Page 1

1000 Series

Piston Type Dierential Pressure Gauges

Electrical Installation and Operating Instructions

1. Safety

Before installing, check the Series Number and verify

compatibility to the process media and temperature in

contact with the wetted parts. Incompatible media and /

or operation at temperature extremes can cause

premature degradation of materials which could result in

safety risk to personnel.

Verify the selected pressure range (dierential pressure and working

pressure) and the switch ratings are within specication for your

application.

Perform all electrical adjustments with power removed.

The 1000 Series Dierential Pressure Gauge utilizes a piston design which inherently has a small amount of

leakage from high process connection to low process (15 SCFH air max at 100 PSID) connection. Do not use

this product in an application with the low side process connection left open to atmosphere.

This product utilizes a magnet as part of the sensing element. Magnet particles in the process, can cause the

piston to stick or become wedged in the bore.

Warning!

Remaining media may result in a risk to personnel, environment etc. Use sucient

precautionary measures when removing and transporting the product.

1.1 Intended use

The indicating / non-indicating dierential pressure switches are used for monitoring dierential pressures in

industrial applications.

The manufacturer shall not be liable for any claims if the product is used in applications contrary to the

intended use.

1.2 Personnel

Personnel installing and putting this instrumentation into service shall be suitably trained and qualied in accordance with local codes, practices and regulations.

1.3 Labeling / Marking

The following Electrical Congurations bear this mark and comply with the relevant European

Directives identied on the declaration of conformity: All NOSHOK 1000 Series Dierential Pressure

Gauges with single and dual switching (Switch options 1-6 in ordering information).

NOSHOK, Inc. I 1010 West Bagley Road, Berea, OH 44017 I Ph: 440-243-0888 I Fax 440-243-3472 I www.noshok.com

Page 2

NOSHOK 1000 Series Piston Type Dierential Pressure Gauges

Electrical Installation and Operating Instructions

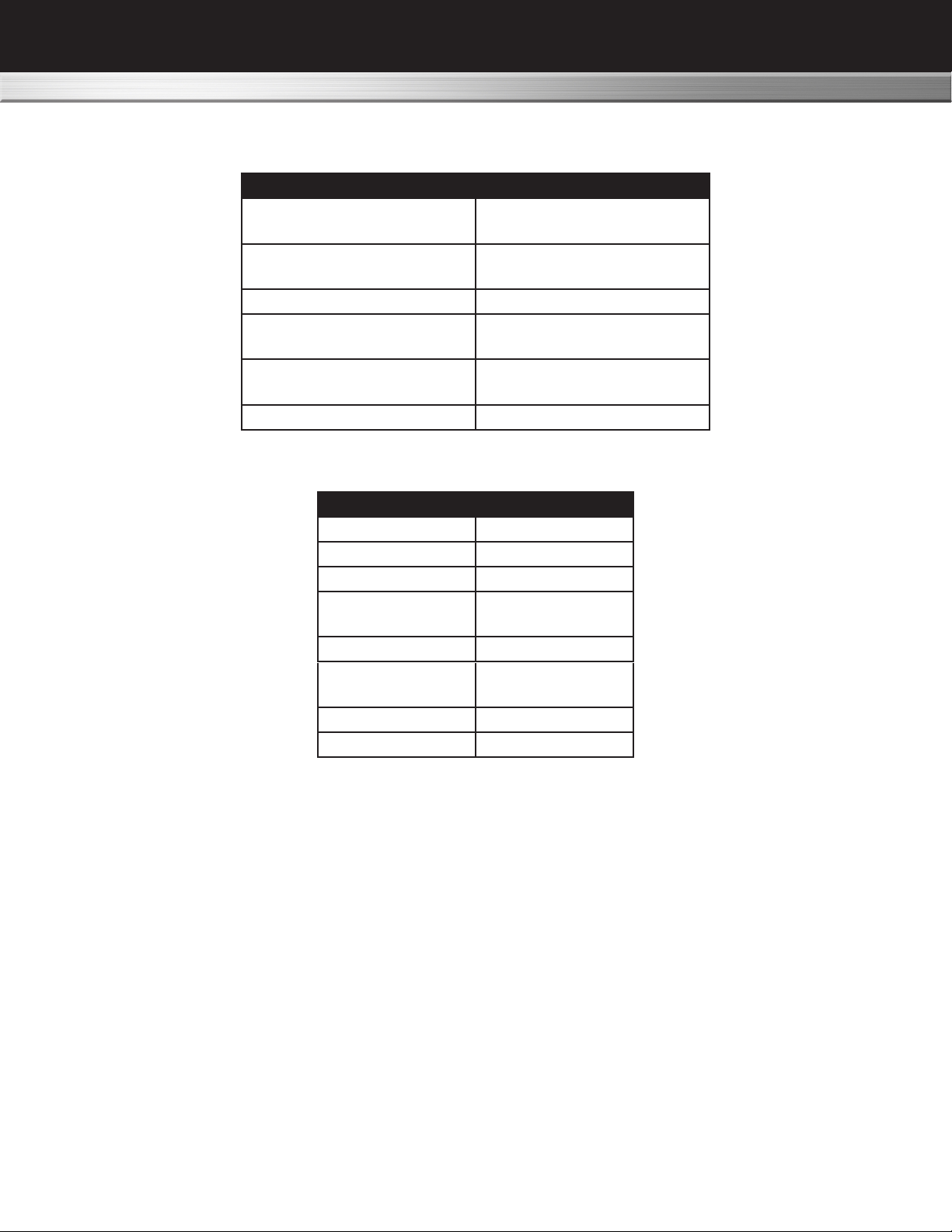

2.0 General Specications

Working Pressure(PSI)

Proof Pressure(PSI)

Dierential Pressure

Indicator Accuracy

Parameter Limits

3000 (AL)

6000 (SS)

12,000 (AL)

20,000(SS)

Temperature -40 °F to 200 °F

Range (PSID)

ASME B40.100

DP Over-Range +/- Proof pressure

0-5 to 0 to 110

2%

Switch Specication

Parameter SPDT

*Power 3W

Max. Current 0.25 Amps

Max. Voltage

VAC/VDC

**Setting ( %F.S.) 10 to 90

Hysterisis

(Max/Nom)

Repeatability 1% F.S.

**Leads 22 Awg. (3), 24”

* Product of the switching voltage and current shall not exceed the power rating of the device.

** Except where otherwise noted

3.0 Product Description

Dierential pressure is sensed by the movement of a oating piston magnet against a calibrated spring. The

magnetically coupled gauge pointer located outside the pressure housing follows the movement of the piston

magnet and indicates dierential pressure on the dial. The switches are also magnetically operated and are

located outside of the pressure housing. The switches are mechanically adjustable allowing the customer to

set the switch within a dened adjustment span of the range of the instrument.

125

10% / 5% F.S.

This instrument is mainly intended for gas / air / oil applications.

NOSHOK, Inc. I 1010 West Bagley Road, Berea, OH 44017 I Ph: 440-243-0888 I Fax 440-243-3472 I www.noshok.com

Page 3

NOSHOK 1000 Series Piston Type Dierential Pressure Gauges

Electrical Installation and Operating Instructions

4.0 Installation

Mechanical Connections

¼” FNPT are provided standard, however check your paperwork to conrm the connections ordered. There

are 2 connections identied on the gauge body as “Hi” and “Lo” for High pressure and Low pressure respectively. Be sure these are plumbed properly in your system. Improper connection will not damage the instrument, but it will not function properly.

Do not allow gauge ttings to rotate when making process connections. Calibration and / or

pressure rating of the product may be compromised.

For end connected or gauges supplied with adapter ttings use two wrenches when making connections. Use

one wrench to hold the pressure port tting on the gauge and the other to tighten the process pipe of tube tting.

Instrument Location

On liquid service the instrument should be mounted below the process connections to facilitate self-bleeding.

On gas service it should be located above the process connections to promote self-draining. If the process

contains particulates, a pigtail loop or drop leg (manometer “U-tube” conguration) in the tubing will minimize

the possibility of it migrating into the instrument.

Temperature Limitations

For process temperatures higher than the rated temperature of the DP gauge / switch, use process tubing to

reduce the temperature. A general “ rule of thumb” is that for horizontal tubing runs the temp drop is 100° F/ ft.

Another option is to use “cooling towers” to protect the instrument.

Verify the selected elastomer option is appropriate for your operating temperature.

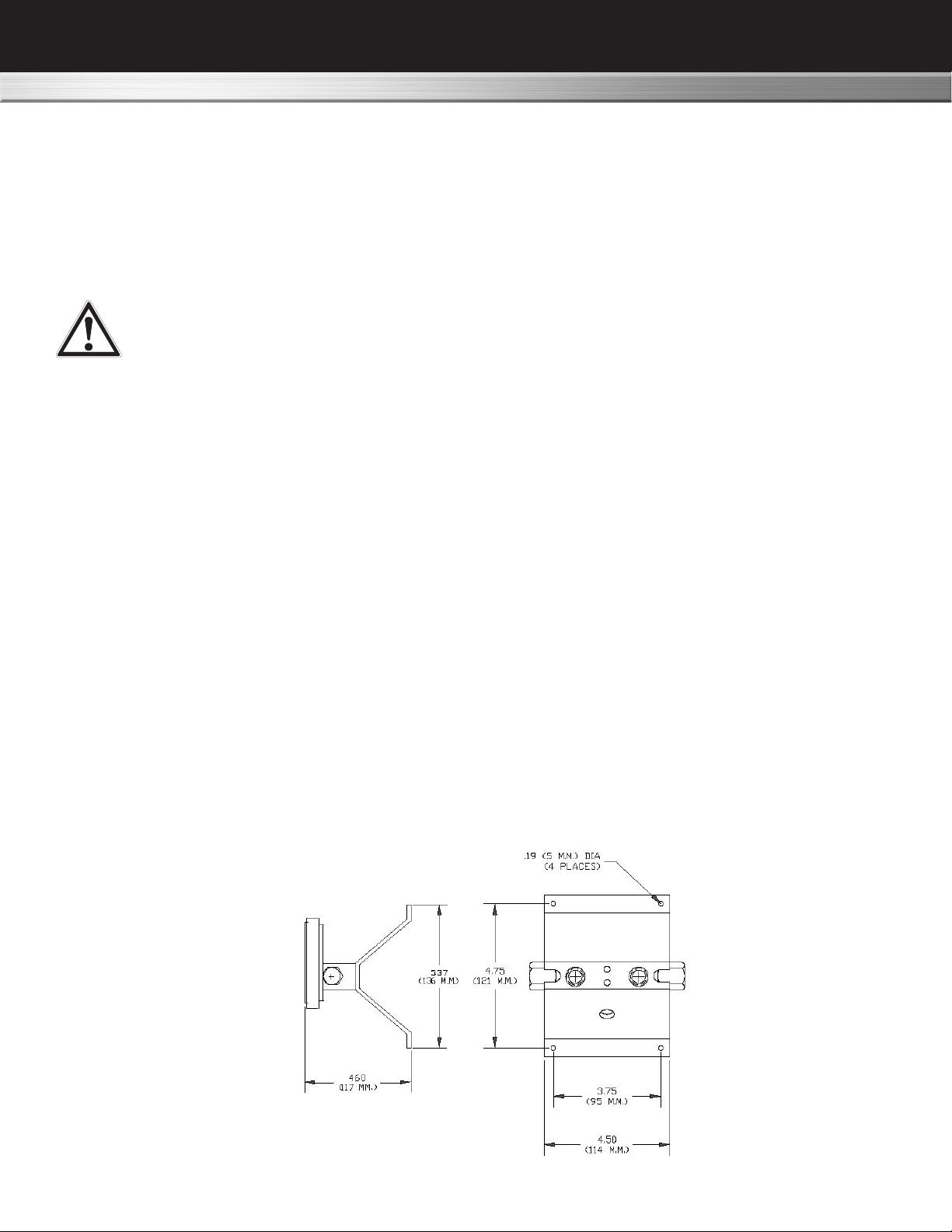

Wall / Pipe/ Panel Mounting

Not all combination of options can be wall, pipe, or panel mounted. If your unit is supplied with a wall or panel

mount, possible congurations are shown below:

Wall Mount Congurations:

NOSHOK, Inc. I 1010 West Bagley Road, Berea, OH 44017 I Ph: 440-243-0888 I Fax 440-243-3472 I www.noshok.com

Page 4

NOSHOK 1000 Series Piston Type Dierential Pressure Gauges

Electrical Installation and Operating Instructions

Wall Mount Congurations (cont'd)

Typical 2nd Pipe Mounting

Pipe mounting brackets are not available for Electrical Congurations Options 3 & 4 with back port

connections.

Panel Mount

Gauges with 2 ½” dials can only be mounted through the rear of the panel. Make the proper panel cutout as

shown below. Remove the (4) bezel screws and insert the gauge front through the rear of the panel. Reinstall

the bezel screws through the front of the panel and into the gauge bezel. Tighten screws securely in an alternating diagonal pattern.

Gauges with 3 ½” dials should be mounted from the front of the panel. Contact the factory for mounting and

dimensional information.

Gauges with 4 ½” dials should be mounted from the front of the panel. Make the cutout as indicted below.

Insert the (4) panel studs, nger tight, into the metal inserts located in the rear of the bezel. Insert the gauge

through the panel, aligning the panel mounting studs with the holes in the panel. Install the (4) 8-32 nuts onto

the studs and tighten securely.

NOSHOK, Inc. I 1010 West Bagley Road, Berea, OH 44017 I Ph: 440-243-0888 I Fax 440-243-3472 I www.noshok.com

Page 5

NOSHOK 1000 Series Piston Type Dierential Pressure Gauges

Electrical Installation and Operating Instructions

Electrical

Warning: Electrical connections should be performed by qualied personnel and meet the

representative country's national electrical code.

Warning: Failure to connect to the protective conductor terminal may result in a shock

hazard.

Warning: Perform all switch adjustments with power removed. Use an ohmmeter or

equivalent to monitor contact operation.

Caution: Preference should be given to setting the switch prior to installation. It is also

recommended to perform adjustments using a non-magnetic screwdriver.

General

All switch types are eld adjustable. The dened range of the adjustment is specied in the table above.

All switches come with a decal to identify adjustment direction to increase the set point.

NOSHOK, Inc. I 1010 West Bagley Road, Berea, OH 44017 I Ph: 440-243-0888 I Fax 440-243-3472 I www.noshok.com

Page 6

NOSHOK 1000 Series Piston Type Dierential Pressure Gauges

Electrical Installation and Operating Instructions

Switch Set Point Adjustment

Do not use excessive force when rotating the adjustment screw as the adjustment

mechanism may be damaged. Also note the location of the screw adjust (See Figure 4.)

Do not mistake it for the calibration adjust for the gauge.

Note: Switches can be set below the dened minimum set point however, the switch may

not remain activated at maximum PSID. If the unit is set below the dened minimum set

point, the customer should verify that the switch remains activated from the set point to over

range of the gauge.

The switch may be set using the indicating dial as a

reference (units with a dial) or by using a reference

pressure gauge.

For setting on increasing pressure increase your

pressure to the desired set point. Increase the switch

set point above the desired switch set (switch

deactivated). Slowly decrease the switch set point

until the contact activates.

Switch Adjust

Contact Protection

Provide standard protection techniques for the switch contacts for capacitive and inductive loads. Use

current limiting techniques near the switch to protect the contacts due to high inrush (i.e.; in line resistor or

inductor) for long cable interfaces. Provide clamping devices at or near inductive loads (i.e.; relay).

Maximum wire length between the 3W switch and its load should not exceed 70 – 100 Feet

for 120 VAC applications. We recommend that you use the 60W rated switches or use a

current limiting resistor wired in series and located near the switch. Contact the factory

for assistance regarding this condition. (For hazardous Locations the resistor option is

not allowed)

Figure 4

Electrical Congurations - Options 1, 2, 3 & 4

Electrical congurations Options 1 & 2, are recommended to

be used in Pollution degree 2 type environments or in large

enclosures / panels where connections to the “ying lead”

wiring can be protected.

Electrical Congurations Options 3 & 4 can be used in Pollution degree 3 Industrial type areas.

Note: Congurations Options 3 & 4 have electrical access holes (1/4” NPT and ½” NPT). The safety

evaluation and the NEMA ratings for these congurations was performed with these accesses sealed

(ie; conduit connections).

NOSHOK, Inc. I 1010 West Bagley Road, Berea, OH 44017 I Ph: 440-243-0888 I Fax 440-243-3472 I www.noshok.com

Page 7

NOSHOK 1000 Series Piston Type Dierential Pressure Gauges

Electrical Installation and Operating Instructions

Connections: (Electrical Congurations Options 1, 2, 3 & 4)

The SPDT switch (Electrical Option 1) lead colors and associated functionality at '0' PSID is shown in

Figure 1. Wires will be labeled identifying their functionality.

Standard location of the SPDT switch (Electrical Specication Option 1) will be on the bottom of the gauge for

a standard port (Hi port on the right) and on the top for a reverse port (Hi on the left).

A standard port gauge has the normally open switch located on the bottom of the gauge body and the

normally closed switch located on the top. This applies to both a single switch unit or a double switch unit

with one of each type. Note: Bottom port assemblies will have the switch always on top.

A reverse port gauge has the normally open switch located on the top and the normally closed switch located

on the bottom.

Electrical Congurations Options 5 & 6 (DIN Plug- in Connector)

Electrical Congurations Options 5 & 6 can be used in Pollution degree 3 Industrial type areas.

The DIN interface conforms to DIN 43650A / ISO 4400 and when mated provides an

IP65 rated protection class. The cable gland seal will accommodate an outer diameter

of 6mm (.24") to 11.5mm (.45"). The right angle mating connector is supplied with the

gauge upon order. Clocking (orientation) can be changed by prying out the insert and

rotating the insert to the desired clocking (90 º increments). (See Figure 4). Single switch

assemblies will have the switch located on the bottom of the gauge except for bottom

ports.

Wiring for the SPDT bottom and top switch for the dened port conguration is as follows:

(switches shown at 0 PSID)

NOSHOK, Inc. I 1010 West Bagley Road, Berea, OH 44017 I Ph: 440-243-0888 I Fax 440-243-3472 I www.noshok.com

Page 8

NOSHOK 1000 Series Piston Type Dierential Pressure Gauges

Electrical Installation and Operating Instructions

6.0 Troubleshooting

A. Gauge accuracy and set point problems

i. Verify your process connections are plumbed properly

ii. Verify gauge is not in an electromagnetic / magnetic environment. i.e.; close proximity to high current

power lines.

iii. Verify the pointer has uid movement as pressure increases. Jumpy movement or no movement may

indicate a stuck piston

iv. All others contact the factory for assistance.

B. Switch doesn't function

i. Make sure that the switch load does not exceed the specied wattage rating of the switch. (steady-state

and transient). Contact factory for assistance for excessive loads, otherwise proceed to the next step.

ii. Perform a continuity check of the switch contacts by trying to actuate the switch using an external

magnet. An operational switch usually indicates a problem with the gauge. If not operational proceed

to the next step.

iii.Verify the reed switch wires are connected to the terminal strip (NEMA 4X enclosure only). Contact

the factory for assistance if the switch is connected and/or request an "RGA" number.

NOSHOK, Inc. I 1010 West Bagley Road, Berea, OH 44017 I Ph: 440-243-0888 I Fax 440-243-3472 I www.noshok.com

Page 9

NOSHOK 1000 Series Piston Type Dierential Pressure Gauges

Electrical Installation and Operating Instructions

7.0 Miscellaneous

CE Marking Statements

Low Voltage Directive

The Electrical Congurations 1, 2, 3, 4, 5 & 6 of this product are CE marked in compliance with the Low Voltage Directive to EN-61010-1.

Warning: The suitability of the application and installation of this dierential pressure switch

/ transmitter is the responsibility of the end user. The applicable certications, listings apply

to the dierential pressure switch / transmitter only.

STANDARDS: All 1000 Series Dierential Pressure Gauges either conform to and/or are designed to the

requirements of the following standards:

ASME B1.20.1 NACE MR0175

ASME B40.1 NEMA Std. 250

EN-61010-1

NOSHOK, Inc. I 1010 West Bagley Road, Berea, OH 44017 I Ph: 440-243-0888 I Fax 440-243-3472 I www.noshok.com NK181000DPGOI

Loading...

Loading...