Page 1

OWNERS

MANUAL

Multiple Application Concrete Saw

GC55 and GC25E

MODEL:

FORM <<GC55-GC25E rev 4/2010

Page 2

WARRANTY

Norton warrants all products manufactured by it against defects in

workmanship or materials for a period of one (1) year from the date of

shipment to the customer.

The responsibility of Norton under this warranty is limited to

replacement or repair of defective parts at Norton's Stephenville,

Texas factory, or at a point designated by it, of such part as shall

appear to us upon inspection at such point, to have been defective in

material or workmanship, with expense for transportation borne by

the customer.

In no event shall Norton be liable for consequential or incidental

damages arising out of the failure of any product to operate properly.

Integral units such as gasoline engines, electric motors, batteries,

tires, transmissions, etc., are excluded from this warranty and are

subject to the prime manufacturer's warranty.

This warranty is in lieu of all other warranties, expressed or implied,

and all such other warranties are hereby disclaimed.

Important: Before placing equipment in operation, record the following

information.

MODEL:_________ SERIAL NO.___________

PURCHASE FROM: _____________________

ADDRESS: ____________________________

CITY_______ STATE ______ ZIP ________

TELEPHONE NO. ______________________

Before using this equipment, make sure that person using it

read and understand the instructions in this owner’s manual.

2

Page 3

Table Of Contents

CONTENTS PAGE

I. Preparation

A. Safety Precautions 4-6

B. Assembly 7

C. GC55 and GC25E Series Concrete Saw Specifications 8-9

D. Engine GC55 Models 10

E. Electrical Connections GC25E 11-12

Wiring Diagram GC25E 12

II. Operation

A. Installing The Blade 12-13

B. Starting The Engine GC55 13

C. Operating The Saw 13-15

D. Cutting Technique 15

E. Green Concrete Cutting 15-18

III. Maintenance

A. Engine 18

B. Bearings 19

C. V-Belts 19-20

D. Depth Control 21

E. Dust Removal System Adjustment 22

IV. Parts List Section

A. Ordering Information 23

B. Parts Drawing / Service Parts List 24-38

Blade Guard Assembly GC55 and GC25E 24

Cutting Head Assembly GC55 and GC25E 25

Blade Shaft Assembly GC55 and GC25E 26

Depth Control Assembly GC55 and GC25E 27

Engine Assembly GC55 Only 28

Motor Assembly GC25E Only 29

Frame Assembly GC55 Only 30

Frame Assembly GC25E Only 31

Front Pointer Assembly GC55 and GC25E 32

Main Assembly GC55 Only 33-35

Main Assembly GC25E 36-38

Read Owners Manual Before Use

Safety Alert Symbol: Information Following This Symbol Is

Very Important.

Use Only Norton Diamond Blades

3

Page 4

I. PREPARATION

A. Safety Precautions

Important! The following safety precautions must always be observed.

Hazard Symbols

Fuel (gasoline) is extremely flammable and its vapors

can explode if ignited. Store gasoline only in approved

containers, in well-ventilated, unoccupied approved

areas, and away from sparks or flames. Do not fill the

the engine near spilled fuel.

Engine components can get extremely hot from operation. To

prevent burns, do not touch the engine or related parts while the

engine is running or immediately after it is turned off. Never

operate the engine with any heat shields or guards removed.

Keep all guards in place when operating any piece of

equipment

Keep hands, feet, hair, and clothing away from all rotating parts

Lethal Exhaust Gas use only in well ventilated areas. Engine

exhaust gases contain poisonous carbon monoxide, which is

orderless, colorless, and can cause death if inhaled. Avoid

inhaling exhaust fumes, and never run the engine in a closed

building or confined area

Never tamper with the governor components of settings to

increase the maximum speed. Severe personal injury and

damage to the engine or equipment can result if operated at

speed above maximum. Always obey the maximum speed

rating of blade.

fuel tank while the engine is hot or running. Do not start

Never use the fuel as a cleaning agent

DO NOT LIFT THE SAW BY THE HANDLE BARS

4

Page 5

Dust and Silica Warning

Grinding/cutting/drilling of masonry, concrete, metal and other materials can

generate dust, mists and fumes containing chemicals known to cause serious or

fatal injury or illness, such as respiratory disease, cancer, birth defects or other

reproductive harm. If you are unfamiliar with the risks associated with the

particular process and/or material being cut or the composition of the tool being

used, review the material safety data sheet and/or consult your employer, the

material manufacturer/supplier, governmental agencies such as OSHA and

NIOSH and other sources on hazardous materials and make certain to comply

with all product warnings and instructions for the safe and effective use of the

material being cut. California and some other authorities, for instance, have

published lists of substances known to cause cancer, reproductive toxicity, or

other harmful effects.

Control dust, mist and fumes at the source where possible. In this regard use

good work practices and follow the recommendations of the

manufacturer/supplier, OSHA/NIOSH, and occupational and trade associations.

Water should be used for dust suppression when wet cutting is feasible. When

the hazards from inhalation of dust, mists and fumes cannot be eliminated

through engineering controls such as vacuum and/or water mist, the operator and

any bystanders should always wear a respirator approved by NIOSH/MSHA for

the material being cut.

Use Approved:

Eye Protection Hearing

Protection

Respiratory

Protection

5

Head Protection

Page 6

1. Before mounting any blade on the saw, the blade should be inspected for

any damage which might have occurred during shipment, handling or

previous use.

2. The blade collars and arbors should be cleaned and examined for

damage before mounting the blade.

3. The blade must be properly fitted over the arbor with the drive pin on the

outside collar projecting through the drive pin hole on the blade and

inside collar.

4. The blade shaft nut, which is a left-hand thread nut, must be tightened

securely against the outside blade shaft collar.

5. The blade must be operated within the specified maximum operating

speed listed on the blade.

6. The blade guard must be in place with the nose guard dow n and locked

when the saw is running.

7. The operator should wear safety glasses and any other appropriate

safety equipment.

8. When starting the saw, the operator should stand away and to the side of

the blade.

9. If for any reason the saw should stall in the cut, raise the blade out of the

cut. Check the outside blade shaft collar and nut for tightness. Inspect

the blade for damage before restarting the saw. Use caution when

resuming a cut. Be certain that the blade is in alignment with the

previous cut.

10.During cutting operations, do not exert excess side pressure on the

handles as a method of steering. Do not force the blade into the cut by

lowering the blade too fast or by pushing the saw too fast.

You Are Responsible For Your Safety!!!

6

Page 7

I. PREPARATION

B. Assembly

The GC55 and GC25E compact concrete saws are shipped completely

assembled and ready for use except for diamond blade, gasoline, oil, and

Handle Bar position for the GC55 and diamond blade, electrical extension

cord, and power supply for the GC25E. Inspect the saw for shipping damage.

If any damage is found, contact the shipper immediately and file a freight

claim. Saint-Gobain Abrasives, Inc. is not responsible for any freight-related

damages.

Adjust the Handle Bars Position:

1. Remove the GC55/GC25E from the box.

2. Remove the Quick Release Pin P/N: 241055 out of it’s retaining hole

3. Loose the Black Knob P/N: 241054.

4. Rotate the Handle Bar from the lowered storage position to the desired

position.

5. Align the hole in the Handle Bar with the holes in the frame.

6. Attach the Quick Release Pin P/N: 241055 by pushing it through the

hole in the Frame and then the hole in the Handle Bar. Make sure that

the Quick Release Pin passes all the way through both sides of the

Frame.

7. Tighten the Black Knob P/N: 241054.

Read and understand the remaining sections of this Owner's Manual. NOTE:

Do not install the blade until it is time to use the saw. ANSI regulations

prohibit the transportation of any concrete saw with the blade installed.

Part # Description QTY

241054 SCR 5/16-18 UNC X 2-1/2" CARRIAGE BOLT 1

241055 PIN QUICKRELEASE 5/16" X 2" GRIP LENGTH 1

241054 KNOB M8 X 1.25 ADJUSTABLE 1

232110 WASHER M8 DIN125 FLAT 1

241055 WASHER 3/8 WAVE 1

7

Page 8

C. GC55 and GC25E Series Concrete Saw Specifications

Dimensions/Weight

Length (Working) 42-23/32” (1,090mm) 42-23/32” (1,090mm)

Length (Transport) 32” (813mm) 32: (813mm)

Width 18-1/8" (460mm) 18-1/8" (460mm)

Height 42-23/32” (1,090mm) 42-23/32” (1,090mm)

Frame Width 18-1/8” (460mm) 18-1/8” (460mm)

Pointer Length 8-7/32” (209mm) 8-7/32”(209mm)

Blade To Wall 7-1/2” (190mm) 7-1/2” (190mm)

Wheel Base Length 19” (483mm) 19” (483mm)

Blade Shaft Maximum Height 9-41/64” (245mm) 9-41/64” (245mm)

Weight Created 135 lbs (61 kg) 155 lbs (71 kg)

Weight Uncreated 115 lbs (52 kg) 135 lbs (61 kg)

Power Source

Engine/Motor Mfg. Honda Gangfon Motor

Spec No. GX160K1QXC Totally Enclosed Air Cooled Thermal

Power Source Single Cylinder 4 Cycle Gasoline Electric

Maximum Horse Power* 5.5 HP (4.1 kW) 2-1/2 HP

Net Horse Power 4.5 HP (3.4 kW) 2-1/2 HP

Max Torque 7.6 lb-ft (10.3 Nm) @ 2500 rpm -NAPower Source RPM 3,600 RPM 3450 RPM

Model GX160 Dual Voltage

Cooling System Forced Air Forced Air

Oil Capacity 0.6 liter (0.63 US qt) -NAFuel Capacity 3.1 liter (3.28 US qt) -NAFuel Type Unleaded Gasoline (86 pump octane) -NALow Oil Sensor Yes -NAAir Filtration Four Stage Cyclone -NAVoltage -NA- 115-230 volts

Cycles/Current/Phase -NA- 60Hz/AC/1

Full Load Amps (115/230 volts) -NA- 15/7.5 Amps

Starting Amps (115/230 volts)2 -NA- 45/22.5 Amps

Displacement 9.9 in3 (0.16 l) -NABore x Stroke 2.7” (68mm) x 1.8” (45mm) -NAStarter Manual Capacitor

Characteristics

Max Blade Ø10" (254mm) Ø10" (254mm)

Depth of Cut 10” (254 mm) 3.5" (88mm) 3.5" (88mm)

8” (203 mm) 2.5" (63mm) 2.5" (63mm)

Arbor Bore 5/8" 5/8"

Blade Shaft Flange Diameter 3-5/64” (78mm) 3-5/64” (78mm)

Blade Shaft Speed 2905 rpm 2905 rpm

Depth Control Hand Wheel With Screw Feed Hand Wheel With Screw Feed

Depth Lock Standard Standard

Depth Gauge Standard Standard

Number Of V-Belts 1 1

Blade Guard Type Screwed On, All Steel Construction Screwed On, All Steel Construction

Cutting Side Center Center

Lifting Bale Built In Built In

Handle Bars Adjustable, Stays Level At All Times Adjustable, Stays Level At All Times

Wheels Non-marking Non-marking

Wheel Size Front and Rear 3-3/8”x2-3/4”x25/32” (85x70x20mm) 3-3/8”x2-3/4”x25/32” (85x70x20mm)

Sound pressure3 88 db (A) -NASound power3 105 db (A) -NA-

1)Net Horsepower Rating provided by engine the manufacturer measured in accordance to SAE j1349 @ 3,600 RPM. The engine may vary from this value.

Actual horsepower on the machine will vary due to operating speed of engine, belt tension, environmental conditions, machine maintenance, and other variables.

2) Starting Amps are instantaneous – for best results use with a 30Amp circuit.

3) The sound measures have been made following pr EN 12638, Annex A; - 2 “Floor sawing, grooving and milling machines – Safety “

GC55 GC25E

Protection

8

Page 9

The GC55 and GC25E concrete saws where designed from the ground up to be

a High Performance Multiple Application saw. The GC55 and GC25E are

capable of cutting Green Concrete (Early Entry), Cured Concrete, Asphalt, and

Decorative Concrete. Being able to cut more than just green gives the GC55 and

GC25E many advantages over the competitor’s machines such as a lower

investment for our customer.

Use For Cutting Multiple Applications:

Green Concrete (Early Entry)

Decorative Concrete

Cured Concrete

Asphalt

Features that make the GC55 and GC25E a High Performance Multiple

Applications Saw:

• Blade in center line of saw helps to reduce tearing of concrete when

cutting green concrete. The center line blade also helps the GC55 and

GC25E to roll straight while cutting due to the blade being parallel to the

blade.

• Reinforced all steel frame reduces bending, flexing, and vibrations which

can damaged the concrete. The reinforced all steel frame is also stronger

than the competitive models

• Soft Silicone Rubber wheels that are based off of a Norton Patient to

absorb vibrations that can create spalling and machine movement. The

wheels also feature a concave profile that helps the machine to roll over

small objects with out upsetting the blade.

• 10” maximum blade capacity with standard 5/8” arbor. The GC55 and

GC25E can use with 7” to 10” diameter Norton blades.

• Hand Wheel with Depth Adjustment Screw & Depth. Allows precise depth

adjustments up to 3-1/2” deep when used with a 10” blade.

• Fully adjustable non-scratching Dust removal system helps stabilize the

GC55 and GC25E by pushing debris way from wheels and undercarriage

of the machine.

• Front and rear pointers for precise alignment.

• Handle Bar and Pointer folds up for compact easy transport.

• Light in weight, the GC55 weights only 115 lbs.

• The GC55 and GC25E are very simple machines to operate.

• The GC55 and GC25E are designed for cutting Multiple applications:

Green Concrete (Early Entry), Cured Concrete, Asphalt, and Decorative

Concrete.

• Includes a free 10” GMAX blade. The GMAX blade is specifically

designed with the following features for improved Green Concrete cutting:

o Anchor Slot Core Technology Reduces Chip Causing Vibrations.

o Thicker Core Resist Flexing and Bending For Improved Cut Quality.

o Optimize Bond And Diamond For Fast Green Concrete And

Aggregate Cutting.

9

Page 10

D. Engine GC55 Models

Prior to attempting to operate the engine, read the information

contained in the engine owner's manual. An engine owner’s manual is

supplied with every gasoline powered concrete saw.

1. Check Oil: Add oil if low. Refer to the engine owner's manual for the

recommended SAE viscosity grades. Capacity of oil is 0.6 liter (0.63 US

qt.)

2. Check Fuel: Fill if low. Use only unleaded gasoline with a pump sticker

octane rating of 86 or higher is recommended. Never use an oil and

gasoline mixture!

3. Air Cleaner: Never run the engine without the air cleaner! Rapid engine

wear will result from contaminants being drawn through the carburetor and

into the engine.

4. Engine Starting: Refer to the engine owner's manual for proper engine

starting procedure.

E. Pointer Alignment

1. Use a straight edge, and carefully mark a line 12 feet long on a smooth

level surface.

2. Place the saw blade on the marked line, move the saw to the center of the

marked line and then lower the blade until it is about 1/16” above the

marked line.

3. Measure from each end of the saw frame to insure that the frame is

parallel to the marked line. Adjust the saw as needed.

4. With the blade centered on the marked line and the saw frame parallel to

the marked line, lower the front pointer.

5. Adjust the nylon nuts until the pointer is aligned with the marked line.

10

Page 11

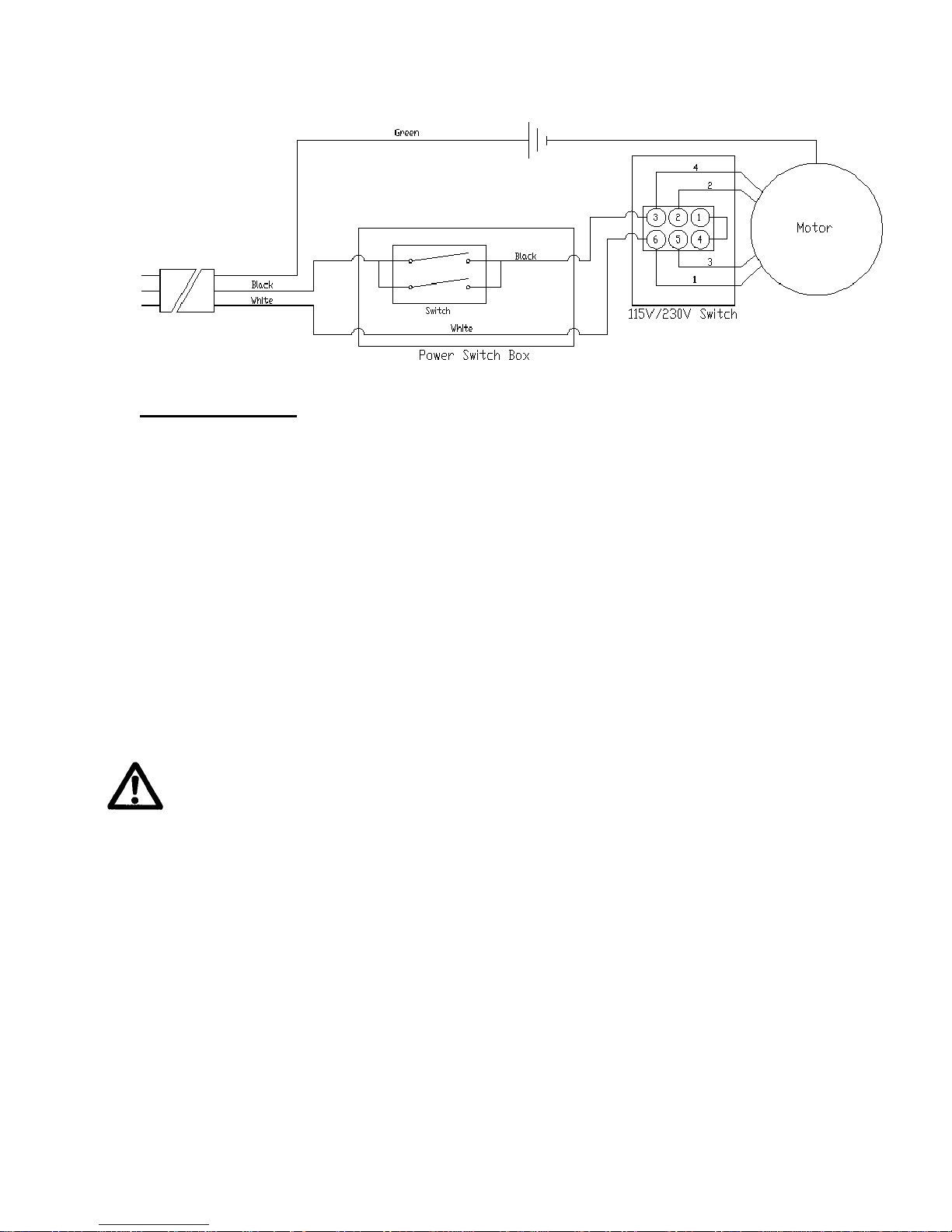

E. Electrical Connections GC25E

Important-Before connecting the motor leads to the power supply be

sure that the voltage, cycles and phase shown on the nameplate of the

motor correspond to the available power supply. Voltage Selection for

the GC25E 3 HP motor is single phase saw motors witch have a dual voltage

capable. Either a 115-volt or 230 volt power supply can be used. To change

voltage simply move the voltage change switch located on the front of the motor

to the required voltage, no rewiring is required. Wherever possible, use 230-volt

power supply for best operation.

Failure to run the motor on the proper voltage will damage the motor and

is not covered under warranty. Improperly wired motors are not covered

under warranty.

The GC25E models are wired for 115 Volt from the factory!!!

Power Connections

Connect the power supply to the pigtail leads of the switch. Direct wiring

connection is preferred, but an extension cord with an electrical plug with 30-amp

minimum capacity may be used. A 30-amp circuit breaker is recommended.

Connecting wires should be as short as possible and in one piece. In no case

should the connecting wires be longer than shown in the following table for use

with the GC25E Single-phase motors:

Wire Gauge 115 Volt 230 Volt

Number 12

Number 10

Number 08

Caution-When wires that are too small gauge or too long are used, loss of

power, over heating, or possible damage to the motor will result. Damage

or failure of motors due to incorrect power supply cord lengths are not

covered under any warranty.

Always use the proper wiring connectors that are UL/CSA approved to

attach the motor to the electrical supply. Any wiring hook ups should be

made by qualified personal and made to National Electrical Code and to

any Local Codes.

25 ft (7.6 m) 100 ft (30.5 m)

50 ft (15.2 m) 150 ft (45.7 m)

75 ft (22.9 m) 175 ft (53.3 m)

Length Of Wire

Generators:

If a generator must be used, it must be of 8kW or larger. The generator must

have a 30A circuit and capable of providing a minimum of 8kW at the required

voltage. Under size generators will cause motor damage and is not covered

under warranty.

11

Page 12

Wiring Diagram GC2E Only

Thermal Reset:

If the thermal reset engages this is a sign that the motor is over heating.

Continued over heating will damage the motor. The thermal reset will

reset it’s self once the motor is cooled. Do not force the thermal reset as it

will damage the reset and motor. The causes of the thermal reset

activating are:

1. Too Long or Too Thin of Extension Cord (Low Voltage). Use

the correct length and gauge of Extension Cord.

2. Low Voltage Power Supply. Use a power supply with the

correct voltage.

3. Incorrect Blade of Application. Contact Norton Clipper’s

customer service or your local sales person for the correct blade

specification for your cutting application.

4. Overloading Machine. At a shallower depth. Make multiple

passes (Step Cutting) at no more than 1-1/4” deep. Cut at a

slower forward speed.

Damage or failure of a motor due to continued over heating as the result

of incorrect extension cord length/size, incorrect power supply, incorrect

application, and continued overloading is not covered under warranty.

.

II. OPERATION

A. Installing the Blade

1. Disconnect the spark plug (GC55 Models Only)

2. Raise the Blade Guard to its highest position.

3. Open the blade nut access door. Remove the blade shaft nut (Turn

clockwise) and remove the outside collar and raise the Blade Guard.

12

Page 13

4. Clean off any foreign particles on the clamping surfaces of both collars

and on the mounting surface of the blade.

4. Position the blade beneath the cutting head and slide the blade into the

blade guard (slide the blade under the blade guard at an angle will simplify

the installation process). Be careful not to hit the blade shaft with the

blade.

5. Locate the blade shaft then slide the blade bore hole onto the blade shaft.

Use only Norton Diamond Blades. This machine was not designed for

the use with abrasive blades. For the best performance when cutting

green concrete use the Norton GMAX series blade.

6. Slide the outside blade shaft collar onto the blade shaft.

7. Tighten the blade shaft nut (Turn counter-clockwise) securely against the

outside collar. Close the blade nut access door.

8. Reconnect the spark plug (GC55 models only).

Use Only Norton Diamond Blades

B. Starting the Engine GC55

1. Refer to the engine owner's manual for the proper starting procedures.

2. Always cut with engine rpm in the full throttle setting.

C. Operating the Saw

1. For blade installation instructions see section II. Operation sub heading

A. Installing the Blade. For the engine starting instructions (GC55), see

the Engine manual and follow the instructions located in section II.

Operation sub heading B. Starting the Engine and for Electrical

Connections (GC25E) see section E. Electrical Connections GC25E

2. Check the Engine Oil level (GC55 only).

3. Raise the saw to the full upright position. Do not let the blade come in

contact with the ground.

4. Maneuver the saw to the desired starting point.

13

Page 14

5. To start the machine

a. GC55: Follow the instructions for starting the engine found in

the Engine manual.

i. Verify that the emergency stop switch is in the up

position

ii. Turn Engine On/Off Switch to the on position

iii. Turn the Fuel Control to the On position

iv. Engage Choke as necessary

v. Pull start rope. If the engine does not start within 3-5

pulls of the start rope, refer to the engine owner’s

manual for more information.

b. GC25E: For Electrical Connections, Extension Cord Set

Information, and Generator Information see section E.

Electrical Connections GC25E

i. Verify that the motor voltage change switch is set to

the same voltage as the circuit.

ii. Verify that the circuit has a 30 Amp breaker installed.

iii. Verify that the extension cords are the correct gauge,

length, and are properly grounded.

iv. Verify that the GC25E power switch in the off position.

v. connect the extension cord set to the machine and

power supply. Follow all local and national electrical

code. If unsure of how to connect the extension cord

set or of the electrical circuit have a qualified

Electrician make all electrical connections.

vi. Move the start switch to the On position and the motor

should start. If the motor doe not start have a

qualified Electrician inspect all electrical connections

and the power supply

6. For the GC55 be sure the engine is running at full throttle!!!

7. Slowly lower the blade by rotating the hand wheel clockwise until the

desired depth of cut is reached. Use a reasonable rate of feed. Do not

force the blade into the cut!! If the engine starts to die slow down the rate

of feed! If the machine tries to climb out of the cut, slow down the rate of

feed!

8. When the end of the cut is reached, slowly raise the blade out of the cut by

rotating the Hand Wheel counter-clockwise until the blade is at least one

(1) inch above the ground.

9. Only move the saw in reverse with the blade in the raised position.

14

Page 15

10. When moving the saw to a new location, be sure the blade is not touching

the ground. Always pay close attention to where you are moving and

where the blade is at all times.

D. Cutting Technique

Lower the blade into the concrete to the required depth by turning the hand

wheel clockwise.

Push the saw steadily forward using the front pointer as a guide. Exert

enough forward pressure so that the engine begins to labor, but does not slow

down. If the saw begins to stall, reduce the forward movement until full rpm is

restored to the blade. If the saw stalls, raise the blade out of the cut before

restarting. Avoid excessive side pressure or twisting of the blade in the cut.

When cutting for best performance do not cut at more than 1-1/2” deep per

pass. Making multiple shallow passes will increase blade life, speed of cut,

and decrease engine/motor loads.

Additional Guide Lines For Sawing:

• Understand and follow all of the instructions in this owner’s manual.

• In critically hard aggregate, be careful not to feed too quickly as it may stall

the saw or ruin the cut.

• If the saw stalls in the cut, immediately stop the forward speed and raise

the blade out of the cut. If this is not done the belts can fail or the blade

may be damaged.

• Go slowly with a new blade until it opens up, that is, until the diamonds

can be seen and felt.

E. Green Concrete Cutting

The new Norton Clipper GC55 and GC25E are much more than a green

concrete saw or as it is some times called an early entry saw. The GC55 and

GC25E where designed from the ground up to be a High Performance

Multiple Application saw. The GC55 and GC2E models are capable of cutting

Green Concrete (Early Entry), Cured Concrete, Asphalt, and Decorative

Concrete. Being able to cut more than just green gives the GC55 and GC25E

many advantages over the competitor’s machines such as a lower investment

for our customer.

15

Page 16

Green Concrete Cutting Important Considerations

Green concrete is concrete that is still in a plastic state that is the concrete

still has a lot of moisture in it, in other words it is not fully cured or dry. As the

concrete starts to hydrate (Dry or Cure), the concrete will change slightly in

volume. Concrete normally shrinks about 1/16” for each 10 feet during the

hydration process. This change in size creates internal stress in the concrete

which will develop into cracks. Joints also known as Crack Control Joints and

or Expansion Joints are normally cut into the concrete in order to relieve the

internal stress and to create an area where a controlled crack will occur. With

the joint in place the concrete will normally crack in a straight line underneath

the joint. The idea behind cutting the green concrete is that the sooner the

stress relieving joints are made the better control over the random cracking

will be obtained. For most green cutting the depth of cut is made at 25% of

the overall thickness of the concrete, for example if the concrete is 6” thick,

the cutting depth would be set to 1-1/2” deep. One important fact to

remember is that Green Concrete is any concrete that has set up but not

hardened. For concrete to become fully hardened it may take 5 to 7 days.

There are a few factors that affect green concrete cutting quality, and time

that the cutting can begin. The following list is extremely important to follow

and to understand in order to create a good quality cut with no spalling or

chipping of the cut line.

1. The concrete must set up long enough to hold the aggregate in place. If

not the aggregate will tumble and move when the Diamond Blade contacts

it, causing internal damage to the concrete and possible tearing or spalling

of the concrete surface. The aggregate along with the concrete must be

cut for proper crack control. With out proper set up the aggregate will roll

or move within the concrete creating voids and spalling or chipping of the

cut line will occur. Concrete set up is the MOST important issue to

obtaining a quality cut line when green concrete cutting. Factors that

affect the concrete set up are:

a) Concrete Mixture – PSI, concrete type, sand type and amount, and

other materials.

b) Water to Cement Ratio – more water the longer the set up

c) Aggregate Size and Type

d) Concrete Additives – some speed up while others slow down the set

up time.

e) Environmental Factors – Sun, Wind, Rain, Temperature

f) Concrete Temperature – cooler the concrete the longer the set up time.

2. Flat surface. Flat surfaces help to insure that the blade is perpendicular to

the concrete which reduces the chances of damaging the concrete

16

Page 17

surface. When the blade meets the concrete surface at a 90° angle

(perpendicular) less side drag is created on the blade. When the blade is

not perpendicular side drag is create that will cause the concrete to chip or

spall.

3. Blade that is designed for green concrete cutting. The GMAX blade has

some unique features that make it an outstanding blade for green concrete

cutting such as:

a) Anchor Slot Core Technology that reduces vibrations in the blade.

Excessive vibrations will cause the blade to flutter or bend from side to

side which will damage the concrete surface and cause the blade to

wear out prematurely.

b) Thicker core that resist flexing and bending. Thin core blades bend

due to excessive pressure during cutting and from over heating. When

blade bends and flexes the concrete and blade will be damaged.

c) Optimized bond and diamond for fast green concrete cutting. The

improper bond will not cut green concrete properly.

When to Start Green Concrete Cutting

Timing is the most important aspect of cutting green concrete. The time that

the operator can start cutting will vary depending on the key factors listed

above. For example if the concrete has a high water to cement ratio or the

day is cooler then more time is required for the concrete to properly set up

and hold the aggregate in place. Typically we are finding that starting around

5 to 6 hours after finishing good results can be obtain. We find in our testing

that at 16 hours in gives the best results. These times to start are assuming

that the concrete has set up long enough to hold the aggregate in place.

Green Concrete Cutting Trouble Shooting

Spalling or Chipping On Both Sides of Cut:

1. Wait at least 1 to 2 more hours before cutting. The very good cut

appearance is achieved at 5 to 6 hours after finishing complete. The best

cut appearance occurs when the concrete has set up enough for the

aggregate to be held in place which may take up to 16 hours. The actual

time to begin cutting will depend on many factors such as: concrete

mixture (PSI, concrete type, sand type and amount, and other materials,

water to cement ratio – more water the longer the set up), aggregate size

and type, concrete additives – some speed up while others slow down the

set up time, environmental factors (Sun, wind, rain, temperature), concrete

temperature (Cooler the concrete the longer the set up time).

17

Page 18

2. Check blade specification. The improper blade specification will create

additional spalling or chipping of the concrete. For best results use a

Norton GMAX series Blade. The Norton GMAX series have unique

features to improve the green concrete cut quality and the overall

efficiency of the blade while cutting green concrete. The GMAX blade

provided with the GC55 was designed exclusively for use on this product

to provide maximum performance and a precision cut appearance!

3. Check blade for wear. As the blade loses width the cut appearance will

get worse. Blades with segments that look like a knife blade need to be

replaced immediately as a blade in this condition will create a poor quality

cut line.

4. Check concrete surface for flatness.

5. Replace the blade with a new blade of the same specification.

6. Replace blade with the correct specification.

Cut Appearance Previously Fine But Now Constantly Spalling or

Chipping On One Side Of The Cut:

1. Check for warped blade. A warped or out of tension blade will create a

cut that has spalling and chipping. Replace blade if necessary.

2. Check the tracking on saw.

3. Check that the machine is being pushed in a straight line.

Thin Shell Chipping of Concrete:

1. Wait 1 to 2 hours for the concrete cure depth to increase. Shell chipping

is caused when the top layer of concrete is curing at a faster rate than the

concrete below. The concrete needs to cure to a deeper depth in order to

prevent the shell chipping.

III. MAINTENANCE

A. Engine GC55

Follow the below schedule for engine maintenance. NOTE: Check the Honda

Engine manual that came with the engine for any changes to the maintenance

schedule. If the charts have any differences, follow the chart in the Honda

Engine Manual. The Norton Company does not warranty the engine. If any

warranty or service of the engine is required contact your nearest Honda

18

Page 19

nearest Honda service center, or from the Internet: http://www.honda-

engines.com/home.htm

Honda engine (Refer to owner's manual for complete maintenance.)

Check the engine oil level before each use when the engine is cool and the

engine is level. Add oil if the level is low. The oil level should be within the

operating range (See the engine owner’s manual for details).

Only use a high-detergent, premium quality motor oil certified to meet or

exceed U.S. automobile manufacturer’s requirements for Service

Classification SG, SF/CC, CD. Motor oils will show the classification on the

container. A SAE viscosity of 10W-30 is recommend by Honda for general,

all temperature use. Please consult the below chart or contact your local

Honda service center for the proper viscosity for your temperature range.

19

Page 20

Always refer to the engine manual for more detailed information on checking

the oil, changing oil, and oil capacity, air filter changes, and fuel type to use.

Use only Honda air filters. Do not clean the air filter with gasoline or other

flammable solvents. A fire or explosion could result. To clean, follow the

instructions found in the Honda engine manual.

Dry Cutting Engine Maintenance

• When operating the engine in dry cutting or dusty environments the

following is required:

• Engine oil changed more often.

• Every 50 hours (or more often if conditions require) clean all of the engine

cooling fins.

• Every 25 hours (or more often if conditions require) clean the engine precleaner.

• Every 100 hours (or more often if conditions require) replace the air filter.

If the engine is equipped with a reusable air cleaner, clean and re-oil it.

• Check and clean the air filter after each use. Replace as needed.

B. Bearings

The GC55 and GC25E are equipped with permanently sealed blade shaft and

wheel bearings that will never need any lubrication. These types of bearings

are designed for long life and minimum maintenance. If any problem occurs

with the blade shaft, or wheel bearings replace the bearing.

The only the Raise Screw and Cutting Head pivot point will need periodic relubrication. Both of these points require just a squirt of a good quality NLGI

#2, aluminum complex type grease is recommended one time a month.

Check the function of the Hand Wheel and Cutting Head before each use.

Lubricate the Raise Screw and Cutting Head pivot point once a month or

when the it becomes hard to turn the Hand Wheel.

C. V-Belts

Warning: Never make adjustments to belts or pulleys while

engine is running!

1. The best tension for a belt drive is the lowest tension at which the belts will

not slip under full load.

2. Simply take up the drive until the belts are snug in the grooves. Run the

drive for about 15 minutes to "seat" the belts. Then impose the peak load.

If the belts slip, tighten them until they no longer slip at peak load.

20

Page 21

3. Remember, too much tension shortens belt and bearing life!

4. Check the belt tension frequently during the first day of operation. Check

the belt tension periodically thereafter and make any necessary

adjustments.

5. The two most common causes of misalignment are shown in the

Figure 1 and Figure 2 to the right.

a). The engine drive shaft and the blade shaft are not parallel.

b). The pulleys are not located properly on the shafts.

6. To check alignment, all you need is a steel straight edge.

7. Line up the straight edge along the outside face of both pulleys as

shown in the drawing.

FIGURE 1

8. Misalignment will show up as a gap between the pulley face and the

straight edge.

9. Make sure that the width of the outside land (Area between the belt and

the edge of the pulley) is equal on both pulleys.

D. Depth Control

The cutting depth is controlled by a chrome turn handle. It is located next to

the push handle base, easily accessible from the rear of the saw. The handle

must first be unlocked before it can be turned. It is locked by a black knob

located on the operator’s left side of the hand wheel near the base of the

handle. This knob must be turned counter-clockwise to unlock the handle.

Once unlocked rotating the handle clockwise will lower the cutting blade.

Rotating it counter-clockwise will raise the cutting blade. When the proper

cutting depth is achieved by reading the depth gauge, relock the turn handle

to ensure a constant cutting depth throughout the cut.

The depth gauge can be found further down the shaft of the turn handle. This

gauge will already be preset for an Ø10" blade, but it still must be calibrated

by the user since blade diameters may vary. When using an Ø8" blade, the

gauge must be readjusted from an Ø10" blade to an Ø8" blade. Simply

loosen the black knob found near the collar of the gauge and slide it

accordingly to achieve the proper reading.

FIGURE 2

21

Page 22

The collar used to support the turn handle's screw should be checked after

each use to make sure it is lubricated and turning freely. If more lubricant

must be added, NLGI #2, aluminum complex type grease is recommended.

E. Dust Removal System Adjustment

The GC55 and GC2E are equipped with a fully adjustable non-scratching

Dust removal system which helps stabilize the machine by pushing debris

way from wheels and undercarriage of the machine. Depending on the

surface and wear the Dust Removal System may need adjustments from time

to time. The Dust removal system consist of two Brushes located in front of

the Front Wheels and a large Squeegee Assembly located under the machine

and in front of the rear wheels. When this system is properly adjusted the

front wheel Brushes, and the Rear Wheel Squeegee System will barely touch

the work surface.

Before making any adjustments turn off the machine

and disconnect the spark plug.

To adjust the Rear Wheel Squeegee Assembly:

1. Loose the Squeegee Assembly mounting

2. Position the Squeegee Assembly to the

3. Tighten the Squeegee Assembly mounting

To adjust the Front Wheel Brush:

1. Loose the Front Wheel Brush mounting

2. Position the Front Wheel Brush to the

3. Tighten the Front Wheel Brush mounting

NOTE: The Left and Right Side Front Wheel

Brushes Are Different Parts

hardware items 1 & 3

required position

hardware items 1 & 3

hardware

required position

hardware

22

Page 23

IV. PARTS LIST SECTION

A. Ordering Information

1. List model number and serial number of machine.

2. List part number and serial number of part not the item number.

3. Wherever alternate parts are shown due to product improvement, inspect

the part you have and provide additional description as necessary.

4. Specify mode of shipping desired, such as, parcel post, truck, U.P.S., best

way, etc.

For the nearest Clipper distributor call 1-800-554-8003

Common Replacement Parts

Description Part Number

WRENCH UNIVERSAL 233041

LOOSE COLLAR GC55/GC25E 241081

TIGHT COLLAR GC55/GC25E 241082

NUT 5/8-11 UNC HEX LEFT HAND THREAD 241083

GUARD BLADE GC55/GC25E 241001

BLADE SHAFT GC55/GC25E 241016

BEARING RADIAL 6204-RS 212142

HAND WHEEL GC55/GC25E 241023

BELLOWS GC55/GC25E 241026

KNOB W/THREADED STUD M6 X 15 1.0 241029

KNOB W/THREADED HOLE M6 X 15 1.0 241032

CUTTING HEAD FLANGE GC55 241037

BRUSH WHEEL OPERATOR'S RIGHT GC55/GC25E 241048

BRUSH WHEEL OPERATOR'S LEFT GC55/GC25E 241049

POINTER WELDMENT GC55/GC25E 241085

SWITCH EMERGENCY STOP GC55 241059

KNOB W/THREADED HOLE M10 X 1.5 X 50mm DIA 241061

WHEEL 75X28X8mm 241086

WHEEL W/BEARING GC55/GC25E 241044

OIL DRAIN HOSE ASSY 5.5HP HONDA GC55 241035

NOTE: All Parts Are Sold As Individual (each) Unless Noted Otherwise

Blades Use Only Norton Diamond Blades. Contact your local Norton

Clipper Distributor or Norton Clipper at 1-800-554-8003 for the best blade for the

application.

23

Page 24

58

1

4

27

3

6

Blade Guard Assembly GC55 and GC25E

Item Description QTY Part No.

1 GUARD BLADE GC55/GC25E 1 241001

2 BLADE SHAFT VENT COVER 1 241002

3 WASHER M6 DIN125 FLAT 4 27539

4 SCR M6 X 16 1.0 DIN933 1 235048

5 SCR M6 X 12 1.0 DIN933 1 300566

6 NUT M6 DIN985 LOCK 1 235136

7 SCR THUMB M6 X 12 1.0 1 241003

8 SPLASH GUARD GC55/GC25E 1 241004

24

Page 25

15

12

19

21

520 1613 10

8

7

1

14

3

17918

4

2

6

11

Cutting Head Assembly GC55 and GC25E

Item DESCRIPTION Qty Part No

1 BEARING CUTTING HEAD SUB ASSY – SEE PG

23 FOR PARTS

2 PULLEY IDLER TENSION ADJUSTER 1 241006

3 SPACER INDLER GC55/GC25E 1 241007

4 PULLEY IDLER ASSEMBLY GC55/GC25E 1 241008

5 ZERK FITTING M6 1 241009

6 SCR M12 X 80 1.75 DIN933 1 241010

7 SCR M8 X 25 1.25 DIN933 FULL THD 2 300323

8 SCR M6 X 55 1.0 DIN933 1 241011

9 SCR M6 X 30 1.0 DIN933 1 241012

10 SCR M6 X 16 1.0 DIN933 3 235048

11 WASHER M12 DIN125 FLAT 2 27505

12 WASHER M8 DIN125 FLAT 2 232110

13 WASHER M6 DIN125 FLAT 3 27539

14 NUT LOCK M12 1.75 DIN985 1 27017

15 WASHER LOCK M8 DIN127 2 300245

16 WASHER LOCK M6 DIN127B 3 300279

17 NUT M12 1.75 DIN934 HEX 1 27007

18 NUT M6 1.0 DIN934 HEX 2 300833

19 SCR M6 X 16 1.0 DIN912 SHCS 1 232113

20 BRACKET DEPTH CONTROL MOUNT GC55 1 241013

BRACKET DEPTH CONTROL MOUNT GC25E 1 241100

21 BUSHING BLADE GUARD GC55/GC25E 1 241014

1 241005

25

Page 26

5

3

2

4

1

Blade Shaft Assembly GC55 and GC25E

Item DESCRIPTION Qty Part No

1 CUTTING HEAD ASSEMBLY GC55/GC25E 1 241015

2 BLADE SHAFT GC55/GC25E 1 241016

3 BEARING COVER BLADE SHAFT GC55/GC25E 1 241017

4 BEARING RADIAL 6204-RS 2 212142

5 RETAINING RING E-STYLE 19mm X 1.8mm

DIN6799

1 241018

26

Page 27

10945711

16

15

14

6

13

2

1

17

3

8

18

12

Depth Control Assembly GC55 and GC25E

Item DESCRIPTION Qty Part No

1 DEPTH TUBE GC55/GC25E 1 241090

2 FIT GREASE ZERK M6 X 1.0 1 241019

3 SCR DEPTH CONTROL GC55/GC25E 1 241020

4 DEPTH CONTROL MOUNT GC55/GC25E 1 241021

5 SPACER HAND WHEEL GC55/GC25E 1 241022

6 HAND WHEEL GC55/GC25E 1 241023

7 KEY 3/16X3/4 1 9201074

8 CLAMP HOSE 13/16" TO 1-3/4" X 1/2"W WORM

TYPE

9 DEPTH GAUGE POINTER GC55/GC25E 1 241025

10 BELLOWS GC55/GC25E 1 241026

11 SCR M5 X 10 0.8 DIN916 SET CUP POINT 1 241027

12 RETAINING RING C-STYLE 10mm X 1.0mm

DIN471

13 KNOB W/THREADED STUD M6 X 15 1.0 1 241029

14 WASHER M4 X 19mm X 2mm 1 241089

15 WASHER LOCK M4 DIN127 1 241030

16 SCR M4 X 16 0.7 DIN933 1 235057

17 DEPTH CONTROL POINTER BAR GC55/GC25E 1 241031

18 KNOB W/THREADED HOLE M6 X 15 1.0 1 241032

2 241024

1 241028

27

Page 28

1

4

3

2

65

Engine Assembly GC55 Only

Item DESCRIPTION Qty Part No

1 ENG 5.5HP HONDA 1 216264

2 SCR M5 X 12 0.8 FLAT HEAD SOCKET CAP 2 241033

3 SCR 5/16"-24 UNF X 3/4" C'SINK SOCKET HEAD 4 241034

4 OIL DRAIN HOSE ASSY 5.5HP HONDA 1 241035

5 BRACKET SELF LEVELING MOUNT GC55 1 241036

6 CUTTING HEAD FLANGE GC55 1 241037

28

Page 29

Motor Assembly GC25E

Item DESCRIPTION Qty Part No

1

2 COVER FAN GC25E 1 241113

3 GASKET RUN CAPACITOR COVER GC25E 1 241114

4 COVER RUN CAPACITOR GC25E 1 241115

5 GASKET START CAPACITOR COVER GC25E 1 241116

6 COVER START CAPACITOR GC25E 1 241117

7 BOX VOLTAGE CHANGE SWITCH GC25E 1 241118

8 TOGGLE SWITCH GC25E 1 241119

9 CABLE GLAND PG-11 2 241120

10 GUARD SWITCH GC25E 1 241121

11 CAPACITOR RUN GC25E 1 241122

12 CAPACITOR START GC25E 1 241123

13 SCR 10-24 X 3/8 PHILLIPS ROUND HEAD 2 241124

14 SCR M5 X 40 0.8 DIN7985 PH PHILLIPS 3 241125

15 SCR M5 X 40 0.8 DIN7985 PH PHILLIPS 1 241126

16 NUT M5 0.8 LOCK DIN985 1 241127

17 FAN GC25E 1 241128

18 WASHER M4 DIN125 FLAT 2 235104

19 NUT M4 0.7 DIN934 1 241129

20 SCR 10-24 X 3/8 PHILLIPS ROUND HEAD 3 241124

21 SCR M6 X 16 1.0 DIN7985 PH PHILLIPS 4 241125

22 SCR 10-24 X 1/4 PHILLIPS ROUND HEAD 4 241126

MOT 2.5HP 115-230v/60/1 GC25E

COMPLETE MOTOR (ITEMS 2 to 21)

1

241112

29

Page 30

12

15

8

7

17

13

5

1116

3

1814

10611 12

2

4

1

9

Frame Assembly GC55 Only

Item DESCRIPTION Qty Part No

1 FRAME GC55 1 241038

2 REAR POINTER GC55/GC25E 1 241039

3 SCR M8 X 65 1.25 DIN931 HEX HEAD CAP 1 241040

4 WASHER M8 DIN125 FLAT 6 232110

5 WASHER M4 DIN125 FLAT 16 235104

6 NUT M8 1.25 LOCK DIN985 3 241041

7 NUT M4 0.7 LOCK DIN985 8 241042

8 GROMMENT GC55 1 241043

9 WHEEL W/BEARING GC55/GC25E 4 241044

10 WASHER M8 X 24MM OD DIN9021B 4 241045

11 WASHER LOCK M8 DIN127 8 300245

12 SCR M8 X 20 1.25 DIN933 HEX HEAD CAP 6 235013

13 SCR M4 X 12 0.7 DIN933 HEX HEAD CAP 8 235103

14 SCR M8 X 65 1.25 DIN931 HEX HEAD CAP 1 241040

15 FRONT AXLE GC55/GC25E 1 241046

16 SCR M8 X 35 1.25 SOCKET HEAD CAP DIN912 2 241047

17 BRUSH WHEEL OPERATOR'S RIGHT

1 241048

GC55/GC25E

18 BRUSH WHEEL OPERATOR'S LEFT

1 241049

GC55/GC25E

19 SQUEEGEE ASSEMBLY ONLY GC55/GC25E 1 241050

30

Page 31

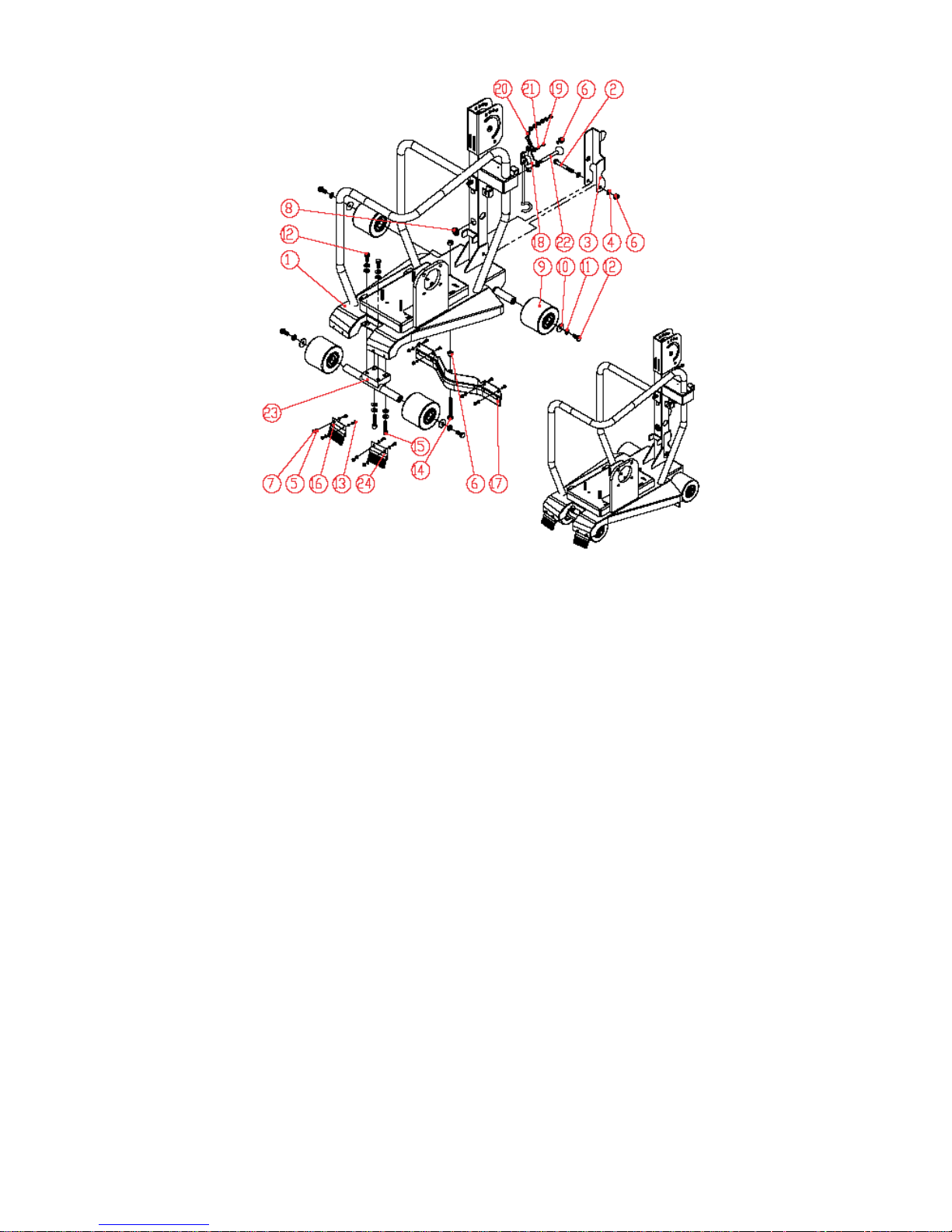

Frame Assembly GC25E Only

Item DESCRIPTION Qty Part No

1 FRAME GC25E 1 241101

2 SCR M8 X 65 1.25 DIN931 HEX HEAD CAP 1 241040

3 REAR POINTER GC55 1 241039

4 WASHER M8 DIN125 FLAT 7 232110

5 WASHER M4 DIN125 FLAT 17 235104

6 NUT M8 1.25 LOCK DIN985 4 241041

7 NUT M4 0.7 LOCK DIN985 8 241042

8 GROMMET GC55 1 241058

9 WHEEL W/BEARING GC55 4 241044

10 WASHER M8 X 24MM OD DIN9021B 4 241045

11 WASHER LOCK M8 DIN127 8 300245

12 SCR M8 X 20 1.25 DIN933 HEX HEAD CAP 6 235013

13 SCR M4 X 12 0.7 DIN933 HEX HEAD CAP 8 235103

14 SCR M8 X 65 1.25 DIN931 HEX HEAD CAP 1 241040

15 SCR M8 X 35 1.25 SOCKET HEAD CAP DIN912 2 241047

16 BRUSH WHEEL OPERATOR'S RIGHT GC55 1 241048

17 SQUEEGEE ASSEMBLY ONLY GC55 1 241050

18 POWER CABLE SUPENSION ARM GC25E 1 241102

19 SCR M4 X 8 0.7 DIN966 PHILIPS 1 235099

20 CHAIN FOR QUICKRELEASE PIN 9" LONG GC55 1 241056

21 WASHER LOCK M4 DIN127 1 241030

22 PIN QUICKRELEASE 5/16" X 2" GRIP LENGTH 1 241092

23 FRONT AXLE GC55 1 241046

24 BRUSH WHEEL OPERATOR'S LEFT GC55 1 241049

31

Page 32

5

4

2

3

1

Front Pointer Assembly GC55 and GC25E

Item DESCRIPTION Qty Part No

1 POINTER WELDMENT GC55/GC25E 1 241085

2 WHEEL 75X28X8mm 1 241086

3 FRONT POINTER ROD GC55/GC25E 1 241087

4 WASHER M8 DIN125 FLAT 2 232110

5 NUT M8 1.25 LOCK DIN985 2 241041

32

Page 33

29

21

5

31

30

45

50

49

48

44

43

3

17 20

19

56

12

11

24

53

18

628

35

52

29 28

16

13

10

15

51

33

55

46

47

27

25

1

7

37

41

57

32

9

34 3938

40

22 4226

4

36

54

Main Assembly GC55 Only

33

Page 34

Main Assembly GC55 Only

Item DESCRIPTION Qty Part No

1 SEE FRAME ASSY GC55 PAGE 30 1 -NA2 HANDLE BAR GC55 1 241052

3 ENGINE ASSEMBLY GC55 SEE PAGE 28 1 -NA4 WASHER M6 DIN125 FLAT 8 27539

5 WASHER M8 DIN125 FLAT 6 232110

6 SCR M6 X 55 1.0 DIN933 HEX HEAD CAP 1 241011

7 SCR M8 X 60 1.25 DIN933 HHC FULL THD 1 360146

8 NUT M6 DIN985 LOCK 1 235136

9 NUT M8 1.25 LOCK DIN985 2 241041

10 SCR 5/16-18 UNC X 2-1/2" CARRIAGE BOLT 1 241054

11 WASHER 3/8 WAVE 1 241055

12 KNOB M8 X 1.25 ADJUSTABLE 1 241091

13 PIN QUICKRELEASE 5/16" X 2" GRIP LENGTH 1 241092

14 CHAIN FOR QUICKRELEASE PIN 9" LONG 1 241056

15 SCR NO18-18 X 3/4" SELF DRILLING ROUND HD 1 241057

16 GROMMENT GC55 1 241058

17 SWITCH EMERGENCY STOP GC55 1 241059

18 SWITCH PANEL GC55 1 241060

19 SCR M4 X 8 0.7 DIN966 PHILIPS 6 235099

20 WASHER LOCK M4 DIN127 6 241030

21 WASHER LOCK M8 DIN127 4 300245

22 WASHER LOCK M6 DIN127B 7 300279

23 DIAMOND BLADE CONTACT CUSTOMER

SERVICE

24 KNOB W/THREADED HOLE M10 X 1.5 X 50mm

DIA

25 SCR M8 X 40 1.25 DIN933 5 235009

26 SCR M6 X 14 1.0 DIN933 6 241062

27 SCR M8 X 30 1.25 DIN933 1 241063

28 SCR M8 X 25 1.25 DIN933 HHC FULL THD 1 300323

29 NUT M8 1.25 DIN934 HEX 5 300273

30 PIN CLEVIS 9.5MM D X 11L - 6.9MM USABLE LG 1 241064

31 HAIR PIN COTTER 1/4 TO 1/2 DIA X 0.062 X 1-

5/16L

32 SEE CUTTING HEAD ASSEMBLY PAGE 25 1 -NA33 COLLAR LOCK GC55 1 241067

34 SCR M6 X 30 1.0 DIN912 SOCKET HEAD HEX 1 241068

35 SCR M6 X 20 1.0 DIN912 SOCKET HEAD HEX 1 241069

36 PULLEY 70MM D X 3/4B 6G J SECTION 1 241070

37 KEY 3/16X3/4 1 9201074

1 Contact Customer

Service

1 241061

1 241065

34

Page 35

Main Assembly GC55 Only

Item DESCRIPTION Qty Part No

38 SCR M5 X 10 0.8 DIN916 CUP POINT SET 4 241027

39 PULLEY 56.5MM D X 3/4B 6G J SECTION 1 241071

40 BELT 350J6 - J SECTION 6 GROOVE 1 241072

41 SEE FRONT POINT ASSEMBLY GC55/GC2E

PAGE 32

42 BELT GUARD GC55 1 241074

43 SEE BLADE GUARD ASSEMBLY GC55/GC25E

PAGE 24

44 RETAINING RING C-STYLE 60mm X 2.0mm

DIN471

45 ARM STAY LEVEL GC55/GC25E 1 241078

46 SPACER M14 1 241079

47 CAM STAY LEVEL GC55/GC25E 1 241080

48 LOOSE COLLAR GC55/GC25E 1 241081

49 TIGHT COLLAR GC55/GC25E 1 241082

50 NUT 5/8-11 UNC HEX LEFT HAND THREAD 1 241083

51 SEE DEPTH CONTROL ASSEMBLY

GC55/GC25E PAGE 27

52 WASHER M6 DIN 125 FLAT 1 27539

53 WRENCH UNIVERSAL 1 233041

54 KEY 3/16X1 ¼ 1 9201080

55 SPACER SHAFT GC55/GC25E 1 241088

56 WASHER M8 DIN125 FLAT 1 232110

57 WASHER M8 DIN125 FLAT 1 232110

1 -NA-

1 -NA1 241076

1 -NA-

35

Page 36

Item DESCRIPTION Qty Part No

1 SEE FRAME ASSEMBLY GC25E PAGE 31 1 -NA2 HANDLE BAR GC55 1 241052

3 SEE MOTOR ASSEMBLY GC25E PAGE 29 1 -NA4 WASHER M6 DIN125 FLAT 8 27539

5 WASHER M8 DIN125 FLAT 12 232110

6 SCR M10 X 60 1.5 DIN931 1 27030B

7 SCR M8 X 60 1.25 DIN933 HHC FULL THD 1 360146

8 NUT M6 DIN985 LOCK 1 235136

Main Assembly GC25E Only

36

Page 37

Item DESCRIPTION Qty Part No

9 NUT M8 1.25 LOCK DIN985 2 241041

10 SCR 5/16-18 UNC X 2-1/2" CARRIAGE BOLT 1 241054

11 WASHER 3/8 WAVE 1 241055

12 KNOB M8 X 1.25 ADJUSTABLE 1 241091

13 PIN QUICKRELEASE 5/16" X 2" GRIP LENGTH 1 241092

CHAIN FOR QUICKRELEASE PIN 9" LONG

14

15

16 GROMMET GC55 1 241058

17 SHIELD POWER SWITCH GC25E 1 241104

18 PANEL POWER SWITCH GC25E 1 241105

19 SCR M4 X 8 0.7 DIN966 PHILIPS 6 235099

20 WASHER LOCK M4 DIN127 6 241030

21 WASHER LOCK M8 DIN127 4 300245

22 WASHER LOCK M6 DIN127B 7 300279

23

24

25 SCR M8 X 35 1.25 SHCS DIN7991 4 241106

26 SCR M6 X 14 1.0 DIN933 6 241062

27 SCR M8 X 30 1.25 DIN933 2 241063

28 SWITCH TOGGLE (POWER) 20A 1 235165

30

31

32

33 COLLAR LOCK GC55 1 241067

34 SCR M6 X 30 1.0 DIN912 SOCKET HEAD HEX 1 241068

35 SCR M6 X 20 1.0 DIN912 SOCKET HEAD HEX 1 241069

36

38 SCR M5 X 10 0.8 DIN916 SET CUP POINT 4 241027

39 PULLEY 56.5MM D X 3/4B 6G J SECTION 1 241071

40 BELT 350J6 - J SECTION 6 GROOVE 1 241072

41 SEE FRONT POINT ASSEMBLY PAGE 27 1 241073

42 BELT GUARD GC55 1 241074

43 BLADE GUARD ASSEMBLY GC55 1 241075

44

45 ARM STAY LEVEL GC55 1 241078

GC55 1 241056

SCR NO18-18 X 3/4" SELF DRILLING ROUND

HEAD 1 241057

DIAMOND BLADE CONTACT CUSTOMER

SERVICE -NAKNOB W/THREADED HOLE M10 X 1.5 X 50mm

DIA 2 241061

PIN CLEVIS 9.5MM D X 11L - 6.9MM USABLE

LENGTH 1 241064

HAIR PIN COTTER 1/4 TO 1/2 DIA x 0.062 x 15/16L 1 241065

SEE CUTTING HEAD ASSEMBLY GC25E PAGE

25 1 -NA-

PULLEY 70MM D X 3/4B 6G J SECTION

RETAINING RING C-STYLE 60mm X 2.0mm

DIN471 1 241076

1

241107

37

Page 38

Item DESCRIPTION Qty Part No

46 SPACER M14 1 241079

47 CAM STAY LEVEL GC55 1 241080

48 LOOSE COLLAR GC55 1 241081

49 TIGHT COLLAR GC55 1 241082

50 NUT 5/8-11 UNC HEX LEFT HAND THREAD 1 241083

51 DEPTH CONTROL ASSEMBLY GC55 1 241084

52 WASHER M6 DIN 125 FLAT 1 27539

53 WRENCH UNIVERSAL 1 233041

54 KEY 5 X 5 X 45mm 1 241108

55 CONDUIT 14.5mm D x 10mm ID FLEXIBLE 1 241109

58 CUTTING HEAD FLANGE GC25E 1 241110

59 CABLE POWER W/FM TWIST LOCK GC25E 1 241111

60 KEY 3/16X3/4 1 9201074

61 NUT M8 1.25 LOCK DIN985 8 241041

38

Page 39

NOTES

39

Page 40

Saint-Gobain Abrasives

2770 West Washington

Stephenville, TX 76401

Phone: 800-554-8003

Fax: 800-443-1092

Loading...

Loading...