Page 1

USER MANUAL

S W I T C H

Electronic

Temperature Switch

SERIES

850

Page 2

Copyright

All rights to these operating instructions are reserved. These operating instructions, including

extracts thereof, must not be copied or translated into other languages without our written

permission.

Safety Instructions and Warnings

Please read these instructions before installing and starting up the pressure switch. Failure to

follow the instructions will make all guarantee, warranty and compensation claims null and

void.

connection, and the correct tools must always be used.

complied with.

• Damaged devices must not be started up. If damage occurs during operation, suitable

measures must be taken to prevent persons or property from being put at risk by the damaged

pressure switch.

• The switch must only be repaired by NOSHOK.

temperature

temperature

The accepted technical regulations and all national guidelines must always be observed and

complied with.

1

Page 3

Exclusion of Liability

NOSHOK guarantees that the pressure switch is in perfect working condition when it is delivered.

The basis consists of the technical data in the data sheet and these operating instructions.

Liability cannot be accepted for the suitability of the pressure switch.

Electrical and Mechanical Connection

The technical regulations must be complied with during installation and dismantling.

The system must be depressurized prior to installation and dismantling.

Safety regulations must be complied with, particularly when working on the electrical

system. All connections to external electrical equipment must be made in accordance with

regulations.

The power to system must always be swit tch is being connected.

Temperature Switch Description

The temperature switch has one analog output and one switching output or two switching outputs. The switching output(s) is (are) adjusted using the two buttons: set point, reset point

(hysteresis), switching function (normally closed/normally open contact).

The programmable analog output is a special feature. It can be adjusted in 0.1° steps within a

span of at least 20% of the temperature range.

2

Page 4

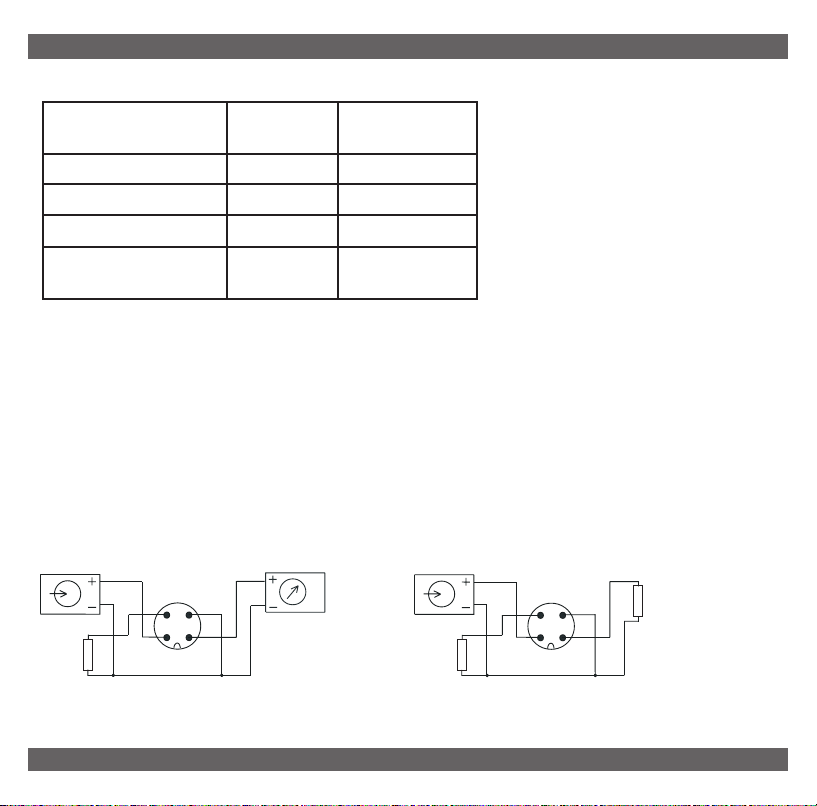

+Supply

S1

1

-Supply

2

3

4

R

L

Sig

+Supply

S1

1

-Supply

2

3

4

S2

R

1

R

2

Round Connector M 12 x 1 (4-pin)

Signal Connector Colors of

Optional Wires

Supply: + 1 brown

Supply: - 3 blue

Switch output S 1 4 black

Switch output S 2 or

2 white

analog output

Recommended accessories:

M12x1 socket with 2m cable

• straight version, order no.: FS-2-4P

• angled version, order no.: FA-2-4P

switching to p potential

1 switching output and 1 analog output 2 switching outputs

3

Page 5

Switching On and Off

Status-LED Switching Output

1 2

The temperature switch is switched on when the supply voltage is applied. There is no on/o

switch. A brief initialization phase occurs when the supply voltage is applied to the switch. The

display and the set point LED illuminate. The measuring range (min- and max. temperature) and

the unit are indicated briey. The outputs are inactive during this time.

After initialization the switch is in normal operating mode. The temperature appears on the display,

the switching outputs are active and the LED’s indicate the status of the switching outputs.

Programming

Briey pressing button S1 or S2 causes the relevant set point to be displayed.

The status LED’s ash for as long as the set points are being displayed.

Pressing the buttons for longer (press and hold down button until display ashes) causes the

current temperature to be taken over as the set point. The hysteresis remains unchanged. The

switching output(s) can be programmed using the control buttons independently from the present

temperature, per the programming sequence on page 6.

The programming sequence must run without interruptions. If delays of about 20 seconds or

more occur, the switch automatically exits programming mode and switches to normal mode.

All previous changes are lost.

4

Page 6

Parameter description / programming

With two switching outputs

Temperature units

Degree Celsius

Degree Fahrenheit

Switch 1, Set Point Select set point for rst switch

Switch 1, Reset Point Select reset point for rst switch

Contact 1 Select contact function for rst switch

normally open Select normally open contact

normally closed Select normally closed contact

Switch 2, Set Point Select set point for second switch

Switch 2, Reset Point Select reset point for second switch

Contact 2 Select contact function for second switch

normally open Select normally open contact

normally closed Select normally closed contact

Store

1) The pressure units setting applies immediately for the switching point settings, the reset points

and for the process pressure 4-digit LED display.

The previous changes are only accepted if button 2 is

pressed about 15 seconds after the previous button press!

5

Page 7

6

Page 8

With one switching output and one analog output

Temperature units

Degree Celsius

Degree Fahrenheit

Switch 1, Set Point Select set point for rst switch

Switch 2, Reset Point Select reset point for rst switch

Contact 1 Select contact function for rst switch

Normally open Select normally open contact

Normally closed Select normally closed contact

Current high Select temperature value for 20mA

Current low Select temperature value for 4mA

Store The previous changes are only accepted if button 2 is

1) The pressure units setting applies immediately for the switching point settings, the reset points

and for the process pressure 4-digit LED display.

pressed about 15 seconds after the previous button press!

7 8

Page 9

Page 10

Technical data

Temperature Ranges -58 to +392°F

Measurement Units °C or °F (selectable)

Sensor PT100 class B or PT100 class A

Supply Voltage 12...30 Vdc, overload and reverse polarity protection

Power Consumption ≤ 50mA, without load current

Process Connections

• Fixed Thread

• Compression Fitting

Materials

• Process Connection

• Housing

Stem and

Working Pressure

Outputs 2 switching outputs PNP or

-58 to +752°F

-58 to +1112°F

-328 to +1112°F

ripple <10%

1/2NPT, 1/4NPT

1/2NPT

Other connections on request

Stainless steel 1.4571 (316Ti); other materials or coatings on request

Stainless steel, display cover plastic

• from stem length (EL) 50mm: ø6 x 0.75mm (up to 40 bar)

• from EL 50mm: ø8 x 1.75mm (up to 100 bar)

• from EL 50mm: Special parts made of solid material (up to 500 bar)

Fast response time version (up to 12 bar)

• EL 25mm: ø3 x 0.25mm without taper

• EL up to 100mm: ø6 x 0.25mm with taper to ø3 x 0.25mm

• from EL 100mm: ø8 x 1.75mm with taper to ø6 x 0.25mm with taper

to ø3 x 0.25mm

1 switching output PNP and analog output 4…20mA

9

Page 11

Switching outputs

A

V

.022

7U

R

Supply

−

=

• Switching function

• Switching rating

• Adjustment

- Set Point

- Reset point

Analog output

Signal

adjustable normally closed (NC) or normally open (NO) contact

100mA per switching output

Programmable via the display

0.1° steps withhin temperature range

0.1° steps from beginning temperature range until max. set point –0.1°

4…20mA; 2-wire, programmable in 0.1° steps,

span at least 20% of the temperature range

Load resistance

Dependent on the supply voltage; the relevant formula is

Display 4-digit 7-segment LED display, red, 7.6mm high

Accuracy Switching output, analog output and Display:

Accuracy of PT100 + 0,1% of the temperature range

Repeatability 0.05%

Electrical connection M12 x 1 (4-Pin)

Temperature range

Storage

Ambient

Thermal Eect

EMV to IEC /

EN 61 326

-22...+176°F

-13...+158°F

0.006% of Full Scale/°F

IEC 61000/4/2 ESD: B

IEC 61000/4/3 HF: A

IEC 61000/4/4 Burst: A

IEC 61000/4/5 Surge: A

IEC 61000/4/6 HF: A

Protection class IP65 according IEC 529

Weight 0.66 lbs.

10

0

Page 12

DIMENSIONS Inches (mm)

11

Page 13

CE – Conformity

Remove the device as soon as device malfunctions start to occur. The internals cannot be

maintained by the customer. Replace the device or return it to the manufacturer to have it

tested.

The switch complies with all requirements of EN 61 326 with regard to interference emission and

immunity for use in industrial areas. NOSHOK recommends the use of shielded cables. Installation

and cable routing must be carried out correctly in order to maintain the eective protection from

electromagnetic interference.

Maintenance

The temperature switches that are described in this document are maintenance free. The equipment will also operate in a stable state for long periods, meaning that regular adjustment or the

like is not required.

12

Page 14

Cleaning

The exterior of the 850 Series Temperature Switch can be cleaned using a soft, moistened cloth. Heavy

soiling can be removed using a mild cleaning agent.

The switch must not be opened for cleaning!

Aggressive chemicals or hard scrubbing can damage the surface, particularly the display lm.

Disposal

The packaging and used parts must be disposed of in accordance with the regulations of the

country in which the device is installed.

13

Page 15

Notes:

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

14

Page 16

CORPORATE HEADQUARTERS

1010 West Bagley Road • Berea,Ohio 44017 • 440-243-0888 • FAX 440-243-3472

E-MAIL:noshok@noshok.com • WEB: www.noshok.com.

NETS07

Loading...

Loading...