Page 1

TR 232 S&L

OPERATING INSTRUCTIONS

Translation of the original instructions

Page 2

VERS. 2016.04.29 TR 232_MAN_EN

2

Page 3

VERS. 2016.04.29 TR 232_MAN_EN

Declaration of conformity

The undersigned manufacturer:

SAINT - GOBAIN ABRASIVES S.A.

190, BD J.F. KENNEDY

L- 4930 BASCHARAGE

Declares that this product:

Tile Saw (code): TR 232 S 230 V (70184601110)

TR 232 S 230 V UK (70184601111)

TR 232 S 115 V (70184601109)

TR 232 L 230 V (70184601103)

TR 232 L 230 V UK (70184601105)

TR 232 L 115 V (70184601104)

Is in conformity with the following Directives:

"MACHINES" 2006/42/CE

"LOW VOLTAGE" 2014/35/UE

"ÉLECTROMAGNÉTIC COMPATIBILITY" 2014/30/UE

"NOISE" 2000/14/CE

and European standard:

EN 12418 – Masonry and stone cutting-off machines – Safety

Valid for machines as of serial number:

1601xxxxxxx

Storage site for the technical documents :

Saint-Gobain Abrasives 190, Bd. J. F. Kennedy 4930 BASCHARAGE, LUXEMBOURG

This declaration of conformity loses its validity when the product is converted or modified

without agreement.

Bascharage, Luxembourg, 04.01.2016

Olivier Plenert, executive officer.

3

Page 4

VERS. 2016.04.29 TR 232_MAN_EN

4

Page 5

VERS. 2016.04.29 TR 232_MAN_EN

TR 232 S&L

OPERATING INSTRUCTIONS

1 BASIC SAFETY INSTRUCTIONS 6

1.1 Symbols 6

1.2 Machine plate 7

1.3 Safety instructions for particular operating phases 7

2 MACHINE DESCRIPTION 9

2.1 Short description 9

2.2 Purpose of use 9

2.3 Layout 9

2.4 Technical Data 11

2.5 Statement regarding the vibration emission 12

2.6 Statement regarding noise emission 13

3 ASSEMBLY AND COMMISSIONING 14

3.1 Assembly of the legs 14

3.2 Assembly of the handles 14

3.3 Cutting head 15

3.4 Assembly of the cooling system 15

3.5 Transport wheels 16

3.6 Longitudinal guide assembly 16

3.7 Side extension assembly 17

3.8 Installation of the handle for the cut in angle 17

3.9 Installation of the material holding system (TR 232 L only) 19

3.10 Tool assembly 18

3.11 Electrical connections 19

3.12 Water cooling system 19

3.13 Starting the machine 19

4 TRANSPORT AND STORING 20

4.1 Securing for transport 20

4.2 Storing of the machine 20

5 OPERATING THE MACHINE 22

5.1 Site of work 22

5.2 Cutting 22

Important for cutting 22

5.3 Cutting with an angle 23

6 MAINTENANCE AND SERVICING 24

7 FAULTS: CAUSES AND CURES 25

7.1 Fault-finding procedures 25

7.2 Trouble-shooting guide 25

7.3 Circuit diagram 26

7.4 Customer service 27

5

Page 6

VERS. 2016.04.29 TR 232_MAN_EN

Read operator's instructions

Ear protection must be worn

Hand protection must be worn

Eye protection shall be worn

Rotation direction of the blade

Danger: risk of cut

1 BASIC SAFETY INSTRUCTIONS

The TR 232 is exclusively designed for the cutting of tiles with NORTON diamond disks mainly on

construction sites.

Uses other than the manufacturer's instructions shall be considered as contravening the regulations.

The manufacturer shall not be held responsible for any resulting damage. Any risk shall be borne

entirely by the user. Observing the operating instructions and compliance with inspection and

servicing requirements shall also be considered as included under use in accordance with the

regulations.

1.1 Symbols

Important warnings and pieces of advice are indicated on the machine using symbols. The following

symbols are used on the machine:

6

Page 7

VERS. 2016.04.29 TR 232_MAN_EN

Machine Model

Machine Code

Weight

Year of production

Maximum blade diameter

Machine type

Serial number

Power

Safety standard

Blade speed

Bore

diameter

1.2 Machine plate

Important data can be found on the following plate located on the machine:

1.3 Safety instructions for particular operating phases

Before commencing work

Before commencing work, make yourself familiar with the working environment at the place of

use. The working environment includes: obstacles in the area of work and manoeuvre, the

firmness of the floor, necessary protection at the site relating to public thoroughfares and the

availability of help in the event of accidents.

Site the machine on an even, firm and stable base!

Check for correct mounting of the blade regularly.

Immediately remove damaged or badly worn blades, as they endanger the operator whilst

rotating.

The material to be cut must be held securely in place on the table to allow no unexpected

movement during cutting operation.

Always cut with the blade guard in position.

Only fit NORTON diamond blades with continuous rim to the machine! The use of other tools

can damage the machine!

Read the blades’ specifications carefully to choose the correct tool for your application.

Attention is drawn to the use of BS2092 safety goggles in conformity with specified Processes

No.8 of the Protection of Eyes Regulation 1974, Regulation 2(2) Part 1. Also use the other

safety equipment as mentioned in the symbols plus a dust mask when dry cutting is applied.

7

Page 8

VERS. 2016.04.29 TR 232_MAN_EN

Electrical powered machine

Always turn off the TR 232 and separate it from the main source of electricity before any work on

the machine is done.

Make all electrical connections securely to eliminate contact of live wires with spray water or

dampness

When TR 232 is used with water, it is IMPERATIVE that you earth the machine properly. Let a

qualified electrician check in case of doubt.

Press the red button (0) on the switch to stop the machine in case of emergency.

In the event of the TR 232 breaking down or stopping for no apparent reason, switch off the

main electricity supply. Only a qualified electrician is allowed to investigate the trouble and

remedy the fault.

8

Page 9

VERS. 2016.04.29 TR 232_MAN_EN

1

5 3 2

4

2 MACHINE DESCRIPTION

Any modification, which could lead to a change in the original characteristics of the machine, may

be done only by Saint-Gobain Abrasives who shall confirm that the machine is still in conformity with

the safety regulations.

2.1 Short description

The TR 232 Saw is designed for durability and high performance for onsite wet cutting operations of

a wide range of tiles.

As with all other NORTON CLIPPER products, the operator will immediately appreciate the attention

given to detail and quality of materials used in construction. The machine and its component parts

are assembled to high standards assuring long life and minimum maintenance.

2.2 Purpose of use

The machine is designed for wet cutting of a large range of building and refractory materials, or tiles.

It is not designed for cutting wood, metals or other materials.

2.3 Layout

Frame (1)

9

Page 10

VERS. 2016.04.29 TR 232_MAN_EN

The frame is made of aluminium and steel to ensure robustness and durability. The folding stand

with 4 legs ensures stability while cutting.

Cutting head (2)

Aluminium console guided with precision. This console supports the electric motor, the guides and

the blade guard. The head can be tilted to cut with an angle from 0 to 45º.

Blade guard (3)

The blade guard assembly with a 230mm-diameter blade capacity is completely closed, but the

outside cover can be disassembled to access the blade. It offers maximum operator protection and

increased visibility of the work piece. The tightening of the fixing flange is done by a hexagonal head

screw (left-hand thread).

Water cooling (4)

The coolant system comprises:

A submersible mechanical water pump.

Plastic suction pipe delivering the water from the water pan to the cutting head.

A removable large capacity plastic water pan located under the cutting table to reduce water

loss.

A nozzle of watering located on the casing of the disc for a good distribution of water on the

disc.

Electric Motor (5)

One phase 1,1 kW motor. The switch with the red and green buttons is used to start and turn off the

engine. The red button is also an emergency stop.

10

Page 11

VERS. 2016.04.29 TR 232_MAN_EN

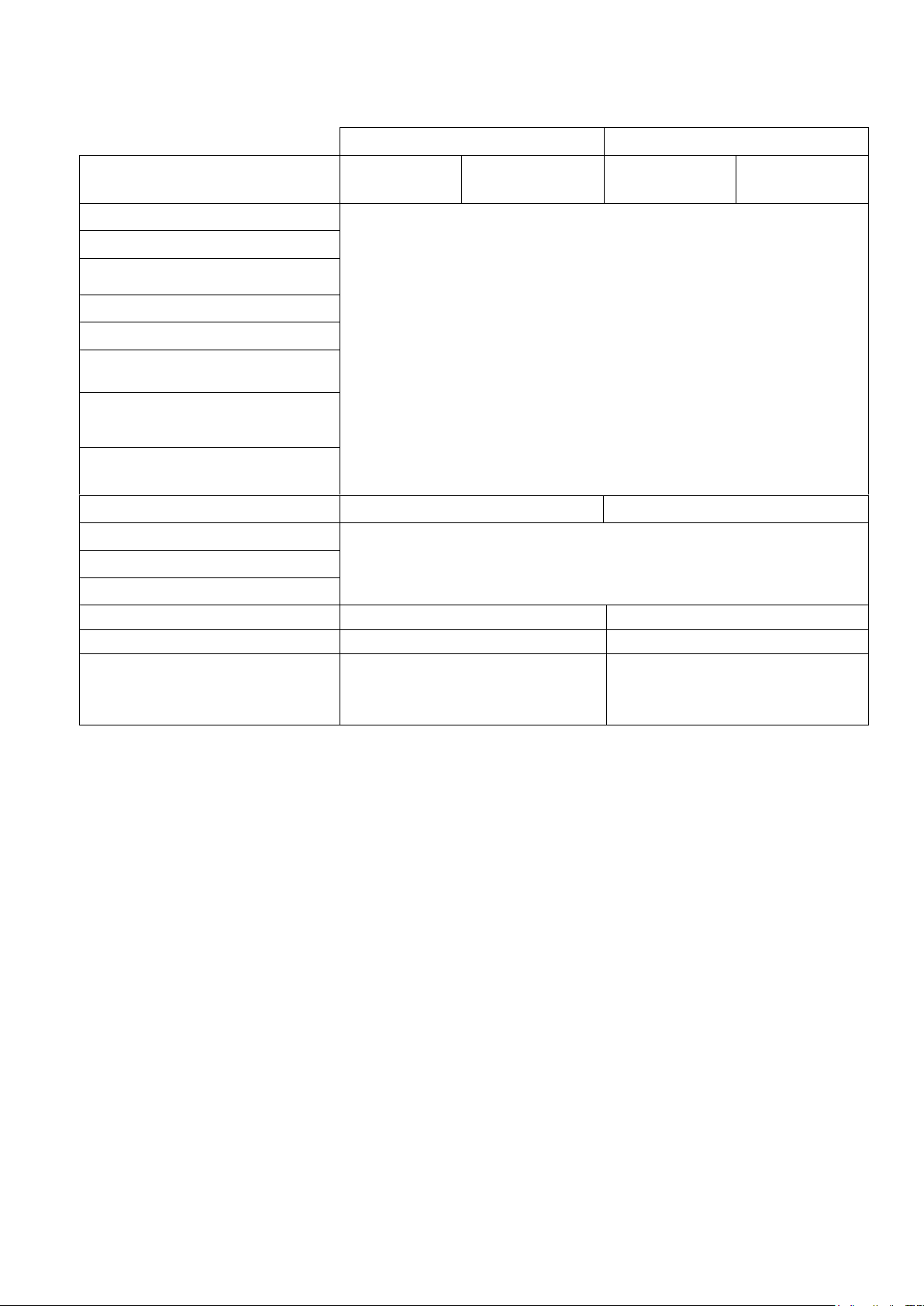

TR 232 L

TR 232 S

Item number

70184601103

70184601105

(UK)

70184601110

70184601111

(UK)

Electric motor

1,1 kW

230V

230V, 50Hz

IP54

230 mm

25,4 mm

2950 min-1

20 mm

20 mm

15 kg

Supply voltage

Rating protection

Blade diameter

Bore

Rotation speed of the blade

Maximum cutting height 0°

45°

Maximum material weight on

table

Cutting length

1200

860

Flange diameter

90

71 dB (A) (selon ISO EN 11201)

79 dB (A) (selon ISO EN 3744)

Sound pressure level

Sound energy level

Table dimensions (LxW)

1200X565 mm

860x565mm

Machine dimensions (LxWxH)

1860x600x1175 mm

1560x600x1175 mm

Weights :

Machine cpl.

Ready for use (with water)

72 kg

94 kg

61 kg

77 kg

2.4 Technical Data

11

Page 12

VERS. 2016.04.29 TR 232_MAN_EN

Machine

Model / code

Measured value of vibration

emission at m/s2

Uncertainty K

m/s2

Tool used

Model / code

TR232 S:

70184601109

70184601110

70184601111

TR232 L:

70184601103

70184601104

70184601105

<2.5

0.5

Clipper Super Gres XT

2.5 Statement regarding the vibration emission

Declared value of vibration emission following EN 12096.

The vibration value is lower and does not exceed 2.5 m /s².

Values determined using the procedure described in the standard EN 12418.

The measurements are made with new machines. Actual values may vary with site conditions, in

terms of:

Materials worked

Wear Machine

Lack of maintenance

Inappropriate tool for application

Tool in poor condition

Unskilled operator

Etc…

The exposure time to vibration is based on the performance of work (related to the adequacy

Machine / Tool / worked material / operator)

When evaluating risks due to hand-arm vibration, you need to take into account effective usage at

rated power of machine during a full day of work; quite often you will realise that effective utilisation

time represents around 50% of overall duration of work. You have to consider, of course, breaks,

water feeding, preparation of work, time to move the machine, disk mounting…

12

Page 13

VERS. 2016.04.29 TR 232_MAN_EN

Machine

Model / code

Sound

Pressure level

L

Peq

EN ISO 11201

Uncertainty K

(Sound

Pressure level

L

Peq

EN ISO 11201)

Sound power

level

L

Weq

NF EN ISO 3744

Uncertainty K

(Sound power level

L

Weq

NF EN ISO 3744)

TR232 S:

70184601109

70184601110

70184601111

TR232 L:

70184601103

70184601104

70184601105

79 dB(A)

2.5 dB(A)

71 dB(A)

4 dB(A)

2.6 Statement regarding noise emission

Declared value of noise emission following EN ISO 11201 and NF EN ISO 3744.

Values determined using the procedure described in the standard EN 12418.

The measurements are made with new machines. Actual values may vary with site conditions, in

terms of:

Wear Machine

Lack of maintenance

Inappropriate tool for application

Tool in poor condition

Unskilled operator

Etc…

Measured values relate to an operator in normal use, as described in the manual position.

13

Page 14

VERS. 2016.04.29 TR 232_MAN_EN

3 ASSEMBLY AND COMMISSIONING

The TR 232 is delivered fully equipped. It is ready for operation after assembly of the diamond blade

and after connection to the appropriate power supply.

3.1 Assembly of the legs

Lift up one side of the saw and unfold the legs without wheels. Lift up the other side of the saw

and unfold the legs with the wheels.

Encase the arm of blocking in the pin and tighten the button knurled to prevent that the feet are

not folded up.

3.2 Assembly of the handles

In order to seize the machine more easily, fix the two handles on the side of the machine using

the screws and nuts.

14

Page 15

VERS. 2016.04.29 TR 232_MAN_EN

3.3 Cutting head

Fix the handle of the cutting head using two screws.

To be able to use your machine, you must release the head of cut. For that unscrew the knurled

button which maintains the head on the right amount during transport.

3.4 Assembly of the cooling system

Fix the cable containing the water pipe along the rail of the head of cut.

Mount the pump in the vat to water and the drain plug

15

Page 16

VERS. 2016.04.29 TR 232_MAN_EN

3.5 Transport wheels

To be able to move your machine easily, assemble the wheels to the bottom of the feet located

on the side opposite of the handles, using the screws butterflies.

3.6 Longitudinal guide assembly

Insert 2 threaded and pined shafts Rotate both shafts by 90°

Insert both guide supports and lock them with knobs

16

Insert the guide in both supports then lock the knobs

Page 17

VERS. 2016.04.29 TR 232_MAN_EN

3.7 Side extension assembly

Insert both pined shafts

Rotate both shafts by 90° to lock side extension

3.8 Installation of the handle for the cut in angle

17

Page 18

VERS. 2016.04.29 TR 232_MAN_EN

3.9 Installation of the material holding system (TR 232 L only)

In order to ensure an optimal material holding during the cut, use the grasshoppers envisaged

for this purpose.

3.10 Tool assembly

Only NORTON blades with a diameter of 230 mm can be used with the TR 232.

All tools used must be selected with regard to their maximum permitted cutting speed for the

machine’s maximum permitted rotation speed. Before mounting a new blade into the machine,

switch off the machine and isolate it from the main source of electricity.

To assemble a new blade, follow these steps:

Loosen the three screws holding the outer cover of the blade guard using the crosshead

screwdriver supplied with TR 232, and remove it.

Loosen the hexagonal nut (left threaded) on the blade shaft using the 18 mm wrench supplied

with TR 232, which holds the removable outer flange.

Remove the outer flange.

Clean the flanges and blade shaft and inspect for wear.

Mount the blade on the shaft ensuring that direction of rotation is correct (check with the arrow

on the blade guard). Wrong direction of rotation blunts the blade quickly.

WARNING: The blade bore must correspond exactly to the blade shaft. Cracked or damaged

bore is dangerous for the operator and for the machine.

Put outer blade flange back in place.

Tighten hexagonal nut using 18 mm wrench.

Put the outer cover of the blade guard back in place and tighten the three holding screws with

the crosshead screwdriver.

WARNING: the blade bore must correspond exactly to the diameter of the blade shaft. Cracked or

damaged bore is dangerous for the operator and for the machine.

18

Page 19

VERS. 2016.04.29 TR 232_MAN_EN

3.11 Electrical connections

Check that:

The voltage/phase supply corresponds to the information indicated on the motor plate.

Available power supply must have ground connection in conformity with safety regulations.

The connecting cables should have at least a 2.5mm2-section per phase.

3.12 Water cooling system

Fill the TR 232 with clean water up to 1cm under the top edge of the water tray. The pump will

switch on together with motor.

Ensure that water is delivered adequately to the blade, as insufficient water supply may result in

premature failure of the diamond blade.

The water pump must never run without water. Always make sure that there is enough water in

the pan and refill if necessary.

In case of frost, empty the water cooling system from its water.

3.13 Starting the machine

Connect your machine to the electric source. To start the machine, press the green button on the

switch. To stop the machine, press the red button. This one is also an emergency stop key.

19

Page 20

VERS. 2016.04.29 TR 232_MAN_EN

4 TRANSPORT AND STORING

Please follow the following instructions to transport and store the TR232 in a safe way.

4.1 Securing for transport

Before transporting the machine, always remove the blade and empty the water pan. Secure the

cutting head on the rail by using the knob. Store the longitudinal cutting guide and the side

extension in the pan. Fold the legs.

WARNING: this machine is not suited to be lifted with a crane.

Lock cutting head

Tighten angular cutting guide

Store the longitudinal cutting guide and the side extension:

o Dismount the table

o Store the elements in the pan, then put the table back in place

4.2 Storing of the machine

20

Page 21

VERS. 2016.04.29 TR 232_MAN_EN

If the machine is not going to be used for a long period, please take the following measures:

Completely clean the machine

Empty the water system

Take the water pump out of the water tray, and clean it thoroughly.

The storage site must be clean, dry and at a constant temperature.

21

Page 22

VERS. 2016.04.29 TR 232_MAN_EN

5 OPERATING THE MACHINE

You will find in this chapter of the advices to use the machine in a safe way.

5.1 Site of work

5.1.1 Siting the machine

Remove from the site anything, which might hinder the working procedure!

Make sure the site is sufficiently well lit!

Observe manufacturer's conditions for connecting to power supplies!

Place electric cables in such a way that damage is excluded!

Make sure you have a continual adequate view of the working area so you can intervene in the

working process at any time!

Keep other staff out of the area, so you can work securely.

5.1.2 Space required for operation and maintenance

Leave 2 m in front of the machine and 1.5 m around it for usage and maintenance of the TR 232.

5.2 Cutting

To use the TR 232 correctly, you must face it with one hand on the cutting head, and the other on

the material to be cut to maintain it against the material stops. Always keep your hands away from

the moving blade.

The long longitudinal cutting guide and the side extension can help you to achieve high accuracy

cuts, even with large materials.

Important for cutting

Only materials with max. dimensions of 1200x800x20mm and max. weight of 15kg can be cut

with the TR 232.

Before commencing work make sure tools are firmly seated!

Select the right tools as recommended by the manufacturer depending on the material to be

worked, the working procedure (wet cut) to be carried out and the required efficiency.

Make sure the water pan contains enough water.

Use only set with diamonds discs NORTON CLIPPER. The use of other tools can involve the

damage of the machine.

Do not force on the engine. This machine is not designed for a continuous use.

22

Page 23

VERS. 2016.04.29 TR 232_MAN_EN

5.3 Cutting with an angle

You can cut from 0º to 45º by tilting the head rail. For this purpose:

Loosen the two knobs maintaining the head rail to tilt the head to the desired angle.

Retighten the two knobs.

According to the angle of cut wished, the position of the handle of the head of cut can be

modified to improve comfort of the user at the time of the cut.

23

Page 24

VERS. 2016.04.29 TR 232_MAN_EN

Before starting work

During tool change

End of each day

or more often if required

During a failure

After a damage

Whole machine

Visual control (general

aspect, water tightness)

Clean

Flange and blade fixing

devices

Clean

Motor cooling fans

Clean

Water pan

Clean

Motor housing

Clean

Reachable nuts and screws

Tighten up

Water pump

Clean

6 MAINTENANCE AND SERVICING

To ensure a long-term quality from the cutting with the TR 232, please follow the maintenance plan

below:

Maintenance of the machine

Always perform the maintenance of the machine with the machine isolated from the electrical

supply.

Lubrication

The TR 232 uses life-lubricated bearings. Therefore, you don’t need to lubricate the machine at all.

Cleaning of the machine

Your machine will last longer if you clean it thoroughly after each day of work, especially water

pump, water pan, motor and blade flanges.

24

Page 25

VERS. 2016.04.29 TR 232_MAN_EN

Trouble

Possible source

Resolution

Motor is not running

No electricity

Check the electrical supply

(fuse for example)

Connection cable section too

small

Change connection cable

Defective connection cable

Change connection cable

Defective switch

CAUTION : can only be solved

by qualified electrician

Defective motor

Change motor or contact motor

manufacturer

Motor stops during the cutting,

but can be restarted after a

short period (overload

protection)

Cutting feed speed too quick

Cut slowly

Blade is blunt or glazed

Sharpen the blade in

calcareous stone

Defective blade

Change blade

Wrong blade specification for

the application

Change blade

No water on the blade

Not enough water in the pan

Refill the water pan

Water supply system is blocked

up

Clean water supply system

Water pump is not working

Change the pump

7 FAULTS: CAUSES AND CURES

7.1 Fault-finding procedures

Should any fault occur during the use of the machine, turn it off, and isolate it from the electrical

supply. Any works dealing with the electrical system or supply of the machine can only be carried

out by a qualified electrician.

7.2 Trouble-shooting guide

25

Page 26

VERS. 2016.04.29 TR 232_MAN_EN

7.3 Circuit diagram

26

Page 27

VERS. 2016.04.29 TR 232_MAN_EN

7.4 Customer service

When ordering spare parts, please mention:

The serial number (7 digits).

The code of the part.

The exact denomination.

The number of parts required.

The delivery address.

Please indicate clearly the means of transportation required such as "express" or "by air".

Without specific instructions, we will forward the parts through the means which seem

appropriate to us --- but which is not always the quickest way.

Clear instructions will avoid problems and faulty deliveries.

If not sure, please send us the defective part.

In the case of a warranty claim, the part must always be returned for evaluation.

Spare parts for the motor can be ordered with the manufacturer of the motor or with their dealer,

which is often quicker and cheaper.

This machine has been manufactured for Saint-Gobain Abrasives S.A.

190, Bd J.F.Kennedy

L- 4930 BASCHARAGE

Grand-Duché de Luxembourg.

Tel. : 00352-50 401-1

Fax : 00352- 50 16 33

www.construction.norton.eu

e-mail:sales.nlx@saint-gobain.com

Guarantee can be claimed and technical support obtained from your local distributor where

machines, spare parts and consumables can be ordered as well:

27

Page 28

VERS. 2016.04.29 TR 232_MAN_EN

www.construction.norton.eu

Saint-Gobain Abrasives

190, Bd. J. F. Kennedy

L-4930 BASCHARAGE

LUXEMBOURG

Tel: ++352 50401-1

Fax: ++352 501633

e-mail: sales.nlx@saint-gobain.com

28

Loading...

Loading...