Norton Abrasives Cut-Off Wheels User Manual

www.nortonabrasives.com

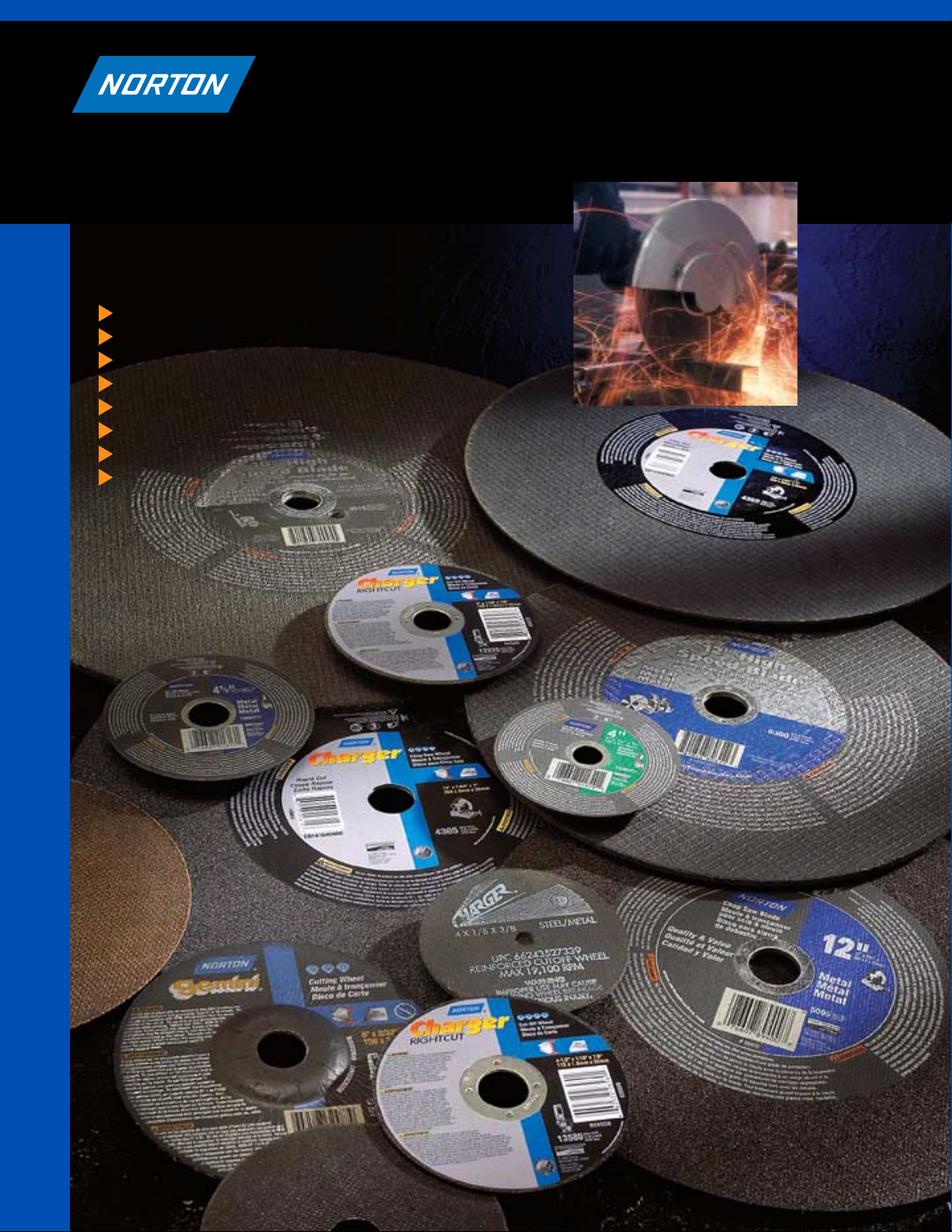

The Choice for Every Metal Fabrication and

Light Construction Cut-Off Application:

Portable Grinder

Right Angle Grinder

Circular Saw

High-Speed Gas/Electric Saw

High-Speed Walk-Behind Road Saw

Stationary Machine

Rail Cut

Chop Saw

The Choice for Every Metal Fabrication and

Light Construction Cut-Off Application:

Portable Grinder

Right Angle Grinder

Circular Saw

High-Speed Gas/Electric Saw

High-Speed Walk-Behind Road Saw

Stationary Machine

Rail Cut

Chop Saw

NORTON ABRASIVES

CUT-OFF WHEELS FOR

METAL FABRICATION

Norton Cut-Off Wheel Line

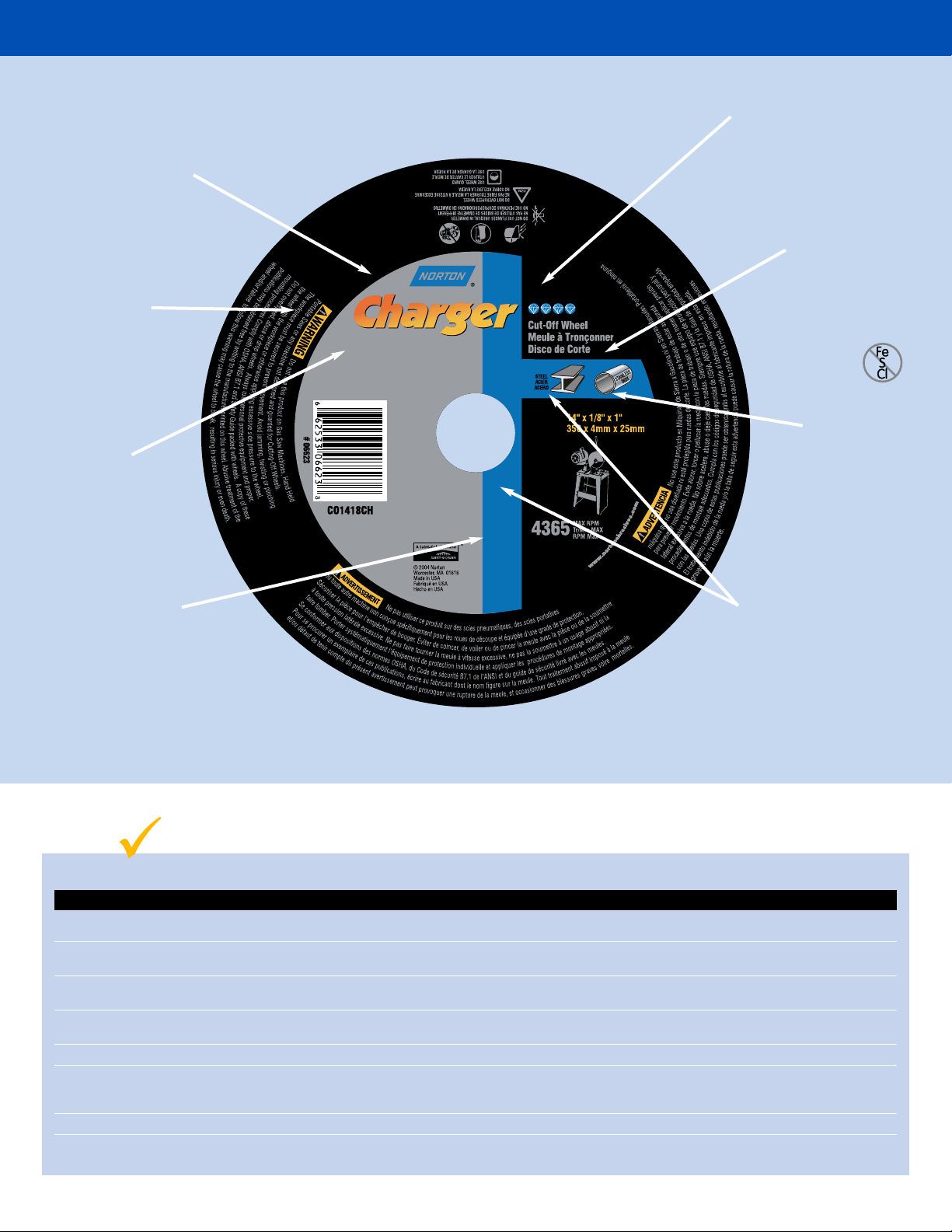

The New Norton Cut-off Wheel Blotter

All important information is in the same location on most NorZon Plus, Charger Plus, Gemini and

Norton Metal and Masonry cut-off wheels for easy application identification and self-serve shopping.

Product Identification

Always in the same place:

• Brand logo

• Product name

• Extended description

i.e. Long Life and Free Cut

Trilingual Safety

Warning

The message will change

depending on the

intended application

of each particular

grinding product.

Product Tier

Left-hand background of

blotter identifies

performance tier

• GOLD – Best

• SILVER – Better

• BLACK – Good/Economy

ANSI / UAMA Symbol

It certifies that the grinding wheels

you buy have been designed and tested

according to the American National Standards

Institute safety requirements (ANSI B7.1). UAMA

is a voluntary association of grinding wheel

manufacturers organized for the promotion of safe and

efficient grinding practices.

Wheel Specific

Information

• Size – in US and metric

• Bar code

• “Smart” part number

• Max RPM speed

• Country of origin

• Icon indicating proper

grinding angle

Application Color Coding

The horizontal and vertical colored

bars indicate the material(s) that this

product can grind or cut:

RED – steel/metal

BLUE – stainless steel

GREEN – masonry

GREY – aluminum

YELLOW – foundry-specific materials

Diamond Marking System

A quick reference to performance

– higher number of diamonds

represents better performance grains

with faster cut rate and longer life than

those with lower diamond values.

Application Icons

Show material to be cut or

ground. Also can indicate if

grinding or cutting wheel is

iron-, sulphur-, or chlorine-

free with this symbol

Cut-off Wheel Starting Recommendations by Material

SMALL RIGHT ANGLE CIRCULAR PORTABLE GAS / STATIONARY

MATERIAL ANGLE GRINDERS GRINDERS SAWS ELECTRIC SAWS WALK BEHIND SAWS SAWS CHOP SAWS

Angle/Channel Iron NorZon Plus NorZon Plus RightCut Norton Metal Norton Metal — Charger Charger Long Life

Bar/Sheet Stock Gemini Long Life Gemini RightCut Gemini Long Life Gemini Long Life

Metal Studs/Tubing — NorZon Plus RightCut Norton Metal Norton Metal — Gemini Long Life Norton Steel Stud

Gemini RightCut

Cast Iron/Pipe Gemini Free Cut NorZon Plus RightCut Norton Metal Norton Metal — Gemini Free Cut Gemini Free Cut

Gemini RightCut

Stainless/Alloys NorZon Plus NorZon Plus RightCut Norton Metal Norton Metal — Charger Charger Free Cut

Charger RightCut

Aluminum/Brass/Bronze Gemini Free Cut Gemini RightCut Norton Metal Norton Metal — Gemini Free Cut Gemini Aluminum

Concrete/Brick/Block — — Norton Masonry Norton Concrete Norton Concrete Norton Masonry Norton Masonry

Asphalt/Green Concrete Norton Asphalt Norton Asphalt/

Green Concrete

Ductile Norton Ductile —

Fiberglass/Plastic Gemini Free Cut Gemini Rightcut Norton Metal — — Gemini Free Cut Gemini Free Cut

Paint/Rust

SPEC check

2

www.nortonabrasives.com

Cut-off Wheel Competitive Cross Reference

NORTON FLEXOVIT METABO SAIT 3M WALTER

FOR SMALL ANGLE OR IN-LINE PORTABLE GRINDERS (2"- 4")

NorZon Plus — — — Green Corps —

Charger FLEXON — SAITECH — —

Gemini Free Cut A36R Slicer A24R — A60-ZIP

Gemini Long Life A46T A 60 TZ A36T — A24-ZIP

FOR RIGHT ANGLE GRINDERS (4" — 9")

NorZon Plus RightCut — — — — —

Charger RightCut — — — — —

Gemini RightCut — — SAITECH .045 — A30-ZIP

FOR CIRCULAR SAWS (6" — 8")

Norton Metal A36TB38 A 30 S — — A30-ZIP

Norton Masonry C30UB64 C 30 S — — C-30

FOR PORTABLE GAS OR ELECTRIC SAWS (12" — 16")

Norton Metal A24TB A 24 N Brute — A24 Portacut

Norton Concrete AC24SB C 24 N C24R — C24 Portacut

Norton Ductile AC24SB AC 24 R Ductile — —

Norton Asphalt C16UB C 16 N Big M.A.C. — —

FOR WALK-BEHIND CONSTRUCTION SAWS (14", 18")

Norton Asphalt/ C16UB C 16 N C16 — —

Green Concrete

Norton Hot Press HPC16AG — Street Walker — —

Asphalt/Green Concrete

FOR STATIONARY SAWS (10" — 20")

Charger Free Cut — — — — —

Charger Long Life — — — — —

Gemini Free Cut A30RB A 30 R A24N — A24-FC RIPCUT

Gemini Long Life A30SB A 30 N A24R — A24-RIP

Norton Masonry C24SB C 30 S C24R — —

FOR CHOP SAWS (10" — 16")

Charger Free Cut — — SAITECH Steel Worker — —

Charger Long Life — — — — —

Gemini Free Cut A30RB A 30 R EZ-CHOP — A30 Chopcut II

Gemini Long Life A30SB A 30 S Iron Worker — A30-HC Chopcut

Gemini Aluminum — — Aluminum — A30-ALU Chopcut

Norton Masonry C30UB — — — —

Norton Steel Stud A30TB — Stud King — —

SPEC check

Troubleshooting Guide

PROBLEM POSSIBLE CAUSES SUGGESTED CORRECTION

Poor cutting rate Insufficient power used Increase feed or pressure to full power

Wheel too hard Use softer grade, Free Cut or thinner wheel

Contact area too large Reduce contact area

Wheel too coarse Use finer grit or Free Cut wheel

Wheel side out of truth Check spindle runout

Non-square cuts Work not clamped properly Check clamp and clean to remove swarf

Misaligned spindle bearings Check for bearing truth and alignment

Poor coolant distribution Ensure equal volume of coolant to each wheel side

Wheel is too hard Use softer acting wheel: softer grade, or finer grit, or Free Cut

Workpiece burn Insufficient feed rate Work machine to maximum power available

Poor coolant flow Increase volume and direct at cutting point

Wheel is too coarse Use finer grit or Free Cut wheel or more machine power

Wheel is too hard Use softer grade, thinner, or Free Cut wheel

Wheel is running out Check spindle and flanges

Wheel speed is too slow Ensure tight flanges and observe maximum speed on wheel

Poor finish Too much burr Use finer grit, or softer grade, or Free Cut wheel

Wheel too coarse Use finer grit or Free Cut wheel

Highest Productivity, Great Performance and Value

Typical Applications

•

Cutting sheet metal

•

Cutting pipe

•

Foundry/forge shops – gate/riser removal, cutting forgings

•

Metal plate dimensioning

•

Ship building – metal fabrication

•

Toolroom – cutting drill bits, steel bar, tubing, metallurgical sectioning

•

Construction – concrete/masonry work

3

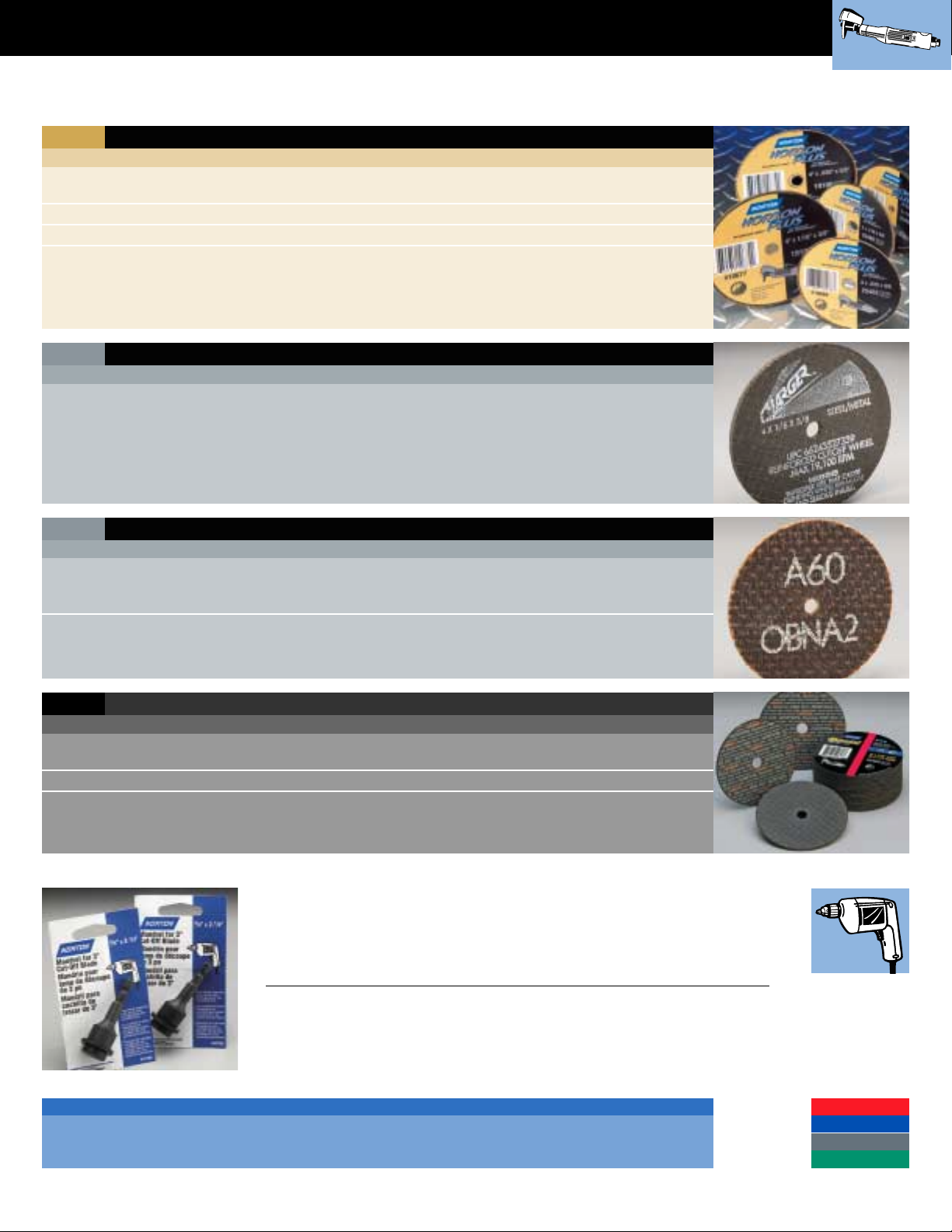

Norton Cut-Off Wheel Line

FEATURES BENEFITS

• Advanced formulation • Free cutting

• Maximizes the performance of conventional aluminum oxide abrasive

• Gemini Free Cut wheels • Engineered to cut hard materials

• Gemini Long Life wheels • Excellent life and cut rate

Gemini Reinforced Cut-off Wheels – All purpose wheels, competitively pricedGOOD

Small Diameter Reinforced Cut-off Wheels (1-1/2" – 6")

DRILL

Drill Mount Mandrel for 2" – 3" Cut-off Wheels

This mandrel is used to safely mount 2" – 3" diameter cut-off wheels with 3/8" arbor holes on

to a drill.

STD PKG SPEC. UPC NO.

5 DRILL-MOUNT MANDREL FOR 2" AND 3" 3/8" HOLE CUT-OFF WHEELS 07660747769

EXAMPLE: CO 4 18 38 G FC

WHEEL TYPE DIAMETER THICKNESS HUB/HOLE SIZE PRODUCT GROUP MODIFIER

CO = CUT-OFF 4 = 4" 18 = 1/8" 38 = 3/8" G = GEMINI FC = FREE CUT, LL = LONG LIFE

Cut-off Wheel Part Number Key

HORIZONTAL/STRAIGHT SHAFT

GRINDER

FEATURES BENEFITS

• Patented Norton SG (ceramic alumina) / NorZon • Fastest initial cut of any wheel; highest productivity

(zirconia alumina) grain combination

• Highly advanced bond system • Free, cool cut

• State-of-the-art manufacturing • Superior wheel balance

• NORZON Plus • Up to 3X life over aluminum oxide wheels on carbon steel,

stainless and cast iron

• 40% faster cut rate over standard aluminum oxide wheels

• NORZON Plus Long Life • Up to 5X life on harder metals and exotic metals

BEST NorZon Plus Reinforced Cut-off Wheels – Fastest initial cut rate

FEATURES BENEFITS

• A unique blend of premium NorZon (zirconia alumina) • 2X the life of aluminum oxide wheels

and aluminum oxide • Free cutting

•

Effectively cuts a variety of metals from alloys and stainless to gray iron

• Long life and economical performance to price ratio lower total cost

• Superior product at a value price

BETTER Charger Reinforced Cut-off Wheels – Versatile; ideal for stainless steel

FEATURES BENEFITS

ALUMINUM OXIDE — OBNA2 WHEELS

• Side reinforced, resin bond • Yield maximum cut rate and minimum kerf loss; ideal when

thin cut is desired

ALUMINUM OXIDE — B25N WHEELS

• Constructed with full diameter side reinforcing; • Versatile: durable, free cutting; offer greatest stiffness

resin bond

BETTER Small Diameter Engineered Reinforced Cut-off Wheels – Precise, thin cuts

STEEL/METAL

STAINLESS

MASONRY

ALUMINUM

4

www.nortonabrasives.com

Loading...

Loading...