NoShok 900 Specifications

Dial Indicating Pressure Gauges

ABS & Stainless Steel Case, Liquid Filled

900 SERIES

•

High quality liquid fi lled gauge

•

Vacuum and compound ranges through 0 psi to 15,000 psi

•

1-1/2", 2", 2-1/2" and 4" gauge sizes

•

Impact-resistant ABS and stainless steel case

•

Copper alloy and brass wetted parts

OPERATING SPECIFICATIONS

1. Working Pressure Limitations

a. Dynamic Pressure

The working pressure should be

limited to 60% of the dial range.

b. Static Pressure

The working pressure, where no

sharp fl uctuations occur, should be

limited to 90% of the dial range

APPLICATIONS

■

Automotive

■

Construction

■

Hydraulics & pneumatics

■

Power generation

■

Transportation

■

Water management

SERIES SPECIFICATIONS

Pressure

ranges

Accuracy 15-910 ±2.5% full scale

Temperature

ranges

Measuring

element

Connection 15-910 1/8″ NPT, brass

Case 15-910, 25-900, 25-910 ABS with safety relief plug

Bezel 25-901, 25-911, 40-901, 40-911 304 stainless steel

Lens 15-910, 25-900, 25-910 Acrylic; ultrasonically welded to the case

Pointer 15-910, 25-900, 25-910, 25-901, 25-911 Molded plastic

Dial 15-910, 25-900, 25-910, 25-901,

Movement 15-910, 25-900, 25-910, 25-901, 25-911 Brass and nylon with highly polished bearing

Fill liquid** 15-910 86.5/13.5 Glycerin:H

900 Series (all) Vacuum and compound ranges through

25-900, 25-910, 25-901, 25-911 ±1.6% full scale

40-901, 40-911 ±1% full scale

900 Series (all)

*

900 Series (up to 600 psi) Copper alloy C-Type Bourdon tube

900 Series (> 600 psi) Coiled safety tube

25-900, 25-910, 25-901, 25-911 1/4″ NPT or 7/16”-20 adjustable, brass

40-901, 40-911 1/4″ NPT, brass

25-901, 25-911, 40-901, 40-911 304 stainless steel

25-901, 25-911 Polycarbonate

40-901, 40-911 Instrument glass

40-901, 40-911 Balanced aluminum, black fi nish

25-911

40-901, 40-911 Aluminum, white background with black

0 psi to 15,000 psi

Media -4 °F to 140 °F (-20 °C to 60 °C) Glycerin fi ll

-40 °F to 140 °F (-40 °C to 60 °C) Special fi ll

Ambient -4 °F to 140 °F (-20 °C to 60 °C) Glycerin fi ll

-40 °F to 140 °F (-40 °C to 60 °C) Special fi ll

1/2″ NPT, brass

Molded plastic, white background with black

primary scale & red secondary scale.

UV resistant

primary scale & red secondary scale.

UV resistant.

surfaces

O

2

For details on accuracy/standard dial confi guration

and dial layouts, see pages 52-56.

26

* For every 18 °F (10 °C) shift in temperature from which the gauge is calibrated, the user can

experience up to ±0.4% additional error.

** See page 51 for gauge fi ll options.

ORDERING INFORMATION

GAUGE SIZES

CASE TYPES

PRESSURE

RANGES

SCALE OPTIONS

CONNECTION SIZES

OPTIONS

15 1-1/2″ 20 2″ 25 2-1/2″ 40 4″

900 ABS Case, bottom connection 910 ABS Case, back connection

901 SS Case, bottom connection

30vac

-30 inHg to 0 psi 100 0 psi to 100 psi

30/15 -30 inHg to 0 to 15 psi 160 0 psi to 160 psi

30/30 -30 inHg to 0 to 30 psi 200 0 psi to 200 psi

30/60 -30 inHg to 0 to 60 psi 300 0 psi to 300 psi

30/100 -30 inHg to 0 to 100 psi 400 0 psi to 400 psi

30/160 -30 inHg to 0 to 160 psi 600 0 psi to 600 psi

30/200 -30 inHg to 0 to 200 psi 800 0 psi to 800 psi

30/300 -30 inHg to 0 to 300 psi 1000 0 psi to 1,000 psi

15 0 psi to 15 psi 1500 0 psi to 1,500 psi

30 0 psi to 30 psi 2000 0 psi to 2,000 psi

60 0 psi to 60 psi 3000 0 psi to 3,000 psi

psi psi single scale psi/kg/cm2psi/kg/cm2 dual scale bar/psi bar/psi dual scale psi/kPa psi/kPa dual scale

psi/bar psi/bar dual scale

1/8 1/8″ NPT 1/4 1/4″ NPT 1/2

PMC Steel Panel Mount Clamp AP Adjustable Pointer SSFF

SPMC 304SS Panel Mount Clamp MIP

SSBU Stainless Steel Bezel & U-clamp SP

SSB Stainless Steel Bezel SG Safety Glass Lens ST

SSCR 304SS Cover Ring BLFF Black Front Flange

Maximum Indicating Pointer

Red Set Pointer

Please consult your local NOSHOK Distributor or NOSHOK, Inc. for availability and delivery information.

NOTE: Refer to 900 Series Options & Accessories chart on page 53 for availability by series number.

* Includes FKM o-ring

900 SERIES

SS Case, back connection

911

5000

0 psi to 5,000 psi 10

6000

0 psi to 6,000 psi 16

7500

0 psi to 7,500 psi 25

10000

0 psi to 10,000 psi 40

15000

0 psi to 15,000 psi 60

−1

−1 bar to 0 bar 100

1

0 bar to 1 bar 160

1.6

0 bar to 1.6 bar 250

2.5

0 bar to 2.5 bar 400

4

0 bar to 4 bar 600

6

0 bar to 6 bar 1000

1/2″ NPT

304SS Front Flange

SSRF

304SS Rear Flange

LM

Laser Marking

Stainless Steel Tagging

ORDERING

INFORMATION

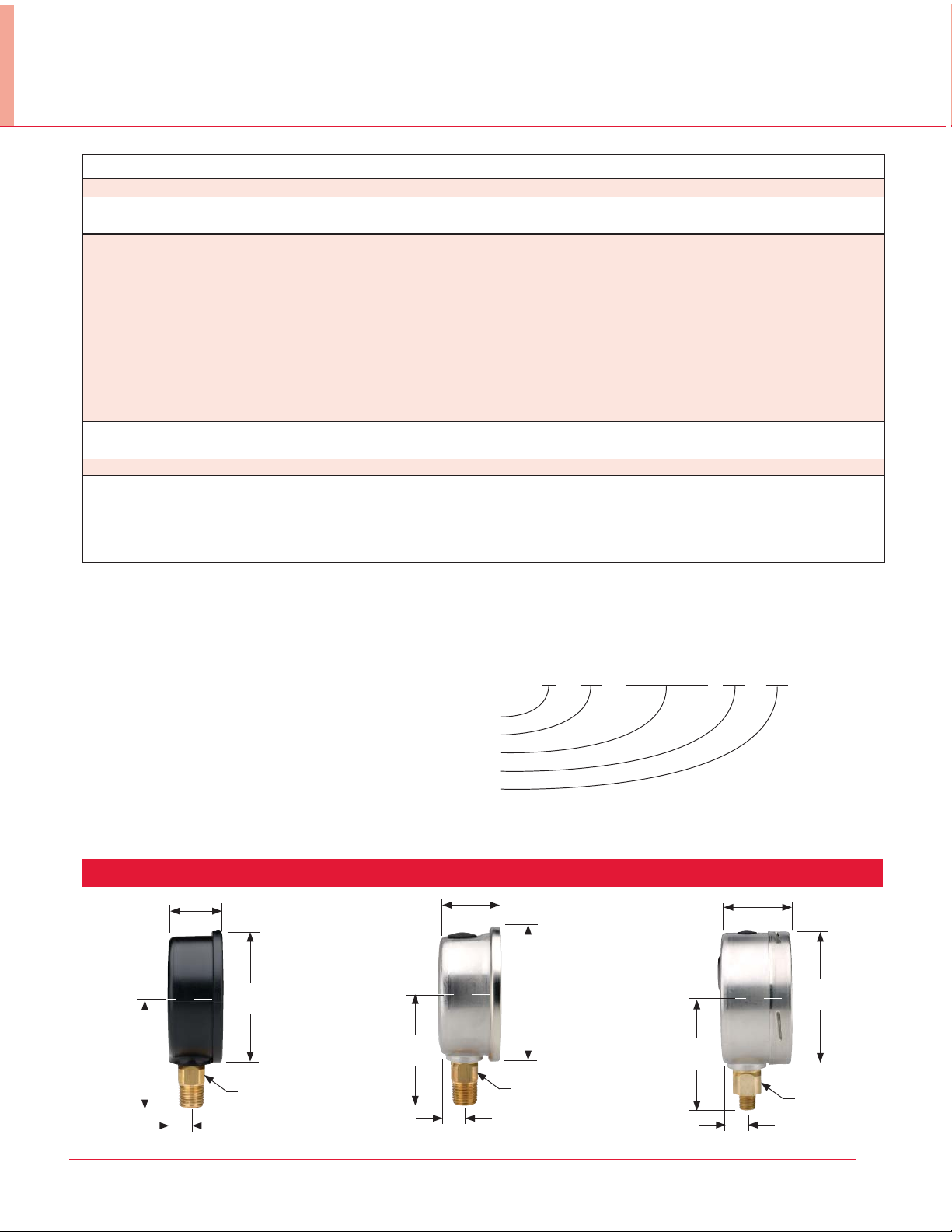

DIMENSIONS

0 bar to 10 bar

0 bar to 16 bar

0 bar to 25 bar

0 bar to 40 bar

0 bar to 60 bar

0 bar to 100 bar

0 bar to 160 bar

0 bar to 250 bar

0 bar to 400 bar

0 bar to 600 bar

0 bar to 1,000 bar

SST

SAE J1926-3:7/16-20 Adjustable*

BP3

Brass Press Fit Orifi ce 0.3 mm

BT5

Brass Threaded Orifi ce 0.5 mm

BT8

Brass Threaded Orifi ce 0.8 mm

EXAMPLE

25 – 910 – 1000 – psi /kPa – 1/4 – PMC

Gauge size ..................................................................2-1/2"

Case type ..............ABS case, liquid fi lled, back connection

Pressure range & scale option ........0 psi to 1,000 psi/kPa

Connection size .....................................................

1/4" NPT

Option ....................................................Panel Mount Clamp

25-900 25-901 40-901

2.13"

(54 mm)

2.13"

(54 mm)

2.83"

(72 mm)

0.55"

(14 mm)

0.45" (11.5 mm)

2.13"

(54 mm)

1.26"

(32 mm)

2.68"

(68 mm)

3.43"

(87 mm)

0.55"

(14 mm)

0.51" (13 mm)

2.13"

(54 mm)

3.95"

(101 mm)

0.87"

(22 mm)

0.70" (17.7 mm)

27

Loading...

Loading...