Page 1

All products are trademarks of Nostalgia Products Group, LLC.

Worldwide design & utility patented or patents pending.

© 2012 Nostalgia Products Group, LLC.

www.nostalgiaelectrics.com

(rev. 10/04/12)

Page 2

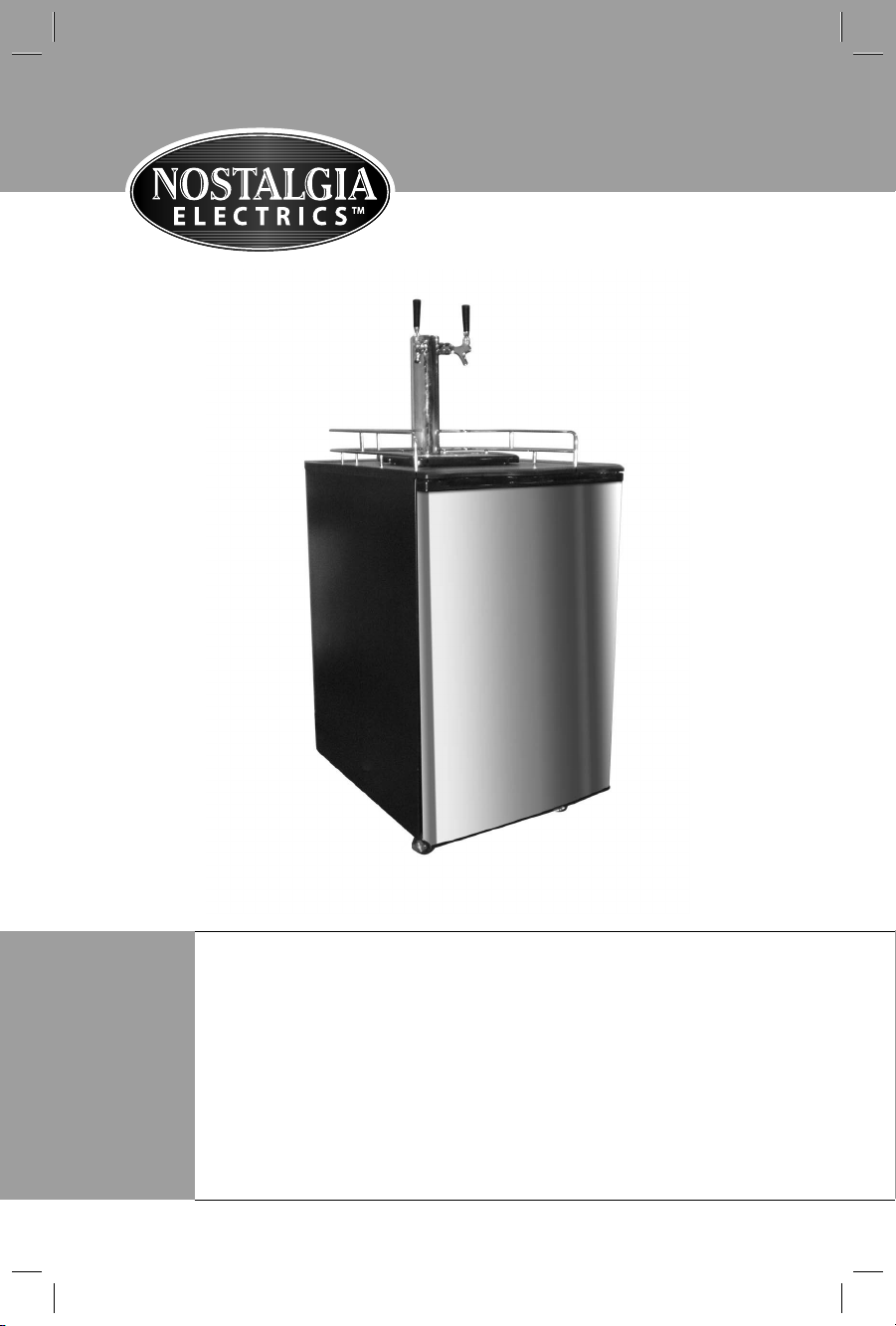

SERIES

KRS6100

Double Kegorator™

Instruction Manual

Page 3

Page 4

Make everyday a party!

Visit www.nostalgiaelectrics.com for more fun products.

CONTENTS

IMPORTANT PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

IMPORTANT SAFEGUARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PARTS & ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

WASHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

REGULATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

INSTALLING THE CASTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

INSTALLING THE GUARDRAIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CO

2 & TAP TOWER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 10

TAPPING THE BEER KEG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

HOW TO OPERATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

HELPFUL TIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

ENGLISH

CLEANING & MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

RETURNS & WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

SAFETY

Your safety and the safety of others is very important.

We have provided many important safety messages in this manual and

on your appliance. Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that

can kill or hurt you and others.

All safety messages will follow the safety alert symbol.

All safety messages will tell you what the potential hazard is, tell you how to reduce the

chance of injury, and tell you what can happen if the instructions are not followed.

Appliance Specications:

115V 60Hz 1.9A UL Approved

2

Page 5

IMPORTANT PRECAUTIONS

1. NEVER use an abrasive sponge, cloth or scouring pad on this appliance.

2. NEVER leave appliance unattended while in use.

3. Unplug unit from outlet when not in use and during cleaning.

4. DO NOT operate this appliance with a damaged cord or

ENGLISH

plug, or if the appliance ever malfunctions.

5. DO NOT clean any parts of this appliance in a dishwasher.

6. Keep out of reach of children.

7. This appliance is NOT A TOY.

8. Unsupervised young children and cognitively challenged

individuals should never operate this appliance.

9. Young children should be supervised while in proximity

of the appliance to ensure their safety.

SAVE THESE INSTRUCTIONS!

IMPORTANT SAFEGUARDS

Basic safety precautions should always be followed when using

electrical appliances, including the following:

1. Use this appliance only for its intended purpose as described in this instruction manual.

2. This appliance must be properly assembled according to the assembly instructions

in this manual before it is used. See the Parts & Assembly section for more details.

3. This appliance must be connected to a proper electrical

outlet with the correct electrical supply.

4. Proper grounding must be ensured to reduce the risk of shock and/or re.

DO NOT cut or remove the grounding plug. If you do not have a three-prong

outlet in the wall, have a certied electrician install the proper outlet.

5. Never unplug your appliance by pulling on the power cord. Always

grasp the plug rmly and pull straight out from the outlet.

6. Immediately replace worn power cords, power outlets and loose plugs.

7. To reduce the risk of electric shock or re, do not use extension cords

or adapters to connect the unit to an electrical power source.

8. Unplug your appliance before cleaning or making any repairs.

9. We suggest that a certied technician perform the service

if for any reason this product requires service.

10. This appliance should not be recessed or built into an enclosed

cabinet. It is designed for freestanding assembly only.

11. Do not operate your appliance in the presence of explosive fumes.

12. Do not tamper with the controls.

3

Page 6

13. Do not operate this appliance when parts are missing or broken.

14. Do not use this appliance for commercial use.

15. This appliance is designed for indoor use only and should not be used outdoors.

16. To reduce is the risk of injury, do not allow children to play in or on the appliance.

Close supervision is necessary when the appliance is used near children.

17. The appliance door must be closed during operation. Do not leave

the door open when children are near the dispenser.

18. DO NOT not attempt to operate this unit with a damaged cord or plug.

DO NOT roll the DOUBLE KEGORATOR™ with loaded beer kegs onto carpet oor.

19. This appliance is not intended for use by young children or

cognitively challenged individuals without supervision.

20. This appliance is NOT A TOY!

21. Young children should be supervised to ensure that they do not play with this appliance.

Before discarding your old appliance, remove the door from its hinges so that

children may not easily become trapped inside.

CO2 (Carbon Dioxide) Gas

1. CO2 gas can be dangerous! CO2 cylinders contain high-pressure compressed

gas, which can be hazardous if not handled properly. Make sure you read and

understand all the procedures for the CO2 cylinders before installation.

2. Always connect the CO2 cylinder to a regulator! Failure to do so may cause an

explosion resulting in possible death or injury when the cylinder valve is opened,

3. Never connect the CO2 cylinder directly to the beer keg.

4. Always follow the correct procedures when changing the CO2 cylinder.

5. Never drop or throw a CO2 cylinder.

6. Always keep CO2 cylinders away from heat. Store extra cylinders in a cool place

(preferably 70° F). Secure fasten with a chain in an upright position when storing.

7. ALWAYS ventilate and leave the area immediately if CO2 leakage has occurred.

8. There are two safety devices in the pressure system in the form of a valve. One

safety feature is on the CO2 bottle. The second is on the regulator.

9. Never attempt to rell CO2 cylinder yourself.

NOTE: If the refrigerator has been placed in a horizontal or tilted position

for any period of time wait 8 hours before plugging the unit in.

ENGLISH

4

Page 7

INTRODUCTION

To ensure that your DOUBLE KEGORATOR™ works to the maximum eciency for which it

was designed, keep it in a location where there is proper air circulation and electrical outlets.

Choose a location where the DOUBLE KEGORATOR™ will be away

from heat and will not be exposed to direct sunlight.

• The DOUBLE KEGORATOR™ is designed for indoor use only. It should not be used outdoors.

ENGLISH

• The DOUBLE KEGORATOR™ is designed to be freestanding and

should not be placed in a built-in or recessed area.

• The DOUBLE KEGORATOR™ comes with a 2.5 lb. CO2 bottle, which

should be able to dispense four 15 gallon kegs of beer.

• DOUBLE KEGORATOR™ capacity: 6 cu. ft.

• DOUBLE KEGORATOR™ unit dimensions: L 21.25" x W 25.50" x H 51"

• The following dimensions are recommended for clearances around the DOUBLE

KEGORATOR™:

Sides …………………… ¾” (19 mm)

Back ……………………. 1” (25 mm)

• DOUBLE KEGORATOR™ unit weight: 94.5 lbs

Compatible Keg Types

The DOUBLE KEGORATOR™ can hold

either two ¹/6 Barrel Kegs, one ¼ Barrel

Short, one ¼ Barrel Slim or one ½ Barrel.

You only need to use two Keg Couplers

when using two ¹/6 Barrel Kegs. DOES

NOT t non-standard keg sizes.

NOTE: Keg Coupler ts D-Sankey Keg

Valves. Attaching the Keg Coupler

will add height to the Keg.

Kegs ¹/6 Barrel ¼ Barrel Short ¼ Barrel Slim ½ Barrel

Gallons 5.16 7.75 7.75 15.50

Keg Capacity 2 1 1 1

12 oz. Beers 55 82 82 165

Weight (Full

in lbs.)

5

58 87 87 161

Page 8

PARTS & ASSEMBLY

Read assembly instructions carefully before installing the DOUBLE KEGORATOR™. If

still unsure whether the DOUBLE KEGORATOR™ has been properly installed after

assembly is complete, it is recommended that you contact a qualied installer.

Allow the DOUBLE KEGORATOR™ to stand in an upright position for about 8 hours before

turning on the power. Once the unit is laid on its side, the coolant in the refrigeration unit is

shifted. The coolant in the refrigeration unit needs to stabilize before the power is turned on.

WASHERS

Most washers are already attached to the DOUBLE KEGORATOR™. Extra washers

are included and are in a plastic bag. They are labeled below. Refer to parts

diagram and corresponding numbers to see where the washers belong.

ENGLISH

#1 Bottom of

Coupler (outside)

(38mm)

#3 Coupler Washer #4

(18mm) Directional Washer

#19 CO2 Line to

Regulator to Coupler (10mm) Washer (22mm)

(7mm)

#21

#1 Bottom of

Coupler (middle) of Coupler (center)

(22mm) (19mm)

CO2 Rubber

CO2 Line

#25 Beer Tap

#1 Bottom

#18 CO2 Tank Band

6

Page 9

Parts

ENGLISH

#1 Keg Coupler #2 Backow Stopper #3 Rubber Washer #4 CO

(Fits D-Sankey Keg Qty. 2 Qty. 2 Directional Washer

Valves) Qty. 2 Qty. 2

2 Rubber

#5 Beer Tower Washer #6 Beer Tap/Hose #7 CO2 Regulator #8 High Pressure

Qty. 1 Assembly Qty. 1 Washer, White

Qty. 1 Nylon Qty. 1

#9 CO2 Tank Valve #10 Guard Rail #11 Drip Tray Grate #12 Drip Tray Pan

Qty. 1 Qty. 1 Qty. 1 Qty. 1

#13 Rubber Foot #14 Keg Base Board #15 Metal Washer #16 Front Casters

Qty. 4 Qty. 1 Qty. 4 with Locking

Mechanism Qty. 2

#17 Casters #18 CO2 Tank Band #19 Air Hose Wing #20 Air Hose

Qty. 2 Qty. 1 Nut Washer Qty. 2

Qty. 2

#21 Air Hose #22 Beer Tap #23 Regulator #24 Beer Tower Hole

Connector Washer Wrench Plug Qty. 1

Qty. 2 Qty. 1 Qty. 1

#25 Beer Tapper & #26 Extra Washers

Handle Qty. 2 & Parts

7

Page 10

REGULATOR

The Double Regulator works the

per square inch), as well as the volume of the

Output Pressure Gauge between 8-12 PSI for a nice, frothy head.

Output

Pressure

Gauge

(0-60 PSI) for

measuring PSI of

CO2 outow from

Tank to Keg

(8-12 PSI

recommended).

Tank Pressure

Gauge (0-3000

PSI) for

CO2 Tank and measures PSI (pounds

CO2 gas in the Cylinder. Set

ENGLISH

Screw adjusts

the output

pressure.

Adjust using

Alan Wrench.

(included)

measuring PSI

CO2 in tank.

of

Pressure

Relief Valve

1. Close the Shut O Valves on the Double Regulator, and

open the CO2 Tank Valve (#9) completely.

2. Unlock Screw using Allen Wrench (included). Slowly turn the Double Regulator

adjustment screw until the desired pressure is shown on the Output Pressure

Gauge (8-12 PSI). Turning clockwise will increase the output pressure,

and turning counter-clockwise will decrease the output pressure.

3. Once desired pressure is reached, you may re-lock Screw using Allen Wrench.

4. Open the CO2 Shut O Valves on the Double Regulator to allow

gas ow from the Double Regulator to the Keg Couplers.

5. When only tapping one Keg, make sure that the unused CO2 Shut O Valve is CLOSED.

6. When the CO2 Shut O Valves are open, you will hear the keg pressurizing.

The output needle will drop momentarily until the pressure has

equalized. Then the needle will return to the point you set it at.

7. The Keg Couplers are designed with a pressure relief valve (PRV). Pull the ring on

the PRV briey to allow gas to vent. This will permit gas to ow through the Double

Regulator and help obtain a more accurate reading on the Output Pressure Gauge.

8. Re-check the output pressure on the Double Regulator, and if necessary re-adjust using step

#2 until the desired pressure is shown. It is always wise to follow up any adjustment to the

Double Regulator with a brief pull of the PRV ring to ensure an accurate output reading.

CO2 Shut O

Valves (shown in

closed position)

8

Page 11

INSTALLING THE CASTERS

Follow the steps below to install the Casters.

Note: Two of the Casters include locking mechanisms to ensure the unit does

not slide on hard oors. These two locking Casters should be fastened at the

front end of the unit, with the unlocked Casters fasted on the rear end.

ENGLISH

1. Empty the inside of the cabinet completely

and lay the DOUBLE KEGORATOR™ down

on it’s side. We recommend that you place

a piece of cardboard or cloth underneath

the cabinet to prevent dents or scratches.

2. Place washers over Caster bolts, then

insert the Casters into the holes on the

bottom corners of the cabinet. Tighten

each Caster by turning the nut clockwise

with a wrench (not provided in the kit).

3. Once all four Casters have been tightened,

stand the cabinet in its upright position.

INSTALLING THE GUARDRAIL

Follow the steps below to install the Guardrail.

1. Place the Guardrail on top of

the DOUBLE KEGORATOR™.

2. Align all holes of the Guardrail with the holes

on the top of the DOUBLE KEGORATOR™.

3. Secure the Guardrail to the

DOUBLE KEGORATOR™ by placing

inside corresponding holes.

9

Page 12

CO

& TAP TOWER INSTALLATION

2

You must read and understand the steps below for the CO2 assembly before installation.

When you purchase the rst keg of beer, you must also have your CO2 cylinder lled at

your local supplier.

party stores, or wherever kegs are purchased.

CO2 tanks can be relled at locations such as welding supply shops,

ENGLISH

STEP 1

Make sure white nylon High Pressure

Washer (already installed) is attached

to

CO2 Double Regulator.

STEP 2

Use Wrench to attach Double

Regulator to

STEP 3

Remove springs from inside the Keg Couplers.

If springs are not present, go on to Step 4.

NOTE: When using ¼ Barrel or ½ Barrel,

only one coupler needs to be used.

STEP 4

Make sure Backow Stoppers are inserted

into the Keg Couplers (the Backow

Stoppers go in with rounded side down).

CO2 Tank connector.

STEP 5

After the Backow Stoppers have

been inserted, remove the three parts

above from each Keg Coupler.

(cont. on next page)

10

Page 13

ENGLISH

STEP 6

The

CO2 Rubber

Directional

Washers go

back into the

Keg Couplers.

STEP 7

Connect the

CO2 lines from

the Double

Regulator to the

Keg Couplers.

STEP 8

Place the Beer Tower Washer (#5) over the

hole. Place the Tap Tower on the DOUBLE

KEGORATOR™ and feed the hose lines through

the hole in the top of the DOUBLE KEGORATOR™.

STEP 10

Make sure the Tap Tower is securely

screwed into the top of the DOUBLE

KEGORATOR™. It should look like the image

above when installation is complete.

STEP 12

After the Tap Tower has been placed on

the DOUBLE KEGORATOR™ and the hose

lines feed through the bottom, attach

the wing nuts to the Keg Couplers.

STEP 9

Screw in the four screws using a

Phillips Head or Flat Head screwdriver.

Screws are located in the bag

containing extra parts and washers.

STEP 11

Place Coupler Washers (#3) on

top of the Keg Couplers.

11

Page 14

Complete

Location of Temperature Gauge

Beer Tower Tap/

Hose Assembly

Connects Beer Tap

to Keg Coupler

CO2 Tank Installation

CO2 Bottle

Double

Regulator

Large Buttery

Nut Secures

Hose to Beer Tap

Beer Tap

Handle

Part Connects

to Keg

ENGLISH

CO2 Tank Band

goes here

CO2 Bottle

CO2 Air Hoses

Connect Regulator

to Bottom of Keg

Couplers

CO2 can be dangerous! CO2 cylinders contain

DANGER!

high-pressured gas, which can be hazardous if handled

improperly. They must be handled with care.

The temperature gauge is located in the upper right-hand

corner on the inside of the DOUBLE KEGORATOR™.

MAX= Increases Coolness / MIN= Decreases Coolness / OFF = Turns O

12

Page 15

TAPPING THE BEER KEG

Black pull handle

Connect to the

Beer Line Tube

Connect to

CO2 Gas

Line Tube

Keg Coupler

T

U

R

N

C

L

O

C

K

W

I

S

E

Beer Keg Neck

T

U

R

N

C

L

O

C

K

W

I

S

E

(SINGLE VALVE-TYPE KEG)

Connect to the

Beer Line Tube

Black pull handle

Connect to

CO2 Gas

Line Tube

ENGLISH

Keg Coupler

g. 1 g. 2 g. 3

g. 4 g. 5

Follow these steps below to tap the Beer Keg.

1. Make sure the black pull handle of the Keg Coupler is in the closed (up)

position before installing it on the keg (Fig. 1). Insert the Keg Coupler into

the locking neck of the Beer Keg and turn clockwise until it locks into

position (Fig. 2). This means that it is secured to the Beer Keg.

2. Make sure the Beer Tower Faucet is in the closed (handle pointing straight back) position

before connecting the Keg Coupler to the Keg (Fig. 3). To secure

the tank connection, pull the Keg Coupler handle out and push down until it locks into

position. Listen for the “click” of the pull handle when it shifts into the nal downward

position (Fig. 4). This will open the beer and CO2 gas valves. The Keg is now tapped.

3. Carefully tilt the Keg and rest the edge on the Keg Base Board on the

bottom of the Interior Cabinet. Slide the Beer Keg slowly, ensuring

that it is properly located (Fig. 5) and carefully close the door.

Beer Keg Neck

Lift Upright

Beer Keg

Keg Support

HOW TO OPERATE

Follow the steps below to dispense beer.

1. Make sure that the DOUBLE KEGORATOR™ is plugged in properly

to a 120V, 60Hz, 15 Amps grounded AC outlet.

2. Place the Drip Tray under the Beer Faucet to avoid messes from excess beer.

3. Open the Beer Faucet by pulling the tap towards you to dispense the beer. If for any reason

the beer does not come out of the tap, please refer to the Tapping the Beer Keg section.

4. Increase the pressure if the beer runs too slowly (see Regulator section).

5. Hold the glass steady at a 45° angle. When it is ²/ 3 full, straighten the

glass. Proper foam should be a tight creamy head and the collar

on an average glass should be ¾” to 1” high, ideally.

13

Page 16

HELPFUL TIPS

• It is recommended that you ush the hoses with water prior to

rst use to remove any dust and debris from shipping.

• Only open the

to adjust to desired pour. If it is not enough, continue to open the

by ¼ turn and use Double Regulator until desired setting is reached.

• It is normal to see condensation form on the Beer Faucet. It is caused

by the dierence in temperature between the cold beer and the inside

of the Beer Faucet when beer is owing through the line.

• If your

to use a bungee cord to secure

• Humidity can cause ice to build up inside the DOUBLE KEGORATOR™, so

you will need to periodically defrost it. There is a hole in the back of the

unit that will allow water to drain out of the DOUBLE KEGORATOR

Foamy Beer

Below are tips for preventing foamy beer.

• Conrm the packing spring in the Coupler is removed and discarded. It

is not to be placed inside the Coupler when unit is assembled.

• Make sure there is only (1) Backow Stopper inserted and it falls out easily if

the Coupler is ipped over. If you have to force it out with a screwdriver, it is

getting lodged in the Coupler. Try exchanging it with the replacement.

• Conrm the beer lines are not kinked and are clean.

To prevent foamy beer, you may need to bring down your pressure,

even if it is below the recommended 8-12 PSI:

• Before lowering the pressure, close the CO2 Shut O Valve (turn to 9 o’clock

position) and use the provided 1.5mm Allen Wrench to loosen the Allen Screw on

the red +/- adjustment dial. This will restrict excess CO2 from entering the keg.

• Adjust the pressure down to 6 PSI. Lock the red +/- dial back

in place by tightening with the Allen Wrench.

• Pull the Release Valve on the Regulator to get an accurate reading of CO2 pressure.

• With the Shut O Valve still closed, move down to your Coupler.

• Pull the release valve on the Coupler to remove any excess CO2 that

may have been pushed into the keg at another point.

• Once most or all has released, open the Shut O Valve (6 o’clock position) and attempt to pour

a beer.

This should prevent and/or correct foamy beer.

• Keep in mind that jostling a keg can create foamy beer.

• Temperature also may aect the beer, so be sure it is not too warm

or too cold. 37 degrees F is an ideal temperature.

• A faulty valve on the keg itself may cause the Coupler to not seat well. Make sure all

connections are secure and tightened (not just tightened by hand). Ensure all O-rings and

Washers are intact and correctly placed. Conrm Directional Washer (#4) has a hole in it when

pinched between the ngers.

CO2 Tank ¼ turn to begin with and then use the Double Regulator

CO2 Tank Band breaks during assembly, it is recommended

CO2 Tank.

CO2 Tank

™.

ENGLISH

14

Page 17

CLEANING & MAINTENANCE

Follow the steps below to clean the Beer Tap and Hoses. (see illustration)

1. Turn o CO2 completely before

attempting to clean.

2. Remove the hose from the Keg

ENGLISH

Coupler and carefully twist the

dispenser faucet o the top of

the DOUBLE KEGORATOR™.

3. Ensure that the dispenser handle

is in the down position before

ushing the hose. If this is not

set correctly, water cannot ow

through. Hold the open end of the

hose under running water for 3-5

minutes, while the Beer Dispenser

Faucet drains into the sink. This will clear any excess beer that is trapped inside,

helping to prevent any bacteria or mold that could accumulate inside.

4. In order to clean and remove any excess beer that may leak into the unit space inside

the door, remove the black rubber insulation and wipe with a wet towel as needed.

Follow the guidelines below to care for your DOUBLE KEGORATOR™ when not in use.

• Please adjust the temperature gauge to MIN in colder environments

because this unit does not self-defrost and ice may build up inside the

unit. The temperature gauge is located on the back side of the DOUBLE

KEGORATOR™ inside the cut out area at the bottom to the lower left.

• Always rinse the beer line if you do not intend to use your DOUBLE KEGORATOR™

for a period of time. First, turn o the CO2 and dispense beer until it stops. This will

release pressure in the Beer Keg so that the Keg Coupler can safely be detached.

• To avoid permanent damage to the unit, never use sharp objects inside the DOUBLE

KEGORATOR™.

Detach beer line

1

Flush hose with water

2

15

Page 18

RETURNS & WARRANTY

SHOULD YOUR UNIT NOT WORK OR IF DAMAGED WHEN YOU FIRST TAKE IT OUT

OF THE BOX, PLEASE RETURN IT TO THE PLACE OF PURCHASE IMMEDIATELY.

DOUBLE KEGORATOR™ / KRS6100 SERIES

Should you have any questions, please contact us via email or at the

customer service number listed below between the hours of 8:00 AM

and 5:00 PM, Monday through Friday, Central Standard Time.

Distributed by:

Nostalgia Products Group LLC

1471 Partnership Dr.

Green Bay, WI 54304-5685

Customer Service

Phone: (920) 347-9122

Web: www.nostalgiaelectrics.com

Customer Service Inquiry

To submit a Customer Service inquiry, go to www.nostalgiaelectrics.com and

ll out the Customer Service Inquiry form and click the Submit button.

A representative will contact you as soon as possible.

This appliance is designed and built to provide many years of satisfactory performance

under normal household use. The distributor pledges to the original owner that

should there be any defects in material or workmanship during the rst 90 days of

purchase, we will repair or replace the unit at our option. Our pledge does not apply

to damages caused by shipping, mishandling or unit being dropped. A product

deemed defective either from manufacturing or being mishandled is up to the

distributor’s discretion. In order to obtain service under this warranty, please contact

Nostalgia Products Group, LLC at the telephone number listed above or by lling

out the Customer Service Inquiry Form located at www.nostalgiaelectrics.com.

This product is not recommended for use outside of North America. The warranty

is void if products are exported outside of the USA, Canada or Mexico.

This warranty does not apply to re-manufactured merchandise.

Please read these instructions carefully. Failure to comply with these instructions,

damages caused by improper replacement parts, abuse or misuse will void this

pledge to you and is being made in place of all other expressed warranties.

For more information, visit us online at www.nostalgiaelectrics.com.

Like us on Facebook at www.facebook.com/NostalgiaElectrics.

ENGLISH

16

Loading...

Loading...