Page 1

Type

U_

-4

Universal

--.

..

'1

I

. )

\

,I

ii - ..

- .

..

.. '

. . . ,

..,_

--.-

Grinding

--

Machine

/

\,

/ ~1

::3

~ -

.....

~

~

.-

=-..:::

~

f

/

------

CATALOG 231-3

Page 2

This machine

Called the

work

lengths

advantages listed

ity

to grind

size 14" diameter wheel.

is

also available

14"

Type

of

36"

and 48",

in

this catalog, plus capac-

14-15/16"

in

14"

swing.

LU-4

diameters with a full

and made in

it

has all the

12" Type U

Universal

~4

Grinding

HYDRAULIC

TABLE

TRAVERSE

Machine

GIVES

VERSATILITY

DOWN

YOU

THE

YOUR

THE EXTRA

THAT

JOBS

COST

BRINGS

OF

Page 3

You

save

ways

with

You

get

capacity

Rapid

on

one

cam-lock

U-4,

you m

180 °

cam-lock

Fast

Changeover

face pl

the

extra

versatility that

in

addit

ion -

Chucking -The

end

of

the

nose

on

the

ay

leave a

to

make

real

nose, the

-

ate -quickly

Type

simplifies your

from

these

swiveling

spindle

other

chuck

time-savings

chuck

Turning a knob

does

changes

for

end

on

the

headstock

your

for

the

in

not

headstock

U-4

set

ups -and

important

dead-center

you

to

cam-l

ock

setting

rotat

e

on

the headstock -and a plunger

has a

mount

nose

up

chucked

when

to

features:

conventional

grinding-

chucks

and

just

jobs.

you

grind

live

or

or

swivel

dead

gives

dog

plus

fixtures.

the

When

on

dead

spindle

you

bro

drive

plate

a

5"

D-1

With

headstock

left

on

centers.

in

operatiou.

ad

the

che

the

Wide

work

The sl

speed

Independent

settings

the

Easy

of

conventional position.

Extra

angular

h

Greater

shafts -or

the

speed

ower speed

U-4

Wheel

the

ead

member

headstock

Work

ranges

in

range

of

wheel

gives

Head

wheel

Capacity

grinds

Length

for

Speed

- 15

range

being

Settings

and

you

swive

Setting-Spr

head

in

or

other

through a rack and

Capacity-

certain chu

spindle.

Range

facilitate

Wheel

-

High -torque

co

150

r.p

gives

you

best

used is obtained

of

Wheel

feed

for

faster

ls

above

ing-loaded

angular

Head

special

You

cked

operations

jobs

.m.

and

work

by

and

Feed -You

performance

and

below

-

You

pinion

have

additional

- because

drive

40

speeds

turning

the

rollers

settings

may

by

device.

headstock

co 400

increase

repositioning

of

r.p.m. -by

for

larger

a dial.

make

of

normally

feed ways.

built

into

and

return

grindiug

capacity

the

1 ¼"

gives you

belt

diameters.

independent

difficult

the lower

of

head

capacity

the

upper

for

grinding

hole

clear

two

change.

Desired

angular

jobs

-

swivel

to

the

for

wheel

long

through

3

Page 4

You perform

the

Type U-4

action these

advantages:

•

and

either

because

you

change

external

of

its

from

or

easy

one

internal

set

up

to

the

grinding

features

other

jobs

and

rapidly

quickly with

fast

grinding

because

of

The individually

front

of

the

quickly swung down

upward out-of-the-way

powered

external grinding

into

•

You perform

minimum

time

an

internal

because

internal

grinding

and

there

grinding

spindle

position -

an

external

is

no

spindle

housing -

grind

disturbance

permitting

or

to

on a

of

is hinged

be

quickly swung

workpiece

the

set

up

it

to

to

the

be

in

---

....

Right

rear

view -12" x 36"

Type

U-4 Univ

ersal

Grinding

Machine

Page 5

In

addition

profit

from

such as:

to

12"

•

Electrical controls

•

Coolant

tank

with

•

Pumps

instant

and

motors

accessib

ility

•

Lubricant

located

flow

valves

to

the

Type

grouped

ramped

mounted

table

savings

U-4

features

flat

from

,n

an

outlet

outside

and

rapid

set

that

simplify

elevated

to

facilitate

the

base

vee

ways controll ed

up

and

maintenance

outside

removal

in locations

fast

grinding,

mounted

of sludge

by

conveniently

functions

enclosure

that

afford

you

Le

ft rear

vie

w - 1

2" x 36

N -7835

"

Typ

e

U-◄

arr

ang

ed with

automati

c:

fee

d

5

Page 6

gives

N -

7988

you

•

You

may

lock

nose

headstock-

quickest

•

The

headstock

and

the

centers

fast

permanently

which

is

on

and

merely

performance

spindle

chuck

does

"get-a-way

mount a chuck

one

end

of

the

swivel

of

chucking

is a combination

not

rotate

spindle

the

jobs

when

on

the

of

headstock

live

and

you gri

5"

the

dead

nd

"

D-1

cam

swiveling

180°

for

type

on

dead

,

...

..

...

,·

, ,.

,

, .

#.

~

...

...,.,_

r,

•

Complete

for

use

swivel

of either

feature of

end

of

spindle

headstock

permits

quick

set-up

•

Complete

fe

atures

capacities

swivel

of wheel

for

many

feature

head

special

of

headstock

and

jobs

table

combines

to

provide

with

swivel

particular

•

Live or

on

' u

No

dead

headstock

idler

is

used

center

body

in

operation

headstock

is

controlled

drive

by

selector

knob

6

:re,_

"Straddle-clamping"

by

assuring firm

N-7058

of

headstock

positioning

on

aids

table

grinding

efficiency

Page 7

•

•

•

on

normally

time-consuming

The

headstock

work

up

to

additi

onal

•

Taper

Jarno

standard

N-

7052

hole

. A No.

has a hollow spindle which

I¼"

diameter

capacity

in

both

12

to

jobs

ends

of ·headstock

No. 9

clear

Jarno

through

adaptor

will

take

your

- thus giving you

spindle

is

is

furnished

No.

12

as

-

·

--

.. • «."

oo

...

0 0

..

_1

0

• •

IU1'

oo

a..31

......

0 0

• -

.3

0

..,....

-

-~ -

~ -

.

G

~-

N-7059

•

Work

rotation

reached

•

In

addition

lever also

workpiece

•

The work

from

an

•

W ork

speed

graduated

is

controlled

by

your

operator

to providing

permits work

run

out

drive

gives you

A.C.

power

changes

dial

after

supp

are

by

a single

from

starting

jogging

mounting

an

infinite

ly

instantly

lever

that

his normal position

and

stopping

for

in

made

speedy

chuck

number

by

control,

checking

of

setting

is

easily

this

of

speeds,

a large,

N-7059

7

Page 8

AUTOMATIC

GRINDING

In

addition

arrangement,

plify

your

the

factory -gives

because you

Automatic

✓

Adjustable

with

✓

Adjustable automatic

ing

✓

Automatic

✓

Automatic

CYCLE

to

the

you

plunge

gee

the

Grinding

automatic

wheel

advantages

may

purchase

grind

jobs. This

you

time-and-effort

following:

Cycle

rapid

cushioning

feed

with

rapid

whe

work

you

automatic

including:

hydraulic

rotating

dwell

el he

rotation

get

from

the

standard

feed

feature -built-in

saving

wheel

head

screw-type

ad retraction

start-stop

to

sim-

benefits

traverse

grind-

at

The standard

give

s y

table reversals

erse g

rindin

enables y

s

lid

e, caper,

12"

Ty

pe

U-4 U niversal

ou automatic wheel feed ac

ou

co simplif

g.

Thi

co

do

face, angular wheel

intern

y y

our tra\'-

s mac

hin

e also

al - and a wide

variety of special jobs which the e

versatility

of

the U

-4 eguip

s y

ou

to

xtr

do.

✓

Automatic

✓

Adjustable

✓

Sele

ctor

(Grinding gages also

POWER

a

SLIDE TRAVERSE

If

th

moveme

WHEEL

e nature of y

nt

of the wheel head a

save time and effo

feature whi ch is available ac ext

power wheel slide pos

s

top

the wheel s

a

nd

speeds

time-sav

whe

ing

s can benefit

coolant

electric

switch

available

our

work

rt

with the Power

itioning.

lid

e at any

el slide se

flow

start-stop

timer

to

provide

ac

additional

for the 12" T y

ppreciable

ra

It

point

during

ttings

output

co the

sub sta

for

manual

\X/hee l

cost.

makes

extent

control

pe

dist

Slide

This give

it

in

or

ntiall

of

cycle

cycle

control

cost)

U-4

reguires

ances, y

ou'll

Traver

s y

possible

out trav

ers

that resultin

y.

se

ou

to

e

g

Page 9

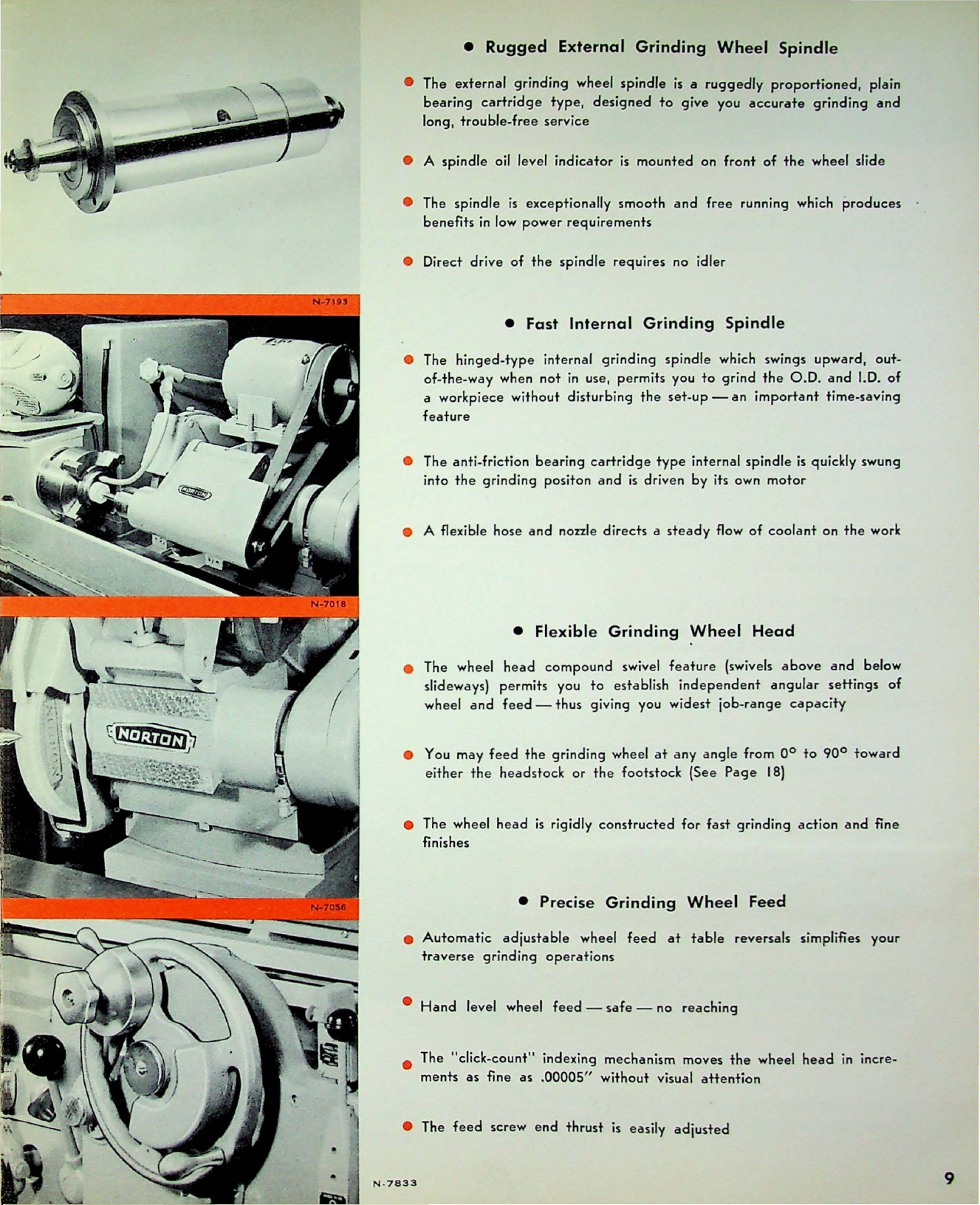

• Rugged External Grinding

Wheel

Spindle

• The external

bearing

long,

trouble-free

• A spindle oil level

• The spindle

benefits

• Direct

• The

• The anti-friction

hinged-type

of-the-way when

a workpiece

feature

i

nto

the

cartridge

is

in

low

drive

•

grinding

grinding

exceptionally

power

of

the

Fast

not

without

bearing

wheel spindle

type,

designed

service

indicator

requirements

spindle

Internal

internal

positon

grinding

in

use, permits you

disturbing

cartridge

and

is

mounted

smooth

requires

Grinding

the

type

is

driven

is

a

to

give

and

no idler

ruggedly

you

on

front

free

proportioned,

accurate

of

running which

grinding

the

wheel slide

produces

Spindle

spindle which swings upward,

to

grind

the

O.D.

and

set-up -an

internal spindle

by

its own

important

is

motor

time-saving

quickly swung

plain

and

out-

I.D. of

• A flexible hose

•

• The wheel

slideways} permits you

wheel

• You

• The wheel

•

may

either

finishes

Automatic

traverse

head

and

feed

feed

the

headstock

head

adjustable

grinding

the

• Precise Grinding

and

nozzle

Flexible

compound

- thus giving you

grinding wheel

is

rigidly

operations

directs a steady

Grinding

swivel

to

establish

or

the

footstock

constructed

wheel

feed

Wheel

feature

independent

widest

at

any

(See

for

Wheel

at

table

flow

of

coolant

Head

(swivels

job-range

angle

Page

fast

grinding

reversals simplifies

from

18)

Feed

above

angular

0°

on

and

settings

capacity

to

90°

action

the

below

toward

and

work

of

fine

your

•

Hand

• The "click-count" indexing mechanism moves

ments as fine as

• The

N .

7833

level wheel

feed

screw

feed -safe

.00005"

end

thrust

- no

without

is

easily

visual

reaching

attention

adjusted

the

wheel

head

in

incre-

9

Page 10

Swivelling

lems - it

Footstock

You

attach

Cam

Lock

Headstock

may

be

Chucks

Nose

on

simplifies

used

or

face

one

with

end

either

plates

of

your

set-up

end

quickly

Headstock

prob-

towards

to

5"

Spindle

D-1

Hing

ed-

changes

type

Grinding

Wheel

Guard

speeds

whe

el

Headstock

diameter

Control

ing

or

You

operate

normal

Fast

or

simple

Table Traverse Handwheel with adjustable graduated

dial reads 0.125" per revolution in slow

and 1.073" in

hollow

stock

clear

Knob,

on

unlocking spin

Work

operating

Slow

in-out

Hand

motion.

fast

position

Table

speed

spindle

each

dle

Start-Stop-Jog

through

side

speed

takes

of

J 1/

4

Headstock

lever

selector

" maximum

for

lock-

easily

from

operates

on

speed,

If---

----

10

Instant

d

r::

sire d work

tu

rn;ng

Separate

for

right-hand

res

ponse Work Speed Control

spee

dia

l

controls

d within

and

permit

left-hand

rang

selection

ends

e b e

of

of

ing

table

table

gives

used

you

by

dwell

travel

Quick-action

operating

between

position

2"

Table

and

Speed

instantly

240"

per

Control

provid

minute

es

in

center .of

desired

speeds

Page 11

You quickly swing

into

not

position

in

use

for

the

grinding

Inte rnal Gri

or

out

of

nding

the

Spindle

way

when

Wheel

you

to

angle

All

guards

.

head

set

mounted

wheel at

are

of qui

on

any

ck-mount

double

angle,

swivels,

and

type

to

to

feed

perm

at

it

any

)

~

'

. ·-

i"

C!Ii7D

""-.-J

.

Combination

stock permits

Dog-actuated

traverse

You

fee

anism, providing

he

ad

movement with

A

pow

er

is

available

Picker

veniently

lever

you

in

normal

d quickly with "

wheel

at

Feed on-

pos

itioned control

and

to

Table

traverse

increments

head

extra

off

hand

select

Reverse

click-count"

out

visual

rapid

cost

selection

wheel operated

for

your

job

Lever

controls

grinding

indexing

of

.

00005

attention

positioning

1s

by

means

Foot-

.

table

Mech

"

of

wheel

mechanism

of

con-

-

Table

Start-Stop

motion.

operator's

It

will

knee

Lever oper

stop

table

or

body

ates

on

traverse

short

on

in-and-out

pressure

of

Whe

el Feed

of oper

Pre

return

ation

Hand

supplementary

-set

operated

Truing

to

same

Handwheel specially d esigned

Table Reverse

means

and

Grinding

speed

after

of

control

Speed

truing

Lever

Control

or

grinding

for ease

provides

assures

a

11

Page 12

Face

Grinding

Performing a

set

at

90°

from

with periphery

face

of

grinding

regular

straight

operation

position

faced

perm

wheel

with work

itti

ng

grinding

N-71

head

01

12

------

..

___

Grinding

Note

not

the

periphery

that the chuck has been left on

rotate

during

dead

of a fac

center

e milling

the

grinding

cutt

er

cam

lock nose end

operations.

preliminary to

of

the

the

spindle

backing-

and

off

that

operation.

it

does

N

-706

1

Page 13

N

-70

18

N-7053

Internal

Grinding

time-loss

with pe

180°

into

rmanently

and

the

Grinding

an

internal

factor

grinding

is

eliminated beca

mount

the internal spi

pos

diameter.

ed chuck is

ndle

iti

on

In

this

use

is quic

job a frequent

the

headstock

merely

kly

swivelled

swung down

Angular

Grinding

Grinding a spindle

set

in

angular

spindle

footstock

is quickly locked

body,

position.

to

thrust

take

by

the

flange

In

this

the

thrust

with

job,

binder

.

grinding

the

footstock

knob

wheel

on

the

Taper

Grinding

Grinding a taper

swivelled

swivel

Type

pound

es

tablish

work

for

taper

capacity

of

U-4 Universal

swivel feature

ed

whereby

by

the

wheel

plug

grinding.

the

table

because

. For the

the

feed

gage

whe

hand

. The

may

of

the

el

is

wheel.

table

Tapers

be

ground

wheel

se

jobs

traversed

is easily

beyond

with

head

settings

along

N

-7062

the

the

com

are

the

N-7054

Special

Externally

the

-

workpiece

ly

may

internal

put

into

be

used.

Grinding

grinding

spindle

design.

grinding

an

to

The

position

under-cut

avoid

interferences

internal

for

diameter

spindle

all

jobs

by

set

is

very

in which

use

up

quick-

of

by

it

13

Page 14

RUGGED

BASE

The

heavy

dampening

The

base

and

wheel slide,

rigidity

base

vibration -maintaining

is

engineered

required

•

Hand

scraping

better

which assures fine

bearing

of

surfaces, and

gives

and

is

for

accuracy

the

lubricant

you

to

give

heavily

of

generous

creates

retention

better

alignment.

rigid

webbed

alignment

way

performance

support

to

provide

areas

gives

minute

oil

properties

to

table

the

you

pockets

by

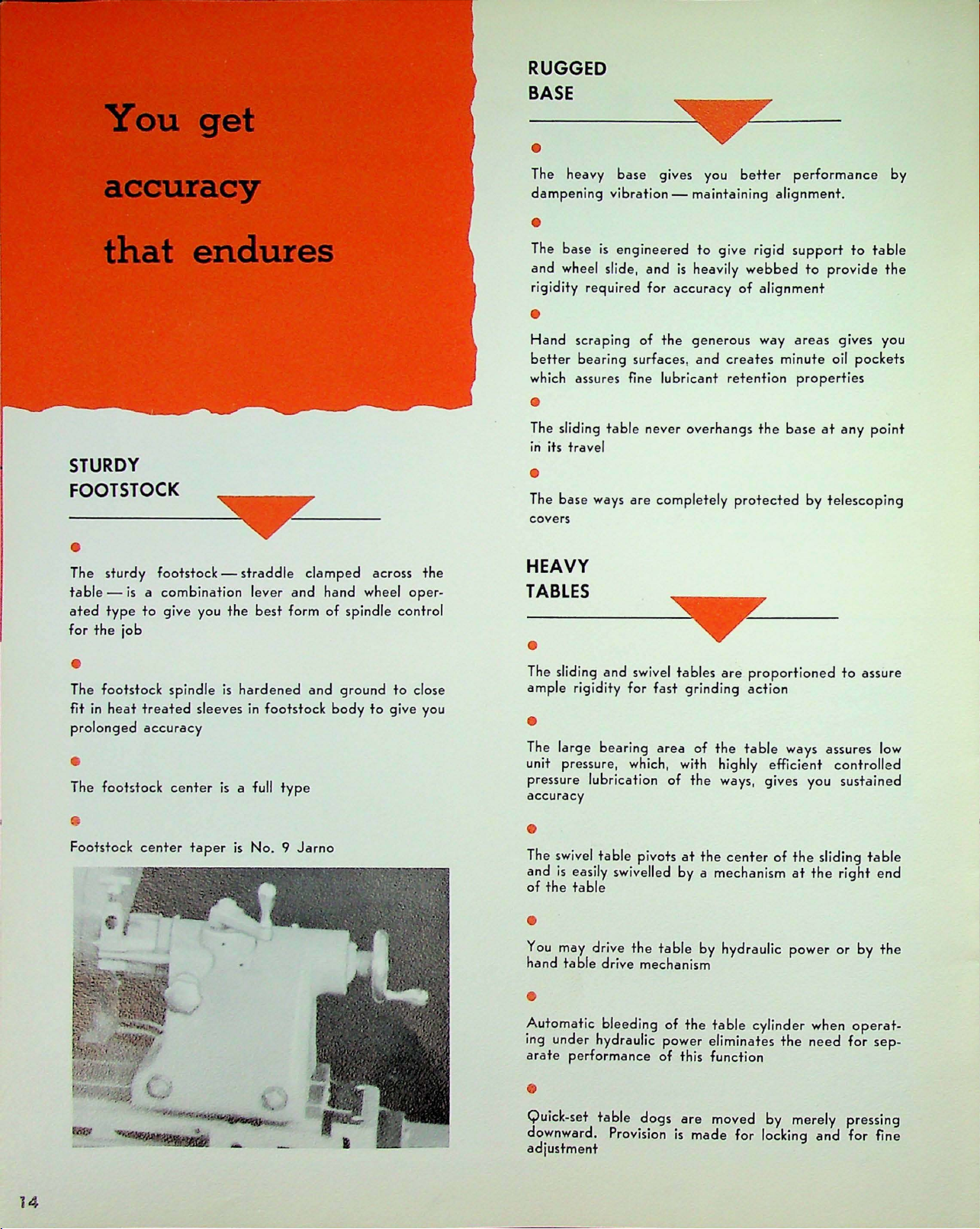

STURDY

FOOTSTOCK

•

The

sturdy

table

- is a

ated

type

for

the

•

The

footstock

fit

in

heat

prolonged

•

The

footstock

Footstock

footstock -straddle

combination

to

give

job

spindle

treated

accuracy

center

center

you

sleeves

is

taper

lever

the

best

is

hardened

in

footstock

a full

is

No. 9 Jarno

and

form

type

clamped

hand

of

spindle

and

ground

body

across

wheel

to

give

the

oper-

control

to

close

you

The sliding

in

its

The

base

covers

travel

ways

table

never

are

completely

overhangs

protected

HEAVY

TABLES

•

The sliding

ample

The

large

unit pressure, which, with highly

pressure lubrication

accuracy

The swivel

and

is

of

the

and

swivel

rigidity

easily swivelled

table

for

bearing

table

fast

area

pivots

tables

are

grinding

of

of

the

at

the

by a mechanism

the

ways,

center

action

table

the

base

at

by

proportioned

ways

efficient

gives

you

of

the

sliding

at

the

any

point

telescoping

to

assure

assures

controlled

low

sustained

table

right

end

14

WJr

..._.

- ' " ...

"Tin

-.cea;1:,a

Sri

~

•

You may

hand

Automatic

ing

arate

g.

.,..

....,

Quick-set

downward.

adjustment

drive

table

drive

bleeding

under

hydraulic

performance

table

the

mechanism

dogs

Provision

table

of

the

power

of

this

are

is

by

hydraulic

table

eliminates

function

moved

made

cylinder

for

power

the

by

merely

locking

when

need

and

or

by

operat

for

pressing

for

the

-

sep-

fine

Page 15

EQUIPMENT

INCLUDED

Headstock -com_bination

type,

with

pilot

ing

No. 9 Jarno

Footstock -combination

ing

No. 9 Jarno

Wheel

Wheel

Footstock

(less

Table

(less di

Internal

motor,

spindle

specified

8" - 4 jaw

guard,

sleeve,

type

diamond)

type

amond)

grinding

control,

(15,000

AND

IN

PRICE

nose

center

full

14"

x 11/i"

5"

hole,

diamond

diamond

unit,

"Ex-Cell-O"

rpm),

independent

spindle

center ( 11/

tool

and

FEATURES

live

and

dead

(5"

D-1

Cam

( I 1/

" dia.)

8

screw

and

lever

"

dia

.)

8

balancing

tool

holder

hinged

9uill # 1183 unless

chuck,

holder

type,

No.

676

5"

type

D-1

spindle, swivel

Lock) includ-

type,

complete

L.H. ball

otherwise

cam-lock

includ-

with

bearing

type

Coolant

gral

A.C.

or

volts.

ance

Note:

this

e9uipment.

power

The

hydraulic

pump

drive

-

'I

◄

type

motor

and

control

motors

60

cycle, with

These

with N.M.T.B.A. Electrical

Due

machine,

source -no

machine

to

The

fluid

included

controls

motors

it

and

the

interrelatonships

is

necessary

entire

D.C.

meets

reservoir

in

machine

J.1.C.

inside

EXTRA EQUIPMENT

AVAILABLE

Radial

Wheel

truing

balancing

device,

table

arbor

H.P. 1800 R.P.M. A.C.

price

of

this

machine

for

any

controls

that

line

is

Hydraulic

type

voltage

are

Standards.

in

we

supply

operates

necessary

base.

(0-1"

wired

the

function

all

from

.

Standards

radius)

up

in

inte-

are

50

to

600

accord-

of

electrical

an

A.C.

with

Face

plate

(fits

Center

Steadyrests

Set

2

1 lfi

I

Hydraulic

Two-speed

Swivel

Universal

wheel

Adjustable

Cartridge-type

Automatic

Pre-set

Hand

Complete

Wrenches,

External

and

Internal

and

Work

speed

Hydraulic

motor

rest

(3)

work

Grinding

II

X 5"

Set

of

table

feed

truing

grinding

control

wheel

control

drive

motor

and

six

table

hand

wheel

ways

table

adjustable

coolant

motor

wheel

- ¾

punio

control

cam

(3

with

drive

wheels,

internal

traverse

table

head

dwell

plain

and

grinding

wheel

pulleys,

drive

drive

H.P.

operated

lock nose)

12 x 36"

dogs

(21/i''.

Type

grinding

traverse

with swivels

control

bearing

in-feed

feed

system

- 3

- I

D.C.

from

drive-¾

, 4 with 12 x 48" machine)

4"

and

6"

capacity)

5,

recessed

wheels ( tl/4" x

with interlock

external

at

each

table

and

protection

H.P.

1800

H.P.

3600

115-1150 R.P.M.

A.C.

H.P. 1200 R.P.M.

speed

power

one

above

wheel

table

control

guards

R.P.M.

R.P.M.

side,

I"

x

and

spindle

reversal

A.C.

A.C.

adjustable

circuit

14"

3/s

")

below

motor

motor

A.C.

Wheel

Positive

indicator

x

Automatic

Power wheel

SWIVALIGN

Dial

Footstock

"Sjogren"

¾",

Extra

"Walker"

(9"

"Jacobs"

1/

"Rubber-Flex"

Extra

balancing

stop

indicator

3/s",

collets

diameter)

16"

to

internal

stand

for

table

Feed

Arrangement

slide

positioning

® Dual Electric

arrangement

half-center,

collet

chuck

I")

for

above

permaneTit

with

adaptor

collet

13/

I/

"

capacity

8

collets

16"-1/

chuck

8

1/s"-¼"

l/4"-3/s"

3/a"-'h"

½"-%"

%"-¾

grinding

with

micrometer

(See

Indicator

for

swivel

No. 9 Jarno

with 6 collets

magnet

for

"

rotary

for

"Rubber-Fler"

above

·'

9uills

(see

screw

Page

mechanism

(See

table

(I/a", 1fi",

type

as

follows:

¾"-3/a"

3/s

"-1"

1"-1'/a"

1

'/s"-1

"I◄"-

'/

13/a"

listing

and

8)

Page

adjustment

chuck

collets

◄"

on

next

dial

17)

1/s",

-#9R

for

page)

15

Page 16

SPINDLE QUILLS GRINDING WHEELS

No.

R.P

.M.

No.

Max.

Hole Min. Dia.

Depth

Width Hole

N674-LH 25,000 1102 I"

llfi"

I"

2"

llfi"

2"

11/i

3"

2"

11/i"

21/i"

I½

3"

I¾"

2½"

llfi"

3"

I¾"

4"

21/i"

4½"

5"

N675-LH

N676-LH

N677-LH

18,000

15

,000

12,500

II 03

II 07

1109

1122

1128

1133 11/i"

1135 21/i"

1141

1144

1157

1162

1164

1170

1173

1180

1183 4"

1193

1199

1202

1209

1212

1220

1222

1230 3"

1232

3/s"

3/s"

1fi"

1fi"

3/s

"

1fi"

%"

%"

"

¾"

¾"

½"

%"

%"

"

¾"

¾"

1/s'

'

1/s"

%"

¾"

¾"

1/s"

1/s"

I"

I"

11

/

"

8

11/s

"

1fi"

½"

%"

%"

'Ii"

%"

¾"

¾"

I"

I"

%"

¾"

¾"

I "

I"

I"

I"

¾"

I"

I"

I"

I"

I"

I"

I"

I "

1/

s"

'I

s"

3/ 16"

3/ 16"

'Is"

3/16"

1/.i"

l

/4"

¾"

¾"

3/ 16"

1/4

"

l/4"

3/s

"

3/s

"

¾"

¾"

l/4"

¾"

¾"

3/s"

3/s"

¾"

¾"

¾"

¾"

Tapered

end

of

all Quills have L.H.

thread

Page 17

SWIVALIGN

*

•

Norton

Electric

measureme

adjusanent.

■

tra

Ind

Dual

Electric

measuring

This

device,

of

swivel

eliminate

pick-up unit

cabl

e,

meter

responds

Connections

direction

cable

is

rotate

Divisions

chousandchs

one

for

per

foot

provided. The

oo

che

side

of

ing

micrometer

Jc

is

necessary

measurement

adjust

mark.

no

guesswork

available

cables

caper

with

and a two-channel

elements

co

movement

are

of

rotation

swiveled

clockwise

oo

the

of

an

extremely

aod

the

front

of

the

instrument

only

of

che

swivel

No

complicat

.

swivel

co

co

correct

in

straight

zero adj

reading

so

arranged

as

clockwise

and vice

meter

inch

accurate

other

desired

the

instrument

case

readings

co

determine

the

work,

of

che

ed

Indicator

table

you

ac

extra

errors

usting

amplifi

oo a common

of

only

the

versa.

scale

per

fooc

settings

of .0005"

range

gives taper

of

work

set

cable

formula,

in

work.

knob

er

one

of

chat

both

swiveling

(as

viewed

indicate

of

taper.

per

is

obtained

case.

diameters.

che correction

the

needles

uocil

no

for

adiustmen

cost,

simplifies

grinding

I c

consists

ac

having a pair

scale. Each

the

needles

of

from

directly

wich

foot

A

conversion

foot

both

cut-aod-try

exact

each

eod

pick-up

move

che

cable.

above),

Two

ranges

graduations

of

by a selector

values

required

for

the

needles

the

adjustment

capers

of

one

electrical

of

che

of

indicating

meter

elements

in

che

Thus

the

taper

changes

of

readings,

of .000

caper

change

chart

for

correspond

by

correction

are

ac

the

adjuscmeocs

t

or

to

swivel

needle

.

same

if

che

needles

in

l"

are

switch

oo

the

actual

aod

zero

aod

-

N-7459-A

Page 18

CAPACITY

Nominal swing . . . . . .

Maximum swing

can

Nominal

Distance from external

work

Maximum . .

Minimum . . .

Internal

Maximum d

Maximum

• Maximum

ground

Standard

Size . . . . . . 14" x

Wheel

guard

Steady

rests

Maximum work

Center

Tap

eter,

of

Coolant

Hyd

Lubrication oil

• {minimum diameter

rests

Maximum

er

Graduations

Inches

Forward .

Back . . .

D

egrees

Forward . . . . . . . . . .

Back . . . . . . . 3 21/i

N

ote:

work

the

tap

raulic oil

and

be

ground

lengths

spindle

per

Actual

tank capacity

spindle

istance

distance

diameter

with a 14"

grinding

capacity

diamet

foot,

tapers

diam

eter

er

with

capacity

capacity

betwe

axis

.......

wheels . . . .

diamet

er

on diameter

reference

whe

work

diam

. . . . . .

en

centers

spindle

........

in

front

in

back

of

work

grinding

er

accommodated

ground

and length and

. . . . . . 43 gals.

. . . . . . . 35 gafs.

. . . . . I I

el

to

grind O" diam

.....

eter

that

..

. . . . .

axis

.

.

of

work

of

work c

that

wheel .

accommodated

depend

to

the

to

. . .

center

enter

can

be

on

on

pivot point

eter

- 8" )

12-31

12 -31

36"

......

.

12 -31

..

I½

14

" x J 1//'

36"

10

wheel

the

/ 32"

/ 32"

-48"

. 211/4"

4"

. 5"

121/4

/ 32"

Type 5

" x 5"

6"

4"

48"

91/i

diam

location

.

qts

Type

Spindle,

(No.

ard

Work

Head

Taper

Wheel head, upper

"

Whe

Wheel

Autom

Wh

30°

Wheel head,

Type

Spind

Spindle

Wheel head

Minimum move

-

Automatic

re

Traverse

.

Table

F

Slow

12

equipment)

speed

stock swivels

hole .

e[

head,

AUTOMATIC

head

atic

eel he

each

le

drive

duction

travel

ast

traverse

traverse

MOTORS

External

Internal

Work

Whe

el Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 h.p.,

Wl,eel

Drive . . . . . . . . . . . . . . . . . . I h.p.,

Drive (Electronic

Control

from

AC

Power Supply) . ¾ h.p.,

Hydraulic Pump Drive ¾ h.p.,

Coolant

Pump Drive . . . . . . . . . . ¼ h.p.,

HEADSTOCK

....

taper

to

Combination

hole

No. 9 Ja

range

both

rno

(approx.)

S

elf-contained,

ends

. .

adaptor

live

and

.....

furnished as

40

dead

Universal

No.

12

to

400 r.p.m.

FOOTSTOCK

No.

WHEEL

swivel . .

lower swive l .

movement

rapid

ad,

advanc

upper

way.

lower swivel . . . swivels

HEAD

Swive

30°

graduated

graduated

FEED

ARRANGEMENT

per

turn

of

hand whee

e stroke . . 2" max.

swivel, swivels 360°,

Swivefs

90°

each way

graduated

30°

each

each

WHEEL SPINDLE

spe

ed . · 1750 r.p.m.

from

movement per

ment with

infeed

in work di

Cartridge type

motor

WHEEL

sizing

at

table

ameter

FEED

turn

reversal -

, plain beari

. 3 Vee belts

of

hand

adjustment

whee

. . 0002" - .003"

l .. 050 "

TABLE

spee

ds (hydraulic

per

revolut

115-1

powe

to

io n

240 " p

of

cycle

r)

hand whee

2"

bO

1800 r.p.m.

3600 r.p.m.

150 r.p .m.

1200 r.p.m.

1800 r.p.m.

er

min.

adjustable

(approx.

l:

15

3000 r.p.m.

1000 r.p.m.

1500 r.p.m.

center

,

Jarno

stand-

.

360°

9 J

arno

ls

360°

,

way

and

is

l . I 00"

way

ng

.00005"

)

~

~ 0.125

50

cycle

00

r.p.m.

speed

11

1.

073

11

?8

Floor

Spac

e . .

.....

Net

Domes

weight,

tic

pounds

shipping weight,

Foreign shipping wei

B

ecause

of

escr

variations

iptions,

are in cubic fee t.

Th

e d

differ in deteil

due

Motor

ill

ustrati

in e

to

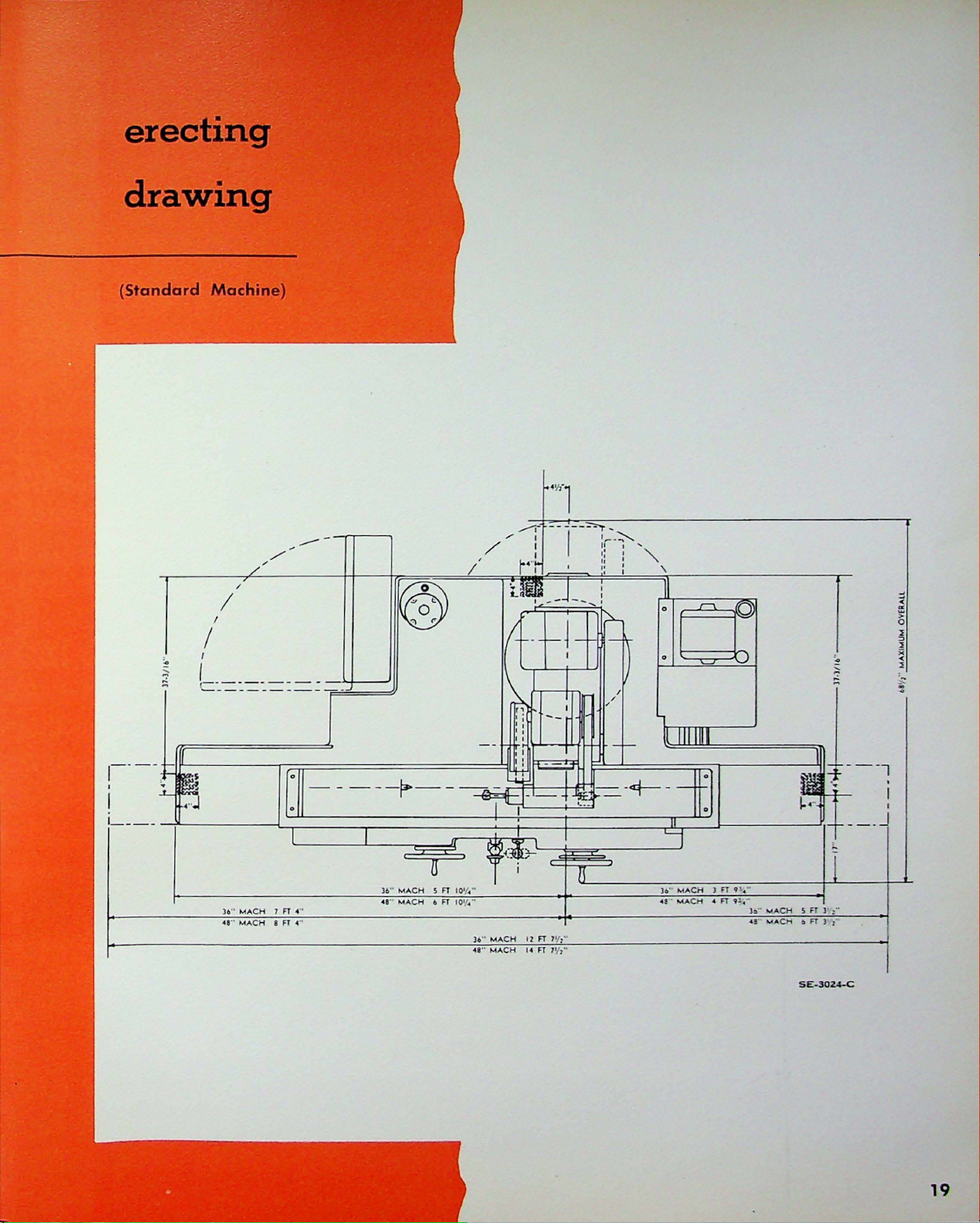

FLOOR SPACE

36 "

. . .

681/i" X 12'

7½"

SHIPPING SPECIFICATIONS

(Approximate)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7870

ght,

quipment

weights are

ons

the

policy

pounds

pounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

and

specifications

of

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

and

castings,

included

Norton

exa

.

in

this booklet

Company

ct weights

to

constantly

and

are

cubics

correct

improve

cannot

at

the

its mac

be

time of

hines

given

. The

above wei

printing. Machines

.

ghts

68

36"

8670

9670

are

built

½"

in

at

48"

X 14'

pounds;

later

dat

7½"

48"

8650

9450

10550

cubics

es

may

Page 19

draw

(Standard Machin

..L

I

I

____

, -

.

..

7L-----

l b

"'

◄

8"

e)

-

-L...,

MACH 7 FT

MACH 8 FT

r,

t-

';

--r

' '

, ,

''

·"

--

1 I

--

--

0 I

---

-,---

--

I I I I

16" MACH ~ FT

◄ I

"

F---~

4"

◄

"

MACH ~ FT

-~~-t=:-:l-1~-'ilt]:-~=

"--;1

-i_--+-~'-·c;..l

- -

...._-+----+----~JL...-_J...-----1i

I

;-

11

1

~

~;--~

FT

1V:'

"

10'/◄

IOI/,."

"

JO" MACH

t~{m

0

0

I

I

I

I

I

/

,

7

IT

11

--

II

ff

'-

-

-

-+-

·

)

~

0

ii,_:_

~

0

.- I

•

--

_-

I

·_I

i

T{

Jo"

MACH l FT

◄

r

-..u..CH • FT

ql•

c,1,

..

-

1~-

,,....A

CH ~ Fl

l

J' -:··

SE-3024-C

19

Page 20

tor

Semiautomatic Cylindrical Grinders

Plain Cylindrical Grinders

Grindi

and

·

ng

Cu,,er

and

Tool Grinders Universal Grinders

Lapping Machines

Loading...

Loading...