Page 1

Gauge Inspection:

Please read the pr

gauge body to insure that this gauge is the same gauge

size, materials of construction, working pressure, di erential

pressure, etc. Inspect for any damage and, if discovered,

report it immediately.

Product Design Features:

The NOSHOK 1300 Series is designed for working pressures to

600 psig and di

erential pressure to 600 psid. This series is

supplied, standard, with a 6” dial or, optionally, with a 4.5”

dial. The gauge has a 316L sensor cell, encapsulating opposed, high (+) and low (-) side SS membranes in a Halocar-

ressure works against the

movement is transferred to a torque-tube assembly, linked to

a horizontally moving, bidirectional overpressure valve (This

valve protects the sensor membranes against damage from

high (+) or low (-) side overpressure of the membranes in the

sensor cell.) A torsion rod, located within the torque-tube

assembly, passes through a sealed compr

(which isolates the sensor cell from the dial case assembly)

into the dial case and is connected to the pinion/sector gear

and pointer assembly. The twisting motion of the torsion rod,

The NOSHOK 1300 Series gauge is supplied, standard, with

four (4) threaded studs and locking nuts. The gauge is

mounted in the panel from front to back and secured to the

back of the panel with the threaded studs and locking nuts.

Optional 2” pipe mount kit or wall mount kits are available

(for units with top/bottom mount connections only)..

Gauge Connections:

Standard dual (2) x 1/4” FNPT top/bottom connections with

high (+) and low (-) connections clearly indicated. Optional

connection sizes and/or back connections are available

Troubleshooting:

If the gauge is not indicating di

erential pressure, check to

insure that both the high (+) and low (-) connections have

been properly installed. Check to insure that there is differential pressure across the device being monitored by

the NOSHOK 1300 Series gauge. If the gauge is being used

together with a three-valve manifold (recommended), check

to insure that the high (+) and low (-) valves are in the open

position and the equalizer valve is in the closed position. If,

after following these steps with no positive result, please

contact the NOSHOK Customer Service Department or your

nearest NOSHOK Distributor.

Degree, linear arc and pointer travel.

Gauge Mounting:

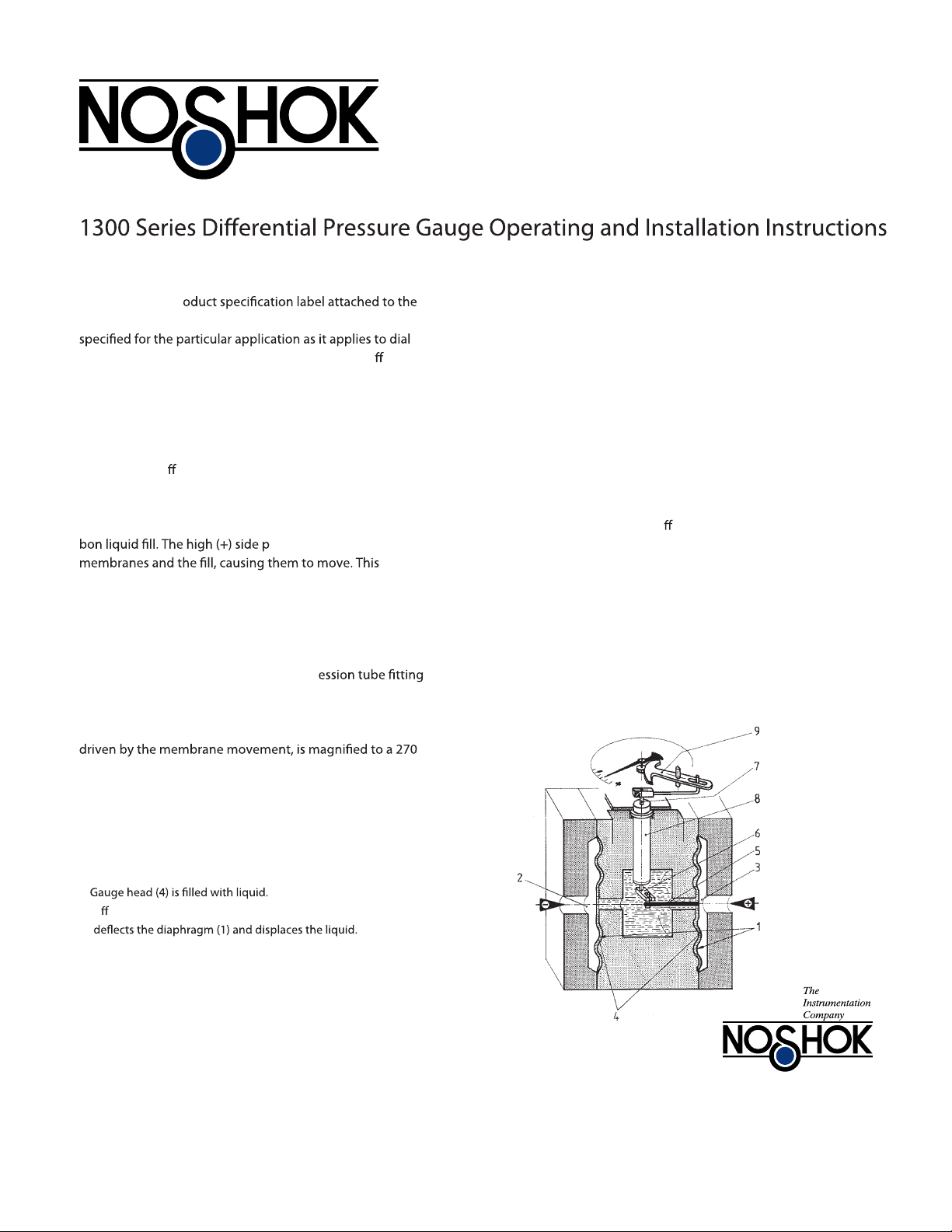

Design and Operating Principle

• Process pressures p1 and p2 are applied to the chambers

- (2) and + (3).

•

• Di erential pressure across + and - pressure sides

• The displacement of the connection rod (5) is converted

through the use of a transmitting lever (6) into rotation,

which is transferred over an axial shaft (7) to the move-

ment (9).

• The torque pipe (8) seals, assuring a frictionless path.

• Overpressure protection in both directions up to the max.

static pressure rating is provided by contoured metal

bolsters.

1300DFGTM-09

INCORPORATED

Corporate Headquarters

1010 West Bagley Road

Berea, Ohio 44017

Ph: 440.243.0888

Fax: 440.243.3472

E-mail: noshok@noshok.com

Web: www.noshok.com

Loading...

Loading...