Page 1

A B C

+ -

C

B

A

+

-

A B C

+ -

3. SPECIFICATIONS

the spe ed

wire s

Avoid any

direc t contac t betwe en power com ponen ts, the rec eiver or the antenna. Th is can

to a

4. INSTALLATION TIPS

2. CONNECTIONS

1. INSTALLATION

* Transis tors rat ing at 25°C junc tion tempe rature Sp ecifica tions subje ct to change w ithout not ice.

** mea sured at 7.2V

USER MANUAL

5. SUPPRESSION

BRUSHLES S + BRUSHED

over 3T (brushless - star)

over 4T (brushed)

# 90750

for distributor a ddress see packaging

www.nosram.com

/

Yellow p ower -w

Speedo

/MOT.B

to

the mo

tor

power-wi re

Speedo

to

Speedo

to mo

tor

Yellow p ower -wir e

Speedo

to mo

tor

Speedo

to mo

tor

Swit

wire

This

rece iver

wire . As supp lied, i t will ea sily f it in all o rdina ry receive rs.

ALL SE NSOR WIR E

This bi-directional multipol e wir e (which co mes w ith t he mo tor a nd NOT the speed -cont rol!) con nects the

speed-con trol and the mot or. Do no t alt er or modif y this cable! Ther e are repl aceab le

/optional

hall sensor

wire s avail able:

AWG power wires

w

are used

The unique splitt ed

solde r-ta bs allo w easy and co nvenient re place ment o f the po wer w ires.

void so ldering long er then 5 sec per s older ing joi nt

to pre vent possible damag e to the sp eed-

Ther e is a

full 1

To a chiev e best

perf omance even under extr eme

The he atsin k is an int egral part o f the spe ed-co ntro l and the refore can not be r emove d.

wher e it is pr otec

ted in t he even t of a cras h.

trol (s ee pict ure)

tape.

speed-con trol. To avo id this, so lder the s upplie d capac i-

tors t o your motor (s ee pic ture).

AUTI ON

Speedo BA

T+ to batt ery „Pl us“

Speedo BAT- to ba tter y „Minus“

to be se t-up (s ee sec tion 6)

The

AWG po wer- wire s wit hout

/colo rs si nce an in

conn ecti on

may

solde r bridges

solde r-ta bs and isolate

aution

A

void so lderi ng longe r then 5sec per sol derin g joint w hen rep lacing the

power w ires

to pre vent possible damag e due to ov erhea ting of the component s!

t

AM MATRIX EVOL UTIO

s peed-

you have ch osen one of the m ost advanced speed- contr ols of today

This spe

the best spee d-con trol s for Tour ingca rs cur rent ly avai lable on the mar ket.

For ward /Br ake

Auto matic Brushless /Br

to ensure , that your

AM MATRI X EV OLUTIO

speed-con trol

alwa ys work s up to your ful l satisfac tion.

With op erating this product

Brush ed

yes

Volta ge Input

4.8-7.4V

AUTO MATIC

Weight ( excl. wire s)

45.0g

yes

yes

Typ. Volt age Drop

@20A

Senso red Brushl ess Syste m

yes

(Brus hless)*

400A /

yes

Star

awg

silic one flex

for

Star winds (Brushless)**

over 3

t

4, 5, 6 cell o ptimised

yes

Typ. Volt age Drop

@20A

Smar t-Temp-Reado ut-Syst em

yes

over

4 turns

yes

400A

yes

4 adjus table Mode s

(NiMH /LiPo, X PS.2/PM S.2 Power Pr ofiles, In itial

- and

Auto maticbra ke

)

yes

Page 2

6. RADIO / SPEED-CONTROL SET-UP 7. MODE PROGRAMMING

AM M ATRIX E VOLU TIO

st ores every s tep w hen you p ress the SET button.

All the set tings w ill be s tore d in the speed -cont rols memor y even i f the sp eed-contr ol will be

fro m the bat ter y.

Thro ttle trave l

Thro ttle expon ential

Thro ttle expon ential

star t with 0

SUB Trim

centr e

Servo r everse

Thro ttle reve rse

any set ting, don‘t cha nge after s et-up proc edure!

any set ting, don‘t cha nge after s et-up proc edure!

TRAN SMIT TER SE TTIN GS

Setu p the fol lowi ng basic f unctions o n your tr ansmi tter ( if avai lable ):

Switch the t ransm itte r on and se t the tr ansmi tter t hrot tle st ick to ne utra l.

the spe ed

switch the unit on.

You entere

SET LED flashe

s

blue

will flash until the

setup is comp

ted).

Leav e transmitt er in neutra l posit ion

Neut ral set ting is stor ed , MODE L

Hold f u

Full- thro ttle s etti ng is sto red,

Hold f u

Bra

This c omple tes the setup p ro

AM MAT RIX EVOL UTIO

At the end of each run

switch of th e car

At the s tart o f each r un swi tch on th e transmitt er first, t hen

switch on th e car.

STATU S

SET LE D

yello w

yello w

full t hrottle

yello w

yello w

full b rake

the

All modes are available for brush less and brush ed motors (

speedo adapt s

The NOSRA M

feat ures 4 modes whi ch enabl e you to adjust it to YO UR special requ irem ents.

The

fact ory setti ngs are shown in grey co lour

)

XPS.2

Brushless Power Profiles

)

only wi th conne cted Bru shless motor

thro ttle

ea

s

The fo llow ing XPS.2

sett ings are the pr eferenc es fr om our te amdri vers:

Tou

WD

Truck:

/12: Bonde d: 3-5

S

WD

(

Brushed Power Profiles

)

only wi th conne cted Bru shed motor

thro ttle

TeaT

s

The fo llow ing PMS. 2

(Br

Tou

WD

Truck:

Brushed

/12:

):

A

T

eam

T

A

set ting o n your radio

for all class es.

s on the r adio on 100 %.

):

Team

t

the same

/3

for

magne ts

for

magne ts

Value

Value

Yellow

Automatic

4-

6

cell NiMH

Pres s

s of the blue SET-LED

x

x

Pres s SET butto n to incr ease v

How to l eave th e progr amming mode

If you are in MOD E.4, pre ss the MO DE but ton

one mor e time

Table of settings

values and modes: see below (grey-shaded values show

tings“).

s a worl d-exclusive the NO SRAM MATRI X EVOLUT ION ISTC

you to read-out the max imum

in tern al

t emper atur e th at the speedo re ached . To save it to the memory you

temperature back in the pits si nce it remai ns

This new feature allow s you to accur ately ch eck i f all is running well or if y ou‘re close to

shutdown al read y

Swit

SET L ED wil l star t to flash blu e (MODE L ED is of f)

T

The higher the n umber

o

flas h

(e.g. the

very f lash

to

°C

flas hes is

40°C b elow sh utd

Well kno wn

fro m our brushed speed os!

Aft er act ivation it gives you mo re powe r

(this

feat ure is only re comme nded t o be used w ith to uring c ars on

Hold tr

for 5s ec bef ore st art.

Ready

and act ive

for th

smar t Smart Cell Syste m ensur es that L iPo bat teries can be used saf ely withou t

the cells.

th e system recognis es v ery low

T

We rec ommend u sing value 2 for 4 -6 cel ls NiMH r acing purpos es, whi ch disengages t he LiP o prot ecti on.

XPS.2

Do not

motor

L

- Power Profiles

T

Brushe d

in to t he NOSRA M M ATRIX EVOLU TION ISTC aswell.

The NOSRAM exc lusiv e Automa tic Bru shles s/

turn -on

/

s

Keep in mind, w hen swopp ing be tween br ushle ss and brushed m otor s, tha t the chosen mo de val ues

will be ident ical!

At rac e even ts you u sually do not ha ve

8. SPECIAL FEATURES

Value1Value 2Value 3Value4Value

Value 6Value 7Value

8

ed

s

s2Xs3Xs

4X

inear4Xinear

X

ogres siveaggres sive

Value 1Value 2Value 3Value4Value

Value

6

ed

smoot h

very

inear

inear,

ch

increas ing

a

ggressive

e

very

aggressi-

ve

essivee

Value 0Value 1Value 2Value 3Value4Value

Value

6

Yellow/ed

Going from lowest to highest inital

Value 0Value 1Value 2Value 3Value4Value

Value

6

Yellow

/Red (same

time)

Automatic

Going from lowest to highest automatic brake setting

fact ory-adju sted

faul ts are grey-

shade d

tore

the

work s def ault se ttings

With the tran smit-

ter switche d on, hold the SE T butt on pressed wh ile you swi tch on the speed- cont rol. Thi s

simpl e

the uni t to the N OSRA M work s default se ttings.

It of fers

tect ion

and for b

for

top lev el compe titi on

was the tar get!

Ther efor e the

a pur e for ward /brake

T

val

-con trol e xcess ivel y)

-con trol e xcess ivel y)

Page 3

!

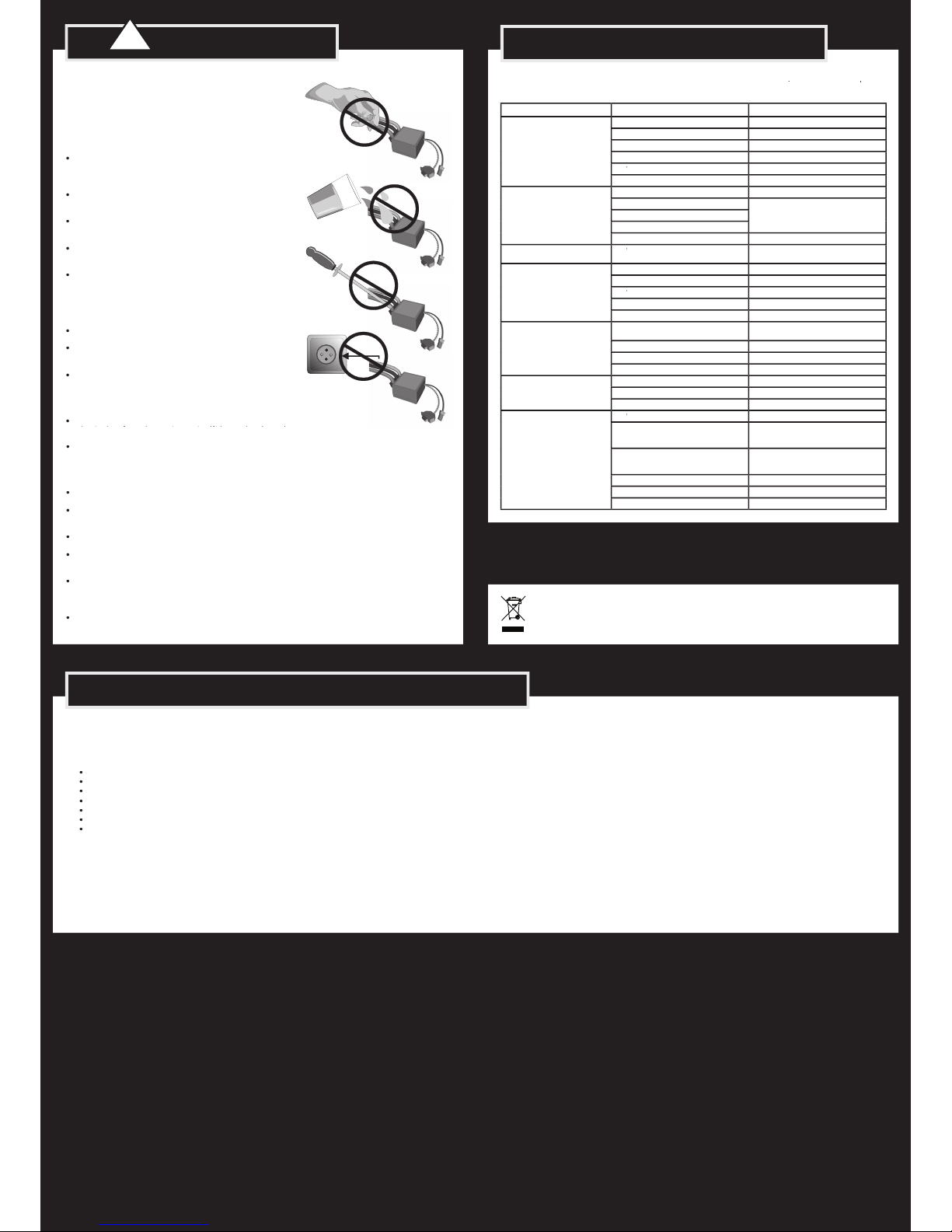

9. WARNING NOTES

stroy the pro duct and void your warr anty. Non-obser vance

of these points can lead to pr opert y damage, personal and

sever e injuries!

Avoid incor rect conne ctions or c onnec tions with reve rsed

All wires and connection s ha ve t o be we ll insulat ed. Shor t-

This w ill red uce pro tection, ma y cause short ci rcui ts and da-

Always remove the batt ery from you r produ ct or disconnect

REPAIR PROCEDURES / LIMITED WARRANTY

the pr oduct f rom the powe r sour ce, if th e produ ct is not in use.

Always remove the batt ery from you r produ ct or disconnect

Always remove the batt ery from you r produ ct or disconnect

Always swit ch o n yo ur t ransm itte r f irst before you sw itch on the receiv er o r th e speed contr ol. The

switch off, make sure you do so in th e rever se seque nce. Fir st switch of f the receive r and speed co ntro l,

then switc h off t he tran smit ter.

Always wir e up all the par ts of the equ ipmen t care full y. If any of the con nect ions co me loos e as a result

Avoid sol derin g longer the n 5 seconds per sol dering joint when replac ing the powe r wires to pr event pos-

sible damage to the prod uct due to ov erhea ting o f the c omponents . Use a high po wer so ldering st ation

for so lderi ng.

10. TROUBLESHOOTING GUIDE

XPL ANATI ON

with

brushles

s or brushed m

If „

rela ting to

All pro ducts from NOSR AM are manufac ture d according to the highe st quali ty standards. NO SRAM guarant ees

this pro duct to be free from def ects in materi als or work manshi p for 90 days (non- europ ean coun tris onl y) from

the original da te of pur chase veri fied by s ales re ceip t. This li mite d warra nty doe sn’t cove r defe cts, wh ich are a

This applies a mong ot her thi ngs on:

Solde red on t he PCB (e xcep t on ext ernal solder -tabs)

To elimin ate al l other possi bilit ies or i mprop er hand ling, f irst c heck al l other compo nents and the t roubl e shoo-

ting guide, if availa ble, be fore you sen d in this produ ct for repai r or war rant y. Produ cts se nt in for repair, that

Warranty c ase. T he ori ginal s ales r eceipt in cludin g date of pur chase need s to be included. Ot herw ise, no war -

The specifi cati ons like weight, size and other s shoul d be seen as guide values. Due to ongoing technic al im-

With Lim ited Lif etime Warr anty prod ucts, the warr anty terms on t he Li mite d Li feti me War rant y car d do also

-Distributor -Service:

• Send pa rcel t o your na tiona l NOSR AM dis tributor.

• Dist ributor repairs o r excha nges the produ ct.

• Sh ipmen t ba ck t o you usually by COD (cash on d elive ry), but thi s is subject to your na tional NO SRAM

The cros sed-o ut w heele d bin means tha t wi thin the Europ ean U nion the p roduc t mus t be tak en

to se pera te co llect ion at the pro duct e nd-o f-lif e. Do not di spose of these produ cts as uns orte d

SYMP TOM

CAUSE

Servo i s working, n o motor func tion.

Speed- control p lugged in inc orrectl y

Overl oad protec tion acti vated

Allow s peed-con trol to cool d own

Wirin g problem

Check w ires and plug s

- Motor br ushes stu ck

Check th at brushes a re moving f reely

Speed- control d efectiv e

Send in pr oduct for r epair

Speed- control p lugged in inc orrectl y

Crys tal defec tive

Transmi tter defe ctive

Speed- control d efectiv e

Send in pr oduct for r epair

ting fo rward on the t ransmit ter.

- Motor c onnected i ncorrec tly

Connec t motor cor rectly

accele ration..

Use smal ler motor pin ion/shor ter gear ra tio

Transmi tter sett ings change d after se t-up

- Motor w orn out

Speed- control d efectiv e.

Send in pr oduct for r epair

Speed- control o verheats o r switche s

off fr equentl y.

too high

Use only m otors and ba tteries w hich are wi thin the

speci fication s of the speed -contro l

Use smal ler motor pin ion/shor ter gear ra tio

Check or r eplace com ponents.

slow spe ed

Transmi tter sett ings change d after se t-up

Speed- control d efectiv e

Send in pr oduct for r epair

- Motor su ppressor s not suff icient

Solder c apacitor s to motor

motor, bat tery or spe ed-contr ol.

See „Ins tallatio n Tips“ and „Ins tallation“

Transmi tter defe ctive, tr ansmitte r output pow er

too low, se rvo probl em

Only use o riginal man ufactur ers crys tals

Check pl ugs and conne cting wir es

Transmi tter batt eries empt y

Transmi tter anten na too shor t

Loading...

Loading...