Page 1

Gauge Inspection:

Please read the pr

the gauge body to insure that this gauge is the same gauge

size, materials of construction, working pressure, di erential pressure, etc. Inspect for any shipping damage and, if

discovered, report it immediately

Product Design Features:

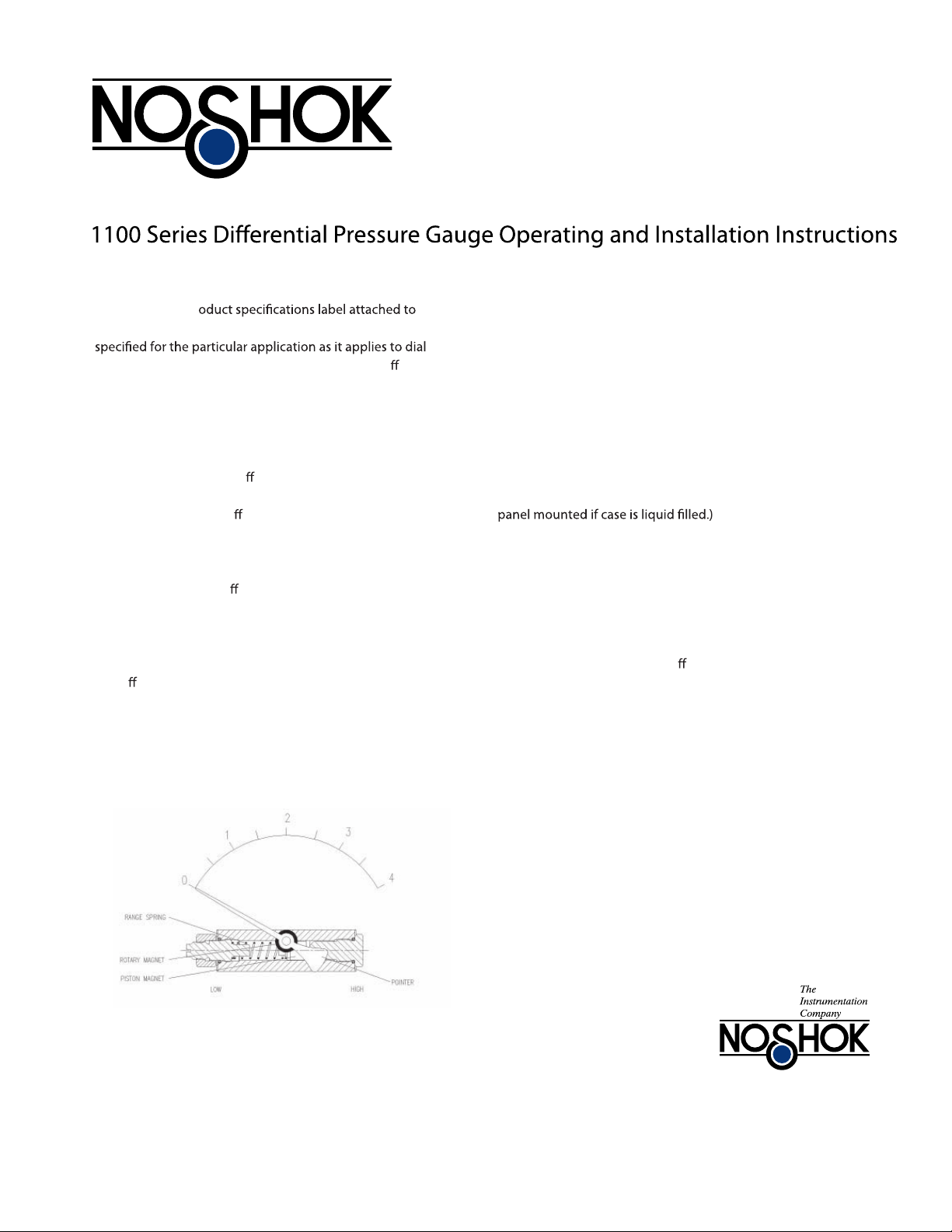

The NOSHOK 1100 Series is a magnetically coupled,

convoluted diaphragm, di

erential pressure gauge. It is

designed for use where particulate matter, carried in the

system media, will not a

ect gauge performance, because

there are no close internal tolerances in the sensor cell and

there is total separation between the high (+) and low (-)

sides of the gauge. Designed for working pressures to 3,000

PSIG and low to high di

erential pressure from 0-50” H2O

to 0-100 PSID. The high side (+) pressure works against the

diaphragm assembly and the calibrated DP range spring. A

follower magnet, attached to the pointer, tracks the linear

movement of this assembly. The pointer, in turn, indicates

the di

erential pressure. The convoluted diaphragm is fully

supported, in either direction, to the rated working pressure

of the gauge.

Measuring system diagram

Gauge Mounting:

This gauge is supplied, standard, for panel mounting. If installing the 2.5” dial gauge, remove the four (4) bezel screws,

mount the gauge from front to back in the panel, then

reinsert the four (4) screws through the panel and into the

bezel and tighten securely to the panel (Do not over-torque).

If installing the 4.5” dial gauge, mount the four (4) threaded

studs into the back of the dial case, where indicated (Do

not over-torque). Mount the gauge from front to back in the

panel and secure the gauge to the panel with the locking

nuts on the threaded studs. Optional pipe mount kits or wall

mount kits are available. (Note: 2 1/2” gauge cannot be

Gauge Connections:

Standard (2) x ¼” FNPT back connections. Optional connection sizes and top, bottom or dual top/bottom connection is

available

Troubleshooting:

If the gauge is not indicating di

erential pressure, check to

insure both the high (+) and low (-) side connections have

been properly installed. Check to insure that there is pressure to the high (+) side of the gauge and that there is differential pressure across the device being monitored by the

NOSHOK 1100 Series. If the system is being used together with

a three-valve manifold, check to insure that the high (+) and

low (-) valves are in the open position and the equalizer valve

is in the closed position. If, after following these steps with

no positive result, please contact the NOSHOK Customer Service

Department or your nearest NOSHOK Distributor.

1100DFGTM-09

INCORPORATED

Corporate Headquarters

1010 West Bagley Road

Berea, Ohio 44017

Ph: 440.243.0888

Fax: 440.243.3472

E-mail: noshok@noshok.com

Web: www.noshok.com

Loading...

Loading...