Page 1

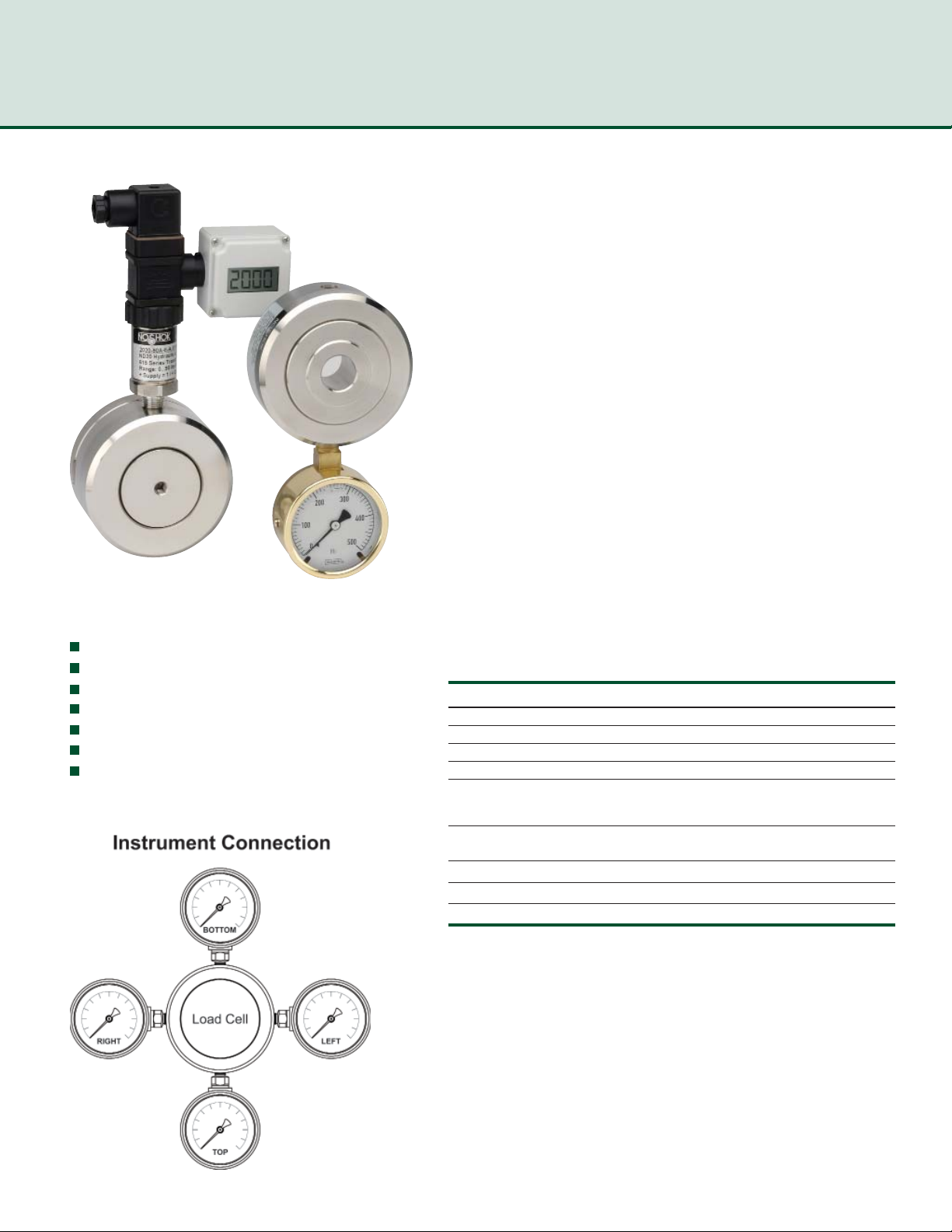

Mechanical Force Measurement

2000

20 cm2 Nominal Diameter Hydraulic Load Cell

2000 SERIES

•

Designed for measuring axial loads and bearing forces

•

Standard or ring design fi ts most applications

•

Ranges from 90 lbf to 22,000 lb

•

Accuracy levels range from ±0.125% full scale (BFSL) to ±1.5% full scale, depending

on the measuring instrument

•

Durable stainless steel housing and piston provide exceptional corrosion resistance

and durability

•

A high quality NOSHOK 300 or 901 Series pressure gauge or 100, 200 or 615 Series

transducer is directly mounted to the load cell for precise measurement indication

•

Operates without an external power supply when using a pressure gauge for indication

•

Provides an extremely high degree of accuracy because the load cell is vacuum fi lled

and sealed, eliminating the error that can be caused by entrapped air

•

Steel jacketed fl exible tubing and capillary systems are offered to accommodate

applications that require remote mounting of the gauge or transducer

•

An optional liquid fi lled gauge dampens the effects of pulsation, vibration and

shock,and lubricates the gauge internals for extended service life

•

Various output signals available in transducer models that are CE compliant

f

APPLICATIONS

Turning and drilling machines

Extruders

Measuring and test equipment

Production lines

Overload protection

Vices

Control systems and machine tools

SPECIFICATIONS

Nominal diameter ND 20

Load cell housing Stainless steel

Piston 20 cm

Max piston stroke 0.02" (0.5 mm)

Connecting type Direct (standard)

Gauge fi ll fl uid

Load cell fi ll Silicone

Operating temperature -4 °F to 140 °F (-20 °C to 60 °C)

Ambient temperature -4 °F to 140 °F (-20 °C to 60 °C)

2

stainless steel

Flexible tubing with spiral steel jacket - optional (max. length 2 m)

Capillary restrictor (optional)

Glycerin

Others available upon request

8

Page 2

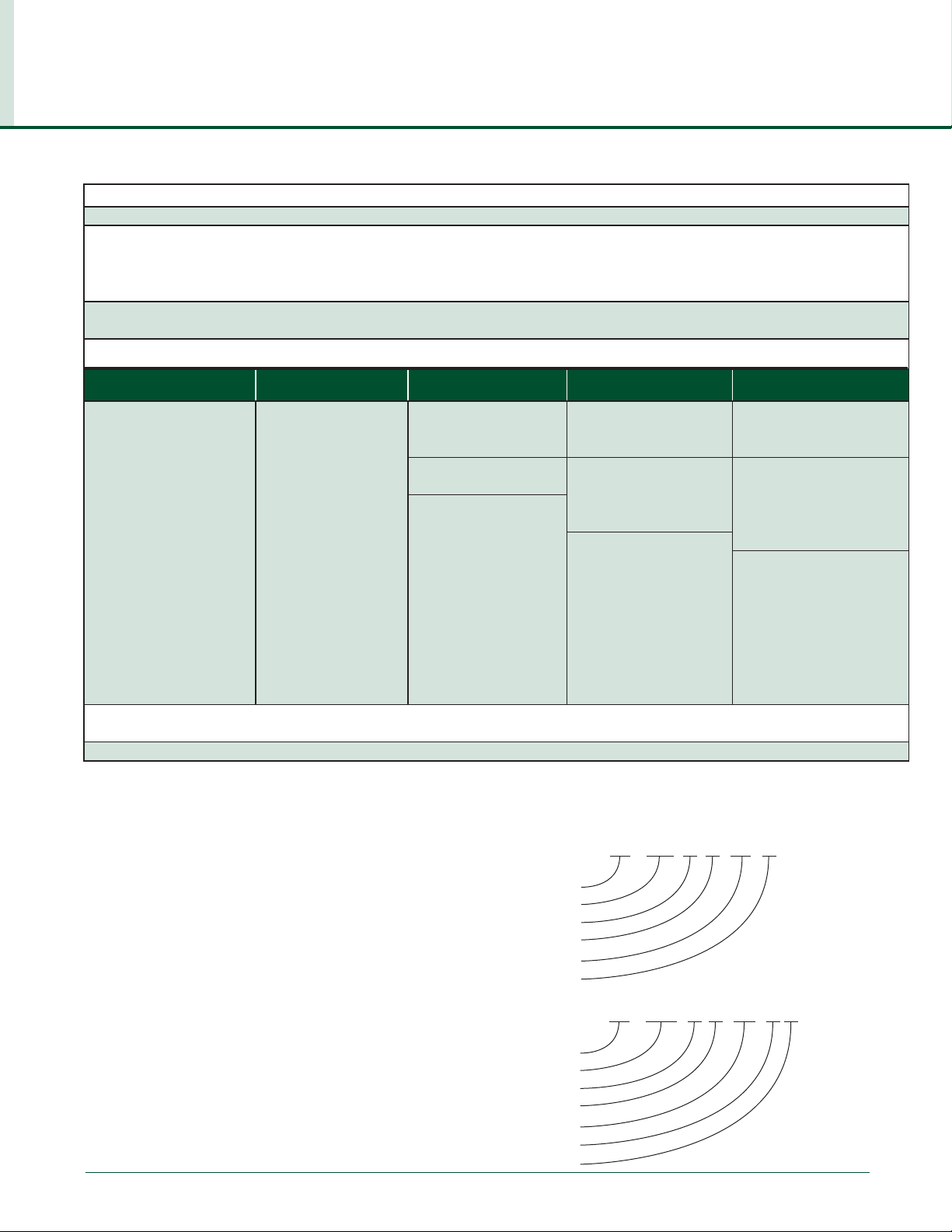

ORDERING

2000

SERIES

INFORMATION

ORDERING INFORMATION

LOAD CELLS 2020 ND 20 - Compression - standard design 2120 ND 20 - Compression or tension - ring design

MEASURING RANGES

90A 90 lb

300A 300 lb

600A 600 lb

Other ranges available, please consult factory.

f

f

f

900A 900 lb

1200A 1,200 lb

1800A 1,800 lb

f

f

f

2500A 2,500 lb

3000A 3,000 lb

4500A 4,500 lb

f

f

f

9000A 9,000 lb

15000A 15,000 lb

22000A 22,000 lbf*

INSTRUMENTS 1 25-300 Series gauge 6 100 Series transmitter 8 615 Series transducer

4 40-901 Series gauge 7 200 Series transducer

INSTRUMENT CONNECTIONS** A Bottom C Right side E None***

B To p D Left side

25-300 SERIES GAUGE

OPTIONS

40-901 SERIES GAUGE

OPTIONS

100 SERIES TRANSMITTER

OPTIONS

200 SERIES TRANSDUCER

OPTIONS

615 SERIES TRANSDUCER

OPTIONS

0 No options 0 No options Accuracy Accur a cy Accuracy

1 Dry gauge 1 Dry gauge 1 0.50% 1 0.50% 1 0.25%

2 Max. indicating pointer 2 Max. indicating pointer 2 0.25% 2 0.25% 2 0.125%

3 Set pointer 3 Set pointer Output Output Output

4 Rubber case protector 4 Rubber case protector 1 4 mA to 20 mA 2 0 Vdc to 5 Vdc 1 4 mA to 20 mA

5 Glass overlay 6 Safety glass Electrical Connection 3 1 Vdc to 5 Vdc 2 0 Vdc to 5 Vdc

6 Safety glass overlay 7 Adjustable pointer 1 Option 7 with 36" cable 5 0 Vdc to 10 Vdc 3 1 Vdc to 5 Vdc

8 SS rear flange 3 6-pin Bendix Electrical Connection 5 0 Vdc to 10 Vdc

9 Spacer plate 6 1/2" NPT conduit w/

36" cable

1 Option 7 with 36" cable

Electrical Connection

7 Mini-Hirschmann 3 6-pin Bendix 1 Option 8 with 36" cable

25

M12 x 1 (4-pin)

6 1/2" NPT conduit w/

36" cable

3 6-pin Bendix

7 Mini-Hirschmann 6 1/2" NPT conduit w/

36" cable

25 M12 x 1 (4-pin) 8 Hirschmann

25 M12 x 1 (4-pin)

CONNECTING TYPES 0 Direct 2 100 mm SS spacer

1 50 mm SS spacer 3 Capillary w/ spiral protective sleeve

CAPILLARY LENGTH

## Specify in feet (for options 3 and 4)

Please consult your local NOSHOK Distributor or NOSHOK, Inc. for availability and delivery information.

* For 2120 only.

** Refer to Instrument Connection diagram on previous page.

*** Not required for transmitters, switches, or any instrument other than a dial indicating gauge.

f

f

Note: Separate multiple

options with forward

slash “/”

EXAMPLE - With Pressure Gauge

Load cell .....................................................................2000 Series

Measuring range .........................................................................

Instrument .............................................................40-901 Series gauge

Instrument connection ................................................. Top connection

Options .................................Dry gauge, set pointer, adjustable pointer

Connecting type ............................................................................Direct

EXAMPLE - With Pressure Transducer

Load cell .....................................................................2000 Series

Measuring range .......................................................................

Instrument ........................................................... 615 Series transducer

Instrument connection ............................................Bottom c onnection

Options ...........0.125% accuracy, 1 Vdc to 5 Vdc, 1/2” NPT w/36” cable

Connecting type .............................Capillary w/spiral protective sleeve

Capillary length ....................................................................................

ND 20

1,200 lb

ND 20

15,000 lb

2020 – 1200A – 4 – B – 1/3/7 – 0

f

2120 – 15000A – 8 – A – 2/3/6 – 3 – 5

f

5′

9

Page 3

Mechanical Force Measurement

Dimensions

With 25-300 Series Pressure Gauge

(2) M10 x 1.5 10 mm

180° apart oriented 90°

from instrument connection

1.50″

(38 mm)

.10 ″

(3 mm)

Ø 2.00″

2″

(50 mm)

50 mm

Ø 2.40″ (61 mm)

Ø 3.54″

(90 mm)

M8 x 1.25

6.50

(165 mm)

Ø 2.50″

(63 mm)

With 100/200 Series Pressure Transducer

(2) M10 x 1.5 10 mm

180° apart oriented 90°

from instrument connection

10

1.50″

(38 mm)

.10 ″

(3 mm)

Ø 2.00″

2″

(50 mm)

50 mm

Ø 2.40″ (61 mm)

Ø 3.54″

(90 mm)

M8 x 1.25

7. 30 ″

(185 mm)

.70″

(17 mm)

Ø 1.06 ″

(27 mm)

Page 4

2000

Ring Design With 25-300 Series Pressure Gauge

Ø 2.36″ (60 mm)

SERIES

DIMENSIONS

(3) M5 x 1 6

120° apart oriented 60°

from instrument connection

1.50″

(38 mm)

.12 ″

(3 mm)

Ø 1.42″ (36 mm)

Ø.79″ (20 mm)

Ø 2.76″ (70 mm)

3.54″

(90 mm)

6.50″

(165 mm)

Ring Design With 100/200 Series Pressure Transducer

Ø 2.36″ (60 mm)

Ø 2.50″

(63 mm)

(38 mm)

(3) M5 x 1 6

120° apart oriented 60°

from instrument connection

1.5″

.12 ″

(3 mm)

Ø 1.42″ (36 mm)

Ø.79″ (20 mm)

Ø 2.76″ (70 mm)

3.54″

(90 mm)

7. 28 ″

(185 mm)

Ø 1.06″

(27 mm)

11

Loading...

Loading...