal

Cop yrig ht © 20 07 NovaTec h, LLC. Al l rights re serv ed. Al l trademarks

are pro pert ies of their re spec tive owners. NovaTech is a register ed

tra dema rk of NovaTech , LLC. The in formati on in this li terat ure is

subject to chan ge with out not ice and is not to be cons true d a s a

warra nty. DS_ 8103 _0607

9

Loading...

Loading...