Page 1

Volume

Numbe

51

r 3

GRITS

and

GRINDS

Page 2

BEHR-MANNING

~

GRITS

VOLUME

1

Message

2

"I Remember ...

7

Grinding

12

60 Y

17

Products

R

20

Plants

1

29

34

39

44

48

orton

Re

sea

Th

e Behr-

Norton Around

P

eople-

• T I

TCJ::

PRINTED

5 1,

from

the

Wheel

ea

rs

of

Building Preci

of

the

efrac

tories

and Electro-C

and Machin ery .

Produ

cls in the Space

rch

and

Dev

fanning

the

Our

~lost

nr-:c. u. s.

IN U .

S.A

and

NUMBER

President

" Ge

Manufacluring

Electric

elopment-

and 1orton

\Vorld

Valu

PAT.

. @ J

3

ion

Furnace

..

Operations

...

able

Asset

OFF. Pt RI.ISII

960

G R I N D S *

.

Milton

Today

Grindin

Ev

- :'-iorton

hemica

Age

\

\li

{lim11

Key

to

\Va/1,ace L. U

Pike

El

llY

NORTOK

org

ls

A.

P. Higg

e N. Jeppso

John Jeppson

g ~fochines

ere

tt

M .

Abm

Howard

and

J.

\Yorkers

C. Fallon, Jr.

Progress

Stor

y

mer C.

Schacht

Donald

F:O SI

NCE

C:O.:-IPA

Hi

ivcs,

Daly

owe

Kel

1

909

ins

cks

so

' Y

Front Cover:

ore

fuse d in

Back Cover: Norton Ele

nace Plan!, Chippawa, Ont.

n

EDITORIAL

Enf ricd

F. K

Tool

Port

A

soc

Flin

Jr

.,

Porter,

\Varrcn,

this

T.

enwood Jone

Divi

er,

Bchr-~lanni

iate

Edi

k, Phot

og

C.

\V

i\1.

Editorial Assistants

Anniversary

photograph

Stockholm.

NORTON

BEHR-MANNING

NORTON

NORTON

COMPANY,

Moss

.,

ond

o division

PIKE, Littleton, N. H.,

o division

INTERNATIONAL

Worcester

"Pig"

of

ALUNDUM

elect

ric

furn

•

ctr

ic

STAFF

Larson

ion,

tors •

rapher • J. Clark,

. H e n o n,

i\

!.

oy

,

Edit

·, i\lachine

Carlto n

ng Co .. Div.,

1':om1

Tym

e ·on, C. B.

Issue • Color

K. W .

Santo Clora,

CO.

of Norton

of

Norton Company

Cull

Worcester

, Troy, N.

Company

INC.,

6,

Moss

.1n

E.

., U.S.A.

ace

Fur

or •

C.

D.

fo

ers,

Calif.

Y.,

-

C.

r

6,

Page 3

he

·

tory

plant

tion

sit

as

products

above

who

ha

all, a

mak

ve macl

It

begin

but

varie

to

w e

ty

Norton

is ·

es

and

world

is

both

tribute

e ·

up

e this record

woulcl be

tell the

hope our read

and scope

story

more than

achi

eve

ments.

's larg

est

a t rust ancl a res

lo

the

our worlcl-wicle organiz

impo

Nor

ton

ers

of the

and their contribut-ion

to

0111

· s

tandard

v

Ve

also

of

living.

tak

e this

our gra.t-itucle and debt

tribut-ed

progres

tributor

s

uppli

and

to

Norton

s-our employ

s,

our

ers

of mat

serv

ices .

cus

erials,

Company

ees

tom

ers

over its

just a compilation

manufacturer

seventy-five-year

We feel that

pon

spl

endicl

111.en

of

sibility

ancl

ation

of

our

abrasive

wom

ancl w

of achievenient possible.

ssible,

story

will

produ

to

our

opportunity

to all those

and

and

of

in

gain

cts

course,

the

se

some ·icl

we

to even

few pages,

ea

manufacture

industrial progress

to acknowledge

's s

who

eve

nty-five years

have

dis-

our

equipment

his-

elates,

posi-

and

en

ho

of

the

and

con-

of

,

I

.......

~J?~~

Pr

msIDENT

Page 4

I• •

I

~

~ :

~·

.

';

-:._

I

"I

renieniber .

by

George

Nathaniel

"

Jeppson

F.

8.

Water

Norton

St.-birthpla

Norton

Pottery

Company

cc

Th

e year I was born , 1873,

years following

pr

essions

the year

I've

in

it

were even

often re

wh ich the

mind

produced.

That

fir

st grinding

I remember

wh ere the

really

which

had

fir

Frank

whee

very little

st

came

ments of an emplo

whe

Norto

l was

int

to his attention

yee

Another employee, Swen Pulson,

cou ld make even a better

on

of

ed

fir

t 1 orton

el was n

n,

made,

ere

with

Chairman,

was

hard

mys

a h

er.

elf

Don

rd

of

ard

yea

In

lat

er

that

1873 was also

r,

grinding wheel was

ot

taken

very

the

owner of

the

as a kindl y person .

t in

the

grinding

becau

an orga

see

wheel

e of

the exper

nic bonded

ing i

t,

was

by

bonding

Directors.

and

the

bad

de-

seriously.

pottery

He

wheel,

i-

wheel.

sure

he

emery

7,age 2

Page 5

with

slip clay, res

bonded whee

(1876),

departm

Turkish

a

potter

able speed

the

observed

saucer-shap

burst when set

to make the two sides of a wheel parall

he

me

ness imply by digging a screw driver

Fini heel whee

it w

a

whee

hand

ciples are now incorpornted inlo mechanical

but

proved

My

t

ome

first cu torners

I I

II

\Vashburn a

\.Vashburn

n

amed

I r

at noon to a

book

to s

took

i\liy

fath er,

ent. vVith a

eme

ry

's kick

devi

kiln

with

that a wheel

ed

tart

ed to "true" the whee

Th

ere were thr

dium

, a

nd oft.

as

an

nrt. He could also tell you

1

l

b:,

le

of

th e

even the experts

when

father

rs by walki

nd

Shops of

Milt on

emem

ber the

kee

per.

ee what he look

ulting

l for which Mr. Norton, a few

out a patent.

John

in a was

whe

el (

ce

th e jugs

during

in

motion.

ee

l.

This was

th e

way

same screw driver. ( All these same prin-

combined

oft

en deliv ered the

ng wilh

were

Moen

Prin

ce

day

nnounce

After

in

the

first vitrified

Jepp

son I,

paddle, he

htub

which

ever design e

and

would often shrink, beco

the firing, th en later

grades

1

i\

fy Father tested for hard-

it sound

agree

with

the whee

the \1Vinslow Skate

Manufacturing

Vlorces ter Tech,

Higgins

in 18

that

school that afternoon I hurri

ed

like. He was only twenty-

becam

. He

he

crocks

It

was

ls

of wheels-

e the

mixed

shav

ed

labell

ed

d"),

then

of

the

in

an

el

af

ter firing. r /:

(,_

int

more

82

Mr.

than

a skill;

many

ed when

that these methods

human sensitivit

whee

ls to the loca l cus-

ls

und

Compan

was in

when

Norton had

my

charg

fath

or

years

whole whee

the

slip clay

the

th e

fired them in

pott

ery.

effort

that

bard,

0._

th e ·--~~

things a

tapp

ed

y.)

er

his arm.

Compan

y, a

wh

ere a

e.

er

came home

hired a new

ceramic

whe

"best

Father

{."'\-

~--.

s:::-

-1

with

method

are

y, th e

nd

ed

els

I

clown

lat

er

l

and

on

vad-

ming

=r--l--_,_.· ·'

r\/~/•'

,u.

;!

t

~;

®/Y

bout

the

s,

im-

Hi

s

the

man

thr

ee

-· -

-:_---..:..::--__

_

':

, !

:..__,,...~

pag

e 3

Page 6

years

old-Charles

younger than all

"Jepp," and fath

and

ever afterwards, he was Mr. Allen.

Meanwhile, the

so

that

one of the stone

ought to get rid of the nuisance

were, he said, cluttering

1'1r.

Norton agreed with him, even though

his bu iness in 1884 h

opportunity came to e

$10,000

in 1885. My father, John Je

was one of them, Charl es Allen

!\lesser ( the shop salesman ) still

Higgin

whee

the new enterprise and was named presid e

pany. Another man from \i\force ter Tech, Geor

Alden, the mathematics

owners, while

Daniels and Horace Young, official

Moen, the wire company.

a few months the newly

Wh

shop. I remember th e

went out to Barbers, an almost

city, to see the site that h

pany.

acr

ing of the Boston

and Gardner railroad line

, he was more than

Th

ere

were seven men

s,

of the

ls

and

recogniz

In

accordance with

eel Company k

It

was a pi

es

in

size, which

Lucius

the

er

called him "Charli e."

whe

\i\tashburn

the

rest of the

ept

ece

formed

and

Allen-and

other men.

el busin ess was

war

e ales

up

th e shop

ad bee

ed

the

an

agre

it quarters

day

ad bee

of

Maine

n in whee

ll

th e wheel manufac

agr

eeable-

who

ppson I (superintendent

Shops,

iJ'

pot

pro

fe sor, join

eme

incorporat

in 1886

n cho en for the new com-

land, about

a tri

and

s.

\Ve

he see

He call

men

of

gri11ding

bough

ano

anoth

who had

ential , also inv

capi

tal

nt

with

right

when

uninhabit

ang

le be

the \i\forces

found a two-acre

med

ed

But

to m e then

growing

told !\fr.

wheels. Th

and

the business.

four

l .

Wh

he was delighted

t th e business

th er, a

ed

came

of \Vashbu

ed

one

nd

er. Milton P.

nt

of

th e

from Fre

Mr.

Nor

Norton

at the potte

Moth

ed

part

and a quarter

tween the cross-

my

, so

Norton

u ed

group

ter

so much

father

much

he

ey

-.nfths

tur

ested

the com-

er a

of

en

the

e for

vValter

the

in

ge

l

ra

of

rn

and

ton, for

Emery

ry

nd

of

the

, Barre

plot

.

)

el

I

Page 7

near-by,

a

nd

There

be

rs w

of

for us to m

city.

within

ju t across the

were

twelve men

ith

the

Nor

1887. P

eop

ove

In

fact,

walking

ton Emery ·wheel Company

le in gen

three

the

months before they

for the

tran

w

eve

year-o

50

adve

draft kilns

ho rsepow

ing,

lamps.

property.

sported

ago

n.

from VVater

Th

ere

n room left

ld boy.

The

Company

' x 120' in ize.

rti

sed

for rent. Th

with spac

er engine

what

\i\lat

little

er

The

wa

on

the wagon for me, an excited,

moved

It had

with

there

wa

pipe from vVeasel Bro

The motto

tary's

han

th e

point:

of

dwriti

,

ve

the

ng

will

of

we do today.

It

was a good motto,

distanc

e, for

our

family

street, Charles Allen rent

who

made

eral thought

miles away from the

directors th emselves

agreed to

pay

manufacturing equip

n't

Street

much

to Barbers in a

to

mov

into a wooden

tlu·ee sto1ies,

ere w

ere

e for a tJ1isd.

a single, s

was,

was

brought into

ok

which

Company,

the early

mak

e better wheels tomorrow than

ran

as recorded

yea

and a good

the

it

quit

debated

the necessa

e.

In

fact, there

builcling

one

two twelve-

There

mall

boiler.

provid

the

ed

shop

through

rs,

was

proph

ecy

move

e 1idiculous

cen

ment was

of

was a

by

by a tw

the

in tJ,e

simple

home,

ed a

hous

to

in

January

ter

of

for

ry

one-horse

thirte

abo

which

foot dow

£fteen

The

light-

keros

o-inch

prop

secr

and

.

e.

Bar-

the

six

$450

all

was

en-

ut

was

n-

ene

erty.

eto

George

keen interes

scene

cessful vitrified

of

N.

t in re

making

Norton

J e

ppson

the

wheel for

film

-cre

takes

ati

first

on

suc

new

a

of

-

Now

when I look

at

the

mil

es

of

buildin

gs

her

e, a

nd

page 5

Page 8

think of the Norton plants a

that day. As yea rs go-se

long ago.

But

so much has

As we consider the Norton business a

- both men and women-who h

it,

it

seems like a dream to u a

Our founders, whom I kn

all

fin

e me

n.

Th

ey understoo d people, a

t

he foresig

Wh

at is remarkable to me is to

ht

and

courage

ll

over the wo

venty-

five of them-

happened

nd

ave shar

ll who h

ew from the b

to ex

pand

- al] over the

see

in

rld

, I re

it

in

those years.

th e many

ed in deve

ave

live d

egi

nnin

nd

they

the

third genera-

member

was

with

g,

tion of our people that same desire to keep Norton

gressive and

Norton folks loyal and

today as we

li

eve it is rath er uniqu e to h

seventy

have been an associate of those who h

Norto n Company wh at

Norton

Comp

fir

st in o

ll

as what

-fi

ve years of o

any,

Worcest

ur field, a

prou

d of

ha bee

ur

history, a

it is.

er, Massachus

nd

also to keep a

ll

what they are doing

n done in the past. I be-

ave lived thrn

nd

I am g

etts

( I

959)

ave

ugh the

rat

eful to

mad e o

not

people

loping

it.

were

had

world

pro-

of

our

se

ur

.

.

- -

',

..

••

. . ~

--.

. . -

. .

--

~

1J

\ -·

#>

~

~~

-~-

I.

Page 9

Plant 8

GRINDING

WHEEL

MANUFACTURING

by

l t is very fitting that we observe our S

Anniversary

Plant

8, our newest

ture of

g

rindin

as

th e focal po

ing

as

it

tury' experi

Th

e fir

for the

equivale

vid

ed

fo r a 50 per

the

fast

e timated incr

sixty million in the next fifteen

mu

st be consider

But

even more

prov

isions th

ucts with a builtpossibl e; also a r

the

use

t

oge

ther

te

chn

iques.

with

th e compl etion a

fac

ility, whi

all orga

g wheel

nic bonded ( res inoid ,

s.

In

fact, this pl

int

of

our

cele

does the culmination

ence

in the manufacture of gri

st

thi

ng that

Br

t time i its enormous si

nt

to five foot ball field

growing

ease

will

cen

t expansion in pro

u e

of

organic

in o

ur

ed

wi e planning.

important than

at

of

the very lat

with

have bee

in

educ

impr

n m

quality a

tion in the manufacturing cycle by

est

oved manu facturing processes a

nd

ch

houses the man

ant

can we

brati

on thi s

of

three-qu

imp

ress anyo ne

ze-i

s.

Sp

bonded

country's po

yea

rs, thi s extra capacit

pla

ade

to insure finish

nd

uniformity

type

mac

hines a

rubb

ace

nt capacit

John

Jeppson

eve

nty-fifth

full op

month

era

er a

nd

ll

be r

, represe nt-

tion of

shellac )

egarded

arters of a cen-

nding whee

seeing

t covers

Pla

an area

has been pro-

ducti

on. \ Vith

whee

ls, a

nd the

pul

ation by

y are the

ed prod-

never befo

nd equipment

ufac

ls.

nt

8

some

y

re

nd

TODAY

*

-

· Vi

ce

Preside

nt and

Genera

l ~l

anage

r, Ab rasive

Divb

ion.

Page 10

Fig. I.

must

and

"Gree

pass inspection for

static

balance

n"

wheel

before burning

blanks

weight

Some of the more

automatic elec b·onic e

processing center, for precise

sives and bonds;

and

equipm ent, som e of

equipm e

nt

and cming

ods for finishjng wheels

apparent improvements

quipment

, ti ed to our

automatic weighing

new

mixi

ng

and

it

fully

automatic

procedur

to close

e ;

new

dimensiona

mo

prec

proved inspection method .

To provide quick deliv

how dis

tant

they m

ing large stocks of

items in our new Plants 7

ous branch

war

ehou ses l

ery

ay

be from \

fini

shed wheels a

and 8 and

ocated

to

our

customers r

i\lo

rces ter,

nd

in major

also in o

throughout the counb')'•

Pl

ant

7, completed a few years

the manufacture

rable to Pl

ant

of

8 in si

vitrified

ze

uct quality is th e key

plant

s,

taken together, include whee

and

not

bond

facilities.

e.

ago and

ed

wheels, is compa-

Here

The products

ls

ranging

from the smallest "i 'vlinigrind" vib·ified mo

only .036"

snagging wheels

in

diam eter to

up

to 36" di

the rugge

ame

ter.

d "BZZ" resinoi

include

IBM

of abra-

lding

methods

; new oven

ision meth-

l limits, im-

egardless

we

are carry-

other

abras

ur

market areas

devo ted to

, too, prod-

from

in size

unt

ed whee

data

ive

vari-

both

ls

cl

pa

ge 8

Page 11

Fig. l shows

tion .

or

weight

side

r

conveyed

bond

insure

After

ganic

the

ejected

After

type, equipp

bond

and

close limits

in

molding

to

th e

bond.

It can be said

(

bonding str

ti

cs are sealed.

wheel

ba

the

hole.

and sharp

tomer

the

cutting

ci ion

are

ic

surfaces

face

or periph

It

is very

receives

molding

points and

truing

, i.e., in

an

imp

ortant

detail .in

each wheel is mol<lcd,

ed, it is

for balance.

carefully

Any

wheel

that have been

th e

"green"

tunnel

exact

eng

th

The

nevertheless very

that

state.

and

kilns

ed

"green"

with

inspection,

or

ovens,

sensitive el

predetenninecl

that

once the wheel

or hardness)

finishing

operations

important.

hav

e to be finished

ery, the two

parallel

important that

condition

the

wheel.

operation

must

edges.

with another

for

The

be "dressed"

This

g1inding wheel, a coni cal steel

the

wheth

checked

blanks

set

depending

ectronic

firing

molding

er vit::rified

for size,

that

up

are

the whee

or

cwing

is

fir

ed, its

opera-

"green"

fall

promptl

ls

upon

controls to

of

gra

and cutting characteris-

perform

or

sides a

the grinding face

g1inding

ed

Th

ere are four

trued,

nd

nam

the a

be

when

the cus-

on

rbor

smooth face left after

to expose sh

is

generally

clone by

or

out-

are

the

the

de

the

ely,

tru

arp

pre-

y

e

Fig.

2.

An on-line ins

pection

station

for

cut

-off

wheels

Page 12

cutter

forced cut-off,

to

or a diamo

put

the

Grinding

nd

other b·uing

face

in r

eady-to-cut conditi

wheels are,

tool.

in

For certain

as "stones" or "rocks," terms

origin

on fa1ms for

They

made

that

provided

size.

sleeve

action

ing

certain types

vanced ma

porat

ab

and

in

the

do

not

grinding

in

spected

tooth

cut

with

ter.

is sh·ucturally

care

Oth

en1/ise

or

spind le which in

and

equipment now

\

iVe have

ed

into our

ling

us

to set new high

produ

ct

quaJTied g

puttin

, h

oweve

whee

the

Tak

e, fo r exa

rindstone

g a keen e

r,

befit

l whi ch, aft

same

care

mple

urufonn

is t

ake

n in

finishjng the hole to the

it

will not be in

finish.

Fig

. 3 shows the strictl y precis

standard

of

wheels.

The

discussed just a

nufactusing methods and

new wheel plant

standa

duplication.

vVe

meth

wheels,

ods have

been

like rein-

devised

on.

some

will also be in

areas, sti

which

dge

the

er

probably

sti

ll

on

modern

firing,

ll referred

very

an

axe

, cie

is

much

finished a

as its counterpart

, the

arbor

hole. A wheel

good

have their

in use

or

scy the.

ntin

cally

.in a multi-

balan

exac

balance

on

the whee

turn can affect the grindin

ion

hon-

for

tole

few

finishi

ran

of

rd for

hould a

ng

the hol

ce

here .is only 0.003".

the very l

tech

s a

nd

ates

niques incor-

which

built-in

arc

qua

cld that the fini sh-

es

t,

to

nd

ce

in

ad-

enlit

t

l

g

y

Fig. 3.

Precision

to

close

honing

arbor

tolerances

holes

page 10

Page 13

Fig.

4.

Speed

resinoid

i

ng operations

satisfied that the wheels are struc

from any

hidd

safe. Fig. 4 sh

cu

t-off a

nd

exce

ption

s, a

tested befor e shipment, after all finishin g operations

testing

cut-off

wheels

are

consider

ed

en flaws that mig

ows

the sp

eed

other relati vely sma

ll whee

ls 6" in diameter a

complete only when we

tmally

ht

render the wheels un-

testi

ng equipment use

ll whee

sound, i.e., free

ls. vV

nd

ith

very few

larger are speed

d for

hav

been compl eted.

Fi

g. 5 show a view of a small

located at the e

Th

ere are 26

larges t stock

nd

of th e Plants 7

1/2 miles of shelf sp

of grinding wheels in the world.

approximately 20,000 sep

ara

sec

tion of th e stock ar

and 8 production

ace

. T

h.i

s r

eprese

It includes

te .items and a total

lines.

nts th e

of

some

six million wheels, in suring q uick delivery on all standar

it

ems to cust

aro

und the cou

ou r anniversa ry sl

thr

ough servi

ome

rs, distr

ntr

y; and, inciden tally, givin g s

ce

to industry."

ogan:

ibut

ors and o

"S

eve

nty-fi

ur five warehouses

upport

ve year

s of prog

ress

are

e

ea

d

to

Fig. 5.

ic

e"

station

small finis

s

hunt

e d

conveyor

At

"cust

omer se rv-

shown here,

hed

whe

be

els are

packed

nt

from overhead

to

shipme

for

Page 14

60

YEARS

Norton

Cr

ankshafts

OF

BUILDING

Crankshaft Gri

for

most

nding Department

early

automobi

les were

around

ground

1910.

here

page

12

PRECISION

Whi

le

the :\•fachine

cannot

ness,

rupt

chines.

of

Charles

Norton

quite

it

can

ed

production

tl1e first

Grinding

First

proving

It rece

H.

GRINDING

Tool

match its pa re

justly take pride in its si

of preci ion

ived its s

heav

Norton, chi

Compan

to

tart

y pr

oduction

ef engineer

his

satisfaction

y.

actually cuts metal, he had the r

signing a cylindiical g1incler that

possible, not

idea. The result

heavy

18"

duty g1inc.l

swing

Vi

ce

and

Preside

as litt

le as poss

1

of

:\

Ir.

Norton's

er that w

eig

96" table lengtl1.

nt an<l

General i\l

Division

nt

division for

grind

in

1900

cylindrical grinder by

evo

would

ible

as was

inventive genius

hed

13,000 pounds, with

It used a grinc

anagc

r, .\fachine Tool Division.

MACHINES

by

Ever

ett

M.

of

Nor

ton

Company

years

xty

yea

in g

and

with the d

of

the

newly

that

a g

rin

luti

onary

do

tl1e

rs

of

uninter-

lapp

evelop

ding

idea

as

much

prevailing

Ung

in busi-

ing ma-

forme

Hicks*

ment

d

wheel

of

de-

as

was

an

wheel

a

Page 15

24"

in

diameter

former

effic

ient

wheel).

than

mechanism

The

first

pany in

New

and

Its

any

other

was

so

of these

York

cutting

accurate

machines

their p1inting presses.

ice,

machine

pany

and

ogy, D

earbo

llight

of

grinding

production

on

the

steel

ton engin

in fifteen

hours

of

No. 1

was

presented

rn, Mich.,

from

the

start,

machines

of

the automobile. As

crankshaft,

eers

showed

minutes

turning

by

, filing a

cepted!

At

first,

most

of

th eir

crankshaft

1905 th

grind

an

ances

l

ower priced

od

machines

auto

ing.

order

The

to

industry

ey

were

Ford i lotor

for

35 machines!

grinding

required

reduce

have

interchangeable

every

1 o

also the

with

garage.

rton

CnANK-O-rvfATIC

long

automatic

cult contours

ground

purchasing

machine

by

mass

automobiles

costs. As a

been

to

provide

parts

These

popular

functions that grinds and

on a

utomotive camshafts

effor t.

2" thick

(four

action was sixteen times

machine

it

served

was

for

grinding

After

27

purchas

to

the

Edison

where

has

that

grinding

the

it

the

development

paralleled

the

backbone

as

much

as

nd

polishing.

automobile

by

machines

Company

made

production,

required

result

develop

which

the

ed

low

has

developments

semi-au

CAl\'1-O-MATIC

times as

in

existence,

as a

sold

to R. H.

wide

and

micromet

cyUnder rolls

years

ed

back

Institute

can

of

continuous

by 1orton Com-

of

be

seen today.

and

the

development

early

as 1903,

of

the engine

work

could

was

being

done

Grinding

manufactur

lorton Compan

to

do

optimisticaUy

possible the

and

mass

precise

the

production

, specialized

over

the

years

cost

mass

production

put

an

automobile

brought

tomatic

crankpin

g1inder, a

finishes

without

as

any

more

its

feed

er.

Hoe

Com-

used

serv-

Technol-

production

and

working

, Nor-

be

done

in

five

was

ers

had

y,

but

their

own

placed

toler-

demand

meth-

grinding

for

forth

grinder;

machine

the

diffi-

manual

on

ac-

by

for

the

of

in

the

Wc1lker

Cutler

ton

Universc1I

grinder

Emery

around

sold

Wheel

Tool

by

Company

1900

~

-

..

-k;S::

'=---'-

~

= e

. -

~

i

and

Nor-

Page 16

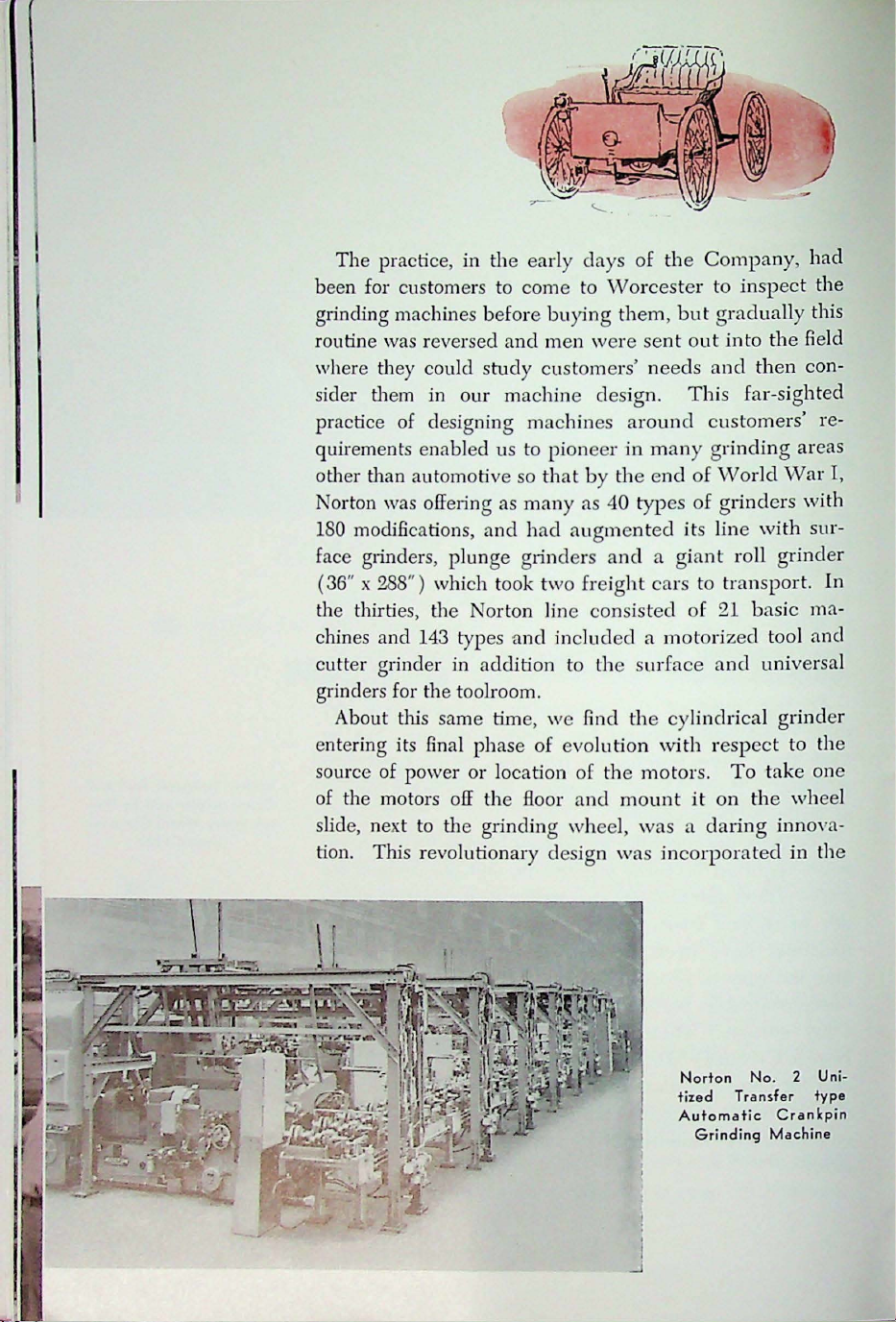

The

practice, in

the

ear

ly

days

of

been for customers to come to \i\lorce

grinding machines before buying them,

routine was reversed

where they could

sider them in

practice of design i

quiremen

ts

enabled us to

and

men

were sent

stu

dy

customers' needs and then con-

our

machin e design. Thi s fa r-sighted

ng

machines

pioneer

around

in

many

other than automotive so that by th e e

Norton was offering as

180

modifications,

face g1inders, plun

( 36" x

288

") whi ch took two

the thirties, the Norton li

chines

and

143 types a

cutter grinder in addition to

grind ers for

About

the

th.is

same time,

tooL-oom.

entering its final

source of pow

er

of the motors off the floor

slide, next to the grinding

man

and

had

ge

grinders

nd

phase of

or

location

y as

40

typ es

augmented

and

a g

freight cars to transport. In

ne

consist

includ

ed

ed a

the surfac

we

find the cylindrical grinder

evoluti

on with respect to

of

the

motor

and

mount

whee

l, was a da

tion. This revolutionary design was

the

Cornpany,

ster to

inspect the

but gradually

out

into

custome

grin

ding

nd

of

·wo

rld \Var

of

grinde

its lin e

iant

of

mot

orized tool and

roll

21 b

with

as

e and univ ersal

s.

To

it

on the whee

ring

incorporat

ed

had

the

field

rs' re-

areas

rs with

grinde

ic ma-

take

innova-

in

this

I,

sur-

r

the

one

l

the

Norton

tized

Automat

I

I

_j

Tra

Grinding

No.

nsfer

ic

Machine

2 Uni-

type

Cran~pin

Page 17

First

Norton

grinder

Institute

Watching

Henry

Ford,

Knight,

heavy-duty

was

of

Technology

uncrating

Howard

Charles

presented

were,

Dunbar, Oscar

Jinnette

cylin

to

in I

drical

Edison

I.

to

928

.

r.,

Norton

de

more

"C type" line of machines.

ign is

oft

atte

en

than

New ideas

e

mploy

th

ea

ing

of

rrc

chines.

Award

ese

rly

out

produ

tting

ed

were

thirtie

the

ct.

rid

The

as "

in

inh·ocluced

s. A

factory

This

of

progr

since been amp

and, of

modern

Starting

utiliz

as possible,

the point

believab

chines

but

specific

simplicity

ch

ines

course,

}.fachine

with

ing

the

grinding

where

le

limits of

built

today

also

spec

requirements.

in

are

available

grinding

The

ted to

and

the

obsolete

Ame1'ica11 i\ln

by

the

fact

almo

st

any

innovations also

building

of

during

houseclea

by

was

ning

machine

a revoluti

equipment and

chi

es ive

lifi

was

Tool

Charles

equ

ed

into a standa

incorporated

Division

Norton's 01iginal

ipme

method to

machines

they

are

now

precision.

includes

not

that

it

other

machine.

app

our

machines.

the

depression years

event

culminated

processes

onary

n-ist

recognized

nt

replacement." It

rd

industiial

into

plant

erected

remove

have

been

capable

The

line

only

plain

ial pm·pose g1inders tailor

design

While

and

with

reflecting

operation,

many

arrangements

soundness

has been

ly to

the

of

copi

methods

Many

of

in

instead

step

buying

as

of

it

entailed

new

it

with

practice

the

Company's

in

1953.

concept

as

much

stock

developed

of

almost

of

Norton

or

basic

types

ed

to customers'

the

trends

of

toward

these ma-

pem1itting semi-

this

ed

of

the

lay-

line

ma-

its

has

of

to

un-

ma-

page

15

Page 18

I I

::

m®~

'

...

-

,

..

-,

;:_,,-.

automatic or full

tion.

In

this category i

Automatic Crankpin

units (stations)

to 360 completely

Another n

con truction

ca l grinde

make the grinding

ing and production rates a

of practically perfect radii on

Last

with our No. 2 Sh·addle-Bearing C

turing traddle-bearing s

regulating wh ee l spindles to permit

si te

surface grinders has

S-3 machines featuring table

Th e acgui

of Gould &

chine tool

hobbing and

In

of the more obvious re

to our machine tool line.

attachments will

chine Tool Exposition this fall

sixty years of building preci sion g1-inding

ma

chin

every Norton man

r.

year,

nt

sizing.

iti

this brief artic le we

es-a

automatic

Grind

capab

le of

ground

ew

concept

fa

reflect

ed

Wheel head

cycle fully automatic, spee

we ent

on of

Eberhardt

product

cutting

heritage and

ered

The effi

been stepped

the

line to

machines.

be

shown

and

operation

the

No. 2 Uniti

er,

comp

automatically

cra

nkpins per hour.

of

unitized machine

in the

cien

well-known , l

last

cent

woman

PLU

NCE

b·uing has been

nd

making

the

whe

the large cent

enterless G1ind er, fea-

upport

cy

have

Our

and

record

of

of the po

speeds

year has

include shapers

only

deve

lopm

latest

demonstrat

in

Chicago.

of

can

for mass

zed

1i

ing

-0-MATI

possibl e the

el co

erle s

both

faster

pul

up

in

as

high

ong

e tablished firm

ext

ended our

touched

ents

model

achieveme

be

justly

produc-

Transfer

type

fow· to seven

turning

rners

grindin g

and

ar 6"

the

and

machines

ed

out

design and

C

cy

lindri-

perfected

ding

up

tru-

truing

.

grinder

as 125 fpm.

upon some

at

They

and

nt

proud.

field

mor

e con-

and

new

Type

and

gear

additions

the i\ifa-

reflect

lapping

of

which

and

ma-

and

up

to

8"

page 16

Page 19

PRODUCTS

OF

THE

ELECTRIC

FURNACE

Abrasives,

formed

done, man

sy

nth

esi

typ

es

of elec

Norton

is also markin g the

ele

ctric

sive, re

born.

Actually its first

at Ni

aga

ab

ility of

future power

Canada

Chippawa,

The two plants continu

the

Niagara Fall

e

ntire opera

Thi

s pl

lar

gest produc

and

in r

The chi

h

ave been and

ALUNDUM

crushed and shipp

abrasives

The

co

ntroll

Vice Preside

Electr

in gen

at

elevated temperatures. 'vVhat

ha

s.

Thi

tric

Comp

furnace

fractory and

ra

Falls, Ne

lar

ge

and a furnac

thr

tion was

ant has

efrac

tories.

ef

products

fused a

for

hig

h standa

ed,

to a great

nt and

o-Chem

era

been able to

s h

as been

furnac

any, in cele

50th year

plant

furna

w York, a

quantities

possibilities appeared

e pla

ee

miles so

s,

New

gro

wn

er

of raw

still

are

luminum oxid

ed to

furth

er

proc

rd

Gen

ical Division.

Norton

and

by

Howard

l,

are

compounds

equal

accomplished

es.

brating its

of

wher

e its va rious

elec

h·o-chcmical

ce

plant

was established in 1901

ttra

cte

of low

nt

was

uth

of

Niagara

ed in

mov

steadi

of

of

degree, rig

ernl

operation

York, facility was closed .

ed to the

ly

and

materials

the

Chipp

CnYSTOLON

es.

Worcester

essing

quality

and

of 1or

ht

;\fanag

cr, · -

Abrasiv

Electr

or

operation

d th

co t

built

Chippawa

is

for use

awa

silic

in

at

o-Chemicals

J. Daly*

which

improve upon

by

use

75th

man-made

compounds

ere

pow

very

at the vill

Falls,

until 1930 when

today

furnace pla

on

Th

ese

bulk

fab1ication .

ton

the

furnace plant

es,

have been

nature has

of

various

anniversary,

of

its

huge

abra-

by the avai

er.

In

1910,

atb·

active

age

Ont

ario.

The

location.

the world's

as

abras

ives

carbide

are

as "crud

products

and

rough

Refractories

by

are

l-

in

of

,

....

• ~ , I

I . ·

nts

e"

1iri

is '

',!?

_.

.J \ -

.;$1J ~

~•r

·~~ 1

~--~

- -

Tuill!!l'ul!l!!J'

,.r,;r.,ffl~~

,;;?;,

:,,

T 1

11

11

Page 20

-<·1'J

='

where

developme

raw

prime ingredie

from South America and clom

pe

Stat

silicon

and

mad

po it for many fused zir

from the rich Californi a re erve

for numerous bori<les.

terials

scientists

developme

for better

taining

niqu es has re

tvlost of the

are at

niques, unique to this

developed. Some

32, 44 a

abra

electrical

MACNOnt

stabilized and unstabilized. R

h·o-chemical

oxide

finding use in areas other

and refractory field .

metallurgical

furnace

their processes.

the

fused

nt

staffs

mat

erials from all

b·ol

eum

and

es

and

Canadian

carbide

Asia from whi

e; zircon from

are being

and

nt

raw

and

impro

Th

e devel

ive, green

:Many of the

opment

proc

temperatur

nd

57 ALUN

CnY

STOLON

TE

refractory

compounds-t

families-was

produ

product

are

nt

of

metallurgical cok

· magnes ite

con lantly s

technician in the Chi

laborat

material is

ving the

ultecl

e se carri ed

es we

of

CnYSTOLON abra ivc

more rece

indu

stries re

cts as

To

is

created.

constant

corners

ALuNou:-r

ou

rce

from

ch 1 IACNOnt

dom

estic, Af1ican

conia

Th

e e

ories.

of

in

the results

ou:-r

materi

added

raw

service

This neve

an

qua

new

or

man

y new

ll

over

industr

abra

al;

gra

in

he

borid

to th e l

ntl y d

than

Th

e electr

quire many Norton electric

materials

and

ly

of

for

and many

tudi

important

impr

out

y,

and

ece

Here,

checking

the

world:

fused

stic sour

es

from

producing

North

TE fused magnesi

produ

are

ed

ppawa resea

lity

of

oved furnacing tec

and useful product

at the

2000 °

hav

e n

of

this re

ive ;

white 38

and ''Special

Nonn

,oE

fu e

ntly a long

e,

carbide,

orton

eveloped

the establish

onic,

or

expand

research

the

bauxite,

aluminum

ce

; silica

many

CnYSTOLON

America, Europe

and Aus

ct ;

the

by

r e

J o

C.

el

intenn

tralian

boric

raw

other

a team

ndi

ng

fac

tor

rton

furnace plants

Special te

ecessa

earc

boron

zirconias,

list

nitride and

product

products

ed

chemical

ediates

this

market,

and

quality

mat

raw

in

products.

rily

h are

ALUNou:-r

of

the

oxide,

sand,

United

it is

de-

oxide

erials

ma-

of

125

rch

and

sea

rch

main-

h-

ch-

been

the

Black"

carbide,

both

of

elec-

lin e.

are

abrasive

and

for

the

.

71a

ge

18

Page 21

Electro-Ch

is

an

only

.field

s,

plants

other opera

nical

operates

furn

ace

To kee

refractories

has

steadjly incr

compl

con carbi

in

Quebec province.

1955, a n

ville,

Atomic Ener

NonnrnE r

of

both these last

s

upply of elec

futur

emical Division was

operating

for deve

but

producin

division

lopm e

also for the

g elecb·ic

ting divisions.

guidance

or has

to

an

plants around

p p

ace

with the growin g de

and elec

ease

etely

cover

de

its 32-acre site.

plant

ew electric

Alabama

gy

efracto

, to

Commi

ry

two sites was based

trical

e lar

ge

ex pansions possible.

pared, both physicall

lenge of the e

xpa

nding

of

nt

of

operation

Norton

int

erest in

created

the

compan

new

products

of

all the

furnace products

In

addition, it

Int

ernational

an

increas ing

in

1956.

y, res

ponsible

for the

Norton

for all

supplies tech-

Inc.

which

numb

the world.

mand

for

abras

tro-chemicals, fusnaci.ng capacity

d.

Chippawa

wa

opened

Thi

s was enl

furnace plant

produce sp

ssion, as we

gra

in, a

nd fuse

power and land

y a

nd tec

space

's

plants now

In

1951, a n

at Cap

ecial

arge

was

ll

as 1

-de-la-Ivla

d in 1959.

built near

product

1

fA

CNO

d zirconia. Selectio n

upon

an

hnicall

age

which

No

y, to

markets.

would

rton is well pre-

meet

s for

HIT

adequate

the

This

not

above

furnace

the

now

er of

ives,

almost

ew

si]j-

cle

leine

In

Hunt

s-

the

E

and

make

cha

l-

CRYSTOLON sili

these

resistance-type elect

con

carbide

is

ric

produced

furn

ace

ALUNDUM

s

Higg

aluminum

ins

arc

-ty

oxide

pe

electric

is

produced

furnac

es

in

these

Page 22

Plants and Machinery

..

Operations

The

basic ingredients

and

high

tempe

horn

in

the electric furnace.

pl10tog

our readers to

Plant

in

coolin

ultra-modem whee

phasis is

th

ment control s

pages.

pa

rapl1

in

Chippawa

g "pigs"

Throug

e firing op eration in electric

ge

of fused alwnininn

g; then

hout

7,lacecl

20

rature refractori

s, all in true color,

the vast Norton Elec

to

the

on

hown

of

, Ontario, where the s

Wo

rcester

l plants, 7

wheel

qttal'ity c

in ·

the pic

and

today

's

es

In

the

tha

t follo

oxid

whe

and

8.

manufacturing cycl

ontrol

kilns

ture

Workers

grinding

are the,nselves

eight

e are seen s

re

as typ-ifiecl

pages

w,

we

tric Furna

till

we visit

ttncler

on the

whee

tak

ce

glow-

lowly

the

e e

m-

by

instru-

center

ls

of

e

Page 23

Carbon electrod

in this H

iggi

ns

ore

es

type

fuse

elec

the

tric

mineral

furnace

bauxite

at

Norton

into ALUNDUM

Electric Furnace

(aluminum

Plant,

Chi

oxide)

ppowo,

abrasive

Ontario

Page 24

"Pigs" of

ALUNDUM

abrasive c

Furnace Plant

ooling

on

the

floo

r at

Chippe

wa Ele

ctr

ic

ROKIDE

(aluminum

ceramic coating is s

missile nose

to

ry

by technical

B

urke.

cone in

Nort

assistant,

pra

yed

on

ox

ide)

on

laboraGordon

a

Page 25

CRYSTOLON

(silicon carbide)

abrasive

elec

tric fur n

aces

is

produced

in these

resistance type

Page 26

Page 27

Page 28

Section

of

stock

area

where

wheels

the

of

every

production

type

lines

ond

size

ore stor

ed

as they

come

off

Furnace

Electr

unloader

ic Furnace Pion!,

, Eugeniusz

Krzemien

Chippewa

,

Page 29

Kiln

car

fireman,

loaded

long

Ola

with

journey

Hokanson,

"green"

through

beside

wheels

tunnel

ready

kiln

typical

to

kiln

start

Press

preparing

grinding

blank

is

operator,

to

mold a vitrified

wheel.

then fired in

The

tunnel

Harold

"green"

kiln

Cooper,

bonded

wheel

on

electric

Pia

nts 7

equipment

and

in

the

8,

world

each

600

for

straight-line

feet

long

, house the most

production

of

up-to-dote

grinding

whee

ls

Page 30

Engineering

Machine

draftsman,

Tool Division

Herbert

Rand,

Group

the finishing

for

leader,

grinding

touches

pulpwood

Fred

on

Anderson,

a g i

ant

for

On

this special

putt

pulpstone

newsprint

ing

machine,

l

arge grinding

exact

thickness

wheels,

and

Aotness

ofter

burning,

ore

trued

to

Page 31

IN

THE

Not

long after

pany made a

' tri al expansion by

duction

silicon ca

grow

th

fo r

producing

purified

organization to

us

to recog

ca

rbide ore and

specialized refractories .

major

of

ALuNou:,_c aluminum

rbid

e

mmwfactured abrasives. This

provid

raw

ed l

and

mat

erials. The

improve

nize the value

SPACE

the

turn

of

the century Norton

contribution

attaining

arge electr

refining th

grain

continuous,

ic

ese

inherent urge

and

diversify its pr

of

aluminum

as

valuable

AGE

by

Willi

am

G.

to the American

larg

oxide

furnace plan

and

electrically fused

of the

oduc

oxide

basic materials for

• • •

Fallo

n,

Jr.*

Com-

indus-

e scale pro-

CRYSTOLON

step

in

our

ts

suitable

and

Norton

ts

caused

and

silicon

.. Vice Pres

ident

and

Cenernl i\fanager, Refractories Division.

I

Page 32

In

those early days, merely the hi gh me

ALuNnmr

important

move into the Space Age, this

tempera

thermal

ucts, remains

dramatically illustrated by the decisi

me

nt

sprayed

of o

ur

The

was a small line

bl

es, boats, cements,

are

highly

of

purit

l

abo

ratory utility.

Only a few examples

high tempera

d

evelopment

together a versa tile array

properties so

unique combination

and

to

indusbi

gra

in ( 3700°F.)

as a

refractory

tur

e,

coupled

conductjvity

important

to use o

first successful satellite, Explorer

first

electrical

ur

aluminum

commerc

regarded

y,

resistance to chemica

ture field can be cited here. Co

work

that

chara

al progress.

with

of

RoKID

ox.ide coating)

ial offering

of

ALu

etc.

by precise che

with

each Norton

of mec

cteristics th at has b

was

raw

mat

same resistance

the

chemical durability

highly purifi ed

to

nation

E "A"

Nnu;,.r laboratory

protecti

on

of

They have

l attack,

of Nort

new

of

on

refrac

materials having "

hanical, the

sufficient to

al

mical ana

mat

lting

point

make

erial.

Today,

to

ALUNDUM

prog

ress.

on

of

ve

coa

the exterior surfac

l.

Norton

cruc

lon g been a

pa1-ticipation

tories h

erial represents a

rmal, chemica

eco

me

This

om

gov

ting

(Bame-

refractori

ibles,

nd

lysts be

and gen

ntinuing

as brought

built-Ln

important

of

it

as

we

high

and

prod-

is

ern-

es

thim-

still

cau

se

era

in the

e

l

"

l

----

----.:

Page 33

The build

ar

e continually

ers

and use

see

king

rs of

large furnaces

more rapid heat

as stronger and, therefore thinn er, lining

characteristics are typical of today's

ALUND

u

on faster ch

Cn

qu

u

fi

ab

meta

less steel a

th

nu

vehicles, and e

UM re

fra

ctories a

se

in

indu

stry becau

ecl

ules a

Th

e d

evelopment

YSTOLON hea

ality for ope

( 1650°C

se

ed

Peo

.).

of

HoT R

grinding wheels, in itse

ility

and

ple h

ting elements h

rat

Nor

ton Company itself

oo hea

unifo

rmit

ave grown

nd

acco

se they permit

nd

to re

qui

of 1 orton "

as set a new stand a

i ng tempe

ting elements in the firing of its vitri-

lf a

seve

y of such heating elements.

familiar

with

l , starting with the conspicuous brig

nd aluminum

roug

h a long list which inc

clea r

reac

tors,

ndin

turb

g w

in o

lud

o-jet engines, missiles a

ith

th e am

unt

re

HoT

ratur

ur

es

manium and silico n transistors that gi

im

prove

d co

mmuni

me

nt.

Be

hind all

consta

con

nt req

h·o

l of alloys. Such

uireme

refractory cont

contamina ti

vari

ety

r

efrac

ALUNUU

oxide, stabili

prod

ucts as well

ca

rbi

de

For

melti ng

on

of cru

tories to meet many of th ese needs.

:M fu

sed

zed zirconia

and boride compo

lar

ger

of a numb

cat

ion, as well as c

th ese miracles of metallur

nt

of

purit

y a

nd precise

cont

rol of com position requi res

ainers or crucibles that res

of such metal a

nd all

cibles is inclu ded in the Nort

alumi

num

oxide, MACNORLT

and CRYSTOL

as

some thoria, s

pin

sitions.

melting op

er

of

metals, these

era

tions,

CRYSTOLO

for

their

furnac

less space.

Ron" non-metallic

es

up

mak

re test of the depend-

the so-called mfracle

homes a

larg

azi

ng, compa

ve

omputin

oy

products.

ON silicon c

e], a

suc

h as the

raw

and

kilns

transfer as we

s.

Th

ese two

N a

wide

spre

es to ope

rd

to 3000°F .

es wide

htn

nd

spr

ess of stain-

going on

e chemical a

nd space

ct

11

s a

ll

types of

g e

quip

gy

is th e

compositi on

ult

in min.i

mum

A wide

on line of

Th

ese include

E magnesium

arbid

nd exp

erimental

inducti

materials h

nd

ad

rat

ead

nd

ger

on

ave

ll

of

e

e

-

CRYSTOLON

-widely

ments

in

"Hot

used

heating

furnaces

and

Rods"

ele-

kilns

-

~ . , 31 I

Page 34

I

nlerior

e

ngine are

coal

in g

surfaces

sprayed

lo

protect

ex

haust

of

X-15

rocket

with

them

and erosion

from

ship

ROKIDE

fiery

been formulat

large e

quipment

ed

into numerous cements used

on the

job

techniques.

Many

of our rea

success of pres u

ot

her wear-resistant

carbide

and som e of o

Among the newer Nort

per

hap

the most

tool bit deve l

nal where work wa carri

tool

materials.

be e timated as ye t,

bit represe

nt

ders

re

blasting nozz

component

spectacu

oped

in

Although its

it appear t

a significa

are

familiar wi

ur

oth er

on d

evelopment

lar i th e

cooperati on w

ed

on

ultimate im

nt

development in

metal cutting.

Probably no deve lopme

aroused more

Th

e e are thin, flame-sprayed cerami

pr

otect metals a

int

erest th an

nd

corrosion and erosion

gas sb·eams, or other de

ness of not more

than

cations. Greater thicknesses,

applied, if needed. This n

ce

ramic coatings will

work and we are daily

cesses in the use

of

nt

RoKtDE protective

oth

er co nsh·ucti

of

high

structiv

0.001" m

ew field

contin

ue u

see

ing additional dra

RoKIDE

coatings

of

velocity,

up

by

ramming

th

the

le liners, anvils

made

of

extra-hard

of

ALUNDUM

ith vVate

to find till

portance ca

hat

the

the pos

t-war

c coatin

on

mat

high temperature

e e

nvironment

ay

be us

ed

to

abo

ut

of

nder

active

.

to

line

and similar

phenomenal

and

NonBLDE boron

mat

erials.

this cha

rtown

better cutt

racte

cera

mic

Arse-

ing

nnot

ALUNDUl\I

the field

yea

rs

tool

of

has

coatings

gs use

d to

erials from

s. A

thic

k-

in

some app

0.050",

thin

protect

can

li-

be

ive

development

matic

suc

r

.

-

page

32

Page 35

Ii

\~=;.~

\

~

'

The

is

much

a

few

in

dicate important

commonly

per million," s

referred

First

trical properti es ui table for use in numerous electric

and

ele

tures . Second i

chemical

1

1

ti

c processes to create

In

this

the physical stru c

po

rt

special

devices furnished to

Some of the most spectacu

have requir ed the

temperalu res.

rocket nozzles

cones,

furnaces

for material to

7000°F . ( 3900°C.). Th.is is

ran

ge where a

pr

essures.

The needs

quire f

refractories.

tin

ue

its efforts to

ized non-metals

conb·ibution to

----

list

of examp

too long to

mor

e,

howev

have

to as "poisons ."

is a

group

ctr

onic circ

indush

ca

e not only the precise

are of crilical

Norton ce

ulh

·a-high tempe

and plas

ll

of

urth

er

The Norton Ile

les of

cove

er,

that

instances of service to

limits on composition specifi

ince trac

of

products

uit

s, parlicularly

our

·)' which h

ture and

importanc

ramics for nucl ear or atomic energy

numero

cont

vVork

and

known

bro

with

indu

in

conlrol vanes, missile re-entry nose

ma (arc)

withstand

the

Nuc

adenin g of

serve industry

the

strial progress.

key

r in a sho

des

es

of

line

of

as permitt

mirac

ainme

such areas as nuclear reactors,

ratur

short

solids me

lear-Missile-Space Age will re-

aim

.P~

uses of Nort

rt

erve

mention

und

esirabl e constituents

with "tailor-m

catalyst

les of i

texture of

us

e chemical reactors, sol

jets

frac

of

ncreased

conb

e. Third is a

AEC projects.

lar r

ecent

nt

of higher

have

exposures

crowding the te

lt

or

the

meaning

tories Division will con-

in the fie

maintaining a significant

Electrical

grain

range

on

article.

because

indu

at

higher

supports

ed

the use of cata-

·ol of

the

catalyst sup-

developments

frequently called

up

volatilize

of

ld

MAGNORITE

is widely

surface

refrac

tories

Th

ere

are

they

stry.

They

ed

in "parts

are

ade" ele

temp

era-

for th e

production.

purity

and

mperature

at

of special-

group

higher

to

about

n01

the

tem1

but

of

ar

mal

used

c-

in

units

Norton

p

roducts

Firebird-symbol

made

in

of new

Norton's electric

electro-chemical

furnaces

~-

~

_,,.

'"-"'~~~:::----::::-

'

..

Page 36

Resea r

ch

and

Development-

KEY TO PROGRESS

by

Wallac

e

L.

How

e*

Norton Comp any's phenomenal gro

of 75 years can

search-mindedness of its

that has been placed on rese

century when the first sampl es

(

ALUNDUM

who was then the whole rese

From :Mildred Tymeson's r

Story,"

pleasa

days

we

nt

though rath er unorganized

of

Norton Company. Ge

dous impetus

company policy when

ganization. By 1912 there

be

abrasiv

read:

to

ath·ibuted in lar

found

ers,

arch

of man-made corundum

e) were analy

zed

arch

ece

nt

"Every

man

a res earch man was the

orge Jeppson

a positive

attitude toward

he started a formal research or-

were

chanical or tests, chemical, ceramic

In

contrast

pletion of the

opm e

nt

*Vice President

faciliti

to

the e

humbl

current

es

and

expansion

in

Chipp

Director of Research a

e beginnings,

of

awa

and ·worc e

wth

over a period

ge mea

and

from

to the

the

by Ge

sur

orge

e to

the

emphasis

turn

of

Jeppson

department.

book, "The Norton

situation

four

and

Rese

nd

in the early

gave tr

rese

emen-

arch

laboratories-me-

organic ....

with

the com-

arch

and Deve

ster

, approxi-

Deve

lopment.

re-

the

in

"

l-

pa

ge

34

Page 37

mately 140,000

to

these

activities.

and

is

made

porting staff

as de

mand

we are staffed so

tifi

c skills

trical

and Elec

istry, Ivl

of the

trat

In

e the

eta

the

following

mor

these are in the

cial

applicati

bringing in addition

Two

new materials

electrolytic cells

num metal.

which co

ond is a

ndu

new

square

feet

Our

up

of

78 engineers

of

125.

ed

by the diversification

such

as Ceramic, Ch

as

In

to

h·o-ch ernical

llurg

y a

nd

Petrography.

para

e r

ecen

t n

ew

div

ersity

on, whil e

of

pilot

our

plant

otJ1

al business.

employed

The

first is a

cts

tJ1e elec

C1ws

TOLON

of this same cell. The

enginee

able to

present

mo

in

ing to

the

only

and it is

ar

es

rs, h

ave been shown

withstand the severely corrosive conditions

in

the cell.

re

efficie

nt

g the use

Ca

talysts

the

of these

are

hidd

well-being

function

jn

this association

e lea

din

g to th e successful

es, a

nd new chemicals.

Th

and economical

mat

erials.

the

keys which

en rni

rnc

of mankind

if

it

is

correc

of

Boor

total

this

provide

space

personnel

and

day

many

will

amounts

scientists with

of specialization,

of

Norton

technical

emical, Mechanical, Elec-

Enginee

gra

phs

produ

cts

work

stage,

ers

are well on the w

hav

e been

in

titanium

b·ic

current

refractory

products

e a

lum

ring, Physics, Che

mention

which

and

is

will serve to illus-

int

erests. Man y of

that